CNC masinw daminɛni titaniyɔmu kan .

Titanium ka ɲɛfɔli: a jogo ni a nafaw .

Titanium ye nɛgɛ ye min bɛ mɔgɔ kabakoya, a ka nafolo bɔlenw bɛ yen minnu b’a to a ka di kosɛbɛ izini suguya caman na. Titanium ka jogo ni a nafa jɔnjɔn dɔw filɛ nin ye:

● Fanga caman: Titanium fanga ni a girinya hakɛ ka ɲi kosɛbɛ, o b’a to a barika ka bon kosɛbɛ k’a sɔrɔ a ka nɔgɔn.

● Ɲɛgɛnɛsiraw kɛlɛli : titaniyɔmu bɛ se ka sɔgɔsɔgɔ kosɛbɛ, hali sigida gɛlɛnw na i n’a fɔ kɔgɔji, asidiw, ani kulori.

● Funteni kunbɛncogo: Titanium bɛ se k’a fanga ni a muɲuni sabati hali ni a bɛ funteni camanba la.

● Biocompatibilité: Titanium tɛ baga ye ani a bɛ bɛn hadamadenw ka ɲɛnamayako ma, o b’a to a ka ɲi furakɛlifɛnw ni minɛnw na.

● A ka nɔgɔn: Titanium girinya bɛ se nɛgɛ tilancɛ ma ani a ka ca dɔɔnin ni nɛgɛ ye min tɛ sɔgɔ, o b’a to a bɛ kɛ sugandili ɲuman ye baarakɛcogo la yɔrɔ minnu na girinya ye haminanko ye.

Titanium kɛcogo dɔw ye:

● Aerospace Engineering (motɛriw, fiɲɛbɔlanw, rotorw)

● Dɔgɔtɔrɔso baarakɛlaw (operelifɛnw, minɛnw, wotoroninw) .

● Mobili industry (motɛri yɔrɔw, suspension springs) .

● Spor minɛnw (Golf kuluw, nɛgɛso, baseball-bats)

CNC masinw nafa ka bon bi fɛn dilanni na .

CNC (Ɔridinatɛri jatebɔcogo) masinw jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni taabolo la, kɛrɛnkɛrɛnnenya la ni baara bɛ kɛ ni fɛnw ye i n’a fɔ titanium. Kun jɔnjɔn dɔw filɛ nin ye minnu b’a to . CNC masinw nafa ka bon:

● Tiɲɛni: CNC masinw bɛ se ka yɔrɔw dilan minnu ka tiɲɛni ni u ka tiɲɛni hakɛ ka bon kosɛbɛ, o bɛ a to a ka kɛ cogo basigilen na.

● Baarakɛcogo ɲuman : CNC masinw bɛ se ka baara kɛ tuma bɛɛ, ka baara musakaw dɔgɔya ani ka dɔ fara sɛnɛfɛnw bɔli kan.

● Fɛn caman kɛli : CNC masinw bɛ se ka porogaramu kɛ walasa ka cogoya ni dilancogo gɛlɛn caman dilan, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw dɛmɛ u ka se ka fɛn suguya caman ɲini.

● Segin-ka-bɔnyew: CNC porogaramuw bɛ se ka mara ani ka baara kɛ ni u ye kokura, o bɛ sira di yɔrɔw dilanni ma min bɛ kɛ tuma bɛɛ ani ka segin u kan.

Titanium ta la, CNC masinw ka teli ka kɛ fɛn dilanni fɛɛrɛ ye min ka fisa ka da nin kun ninnu kan:

● Titanium filili walima a dilanni ka gɛlɛn ka ɲɛ ka da a sɔgɔli yɔrɔba kan ani a ka se ka kɛ ni oksizɛni ye.

● CNC machining bɛ tiɲɛni ni tiɲɛni di min ka kan ka kɛ walasa ka titanium yɔrɔ ɲumanw dilan.

● A bɛ sira di cogoya ni dilancogo gɛlɛnw dabɔli ma minnu bɛna gɛlɛya sɔrɔ fɛn dilanni fɛɛrɛ wɛrɛw fɛ.

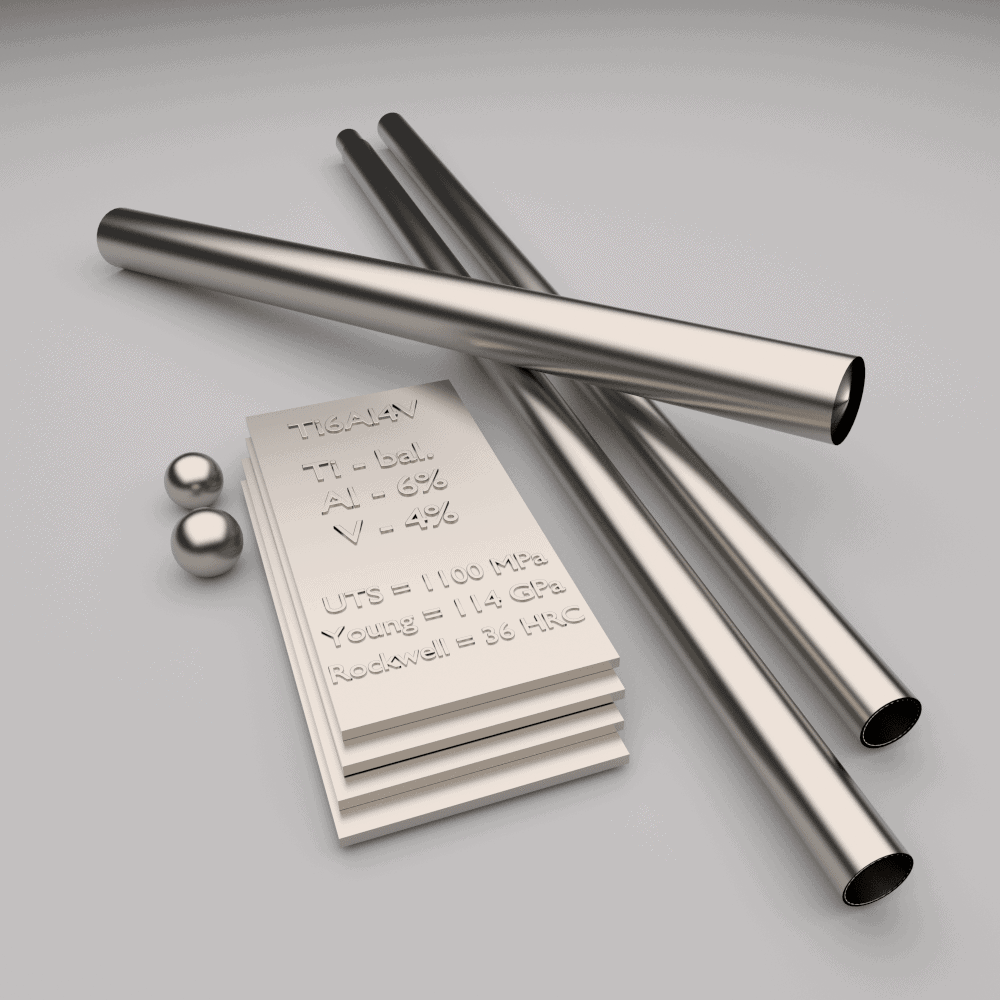

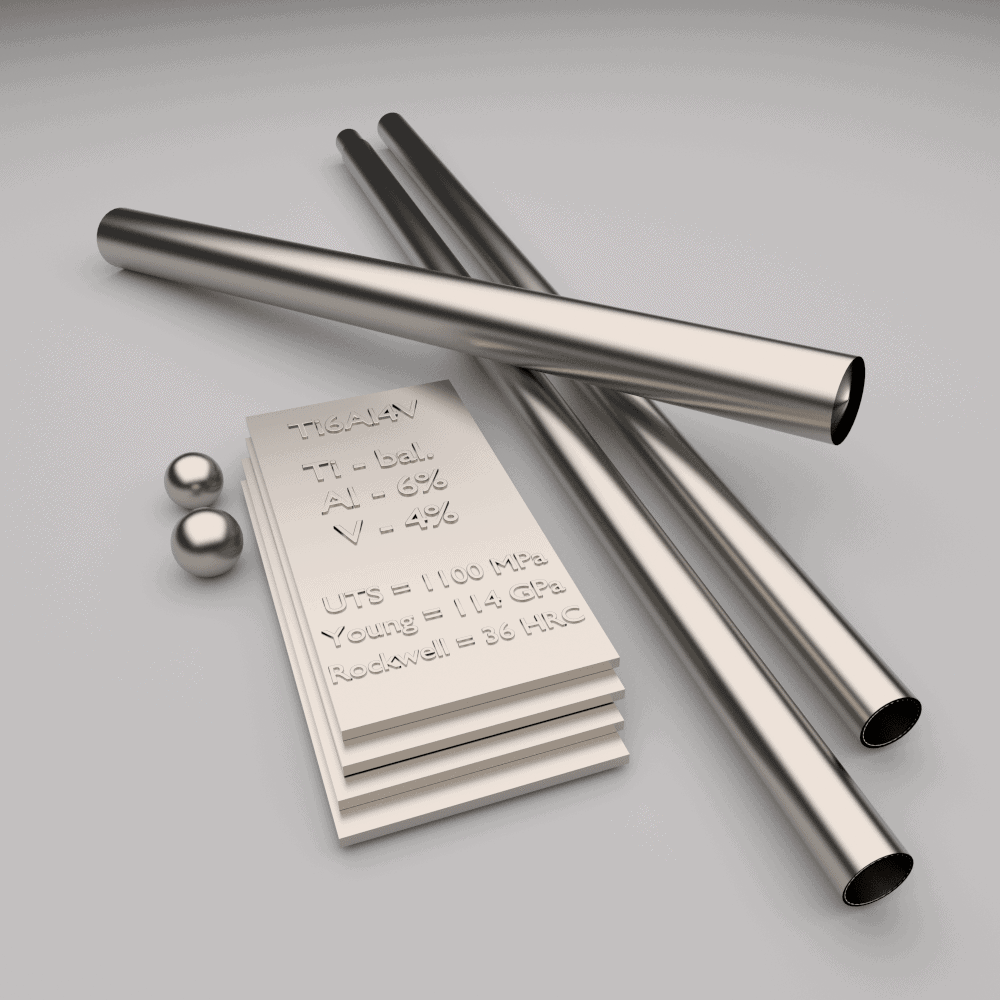

Faamuyali Titanium Alloys .

Titanium alloys ka danfara .

Titanium alloys bɛ se ka tila ka caya ka kɛ kulu saba ye:

● Titanium saniyalen: O bɛ tali kɛ titaniyɔmu na ni fɛn dɔw faralen don a kan. Titanium saniyalen ka nɔgɔn kosɛbɛ ani a dilanni ka nɔgɔn.

● Alpha Alloys: Nin fɛn ninnu bɛ sɔrɔ fɛn minnu na, olu bɛ sɔrɔ fɛnw na minnu bɛ kɛ ka fɛnw sɔgɔ i n’a fɔ aliminiyɔmu, oksizɛni, ani azote. U fanga ka bon ni titaniyɔmu saniyalen ye nka u ka dɔgɔn ni ductile ye.

● Beta alloys (Bɛta bɔgɔlanw) : o fɛnw bɛ sɔrɔ fɛn minnu na i n’a fɔ molibdɛni, nɛgɛ, vanadiyɔmu, chrome ani manganɛsi. U ka ca ni ductile ye wa u bɛ se ka funteni furakɛ walasa ka fanga bonya.

Titanium saniyalen ka jogo .

Titanium saniyalen, n’a bɛ fɔ fana ko jagofɛn saniyalen (CP) titanium, o bɛ ni nin jogo ninnu ye:

● Ɲɛgɛnɛsiraw kɛlɛli ɲuman: Titanium saniyalen bɛ se ka sɔgɔsɔgɔ kosɛbɛ, hali sigida gɛlɛnw na.

● A cogoya ɲuman: Titanium saniyalen ka nɔgɔn ani a ka kan ka kɛ fɛn ye, o bɛ kɛ sababu ye ka a cogoya ni a dilanni nɔgɔya.

● Fanga hakɛ danmadɔ: Hali ni a barika man bon i n’a fɔ titaniyɔmu bɔgɔlanw, titaniyɔmu saniyalen fanga ka ɲi hali bi ni a bɛ tali kɛ nɛgɛ tɔw la.

Titaniyɔmu saniyalen hakɛ minnu bɛ sɔrɔ ɲɔgɔn fɛ, olu ye hakɛ 1 ye (oksizɛni hakɛ dɔgɔman), hakɛ 2 (oksizɛni hakɛ basigilen), hakɛ 3 (oksizɛni hakɛ cɛmancɛ), ani hakɛ 4 (oksizɛni hakɛ caman).

Alpha ni beta titanium alloys ka jogo .

Alpha Titanium Alloys:

● Aluminiyɔmu ni tintin bɛ sɔrɔ a kɔnɔ i n’a fɔ fɛn fɔlɔw .

● Aw ka fanga ni fanga sɔrɔ ka ɲɛ funteni caman na .

● Ductile ka dɔgɔn ka tɛmɛ beta alloys kan .

● Misali: TI-5AL-2.5SN (kalansen 6nan) .

Beta titanium alloys:

● Fɛnw bɛ sɔrɔ a kɔnɔ i n’a fɔ vanadium, molybdenum ani nɛgɛ .

● A ka ca ni ductile ani a cogoya ye ka tɛmɛ alpha alloys kan .

● A bɛ se ka furakɛ ni funteni ye walasa ka fanga bonya .

● Misali: TI-6AL-4V (kalansen 5nan) .

Titanium kalasi danfaralenw .

Jala | Alloy/CP . | Barika | Formulabilité . | Machinability . | Aplikasi typique . |

1 | CP 1000 . | A ka dɔgɔn . | Ɲuman ɲuman | Jamanjan | kemikɛli baarakɛcogo, furakɛli . |

2 | CP 1000 . | Fɛ́gɛn | Jamanjan | Ka bɛrɛbɛn | Aerospace, Marine . |

3 | CP 1000 . | Hakɛ | Ka bɛrɛbɛn | Fɛ́gɛn | Airframes, Cryogenes . |

4 | CP 1000 . | Jamanjan | Fɛ́gɛn | A ka dɔgɔ kosɛbɛ . | Aerospace, Industrie . |

5 | TI6AL4V . | Kosɛbɛ sanfɛ . | Ka bɛrɛbɛn | Fɛ́gɛn | Aerospace, furakɛli implants . |

6 | TI5AL2.5SN . | Jamanjan | Ka bɛrɛbɛn | Ka bɛrɛbɛn | Aerospace, Motɛri yɔrɔw . |

7 | TI-0.15PD . | Fɛ́gɛn | Jamanjan | Jamanjan | kemikɛli baarakɛcogo . |

11 | TI-0.15PD . | Fɛ́gɛn | Jamanjan | Jamanjan | Kɔgɔli, kemikɛli baarakɛcogo . |

12 | TI-0.3Mo-0.8NI . | Jamanjan | Ka bɛrɛbɛn | Ka bɛrɛbɛn | Kɔgɔjida la, kemikɛli siraw . |

23 | TI6AL4V ELI . | Jamanjan | Jamanjan | Fɛ́gɛn | kolotuguda ni ɲinw doncogo . |

Titanium alloy ɲuman sugandi ka kɛ masin ye .

Ni aw bɛ titanium alloy sugandi ka kɛ masin ye, aw bɛ nin ko ninnu jateminɛ:

● Fanga wajibiyalenw: Ni fanga ka bon, aw bɛ beta alloy dɔ sugandi i n’a fɔ TI-6AL-4V (Grade 5).

● Formulabɛn: Baara minnu bɛ kɛ ka kɛɲɛ ni cogoya caman ye, titanium saniyalen (grades 1-4) walima alpha-beta alloys i n’a fɔ TI-6AL-4V (grade 5) olu ye sugandili ɲumanw ye.

● Masina sɔrɔcogo: Titanium saniyalen (kalansen 1-2) ani alfa dɔw ka nɔgɔn ka tɛmɛ beta alloy kan.

● ƝƐNAJƐ ƝƐNAJƐW: Ka ɲɛsin sigidaw ma minnu bɛ sɔgɔ kosɛbɛ, titaniyɔmu saniyalen (min bɛ wele ko 1-4) walima beta alloy i n’a fɔ Ti-0.3Mo-0.8NI (Grade 12) bɛ fɔ.

● musaka: Titanium saniyalen ni alfa alloyw sɔngɔ man gɛlɛn ka tɛmɛ beta alloys kan.

Nafa ni dɛsɛ minnu bɛ sɔrɔ titaniyɔmu tali la .

Mun na Titanium sugandi: Nafaw .

Titanium nafa caman bɛ a la minnu b’a kɛ sugandili ye min bɛ mɔgɔ sama ka taa baara suguya caman na:

● Fanga ni girinya hakɛ caman: Titanium barika ka bon kosɛbɛ k’a sɔrɔ a ka nɔgɔn, a girinya bɛ se a tilancɛ ma i n’a fɔ nɛgɛ.

● Ɲɛgɛnɛsiraw bɛ se ka sɔgɔsɔgɔ kosɛbɛ: Titanium bɛ se ka sɔgɔsɔgɔ kosɛbɛ, hali ni fɛnw ye i n’a fɔ kɔgɔji, kulori ani asidiw.

● Funteni kunbɛncogo: Titanium bɛ se k’a fanga ni a muɲuni sabati funteni camanba la.

● Biocompatibilité: Titanium tɛ baga ye ani a bɛ bɛn hadamadenw ka ɲɛnamayako ma, o b’a to a ka ɲi furakɛlifɛnw ni minɛnw na.

● Masinaya: Hali n’a ka gɛlɛyaw, titaniyɔmu bɛ se ka kɛ ni masinw ye ni fɛɛrɛ ɲumanw ni baarakɛminɛnw ye.

● A bɛ se ka segin ka kɛ fɛn wɛrɛ ye: Titanium bɛ se ka segin a cogo kɔrɔ la, o b’a to a bɛ kɛ sugandili ye min bɛ sigida lakana.

Gɛlɛya minnu bɛ masinw ka titaniyɔmu na: Nafa tɛ minnu na .

Hali ni Titanium bɛ nafa caman di, a bɛ gɛlɛya caman fana lase masinw dilanni waati la:

● Funteni caman sɔrɔli : Titanium ka funteni jiginni ka dɔgɔn, o bɛ kɛ sababu ye ka funteni dalajɛ tigɛminɛn na, o bɛ na ni baarakɛminɛn sɛgɛn teliya ye.

● Galing: Titanium bɛ se ka tugu tigɛminɛn na, o ye ko ye min bɛ wele ko galling, o bɛ se ka baarakɛminɛn ni baarakɛminɛn tiɲɛ.

● Kumakan ni yɛrɛyɛrɛ: Titanium ka modulu dɔgɔman min bɛ kɛ ka mɔgɔw lamaga, o bɛ se ka kɛ sababu ye ka kumakan ni yɛrɛyɛrɛ jugumanba lase masinw ma, ka nɔ bila dugukolo sanfɛla cogoya la.

● Baara gɛlɛya: Titanium bɛ se ka baara kɛ masinw na, ka gɛlɛya ani ka kɛ fɛn ye min bɛ mɔgɔ sɔgɔ, ka dɔ fara baarakɛminɛnw sɛgɛnni kan.

● musaka: Titanium ye fɛn sɔngɔ gɛlɛn ye ni i ye a suma ni nɛgɛ tɔw ye i n’a fɔ aliminiyɔmu walima nɛgɛ.

Titanium ni nɛgɛ wɛrɛw suma ɲɔgɔn na .

Titanium vs.

● Titanium ka nɔgɔn ani a bɛ se ka sɔgɔ ka tɛmɛ nɛgɛ kan.

● A ka c’a la, nɛgɛ sɔngɔ ka dɔgɔ ani a dilanni ka nɔgɔn ka tɛmɛ titanium kan.

● Titanium fanga ni a girinya hakɛ ka ca ni nɛgɛ ye.

Titanium vs.

● Titanium barika ka bon ani a bɛ funteni kɛlɛ ka tɛmɛ aluminiyɔmu kan.

● Aluminiyɔmu sɔngɔ man gɛlɛn ani a dilanni ka nɔgɔn ka tɛmɛ titanium kan.

● Titanium fanga ni a girinya hakɛ ka ca ni aluminiyɔmu ye.

Hali ni Titanium bɛ nafolo sanfɛtaw di, a ka gɛlɛyaw n’a musakaw ka teli k’a kɛ sugandili ye baarakɛminɛnw na, a nafa ka bon yɔrɔ minnu na, i n’a fɔ aerospace, furakɛli, ani baarakɛyɔrɔ minnu bɛ baara kɛ kosɛbɛ.

Gɛlɛya minnu bɛ machining titanium kan .

Titanium ka kemikaliya waleyali ni a ka ko kɛlenw faamuyali .

Titanium ye nɛgɛ ye min bɛ se ka baara kɛ kosɛbɛ. A bɛ se ka kɛ ni gaziw ye masin dilanni waati la, o bɛ na ni gɛlɛyaw ye i n’a fɔ surface oxydation ani embrittlement. O bɛ se ka a yɔrɔw fanga dɔgɔya ani ka dɔ bɔ u ka sɔgɔli la.

Titanium fana bɛ ni modulu dɔgɔman ye min bɛ kɛ ni a fanga ka bon. O b'a Kɛ 'Gummy' fɛn ye ka Kɛ masin ye. Titanium bɛ se ka tugu tigɛminɛn na, o bɛ kɛ sababu ye ka baarakɛminɛnw tiɲɛ ani ka u tiɲɛ. O bɛ Weele ko galling.

Galling fana bɛ nɔ bila titanium yɔrɔw la minnu bɛ masina kɔnɔ.

Sumaya ni tigɛ fanga ɲɛnabɔli machining waati la .

Ka funteni nɛnɛ masina waati la, o ye gɛlɛyaba ye ni titaniyɔmu ye. Titanium ka funteni-taama-cogo ka dɔgɔn, o bɛ kɛ sababu ye ka funteni sɔrɔ tigɛminɛn sigiyɔrɔ la. O bɛ na ni baarakɛminɛnw sɛgɛn teliya ye wa a bɛ se ka nɔ jugu bila tigɛyɔrɔw cogoya la.

Titanium alloys gɛlɛnw bɛ ladonni wɛrɛw de wajibiya. Puce loads belebelebaw ani RPM ka dɔgɔya CNC masin kan, olu de ka ɲi. Ni aw bɛ baara kɛ ni nɛnɛmadalan ye, o fana bɛ se ka tigɛminɛnw dɛmɛ u ka baara kɛ ka ɲɛ ani ka titaniyɔmu yɔrɔw dilan minnu ka ɲi kosɛbɛ.

Titanium alloys fana bɛ tigɛ fanga caman de wajibiya, o de b’a to u tigɛ ka gɛlɛn. O fanga ninnu bɛ se ka kɛ sababu ye ka:

● Baarakɛminɛnw doncogo teliya .

● Yɔrɔw tiɲɛnenw .

● Yɛrɛyɛrɛli ka bon, min bɛ nɔ bila fɛn dilannenw ka ɲumanya la ani u ka finiw na .

Degunw ni fɛnw gɛlɛyali tolenw ɲɛnabɔli .

Titanium alloys bɛ ni kristalɛ jɔcogo ye min b’a to u tɛ se ka fɛn caman kɛ. O bɛ se ka dɔ fara tigɛ fanga kan masinw waati la, ka dɔ bɔ masinw sɔrɔli la.

Kristali jɔcogo fana bɛ se ka kɛ sababu ye ka degun tolenw sɔrɔ baarakɛminɛn kɔnɔ. O degunw bɛ se ka kɛ sababu ye ka:

● A yɔrɔ in wulili walima a tigɛli .

● ka cracking .

● A yɔrɔ dɔw bɛ dɔgɔya .

Titanium ka fɛn caman sɛgɛsɛgɛli dɔgɔyali fana bɛ kɛ sababu ye ka degunw gɛlɛya masinko waati la. Ni fɛn in tigɛra, a bɛ gɛlɛya ka taa a fɛ tigɛminɛnw na.

Masini kɛcogo ka ɲɛsin titaniyɔmu ma .

Titanium machining gɛlɛyaw lajɛlen .

Titanium ye fɛn gɛlɛn ye min bɛ se ka baara kɛ ni a ye. A bɛ ni jogo dɔw ye minnu bɛ kɛ sababu ye ka masinw kɛcogo kɔrɔw kɛ nafa tɛ. Nin gɛlɛya ninnu faamuyali nafa ka bon furakɛli fɛɛrɛw sɔrɔli la walasa ka titaniyɔmu yɔrɔw dilan minnu ka ɲi kosɛbɛ.

● Funteni dalajɛli: Titanium ka funteni jiginni dɔgɔyali bɛ kɛ sababu ye ka funteni sɔrɔ teliya la baarakɛminɛnw sigiyɔrɔ la. O bɛ dɔ fara baarakɛminɛnw sɛgɛnni kan ani ka titaniyɔmu gɛlɛya ka taa a fɛ, ka gɛlɛya juguya.

● 'Gummy' Material: Titanium ka modulu min ka dɔgɔ ni a fanga ka bon, o b'a kɛ 'gummy' fɛn ye. A bɛ se ka tugu tigɛminɛn na, o bɛ kɛ sababu ye ka baarakɛminɛn dɛsɛ ani ka a sanfɛla dafa.

● Chatter ni Springback: Titanium ka elasticité bɛ se ka kɛ sababu ye ka baarakɛminɛnw yɛrɛyɛrɛ (chatter) ani ka springback kɛ tigɛyɔrɔ la, ka masinw cogoya juguw dilan ani ka muɲuliw tiɲɛ.

Titanium tigɛminɛn ɲumanw sugandili .

Tigɛminɛn ɲuman sugandili nafa ka bon kosɛbɛ titaniyɔmu dilanni na. Nɛgɛdaga teliyalen minnu dilannen don, minnu dilannen don ni tungsten, carbone ani vanadium ye, olu bɛ se ka gɛlɛya mara fo ka se 600°C ma. U bɛ sira Di tigɛw ma minnu ka dun ani ka dɔ Bɔ dakunw na minnu tigɛra.

Titanium ka dɔnniya bɛ bonya cogo min na, baarakɛminɛnw dilannikɛlaw bɛ ka fura kɛrɛnkɛrɛnnenw labɛn:

● Datugulanw: Datugulan minnu bɛ se ka funteni sɔrɔ i n’a fɔ titanium aluminiyɔmu nitiridi (tialn) walima titanium carbo-nitride (TITN) bɛ se ka baarakɛminɛnw ɲɛnamaya janya.

● Tigɛcogo minnu tɛ kelen ye: tigɛdaw ni ɲɔgɔn cɛ janya tɛ kelen ye, o bɛ dɛmɛ ka kumakan tiɲɛ.

Aw bɛ baara kɛ ni titaniyɔmu kɛrɛnkɛrɛnnen baarakɛminɛnw ye minnu ka ɲi kosɛbɛ ani ka baarakɛminɛnw bila u nɔ na tuma caman. Aw bɛ jateminɛ kɛ baarakɛminɛn fitininw na minnu bɛ ni tigɛda caman ye walasa ka nɛgɛ bɔli hakɛw mara ka sɔrɔ ka funteni hakɛ dɔgɔya.

Baarakɛminɛnw dacogo jɔyɔrɔ ka ɲɛsin baarakɛcogo yiriwali ma .

Baarakɛminɛnw dacogo bɛ se ka baarakɛminɛn dɔ ka seko ɲɛ kosɛbɛ ka funteni min sɔrɔ ni a bɛ titaniyɔmu kɛ ni masin ye, o muɲu. Tialn (titanium aluminium nitride) ye finimugu bɛnnen ye min:

● A bɛ tulumafɛnw di walasa ka dakunw, galari, ani chip welding kɛlɛ.

● A bɛnnen don kosɛbɛ funteni caman ma minnu bɛ sɔrɔ ni titaniyɔmu ye.

Nafa min bɛ surface sabatilen na ani min bɛ kumaw dɔgɔya .

Titanium ka teli ka kɛ sababu ye ka baarakɛminɛnw ka kumaɲɔgɔnya kɛ (yɛrɛyɛrɛ), o la, ka yɛrɛyɛrɛli dɔgɔya, o nafa ka bon kosɛbɛ. Aw bɛ baarakɛminɛn in siri kosɛbɛ walasa ka a tanga. Aw bɛ baara kɛ ni CNC masin ɲumanw ye minnu ka baarakɛminɛnw sigicogo ka gɛlɛn kosɛbɛ. Aw bɛ a lajɛ ka baara kɛ ni tigɛminɛn surunw ye walasa ka baarakɛminɛnw deflection dɔgɔya.

jiginni milling vs. mansin conventionnelle pour titanium .

Milling conventionnel : Nin laadala fɛɛrɛ in na, chip width bɛ daminɛ ka fin ani ka bonya, ka funteni caman bila baarakɛminɛn kɔnɔ ani ka dɔ fara degun gɛlɛyali kan.

Yɛlɛn milling: chip width bɛ daminɛ sanfɛ ka dɔgɔya, ka funteni jiginni sabati ka taa chip la baarakɛminɛn nɔ na. A bɛ sɔgɔlilan saniyalen fana dilan ani ka chips sama tigɛlan kɔfɛ, ka dankarili bali.

Climb milling ye fɛɛrɛ nafama ye walasa ka chips to a ka sɛgɛsɛgɛli kɛ ni a bɛ titanium machining.

Titanium machining tips .

Funteni ɲɛnabɔli: Fɛɛrɛ minnu ka kan ka kɛ walasa ka funteni hakɛ dɔgɔya .

Ni aw bɛ funteni jigin, o nafa ka bon kosɛbɛ ni aw bɛ titanium kɛ masin na. Komin titaniyɔmu tɛ funteni Kɛ ka ɲɛ, fanga fanba bɛ Taa tigɛ-minɛn na. Nin funteni in bɛ se ka kɛ sababu ye ka:

● Baarakɛminɛnw tiɲɛni ka kɔn a waati ɲɛ .

● Baarakɛminɛnw ni fɛn caman wɛrɛw dulling, ka funteni caman wɛrɛw lawuli .

● Tasuma farati ni fɛn dɔw ye .

Aw bɛ nɛnɛmadalan hakɛ caman kɛ walasa ka funteni jigin. Fɔɲɔba min bɛ baara kɛyɔrɔ ni baarakɛminɛn fiyɛ ni nɛnɛlan 10% ye, o bɛ baara kɛ ka ɲɛ. Ni nɛnɛmadalan hakɛ bɛ ka caya, o fana bɛ se ka dɛmɛ.

ka sabatili sabati walasa ka masinw sɔrɔ ka ɲɛ .

Ni aw ye aw ka baarakɛminɛnw jira fanga la min bɛ mɔgɔ kabakoya ani ka jarring kɛ, o bɛ dɔ fara degun kan, o bɛ na ni sɛgɛn teliya ye. Aw kana baarakɛminɛn in don titaniyɔmu kɔnɔ. No na:

● A bɛ baarakɛminɛn in kɔnɔna nɔgɔya walasa k’a nɔgɔya ka don tigɛ la .

● Aw bɛ tugu ɲɔgɔn kɔ ni fɛn ye min ka bon fo ka se a dan ma (waatibolo walima waatibolodacogo) ni baarakɛminɛn ye .

Tigɛ laban na, aw bɛ chamfer (sloped groove) kɛ. O b’a To baarakɛminɛn in juguya bɛ Dɔgɔya dɔɔnin dɔɔnin, o bɛ 'tɛmɛsira nɔgɔya ni fanga dɔgɔyali ye.

Baarakɛminɛnw ladonni: Ka i ka baarakɛminɛnw to u ka kɛ fɛn ye min bɛ se ka kɛ .

Baarakɛminɛn minnu bɛ kɛ ni nɛgɛ ye, olu ka kan ka kɛ walasa ka titaniyɔmu tigɛcogo ɲuman sɔrɔ. Nka, titanium bɛ se ka teliya ka aw ka baarakɛminɛnw ɲɛnafin bɔ. Aw bɛ u lajɛ tuma bɛɛ ani ka sɛgɛn taamasiɲɛ o taamasiɲɛ jira.

Baarakɛminɛn min bɛ kɛ ni dusu ye, o bɛna funteni caman sɔrɔ ani ka sɛgɛn ka tɛmɛ fɔlɔ kan, ka ko in caya.

Fɛɛrɛ minnu bɛ kɛ ka galɛli ni chipping dɔgɔya .

GALLING: Titanium bɛ sɔrɔ nɔgɔya la ni fɛn wɛrɛw ye, o bɛ kɛ sababu ye ka dawolow sɔgɔsɔgɔ ani ka u lasegin u cogo kɔrɔ la tigɛ waati. Ni aw bɛ funteni mara, ka baara kɛ ni baarakɛminɛn nɔgɔlenw ye, ani tulumafɛnw, o bɛ se ka dɔ bɔ o la.

Chipping: Ni nɛgɛ yɔrɔw tigɛra ka bɔ degun na ani ka nɔrɔ tigɛda la, a bɛ fɔ a ma ko chipping. Buildup caman bɛ nɔ bila baarakɛcogo la ani a bɛ se ka baarakɛminɛn tiɲɛ kosɛbɛ.

Baarakɛminɛnw ni tulumafɛnw fana bɛ dɛmɛ ka chipping dɔgɔya titanium machining waati la.

Masini gɛlɛyaw ni a furakɛcogo .

Funteni ɲɛnabɔli masinw waati .

Gɛlɛyabaw dɔ la kelen min bɛ kɛ ni titaniyɔmu ye, o ye ka fɛn bɛɛ nɛnɛ. Titanium ka funteni dɔgɔyali bɛ kɛ sababu ye ka funteni sɔrɔ teliya la baarakɛminɛn yɔrɔ la.

Role de coolant .

Funteni kojugu fura jɛlen dɔ ye ka nɛnɛmadalan caman kɛ. Ni aw ye baarakɛyɔrɔ ni baarakɛminɛn fiyɛ ni 10% concentré coolant ye, o bɛna a to contact yɔrɔ ka nɛnɛ. A bɛna funteni-ta-minɛnw fana ko.

Fɔɲɔba minnu bɛ kɛ ni degunba ye .

Walasa ka fɛnw tigɛli kɛ, nɛnɛmadalan jɔyɔrɔ ni a tansiyɔn nafa ka bon kosɛbɛ. Ni a kɛcogo ɲuman bɛ yen, a sanfɛla teliya ni nɛgɛ bɔli hakɛ caman bɛ se ka sɔrɔ.

Nka, nɛnɛmadalan min bɛ tansiyɔnba la, o bɛ se ka kɛ sababu ye tuma dɔw la ka fɛnw bila yɔrɔ la. O bɛ se ka kunbɛn ni tigɛcogo labɛnni ye ani ka nɛnɛmadafɛ degun dɔgɔya ka ɲɛsin fini labanw tigɛcogo ma.

Baara gɛlɛyali bali .

Titanium ka teli ka baara gɛlɛya. Ni fɛn in tigɛra, a bɛ gɛlɛya ka taa a fɛ, ka a sɔgɔ baarakɛminɛnw na.

Balo basigilen nafa .

Ni aw bɛ balo hakɛ basigilen mara, o b’a to baara gɛlɛya bɛ fɛn minnu na, olu ka to a dan na. O bɛ baara gɛlɛyali wɛrɛw bali ani ka baarakɛminɛnw sɛgɛn kojugu.

Balo hakɛ ladilanni .

Ni a bɛ se ka kɛ, ka dɔ fara balo hakɛ kan, o bɛ se ka nafa sɔrɔ. O kɔrɔ ye ko baarakɛminɛn bɛ waati dɔɔnin Kɛ yɔrɔ kɛrɛnkɛrɛnnen dɔ la, o bɛ a To funteni ka dɔgɔn ani ka baara gɛlɛya tigɛyɔrɔ la.

Baarakɛminɛnw jateminɛw titaniyɔmu kan .

Baarakɛminɛn ɲumanw sugandili .

Baarakɛminɛn minnu bɛ kɛ ni karɔti ye, olu ni PVD dacogo bɛnnen don kosɛbɛ titaniyɔmu tigɛcogo ma. Datugulan kuraw i n’a fɔ Tialn (titanium aluminium nitride) olu fana bɛ sɔrɔ.

Titanium ye fɛn ye min bɛ fɔ kosɛbɛ, o la, baarakɛminɛn min bɛ kɛ ni fɛn ye, o ye fɛn ye min nafa ka bon kosɛbɛ. Baarakɛminɛn minnu bɛ kɛ ni blunt ye, olu bɛna a sanfɛla sɔgɔ ani ka kumakanw lawuli.

Baarakɛminɛnw dacogo ani u ladonni .

Coatings i n’a fɔ Tialn bɛ baarakɛminɛn dɔ ka se ka funteni caman muɲu ni a bɛ titanium kɛ masin na. U bɛ tulumafɛnw di ani u bɛnnen don kosɛbɛ funteni caman ma.

Baarakɛminɛn minnu bɛ kɛ tuma bɛɛ, olu sɛgɛsɛgɛli ni u falenni ye, o ye wajibi ye, bawo baarakɛminɛn dulenw bɛ funteni caman bɔ ani ka sɛgɛn joona.

chip control stratégies nafamaw .

Titanium bɛ se ka chips janw dilan minnu bɛ se ka baarakɛminɛnw tiɲɛ nɔgɔya la ani ka baarakɛminɛn in sanfɛla taamasiyɛn. Chips janw, finmanw fana tɛ dɛmɛ ka funteni bɔ baarakɛyɔrɔ la.

Baara kɛ ni baarakɛminɛnw ni baarakɛminɛnw siraw ye minnu bɛ chips misɛnninw dilan minnu ka bon, olu ka ɲi kosɛbɛ ni i bɛ titanium kɛ ni masin ye. Chip control ɲuman nafa ka bon.

Baarakɛcogo fɛɛrɛw walasa ka u ɲɛfɔ ka ɲɛ ani ka u lakana .

Baarakɛcogo lakananen nafa ka bon kosɛbɛ ni aw bɛ titaniyɔmu masina. A bɛ yɛrɛyɛrɛ Bɔ o baara la, o bɛ sira Di kunnafoni tigɛcogo ɲuman ma.

Titanium yɔrɔ caman bɛ ni yɔrɔ finmanw ye, o la, ka baara kɛ ni ladamu baarakɛcogo fɛɛrɛw ye walasa ka baara labanw kɛ, o bɛ na ni nɔ ɲuman ye. A ka c’a la, a bɛ sira di ka se ka sɔrɔ ani ka dɛmɛ don kosɛbɛ o yɔrɔ la.

Baarakɛminɛnw sira ɲɛnabɔli ka ɲɛsin masinw ma minnu bɛ baara kɛ ka ɲɛ .

Baarakɛminɛn sira ɲuman sugandili nafa ka bon i n’a fɔ baarakɛminɛn ɲuman sugandili ni i bɛ titaniyɔmu masina.

Baarakɛminɛn sira minnu bɛ tigɛlan baara kɛ baarakɛminɛn kɔnɔ tuma bɛɛ, olu ka kan. Misali la, trochoidal pattern ni slot tigɛra, o bɛ dɔ bɔ waati la min bɛ fɔ ni flute kelen ye, ka dan sigi funteni na.

Baarakɛminɛn in ka don baarakɛminɛn kɔnɔ ani ka bɔ a kɔnɔ, o bɛ dɔ bɔ sɔgɔsɔgɔ ni lamaga barikamaw la minnu bɛ se ka baarakɛminɛnw tiɲɛ kosɛbɛ.

Surface Finishing Techniques ka ɲɛsin titaniyɔmu yɔrɔw ma .

Gafe min bɛ ɲɛfɔli kɛ polishing, anodizing ani chroming kan .

CNC masina kɔfɛ, titaniyɔmu yɔrɔw bɛ se ka ɲɛ ni ɲɛda furakɛli suguya caman ye. O furakɛli ninnu bɛ se ka baara kɛ walima ka ɲɛnajɛ kɛ.

Polishing ye surface finishing technique ye min bɛ sɔrɔ tuma bɛɛ. A bɛ dɛmɛ ka titaniyɔmu yɔrɔw cogoya nɔgɔya ani k’u bonya.

Anodizing ye kuran-sɛnɛcogo ye min bɛ ɔkisizɛni-datugulan min bɛ mɛn, o bɛ kɛ titaniyɔmu sanfɛ. A bɛ sɔgɔli kɛcogo ɲɛ ani ka a yɛrɛ tanga.

Kɔrɔmu bɛ kɛ ni chrome (kɔrɔmu) finman dɔ bilali ye titanium (titani) yɔrɔ kan. A bɛ sanfɛla cogoyaw bonya i n’a fɔ a ɲɛda cogoya, a gɛlɛya, ani a sɔgɔli.

Faamuyali mugu dacogo, PVD dacogo, ani burusi .

mugu dacogo ye finimugu jalen ye min na mugu chargelen bɛ kɛ ka sɔrɔ ka kɛnɛya funteni na. A bɛ muɲuli ɲuman ni sɔgɔli lakanani ɲuman di titaniyɔmu yɔrɔw ma.

PVD (fiziki vapor deposition) dacogo ye vacuum deposition processus ye min bɛ dacogo finmanw ni gɛlɛnw dilan titanium yɔrɔw kan. PVD dacogo bɛ fɛnw ɲɛ ka ɲɛ i n’a fɔ sɛgɛn ani sɔgɔli.

Brushing ye fɛɛrɛ nɔgɔman ye min bɛ kɛ ka misaliw walima fɛnw dilan titanium sanfɛ ni abrasive filaments ye. A bɛ se ka finiw dilan minnu bɛ mɔgɔ sama i n’a fɔ kunsigi walima burusi sɛrɛkiliw.

Nin furakɛli ninnu bɛ kɛ sababu ye ka titanium ka nafaw labɛn ka kɛɲɛ ni baarakɛcogo kɛrɛnkɛrɛnnenw ye walima ka ɲɛnajɛko nɔ ɲininenw sɔrɔ baara suguya caman na.

CNC masinw ka titaniyɔmu yɔrɔw baarakɛcogo suguya caman .

Titanium min bɛ aerospace kɔnɔ: a basigilen kɔfɛ .

Titanium bɛ baara kɛ kosɛbɛ aerospace (aerospace) baara la k’a sababu kɛ a ka jogo danma ye. A fanga ni a girinya hakɛ ka bon, a bɛ se ka sɔgɔsɔgɔ kosɛbɛ, wa a bɛ se ka sigida funtenimaw muɲu kosɛbɛ.

Aerospace kɔnɔ, CNC masinw titaniyɔmu yɔrɔw ye:

● awiyɔn motɛri yɔrɔw i n’a fɔ turbine blades ani compresseur yɔrɔw .

● Airframe structures ani a yɔrɔw .

● Rotors ni shafts .

Titanium bɛ awiyɔnw dilanni boli - diɲɛ titaniyɔmu sɔrɔli tilancɛ fila ɲɔgɔn bɛ taa awiyɔn motɛriw ni awiyɔnw kɔnɔ.

Kɔgɔji ni kɔgɔjida la baarakɛcogo: A bɛ mɛn kɔgɔji jukɔrɔ .

Ni aw ye a suma ni nɛgɛ fanba ye, titaniyɔmu bɛ se ka sɔgɔli kɛ ka ɲɛ. O b’a to a dafalen don kɔgɔjida lamini gɛlɛnw muɲuni na kɔgɔjida la.

Titanium kɔgɔji yɔrɔw ye:

● Propeller shafts .

● Ji jukɔrɔ robotikɛ yɔrɔw .

● rigging minɛnw .

● Balonw .

● Kɔgɔjida la funtenibɔlanw .

● Tasuma-fanga-minɛnw .

● Pompiw .

● Stack Stack Liners .

● Onboard Cooling Systems .

Titanium jɔyɔrɔ mobili kurayali la .

Hali ni aluminiyɔmu bɛ fanga sɔrɔ mobili seko ni dɔnko siratigɛ la, Titanium ka jogo danmadɔw b’a to a bɛnnen don mobili yɔrɔ dɔw ma:

● Motɛriw ka bɔlɔnw ni u ka bɔgɔdagaw .

● A minɛbagaw .

● Suspension Springs .

● freinw kalifaw ni pistonw .

● Ka berew siri ɲɔgɔn na .

● Piston pins .

● Motɛriw ka rockers .

Titanium bɛ baara kɛcogo ɲɛ ka sɔrɔ ka girinya dɔgɔya o yɔrɔw la.

Titanium bɛ nɔ min bila furakɛli ni ɲinw na .

Titanium ka biyocompatibilité, resistance de corrosion, ani électrique conductivité dɔgɔyali b’a to a nafa ka bon furakɛli la. A farikolo ka pH hakɛw bɛ osseointegration (kolo-ni-da-ɲɔgɔn-ɲɔgɔnna) sabati.

Titanium furakɛli yɔrɔw minnu ka teli ka sɔrɔ, olu ye:

● Orthopedic Implants (hip, gɛnɛgɛnɛ) .

● Kolow ni juruw .

● Kɔkolo fixation rods, plates, connecteurs .

● Denw ka donsow, bɔrɔw, koronawirisi .

● Opereli minɛnw .

Titanium ka jogo b’a to a bɛ se ka kɛ hadamaden farikolo kɔnɔ, ka nɔ bila mɔgɔ si la don o don.

Jɛɲɔgɔnya ni TeamFG ye titaniyɔmu masinw kama .

TeamMFG ka titaniyɔmu masinw ka seko ni dɔnko ɲɛtaa .

TeamMFG bɛ bɔ kɛnɛ kan tigitigi masinko la n’a ka fɛɛrɛ kura ye ani a ka dɔnniya jugu, kɛrɛnkɛrɛnnenya la CNC masinw ka titaniyɔmu mara la. Sosiyete ka masinko seko minnu bɛ taa ɲɛ, olu dabɔra walasa ka gɛlɛya kɛrɛnkɛrɛnnenw kunbɛn minnu bɛ sɔrɔ Titanium ka nafolo fɛ, ka a jira ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ cogo min na, ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka gɛlɛya kɛrɛnkɛrɛnnenw kunbɛn, ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ.

TeamMFG ka ɲɛtaa jusigilan titanium machining la, o bɛ sɔrɔ a ka minɛnw ni fɛɛrɛw tigɛcogo la. A bɛ ni CNC masin 5 ye, TeamMFG bɛ se ka tigɛ gɛlɛnw kɛ ani kunnafoni gɛlɛnw titaniyɔmu yɔrɔw kan ni tiɲɛni ye min tɛ se ka suma ni ɲɔgɔn ye. O seko in nafa ka bon kosɛbɛ iziniw bolo minnu bɛ fɛnw ɲini minnu ka ɲi kosɛbɛ, i n’a fɔ aerospace ani furakɛli minɛnw.

O tɛmɛnen kɔ, TeamMFG ka cɛsiri kokuradonni na, o bɛ taa a ka baarakɛminɛnw n’a ka porogaramuko fɛɛrɛw la, kɛrɛnkɛrɛnnenya la, minnu dabɔra titaniyɔmu dilanni kama. Ni baarakɛminɛnw ye minnu ka ɲi kosɛbɛ ani ka masinw paramɛtiriw ɲɛnabɔ, TeamMFG bɛ ko minnu bɛ kɛ ɲɔgɔn fɛ i n’a fɔ baarakɛminɛnw doncogo ani fɛnw tiɲɛni, o bɛ dɔ bɔ fɛn dilanni na min tɛ fɛn tiɲɛ kabini a daminɛ fo a laban. Aw ye anw sɔrɔ bi!

Ɲɛtaa maanaw: Hakilina caman tigɛli ka kɛ tiɲɛ ye .

TEAMMFG ka ɲɛtaa maanaw portfolio bɛ porozɛw suguya caman n’u gɛlɛya jira, sosiyete ye minnu daminɛ. Misali kɛrɛnkɛrɛnnen dɔ ye aerospace-grade titanium components dilanni ye, yɔrɔ min na TeamMFG ka dɔnniya bɛ dɔ bɔ kosɛbɛ a dilanni waati ni a musakaw la ka sɔrɔ ka aerospace sariya gɛlɛnw mara.

Ɲɛtaa maana wɛrɛ bɛ TeamMFG jɔyɔrɔ jira furakɛli baara la, yɔrɔ min na, a ka baarakɛda ka masinko ɲɛnabɔli baara ye titaniyɔmu furakɛli fɛnw doncogo ɲɛ. O fɛnw dontaw, minnu bɛ dɔn u ka biyokɔmpatibiliti n’u muɲuni fɛ, olu ye banabagatɔw ka sɔrɔw caya ani ka TeamFG sigi senkan ka taa a fɛ i n’a fɔ jɛɲɔgɔn dannamɔgɔ furakɛli la.

Nin ɲɛtaa ninnu tɛ TeamMFG ka seko ni dɔnko dɔrɔn jira, nka a bɛ a ka cɛsiri fana jira kiliyanw wasako la ani porozɛ ɲɛtaa la. A kɛlen ka jɛkafɔ kɛ ni kiliyanw ye, k’u mago kɛrɛnkɛrɛnnenw faamuya, ani k’a ka masinko seko kɔrɔw ta, TeamMFG ye jagokɛla caman dɛmɛ k’u ka hakilina kura caman sɛmɛntiya ka kɛ titaniyɔmu yɔrɔw ye minnu bɛ se ka ye, minnu ka ɲi kosɛbɛ.

Ka jɛɲɔgɔnya kɛ ni TeamMFG ye titanium machining kama, o kɔrɔ ye ka tɛmɛn ka se ka baara kɛ ni masinw ye minnu ka bon kosɛbɛ; A bɛ tali kɛ fanga la ni jɛɲɔgɔnya kɛrɛnkɛrɛnnen ye min cɛsirilen don ka danw gɛlɛya fɛn dilanni ɲɛtaa ma. I mana kɛ aerospace la, mobili la, furakɛli la, walima kɔgɔji la, TeamMFG ka furakɛlicogo labɛnni ani dɛmɛ min tɛ wuli, o bɛna a to i ka titaniyɔmu masin porozɛw ka ɲɛ, waati la, ani baarakɛnafolo kɔnɔ.

Kuncɛli

CNC Machining Titanium kan, a bɛ kuma kunbaba minnu kan .

Titanium ye fɛn ye min tɛ ɲɔgɔn ta ye, a ka nafaw faralen ɲɔgɔn kan cogo kabakoma na i n’a fɔ fanga ka bon, a ka nɔgɔn, a bɛ se ka sɔgɔsɔgɔ, ani a bɛ se ka funteni jugumanba muɲu. Nka, o jogo kelenw minnu b’a to a ka ɲi kosɛbɛ, olu fana bɛ gɛlɛyabaw lase u ma ni u bɛ titaniyɔmu yɔrɔw kɛ masin ye.

Ka se sɔrɔ ko dɔw kan i n’a fɔ funteni teliya la, galonw, kumakanw, ani baara gɛlɛyali, o bɛ fɛn dɔw de wajibiya minnu bɛ se ka mɔgɔw kunbɛn kosɛbɛ i n’a fɔ:

● Ka baara kɛ ni tigɛminɛnw ni finimuguw ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ .

● sigicogo gɛlɛnw ni sabatilenw marali walasa ka yɛrɛyɛrɛli dɔgɔya .

● tigɛcogo paramɛtiriw ladilanni i n’a fɔ balo hakɛw ani ka nɛnɛmadalanba kɛ .

● Ka fɛɛrɛw tigɛ i n' a fɔ jiginni ka ɲɛsin chip control ɲuman ma .

O fɛɛrɛ ninnu dɔnni b’a to fɛn dilannikɛlaw bɛ se ka Titanium ka seko bɛɛ da wuli izini suguya caman kɔnɔ.

Titanium ka siniɲɛsigi CNC masinw ni iziniw kɔnɔ .

Ni fɛn dilanni fɛɛrɛw bɛ ka taa ɲɛ, an bɛ se k’a jira ko titanium bɛ baara kɛ kosɛbɛ seko ni dɔnko siratigɛ la. Fɛɛrɛ minnu bɛ kɛ CNC masinko seko la, farali kɛcogo la titanium na, ani titanium alloy yiriwali kura bɛna kɛ sababu ye ka nin yiriwali in bila sen kan.

Aerospace bɛna to titaniyɔmu ɲinini sababuba ye. Nka an bɛna titaniyɔmu baarakɛcogo fana ye mobili, fanga, musakabɔlaw ka fɛnw na, ani kɛrɛnkɛrɛnnenya la furakɛli baara la k’a sababu kɛ a ka ɲɛnamaya kɛcogo ye.

Ni dɔnniya bɛnnen don ani ni minɛn tigɛlenw ye, fɛn dilannikɛlaw bɛ se ka se sɔrɔ titaniyɔmu dilanni gɛlɛyaw kan. O bɛna sababu kura dɔw da wuli walasa ka nin nɛgɛ danfaralen in nafa sɔrɔ fɛn kuraw la minnu tun tɛ se ka kɛ fɔlɔ walima minnu tun tɛ sɔrɔ ka sɔrɔ.

Ɲininkaliw bɛ kɛ CNC machining titanium .

J: Nɛnɛmafɛn sugandili bɛ nɔ bila titaniyɔmu masin na cogo di?

A: Coolant sugandili nafa ka bon kosɛbɛ. Tansiyɔnba, 10% nɛnɛmadalan bɛ baarakɛminɛn nɛnɛ. Nɛnɛmadalan ɲuman bɛ funteni kojugu bali, ka baarakɛminɛnw ɲɛnamaya janya.

J: Gɛlɛya jumɛnw bɛ sɔrɔ ka caya ni titaniyɔmu masina ye?

A: Ko minnu bɛ kɛ tuma caman na, olu ye heat build, galling, chatter, ani baara gɛlɛyali ye. O gɛlɛyaw bɛ fɛɛrɛ kɛrɛnkɛrɛnnenw de wajibiya walasa ka se sɔrɔ u kan.

J: Ne bɛ se ka baara kɛ ni baarakɛminɛnw ye minnu bɛ kɛ ka ɲɛsin machining titanium ma wa?

A: Ayi, baarakɛminɛn jɔnjɔnw tɛ nafa sɔrɔ. Aw bɛ karɔti minɛnw kɛ minnu datugulen don, minnu dilannen don kɛrɛnkɛrɛnnenya la titaniyɔmu kama walasa ka u bali ka don joona.

J: Mun de bɛ titaniyɔmu ni nɛgɛ tɔw danfara bɔ masinw na?

A: Titanium ka funteni-taama-cogo dɔgɔyali bɛ na ni funteni caman sɔrɔli ye. A ka modulu dɔgɔmannin b'a Kɛ 'gummy' ye ani a bɛ Se ka 'fɔli Kɛ.

J: Titanium ka funteni kunbɛncogo bɛ nɔ bila a ka masinko kɛcogo la cogo di?

A: Titanium ka funteni kunbɛncogo bɛ na ni tigɛ fanga caman ye minnu ka kan. Nɛnɛ ni paramɛtiriw optimiséw ka kan ka kɛ.

J: Nafa jumɛnw bɛ sɔrɔ ka jiginni kɛ ka tɛmɛ milling conventionnel kan titanium kama?

A: Yɛlɛn sɔgɔli bɛ funteni jiginni sabati ka taa chips la baarakɛminɛn nɔ na. A fana bɛ dɔ bɔ mugumuguli la walasa a ka se ka kɛ ka ɲɛ.

J: Ne bɛ se ka baarakɛminɛnw sɛgɛnni ni u dɛsɛli bali cogo di ni i bɛ titanium masina?

A: Aw bɛ finimugu bɛnnenw kɛ i n’a fɔ Tialn ani ka baarakɛminɛnw bila u nɔ na tuma bɛɛ. Setups sabatilenw ani paramètres optimisés fana bɛ dɔ bɔ sɛgɛn na.

J: Titanium yɔrɔ masinw bɛ kɛ cogo jumɛnw na?

A: Aerospace, furakɛli, mobili, ani kɔgɔjida la iziniw bɛ baara kɛ ni titaniyɔmu masin ye a fanga, a biyocompatibilité, ani a ka corrosion resistance kama.