Fɔ bil tul ɛn mold dɛn nid bɔku invɛstmɛnt dɛn we i kam pan tɛm ɛn mɔni. Di in-dimand industrial aplikeshɔn dɛn tide nid biznɛs fɔ yuz wan we fɔ mek tin dɛn we fast, we go wok fayn, we nɔ go tek bɔku mɔni, ɛn we pɔsin kin abop pan. Rapid tooling na di bes solushon fo dat. Yu kin yuz di aditiv manufakchurin we fɔ wok wit protɔtayp ɛn prodak sɛmpul dɛn. Yu kin mek sɔm mold komponent dɛn bak wit rapid tul insay aditiv manufakchurin.

Fɔ no bɔt di we aw dɛn de mek di tin dɛn we dɛn dɔn ad .

Wetin na aditiv manufakchurin? Lɛ wi lan bɔt sɔm impɔtant tin dɛn fɔ no bɔt di we aw dɛn de mek tin dɛn we dɛn ad:

• Na di we aw dɛn de mek tin dɛn we de ad matirial to di pat dɛn we dɛn dɔn mek.

Aditiv manufakchurin na di prodakshɔn we de mek yu nid fɔ ad matirial to di pat we dɛn prodyuz instead fɔ pul dɛn. Yu kin pik bitwin plastic ɛn mɛtal matirial ɛn prosɛs di matirial dɛn we yu de yuz aditiv manufakchurin ikwipmɛnt. I go fala spɛsifikɛd kɔmpyuta kɔmand fɔ mek shɔ se di ay ay akkuracy ɛn prɛsishɔn fɔ di pat dɛn we dɛn dɔn prodyuz. Di aditiv manufakchurin ikwipmɛnt go fala di bɛsis prinsipul dɛn fɔ 3D printin.

• SMƆL TƆK: CAD ɛn 3D mɔdel dizayn as di pat blueprint.

Wit aditiv manufakchurin, CAD ɛn 3D mɔdel dizayn go bi di blueprint fɔ di pat we yu prodyuz. Mɔs aditiv manufakchurin ikwipmɛnt dɛn kin rid CAD ɛn 3D mɔdel dizayn fayl dɛn. Yu go mek di 3D mɔdel dizayn fɔ di pat dɛn we yu nid fɔ bil ɛn sɛn di fayl to di aditiv manufakchurin ikwipmɛnt. Na da tɛm de nɔmɔ yu go ebul fɔ stat di prodakshɔn prɔses fɔ di prɔdak.

• Kɔmpyuta ɛn ɔtomɛtik prodakshɔn prɔses.

Aditiv manufakchurin de yuz wan ful kɔmpyuta-kɔntroled we fɔ prodyuz wit smɔl mɔtalman leba. Yu jɔs nid fɔ pripia di matirial dɛn ɛn sɛt di kɔnfigyushɔn dɛn fɔ di aditiv manufakchurin mashin. Dɔn, di ikwipmɛnt go yuz di ɔtomɔn sistem fɔ dɔn di prodakshɔn prɔses bays pan yu sɛtin dɛn.

• SMƆL TƆK: 3D printin teknɔlɔji.

Mɔs aditiv manufakchurin sistem tide de yuz 3D printin teknɔlɔji na dɛn praymari ɔpreshɔn. Pan ɔl we bɔku kategori dɛn de fɔ ad pan aditiv, ɛni wan pan dɛn gɛt di men prinsipul fɔ 3D printin. Yu kin yuz Rapid Tooling fɔ mek prɔdak sɛmpul dɛn we yu de yuz 3D printin ikwipmɛnt. Dis teknɔlɔji go alaw yu fɔ inspɛkt ɛn tɛst di prɔdak sɛmpul dɛn bifo yu go pan ful-skel prodakshɔn.

• Lay-bay-layer matiryal bildup.

Di layering proses go fala di 3D dizayn blueprint we yu dɔn input insay di manufakchurin ikwipmɛnt. Di ikwipmɛnt go mek di ɛnd prodak frɔm di bɔt to di layt we de ɔp. Wit dis layt-bay-layer matiryal buildup, yu kin get di most ditel pat, mold, or komponent. I go lɛf smɔl ples fɔ mek mistek dɛn we yu de mek.

Rapid tul in aditiv manufakchurin - Di fast-paced prodakshɔn we fɔ tul ɔ mold

Yu fɔ no se kwik tul dɛn na aditiv manufakchurin gɛt in gud ɛn bad tin dɛn. Luk fɔ dɛn prɔs ɛn bad tin ya bifo yu pik kwik tul fɔ favɔyd di kɔvɛnshɔnal we.

Pros dɛn .

• SMƆL TƆK: Bil tul ɔ mol fast.

Rapid tul de pe atɛnshɔn pan di tul prɔses, we min di prodakshɔn fɔ tul ɔ mol fɔ difrɛn manufakchurin ɔpreshɔn dɛn. Di gud tin bɔt dis we na dat yu kin bil tul ɔ mol kwik kwik wan pas tradishɔnal tul. Yu kin pripia di . Injɛkshɔn mold fɔ difrɛn manufakchurin ɔpreshɔn dɛn insay 24 awa wit di ɛp fɔ kwik tul.

• Lɔw kɔst fɔ tul fabrikeshɔn.

Aside frɔm di tul spid we i de gi, Rapid Tooling de gi bak lɔwa kɔst fɔ tul fabrikeshɔn. Fɔ mek mold ɛn tul dɛn wit kwik tul go gɛt bak minimal ɔvahɛd ɛkspɛns kɔmpia to di tradishɔnal tul we dɛn de yuz. I kin kɔntribyut to di ɔvala minim prodakshɔn kɔst fɔ yu manufakchurin prɔjek dɛm.

• Mɔ efishɔnal pas kɔvɛnshɔnal tul dɛn.

Kɔnvɛnshɔnal tul nid fɔ gɛt siriɔs kɔmplikɛt prɔses wit bɔku bɔku manual leba involv. Tradishonal tul nɔ gɛt ay efyushɔn lɛvɛl, ɛn di prɔses na lɔng ɛn tranga. So, rapid tul kin gi yu mɔ efyushɔn na di prodakshɔn prɔses.

• Bɔku pan di plastic matirial dɛn kin kɔmpit.

Rapid tul kin prosɛs mɔs plastic matirial dɛn yuz di aditiv manufakchurin mɛtɔd. Plastik matirial dɛm lɛk ABS, naylon, resin, ɛn PETG kin kɔmpit wit kwik tul. Yu kin yuz dɛn plastic tin ya fɔ bil di pat ɔ kɔmpɔnɛnt dɛn akɔdin to yu dizayn blueprint.

• Difrɛn aplikeshɔn fɔ kwik tul.

Naw, di wan dɛn we de mek tin dɛn nid fɔ mek tul dɛn ɛn mol fast as di diman fɔ dɛn manufakchurin tul dɛn ya de go ɔp. Yu kin yuz rapid tul fɔ mek insɛt fɔ di moldin ɔpreshɔn dɛn. Ɔda aplikeshɔn dɛn na fɔ mek sheet mɛtal ɛn tul fɔ injɛkshɔn moldin.

Di tin dɛn we de apin .

• I bɛtɛ fɔ prodyuz ɔda mold kɔmpɔnɛnt dɛn nɔmɔ.

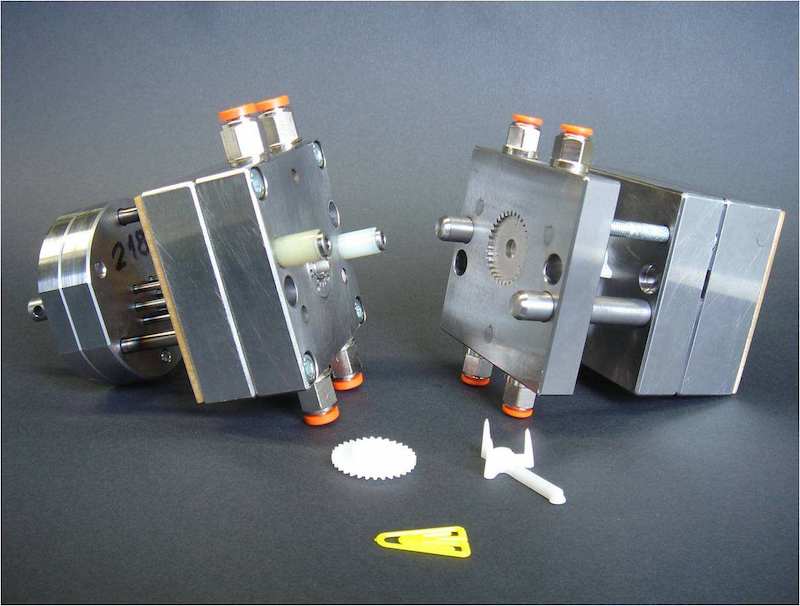

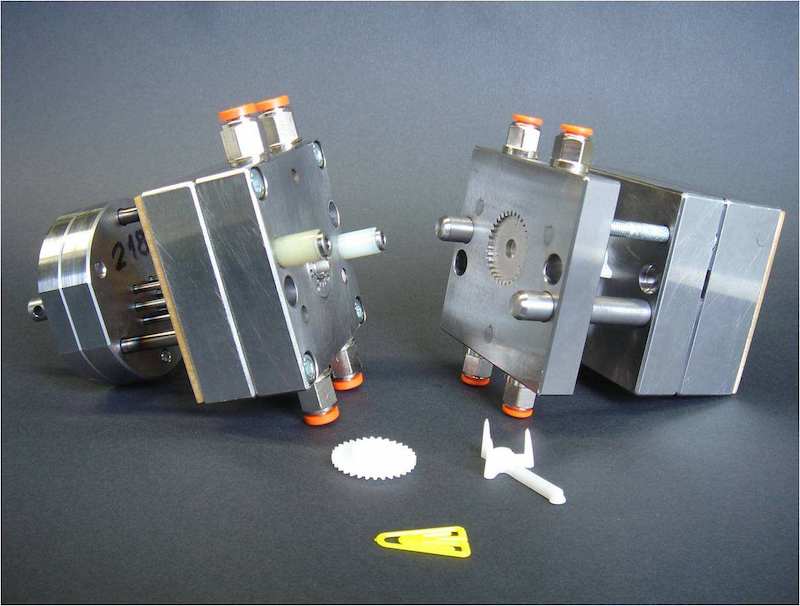

Rapid tul in aditiv manufakchurin na di bɛst fɔ prodyuz ɔda mold kɔmpɔnɛnt ɔ kɔmpɔnɛnt protɔtayp dɛn. Yu kin mek smɔl komponent ɛn pat dɛn insay lɔw volyum izi wan. Yu kin tɛst sɛmpul dɛn bak ɛn mek difrɛn itɛreshɔn dɛn fɔ di mold kɔmpɔnɛnt dɛn fast wit kwik tul dɛn na aditiv manufakchurin.

• I fayn fɔ protɔtayp prodakshɔn.

In aditiv manufakchurin, rapid tul na onli bes fo prodyuz prototypes of pat o komponent fo industrial aplikeshon. Fɔ bil protɔtayp dɛn fɔ mold ɔ tul dɛn bak kin pɔsibul wit kwik tul dɛn na aditiv manufakchurin. Wit dis mold prototypes, yu kin inspek difrɛn pat dɛn na di mold ɔ tul dɛn bifo yu prodyuz di praymari mold dɛn.

• Yu nɔ go ebul fɔ prodyuz praymari mold wit aditiv manufakchurin.

Aditiv manufakchurin nɔto di bɛst we fɔ mek mɛtal kɔmpɔnɛnt dɛn, lɛk fɔ mek di praymari mol fɔ injɛkshɔn moldin. Insted, yu kin bil praymari tul fɔ mold opareshɔn wit sɔbtraktiv manufakchurin mɛtɔd, lɛk . CNC Mashining we de wok fɔ mek yu bɔdi wok . Wi gladi fɔ no se, Rapid Tooling de sɔpɔt ɔl tu di aditiv ɛn sɔbtraktiv manufakchurin mɛtɔd dɛn. Dɛn kin go an to an fɔ fulfil yu prodakshɔn nid dɛn.

• Mɛtal matirial dɛn fɔ yuz sɔbtraktiv manufakchurin prɔses.

Rapid tul in aditiv manufakchurin kin onli yuz metal matiryal in wan limited kapasiti. So, yu nɔ go ebul fɔ yuz additiv manufakchurin fɔ prodyuz mɛtal kɔmpɔnɛnt dɛn, lɛk praymari mold dɛn, na ful skel. Bifo dat, yu fɔ chenj to sɔbtraktiv manufakchurin fɔ mek pat ɔ kɔmpɔnɛnt dɛn we de yuz ay amɔnt mɛtal.

Dɔn

Yu nid fɔ jɔyn di aditiv ɛn sɔbtraktiv manufakchurin we dɛn de yuz fɔ mek tul dɛn kwik kwik wan. I go alaw yu fɔ gɛt di bɛst pan dis manufakchurin ɔpreshɔn. Yu nɔ go ebul fɔ lɛf di sɔbtraktiv manufakchurin prɔses kɔmɔt na di iqwɔ wit kwik tul. I fɔ go an to an wit aditiv manufakchurin fɔ mek di bɛst kwaliti mol ɛn tul dɛn fɔ yu prɔjek dɛn.

Team MFG na profeshɔnal rapid manufakchurin kɔmni, wi de ɛp bɔku kɔstɔma dɛn fɔ lanch dɛn prɔjek dɛn fayn fayn wan, Kontakt wi tide fɔ aks fɔ fri kot naw.