Frɔm we dɛn bigin di ɔtomotiv industri insay di let 19t sɛntinari, di tin dɛn we dɛn dɔn mek fɔ mek tin dɛn dɔn bi di fɔs tin we dɔn mek i gro ɛn gɛt sakrifays. Frɔm di introdɔkshɔn fɔ di asɛmbli layn bay Ɛnri Fɔd insay 1913 to di rayz fɔ ɔtomɛshɔn insay di las dikɛd ia, di ɔtomotiv industri dɔn kɔntinyu fɔ evolv fɔ mit di dimand dɛn fɔ wan chenj wɔl.

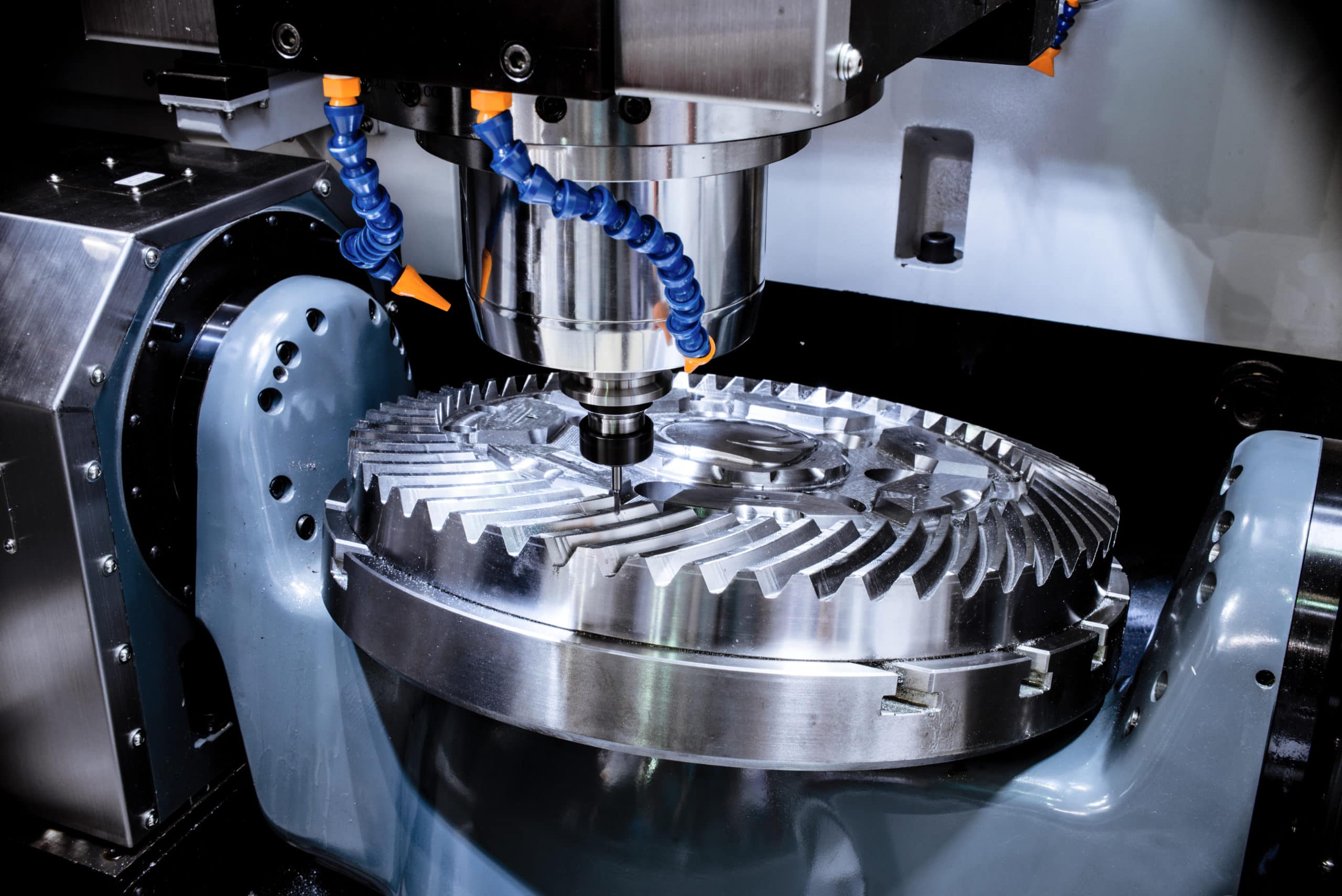

Tide, CNC mashin dɔn kɔmɔt as wan impɔtant kɔmpɔnɛnt insay di mɔdan ɔtomotiv manufakchurin, we de mek dɛn ebul fɔ prodyuz ay-kwaliti, prɛsis, ɛn kɔmpleks pat dɛn wit efyushɔn ɛn ripitabiliti we nɔ gɛt wan kɔmpitishɔn.

Dis atikul go ɛksplɔrɔ di impɔtant wok we CNC mashin de du na di ɔtomotiv industri ɛn aw i dɔn rivɔlɔshɔn di we aw dɛn de mek motoka dɛn.

Wetin na CNC mashin?

CNC mashin, shɔt fɔ kɔmpyuta nɔmba kɔntrol mashin, na wan manufakchurin prɔses we de yuz kɔmpyuta kɔntrol ɛn kɔt tul fɔ pul matirial frɔm wokpies, we de mek kɔstɔm-dizayn pat dɛn wit ay akkuracy ɛn ripitabiliti. Dis teknɔlɔji dɔn rivɔlɔshɔn di ɔtomotiv industri bay we dɛn ebul fɔ mek kɔmpleks, ay kwaliti kɔmpɔnɛnt dɛn insay wan kɔst-ɛfɛktiv ɛn efishɔnal we.

Aw CNC mashin dɛn de wok .

CNC mashin dɛn de wok bay we dɛn de fala wan sɛt fɔ instrɔkshɔn dɛn we dɛn dɔn program bifo tɛm, we dɛn kɔl G-Kɔd, we de gayd di tin dɛn we dɛn de kɔt fɔ pul di tin dɛn we dɛn de yuz fɔ wok na di wok we dɛn de du insay wan prɛsis ɛn kɔntrol we. Di prɔses involv dɛn step ya:

1. Dizayn: Ɛnjinia dɛn de mek wan 3D mɔdel fɔ di pat we dɛn want we dɛn de yuz CAD (kɔmpyuta-ɛd dizayn) softwe.

2. G-Kɔd Jɛnɛreshɔn: Dɛn kin chenj di CAD mɔdel to G-kɔd we dɛn de yuz CAM (kɔmpyuta-ɛd manufakchurin) softwe.

3. Setup: Dɛn kin klamp di wokpies fayn fayn wan pan di CNC mashin, ɛn dɛn kin instɔl di rayt tin dɛn fɔ kɔt.

4. Eksekyushɔn: Di CNC mashin de rid di G-kɔd ɛn ɛksɛkutiv di program dɛn we dɛn dɔn program, we de pul di matirial frɔm di wokpies lɛk aw dɛn dɔn sho.

5. Fɔ dɔn: We dɛn dɔn fɔ mek di mashin, dɛn kin pul di pat we dɔn dɔn na di mashin, dɛn kin inspɛkt am, ɛn dɛn kin du ɛnitin we dɛn nid fɔ du afta dɛn dɔn prosɛs am (lɛk fɔ klin ɔ fɔ trit am na di grɔn).

Tayp dɛn fɔ CNC mashin dɛn we dɛn kin yuz na di ɔtomotiv industri .

Di ɔtomotiv industri de dipen pan difrɛn CNC mashin dɛn fɔ prodyuz di bɔku bɔku kɔmpɔnɛnt dɛn we dɛn nid fɔ mek motoka. Sɔm pan di kayn dɛn we dɛn kin yuz mɔ na:

1. CNC Milling Machines : Dɛn mashin ya de yuz rotary cutting tools fɔ pul matirial frɔm di wokpies, we de mek tin dɛn lɛk ol, slot, ɛn poket. Dɛn fayn fɔ mek dɛn prodyuz injin kɔmpɔnɛnt dɛn, transmishɔn pat dɛn, ɛn sɔspɛns kɔmpɔnɛnt dɛn.

2. CNC Turning Machines : Dɛn kin kɔl dɛn bak CNC lathes, dɛn mashin ya kin rɔta di wokpies we wan kɔt tul de pul matirial, we de mek silinda pat dɛn lɛk shaft, bush, ɛn bia.

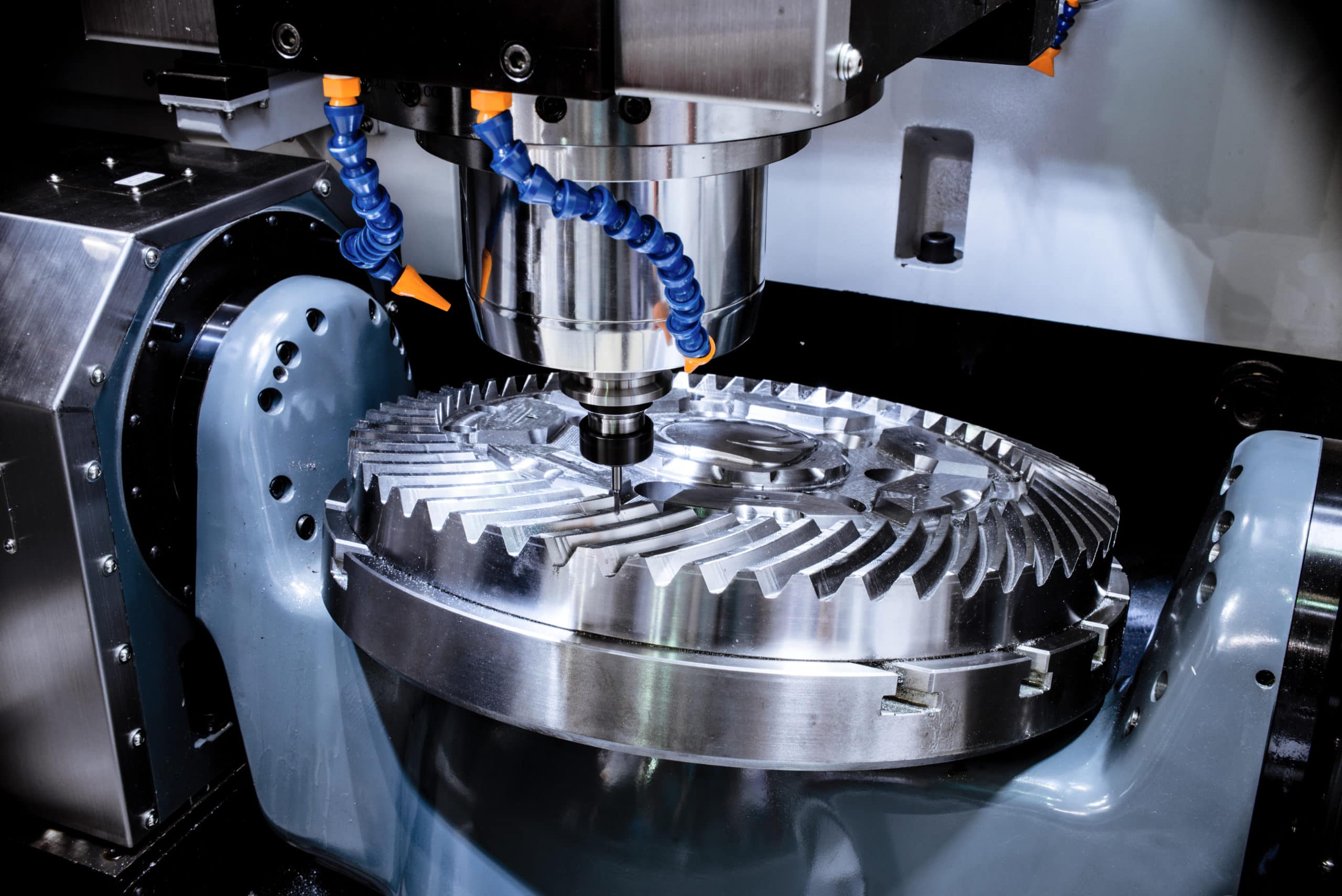

3. CNC grindin mashin dɛm : Dɛn mashin ya de yuz abrasive wil fɔ pul smɔl smɔl tin dɛm frɔm di wokpies, fɔ ajɔst rili tayt tolɛreshɔn ɛn smol finish. Dɛn kin yuz dɛn fɔ mek transmishɔn gia, kamshaft, ɛn ɔda ay-prɛsishɔn kɔmpɔnɛnt dɛn.

4. CNC laser cutting mashin : Dɛn mashin ya de yuz ay-pawa laser fɔ kɔt, drɔ, ɔ engrave matirial, we de mek dɛn fayn fɔ mek intrɛst shit mɛtal kɔmpɔnɛnt dɛn, lɛk bɔdi panɛl ɛn intɛriɔ trim pis dɛn.

Bay we dɛn de leva di kapasiti fɔ dɛn difrɛn CNC mashin dɛn ya, ɔtomotiv manifakta dɛn kin prodyuz bɔku bɔku kɔmpɔnɛnt dɛn wit prɛsishɔn we nɔ gɛt wan kɔmpitishɔn, efyushɔn, ɛn ripitabiliti, we kin mek dɛn gɛt ay kwaliti motoka dɛn ɛn mɔ strimlayn prodakshɔn prɔses dɛn.

Advantej dɛn fɔ CNC mashin fɔ di ɔtomotiv industri .

CNC mashin dɔn bi wan indispɛnsabl tul na di ɔtomotiv industri, we de gi bɔku bɛnifit dɛn we dɔn rivɔlɔshɔn di manufakchurin prɔses. Frɔm prɛsishɔn ɛn akkuracy to ɔtomɛshɔn ɛn kɔst-ɛfɛktiv, CNC mashin dɔn pruv fɔ bi gem-chenja fɔ ɔtomotiv manifakta dɛn.

Prɛsishɔn ɛn Akkurayt .

Wan pan di bɛst bɛnifit dɛn we CNC mashin gɛt na in ebul fɔ prodyuz pat dɛn wit ɛksɛpshɔn prɛsishɔn ɛn akkuracy. Dis na impɔtant tin na di ɔtomotiv industri, usay ivin di smɔl smɔl dɛvyayshɔn kin gɛt siriɔs kɔnsikuns pan motoka pefɔmɛns ɛn sef.

1. Tayt tolerans : . CNC mashin dɛn kin ajɔst tolɛreshɔn dɛn we tayt lɛk ±0.0001 inch, we de mek shɔ se di pat dɛn fit togɛda fayn fayn wan ɛn wok lɛk aw dɛn bin want am.

2. Kɔnsistɛns insay pat prodakshɔn : CNC mashinin de garanti kɔnsistɛns rizɔlt akɔdin to bɔku prodakshɔn rɔn, ridyus di risk fɔ mek mistek ɛn mek shɔ se ɛvri pat mit di sem ay standad.

Ɔtomɛshɔn ɛn Efisiɛns .

CNC mashin na wan ay ɔtomatik prɔses, we translet to inkris efyushɔn ɛn prodaktiviti na di ɔtomotiv manufakchurin sɛktɔ.

1. Ridyus di leba kɔst : We dɛn ɔtomayz di mashin prɔses, di wan dɛn we de mek dɛn kin ridyus di leba kɔst dɛn we gɛt fɔ du wit manual mashin ɔpreshɔn dɛn bad bad wan.

2. Faster prodakshɔn tɛm : CNC mashin dɛn kin wok wit ay spid ɛn wit smɔl dawt tɛm, we kin mek di wan dɛn we de mek am ebul fɔ prodyuz pat dɛn kwik kwik wan pas di tradishɔnal we fɔ mek mashin dɛn.

3. 24/7 Opareshɔn : CNC mashin dɛn kin rɔn kɔntinyu, 24 awa ɛvride, 7 dez insay di wik, maksimayz di prodakshɔn autput ɛn minimiz di lida tɛm dɛn.

Fleksibul ɛn adaptabiliti .

CNC Machining de gi yu fleksibiliti we nɔ gɛt wan kɔmpitishɔn ɛn adaptabiliti, we de alaw ɔtomotiv manifakta dɛn fɔ ansa kwik kwik wan to di chenj we di makit dimand de chenj ɛn prodyuz bɔku bɔku kɔmpɔnɛnt dɛn.

1. Abiliti fɔ prodyuz kɔmpleks jɔyometri : CNC mashin dɛn kin izi fɔ handel kɔmpleks pat jɔyometri, inklud intrikɛt kɔv, angul, ɛn kɔntɔ, we mek dɛn fayn fɔ prodyuz advans ɔtomotiv kɔmpɔnɛnt dɛn.

2. Kwik Tul Chenj : CNC mashin dɛn de alaw fɔ chenj di tul kwik kwik wan, we de mek di wan dɛn we de mek di tin dɛn chenj bitwin difrɛn pat dizayn ɛn matirial dɛn wit smɔl dawt tɛm.

3. Kɔmpatibiliti wit difrɛn matirial dɛn : CNC mashinin na kɔmpitabl wit bɔku bɔku matirial dɛn, lɛk mɛtal, plastic, ɛn kɔmpɔzit, we de gi ɔtomotiv manifakta dɛn di fleksibiliti fɔ pik di bɛst matirial fɔ ɛni aplikeshɔn.

Kost-ɛfɛktiv .

Pan ɔl di fɔs invɛstmɛnt na CNC mashin dɛn, di teknɔlɔji de gi bɔku kɔst sevings insay di lɔng tɛm, we mek i bi wan atraktiv opshɔn fɔ ɔtomotiv manifakta dɛn.

1. Ridyus di west matirial : CNC mashin na wan prɔses we rili ebul fɔ wok we de mek di west matirial nɔ bɔku, we de ridyus di ɔl matirial kɔst ɛn di envayrɔmɛnt impak.

2. Long Tul Layf : CNC mashin dɛn de yuz advans kɔt tul ɛn optimized tulpat, we kin ɛkstɛnd tul layf ɛn ridyus tul kɔst ova tɛm.

3. Lɔwa prodakshɔn kɔst fɔ ay-volyum pat : CNC mashinin na patikyula kɔst-ɛfɛktiv fɔ ay-volyum prodakshɔn rɔn, as di fɔs sɛtup kɔst dɛn de spred ɔp wan big nɔmba pan pat dɛn.

Bay we dɛn de yuz di prɛsishɔn, efyushɔn, fleksibiliti, ɛn kɔst-ɛfɛktiv fɔ CNC mashin, ɔtomotiv manifakta dɛn kin prodyuz ay-kwaliti kɔmpɔnɛnt dɛn, strimlayn dɛn prodakshɔn prɔses, ɛn kɔntinyu fɔ kɔmpit insay wan industri we de ɛva chenj.

Aplikeshɔn dɛn fɔ CNC mashin na di ɔtomotiv industri .

CNC mashinin de ple wan impɔtant pat pan di prodakshɔn fɔ wan big rɛnj ɔf ɔtomotiv kɔmpɔnɛnt dɛn, frɔm injin pat dɛn to sɔspɛns sistɛm dɛn. I prɛsishɔn, efyushɔn, ɛn versatility mek am wan indispɛnsabl tul fɔ manifakta dɛn we de luk fɔ mek ay kwaliti, rilibul pat dɛn. Insay dis sɛkshɔn, wi go ɛksplɔrɔ sɔm pan di ki aplikeshɔn dɛn fɔ CNC mashinin na di ɔtomotiv industri.

Enjin komponent dɛn .

Di injin na di at fɔ ɛni motoka, ɛn CNC mashinin impɔtant fɔ mek bɔku pan in impɔtant pat dɛn. Na sɔm ɛgzampul dɛn:

1. Silinda ed : Dɛn kin yuz CNC mashin fɔ mek di kɔmpleks jɔyometri ɛn di prɛsis ficha dɛn we di silinda ed dɛn gɛt, lɛk di valv sit dɛn, di spak plɔg ol dɛn, ɛn di kulant pasej dɛn. Di akkuracy ɛn kɔnsistɛns we dɛn ajɔst tru CNC mashinin de mek shɔ se di injin pefɔmɛns ɛn efyushɔn go fayn.

2. Enjin blɔk : CNC mashin de wok fɔ mek di intrikɛt intanɛnt jɔyometri dɛn fɔ injin blɔk dɛn, we inklud silinda bor dɛn, men biɛrin kap dɛn, ɛn ɔyl pasej dɛn. Di ay prɛsishɔn ɛn ripitabiliti fɔ CNC mashinin garanti se di injin blɔk mit di rikwayd tolɛreshɔn fɔ smol ɔpreshɔn ɛn lɔng layf.

3. Pistons and Connecting Rods : Dɛn kin mek dɛn pat dɛn ya we rili impɔtant insay di injin we dɛn de yuz CNC mashin fɔ mek shɔ se di prɛsishɔn we dɛn nid ɛn di tɛm we dɛn fɔ de fɔ lɔng tɛm. Bɔku tɛm dɛn kin mek piston dɛn frɔm aluminiɔm alɔy dɛn, ɛn dɛn kin mek kɔnɛktin rod dɛn frɔm fɔj stɛl. Di akchual mashin fɔ dɛn komponent ya na impɔtant tin fɔ mek dɛn fit, balans fayn fayn wan, ɛn wok fayn fayn wan.

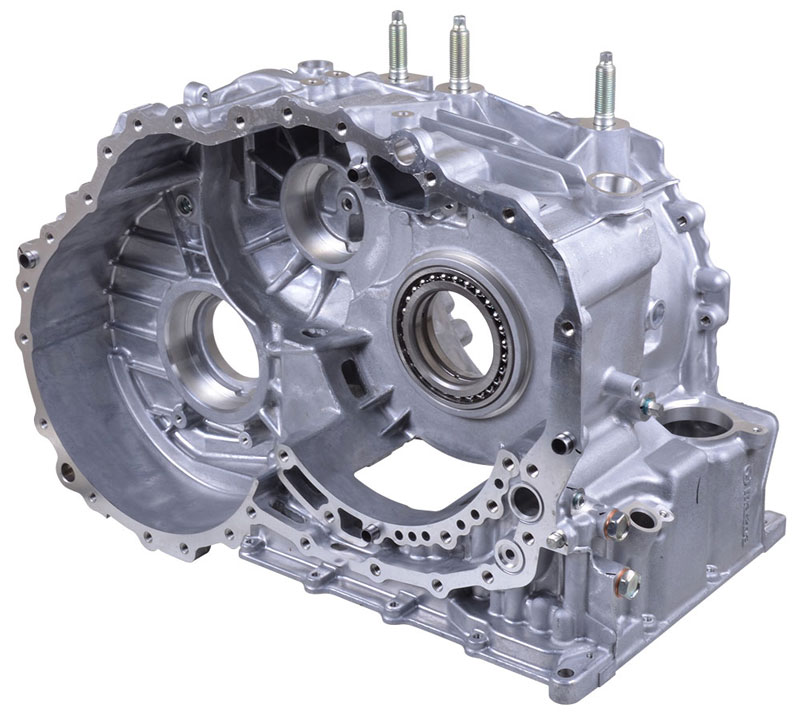

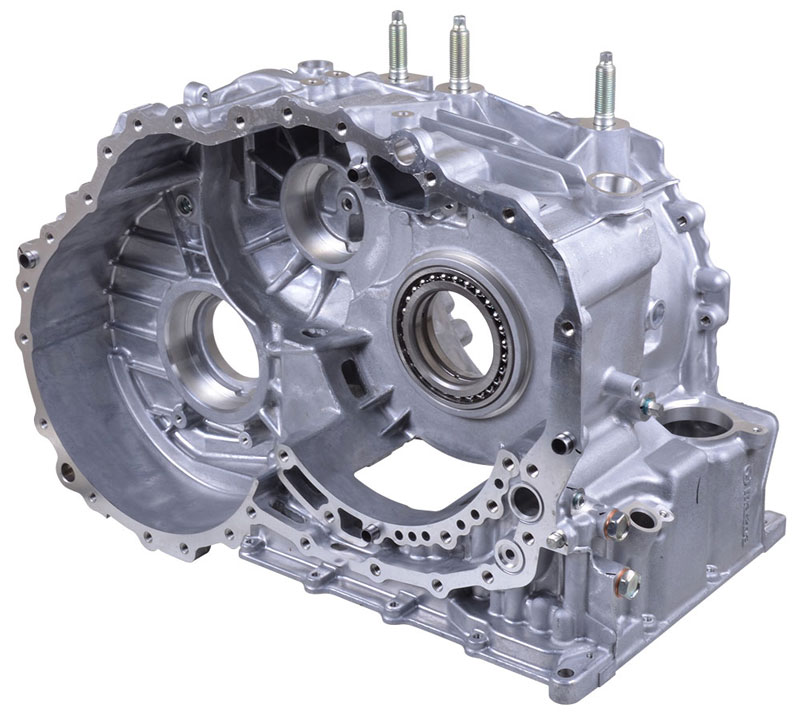

Transmishɔn Pat dɛn .

CNC mashinin de ple wan impɔtant pat pan di prodakshɔn fɔ transmishɔn kɔmpɔnɛnt dɛn, we impɔtant fɔ transfa pawa frɔm di injin to di wil dɛn. Di prɛsishɔn ɛn akkuracy we dɛn ajɔst tru CNC mashin de mek shɔ se dɛn pat ya de wok fayn fayn wan, we de gi smol ɛn efishɔnal motoka ɔpreshɔn. Na sɔm ki transmishɔn kɔmpɔnɛnt dɛn we dɛn prodyuz we dɛn de yuz CNC mashin:

1. Gia : Transmishɔn gia na kɔmpleks kɔmpɔnɛnt dɛn we nid prɛsis tut profayl ɛn jɔyometri fɔ mek shɔ se dɛn transfa pawa smol ɛn efyushɔn. CNC mashinin na fayn tin fɔ mek dɛn intrɛst shep ya, bikɔs i kin ajɔst tayt tolɛreshɔn ɛn kɔnsistɛns rizɔlt. Di akkuracy of CNC-machin gia na impɔtant tin fɔ ridyus nɔys, vaybreshɔn, ɛn wear insay di transmishɔn.

2. Shafts : Transmishɔn shaft, lɛk input ɛn ɔtput shaft, na impɔtant kɔmpɔnɛnt dɛn we de transmit tɔk bitwin gia ɛn ɔda transmishɔn pat dɛn. CNC mashin de yuz fɔ mek dɛn shaft ya wit di dimɛnshɔn dɛn we dɛn nid, sɔfays finish, ɛn ficha dɛn lɛk splayn ɛn kiwe. Di prɛsishɔn fɔ CNC-machin shaft dɛn de mek shɔ se dɛn gɛt di rayt alaynɛshɔn ɛn balans insay di transmishɔn, we de ridyus di vaybrɛshɔn ɛn ɛkstɛnd di layfspan fɔ di kɔmpɔnɛnt dɛn.

3. Haus : Di transmishɔn haus na kɔmpleks kɔmpɔnɛnt we de ɛnkɛs ɛn sɔpɔt di difrɛn gia dɛn, shaft dɛn, ɛn bia dɛn insay di transmishɔn. CNC mashin de yuz fɔ mek di intrikɛt intanɛnt jɔyometri ɛn prɛsis mawntin sɔfays dɛn na di haus. Di akkuracy fɔ CNC mashin de mek shɔ se ɔl di transmishɔn kɔmpɔnɛnt dɛn fit fayn fayn wan insay di haus, we de alaw fɔ mek dɛn ebul fɔ du di wok fayn fayn wan ɛn fɔ mek dɛn go de fɔ lɔng tɛm.

Bay we dɛn de yuz CNC mashin fɔ di prodakshɔn fɔ transmishɔn pat dɛn, ɔtomotiv manifakta dɛn kin ajɔst sɔm bɛnifit dɛn:

l Impɔtant efyushɔn ɛn pefɔmɛns .

l Ridyus nɔys ɛn vaybreshɔn .

l Ekstend komponent layfspan .

l Kɔnsistɛnt ɛn rilibul ɔpreshɔn .

Di prɛsishɔn ɛn akkuracy fɔ CNC-machin transmishɔn kɔmpɔnɛnt dɛn de kɔntribyut to di ɔvala kwaliti ɛn pefɔmɛns fɔ di motoka, we de gi bɛtɛ drayv ɛkspiriɛns to kɔstɔma dɛn.

Di komponent dɛn we dɛn dɔn mek fɔ di suspension .

CNC mashin de yuz bɔku bɔku wan fɔ mek di suspension komponent dɛn, we de ple impɔtant pat fɔ mek shɔ se motoka stebul, handle, ɛn rayd kɔmfɔt. Di prɛsishɔn ɛn di tɛm we CNC-mashin sɔspɛns pat dɛn go de fɔ lɔng tɛm de kɔntribyut to di ɔl sef ɛn pefɔmɛns fɔ di motoka. Na sɔm ki sɔspɛns kɔmpɔnɛnt dɛn we dɛn prodyuz we dɛn de yuz CNC mashin:

1. Kontrol Arms : Kontrol arm na krichal suspenshon komponent we de konekt di vehikul in fram o sabframe to di stiarin knuckle, we de alaw fo wil muv en alayne. CNC mashin de yuz fɔ mek kɔntrol an dɛn wit di trɛnk we nid, stiffnɛs, ɛn prɛsis jɔyometri. Di akkuracy of CNC mashinin de mek shɔ se di kɔntrol an dɛn fit pafɛkt wan ɛn gi di bɛst wil alaynɛshɔn ɛn kɔntrol.

2. Knuckles : Stiarin knuckles, we dɛn kin kɔl bak spindles, na di komponent dɛn we de kɔnɛkt di wil hab to di kɔntrol an dɛn ɛn alaw fɔ roteshɔn na wil ɛn stiarin. CNC mashin de yuz fɔ mek di kɔmpleks jɔyometri ɛn prɛsis mawntin pɔynt dɛn fɔ di nɛk. Di akkuracy of CNC-machined knuckles de mek shɔ se di rayt wil alaynɛshɔn ɛn smol smol stiarin ɔpreshɔn.

3. Hubs : Wil hab na di sentral komponent dɛm we de kɔnɛkt di wil ɛn brek rɔta to di motoka in sɔspɛns ɛn drayvtreyn. CNC mashin de yuz fɔ mek di prɛsis bor ɛn mawntin sɔfays fɔ di hab dɛn, mek shɔ se dɛn fit pafɛkt wan wit di bia ɛn ɔda kɔmpɔnɛnt dɛn. Di akkuracy ɛn durability fɔ CNC-machin hab dɛn impɔtant fɔ mentɛn wil alaynɛshɔn ɛn ridyus vaybrɛshɔn.

Di bɛnifit dɛn we yu go gɛt we yu yuz CNC mashin fɔ di prodakshɔn fɔ di suspension kɔmpɔnɛnt dɛn na:

L Impɔtant hanlin ɛn stebiliti .

l Ridyus di vaybreshɔn ɛn nɔys .

l Ekstend komponent layfspan .

l Kɔnsistɛnt ɛn rili pefɔmɛns .

Bay we yu mek shɔ se di prɛsishɔn ɛn di tɛm we dɛn go ebul fɔ du di suspension components, CNC mashin de kɔntribyut to di ɔvala sef, kɔmfɔt, ɛn pefɔmɛns fɔ di motoka. Dis, in turn, de gi beta draiv expiriens fo konsuma dem en helep otomotiv manifakta dem maintain dem kompititiv edj in di market.

Brek sistem komponent dɛn .

CNC mashinin de ple wan impɔtant pat pan di prodakshɔn fɔ brek sistɛm kɔmpɔnɛnt dɛn, we impɔtant fɔ mek shɔ se motoka sef ɛn pefɔmɛns. Di prɛsishɔn ɛn rilaybiliti fɔ CNC-mashin brek pat dɛn de kɔntribyut to di ɔvala brek efyushɔn ɛn rispɔnsivnɛs fɔ di motoka. Na sɔm ki brek sistem kɔmpɔnɛnt dɛn we dɛn prodyuz we dɛn de yuz CNC mashin:

1. Brek Calipers : Brek kalipa na di komponent we de haus di brek pad ɛn put prɛshɔn pan di brek rɔta, we de mek di motoka slo ɔ stɔp. CNC mashin de yuz fɔ mek di kɔmpleks jɔyometri ɛn prɛsis bor sɔfays dɛn fɔ di kalipa dɛn, fɔ mek shɔ se dɛn fit am fayn ɛn fɔ mek dɛn wok fayn fayn wan. Di akkuracy of CNC-machined kalipa na impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns brek pefɔmɛns ɛn fɔ ridyus di brek fade.

2. Brek rɔta : Brek rɔta, we dɛn kin kɔl bak brek disk, na di kɔmpɔnɛnt dɛn we de rɔn we di brek pad dɛn kin klem pan fɔ mek dɛn gɛt frikshɔn ɛn slo di motoka. CNC mashin de yuz fɔ mek di prɛsis sɔfays ɛn kol vane dɛn na di rɔta dɛn, mek shɔ se dɛn ebul fɔ dissipate di ɔt fayn fayn wan ɛn di kɔnsistɛns brek pefɔmɛns. Di akkuracy of CNC-machined rotors na impɔtant tin fɔ minimiz brek vaybreshɔn ɛn mek shɔ se ivin wear fɔ di brek pad dɛn.

3. Masta silinda : Di masta silinda na di at fɔ di brek sistem, we gɛt di wok fɔ kɔnvɔyt di fɔs we dɛn aplay to di brek pedal to haydrolik prɛshɔn we de aktyuet di brek kalipa dɛn. CNC mashin de yuz fɔ mek di prɛsis bor ɛn piston surfaces fɔ di masta silinda, fɔ mek shɔ se dɛn ebul fɔ wok fayn ɛn dɛn kin abop pan dɛn. Di akkuracy of CNC-machined masta silinda impɔtant fɔ mentɛn kɔnsistɛns brek pedal fil ɛn brek pefɔmɛns.

Di bɛnifit dɛn we yu go gɛt we yu yuz CNC mashin fɔ mek di brek sistɛm kɔmpɔnɛnt dɛn na:

l Impɔtant brek pefɔmɛns ɛn efyushɔn .

l Ridyus di brek fade ɛn vaybreshɔn .

l Ekstend komponent layfspan .

l Kɔnsistɛnt ɛn rilibul brek ɔpreshɔn .

Bay we yu mek shɔ se di prɛsishɔn ɛn rilaybiliti fɔ di brek sistɛm kɔmpɔnɛnt dɛn, CNC mashin de kɔntribyut to di ɔvala sef ɛn pefɔmɛns fɔ di motoka. Dis, in turn, de gi pis na maynd to kɔstɔma dɛn ɛn ɛp ɔtomotiv manifakta dɛn fɔ kip dɛn reputeshɔn fɔ prodyuz ay kwaliti, sef motoka dɛn.

Stiarin sistem komponent dɛn .

CNC mashin de yuz bɔku bɔku wan fɔ mek di stiarin sistɛm kɔmpɔnɛnt dɛn, we rili impɔtant fɔ mek shɔ se dɛn de yuz di prɛsis ɛn rispɔnsiv we aw dɛn de handle di motoka. Di akkuracy ɛn durabiliti fɔ CNC-machin stiarin pat dɛn de kɔntribyut to di ɔvala sef ɛn pefɔmɛns fɔ di motoka. Na sɔm ki stiarin sistɛm kɔmpɔnɛnt dɛn we dɛn prodyuz we dɛn de yuz CNC mashin:

1. Stiarin rek ɛn piniɔn : Di stiarin rɛk ɛn piniɔn na di at fɔ di stiarin sistem, we gɛt di wok fɔ chenj di rɔta muvmɛnt fɔ di stiarin to di linya muvmɛnt we de tɔn di wil dɛn. CNC mashin de yuz fɔ mek di prɛsis gia tit ɛn haus sɔfays fɔ di rɛk ɛn piniɔn, we de mek shɔ se di stiarin we de wok fayn ɛn kɔrɛkt. Di akkuracy of CNC-machined rack en pinion assemblies na impɔtant tin fɔ mentɛn prɛsis stiarin kɔntrol ɛn ridyus stiarin ple.

2. Stiarin Kɔlɔm : Di stiarin kɔlɔm na di kɔmpɔnɛnt we de kɔnɛkt di stiarin to di stiarin rɛk, we de transmit di drayva in input to di wil dɛn. CNC mashin de yuz fɔ mek di prɛsis biɛrin sɔfays ɛn mawntin pɔynt dɛn na di stiarin kɔlɔm, fɔ mek shɔ se dɛn de rɔtin fayn fayn wan ɛn ridyus di vaybrɛshɔn. Di akkuracy of CNC-machined stiarin kolm na impɔtant fɔ mentɛn prɛsis stiarin fil ɛn minimiz stiarin shaft fleks.

3. Tay Rod : Tay rod na di komponent dɛn we de kɔnɛkt di stiarin rɛk to di stiarin knuckles, we de transmit di stiarin fɔs to di wil dɛn. CNC mashin de yuz fɔ mek di prɛsis trɛdin ɛn bɔl jɔyn sɔfays dɛn na di tay rod dɛn, fɔ mek shɔ se di wil alaynɛshɔn kɔrɛkt ɛn fɔ mek di stiarin wok fayn fayn wan. Di akkuracy of CNC-machined tie rods na impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt prɛsis stiarin jɔyometri ɛn fɔ ridyus di taya wear.

Di bɛnifit dɛn we yu go gɛt we yu yuz CNC mashin fɔ di prodakshɔn fɔ di stiarin sistɛm kɔmpɔnɛnt dɛn na:

L Impɔtant stiarin prɛsishɔn ɛn rispɔnsivnɛs .

l Ridyus stiarin ple ɛn vaybreshɔn .

l Ekstend komponent layfspan .

l Kɔnsistɛnt ɛn rili stiarin pefɔmɛns .

Bay we yu mek shɔ se di stiarin sistɛm kɔmpɔnɛnt dɛn kɔrɛkt ɛn te, CNC mashin de kɔntribyut to di ɔl sef, hanlin, ɛn pefɔmɛns fɔ di motoka. Dis, in turn, de gi wan mɔ ɛnjɔymɛnt ɛn kɔnfidɛns drayv ɛkspiriɛns fɔ kɔstɔma dɛn ɛn ɛp ɔtomotiv manifakta dɛn fɔ kip dɛn kɔmpitishɔn edj na di makit.

Intɛriɔ ɛn ɛkstirian trim pat dɛn .

CNC mashin na di wan we dɛn kin yuz bɔku bɔku wan fɔ mek di intɛriɔ ɛn ɛkstirian trim pat dɛn, we kin kɔntribyut to di aesthetic apil, kɔmfɔt, ɛn funkshɔnaliti fɔ di motoka. Di prɛsishɔn ɛn versatility fɔ CNC mashin de alaw fɔ mek kɔmpleks shep ɛn intrikɛt ditil dɛn we de ɛp fɔ mek di ɔl kwaliti ɛn di we aw di motoka luk fayn. Na sɔm ki intɛriɔ ɛn ɛkstirian trim pat dɛn we dɛn prodyuz yuz CNC mashin:

1. Dashbɔd Kɔmpɔnɛnt : Dɛn kin yuz CNC mashin fɔ mek difrɛn dashbɔd kɔmpɔnɛnt dɛn, lɛk inschrumɛnt panɛl, sɛnta kɔnsol, ɛn ɛya vent. Di prɛsishɔn fɔ CNC mashin de alaw fɔ mek kɔmpleks shep dɛn, tayt tolɛreshɔn dɛn, ɛn smol smol sɔfays dɛn we nɔ gɛt wan prɔblɛm intagret wit di motoka in intɛriɔ dizayn. CNC-machined dashbɔd kɔmpɔnɛnt dɛn nɔ jɔs de ɛp fɔ mek di vijual apil bɛtɛ bɔt i de mek shɔ bak se di difrɛn kɔntrol ɛn displei dɛn de wok fayn fayn wan.

2. Door handels and panels : CNC mashin de yuz fɔ prodyuz doa handel, doa panɛl, ɛn ɔda intɛriɔ trim kɔmpɔnɛnt dɛn. Di akkuracy ɛn kɔnsistɛns fɔ CNC mashin de mek shɔ se dɛn pat ya fit fayn fayn wan ɛn wok fayn fayn wan, we de gi ay kwaliti fil to di motoka in intɛriɔ. Dɛn kin mek CNC-mashin domɔt handel ɛn panɛl dɛn wit intrikɛt dizayn dɛn, tɛkstɔr sɔfays dɛn, ɛn prɛsis mawntin pɔynt dɛn, ɛnhans ɔl tu di aesthetics ɛn funkshɔnaliti fɔ di motoka in domɔt dɛn.

3. Grilles and Emblems : Dɛn kin yuz CNC mashin fɔ mek ɛkstirian trim pat dɛn lɛk gril ɛn emblem, we na impɔtant tin dɛn we de na motoka in frɔnt fascia. Di prɛsishɔn ɛn versatility fɔ CNC mashin alaw fɔ mek di intrɛstin ɛn difrɛn dizayn dɛn we de sho di motoka in brand aydentiti. CNC-mashin gril ɛn emblem kin prodyuz wit tayt tolɛreshɔn, we de mek shɔ se i fit fayn fayn wan ɛn alaynɛshɔn fayn wit di bɔdi wok we de rawnd am. Dɛn pat ya nɔ jɔs de ɛp fɔ mek di motoka in aesthetic apil bɛtɛ bɔt i de ɛp bak fɔ mek i ebul fɔ du di aerodaynamik pefɔmɛns ɛn fɔ mek i kol.

Di bɛnifit dɛn we yu go gɛt we yu yuz CNC mashin fɔ mek di intɛriɔ ɛn ɛkstirian trim pat dɛn na:

l Enhansed vijual apil ɛn brand aydentiti .

l Impɔtant fitmɛnt ɛn funkshɔnaliti .

l Kɔnsistɛnt ɛn ay kwaliti apia .

l Abiliti fɔ mek kɔmpleks shep ɛn intrɛst ditil dɛn .

Bay we yu mek shɔ se di prɛsishɔn, kwaliti, ɛn aesthetic apil fɔ intɛriɔ ɛn ɛkstirian trim pat dɛn, CNC mashin de kɔntribyut to di ɔvala kastoma satisfayshɔn ɛn di we aw pipul dɛn de si di motoka. Dis, in turn, de ɛp ɔtomotiv manifakta dɛn fɔ difrɛns dɛn prɔdak ɛn mentɛn dɛn kɔmpitishɔn edj na di makit.

CNC Machining Materials fɔ di Ɔtomotiv Indastri .

Di ɔtomotiv industri de dipen pan bɔku bɔku matirial dɛn fɔ prodyuz ay kwaliti, durable, ɛn pefɔmɛns-oriɛnted kɔmpɔnɛnt dɛn. CNC mashinin na kɔmpitabl wit bɔku pan dɛn matirial ya, we de alaw di manifakta dɛn fɔ mek pat dɛn wit spɛshal prɔpati dɛn we dɛn mek fɔ dɛn aplikeshɔn dɛn.

Mɛtal dɛn .

Mɛtal na di tin dɛn we dɛn kin yuz pas ɔl na di ɔtomotiv industri bikɔs dɛn gɛt trɛnk, dɛn kin te, ɛn dɛn kin yuz dɛn fɔ du mɔ. CNC mashin na wel-suited fɔ prosɛs difrɛn mɛtal alɔy, we de mek dɛn ebul fɔ mek kɔmpleks jɔyometri ɛn prɛsis tolɛreshɔn. Na sɔm pan di kɔmɔn mɛtal alɔy dɛn we dɛn kin yuz fɔ CNC mashin fɔ ɔtomotiv aplikeshɔn dɛn:

1. Aluminium Alloys : Aluminium alɔy dɛn layt, dɛn nɔ de kɔrɛshɔn, ɛn dɛn de gi fayn fayn mashin dɛn. Dɛn kin yuz dɛn fɔ di injin kɔmpɔnɛnt dɛn, di pat dɛn we dɛn kin yuz fɔ mek di injin, ɛn di panɛl dɛn we dɛn kin yuz fɔ mek di bɔdi. Populɔr aluminiɔm alɔys fɔ ɔtomotiv CNC mashin inklud:

wan. 6061: Dɛn sabi am fɔ in fayn fayn balans fɔ trɛnk, kɔrɛshɔn rɛsistɛns, ɛn mashinabiliti.

B. 7075: de gi ay trɛnk ɛn wear resistans, we de mek i fayn fɔ strɔkchɔral ɛn lod-bia kɔmpɔnɛnt dɛn.

2. Stilin alɔy : Stilin alɔy dɛn gɛt nem fɔ dɛn trɛnk, taf, ɛn we go de fɔ lɔng tɛm. Dɛn kin yuz dɛn na difrɛn ɔtomotiv aplikeshɔn dɛn, lɛk drayv tren kɔmpɔnɛnt dɛn, sɔspɛns pat dɛn, ɛn fastɛns dɛn. Kɔmɔn stɛl alɔy fɔ CNC mashin inklud:

wan. 4140: Wan kromium-molibden alɔy wit ay tɛnsiɛl trɛnk ɛn taya rɛsistɛns, we dɛn kin yuz bɔku tɛm fɔ gia ɛn shaft.

B. 1045: Wan midul kabɔn stɛl wit gud mashinabiliti ɛn wear resistans, we fayn fɔ brakɛt ɛn fiks.

3. Titanium aloys : Titanium alɔy dɛn de gi wan ɛksɛpshɔn trɛnk-to-weyt rɛsɛshɔn, kɔrɛshɔn rɛsistɛns, ɛn ay-tɛmpracha pefɔmɛns. Dɛn kin yuz dɛn na ay-pafɔmɛnshɔn aplikeshɔn dɛn, lɛk injin valv dɛn, kɔnɛktin rod dɛn, ɛn tɔbochaja kɔmpɔnɛnt dɛn. Di mɔs kɔmɔn taytaniɔm alɔy fɔ ɔtomotiv CNC mashin na:

wan. TI-6AL-4V: Dɛn sabi am fɔ in ay trɛnk, layt wet, ɛn fayn fayn fatigue resistans.

4. Magnesium alloys : Magnesium alloy na di layt strukchɔral mɛtal dɛm, we de gi fayn fayn trɛnk-to-weyt rεshɔn ɛn gud mashinabiliti. Dɛn kin yuz dɛn na aplikeshɔn usay fɔ ridyus di wet impɔtant, lɛk injin blɔk, transmishɔn kes, ɛn stiarin wil frem. Kɔmɔn magnɛsiɔm alɔy fɔ CNC mashin inklud:

wan. AZ91D: de gi gud kastabiliti, trɛnk, ɛn kɔrɛshɔn rɛsistɛns.

B. AM60B: Dɛn sabi am fɔ in fayn fayn daktiliti, impak rɛsistɛns, ɛn mashinabiliti.

Tin dɛn | Densiti (g/cm³) | Tensil Strɔng (MPA) . | Machinabiliti fɔ di wan dɛn we de wok . |

Aluminium (6061-T6) | 2.70 | 310 | Wɛl dɔn |

Stiɛl (4140) . | 7.85 | 655 | Gud |

Titanium (Ti-6al-4V) | 4.43 | 950 | Du tin tret |

Magnɛsiɔm (AZ91D) . | 1.81 | 230 | Wɛl dɔn |

Plastik dɛn .

Apat frɔm mɛtal, dɛn de yuz plastic mɔ ɛn mɔ na di ɔtomotiv industri fɔ difrɛn aplikeshɔn dɛn, frɔm intɛriɔ trim kɔmpɔnɛnt dɛn to funkshɔn pat dɛn. CNC mashinin na wɛl-suited fɔ prosɛs injinɛri plastic, ɔfr di abiliti fɔ mek kɔmpleks jɔyometri, tayt tolɛreshɔn, ɛn smol surface finish. Na sɔm pan di kɔmɔn plastic dɛn we dɛn kin yuz fɔ CNC mashin fɔ ɔtomotiv aplikeshɔn dɛn:

1. ABS (Acrylonitrile Butadiene Styrene) : ABS na wan pɔpul tɛmplastik we dɛn sabi fɔ in impak rɛsistɛns, taf, ɛn dimɛnshɔnal stebiliti. I kin yuz am fɔ intɛriɔ trim kɔmpɔnɛnt dɛn, lɛk dashbɔd panɛl, kɔnsol kɔva, ɛn ɛya vent. ABS de gi gud mashinabiliti, we de alaw fɔ mek di intrikɛt dizayn dɛn ɛn di smol smol say dɛn.

2. Nylon : Naylon na wan versatile enjinering plastic wit fayn fayn mɛkanikal prɔpati dɛm, we inklud ay trɛnk, wear resistance, ɛn low friction. Dɛn kin yuz am na difrɛn ɔtomotiv aplikeshɔn dɛn, lɛk gia, bia, ɛn fastɛns. Naylon in sɛlf-lɔbrik prɔpati dɛn de mek am fayn fɔ muv pat dɛn, we de ridyus di nid fɔ ɔda lɔbrikeshɔn.

3. Asetal : asetal, we dɛn kin kɔl bak polyoxymethylene (POM), na wan ay-perfɔmans plastic we gɛt fayn fayn dimɛnshɔnal stebiliti, stiffness, ɛn wear resistance. Dɛn kin yuz am fɔ prɛsishɔn ɔtomotiv kɔmpɔnɛnt dɛn, lɛk fiul sistɛm pat dɛn, domɔt lɔk mɛkanism dɛn, ɛn winda rɛgyulatɔ dɛn. Asetal in lɔw mɔstɔ absɔpshɔn ɛn gud mashinabiliti mek i fayn fɔ tayt-tɔlerans aplikeshɔn dɛn.

4. Peek (Polyether Ether Ketone) : Peek na wan ay-perfomans tɛmplastik wit ɛksɛpshɔn mɛkanikal ɛn tɛmral prɔpati dɛn. I de gi ay trɛnk, stiffnɛs, ɛn dimɛnshɔnal stebiliti, ivin na ɛlevɛt tɛmpracha. Peek na yuz in dimand otomotiv aplikeshɔn, lɛk injin kɔmpɔnɛnt, transmishɔn pat, ɛn brek sistem. I fayn fayn wear resistans ɛn kemikal resistans de mek i fayn fɔ harsh envayrɔmɛnt.

Tin dɛn | Densiti (g/cm³) | Tensil Strɔng (MPA) . | Maks. Kɔntinyu fɔ yuz di tɛmpracha (°C) . |

ABS na ABS | 1.04 | 44 | 85 |

Naylon 6 . | 1.14 | 79 | 100 |

Asɛtal . | 1.41 | 68 | 100 |

Peek na peek . | 1.32 | 100 | 250 |

We dɛn de pik wan plastic matirial fɔ CNC mashin na di ɔtomotiv industri, injinia dɛn kin tink bɔt tin dɛn lɛk mɛkanikal prɔpati, tɛmpracha rɛsistɛns, kemikal rɛsistɛns, ɛn kɔst. Di we aw dɛn de yuz plastic na ɔtomotiv aplikeshɔn dɛn de gi sɔm bɛnifit dɛn, lɛk fɔ ridyus di wet, fɔ mek dɛn nɔ gɛt kɔrɛshɔn, ɛn fɔ mek dɛn nɔ gɛt ilɛktrik insuleshɔn.

Bay we dɛn de yuz di tin dɛn we CNC mashin dɛn ebul fɔ du ɛn di prɔpati dɛn we dɛn injinia plastic ya gɛt, di wan dɛn we de mek motoka dɛn kin mek layt we nɔ at fɔ yuz, we go de fɔ lɔng tɛm, ɛn we dɛn kin yuz prɛsishɔn fɔ mek dɛn ebul fɔ wok fayn, ɛn dɛn kin mek dɛn fil fayn.

Kɔmpɔzit dɛn .

Kɔmpɔzit matirial dɛn de yuz mɔ ɛn mɔ na di ɔtomotiv industri bikɔs ɔf dɛn yon kɔmbaynshɔn fɔ prɔpati dɛn, lɛk ay trɛnk-to-weyt rɛsɛshɔn, kɔrɛshɔn rɛsistɛns, ɛn dizayn fleksibiliti. CNC mashinin de ple wan impɔtant pat pan di prɔsesin fɔ kɔmpɔzit kɔmpɔnɛnt dɛn, we de mek dɛn ebul fɔ mek kɔmpleks shep dɛn ɛn prɛsis ficha dɛn. Na tu pan di kɔmɔn kɔmpɔzit matirial dɛn we dɛn kin yuz fɔ CNC mashin fɔ ɔtomotiv aplikeshɔn dɛn:

1. Kabon Fayba Riinfɔs Plastik (CFRP) : CFRP na ay-perfɔmans kɔmpɔzit matirial we gɛt kabɔn fayba dɛn we dɛn ɛmbas insay wan polima matris. I de gi spɛshal trɛnk-to-weyt rɛsɛshɔn, stiffnɛs, ɛn taya rɛsistɛns. CFRP de yuz insay difrɛn ɔtomotiv aplikeshɔn dɛn, inklud:

wan. Struktural komponent: Chasis, suspension arms, ɛn roll kech.

B. Ekstirian bɔdi panɛl dɛn: hud, ruf, ɛn trɔnk lid dɛn.

c. Trim intɛriɔ: Dashbɔd, sit frem, ɛn stiarin wil.

CNC mashin de yuz fɔ trim, drɔ, ɛn mil CFRP kɔmpɔnɛnt dɛn, fɔ mek shɔ se di dimɛnshɔn dɛn we dɛn gɛt ɛn di smol smol say dɛn we de na di say dɛn we dɛn de. Bɔt, mashin CFRP nid spɛshal tul ɛn tɛknik fɔ minimiz delamination ɛn fayv pul ɔut.

2. Glas fayba riinfɔs plastic (GFRP) : GFRP na kɔmpɔzit matirial we gɛt glas fayba dɛn we dɛn ɛmbas insay wan polima matris. I de gi gud trɛnk-to-weyt rɛsɛshɔn, ilɛktrik insuleshɔn, ɛn kɔrɛshɔn rɛsistɛns. GFRP de yuz insay difrɛn ɔtomotiv aplikeshɔn dɛn, lɛk:

wan. Bɔdi panɛl dɛn: Fɛnda, domɔt skin, ɛn spay taya kɔva.

B. Ilɛktrik Kɔmpɔnɛnt dɛn: Batri trey, fiuz bɔks, ɛn kɔnɛkta os dɛn.

c. Struktural Pat: Lif spring, bampa bim, ɛn krɔs mɛmba.

CNC mashin de yuz fɔ kɔt, drɔ, ɛn shep GFRP kɔmpɔnɛnt dɛn, we de alaw fɔ mek kɔmpleks jɔyometri ɛn tayt tolɛreshɔn. Machining GFRP nid fɔ tek tɛm sɛlɛkshɔn fɔ kɔt tul ɛn paramita fɔ minimiz fayba brek ɔut ɛn mek shɔ se klin edj finish.

Tin dɛn | Densiti (g/cm³) | Tensil Strɔng (MPA) . | Elastik modulus (GPA) . |

CFRP we de na di wɔl. | 1.55 | 2000-2500 na di | 130-150 we dɛn bin de yuz. |

GFRP we de na di . | 1.85 | 500-1000 na di | 20-40. |

Di yus fɔ kɔmpɔzit matirial dɛn na di ɔtomotiv industri de gi sɔm bɛnifit dɛn, lɛk fɔ ridyus di wet, fɔ mek di fiul fayn fayn wan, ɛn fɔ mek dɛn wok fayn. Bɔt, mashin kɔmpɔzit dɛn de prɛzɛnt spɛshal chalenj dɛn we yu kɔmpia am wit mɛtal ɛn plastic. Prɔpa tul sɛlɛkshɔn, kɔt paramita, ɛn mashin strateji impɔtant fɔ mek shɔ se di kwaliti ɛn intɛgriti fɔ di mashin kɔmpɔzit kɔmpɔnɛnt dɛn.

Bay we dɛn de yuz di tin dɛn we CNC mashin dɛn ebul fɔ du ɛn di prɔpati dɛn we dɛn kɔmpɔzit matirial ya gɛt, di wan dɛn we de mek motoka kin mek layt, ay-strɛng, ɛn prɛsishɔn-ɛnjɛnɛri kɔmpɔnɛnt dɛn we de push di bɔda dɛn fɔ di motoka in pefɔmɛns ɛn di efyushɔn.

Di fiuja fɔ CNC mashin na di ɔtomotiv industri .

As di ɔtomotiv industri de kɔntinyu fɔ evolv, CNC mashin de rɛdi fɔ ple wan ivin mɔ impɔtant pat fɔ shep di fiuja fɔ mek motoka. Wit di advansmɛnt dɛn we dɛn dɔn mek pan tɛknɔlɔji ɛn di bɔku bɔku nyu tin dɛn we de apin, lɛk di industri 4.0, aditiv manufakchurin, ɛn ilɛktrik ɛn ɔtonamɛnt motoka dɛn, CNC mashin de adap fɔ mit di chenj we di industri nid.

Indastri 4.0 ɛn Smart Manufakchurin .

Indastri 4.0, we dɛn kin kɔl bak di Fɔs Indastrial Rivɔlɔshɔn, de chenj di we aw dɛn de mek ɔtomotiv kɔmpɔnɛnt dɛn. Dis nyu tɛm we dɛn de mek tin dɛn de pe atɛnshɔn mɔ pan di intagreshɔn fɔ advans tɛknɔlɔji dɛn, lɛk di Intanɛt fɔ Tin dɛn (IoT), Atikul Intɛlijɛns (AI), ɛn Big Data Analitiks, fɔ mek smat faktri dɛn. Insay di kɔntɛks fɔ CNC mashin, dis min se:

1. Integreshɔn fɔ CNC mashin dɛn wit IoT divays dɛn : Bay we dɛn de gi CNC mashin dɛn wit IoT sɛns ɛn kɔnɛktiviti, di wan dɛn we de mek dɛn kin gɛda rial-taym data bɔt mashin pefɔmɛns, tul wear, ɛn prodak kwaliti. Dis data kin yuz fɔ optimize mashin prɔses, ridyus dauntaym, ɛn impruv ɔl di ikwipmɛnt ɛfifishins (OEE).

2. Rial-taym data analisis fɔ prɛdiktiv mentenɛns : Wit di ɛp fɔ AI ɛn mashin lanin algɔritm, di data we dɛn gɛda frɔm IoT-ɛnibɛl CNC mashin dɛn kin analayz fɔ prɛdikt pɔtɛnɛshɛl mashin fayl ɛn schedule mentenɛns proaktiv wan. Dis prɛdiktiv mentenɛns apɔshɔn de minimiz ɛkspɛkt dawt dawɔntaym, ridyus mentenɛns kɔst, ɛn impruv di rilaybiliti fɔ di manufakchurin prɔses.

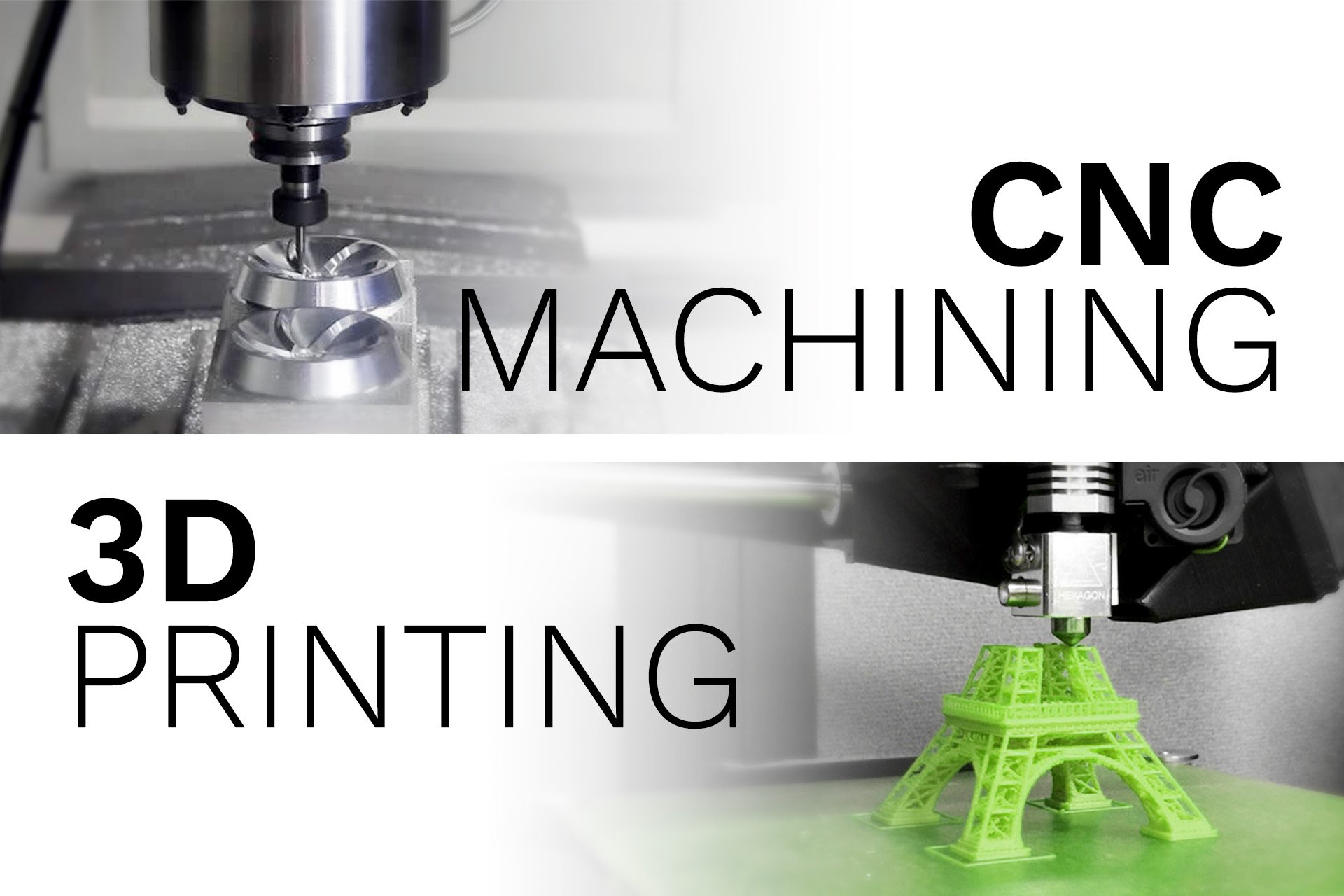

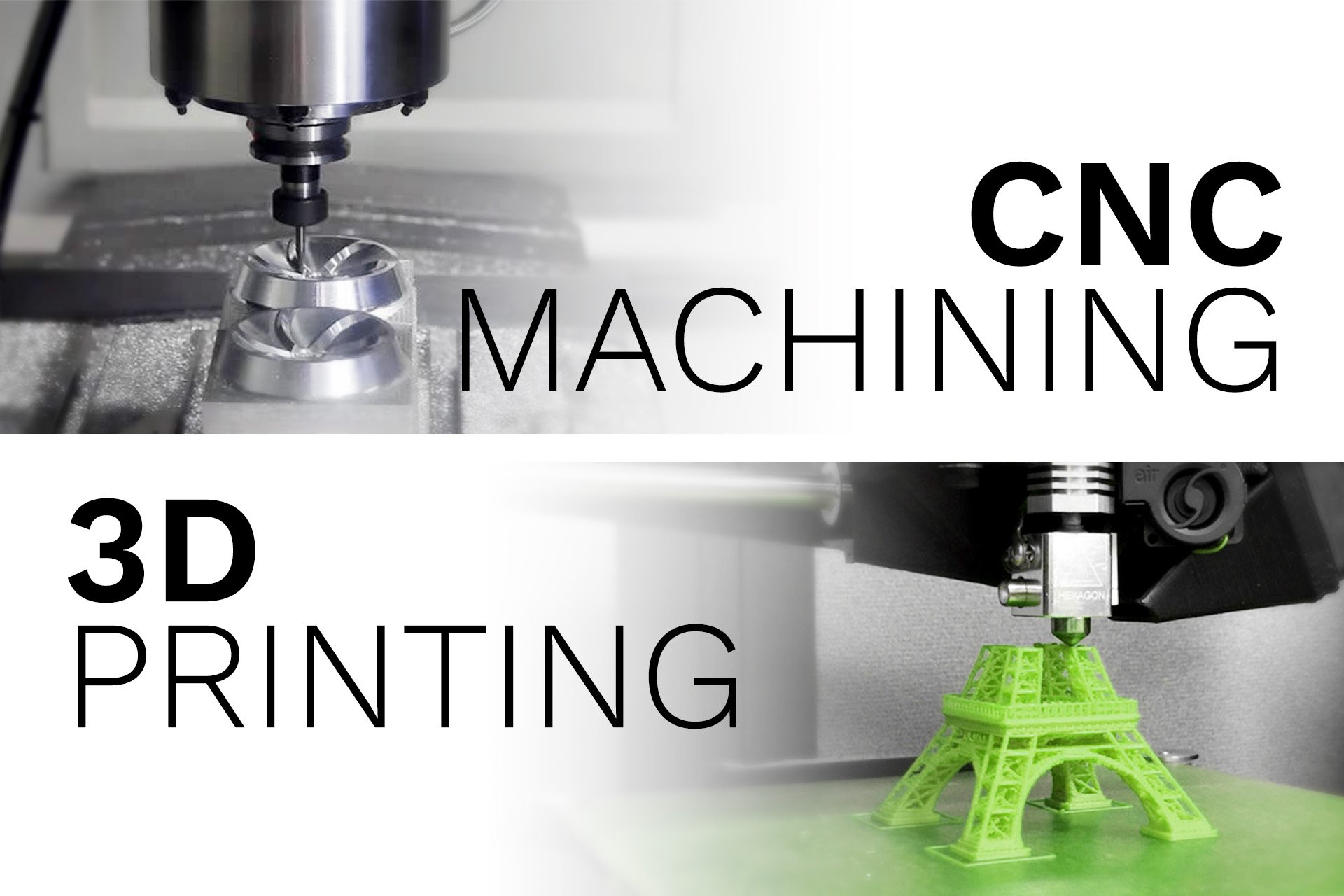

Aditiv manufakchurin ɛn 3D printin .

Aditiv manufacturing, we dɛn kin kɔl bak 3D printin, de yuz mɔ ɛn mɔ na di ɔtomotiv industri fɔ protɔtayp, tul, ɛn ivin di las pat prodakshɔn. Wail CNC mashin stil de bi di praymar we fɔ prodyuz ay-volyum, prɛsishɔn kɔmpɔnɛnt dɛn, aditiv manufakchurin de gi nyu pɔsibul fɔ kɔmpleks jɔyometri ɛn laytwɛt dizayn dɛn.

1. Kɔmbayn CNC mashin wit aditiv manufakchurin : Bay we dɛn jɔyn di trɛnk dɛn fɔ ɔl tu di teknɔlɔji dɛn, ɔtomotiv manifakta dɛn kin mek haybrid pat dɛn we de leva di prɛsishɔn ɛn sɔfays finish fɔ CNC mashin wit di dizayn fridɔm ɛn wet ridɔkshɔn fɔ aditiv manufakchurin. Fɔ ɛgzampul, wan 3D-printed pat kin bi CNC mashin fɔ ajɔst tayt tolɛreshɔn ɛn smol smol sɔfays na impɔtant eria dɛn.

2. Rapid prototyping ɛn tul : Aditiv manufakchurin de mek dɛn ebul fɔ prodyuz kwik ɛn kɔst-ɛfɛktiv fɔ protɔtayp pat ɛn tul dɛn, lɛk mold ɛn fiks. Dis rapid prototyping kapabiliti de alaw ɔtomotiv injinia dɛn fɔ itɛrayt dizayn dɛn fast fast, validet kɔnsɛpt dɛn, ɛn briŋ nyu prɔdak dɛn fɔ makɛt kwik kwik wan. CNC machining kin den yuz fɔ rifin ɛn optimize di fainal dizayn fɔ mas prodakshɔn.

Ilɛktrik ɛn ɔtonamɛnt motoka dɛn .

Di rayz fɔ ilɛktrik ɛn ɔtonamɛnt motoka dɛn de drɛb nyu dimand fɔ laytwɛt kɔmpɔnɛnt ɛn prɛsishɔn-machin pat dɛn. CNC mashin de adap fɔ mit dɛn chalenj ya ɛn sɔpɔt di divɛlɔpmɛnt fɔ nɛks-jɛnɛreshɔn motoka dɛn.

1. CNC mashin fɔ laytwɛt kɔmpɔnɛnt dɛn : Ilɛktrik motoka dɛn nid laytwɛt kɔmpɔnɛnt dɛn fɔ maksimayz bateri rɛnj ɛn efyushɔn. Dɛn de yuz CNC mashin fɔ mek layt pat dɛn frɔm advans matirial dɛn, lɛk aluminiɔm alɔy, magnɛsiɔm alɔy, ɛn kɔmpɔzit. Bay we dɛn optimize dizayn ɛn leva di prɛsishɔn fɔ CNC mashin, di manifakta dɛn kin mek kɔmpɔnɛnt dɛn we de gi di bɛst balans fɔ trɛnk, stiffnɛs, ɛn wet.

2. Prɛsishɔn mashin fɔ sɛns ɛn ilɛktroniks : Ɔtonɔm motoka dɛn de abop pan wan kɔmpleks arenjmɛnt fɔ sɛns, kamɛra, ɛn ilɛktronik kɔmpɔnɛnt dɛn fɔ no ɛn nevigayt dɛn envayrɔmɛnt. CNC mashinin de ple wan impɔtant rol fɔ prodyuz di ay-prɛsishɔn haus, brakɛt, ɛn kɔnɛkta dɛn we de mek dɛn sistɛm ya ebul fɔ wok fayn fayn wan. As di dimand fɔ ɔtonamɛnt motoka teknɔlɔji de gro, di nid fɔ prɛsishɔn CNC-mashin kɔmpɔnɛnt dɛn go jɔs inkrisayz.

Di fiuja fɔ CNC mashin na di ɔtomotiv industri na brayt, dɛn de drɛb am bikɔs ɔf di advansmɛnt dɛn we dɛn dɔn mek pan tɛknɔlɔji, di rayz we nyu manufakchurin paradaym dɛn de go ɔp, ɛn di nid dɛn we de evolv fɔ nɛks-jɛnɛreshɔn motoka dɛn. We dɛn ebul fɔ tek dɛn chenj ya ɛn adap to nyu prɔblɛm dɛn, CNC mashin go kɔntinyu fɔ bi wan impɔtant tin fɔ di wan dɛn we de mek motoka dɛn insay di ia dɛn we de kam.

Tim MFG: Yu patna in inovashɔn

Custom CNC Machining Services .

Na Tim MFG, wi de gi tayla CNC mashin sɔlvishɔn fɔ mit di yunik nid dɛn fɔ ɔtomotiv manifakta dɛn. Wi stet-ɔf-di-at fasiliti ɛn ɛkspɛkt tim de gi kɔstɔm pat dɛn wit ɛksɛpshɔn prɛsishɔn ɛn kwaliti. Frɔm rapid prototyping to mas prodakshɔn rɔn, wi de gi:

L 3, 4, ɛn 5-aks CNC mashin kapabiliti dɛn .

L kompitibul wit mɛtal, plastic, kɔmpɔzit ɛn mɔ

l Fast tɔn-arawnd tɛm dɛn .

l In-haus dizain fɔ mek (DFM) sɔpɔt .

l Rigorous kwaliti kɔntrol ɛn inspekshɔn .

Fɔ bigin wit Tim MFG .

Wi tim redi fɔ briŋ yu ɔtomotiv vishɔn dɛn to layf tru inovativ mashin sɔlvishɔn dɛn. Na so yu go stat:

1. Kɔntakt Wi : Rich aut via fon, imel ɔ wɛbsayt fɔm fɔ tɔk bɔt yu prɔjek.

2. Disain Rivyu : Wi injinia dɛn de analayz yu CAD mɔdel dɛn ɛn gi DFM fidbak.

3. Prototyping : Wi kin prodyuz protɔtayp dɛn kwik kwik wan fɔ dizayn verifyeshɔn ɛn tɛst.

4. Prodakshɔn : Wit yu aprɔval, wi de muf to kɔst-ɛfɛktiv, ay kwaliti manufakchurin.

5. Delivery : Dɛn kin ship prɛsishɔn ɔto pat dɛn dairekt to yu fasiliti.

Tek di fɔs step fɔ patna wit di mashin ɛkspɛkt dɛn na Tim MFG tide!