Welding joints de ple wan impɔtant pat pan di sakses fɔ ɛni fabrikeshɔn ɔ kɔnstrɔkshɔn projɛkt. Dɛn kɔnɛkshɔn ya, we dɛn mek bay we dɛn jɔyn tu ɔ mɔ pat pan di mɛtal, de disayd di trɛnk, di tɛm we dɛn go de, ɛn di ɔvala kwaliti fɔ di weld strɔkchɔ.

Insay dis kɔmprɛhɛnsif gayd, wi go dayv insay di fayv praymari kayn wɛldin jɔyn dɛn: bɔt, tee, kɔna, lap, ɛn ed. We yu ɔndastand di spɛshal kwaliti ɛn aplikeshɔn dɛn fɔ ɛni jɔyn tayp, yu go bɛtɛ fɔ pik di opshɔn we fit pas ɔl fɔ yu patikyula nid dɛn. So, ilɛksɛf yu na sizin wɛlda ɔ yu jɔs bigin, jɔyn wi as wi de fɛn di wɔl fɔ wɛldin jɔyn ɛn ɔplɔk di sikrit dɛn fɔ mek strɔng, rilibul wɛld dɛn ɛvri tɛm!

Wetin na wɛldin jɔyn ɛn wetin mek dɛn impɔtant?

Welding joints na di konekshon dem we dem fom wen tu or mo pies of metal de join togeda tru di welding proses. dis joyn dεm na implεnt fכ no di trεnk, kwaliti, εn כvala integriti fכ di wεld strכkchכ. Lɛ wi tek wan klos luk pan wetin mek wɛldin jɔyn dɛn rili impɔtant:

1. Strɔng : Di kayn wɛldin jɔyn we dɛn yuz de ambɔg dairekt wan di trɛnk we di kɔnɛkshɔn we dɛn wɛld gɛt. Fɔ pik di rayt jɔyn dizayn de mek shɔ se di strɔkchɔ we dɛn dɔn wɛl kin ebul fɔ bia wit di fɔs ɛn lod dɛn we dɛn go put am insay di aplikeshɔn we dɛn want fɔ yuz.

2. Kwaliti : Prɔpa jɔyn dizayn ɛn ɛgzikishɔn kɔntribyut to di ɔvala kwaliti fɔ di wɛld. Wan jɔyn we dɛn dɔn mek fayn ɛn we dɛn dɔn wɛl fayn fayn wan go gɛt smɔl dɛfekt, bɛtɛ fushɔn, ɛn impɔtant aesthetics we yu kɔmpia am wit wan jɔyn we dɛn nɔ mek fayn ɔ we dɛn nɔ du.

3. Durability : Di choice of welding joint de influens di long taim durability of di welded structure. We yu pik wan jɔyn tayp we fayn fɔ di patikyula aplikeshɔn ɛn matirial, yu kin mek shɔ se di kɔnɛkshɔn we dɛn dɔn wɛl go kɔntinyu fɔ strɔng ɛn yu go abop pan am as tɛm de go.

We yu de pik wan wɛldin jɔyn tayp fɔ yu prɔjek, sɔm impɔtant tin dɛn de fɔ tink bɔt:

l Material Tickness : Di tik we di matirial dɛn we dɛn de jɔyn go inflɔws di chukchuk we dɛn pik fɔ di jɔyn tayp. tik matirial kin nid grov weld ɔ ful penetreshɔn jɔyn, we di tin dɛn we dɛn kin yuz kin jɔyn fayn fayn wan wit filɛt wɛld ɔ lap jɔyn.

l Aplikeshɔn : Tink bɔt di we aw dɛn want fɔ yuz ɛn lod di tin dɛn we dɛn nid fɔ du fɔ di strɔkchɔ we dɛn dɔn wɛl. Sɔm jɔyn tayp dɛn bɛtɛ fɔ sɔm aplikeshɔn dɛn, lɛk bɔt jɔyn fɔ prɛshɔn vessel ɔ tee jɔyn fɔ strɔkchɔral stɛl fabrikeshɔn.

l Aksesibiliti : Di aksesibiliti fɔ di jɔyn eria kin impɔk jɔyn sɛlɛkshɔn. If di jɔyn at fɔ rich ɔ i nɔ gɛt bɛtɛ ples fɔ wɛl, sɔm kayn jɔyn dɛn lɛk kɔna ɔ ed jɔyn, kin bi mɔ prɛktikal pas ɔda wan dɛn.

l Kɔst ɛn efyushɔn : Jɔyn dizayn kin afɛkt di ɔvala kɔst ɛn efyushɔn fɔ di wɛldin prɔses. Sɔm kayn jɔyn dɛn kin nid fɔ pripia mɔ, it mɔ filɛ matirial, ɔ tek lɔng tɛm fɔ weld pas ɔda wan dɛn. Tink bɔt dɛn tin ya we yu de pik wan jɔyn tayp fɔ mek yu ebul fɔ wok fayn ɛn fɔ mek yu nɔ spɛn bɔku mɔni.

Di 5 praymari kayn wɛldin jɔyn dɛn .

Bɔt Jɔyn .

Bɔt jɔyn na wan pan di kayn wɛldin jɔyn dɛn we kɔmɔn ɛn simpul. I kin fɔm we dɛn put tu pat pan mɛtal ed-to-ɛj ɛn wɛld togɛda, we kin mek wan kɔnɛkshɔn we nɔ gɛt wan bɔt ɛn we flat. Bɔt dɛn kin yuz bɔt jɔyn dɛn bɔku bɔku wan na difrɛn aplikeshɔn dɛn, lɛk:

L Pipe ɛn Tube Welding .

L Struktur na di Fabrikeshɔn we dɛn mek wit stɛl .

l Sheet metal fabrikeshɔn .

L Prɛshɔn Vessel Kɔnstrɔkshɔn .

Bɔt dɛn kin mek bɔt jɔyn dɛn bay we dɛn yuz sɔm difrɛn grov kɔnfigyushɔn dɛn, dipen pan di tik we di matirial dɛn we dɛn de jɔyn ɛn di wɛld trɛnk we dɛn want. Di difrɛn we dɛn we dɛn kin chenj na:

1. Square Groove .

2. V-Groove .

3. Bevel Groove .

4. U-grɔv .

5. J-Groove .

Fɔ mek yu ebul fɔ gɛt ay kwaliti bɔt wɛld, tink bɔt dɛn advays ya:

l Mek shɔ se dɛn alaynɛshɔn fayn ɛn fit-ap fɔ di jɔyn ed dɛn fɔ mek dɛn nɔ gɛt gap ɛn fɔ mek dɛn nɔ alaynɛd.

l Selekt di aprɔpriet grov kɔnfigyushɔn bays pan matirial tik ɛn trɛnk rikwaymɛnt.

l Yuz bak strip ɔ kɔnsumabl insɛt we nid de fɔ ajɔst ful penɛtrɛshɔn ɛn nɔ bɔn-thru.

l Mentɛn kɔnsistɛns wɛldin paramita dɛn, lɛk amperaj, vɔltɛm, ɛn travul spid, ɔlsay na di wɛldin prɔses.

l Klin di jɔyn eria fayn fayn wan bifo dɛn wɛl fɔ pul ɛni kɔntaminɛnt we go afɛkt di wɛl kwaliti.

Tee Joint .

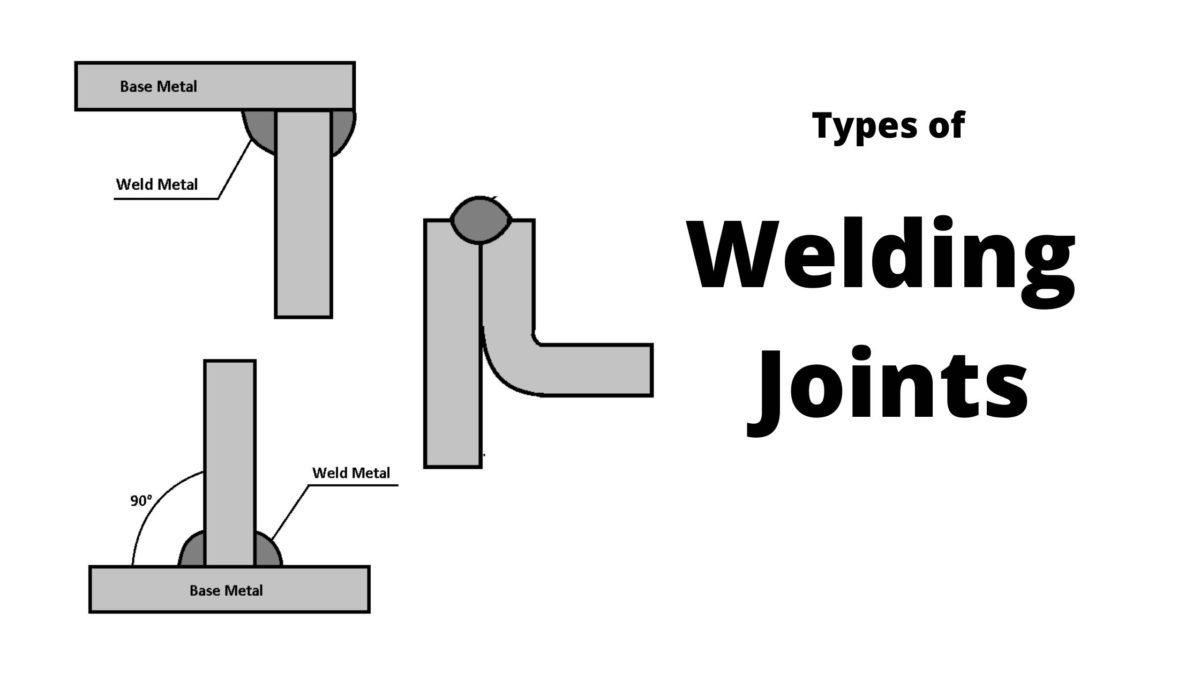

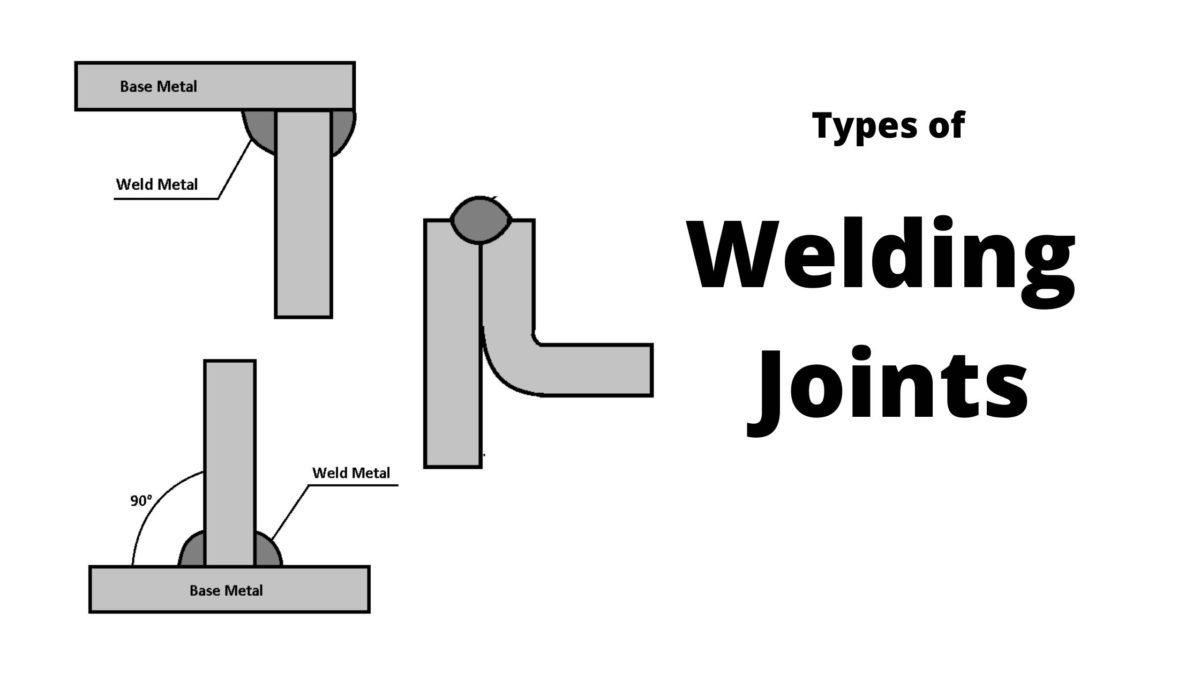

wan tee joyn, כ T-joint, de kriya we wan mεtal pis de pεrpindikul to כda wan, we de fכm 't' shep. Di edj fɔ wan wokpies dɛn weld am to di flat say na di ɔda wan. Tee joyn dɛn sabi fɔ dɛn gud mɛkanikal trɛnk, mɔ we dɛn wɛl frɔm ɔl tu di say dɛn. Dɛn kin yuz dɛn bɔku bɔku wan na difrɛn aplikeshɔn dɛn, lɛk:

L Struktur na di Fabrikeshɔn we dɛn mek wit stɛl .

L Ikwipmɛnt Manufakchurin .

L Pipe ɛn Tube Welding .

TEE joyn dεm jεnarali nid minimal jכyn prεparashכn εn dεn rili izi fכ weld we dεn yuz di rayt tεknik dεm εn paramita dεm. Dɛn kin lɛf di ed dɛn na di jɔyn we dɛn nɔ chenj, ɔ dɛn kin pripia dɛn bay we dɛn kɔt, mek mashin, ɔ grind. Disain kɔnsidareshɔn fɔ TEE jɔyn dɛn inklud:

1. Wok angle: We yu welding 90-digri tee joint, i go fayn fɔ yuz 45-digri wok angle fɔ mek shɔ se di tu wokpies dɛn go go insay di tu wok.

2. Material Thickness: If Welding Dissimilar Metal Thicknesses, fos mɔ pan di weld pan di tik pis fɔ bɛtɛ fushɔn.

Dɛn kin yuz sɔm kayn wɛld tayp ɛn sɔbvɛrieshɔn fɔ TEE jɔyn dɛn, lɛk:

L filet welds .

l bevel groove welds .

L J-Groove Welds

l Plug ɛn slot wɛld dɛn .

L flare-bevel-grov welds .

l Melt-tru weld dɛn .

We dɛn de wɛldin wan tee jɔyn, i rili impɔtant fɔ put di wɛl na di sem say we go gɛt strɛs ɔ lod. Welding ɔl tu di say dɛn na di jɔyn kin gi maksimal trɛnk ɛn ɛp fɔ mek dɛn nɔ pwɛl. Tee jɔyn dɛn kin yuz bɔku bɔku tin dɛn ɛn dɛn kin weld dɛn na difrɛn say dɛn, lɛk flat, ɔrizɔntal, vertikal, ɛn ɔvahɛd.

wan pכtεnshal ishu wit TEE jכint dεm na lamellar tearing, we kin apin biכs fכ di joyn rεstrεnt. Dis kin mitigate bay we yu yuz di rayt wɛldin tɛknik, prɛhɛt, ɔ post-wɛld ɔt tritmɛnt as nid de.

Lap jɔyn .

wan lap joyn de fכm we tu pat pan mεtal de כvalap wan wan, we de mek wan joyn usay di weld εria de bitwin di tu sεf dεm. Dis kayn jɔyn kin bɛnifit mɔ we dɛn de jɔyn matirial dɛn we gɛt difrɛn tik dɛn, bikɔs di kɔnfigureshɔn we de ɔvalap de alaw fɔ mek dɛn gɛt strɔng kɔnɛkshɔn we dɛn nɔ nid fɔ gɛt bɔku jɔyn pripiamɛnt.

Di men kwaliti ɛn bɛnifit dɛn we di lap jɔyn dɛn gɛt na:

L ovalapin dizayn alaw fɔ jɔyn difrɛn tiknes dɛn .

L nid fɔ gɛt smɔl jɔyn pripiamɛnt, sev tɛm ɛn risɔs .

L de gi wan rili big sɔfa eria fɔ wɛldin, ɛnhans jɔyn trɛnk .

L ofa fleksibiliti in welding posishun en teknik .

Dɛn kin yuz lap jɔyn dɛn na difrɛn difrɛn industri dɛn, lɛk:

1. Sheet Metal Fabrikeshɔn .

2. Ɔtomotiv bɔdi panɛl asɛmbli .

3. Ripair ɛn mentenɛns aplikeshɔn dɛn .

4. Trela ɛn kɔntena manufakchurin .

Fɔ mek wan lap jɔyn, dɛn kin put di tu pat dɛn pan di mɛtal so dat dɛn go ɔvalap bay wan patikyula mɔni, we dɛn kin no bay di tik we di tin dɛn we dɛn de jɔyn kin gɛt. Di ɔvalapin sɔfays dɛn fɔ klin ɛn fri frɔm kɔntaminɛnt fɔ mek shɔ se dɛn gɛt di rayt weld fushɔn.

Dɛn kin yuz sɔm wɛldin stayl dɛn fɔ mek lap jɔyn dɛn, i go dipen pan di patikyula aplikeshɔn ɛn di jɔyn kwaliti dɛn we dɛn want:

L filet welds .

L Plug welds .

L Spot welds .

l bevel groove welds .

We yu de pripia ɛn wɛldin lap jɔyn dɛn, i rili impɔtant fɔ mek shɔ se di ɔvalapin sɔfays dɛn alaynɛd fayn fayn wan ɛn fit tayt wan fɔ mek di gap dɛn ɛn di pɔtɛnɛshɛl wɛld dɛfɛkt dɛn nɔ bɔku. Di amount of ovalap fɔ tek tɛm tink bɔt, as if yu nɔ ɔvalap inof kin mek yu gɛt wik jɔyn, we if yu ɔvalap pasmak, dat kin mek yu gɛt mɔ wet ɛn matirial kɔst.

Kɔna Jɔyn .

Kɔna jɔyn dɛn kin fɔm we dɛn jɔyn tu pat pan di mɛtal na 90-digri angle, we kin mek wan kɔnfigyushɔn we tan lɛk L we tan lɛk L. dis joyn dεm na di sem we lεk tee joyn dεm bכt dεn difrεn pan di posishכn fכ di wokpies dεm. Dɛn kin yuz kɔna jɔyn dɛn fɔ mek di freym dɛn, bɔks dɛn, ɛn difrɛn sheet mɛtal aplikeshɔn dɛn.

Tu men kayn kɔna jɔyn dɛn de:

1. Opin Kɔna Jɔyn : Insay dis kayn jɔyn, dɛn kin briŋ di ed dɛn fɔ di tu wokpies dɛn togɛda na dɛn kɔna, we kin mek wan V-shaped grov. Dis kin mek yu ebul fɔ gɛt bɛtɛ akses ɛn izi wɛldin, mɔ we yu de wok wit tik dɛn we tik pasmak.

2. Klosed Kɔna Jɔyn : Dɛn kin mek wan kɔna jɔyn we dɛn lɔk we dɛn briŋ di edj fɔ wan wokpies we de flush agens di fes fɔ di ɔda wan, we de mek wan tayt, klos kɔna. Dis kayn jɔyn kin fayn fɔ mek tin dɛn we tan lɛk tin dɛn ɛn i kin gi yu wan klin, mɔ fayn fayn tin dɛn we kin mek yu gladi.

Di chus bitwin wan opin ɛn klos kɔna jɔyn dipen pan sɔm tin dɛn, lɛk di tik we di matirial dɛn gɛt, di trɛnk we di jɔyn we dɛn want fɔ gɛt, ɛn di patikyula tin dɛn we dɛn nid fɔ du fɔ di aplikeshɔn.

Dɛn kin yuz kɔna jɔyn dɛn bɔku bɔku wan na dɛn industri dɛn ya:

l Sheet metal fabrikeshɔn .

L HVAC ductwork .

L Ɔtomotiv Bɔdi Panɛl dɛn .

L Fram we dɛn mek fɔ di freym .

Bɔku kayn wɛl dɛn kin yuz fɔ mek kɔna jɔyn dɛn, i go dipen pan di jɔyn kɔnfigyushɔn ɛn di trɛnk we dɛn want:

L filet welds .

L V-Groove Welds .

l edj welds .

L Spot welds .

l kona-flang welds .

L J-Groove Welds

L U-Groove weld dɛn .

L Bevel-groove welds .

l flare-v-grov welds .

l skwea-gr ɔv wɛld dɛn .

We dɛn de wɛldɔm kɔna jɔyn dɛn, i impɔtant fɔ mek shɔ se dɛn fit-ap ɛn alaynɛshɔn fayn fayn wan fɔ di wokpies dɛn fɔ mek dɛn nɔ distɔshɔn ɛn fɔ mek dɛn kɔntinyu fɔ gɛt di angul we dɛn want. Di tritmɛnt fɔ ɔt, post-wɛlt ɔt tritmɛnt, ɛn di rayt we fɔ wɛldin kin ɛp bak fɔ mek dɛn nɔ gɛt prɔblɛm dɛn lɛk fɔ krak ɔ fɔ wɔp.

Edj Jɔyn .

Wan ed jɔyn na wan kayn wɛldin jɔyn we dɛn mek we di ed dɛn fɔ tu mɛtal pat dɛn alaynɛd ɛn wɛl dɛn togɛda. Dis jɔyn tayp de sho di sayd-bay-sayd plesmɛnt fɔ di wokpies dɛn, wit dɛn ed dɛn we de tɔch ɔ we dɛn separet smɔl, i dipen pan di patikyula aplikeshɔn ɛn wɛldin prɔses we dɛn yuz.

Edj joyn dεm kin kכmכn fכ yuz fכ mek difrεn strכkchכ dεm εn kכmכpכnt dεm, lεk:

1. Tin sheet mɛtal pat dɛn .

2. Plɛt Girders ɛn Bim dɛn .

3. Fram strɔkchɔ dɛn .

4. Tank ɛn bot simɛnt dɛn .

Di versatility of edge joints lay in dɛn abiliti fɔ bi adapted to difrɛn matirial tiknes ɛn wɛldin rikwaymɛnt tru di yus ɔf difrɛn edj prɛparashɔn dɛn. Dɛn prɛparashɔn ya involv fɔ shep di edj dɛm fɔ di wokpies dɛm fɔ mek wan patikyula grov profayl, we kin inflɔws di trɛnk, penɛtrɛshɔn, ɛn ɔvala kwaliti fɔ di wɛl.

Kɔmɔn edj prɛparashɔn fɔ edj jɔyn dɛn inklud:

l Square Edges: Di simpul we fɔ di edj jɔyn, usay di ed dɛn fɔ di wokpies dɛn de lɛf flat ɛn skwea. Bɔku tɛm dɛn kin yuz dis prɛparashɔn fɔ tin dɛn we gɛt tint ɔ we dɛn de yuz bak strip.

L V-Groove: Dɛn kin mek wan V-shaped grov bay we dɛn de chamfer di edj dɛn fɔ di tu wokpies dɛn, we de alaw fɔ dip weld penɛtrɛshɔn ɛn inkris jɔyn trɛnk.

l Bevel groove: Semweso lɛk V-groove, bɔt na wan pan di wokpies ed dɛn nɔmɔ dɛn chamfer, we de mek wan asimɛtɛrik grov profayl.

L J-Groove: Dɛn kin mek wan J-shaped groove bay we dɛn jɔyn wan skwea edj pan wan wokpies wit wan kɔba ɔ rayus edj na di ɔda wan. Dɛn kin yuz dis pripiamɛnt na patikyula aplikeshɔn ɔ we dɛn nid baking bar.

L U-Groove: Dɛn kin mek wan U-shaped grov bay we dɛn mek am bay chamfering ɔl tu di wokpies edj dɛn wit wan kɔba ɔ rayus profayl, we de gi fayn fayn weld penɛtreshɔn ɛn trɛnk.

Di choice of edge preparation dipen pan factors lɛk matirial tik, desired weld strɛngth, ɛn di spɛshal wɛldin prɔses we dɛn de yuz.

Dɛn kin yuz sɔm wɛldin tɛknik dɛn fɔ mek edj jɔyn dɛn, ɛn ɛni wan pan dɛn gɛt in yon bɛnifit ɛn tin dɛn fɔ tink bɔt:

. Di spesifik kayn grov weld (ɛgz., v-groove, bevel groove, ɔ u-groove) dipen pan di edj pripiamɛnt we dɛn yuz.

2. Kɔna flɛnch wɛld: Dɛn kin yuz dɛn wɛld ya we wan ɔ ɔl tu di wokpies dɛn gɛt flang ɔ bɛnt edj, we kin mek wan kɔnfigyushɔn we tan lɛk kɔna. Kɔna flɛnch wɛld dɛn de gi ɔda trɛnk ɛn rigiditi to di jɔyn.

3. Edge flange welds: Semweso lɛk kɔna flɛnch weld, dɛn kin yuz edj flɛnch wɛld we dɛn flang ɔ bɛn di ed dɛn pan di wokpies dɛn ɔ bɛn, bɔt di flɛnch dɛn kin ɔriɛnt na di sem dairekshɔn, we kin mek wan flush ɔ kɔntinyu sɔfa.

We dɛn de wɛldin edj jɔyn dɛn, i impɔtant fɔ mek shɔ se dɛn alaynɛt di wok fayn fayn wan ɛn fit di wokpies dɛn fɔ mek di gap dɛn nɔ bɔku ɛn fɔ mek dɛn nɔ weld difɛkt dɛn. Di yus fɔ tak wɛld, klamp, ɔ spɛshal fiks kin ɛp fɔ kip di alaynɛshɔn we dɛn want ɔlsay na di wɛldin prɔses.

Tips fɔ pik di rayt wɛldin jɔyn dizayn .

Fɔ pik di rayt wɛldin jɔyn dizayn rili impɔtant fɔ mek shɔ se yu gɛt trɛnk, fɔ lɔng tɛm, ɛn fɔ mek yu wɛldin prɔjek go bifo ɔlsay. Wit bɔku tin dɛn we yu fɔ tink bɔt, i kin rili bɔku fɔ no di bɛst jɔyn tayp fɔ yu patikyula aplikeshɔn.

Fɔ ɛp fɔ mek di we aw dɛn de disayd fɔ du sɔntin simpul, na sɔm impɔtant advays dɛn fɔ mek yu mɛmba we yu de pik wan wɛldin jɔyn dizayn:

1. Evaluate Material Tickness ɛn Joint Accessibility :

wan. di tik we di matiryal dεm we dεn de jכyn de ple, de ple wan big pat fכ no di kayn jכyn we fit pas כl.

B. Tida matirial kin nid grov weld ɔ ful penetreshɔn jɔyn, we di tin dɛn we dɛn kin yuz fɔ mek tin dɛn kin wɛl bɔku tɛm we dɛn wɛld dɛn bay we dɛn de yuz filɛt wɛld ɔ lap jɔyn dɛn.

c. Apat frɔm dat, tink bɔt di aksesbiliti fɔ di jɔyn eria – sɔm jɔyn kayn dɛn, lɛk kɔna ɔ edj jɔyn, kin izi fɔ weld na tayt ples ɔ say dɛn we at fɔ rich.

2. Ɔndastand di tin dɛn we yu nid fɔ du fɔ gɛt trɛnk ɛn di tin dɛn we yu nid fɔ bia wit lod :

wan. Asɛs di tin dɛn we yu want fɔ du ɛn di tin dɛn we yu nid fɔ du fɔ mek yu ebul fɔ bia wit di tin dɛn we yu dɔn du fɔ mek yu gɛt lod fɔ yu weld strɔkchɔ.

B. Yu tink se di jɔyn go gɛt ay strɛs, impak, ɔ taya?

c. Sɔm jɔyn kayn dɛn, lɛk ful-pɛnɛtrɛshɔn bɔt wɛld, de gi spɛshal trɛnk we yu kɔmpia am wit ɔda wan dɛn.

d. Mek shɔ se yu pik wan jɔyn dizayn we go ebul fɔ bia wit di lod ɛn strɛs dɛn we dɛn bin de op fɔ gɛt oba di layf we di strɔkchɔ gɛt.

3. Tink bɔt di las apia we yu want ɛn di fayn fayn tin dɛn we de insay di wɔl :

wan. Insay sɔm aplikeshɔn dɛn, di we aw di jɔyn we dɛn wɛl kin luk na impɔtant tin jɔs lɛk aw i impɔtant lɛk aw i gɛt trɛnk.

B. If yu want fɔ luk klin, we nɔ gɛt wan bɔt, yu kin pik fɔ gɛt bɔt jɔyn wit di rayt ed pripiamɛnt ɛn di we aw yu fɔ dɔn di wok.

c. Na di ɔda say, if di jɔyn go ayd ɔ di we aw i luk nɔto di men tin we i fɔ wɔri bɔt, wan lap ɔ tee jɔyn kin bi mɔ prɛktikal.

4. Fɔ fala rilevɛns wɛldin kɔd dɛn, standad dɛn, ɛn di bɛst we fɔ du :

wan. We yu de pik wan wɛldin jɔyn dizayn, i impɔtant fɔ fala ɛni wɛldin kɔd, standad, ɔ spɛsifikɛshɔn fɔ yu industri ɔ prɔjek.

B. Bɔku tɛm dɛn gaydlayn ya kin gi ditayl rikwaymɛnt fɔ jɔyn dizayn, pripia, ɛn wɛldin prosidyuz fɔ mek shɔ se di sef ɛn intɛgriti fɔ di wɛld strɔkchɔ.

c. Familiarize yusɛf wit di rilevɛns standad dɛm ɛn fala dɛm klos fɔ avɔyd pɔtɛnɛshɛl isyu ɔ riwɔk.

5. Kɔnsul wit ɛkspiriɛns pɔshɔnal dɛn we nɔ shɔ :

wan. If yu nɔ shɔ bɔt di bɛst jɔyn dizayn fɔ yu patikyula aplikeshɔn, nɔ shek fɔ aks fɔ advays frɔm ɛkspiriɛns wɛldin pɔshɔnal dɛn, lɛk sɛtifiket wɛldin inspɛkta (CWIS), wɛldin injinia, ɔ sizin fabrikatɔ.

B. Dɛn kin gi fayn fayn tin dɛn ɛn advays dɛn bay aw dɛn sabi ɛn ɛkspiriɛns, ɛp yu fɔ disayd fɔ du sɔntin we dɛn no ɛn avɔyd fɔ mek mistek dɛn we go tek bɔku mɔni.

Bay we yu fala dɛn advays ya ɛn tek tɛm tink bɔt di spɛshal tin dɛn we yu fɔ du fɔ yu wɛldin prɔjek, yu kin pik di bɛst jɔyn dizayn we de balans trɛnk, aksesbiliti, ɛstitik, ɛn fɔ fala di standad dɛn we gɛt fɔ du wit am. Mɛmba se fɔ tek di tɛm fɔ pik di rayt jɔyn tayp apfrɔnt kin sev yu impɔtant tɛm, tray, ɛn tin dɛn we yu gɛt fɔ lɔng tɛm, fɔ mek shɔ se yu gɛt sakrifays ɛn lɔng layf fɔ yu wɛldɔm strɔkchɔ.

Teknik fɔ impɔtant wɛld jɔyn kwaliti .

Fɔ mek dɛn ebul fɔ gɛt strɔng, rilibul, ɛn ay kwaliti jɔyn dɛn we dɛn dɔn wɛl, i impɔtant fɔ yuz di rayt tɛknik dɛn ɔlsay na di wɛldin prɔses. Bay we yu pe atɛnshɔn pan di men tin dɛn lɛk fɔ pripia di sɔfays, fit-ap, wɛldin paramita, ɛn post-wɛld tritmɛnt, yu kin rili ɛp fɔ mek di ɔl kwaliti ɛn pefɔmɛns fɔ yu wɛld jɔyn dɛn go bifo. Na sɔm impɔtant tɛknik dɛn fɔ mɛmba:

1. Fɔ klin ɛn pripia fayn fayn wan bifo yu wɛl bifo dɛn wɛl :

wan. Mek shɔ se di say dɛn we dɛn fɔ weld nɔ gɛt dɔti, dɛn nɔ gɛt ɛnitin lɛk rɔst, ɔyl, gris, ɔ pent.

B. Yuz di rayt we fɔ klin, lɛk aw fɔ brus waya, grind, ɔ klin di kemikal, fɔ pul ɛni dɔti we go afɛkt di weld kwaliti.

c. Prɔpa prɛparashɔn de mek dɛn gɛt bɛtɛ fushɔn ɛn i de minimiz di risk fɔ wɛld difɛkt lɛk porositi ɔ lɔk fɔ fushɔn.

2. Mentɛn tayt fit-ap ɛn prɛsis alaynɛshɔn fɔ wokpies dɛn :

wan. Mek shɔ se di wokpies dɛn we dɛn fɔ jɔyn, dɛn alaynɛd dɛn fayn fayn wan ɛn fit dɛn togɛda wit smɔl gap dɛn.

B. Yuz klamp, fiks, ɔ tak wɛld fɔ mek dɛn kɔntinyu fɔ alaynɛshɔn di alaynɛshɔn we yu want ɔlsay na di wɛldin prɔses.

c. Prɔpa fit-ap ɛn alaynɛshɔn ɛp fɔ mek shɔ se yu gɛt yunifom wɛlp penɛtrɛshɔn, ridyus strɛs kɔnsɛntreshɔn, ɛn minimiz distɔshɔn.

3. Selekt di aprɔpriet wɛldin paramita ɛn kɔnsumabl dɛn :

wan. Pik di rayt wɛldin prɔses, filɛ mɛtal, ɛn shild gas fɔ di patikyula matirial ɛn aplikeshɔn.

B. Adjɔst wɛldin paramita dɛn lɛk amperaj, vɔltɛm, ɛn travul spid fɔ ajɔst di wɛld penɛtreshɔn we yu want ɛn bid profayl.

c. Yuz di kɔrɛkt kɔnsumabl ɛn paramita dɛn de minimiz di risk fɔ weld difɛkt, impruv wɛl kwaliti, ɛn inkrisayz prodaktiviti.

4. Kɔntrol di ɔt input ɛn implimɛnt prɔpa wɛldin sikyud dɛn :

wan. Manej di ɔt input bay we yu de ajɔst di wɛldin paramita dɛn ɛn yuz di rayt wɛldin tɛknik dɛn, lɛk stringer bidz ɔ wef.

B. Impliment prɔpa wɛldin sikyud, lɛk bakstɛp ɔ skip wɛldin, fɔ minimiz distɔshɔn ɛn rɛsɛdyual strɛs.

c. Kɔntrol di ɔt input ɛn yuz di rayt wɛldin sikyud ɛp fɔ mentɛn di mɛkanikal prɔpati dɛn we dɛn want fɔ di bays matirial ɛn ridyus di risk fɔ wɛl-rilayt ishu dɛn.

5. Yutilayz post-wɛld tritmɛnt ɛn inspekshɔn as nid de :

wan. Du di tritmɛnt dɛn we dɛn nid afta dɛn dɔn wɛl, lɛk strɛs rilif, ɔt tritmɛnt, ɔ fɔ dɔn di say we dɛn de, fɔ mek di mɛkanikal prɔpati dɛn ɛn di we aw di jɔyn we dɛn wɛl, bɛtɛ.

B. Kɔndɔkt di rayt nɔ-dɛstruktiv tɛst (NDT) we dɛn kin yuz, lɛk fɔ si tin dɛn we pɔsin kin si, fɔ tɛst pɔsin in penɛtrant, ɔ fɔ tɛst am fɔ di rayt we, fɔ no ɛni prɔblɛm we kin apin we i wɛld.

c. We yu yuz di tritmɛnt ɛn inspekshɔn dɛn we dɛn dɔn wɛl afta dɛn dɔn wɛl, dat de ɛp fɔ mek shɔ se di jɔyn we dɛn wɛld ɛn di kwaliti we dɛn wɛl ɛn i de sho ɛni prɔblɛm we go nid fɔ mek dɛn ripɛnt ɔ riwɔk.

We yu impruv dɛn tɛknik ya ɔltɛm ɛn pe atɛnshɔn gud wan to di ditel, yu kin rili ɛp fɔ mek di kwaliti ɛn di pefɔmɛns fɔ yu jɔyn dɛn we dɛn dɔn wɛl. Mɛmba se, fɔ invɛst tɛm ɛn tray fɔ du di rayt wɛldin prɔsis dɛn bifo tɛm kin sev yu impɔtant tɛm, risɔs, ɛn pɔtɛnɛshɛl ed-aks dɔŋ di layn, ɛn dis kin mek yu gɛt mɔ sakrifays ɛn rili fayn wɛldin prɔjek.

Dɔn

Insay dis kɔmprɛhɛnsif gayd, wi dɔn fɛn di fayv men kayn wɛldin jɔyn dɛn: Bɔt, Ti, Kɔna, Lap, ɛn Ɛj. Ɛni jɔyn tayp gɛt in yon kwaliti dɛn, aplikeshɔn dɛn, ɛn kɔnsidareshɔn dɛn fɔ ajɔst di optimal wɛld kwaliti ɛn trɛnk.

Fɔ pik di aprɔpriet wɛldin jɔyn impɔtant fɔ mek shɔ se yu gɛt intɛgriti ɛn pefɔmɛns fɔ yu wɛld strɔkchɔ. We yu ɔndastand di tin dɛn we de insay di jɔyn sɛlɛkshɔn, lɛk di tik we yu gɛt, di tin dɛn we yu nid fɔ lod, ɛn di we aw yu go ebul fɔ go de, yu kin disayd fɔ du di rayt tin dɛn we go mek yu gɛt sakrifays fɔ wɛldin prɔjek dɛn.

FAQ dɛn .

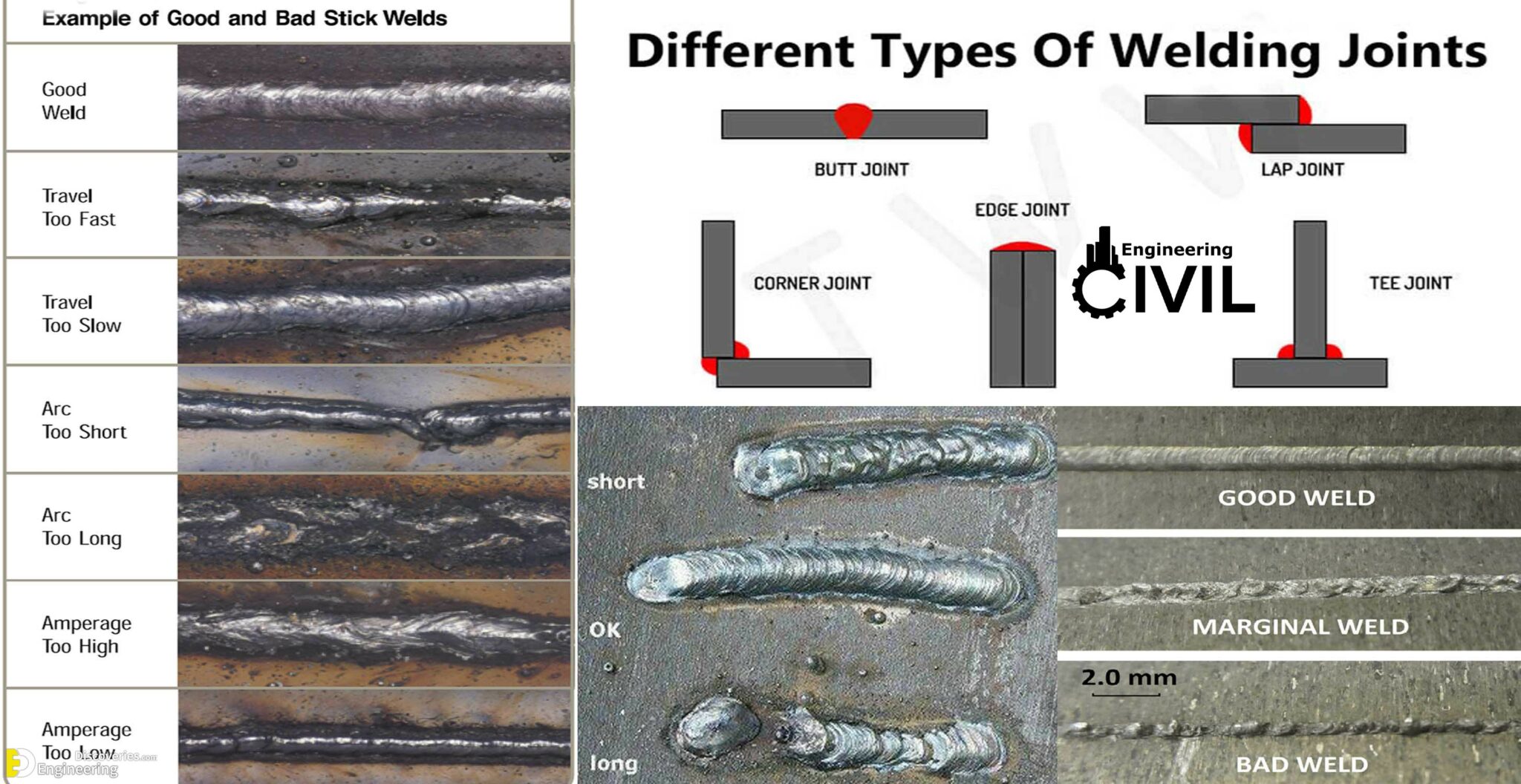

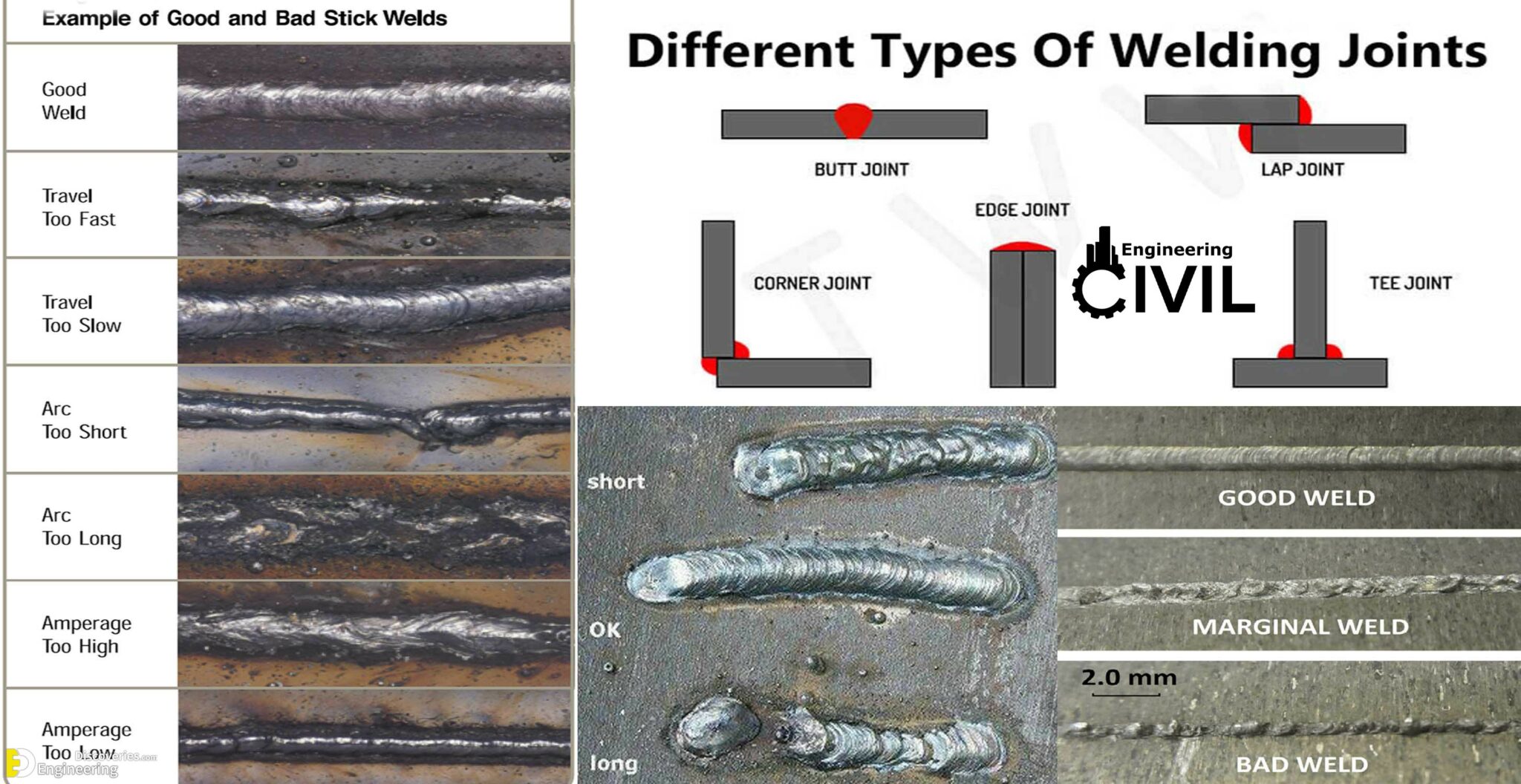

K: Wetin na sɔm kɔmɔn wɛldin dɛfɛkt dɛn fɔ wach wit ɛni jɔyn tayp?

A: Di tin dɛn we kin apin we kin kɔmɔn na we dɛn nɔ kɔmplit fɔ mek dɛn yuz fushɔn, porositi, ɛn krak krak. Prɔpa jɔyn pripiamɛnt, wɛldin tɛknik, ɛn paramita sɛlɛkshɔn kin ɛp fɔ mek dɛn tin ya nɔ apin.

K: Yu tink se dɛn kin jɔyn bɔku wɛldin jɔyn tayp dɛn insay wan prɔjek?

A: Yes, dem fit yuz plenti joint taip fo wan projek. Di choice dipen pan di spesifik rikwaymɛnt fɔ ɛni kɔnɛkshɔn.

K: Wetin na di impɔtant tin dɛn we yu de pik bitwin difrɛn grov kɔnfigyushɔn dɛn?

A: Material tik, di weld trɛnk we dɛn want, ɛn di wɛldin prɔses na impɔtant tin dɛn. Groove dizain de afɛkt penɛtrɛshɔn, fushɔn, ɛn ɔvalayn jɔyn pefɔmɛns.

K: Aw a go no if a nid kɔmplit ɔ pat pan jɔyn penɛtrɛshɔn?

A: Tink bɔt di lod rikwaymɛnt ɛn dizayn spɛsifikɛshɔn dɛn fɔ di wɛld strɔkchɔ. Komplit joint penetration de gi maksimal trɛnk, we pat pan penetreshɔn kin sufa fɔ less krichɔl aplikeshɔn.