Milling machinis sunt versatile apparatus instrumenta disposito ad figura solidum materiae per removendo excessum materia. Et utuntur gyrum Cutters creare precise partes et components. Haec machinas potest praestare variis operationibus quasi secans, EXERCITATIO et effingens metalla, plastica lignum et aliis.

Brevis historia milling machinis

In Evolutionis Milling Machines Dates ad mane 19th century:

MDCCCXVIII: Heli Whitney inventa primum milling apparatus in novo portum, Connecticut.

Antequam hoc invention: opifices fiducia in manu files, tempus consumens et arte, dependens processus.

Early Applications: praesertim propter imperium contrahit, ut vestibulum diripiat partes.

Subsequent progressu: duci ad auctus praecisione, efficientiam, et versatility in vestibulum processus.

Momentum Milling Morte in Manufacturing Industria

Milling velit ludere a crucial munus in modern vestibulum:

Versatility: Non possunt creare variis figuris, a simplex plana superficies ad universa 3D Venustates.

Precisione, capaces producendo partes cum stricta tolerances, essential ad industries quasi aerospace et eget.

Efficens: CNC Milling machinis automate processibus, augendae productio rates et reducendo humana errore.

Material flexibilitate potest operari cum amplis materiae, inter metalla, plastica et composita.

Cost-efficaciam: obstante initial investment, offerimus diu-term peculi per improved productivity et reducitur vastum.

Industria benefiting a milling machinis includit:

Eget

Aerospace

Electronics

Medicinae cogitationes

Tooling et mori faciens

Per providente precise, efficient, et versatile materia remotionem capabilities, milling machinis facti sunt necessaria in modern vestibulum processus per numerosis industrias.

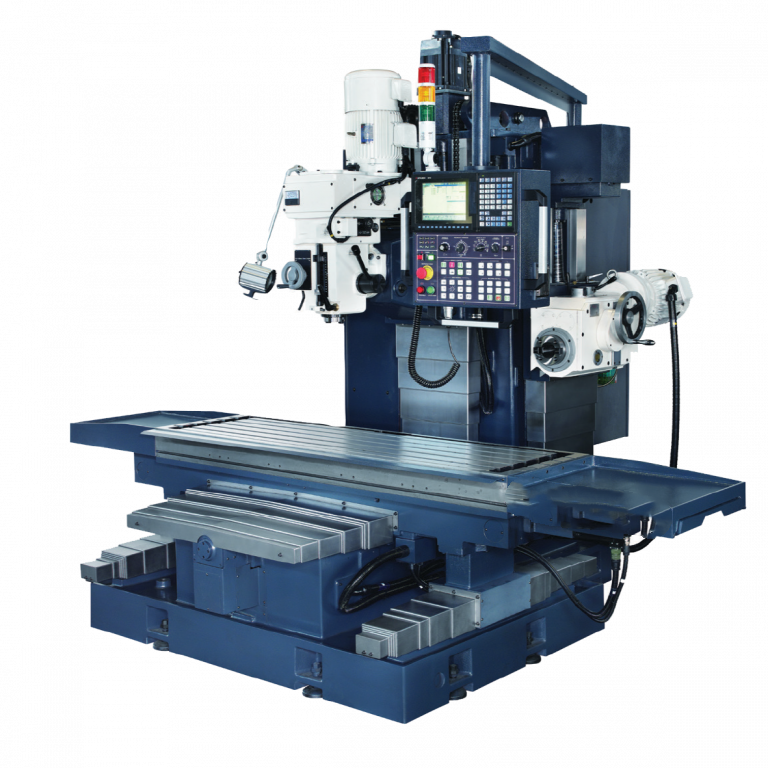

Structuram et clavis components de milling machinis

Milling machinarum consistit ex pluribus pendet components operantes in harmonia ad curare precise et agentibus machining operationes.

Basis

Et basis format fundamenta de milling apparatus:

Function: praebet stabilitatem et absorbet vibrationum per operationem

Material: typically mittebant ferrum, offering diuturnitatem et rigiditatem

Design: Saepe incorporat coolant alveus ad efficientem calor administratione

Columna

Sicut ToBack Milling Machina, columna:

Genu

Et genu est a discrimine Novifacta pars:

Sustinet et sella et worktable

Features vertical pascuntur screw ad praecise profundum imperium

Dat vertical motus per columna accurate positioning

Sella

Hoc pars facilitates multi-directional motus:

Labitur per genu in y axis

Concedit worktable motus in X axis

Enhances altiore positioning flexibilitate

LIBER

In worktable est prima workpiece firmamentum:

Movet per x et y axes per sella et genu

Features T-foramina ad secure workpiece et Fibulae affectum

Providet stabilis suggestus pro variis machining operationes

Fusus

Ut media pars, in fusum:

Tenet et gotates Cutting Tools

Potest oriented verticaliter aut horizontaliter secundum apparatus type

Offers Novifacta feed rates pro diversis machining requisita

Overarm, Arbor et Quill

Haec components variantur secundum apparatus type:

Horizontal M.: Usus Overarm et Arbor pro Cutting Instrumentum Support

Vertical Morte: Usus Passim ad dux tool sursum et-descendit motus

Et augendae sectandum praecisione et versatility

Additional components

Complures partes contribuere ad milling apparatus functionality:

Fusum caput: domibus et fusum et Swivel enim angularis motus

Tool Holders: Secure variis secans instrumenta ad fusum

Dividing caput: dat precise workpiece gyrationis ad complexu operationes

Opus principium milling machinis

Milling machinis agunt in fundamental principle materialis remotionem usura gyratorius cutters. Et offerunt praecisione et versatility in effingendo variis materiae ad vestibulum applications.

Materia remotionem processus

Core munus de milling machinis involves:

Rotating Multi-Point Cutters ad High Speeds

Progredientes has in stabilem workpiece

Selectively removere materiam ad consequi desideravit shapes et dimensiones

Clavis parametri

Felix milling operationes confidunt diligenter temperatio pluribus parametri

Pressura: controls vim applicari a Cutter in workpiece

Cutter caput Volo: decernit rate of materia remotionem

Pascere directionem: influit qualis est perfecta superficies

Critical operational factors

Ad curare meliorem machining results, operators est considerandum:

Fusum celeritate: afficit secans efficientiam et superficiem metam qualis

Tabula Feed Rate: Impacts Material remotionem Rate et Mors Principium Vita

Profundum Conscidisti determinat moles materia removetur in singulis

Cutter Gyrationis directionem: Influxus Chip formation et Superficiem Quality

Machining species et efficientiam

Pluribus factores significantly afficiunt altiore qualitas et efficientiam de milling operationes:

Cutting tool Electio

Material: ut aequare vel excedere workpiece durum

Geometria: Influxibus chip formation et evacuatione

Coating: Enhances tool vitae et reduces friction

Secans parametri optimization

| modularis | effectus in qualis | effectus in efficientiam |

| Celeritate | Superficiem metam | Materia remotionem rate |

| Pascere | Dimensional accurate | Tool induendum |

| Profundum | Integritas | Processing tempore |

Refrigerationem et lubricatae

Refrigerant et Pulication Systems propriis:

Redigendum friction inter instrumentum et workpiece

Dissipate calor generated in secans

Extend tool vitae et amplio superficiem metam

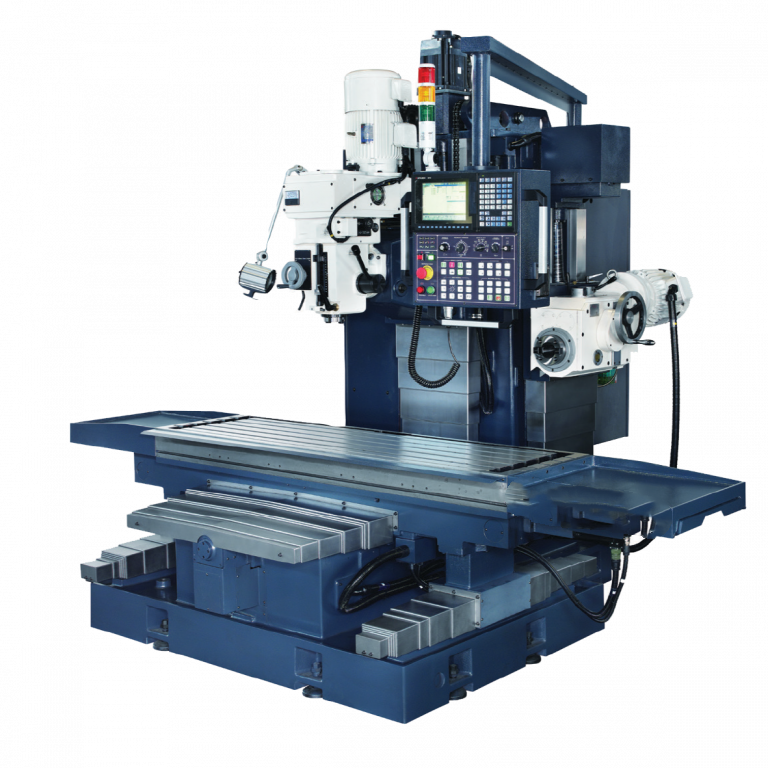

Genera milling machinis

Vertical milling machinis

Verticalis milling machinis habere fusum oriented directionaliter per z-axis. Fusum movet et descendens, faciens haec machinis idealis pro mersco secans et EXERCITATIO. Excellere operationes requirere praecisione positioning praesertim creando complexu. Eorum versatility permittit ea praestare effingens, secans, et EXERCITATIO tasks cum princeps accurate, faciens eos popularibus in industrias ut aerospace et automotive.

Key features of vertical Milling Morte:

Fusum orientation : verticaliter aligned fusum per z-axis.

Suitability : Optimus quia Mercerge secans, EXERCITATIO et praecisione shaping.

Versatility , potest tractare universa partes trans variis materiae.

Horizontalis Milling Morte

Horizontalis Milling Morte pluma est fusum parallel ad worktable, quod dat melius tractantem maius et densior materiae. Sunt plerumque adhibetur ad applications ut sloting, ingemuit, et planning plana superficiebus. Horizontal mola providere auctus rigiditatem faciens ea specimen ad rouging processus requirit potentes secare instrumenta.

Milling Milling Morte commoda:

Fusum orientation : parallela ad worktable, augendae stabilitatem.

Applications : propter slotting, grooing et planning plana superficiebus.

Materia pertractatio : agentibus ad magnum, densissima workpieces et summus celeritate operationes.

Vos quoque can adepto de cognitione et comparatione inter horizontalem et vertical milling machinis.

CNC Milling Morte

CNC Milling machinarum integrate Computer numerical Imperium (CNC) Technology, permittens praecise imperium super machining processus. Haec machinis uti pre-programmed computatrum instructiones ad automate secare, EXERCITATIO et effingens tasks. CNC Mills notum est in altum accurate et facultatem ad producendum complexu components cum consistent results, faciens eos necessaria in industrias postulantes praecisione, ut aerospace et medicinae cogitationes.

Victoria facies CNC Milling machinis:

CNC Technology : Automated processibus ab computatrum progressio.

Subtilitas : High accurate in creando complexu et delicata components.

Efficens : 24/7 currit, augendae productivity.

Universalis milling machinis

Universalis milling machinis miscere ad capabilities et verticalis et horizontali milling machinis. Et pluma a swiveling worktable quod permittit angulari milling operationes, faciens eos valde versatile pro variis officiis. Haec machinis saepe in toulgrooms, reparare tabernas, et officinas ubi amplis operations opus est in unum apparatus.

Key features universalis milling machinis:

Compositum de capabilities : sustinet utrumque vertical et horizontali milling.

Swiveling worktable : enables angulari milling ad universa figuris.

Applications : Specimen ad Toolom, Restituo Shop et Workshop usum.

Lectum Milling Morte

Lectum Milling machinis sunt disposito gravibus-officium res. Habent fixum worktable et fusum movet per z axem praestare secans. Haec machinis offerre magnam et fortitudinem, faciens ea idoneam operantes magnis, grave, ut qui in automotive aerospace et constructione industries.

Main characteres lectum milling machinis:

Fixum mensam : Possidet stabilitatem ad grave-officium milling operationes.

Motus fusum movet perpendiculariter per z axis altum secat.

Applications : late in automotive, aerospace et constructione industries.

SPECIALIBUS ad Milling Morte

Disposito enim propria milling requisita:

Milling machinis Milling

Circularis Tabula conuertitur axis

Multiplici Cutters in diversis iuga

Continua loading / unloading per operationem

Gantry milling machinis

Large lectum supporting a mobilibus gantry

Multiplex Cutters mounted in gantry frame

Specimen enim machining oversized partes

V, axis milling machinis

Offert motus in tres linearibus et duo gyratorius axes

Gignit complexu figuris et Venustates

Enhances praecisione et reduces setup tempus

Molendini machina operationes et artes

Faciem milling

Faciem milling gignit plana superficiei perpendicularis ad instrumentum axis:

Utilitas faciem milling Cutters cum multiple secans marginibus

Profundum Conscidisti accommodetur per crucem-feed screw in mensa

Producit summus qualitas superficies finiatur magnam areas

Applications: Engine Block Superficies, finge bases, structural components

Planto milling (Slaeb Milling)

Hoc operatio producit lenis, horizontalis superficiebus:

Cutter axem parallel ad machined Superficiem

Communiter ad reducing workpiece crassitudine

Generat plana superficiebus cum bono dimensional accurate

Applications: Keyways, foramina, plana baseplatis superficiebus

Angulari

Angularis milling generat superficies ad certis angulis:

Emendo anglos incidet aut in worktables tilted

Creates praecise angularis features in workpieces

Late in V-obstructionum vestibulum et chamfering

Applications: Dovetail articulis, anguses uncis, calces dentium

FORMA

Forma milling producit irregularis figuras per specialized Cutters:

Utilitas forma Cutters disposito pro propria profiles

Slower Cutting rates comparari ad Planto milling

Gignit complexu Venustates in unum transitum

Applications: Architecturae Colores, Custom Machina Partibus

Straddle milling

Hoc ars eodem modo mola duas parallel superficies:

Utitur duae milling incitteris eundem Arbor

Spacing inter Cutters Populi Collars

Agentibus ad producendo plures parallelas

Applications: T-Slote milling, Hexagonal / Quadratum Superficiem generationem

Cohors milling

Gang Milling multiple Cutters in unum Arbor:

| Commodum | Description |

| Productio | Performs multiplex operationes in uno |

| Efficacitas | Reduces setup et improves accurate |

| VERSIO | Combines roughing et consummatione operationes |

Applications: Automotive Components, Mass-productum partium

Profile milling

Profile milling replicates complexu figuris onto workpieces:

Usus Helical patet Cutters aut finem molendini Cutters

Sequitur a template vel CNC progressio ad precise replicatione

Idoneam 2D 3D profiling res

Applications: M. Faciens, Aerospace Components, Custom Partibus

Additional Milling Techniques

Advanced Milling Strategies Enhance Efficens et quality:

Ramping, Gradual Tool Profertur ad improved tool vitae

Helical Milling, creates precise foramina et relatorum

Milling milling, reduces tool gerunt in durum materiae

High-celeritate machining et optimized chip potestate strategies ulterius amplio productivity et superficiem qualis per varios milling operationes.

Commoda et applications de milling machinis

Milling machines offerre numerosis beneficia per varia industries, faciens ea necessaria in modern vestibulum processus.

Commoda

Precisione et accurate

Capax Achieving stricta tolerances, saepe in microns

Consistent results, praesertim cum cnc, imperium machinis

Repeatable processus ad altum-volumine productio

VERSIO

Handles diverse materiae: metallis, plastics, compositorum et lignum

Performs variis operationes: Cutting, EXERCITATIO, odiosis et effingens

Adaptable diversis magnitudinum et complexities

Improved superficies metam

Producit summus qualitas superficies finiatur

Reduces opus secundarium consummatione operationes

Enhances productum AESTHETICS et functionality

Auxit efficientiam cum cnc technology

Automates complex machining processibus

Reduces humana errore et crescit productivity

Enables 24/7 operationem in summus volumine vestibulum

Applications

Milling machinis invenies extensive usu per numerosis industries:

Automotive industria

Umbra et cuneos, cylindri capitibus et transmissione components

Producit complex partes cum alta praecisione et repeatability

Enables celeri prototyping et tooling ad novum vehiculum exempla

Aerospace industria

Machines Lightweight tamen fortes components ad aircraft et spatii

Gignit intricatus Turbine Laminae et structural partes

Ensures obsequio cum Stringent Industry Signa

Electronics Industry

Fabricated circuitu tabulas cum praecise exempla et foramina

Producit housings et calor submittit ad electronic cogitationes

Dat miniaturization components per summus praecisione milling

Metalworking industria

Creates Fingit et moritur pro variis vestibulum processus

Producit consuetudinem tolerent components et fixtures

Dat celeri prototyping et parva-batch productio

Medicinae et dentalis industria

Prosthetics et biocappatible Materials implantatorum

Producit chirurgicam instrumenta cum complexu Geometries

Creates mos dentalis coronas pontes

Imprimis application exempla

| application | description | key beneficia |

| Fingunt et mori faciens | Creates complexu formae pro iniectio CUMATIUM et mori-casting | Princeps praecisione, optimum superficiem metam |

| Calces vestibulum | Producit variis calces types cum precise dens profiles | Consistent qualis, princeps productio rates |

| Complex superficies machining | Generat intricatum 3D superficiei aerospace et automotive partes | Facultatem creare unique geometries, stricta tolerances |

Lectio et sustentationem de milling machinis

Propriis lectio et sustentacionem milling machinarum curare meliorem perficientur, Vivacitas et sumptus-efficaciam in vestibulum res.

Discriptis ius milling apparatus

Elige a milling apparatus secundum specifica machining requisita:

Workpiece magnitudine et materiales

Requiritur praecisione et superficies metam

Productio volumen et flexibilitate necessitates

Available area spatio et budget cohiberi

Key factores enim apparatus lectio

Considerans hos crucial facies cum eligens a milling machina:

Freditus celeritate et virtute

Adaequatum potentia ad intendebat materiae et secans profundis

Satis celeritas range variis operationibus

Torque characteres matching typical workloads

Table magnitudine et peregrinatione

| factor | momenti |

| Mensa magnitudine | Determinat maximam workpiece dimensiones |

| X Axis Travel | Afficit longitudinalis machining facultatem |

| Y axis itinerantur | Influxibus transversus secans range |

| Z-Axis Travel | Decernit vertical machining facultatem |

Imperium ratio et Automation Level

Manual controls enim simplex operationes humilis volumina

CNC Systems ad complexu partes et summus volumen productio

Consideratione operator arte campester et disciplina requisitis

Sustentationem et troubleshooting

Propriis sustentationem ensures reliable operationem et extendit apparatus vitae.

Iusto Purgato et lubricatae

Daily Purgato chips et coolant residue

Weekly lubricatae de movens partes et dux via

Vestibulum inspectionem coolant qualitas et filtration systems

Inspectionem et postea gerunt partes

Reprehendo et reponere trita secans instrumenta semper

Inspicere fusum gestus ad insolitum sonitus vel vibrationis

Monitor et adjust balteus contentiones ut opus

Commune exitibus et solutions

Pauperes superficies metam

Nimia vibrationis

INACRENTATIO

Insolitum strepitus

Per diligenter eligendo oportet milling apparatus et exsequendam a robust sustentationem progressio, manufacturers potest maximize productivity, qualis et apparatu Vivacitas in operationibus.

Endnotes

Milling velit ludere a crucial munus in modern vestibulum. Et providebit praecisione versatility, et efficientiam variis industries.

Hoc articulus extulit clavem facies milling machinis, comprehendo eorum genera, munera, et applications. Intelligentes verticalis, horizontalis, cnc, et universalis milling machinis potest auxilium optimize productio procedit.

Nos robora te explorare porro et applicare hanc scientiam in vestri projects.