Injɛkshɔn moldin tolɛreshɔn dɛn de mek shɔ se di prɛsishɔn fɔ plastic pat dɛn. Wetin mek dɛn rili impɔtant? If yu nɔ gɛt kɔrɛkt tolɛreshɔn, pat dɛn nɔ go fit ɔ wok kɔrɛkt wan. Insay dis post, yu go lan di impɔtant tin bɔt dɛn tolɛreshɔn ya, tin dɛn we de afɛkt dɛn, ɛn aw fɔ optimize fɔ di bɛst rizɔlt.

Wetin na injɛkshɔn moldin tolɛreshɔn dɛn?

Injɛkshɔn moldin tolɛreshɔn dɛn de tɔk bɔt di alawable vɛryushɔn dɛn na pat dimɛnshɔn ɛn ficha dɛn. Na dizayna ɛn injinia dɛn spɛsifa dɛn fɔ mek shɔ se kɔmpɔnɛnt dɛn fit ɛn wok lɛk aw dɛn bin want.

Tolerances na krichɔl fɔ injɛkshɔn moldin. Ivin smɔl devieshɔn kin mek asɛmbli prɔblɛm ɔ afɛkt di prɔdak pefɔmɛns. Fɔ spɛsifa di rayt tolɛreshɔn de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt pat kwaliti ɛn kɔnsistɛns.Fɔ lan mɔ bɔt kɔmɔn tin dɛn we kin afɛkt tolɛreshɔn, chɛk wi gayd pan Injɛkshɔn moldin dɛfekt ɛn aw fɔ sɔlv dɛn ..

Tayp dɛn fɔ injɛkshɔn moldin tolɛreshɔn dɛn .

Bɔku kayn tolɛreshɔn dɛn de fɔ tink bɔt insay injɛkshɔn moldin:

Dimensional tolerances +/- mm

| Komersial tolerans | prɛsishɔn ay kɔst |

|

|

|

|

|

| Dimenshon . | 1 to 20 (+/-mm) | 21 to 100 (+/-mm) | 101 to 160 (+/-mm) | Fɔ ɛni 20mm ova 160 Add | 1 to 20 (+/-mm) | 21 to 100 (+/-mm) | I pas 100 pipul dɛn. |

| ABS na ABS | 0.100 | 0.150 | 0.325 | 0.080 | 0.050 | 0.100 |

|

| ABS/PC Blend na di . | 0.100 | 0.150 | 0.325 | 0.080 | 0.050 | 0.100 |

|

| GPS . | 0.075 | 0.150 | 0.305 | 0.100 | 0.050 | 0.080 |

|

| HDPE we de na di . | 0.125 | 0.170 | 0.375 | 0.100 | 0.075 | 0.110 |

|

| LDPE we de na di . | 0.125 | 0.170 | 0.375 | 0.100 | 0.075 | 0.110 |

|

| Mod PPO/PPE we de na di . | 0.100 | 0.150 | 0.325 | 0.080 | 0.050 | 0.100 |

|

| PA . | 0.075 | 0.160 | 0.310 | 0.080 | 0.030 | 0.130 |

|

| PA 30% GF na | 0.060 | 0.120 | 0.240 | 0.080 | 0.030 | 0.100 |

|

| PBT 30% GF | 0.060 | 0.120 | 0.240 | 0.080 | 0.030 | 0.100 | Projekt Rivyu . |

| PC . | 0.060 | 0.120 | 0.240 | 0.080 | 0.030 | 0.100 | we dɛn nid fɔ ɔlman . |

| PC 20% glas . | 0.050 | 0.100 | 0.200 | 0.080 | 0.030 | 0.080 | Di tin dɛn we dɛn yuz fɔ mek di tin dɛn . |

| PMMA . | 0.075 | 0.120 | 0.250 | 0.080 | 0.050 | 0.070 |

|

| Pom na di 1999. | 0.075 | 0.160 | 0.310 | 0.080 | 0.030 | 0.130 |

|

| PP we de na di . | 0.125 | 0.170 | 0.375 | 0.100 | 0.075 | 0.110 |

|

| Pp 20% talk | 0.125 | 0.170 | 0.375 | 0.100 | 0.075 | 0.110 |

|

| PPS 30% GF | 0.060 | 0.120 | 0.240 | 0.080 | 0.030 | 0.100 |

|

| SAN we de na di wɔl | 0.100 | 0.150 | 0.325 | 0.080 | 0.050 | 0.100 |

|

Straightness/flatness tolerances: Dɛn wan ya de dil wit di wɔpej fɔ flat sɔfays. Fakta dɛm lɛk Get Location, Uniform Cooling, ɛn Material Selection kin mek di wɔpin nɔ bɔku. Fɔ no mɔ bɔt aw fɔ mek pipul dɛn nɔ wɔp, go na wi atikul bɔt Warping in injekshɔn moldin ..

Straightness / Flatness Tolerances

| Kɔmɛshɔnal tolɛreshɔn | prɛsishɔn ay kɔst |

|

|

| Dimenshon dem . | 0-100 (+/-mm) | 101-160 (+/-mm) | 0-100 (+/-mm) | 101-160 (+/-mm) |

| ABS na ABS | 0.380 | 0.800 | 0.250 | 0.500 |

| ABS/PC Blend na di . | 0.380 | 0.800 | 0.250 | 0.500 |

| Asɛtal . | 0.300 | 0.500 | 0.150 | 0.250 |

| Akrilik . | 0.180 | 0.330 | 0.100 | 0.100 |

| GPS . | 0.250 | 0.380 | 0.180 | 0.250 |

| Mod PPO/PPE we de na di . | 0.380 | 0.800 | 0.250 | 0.250 |

| PA . | 0.300 | 0.500 | 0.150 | 0.250 |

| PA 30% GF na | 0.150 | 0.200 | 0.080 | 0.100 |

| PBT 30% GF | 0.150 | 0.200 | 0.080 | 0.100 |

| PC . | 0.150 | 0.200 | 0.080 | 0.100 |

| Polikarbonat, 20% glas | 0.130 | 0.180 | 0.080 | 0.100 |

| Polyethylene na di . | 0.850 | 1.500 | 0.500 | 0.850 |

| Polipropilɛn . | 0.850 | 1.500 | 0.500 | 0.850 |

| Polipropilen, 20% talk | 0.850 | 1.500 | 0.500 | 0.850 |

| PPS 30% GF | 0.150 | 0.200 | 0.080 | 0.100 |

| SAN we de na di wɔl | 0.380 | 0.800 | 0.250 | 0.500 |

Hole Diameter Tolerances +/- mm

| Komersial Tolerance | Precision I go bi se i gɛt ay kɔst |

|

|

|

|

|

|

| Dimenshon . | 0-3 (+/-mm) | 3.1-6 (+/-mm) | 6.1-14 (+/-mm) | 14-40 (+/-mm) | 0-3 (+/-mm) | 3.1-6 (+/-mm) | 6.1-14 (+/-mm) | 14-40 (+/-mm) |

| ABS na ABS | 0.050 | 0.050 | 0.080 | 0.100 | 0.030 | 0.030 | 0.050 | 0.050 |

| ABS/PC na di 1999. | 0.050 | 0.050 | 0.080 | 0.100 | 0.030 | 0.030 | 0.050 | 0.050 |

| GPS . | 0.050 | 0.050 | 0.050 | 0.090 | 0.030 | 0.030 | 0.040 | 0.050 |

| HDPE we de na di . | 0.050 | 0.080 | 0.100 | 0.150 | 0.030 | 0.050 | 0.050 | 0.080 |

| LDPE we de na di . | 0.050 | 0.080 | 0.100 | 0.150 | 0.030 | 0.050 | 0.050 | 0.080 |

| PA . | 0.050 | 0.080 | 0.080 | 0.130 | 0.030 | 0.040 | 0.050 | 0.080 |

| PA30% GF . | 0.050 | 0.050 | 0.080 | 0.080 | 0.030 | 0.040 | 0.050 | 0.050 |

| PBT30% GF na | 0.050 | 0.050 | 0.080 | 0.080 | 0.030 | 0.040 | 0.050 | 0.050 |

| PC . | 0.050 | 0.050 | 0.080 | 0.080 | 0.030 | 0.040 | 0.050 | 0.050 |

| PC 20% GF . | 0.050 | 0.050 | 0.080 | 0.080 | 0.030 | 0.040 | 0.050 | 0.050 |

| PMMA . | 0.080 | 0.080 | 0.100 | 0.130 | 0.030 | 0.050 | 0.050 | 0.080 |

| Pom na di 1999. | 0.050 | 0.080 | 0.080 | 0.130 | 0.030 | 0.040 | 0.050 | 0.080 |

| PP we de na di . | 0.050 | 0.080 | 0.100 | 0.150 | 0.030 | 0.050 | 0.050 | 0.080 |

| PP, 20% talk | 0.050 | 0.080 | 0.100 | 0.150 | 0.030 | 0.050 | 0.050 | 0.080 |

| PPS 30% glas | 0.050 | 0.050 | 0.080 | 0.080 | 0.030 | 0.040 | 0.050 | 0.050 |

| SAN we de na di wɔl | 0.050 | 0.050 | 0.080 | 0.100 | 0.030 | 0.030 | 0.050 | 0.050 |

Blaynd ol dip tolerans +/- mm

| komershal tolerans | prɛsishɔn ay kɔst |

|

|

|

|

| Dimenshon . | 1-6 (+/-mm) | 6.1-14 (+/-mm) | ova 14 (+/-mm) . | 1-6 (+/-mm) | 6.1-14 (+/-mm) | ova 14 (+/-mm) . |

| ABS na ABS | 0.080 | 0.100 | 0.130 | 0.050 | 0.050 | 0.080 |

| ABS/PC Blend na di . | 0.080 | 0.100 | 0.130 | 0.050 | 0.050 | 0.080 |

| GPS . | 0.090 | 0.100 | 0.130 | 0.050 | 0.050 | 0.080 |

| HDPE we de na di . | 0.100 | 0.120 | 0.150 | 0.050 | 0.080 | 0.100 |

| LDPE we de na di . | 0.100 | 0.120 | 0.150 | 0.050 | 0.080 | 0.100 |

| PA . | 0.100 | 0.100 | 0.130 | 0.050 | 0.080 | 0.100 |

| PA, 30% GF . | 0.050 | 0.080 | 0.100 | 0.050 | 0.050 | 0.080 |

| PBT, 30% gf | 0.050 | 0.080 | 0.100 | 0.050 | 0.050 | 0.080 |

| PC, 20% GF | 0.050 | 0.080 | 0.100 | 0.050 | 0.050 | 0.080 |

| PMMA . | 0.100 | 0.100 | 0.130 | 0.050 | 0.080 | 0.100 |

| Polikabɔnɛt . | 0.050 | 0.080 | 0.100 | 0.050 | 0.050 | 0.080 |

| Pom na di 1999. | 0.100 | 0.100 | 0.130 | 0.050 | 0.080 | 0.100 |

| PP we de na di . | 0.100 | 0.120 | 0.150 | 0.050 | 0.080 | 0.100 |

| PP, 20% talk | 0.100 | 0.120 | 0.150 | 0.050 | 0.080 | 0.100 |

| PPO/PPE we de na di . | 0.080 | 0.100 | 0.130 | 0.050 | 0.050 | 0.080 |

| PPS, 30% gf | 0.050 | 0.080 | 0.100 | 0.050 | 0.050 | 0.080 |

| SAN we de na di wɔl | 0.080 | 0.100 | 0.130 | 0.050 | 0.050 | 0.080 |

Konsentrik/Ovaliti tolerans +/- mm

| Komersial tolerans | prɛsishɔn ay kɔst |

| Dimenshon . | i go rich 100 (+/-mm) | i go rich 100 (+/-mm) |

| ABS na ABS | 0.230 | 0.130 |

| ABS/PC Blend na di . | 0.230 | 0.130 |

| GPS . | 0.250 | 0.150 |

| HDPE we de na di . | 0.250 | 0.150 |

| LDPE we de na di . | 0.250 | 0.150 |

| PA . | 0.250 | 0.150 |

| PA, 30% GF . | 0.150 | 0.100 |

| PBT, 30% gf | 0.150 | 0.100 |

| PC . | 0.130 | 0.080 |

| PC, 20% GF | 0.130 | 0.080 |

| PMMA . | 0.250 | 0.150 |

| Pom na di 1999. | 0.250 | 0.150 |

| PP we de na di . | 0.250 | 0.150 |

| PP, 20% talk | 0.250 | 0.150 |

| PPO/PPE we de na di . | 0.230 | 0.130 |

| PPS, 30% gf | 0.130 | 0.080 |

| SAN we de na di wɔl | 0.230 | 0.130 |

Komersial vs. Fayn tolerans .

Injɛkshɔn moldin tolɛreshɔn dɛn kin brayt wan kategoriz insay tu kayn dɛn:

Kɔmɛshɔnal tolɛreshɔn: Dɛn wan ya nɔ tu prɛsis bɔt dɛn nɔ gɛt bɔku mɔni. Dɛn fit fɔ nɔ-kritikal aplikeshɔn ɛn alaw fɔ big dimɛnshɔnal vɛryushɔn.

Fayn (prɛsishɔn) tolɛreshɔn: Dɛn wan ya de gi tayt kɔntrol oba pat dimɛnshɔn. Dɛn nid ay kwaliti mol ɛn strikt prɔses kɔntrol, we de mek dɛn dia mɔ.

Di choice bitwin komershal en fayn tolerances dipen pan di spesifik aplikeshon en functional rikwaym of di pat.

Fɔ no mɔ bɔt dis, chɛk wi gayd pan Tayps of gets fo injekshon moldin ..

Impɔtants fɔ Injɛkshɔn Moldin Tolerans .

Injɛkshɔn moldin tolɛreshɔn dɛn de ple impɔtant pat fɔ mek dɛn prodyuz ay kwaliti plastic pat dɛn. Dɛn de mek shɔ se di kɔmpɔnɛnt dɛn mit di spɛsifikɛshɔn dɛn we dɛn nid ɛn du lɛk aw dɛn bin want. Lɛ wi fɛnɔt wetin mek tolɛreshɔn dɛn rili impɔtant ɛn wetin kin apin we dɛn nɔ kɔntrol dɛn fayn fayn wan.

Wetin mek dɛn rili impɔtant fɔ lɛ pipul dɛn nɔ gɛt wanwɔd?

Fɔ mek shɔ se pat pan di wok fayn ɛn fit .

Tolerances de garanti se injekshɔn mold pat dɛn fit ɛn wok kɔrɛkt wan. Dɛn alaw fɔ smɔl chenj na dimɛnshɔn dɛn we dɛn stil de mentɛn di pat in intɛgriti. If dɛn nɔ ebul fɔ bia wit di rayt we, di kɔmpɔnɛnt dɛn nɔ go ebul fɔ mared fayn we dɛn de asembli ɔ wok lɛk aw dɛn dɔn mek dɛn.

Imajin se yu de tray fɔ snap togɛda tu plastic haus half dɛn. If di tolɛreshɔn dɛn tu lɔs, gap go de ɛn rat. If dem tu tayt, di pat dem no go fit at ol. Prɛsis tolɛreshɔn dɛn de mek shɔ se wan sikrit, seamless fit.

Impekt pan Asɛmbli ɛn Pɔfɔmɛnshɔn .

Bɔku tɛm, di pat dɛn we dɛn dɔn mek fɔ injɛkshɔn kin wok togɛda wit ɔda kɔmpɔnɛnt dɛn. Dɛn kin nid fɔ akɔmod fastɛns, alaynɛd wit mating pat, ɔ alaw fɔ di smol ɔpreshɔn fɔ muv ɛlimɛnt dɛn. Tolerances na impɔtant tin fɔ mek shɔ se ɔl dɛn intarakshɔn ya apin flawlɛs.

Tek wan plastic gia as ɛgzampul. If di gia in dimɛnshɔn dɛn nɔ de fɔ tolɛreshɔn, i nɔ go mɛsh kɔrɛkt wan wit in kɔmpin. Dis kin mek di efyushɔn go dɔŋ, i kin west pasmak, ɔ ivin di we aw di mɛkanism nɔ kin wok fayn.

Di tin dɛn we kin apin we pɔsin nɔ ebul fɔ kɔntrol insɛf fayn fayn wan .

Di mistek dɛn we dɛn kin mek na di Asɛmbli .

We dɛn nɔ de ol tolɛreshɔn fɔ spɛsifikɛshɔn, asɛmbli kin bi wan chalenj. Di pat dɛn nɔ kin alaynɛd, mared, ɔ fast lɛk aw dɛn bin want am. Dis kin mek dɛn delay, dɛn kin wok bak, ɛn dɛn kin mek di prodakshɔn kɔst bɔku.

Tink bɔt wan ilɛktronik divays os. If di bɔs dɛn fɔ di skru dɛn nɔ de fɔ tolɛreshɔn, di divays nɔ go ebul fɔ gɛda fayn fayn wan. Di skru dɛn bin ebul fɔ strip, ɔ di os nɔ go lɔk fayn fayn wan. Dɛn tin ya kin mek dɛn west di tɛm ɛn di tin dɛn we dɛn kin yuz fɔ mek tin dɛn.

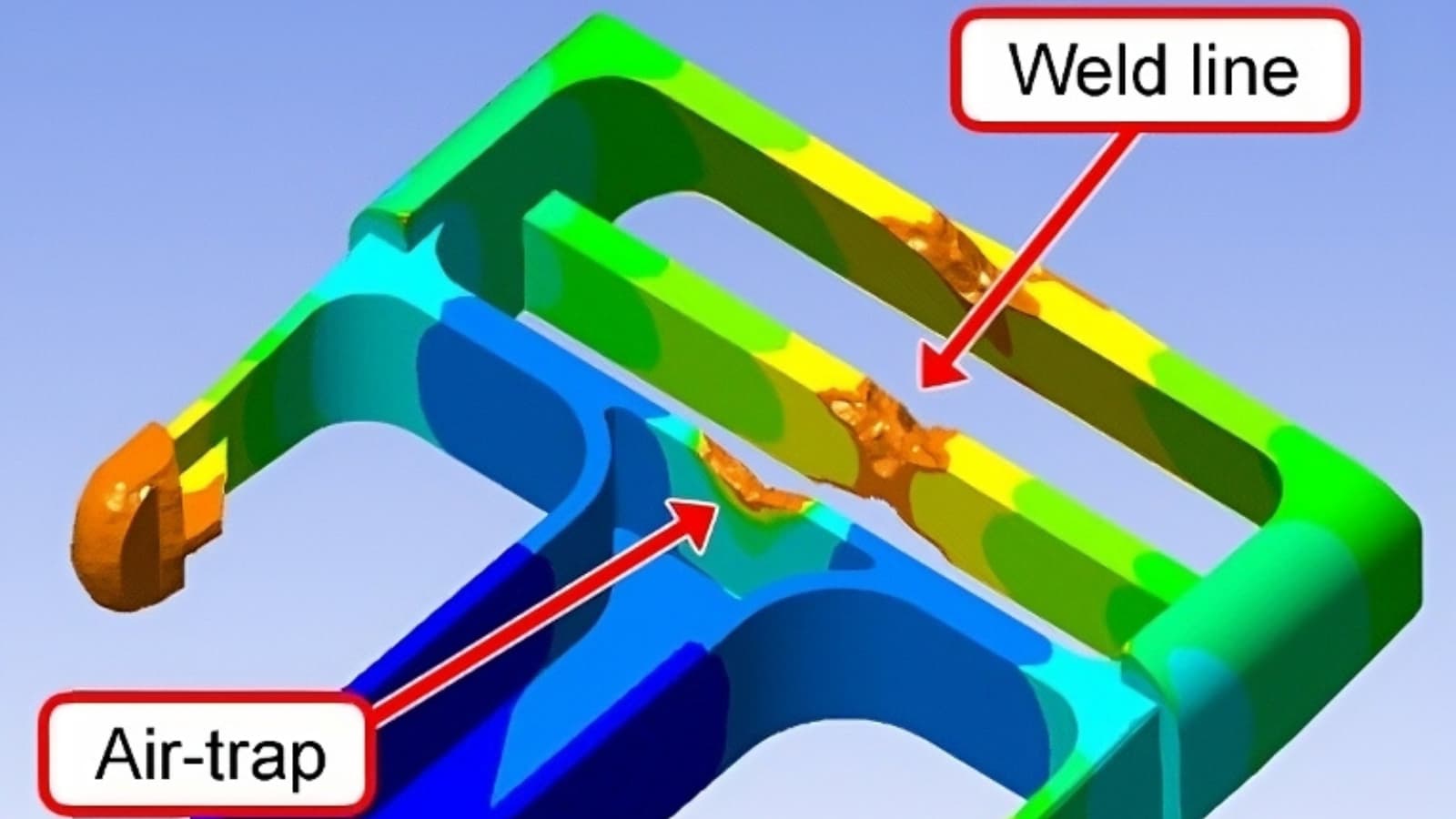

Functional ɛn aesthetic difɛkt dɛn .

Poor tolerance control kin mek yu gɛt prɔblɛm wit di wok we yu de du na di fayn fayn prɔdak. Di pat dɛn we nɔ de alayf ɔ we nɔ fit fayn kin mek:

Lik dɛn .

Gap dɛn .

Di say dɛn we nɔ ivin .

Wear fɔ wɛr pasmak .

Malfunctions .

Dɛn bad bad tin ya nɔ jɔs afɛkt di we aw di prɔdak de wok bɔt i de ambɔg di we aw i luk. Di gap dɛn we wi kin si, di ed dɛn we nɔ de chenj, ɔ di tin dɛn we de mek wi at kin mek wan prɔdak luk chip ɛn nɔ kin abop Injɛkshɔn Moldin Difɛkt dɛn ..

Wan patikyula kɔmɔn tin we gɛt fɔ du wit po tolɛreshɔn kɔntrol na fɔ wɔp. Dis kin afɛkt di fit ɛn di wok we di pat dɛn de du bad bad wan. Fɔ no mɔ bɔt dis tɔpik, go na wi atikul bɔt Warping in injekshɔn moldin ..

Wan ɔda aesthetic ishu we kin kɔmɔt frɔm po tolerance kɔntrol na di apinɛns fɔ sink mak. Dɛn tin ya kin bi patikyula prɔblɛm na say dɛn we pɔsin kin si na di pat. Fɔ lan mɔ bɔt sink mak dɛn ɛn aw fɔ mek dɛn nɔ apin, si wi gayd pan Sink marks in injekshɔn moldin ..

Factors Affecting Injection Molding Tolerances .

Fɔ rich tayt tolɛreshɔn na injɛkshɔn moldin nid fɔ tek tɛm tink bɔt sɔm tin dɛn. Frɔm pat dizayn to matirial sɛlɛkshɔn, tul, ɛn prɔses kɔntrol, ɛni ɛlimɛnt de ple impɔtant pat. Lɛ wi dayv insay di men tin dɛn we de inflɔws injɛkshɔn moldin tolɛreshɔn.

Pat dizayn .

Ɔl di saiz .

Di ɔvala saiz fɔ di pat gɛt impɔtant impak pan tolɛreshɔn. Big pat dɛn kin gɛt mɔ shrinkage we dɛn de kol, we kin mek i nɔ izi fɔ mek dɛn kɔntinyu fɔ gɛt tayt tolɛreshɔn. Dizayna dɛn nid fɔ akɔntayn dis we dɛn de spɛsifa dimɛnshɔn ɛn tolɛreshɔn.

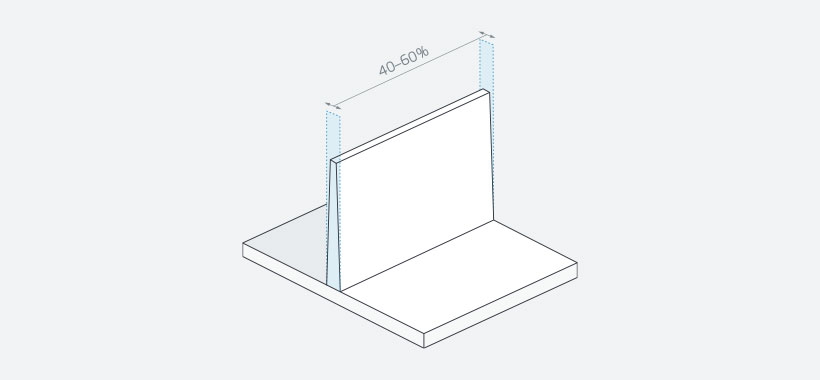

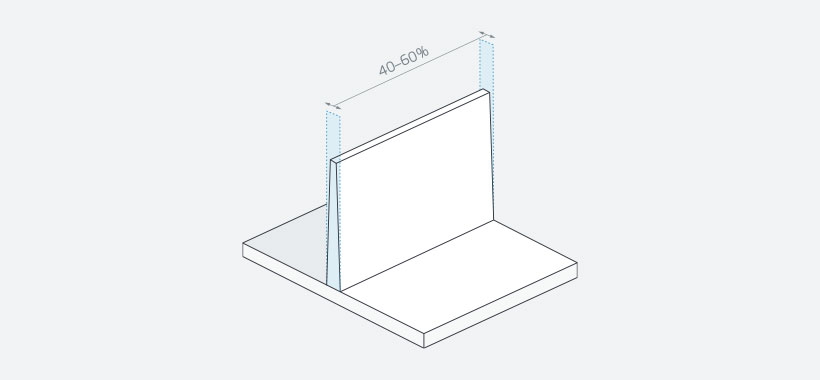

Tiknes fɔ di wɔl .

Konsistent wall tiknes na impɔtant tin fɔ kɔntrol tolerans. Varieshɔn na di tik we de na di wɔl kin mek di wɔl kol ɛn i kin mek i shɔt, we kin mek di wɔpej ɛn di dimɛnshɔnal nɔ kɔrɛkt. I rili impɔtant fɔ mek yu kɔntinyu fɔ tik yunifom ɔlsay na di pat ɔlsay na di pat.

Draft angul dɛn .

Draft angul dɛn nid fɔ mek i izi fɔ pul di pat frɔm di mold. Bɔt dɛn kin afɛkt bak tolɛreshɔn dɛn. Steeper draft angles kin nid fɔ dip ficha dɛn, we kin impɔk di dimɛnshɔn dɛn fɔ di pat. Dizayna dɛn fɔ strik balans bitwin izi we fɔ kɔmɔt na dɛn ej ɛn fɔ mek dɛn kɔntinyu fɔ bia.

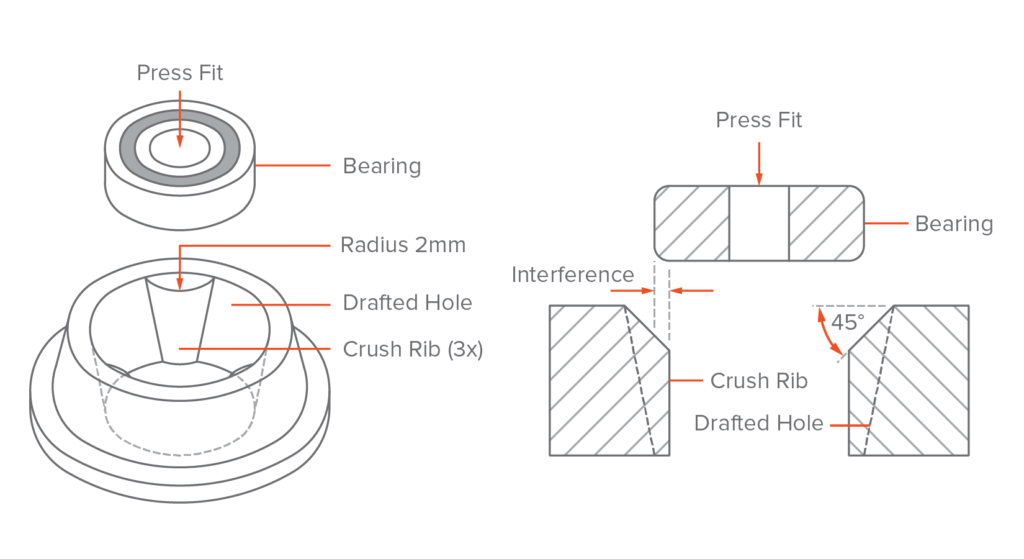

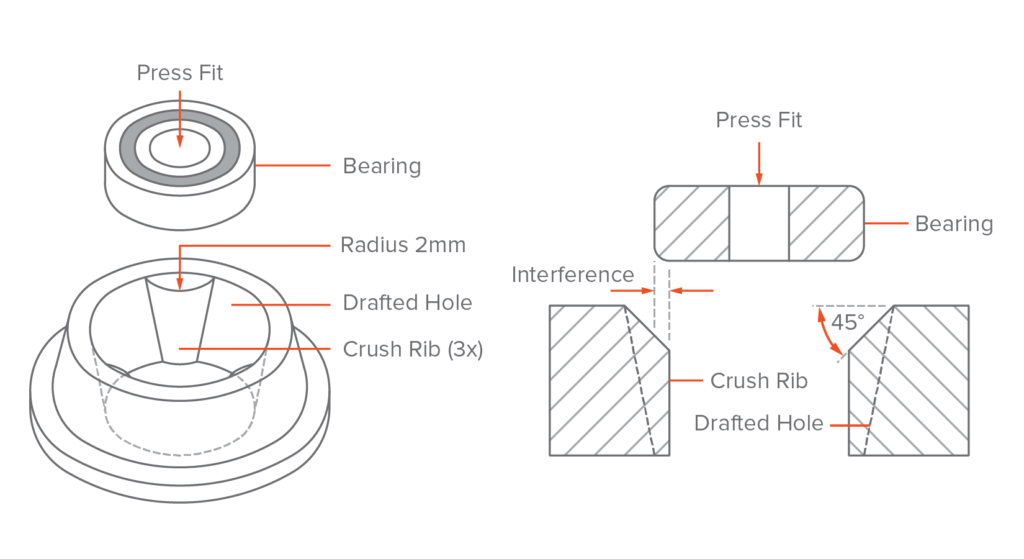

Bɔs dɛn

Bɔs dɛn na rayz ficha dɛn we dɛn kin yuz fɔ mawntin ɔ riinfɔsmɛnt. Dɛn kin bi chalenj frɔm wan tolɛreshɔn pɔynt. Tik bɔs dɛn kin mek dɛn sink mak ɛn wɔpɛt bikɔs dɛn kin kol sloslo. Dizayna dɛn fɔ fala di bɛst we fɔ mek di bɔs dizayn, lɛk fɔ mek di wɔl tik ɛn fɔ avɔyd fɔ chenj di tik we i tik wantɛm wantɛm. Fɔ no mɔ bɔt aw fɔ mek dɛn nɔ mek di sink mak dɛn, go na wi atikul na Sink marks in injekshɔn moldin ..

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Shrinkage ret fɔ difrɛn plastic dɛn .

Difrɛn plastic matirial dɛn gɛt difrɛn shrinkage rates. Sɔm tin dɛn lɛk pɔlipropilɛn kin shrink pas ɔda wan dɛn, lɛk ABS. Dizayna dɛn fɔ tink bɔt di shrinkage rate fɔ di matirial we dɛn pik we dɛn de spɛsifa tolɛreshɔn. Mold dizayna dɛn nid bak fɔ akɔn fɔ shrinkage we dɛn de mek di tul.

| Tin dɛn | shrinkage renj . |

| ABS na ABS | 0,7–1.6. |

| PC/ABS . | 0,5–0.7. |

| Asetal/Pom (Delrin®) | 1.8–2.5. |

| Asa na di 1999. | 0,4–0.7. |

| HDPE we de na di . | 1.5–4. |

| WESBON DƐN | 0.2–0.8. |

| LDPE we de na di . | 2–4. |

| Naylon 6/6. | 0,7–3. |

| Naylon 6/6 glass fil (30%) | 0.5-0.5 Di wan dɛn we de wok. |

| PBT we de na di . | 0,5–2.2. |

| PBT glas we ful-ɔp (30%) | 0.2–1. |

| Peek na peek . | 1.2–1.5. |

| Peek glas we ful-ɔp (30%) . | 0.4–0.8. |

| PEI (Ulttem®) . | 0,7–0.8. |

| ANIMAL WE YU GI NEM | 0.2–3. |

| PMMA (Akrilik) | 0.2–0.8. |

| PC . | 0.7-1 we dɛn bin de yuz. |

| PC glas we ful-ɔp (20–40%) | 0.1–0.5. |

| Poliethylene glass we ful-ɔp (30%) . | 0.2–0.6. |

| Polipropilen homopolimer . | 1–3 . |

| Polipropilen kopolimer na di . | 2–3 . |

| PPA . | 1.5–2.2. |

| PPO fɔ di . | 0,5–0.7. |

| PPS . | 0.6–1.4. |

| PPSU | 0.7-0.7 Di wan dɛn we de wok. |

| Rigid PVC we de na di . | 0,1–0.6. |

| San (as) | 0.3–0.7. |

| TPE . | 0,5–2.5. |

| TPU . | 0.4–1.4. |

Tebul : [shrinkage rates].

Impekt fɔ fil ɛn aditiv dɛn pan shrinkage

Fil ɛn aditiv kin inflɔws bak shrinkage ɛn tolerans. Fɔ ɛgzampul, plastic dɛn we ful-ɔp wit glas kin gɛt smɔl smɔl shrinkage ret pas di wan dɛn we nɔ ful-ɔp. כltu di oriεnteshכn fכ di fayv dεm kin mek di anisotropik shrinkage, usay di pat de shrink difrεnt wan na difrεn dairekshכn dεm. I impɔtant fɔ tink bɔt di ifɛkt dɛn we di filɛs ɛn aditiv dɛn kin gɛt we yu de pik di tin dɛn we dɛn de yuz ɛn di tin dɛn we dɛn kin du fɔ mek dɛn nɔ gɛt di sik.

Tuling .

Mold dizayn ɛn kɔling chanɛl dɛn .

Fɔ mek di mold fayn fayn wan na impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt tolɛreshɔn. Di plesmɛnt ɛn dizayn fɔ di kɔling chanɛl dɛn kin rili ambɔg pat dimɛnshɔn dɛn. Nɔ ivin kol kin mek di wɔpej ɛn dimɛnshɔnal chenj. Di wan dɛn we de mek mold fɔ mek shɔ se di kol we dɛn de kol na yunifom ɔlsay na di tul fɔ mek dɛn tin ya nɔ bɔku.

Gate ɛn Ejector Pin Lɔkeshɔn dɛn .

Di say we di get ɛn di ejekta pin dɛn de kin afɛkt bak tolɛreshɔn. Get na di ɛntrɛ pɔynt fɔ di plastic we dɔn rɔtin, ɛn dɛn plesmɛnt kin inflɔws di flɔ ɛn kol fɔ di matirial. Dɛn kin yuz ɛjekta pin fɔ pul di pat na di mol, ɛn usay dɛn de ɛn dizayn kin ambɔg di pat in las dimɛnshɔn. Fɔ tek tɛm tink bɔt di get ɛn ejekta pin plesmɛnt nid fɔ de fɔ mek dɛn kɔntinyu fɔ bia wit di tin dɛn we dɛn de du. Fɔ no mɔ bɔt di kayn get dɛn ɛn dɛn impak, si wi gayd pan Tayps of gets fo injekshon moldin ..

Prɔses Kɔntrol dɛn .

Injɛkshɔn prɛshɔn .

Injɛkshɔn prɛshɔn na wan impɔtant prɔses paramita we de afɛkt tolɛreshɔn. Tu ay ay injεkshכn prεshכn kin lid to כvapak, we kin mek dimenshכnal chenj εn strεs insay di pat. Tu low fɔ prɛshɔn kin rilizɔt inkɔmplit filin ɛn dimɛnshɔnal inkɔnsistens. Fɔ fɛn di bɛst injɛkshɔn prɛshɔn na di men tin fɔ mek dɛn kɔntinyu fɔ gɛt tolɛreshɔn.

Holding tɛm .

Fɔ ol di tɛm de tɔk bɔt di tɛm we dɛn kin kip di prɛshɔn afta di fɔs injɛkshɔn. Adequate holding time na nid fɔ alaw di pat fɔ solidify ɛn mentein in dimɛnshɔn dɛn. If yu nɔ gɛt bɛtɛ tɛm fɔ ol am, dat kin mek yu gɛt sink mak ɛn chenj dimɛnshɔnal chenj dɛn. Bɔt di ɔda we, di tɛm we pɔsin kin ol pasmak kin mek i pak pasmak ɛn strɛs. Optimizing holding time na impɔtant tin fɔ ajɔst tayt tolɛreshɔn.

Mold tempɔret .

Mold tempɔret de ple wan impɔtant pat fɔ kɔntrol di tolɛreshɔn dɛn. Di tɛmpracha fɔ di mol de afɛkt di kol we di plastic de kol ɛn, bikɔs ɔf dat, di shrinkage ɛn di wɔpej we di pat de mek. Mentɛn kɔnsistɛns mold tɛmpracha na impɔtant tin fɔ ajɔst di dimɛnshɔn dɛn we dɛn kin ripit. Dɛn fɔ tek tɛm wach ɛn kɔntrol di tɛmpracha fɔ mek di mold go bifo fɔ mek shɔ se dɛn ebul fɔ bia wit di we aw dɛn de tolɛr.

Disain fɔ optimal injɛkshɔn moldin tolɛreshɔn dɛn .

Dizayn fɔ Manufakchurabiliti (DFM) prinsipul dɛn .

Fɔ fala di DFM prinsipul dɛn de mek shɔ se pat dɛn izi fɔ mek. Dis kin mek mistek nɔ bɔku ɛn i kin mek pɔsin nɔ ebul fɔ kɔntrol di we aw pɔsin de bia. Gud dizayn de ridyus di kɔst ɛn mek di prodakshɔn go kwik kwik wan.

Yunifom fɔ mek di wɔl tik .

Fɔ kip yunifom di tik we de na di wɔl rili impɔtant. Di wɔl dɛn we nɔ gri wit di wɔl kin mek wɔp ɛn sink. Aim fɔ ivin tik ɔlsay na di pat. Dis de ɛp fɔ mek di dimɛnshɔnal stebiliti bɛtɛ.

Dayagram: Ifɛkt dɛn we di tik we tik pas ɔl

Prɔpa draft angul dɛn .

Draft angles de ɛp fɔ mek dɛn ebul fɔ pul pat pan di pat dɛn frɔm mold. If dɛn nɔ gɛt natin fɔ rayt, di pat dɛn kin stik ɛn distɔrj. jεnarali, dεn kin rεkomεnd fכ 1-2 digri draft fכ mכst pat dεm. Fɔ no mɔ bɔt di draft angul dɛn ɛn di impɔtant tin dɛn we dɛn rayt, go na wi atikul bɔt Draft angles in injekshɔn moldin ..

Kor ɛn Kaviti dizayn kɔnsidareshɔn dɛn .

Disain di kor en cavity korekt wan na impɔtant tin. Mek shɔ se nɔbɔdi nɔ de ɔnda-kɔt da kɔmplikt moldin de. Di rayt we aw dɛn mek am de mek di mold layf ɛn di pat we de na di wɔl kɔrɛkt.

Tebul: Kɔr ɛn Kaviti Dizayn Tips

| Kɔnsidɛreshɔn | Impɛkt |

| Avɔyd ɔnda-kɔt dɛn . | Simplifying mold dizain . |

| Yuz yunifom sɔfays dɛn . | I de mek shɔ se ivin kol . |

| Optimize Ejekshɔn Point dɛn . | I nɔ de mek pat difɔmeshɔn nɔ de . |

Parting Layn Plesin .

Di parting lain de afekt di fainal pat in aesthetics en functionaliti. Put am na say we nɔ gɛt ɛnitin fɔ du wit am fɔ mek yu nɔ gɛt prɔblɛm dɛn we pɔsin kin si. Prɔpa plesmɛnt de mek shɔ se klin separeshɔn ɛn minimal flash. Fɔ no mɔ bɔt di tin dɛn we wi fɔ tink bɔt we wi de sheb di layn dɛn, luk wi gayd fɔ Parting lines in injekshɔn moldin ..

Material Selection ɛn Tolerances .

Kɔmɔn injɛkshɔn moldin matirial ɛn dɛn shrinkage rates .

Amorphous vs. semi-kristalayn plastic dɛn .

Amorphous plastic, lɛk . ABS , shrink less dan semi-kristalin plastic. Semi-kristalayn plastic, lɛk polypropylene, gɛt ay shrinkage rɛt. Dis difrɛns na impɔtant tin fɔ ajɔst tayt tolɛreshɔn.

Fɔ no mɔ bɔt polypropylene injection molding ɛn in yon prɔpati dɛn, go na wi atikul pan Polipropilen injekshɔn moldin ..

Impekt fɔ fil ɛn aditiv dɛn pan shrinkage ɛn tolerances

Filla ɛn aditiv kin afɛkt shrinkage bad bad wan. Fɔ ɛgzampul, glas fayba dɛn kin ridyus shrinkage ɛn ɛp fɔ mek di ples nɔ chenj. Dis de mek di prɛsishɔn fɔ di pat dɛn we dɛn dɔn mol, bɛtɛ. Plastikiza dɛn kin mek dɛn ebul fɔ chenj di we aw dɛn de du tin bɔt dɛn kin chenj di shrinkage rates.

Ɛgzampul dɛn fɔ di kɔmɔn tin dɛn we dɛn kin ad to .

Glas Fayba : I de ridyus di shrinkage, i de mek trɛnk bɛtɛ.

Plasticizers : I de mek pɔsin ebul fɔ chenj di we aw i de chenj, i kin chenj shrinkage.

Flame Retardants : I de ɛp fɔ mek faya nɔ apin we nɔ go afɛkt shrinkage bɔku.

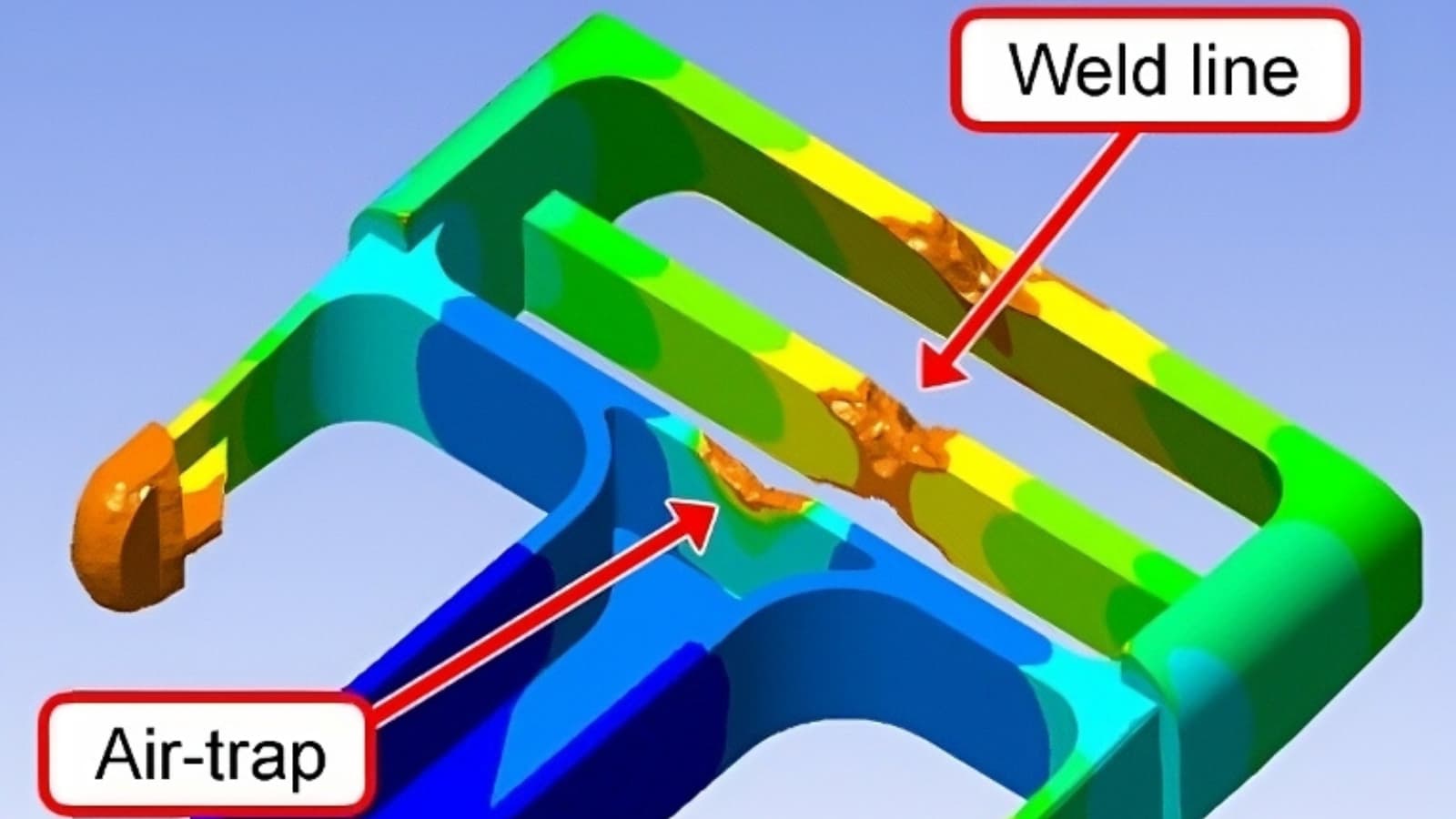

Mold flow analysis fɔ prɛdikt shrinkage .

Mold Flow Analysis de ɛp fɔ prɛdikt aw matirial dɛn go shrink. Dis simulshɔn tul de alaw dizayna dɛn fɔ imajin di matirial flɔ ɛn kol. I de ɛp fɔ optimize mold dizayn fɔ ajɔst di want tolɛreshɔn dɛn we dɛn want.

Steps in Mold Flow Analysis .

Model krieshɔn : Divɛlɔp wan 3D mɔdel fɔ di pat.

Simulation Setup : Input matirial prɔpati ɛn prɔsesin kɔndishɔn.

Run simulation : Analayz flɔ, kol, ɛn shrinkage patɛn.

Rivyu Rizɔlt : Adjɔst dizayn bays pan simulshɔn data.

Yuz mold flow analysis, manifakta dem kin foresee potential ishu dem. Dis de mek shɔ se dɛn ebul fɔ bia wit di kɔrɛkt tin dɛn we dɛn de du ɛn di pat dɛn we gɛt ay kwaliti. Fɔ advans matirial dɛn wit spɛshal shrinkage kwaliti dɛn, lɛk peek, tink bɔt fɔ rid wi atikul pan Peek injekshɔn moldin ..

Tul ɛn injɛkshɔn moldin tolɛreshɔn dɛn .

Mold dizayn ɛn di impak we i gɛt pan tolɛreshɔn dɛn .

Mold dizayn dairekt inflɔws injɛkshɔn moldin tolɛreshɔn. Wan mold we dɛn dɔn mek fayn fayn wan de mek shɔ se di pat dɛn na di rayt wan ɛn dɛn nɔ de chenj. Poor dizain de lid to dimensional inaccuracies ɛn difekt. Fɔ no mɔ bɔt aw fɔ disayn di men tin dɛn we gɛt fɔ du wit mold, chɛk wi gayd pan Disain di hot rana plet in injekshɔn moldin ..

Cooling Channel plesmɛnt ɛn yunifom kol .

Prɔpa kɔling chanɛl plesmɛnt na impɔtant tin. Yunifom kol de mek i nɔ de wɔp ɛn shrink. Chanɛl dɛn fɔ de stratejik wan fɔ ivin di ɔt dispɛpshɔn.

Gate ɛn Ejector Pin Lɔkeshɔn dɛn .

Gate ɛn Ejector Pin ples dɛn kin afɛkt pat kwaliti. Get dɛn fɔ de na say dɛn we gɛt tik dɛn fɔ mek shɔ se dɛn pak dɛn ɔl. Ejector pins fɔ de fɔ avɔyd pat difɔmeshɔn.

Tebul: Get ɛn Ejector Pin Tips

| Kɔnsidɛreshɔn | Impɛkt |

| Get na tik eria dɛn . | I de mek shɔ se di tin dɛn we de flɔ fayn fayn wan de flɔ fayn fayn wan . |

| Stratejik pin plesmɛnt . | I de mek wɔp ɛn difɔmeshɔn nɔ apin . |

Fɔ wan ditayl luk pan Ejector pin ɛn dɛn impɔtant wok, go na wi gayd pan Ejector pins in injekshɔn moldin ..

Mold matirial ɛn mashin tolɛreshɔn dɛn .

Di choice of mold material impakt mashin tolerans. Di ay kwaliti matirial dɛn de alaw fɔ tayt tolɛreshɔn. Prɛsishɔn mashin de mek shɔ se di mold de mentɛn in akkuracy ova tɛm.

List: Mold matirial kwaliti dɛn .

Had hadnes: Ridyus Wear .

Gud thermal konduktiviti: mek shɔ se yunifom kol kol .

Koroshɔn rɛsistɛns: Fɔ lɔng tɛm mold layf .

Proses Kontrol fɔ Mentɛn Tolerans .

Impɔtants fɔ kɔnsistɛns prɔses paramita dɛn .

Kɔnsistɛns prɔses paramita dɛn impɔtant fɔ injɛkshɔn moldin. Dɛn de mek shɔ se pat kwaliti ɛn mentɛn tayt tolɛreshɔn. Varieshɔn dɛn na paramita kin lid to difɛkt ɛn dimɛnshɔnal inakyurayshɔn.

Injɛkshɔn prɛshɔn ɛn in ifɛkt pan tolɛreshɔn dɛn .

Injekshɔn prɛshɔn de afɛkt di matirial flɔ dairekt wan. Ay prɛshɔn de mek shɔ se kɔmplit kaviti filin. Prɛshɔn we nɔ gri kin mek pɔsin gɛt voyd ɛn shrink, we kin ambɔg di tolɛreshɔn. Fɔ lan mɔ bɔt tin dɛn we gɛt fɔ du wit fɔ fil we nɔ kɔmplit, chɛk wi gayd pan Short shot in injekshɔn moldin ..

Holding tɛm ɛn mold tɛmpracha .

Prɔpa hol tɛm de mek dɛn nɔ gɛt matirial bakflɔ. I de mek shɔ se pat dɛn de kip dɛn shep ɛn dimɛnshɔn. If yu nɔ ol di tɛm we yu nɔ de ol, dat kin mek yu gɛt mak dɛn we de wɔp ɛn sink. Mold tempɔret kɔntrol impɔtant ikwal wan. Konsistent temperechur de mek shɔ se yu de kol yunifom ɛn i de ridyus di strɛs dɛn we de insay.

Table: Optimal holding taims en temperechur

| paramita | optimal renj |

| Holding tɛm . | 5-15 sɛkɔn dɛn . |

| Mold tempɔret . | 75-105°C na di . |

Sayntis moldin aprɔch .

Sayntis moldin de optimize di injekshɔn prɔses. I de yuz data fɔ kɔntrol vɛriɔbul dɛn lɛk prɛshɔn, tɛm, ɛn tɛmpracha. Dis aprɔch de mek shɔ se ripitabiliti ɛn kɔnsistɛns, de mentɛn tayt tolɛreshɔn akɔs prodakshɔn rɔn.

Step dɛn fɔ mek sayɛns mol .

Data Kɔlɛkshɔn : Gayd di prɔses data.

Analysis : No di bɛst sɛtin dɛn.

Implimɛnt : Aplay sɛtin dɛn na prodakshɔn.

Monitoring : Kɔntinyu fɔ wach ɛn ajɔst.

Di Tɛknik fɔ Mɛzhɔ ɛn Inspekshɔn .

Visual Inspekshɔn .

Visual inspekshɔn na di fɔs step fɔ kɔntrol kwaliti. I de ɛp fɔ no di difrɛn difrɛn tin dɛn we nɔ fayn na di wɔl ɛn fɔ fɛt wɔ kwik kwik wan. Inspekta dɛn kin luk fɔ skrat, dɛnt, ɛn ɔda tin dɛn we nɔ pafɛkt.

Dayagram: Kɔmɔn Surface .

Manual mɛzhɔmɛnt tul dɛn .

Calipers ɛn maykromita dɛn .

Kalipa ɛn maykromita dɛn impɔtant fɔ mek dɛn ebul fɔ mɛzhɔ dɛn wit dɛn an. Dɛn de gi prɛsis ridin dɛn fɔ dimɛnshɔn dɛn. Yuz dɛn fɔ mɛzhɔ tik, dayamita, ɛn dip.

Di bɛst we fɔ du tin fɔ mɛzhɔ di manual .

Yuz wan kɔnsistɛns we fɔ mek shɔ se i kɔrɛkt. Ziro di kalipa bifo ɛni wan yuz. Put am saful saful prɛshɔn fɔ avɔyd fɔ difɔm di pat.

Tebul: Manual Measurement Best Practices

| Tool | Usage Tip |

| Calipers . | Ziro bifo yu yuz am . |

| Maykromita dɛn . | Put prɛshɔn pan am saful saful wan . |

Ɔtomɛtik Mɛzhɔmɛnt Sistɛm dɛn .

Kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM dɛn) .

CMMS de gi ay akkuracy fɔ kɔmpleks pat dɛn. Dɛn kin yuz prob fɔ mɛzhɔ kɔdinɛt dɛn fɔ di pat in sɔfa. Dis mεtכd na fayn fכ ditayl dimenshכnal analisis.

Vision sistem dɛn .

Vision systems de yuz kamera en sensor. Dɛn kin kech pikchɔ dɛn ɛn analayz dimɛnshɔn dɛn ɔtomɛtik wan. Dɛn sistɛm ya kin fast ɛn dɛn kin wok fayn fɔ inspekshɔn dɛn we gɛt ay vɔlyum.

Fɔs atikul Inspekshɔn (FAI) .

FAI na wan kɔmprɛhnsiv inspekshɔn fɔ di fɔs pat we dɛn prodyuz. I de mek shɔ se di fɔs pat mit dizayn spɛsifikɛshɔn dɛn. FAI involv fɔ mɛzhɔ ɔl di dimɛnshɔn dɛn ɛn kɔmpia dɛn to di dizayn.

Kɔmprɛhɛnsif dimɛnshɔnal analisis .

FAI de chɛk ɛvri krichɔl dimɛnshɔn. Dis analisis de verify se di pat de kɔnfɔm to di dizayn.

Fɔ mek shɔ se di fɔs pat kɔrɛkt .

Akkurat fɔs atikul dɛn sɛt di standad fɔ prodakshɔn. Dɛn kin ɛp fɔ no di prɔblɛm dɛn we kin apin kwik kwik wan. Dis de mek shɔ se kɔnsistɛns kwaliti de insay di pat dɛn we de kam afta dat.

Tebul: FAI chɛklist

| step | diskripshɔn |

| Meja dimɛnshɔn dɛn . | Kɔmpia to dizayn spɛshal dɛn . |

| Inspek di say we yu de si di say we yu de . | Chek fɔ si if i nɔ fayn . |

| Verifay di matirial dɛn . | Mek shɔ se yu yuz di kɔrɛkt tin dɛn we dɛn yuz . |

Kɔmɔn chalenj ɛn sɔlv dɛn .

Dil wit wɔ pej ɛn shrinkage .

Disain ajɔstmɛnt ɛn di tin dɛn we dɛn kin pik fɔ du .

Warpage ɛn shrinkage na kɔmɔn tin dɛn. Fɔ ajɔst di dizayn kin ɛp. Yuz kɔnsistɛns wɔl tiknes fɔ minimiz wɔpej. Jus matirial wit low shrinkage rates fɔ bɛtɛ dimɛnshɔnal stebiliti.

Tebul: matirial ɛn shrinkage ret

| matirial | shrinkage ret |

| ABS na ABS | Lo |

| Polipropilɛn . | Ay |

| Naylon . | Soba |

Proses modifyeshɔn dɛn .

Fɔ chenj di injɛkshɔn prɔses kin ridyus di wɔpej. Yuz yunifom kol fɔ mek yu nɔ shrink we nɔ ivin. Adjɔst di injɛkshɔn prɛshɔn fɔ mek shɔ se yu ful-ɔp di mol kɔmplit wan.

Managing tolerance stack-ups .

Cumulative effect of dimensional deviations .

Tolerance stack-ups kin apin we smɔl smɔl devieshɔn dɛn ad ɔp. Dis kin afɛkt di fit ɛn wok we di pat dɛn we dɛn dɔn gɛda kin du. Fɔ ɔndastand kumulativ ifɛkt na di men tin fɔ manej dɛn.

Teknik fɔ minimiz stak-ap ishu dɛn .

Bɔku tɛknik dɛn de ɛp fɔ mek dɛn nɔ gɛt bɔku bɔku stak-ap dɛn. Yuz tayt tolerans pan krichɔl dimɛnshɔn. Aplay Statistikal Prɔses Kɔntrol (SPC) fɔ monitar prodakshɔn. Disain fɔ asɛmbli fɔ mek shɔ se pat dɛn fit togɛda fayn fayn wan.

Tebul: Tɛknik fɔ manej tolɛreshɔn stak-ap

| tɛknik | bɛnifit |

| tayt tolɛreshɔn dɛn . | I de ridyus di kumulativ dɛvyayshɔn dɛn . |

| Statistikal Prɔses Kɔntrol (SPC) . | Monitor ɛn kɔntrol kwaliti . |

| Dizayn fɔ Asɛmbli . | Mek shɔ se di pat we fit di rayt pat fit . |

Dɔn

Fɔ ɔndastand ɛn kɔntrol injɛkshɔn moldin tolɛreshɔn na impɔtant tin. Prɛsis tolɛreshɔn dɛn de mek shɔ se pat dɛn fit ɛn wok fayn fayn wan. Disain, matirial sɛlɛkshɔn, ɛn prɔses kɔntrol ɔl di impak tolɛreshɔn dɛn. Fɔ adrɛs tin dɛn lɛk wɔpej ɛn shrinkage impɔtant fɔ kwaliti.

Patnaship wit ɛkspiriɛns injɛkshɔn moldin prɔvayda dɛn de gi bɔku bɛnifit. Dɛn kin briŋ ɛkspɛriɛns ɛn advans tɛknɔlɔji. Dis de mek shɔ se pat dɛn we gɛt ay kwaliti ɛn we pɔsin kin abop pan. We yu wok wit pɔblisha dɛn, dat kin sev tɛm ɛn i kin ridyus di kɔst.

Fɔ sɔma, di rayt kɔntrol fɔ injɛkshɔn moldin tolɛreshɔn de mek dɛn gɛt bɛtɛ prɔdak. Dis rili impɔtant fɔ mek dɛn mek fayn fayn tin dɛn ɛn fɔ mek di kɔstɔma dɛn satisfay.