Mansinw ye masinw ye minnu bɛ se ka kɛ fɛn caman ye, minnu dilannen don walasa ka fɛn gɛlɛnw dilan ni fɛn tɛmɛnenw bɔli ye. U bɛ baara Kɛ ni tigɛlanw ye minnu bɛ Yɛlɛma-yɛlɛma walasa ka yɔrɔw ni yɔrɔ tigitigiw Dabɔ. O masinw bɛ se ka baara suguya caman kɛ i n’a fɔ nɛgɛw tigɛcogo, u sɔgɔli, ani u dilanni nɛgɛw, plastikiw, jiriw ani fɛn wɛrɛw kan.

Tariku surun min bɛ sɔrɔ mansinw na .

Mili masinw jiginni bɛ daminɛ san kɛmɛ 19nan daminɛ na:

1818: Eli Whitney ye mansin fɔlɔ dilan New Haven, Connecticut.

Sani nin ko in ka kɛ: Baarakɛlaw y’u jigi da bolola dosiyew kan, o ye wale ye min bɛ waati caman ta ani min bɛ tali kɛ seko la.

Aplikasi fɔlɔw: A bɛ kɛ fɔlɔ gɔfɛrɛnaman ka bɛnkansɛbɛnw kama, i n’a fɔ marifaw dilanni.

Ko minnu kɛra o kɔfɛ: o kɛra sababu ye ka dɔ fara fɛnw dilanni taabolo kan, ka baara kɛcogo ɲuman, ani ka fɛn caman kɛ fɛn dilanni taabolo la.

Mili masinw nafa ka bon fɛn dilanni na .

Mili masinw jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni na:

Fɛn caman kɛli: U bɛ se ka cogoya suguya caman dilan, k’a ta yɔrɔ fla nɔgɔmanw na ka se 3D contours complexew ma.

Precision (Jɛkulu): Se bɛ yɔrɔ minnu na ni muɲuli gɛlɛnw ye, minnu nafa ka bon kosɛbɛ iziniw na i n’a fɔ aerospace ani mobili.

Baarakɛcogo ɲuman : CNC mansinw bɛ taabolo kɛ otomatiki ye, ka dɔ fara sɛnɛfɛnw bɔli hakɛ kan ani ka hadamadenw ka filiw dɔgɔya.

Fɛnw sɛgɛsɛgɛli: A bɛ se ka baara kɛ ni fɛn caman ye, i n’a fɔ nɛgɛw, plastikiw, ani fɛnɲɛnamafagalanw.

musaka dɔgɔyali : Hali ni wari bilali fɔlɔ la, u bɛ musaka kuntaalajanw di u ka baarakɛcogo ɲuman fɛ ani tiɲɛni dɔgɔyali fɛ.

Industries minnu bɛ nafa sɔrɔ mansinw na, olu dɔw ye:

Ni fɛnw bɔli seko tigitigiw, minnu bɛ baara kɛ, ani minnu bɛ se ka kɛ fɛn caman ye, olu kɛra fɛn nafamaw ye bi fɛn dilanni taabolo la, izini caman kɔnɔ.

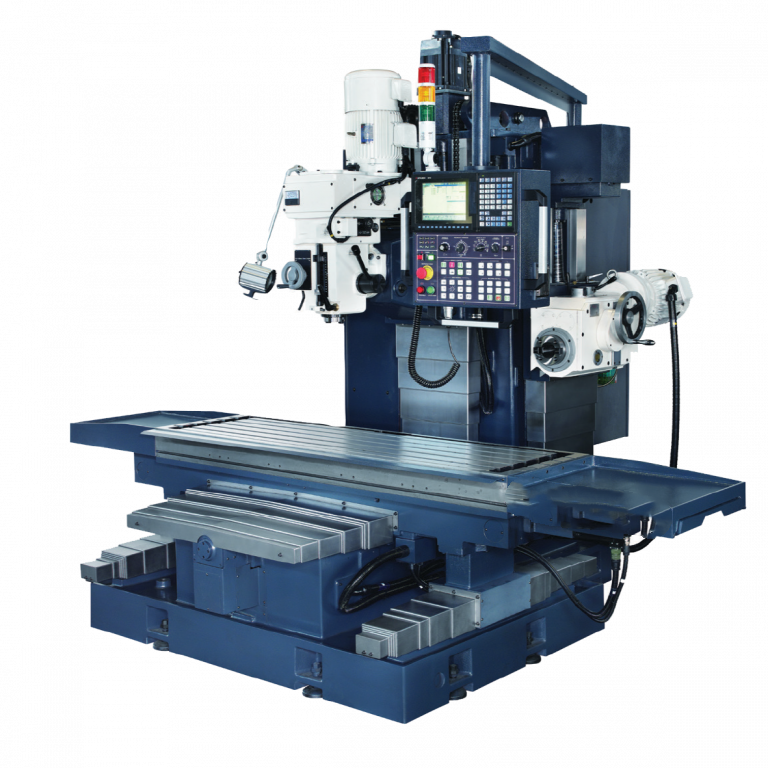

Mansinw ka baarakɛminɛnw jɔcogo n’u yɔrɔ kolomaw .

Mansinw bɛ kɛ fɛn nafama caman ye minnu bɛ baara kɛ ɲɔgɔn fɛ walasa ka masinw baaracogo tigitigiw ni nafamaw sɔrɔ.

Bazi

Basi in bɛ kɛ mansin dɔ jusigilan ye:

Baarakɛcogo: A bɛ sabatili di ani ka yɛrɛyɛrɛw minɛ baara kɛtuma na .

Fɛn min bɛ kɛ: A ka c’a la, nɛgɛ min bɛ kɛ, o bɛ a muɲu ani a ka gɛlɛn .

A dilanni: A ka ca a la a bɛ nɛnɛmadalan dɔ don a kɔnɔ walasa ka funteni maracogo ɲuman sɔrɔ .

Kɔlɔni

I n’a fɔ jirituru-masin kɔkolo, o ye kolon ye:

Kunbere

Gɛnɛgɛnɛ ye fɛn ye min bɛ se ka ladilan kosɛbɛ:

A bɛ dɛmɛ don Saddle ni Worktable fila bɛɛ la .

A bɛ ni balolan jɔlen ye walasa ka a kunbɛn tigitigi .

A bɛ se ka lamaga jɔlen kɛ kulu kan walasa ka jɔyɔrɔ tigitigi sɔrɔ .

Saddle .

O yɔrɔ in bɛ sira caman lamagacogo nɔgɔya:

A bɛ sɛgɛn gɛnɛgɛnɛ kan y-axis kɔnɔ .

A bɛ sira Di baarakɛ-tabali lamagacogo ma X-axis kɔnɔ .

A bɛ jɔyɔrɔfalen bɛɛ lajɛlen kɛcogo ɲɛ .

Tabali min bɛ baara kɛ .

Baarakɛtabali ye baarakɛminɛn fɔlɔ ye min bɛ baara kɛ ni a ye:

A bɛ taa x ni y axes fɛ ka tɛmɛ saddle ni gɛnɛgɛnɛ kan .

A bɛ T-slots sɔrɔ baarakɛminɛn lakananenw na ani ka a siri ni fɛn bɛɛ ye .

A bɛ plateforme sabatilen di masin baara suguya caman ma .

Spindle .

I n’a fɔ cɛmancɛ yɔrɔ, spindle:

Tigɛminɛnw minɛni ani u wuli .

A bɛ se ka kɛ ko a bɛ ɲɛsin a jɔlen ma walima a jiginni ma ka da masin suguya kan .

A bɛ balo hakɛ ladilantaw di masinw ka wajibi suguya wɛrɛw ma .

Bolo caman, Arbor, ani Quill .

O yɔrɔw bɛ danfara ka kɛɲɛ ni masin suguya ye:

Masina tilennenw: Aw bɛ baara kɛ ni bolokɔfɛfɛnw ni arbor ye tigɛminɛnw dɛmɛni kama .

Masina jɔlenw: Aw bɛ quill kɛ ka baarakɛminɛnw bila sanfɛ-ni-jigin lamagacogo la .

U fila bɛɛ bɛ tigɛcogo ɲuman ni fɛn caman kɛcogo ɲɛ .

A yɔrɔ wɛrɛw .

Yɔrɔ damadɔ wɛrɛw bɛ kɛ sababu ye ka mansinw ka baarakɛcogo ɲɛnabɔ:

Spindle Head: A bɛ spindle bila a la ani a bɛ se ka wuli ka taa a yɛrɛ lamaga-lamagaliw kama .

Baarakɛminɛnw tigiw: Aw bɛ tigɛminɛn suguya caman siri ka u siri spindle la .

Dividing Head: A bɛ se ka baarakɛminɛnw jiginni tigitigi kɛ baara gɛlɛnw kama .

Baarakɛcogo sariya min bɛ kɛ ka mansinw kɛ .

Mili masinw bɛ baara kɛ ni sariya jɔnjɔn ye min bɛ tali kɛ fɛnw bɔli la ni tigɛlanw ye minnu bɛ wuli. U bɛ fɛn suguya caman dilan ka ɲɛ ani ka fɛn caman kɛ fɛn dilanni na.

Materiel bɔli taabolo .

Mili masinw ka baara koloma bɛ tali kɛ:

Tigɛda caman bɛ wuli ni teliyaba ye .

o tigɛtigɛlaw ɲɛtaa ka kɛ baarakɛminɛn jɔlen ye .

Fɛn minnu bɛ se ka kɛ ka fɛnw bɔ u la walasa u ka se ka siginidenw ni u hakɛw sɔrɔ .

Paramɛtɛrɛ jɔnjɔnw .

Milling baara minnu bɛ ɲɛ sɔrɔ, olu bɛ tali kɛ paramɛtɛrɛ caman ladilancogo ɲuman na:

Degun: A bɛ fanga min bɛ kɛ tigɛbaga fɛ baarakɛminɛn kan .

Tigɛbaga kunkolo teliya: A bɛ fɛnw bɔli hakɛ latigɛ .

Balo siratigɛ la: A bɛ nɔ bila yɔrɔ dafalen jogo la .

Baarakɛcogo jɔnjɔnw .

Walasa ka masinw ka jaabi ɲumanw sɔrɔ, baarakɛlaw ka kan ka jateminɛ kɛ:

Spindle Speed: A bɛ nɔ bila tigɛcogo ɲuman na ani surface finish quality .

Tabali balo hakɛ: A bɛ nɔ bila fɛnw bɔli hakɛ la ani baarakɛminɛnw ɲɛnamaya .

Tigɛ juguya: A bɛ fɛn hakɛ min bɔ tɛmɛsira kelen-kelen bɛɛ la .

tigɛlan jiginni sira: bɛ nɔ bila chip dilancogo la ani surface quality .

Masini kɛcogo ɲuman ani a kɛcogo ɲuman .

Fɛn caman bɛ nɔba bila sɛnɛfɛnw dilanni baarakɛcogo bɛɛ lajɛlen na ani u kɛcogo ɲuman na:

Tigɛ baarakɛminɛn sugandili .

Fɛn min bɛ kɛ: A ka kan ka bɛn walima ka tɛmɛ baarakɛminɛn gɛlɛya kan .

Jateminɛ: A bɛ nɔ bila puce (puce) dilancogo la ani a bɔli la .

Coating: A bɛ baarakɛminɛnw ɲɛnamaya bonya ani ka dɔ bɔ ɲɔgɔnkanu na .

Tigɛ paramɛtiriw optimisation

| parameter | effect kan qualité | effect kan efficient . |

| Teliya | Surface Finish . | Material bɔli hakɛ . |

| Ka balo | Dimensional tiɲɛni . | Baarakɛminɛn don . |

| Dunya | A yɔrɔ dɔ ye integrité ye . | baarakɛwaati . |

nɛnɛ ni tulumafɛnw .

Nɛnɛ ni tulumafɛnw kɛcogo ɲuman:

Aw bɛ dɔ bɔ ɲɔgɔnkanu na baarakɛminɛn ni baarakɛminɛn cɛ .

funteni min bɛ sɔrɔ tigɛ waati la .

Baarakɛminɛnw ɲɛnamaya janya ani ka Surface Finish ɲɛ .

mansinw suguya minnu bɛ kɛ .

Machines verticales .

Mili masin jɔlenw bɛ ni spindle ye min ɲɛsinnen bɛ z-axis ma. Spindle bɛ taa sanfɛ ni duguma, o bɛ kɛ sababu ye ka o masinw kɛ fɛn ɲumanw ye walasa ka tigɛ ani ka u sɔgɔ. U bɛ tɛmɛ baarakɛcogo kan minnu bɛ jɔyɔrɔko tigitigi de wajibiya, kɛrɛnkɛrɛnnenya la walasa ka yɔrɔ gɛlɛnw dilan. U ka fɛn caman kɛli b’a to u bɛ se ka baara kɛ ni u cogoya ye, ka u tigɛ, ani ka baara kɛ ni u ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

Fɛn minnu bɛ se ka kɛ ka ɲɛsin fɛnw ma minnu bɛ kɛ ka fɛnw sɔgɔ, olu ye fɛn kolomaw ye:

Spindle orientation : Spindle vertikalilen bɛ z-axis sira fɛ.

A bɛ bɛn : a ka fisa ka tigɛ, ka jirituru, ani ka kɛ cogo la min bɛ se ka kɛ ka ɲɛ.

Versatility : A bɛ se ka yɔrɔ gɛlɛnw ɲɛnabɔ fɛn suguya caman na.

Machines de millage horizontales .

Mili masinw jiginni bɛ ni sɔgɔlilan ye min bɛ tali kɛ baarakɛminɛn na, o min bɛ se ka kɛ sababu ye ka fɛn belebelebaw ni fɛn belebelebaw minɛ ka ɲɛ. U bɛ Kɛ ka caya baarakɛminɛnw na i n’a fɔ slotting, grooving ani planning flat surfaces. Horizontale mansinw bɛ dɔ fara u ka gɛlɛya kan, o b’a to u ka ɲi kosɛbɛ ka ɲɛsin fɛnw ma minnu bɛ tigɛ ni tigɛminɛn barikamaw ye.

Nafa minnu bɛ sɔrɔ jirituru-masinw na minnu bɛ kɛ ni jiri ye:

Spindle orientation : parallèle à l’obforme, ka dɔ fara sabatili kan.

Aplikasi : A bɛ kɛ ka slotting, grooving, ani planning flat surfaces.

Fɛnw minɛcogo : A bɛ baara kɛ ka ɲɛ baarakɛminɛnw na minnu ka bon, minnu ka bon ani minnu teliya ka bon.

Aw fana bɛ se ka dɔnniya sɔrɔ ko . O ɲɔgɔndan min bɛ kɛ ni jirituru-masinw ye minnu bɛ ɲɔgɔn kan ani minnu bɛ jɔ ..

CNC mansinw .

CNC Milling Machines bɛ ɔridinatɛri jatebɔcogo (CNC) fɛɛrɛ in fara ɲɔgɔn kan, o bɛ se ka kɛ sababu ye ka masinw ka baarakɛcogo tigitigiw ɲɛnabɔ. O masinw bɛ baara kɛ ni ɔridinatɛri cikanw ye minnu bolodara ka kɔn walasa ka tigɛ, ka fɛnw tigɛ, ani ka baara kɛ ni u ye u yɛrɛma. CNC mansinw bɛ dɔn u ka tiɲɛniba n’u ka seko la ka fɛn gɛlɛnw dilan minnu bɛ sɔrɔ tuma bɛɛ, o b’a to u nafa ka bon kosɛbɛ iziniw kɔnɔ minnu bɛ fɛn tigitigiw ɲini, i n’a fɔ aerospace ani furakɛli minɛnw.

CNC milling masinw yɔrɔ kɛrɛnkɛrɛnnenw:

CNC Technology : Baarakɛminɛnw otomatiki minnu bɛ ɲɛminɛ ɔridinatɛri porogaramuw fɛ.

Tiɲɛni : Tiɲɛniba bɛ sɔrɔ yɔrɔ gɛlɛnw ni fɛn nɔgɔlenw dilanni na.

Nafa : Se bɛ baara la 24/7, ka dɔ fara baarakɛcogo kan.

Universel ka mansinw .

Universel mansin-masinw bɛ se ka vertical ani horizontal milling machines fila bɛɛ ka sekow fara ɲɔgɔn kan. U bɛ ni baarakɛ-tabali ye min bɛ wuli-wuli min bɛ sira Di angular milling operations ma, o b’a To u bɛ Se ka Kɛ fɛn caman ye baara suguya caman na. O masinw bɛ kɛ baarakɛminɛnw ye tuma caman na, dilan butikiw, ani baarakɛyɔrɔw la, baara caman ka kan ka kɛ yɔrɔ minnu na masin kelen kan.

Universel ka mansinw ka fɛn kolomaw:

Seko ni dɔnko faralen ɲɔgɔn kan : a bɛ sɔgɔli jɔlen ni jiginni fila bɛɛ dɛmɛ.

Swiveling Worktable : A bɛ se ka angular milling kɛ cogoya gɛlɛnw na.

Aplikasi : A ka ɲi baarakɛminɛnw, dilan butiki, ani baarakɛyɔrɔ la.

Bed Milling Machines .

Bed milling machines dabɔra baara gɛlɛnw kama. U bɛ ni baarakɛ-tabali jɔlen ye, wa sɔgɔli bɛ Taa z-yɔrɔ la walasa ka tigɛ Kɛ. O masinw bɛ gɛlɛya ni fanga di u ma kosɛbɛ, o b’a to u bɛ se ka baara kɛ yɔrɔbaw la minnu ka bon, i n’a fɔ minnu bɛ mobili, aerospace ani so jɔli baara la.

Dilan-masinw ka jogo jɔnjɔnw:

Tabali jɔlen : A bɛ sabatili di mansin baara gɛlɛnw ma.

Spindle lamaga : A bɛ taa jɔlen na z-axis sira fɛ walasa ka tigɛ jugumanw sɔrɔ.

Aplikasi : A bɛ baara kɛ kosɛbɛ mobili, aerospace ani so jɔli baarakɛyɔrɔw la.

Marifa kɛrɛnkɛrɛnnenw kuntilenna .

A dabɔra mansinko kɛrɛnkɛrɛnnenw kama:

Tabali-masinw minnu bɛ wuli .

Tabali sɛrɛkili bɛ wuli ka wuli aksidan jɔlen kan .

Tigɛbaga caman bɛ sɔrɔ a janya danfaralenw na .

Loading/Dowing (Donni/Jiginni) kɛli baarakɛtuma na .

Gantry ka mansinw .

Dilanba min bɛ gantiri lamagatɔ dɛmɛ .

Tigɛbaga caman bɛ sigi gantry frame kan .

A ka ɲi ka kɛ masinw ye minnu ka bon kojugu .

5-axis mansinw .

A bɛ lamaga-lamagali Kɛ 'sèn saba la minnu bɛ 'yɔrɔ la min bɛ 'yɔrɔ la min bɛ 'yɔrɔ la .

A bɛ siginidenw ni kontoronw dilan .

A bɛ ɲɛfɔli kɛ ka ɲɛ ani ka dɔ bɔ sigicogo waati la .

Mill Machine baarakɛcogo ani a kɛcogo .

Face milling .

Face milling bɛ yɔrɔ fla dilan minnu bɛ jɔ ni baarakɛminɛnw ye:

A bɛ baara kɛ ni ɲɛda sɔgɔli tigɛlanw ye ni tigɛda caman ye .

Depth of cut adjusted via cross-feed vis kan tabali kan .

A bɛ surface fini ɲumanw dilan yɔrɔbaw kan .

Baarakɛcogo: Motɛri bloki surfaces, moule bases, structurel components .

mansin gansan (slab milling) .

O baara in bɛ yɔrɔ nɔgɔlenw bɔ, minnu bɛ kɛ cogo tilennen na:

cutter axis parallel to the machine surface .

A bɛ kɛ ka caya walasa ka baarakɛminɛnw girinya dɔgɔya .

A bɛ surfaces flat (yɔrɔ fla) Bɔ ni dimensional accuracy (hakɛ tiɲɛni) ɲuman ye .

Baarakɛcogo: Keyways, slots, flat baseplate surfaces .

Milling angular .

Angular milling bɛ surfaces (yɔrɔw) Sɔrɔ angle (yɔrɔ) kɛrɛnkɛrɛnnenw na:

A bɛ baara kɛ ni tigɛlanw ye minnu bɛ kɛ kɛrɛ fɛ walima baarakɛtabali minnu bɛ wuli .

A bɛ angular features tigitigiw Dabɔ baarakɛminɛnw kan .

A bɛ kɛ ka caya V-block dilanni na ani chamfering .

Baarakɛcogo: Dovetail joints, brackets angles, gese ɲinw .

Formulaire de formulaire .

Formulaire milling bɛ cogoya sabatilenw Bɔ ni tigɛlan kɛrɛnkɛrɛnnenw ye:

A bɛ baara kɛ ni foroko tigɛlanw ye minnu dabɔra profiles kɛrɛnkɛrɛnnenw kama .

Tigɛcogo teliya la ni i ye a suma ni sɛnɛfɛnw tigɛcogo jɛlen ye .

A bɛ contours gɛlɛnw Dabɔ tɛmɛsira kelen kɔnɔ .

Aplikasi: Sow dilanni, masinw ka yɔrɔw

Milling de straddle .

O fɛɛrɛ in bɛ yɔrɔ fla Kɛ ɲɔgɔn fɛ waati kelen na:

A bɛ baara kɛ ni kɛrɛfɛla tigɛlan fila ye minnu sigilen bɛ arbor kelen kan .

Yɔrɔ janya tigɛlanw ni ɲɔgɔn cɛ minnu bɛ se ka ladilan ni kɔliw ye .

A bɛ baara kɛ ka ɲɛ ka ɲɛsin yɔrɔ caman ma minnu bɛ taa ɲɔgɔn fɛ .

Baarakɛcogo: T-slot milling, hexagonal/square surface generation .

gang milling .

gang milling bɛ baara kɛ ni tigɛbaga caman ye arbor kelen kan:

| nafa | ɲɛfɔli . |

| nafa sɔrɔli . | A bɛ baara caman kɛ tɛmɛsira kelen kɔnɔ . |

| Nɔ kaɲi | A bɛ sigili waati dɔgɔya ani ka tiɲɛni ɲɛ . |

| versatility . | A bɛ sɛgɛsɛgɛli ni finiko baaraw fara ɲɔgɔn kan . |

Aplikasi: Mobili yɔrɔw, yɔrɔ minnu bɛ dilan ni mass ye .

Profil Milling .

Profil milling bɛ cogoya gɛlɛnw lasegin baarakɛminɛnw kan:

A bɛ baara kɛ ni helical plain cutters walima end mill cutters ye .

A bɛ tugu template walima CNC porogaramu dɔ kɔ walasa ka replication tigitigi sɔrɔ .

A bɛnnen don 2D ni 3D profiling baara fila bɛɛ ma .

Aplikasi: Die dilanni, aerospace components, custom parts

Milling fɛɛrɛ wɛrɛw .

Milling fɛɛrɛ minnu bɛ taa ɲɛ, olu bɛ baara kɛcogo ɲuman ni a kɛcogo ɲɛ:

Ramping: Baarakɛminɛnw ka baara kɛcogo ɲuman baarakɛminɛnw ɲɛnamaya ɲɛtaa kama .

Helical Milling: A bɛ dingɛw ni jiriw tigitigiw dilan .

Trochoidal milling: A bɛ baarakɛminɛnw sɛgɛn dɔgɔya fɛn gɛlɛnw na .

Masini teliyaba ani chip control fɛɛrɛ ɲumanw bɛ ka ɲɛtaa ni dugukolo sanfɛla cogoya ɲɛ ka taa a fɛ mansin baara suguya caman na.

Nafa ni baarakɛcogo minnu bɛ sɔrɔ mansinw na .

Mili masinw bɛ nafa caman di izini suguya caman kɔnɔ, o b’a to u nafa ka bon kosɛbɛ bi fɛn dilanni taabolo la.

Nafaw .

Tiɲɛni ni tiɲɛniba .

A bɛ se ka muɲuli gɛlɛnw sɔrɔ, a ka c’a la, mikronw kɔnɔ .

Jateminɛ minnu bɛ kɛ tuma bɛɛ, kɛrɛnkɛrɛnnenya la ni CNC ka masinw ye .

Taabolow minnu bɛ se ka segin-ka-bɔnyew kɛ ka ɲɛsin sɛnɛfɛnw dilanni ma .

versatility .

A bɛ fɛn suguya caman minɛ: nɛgɛw, plastikiw, fɛnɲɛnamafagalanw, ani jiri .

A bɛ baara suguya caman kɛ: tigɛ, sɔgɔli, sɛgɛn ani cogoya .

A bɛ se ka ladilan ka kɛɲɛ ni a yɔrɔ hakɛ ni a gɛlɛyaw ye minnu tɛ kelen ye .

Surface Finish (Sɔrɔdasi) ɲɛtaa .

A bɛ surface finiw dilan minnu ka ɲi kosɛbɛ .

A bɛ dɔ bɔ magoɲɛ baara filananw na .

A bɛ fɛn dilannenw cɛɲi ni u baarakɛcogo ɲɛ .

Ka dɔ fara baarakɛcogo ɲuman kan ni CNC fɛɛrɛ ye .

A bɛ kɛ otomatiki ye masinw ka baarakɛcogo gɛlɛnw na .

A bɛ dɔ bɔ hadamaden ka fili la ani ka dɔ fara a ka baarakɛcogo kan .

A bɛ se ka baara kɛ tile 24/7 walasa ka fɛn dilanni hakɛ caman sɔrɔ .

Aplikasi .

Mili masinw bɛ baara caman sɔrɔ izini caman kɔnɔ:

Mobili industrie .

A bɛ motɛri blokiw, silindaw, ani transmission yɔrɔw dilan .

A bɛ yɔrɔ gɛlɛnw dilan minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ .

A bɛ se ka kɛ sababu ye ka prototyping teliya ani ka baarakɛminɛnw kɛ mobili modɛli kuraw kama .

Aerospace industrie .

Masina minnu ka nɔgɔn nka u barika ka bon awiyɔn ni sanfɛla la .

A bɛ turbine blades intricate ani structurel yɔrɔw dilan .

A b’a to a ka sariyaw labato minnu ka gɛlɛn iziniw kɔnɔ .

Elektroniki baarakɛyɔrɔ .

A bɛ circuit boards dilan ni a cogoya tigitigiw ni a dingɛw ye .

A bɛ sow ni funteni-minɛnw dilan ɛntɛrinɛti minɛnw kama .

A bɛ se ka yɔrɔw fitininw kɛ ka tɛmɛ ni fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ .

Metalworking industry .

A bɛ mɔli ni sa dilan fɛn dilanni taabolo suguya caman kama .

A bɛ baarakɛminɛnw yɔrɔw ni fɛnw labɛn minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

A bɛ se ka kɛ sababu ye ka prototyping teliya ani ka misɛn-batch sɔrɔ .

Dɔgɔtɔrɔso ni ɲinw furakɛli baara .

A bɛ fɛnw dilan ni fɛnw ye minnu bɛ se ka kɛ fɛn ye .

A bɛ opereli minɛnw dilan ni jateminɛ gɛlɛnw ye .

A bɛ ɲinw koronw ni bɔrɔw dilan minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

Baarakɛcogo kɛrɛnkɛrɛnnenw Misaliw

| Baarakɛcogo | ɲɛfɔli | Nafa jɔnjɔnw . |

| Mold and die Making . | A bɛ mɔli gɛlɛnw dilan pikirijikɛlanw dilanni na ani u ka di-casting . | Haute precision, excellent surface fini . |

| Gear Manufacturing . | A bɛ girin suguya caman dilan ni ɲin ɲɛfɔli tigitigiw ye . | Jogoɲumanya sabatili, sɛnɛfɛnw bɔli hakɛ caman . |

| Machining de surface complexe . | A bɛ 3D surfaces gɛlɛnw dilan aerospace ani mobili yɔrɔw kama . | Se ka jateminɛ kɛrɛnkɛrɛnnenw dilan, tolerances tights . |

mansinw sugandili ni u ladonni .

mansinw sugandili n’u ladonni ɲuman bɛ baara kɛcogo ɲuman, ɲɛnamaya jan, ani musaka dɔgɔyali sabati fɛn dilanni baara la.

Mili-masin ɲuman sugandili .

Aw bɛ mansin dɔ sugandi ka da masinw ka wajibi kɛrɛnkɛrɛnnenw kan:

Baarakɛminɛn hakɛ ani a kɔnɔfɛnw .

A ka kan ka kɛ ni tiɲɛni ye ani ka fini don .

Production volume ani flexibilité magow .

Dugukolo yɔrɔ ni baarakɛnafolo gɛlɛyaw bɛ sɔrɔ .

Fɛn minnu ye masinw sugandiliko ye .

Aw ye nin ko nafamaw jateminɛ ni aw bɛ mansin dɔ sugandi:

Spindle teliya hakɛ ani fanga .

Fanga dafalen bɛ sɔrɔ fɛnw na minnu laɲininen don ani tigɛ juguya .

Teliya hakɛ bɛrɛbɛn baara suguya caman na .

Torque characteristics matching typical workloads .

Tabali hakɛ ani taama

| factor | important . |

| Tabali bonya . | A bɛ baarakɛminɛnw hakɛ maksimali latigɛ . |

| X-Axis ka taama . | A bɛ nɔ bila masinw ka seko janya la . |

| Y-Axis ka taama . | influences transversale cutting range . |

| Z-Axis ka taama . | A bɛ masinw ka seko jɔlenw latigɛ . |

Kunnafoni-falen-falen-sistɛm ani otomatiki nivo .

Manuel controls ka ɲɛsin baara nɔgɔmanw ma ani hakɛ dɔgɔmanw ma .

CNC sigidaw ka ɲɛsin yɔrɔw ma minnu ka gɛlɛn ani u dilanni hakɛ caman .

Baarakɛlaw ka seko ni dɔnko hakɛ jateminɛni ani kalan wajibiyalenw .

Ladonni ni gɛlɛyaw ɲɛnabɔli .

Ladonni ɲuman bɛ baara kɛ ni dannaya ye ani ka masinw ka ɲɛnamaya janya.

Saniya ni tulumafɛnw bɛ kɛ tuma bɛɛ .

Don o don saniya chips ni nɛnɛma tolenw .

Dɔgɔkun o dɔgɔkun tulu bɛ kɛ yɔrɔw lamagatɔw la ani ka siraw ɲɛminɛ .

Kalo o kalo sɛgɛsɛgɛli kɛra nɛnɛmafɛnw jogo ɲuman ni u filɛcogo kan .

Sɛgɛsɛgɛli ni fɛn falen falen yɔrɔw sɛgɛsɛgɛli .

Aw bɛ to ka tigɛminɛnw lajɛ ani ka u falen u nɔ na tuma bɛɛ .

Aw bɛ spindle bearings lajɛ ni mankan walima yɛrɛyɛrɛ tɛ kɛ cogo la min tɛ deli ka kɛ .

Aw bɛ cɛsirilan tansiyɔnw kɔlɔsi ani ka u ladilan i n’a fɔ a mago bɛ cogo min na .

Ko minnu bɛ kɛ ɲɔgɔn fɛ ani furaw .

A ka kan ka kɛ cogo min na .

Yɛrɛyɛrɛli kojugu .

Dimensions inaccurate .

Mankan minnu tɛ deli ka kɛ .

Ni u bɛ mansin masin bɛnnen sugandi koɲuman ani ka ladonni porogaramu barikama dɔ waleya, a dilannikɛlaw bɛ se ka baara kɛcogo ɲuman, a kɛcogo ɲuman ani a minɛnw janya u ka baarakɛcogo la.

labanko .

Mili masinw jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni na. U bɛ fɛn caman ɲɛfɔ, ka fɛn caman kɛ, ani ka baarakɛcogo ɲuman di izini suguya caman ma.

Nin barokun in ye jirituru masinw yɔrɔ kolomaw jira, u suguyaw, u baarakɛcogo ani u baarakɛcogo. Faamuyali jɔlen, tilennen, CNC, ani diɲɛ bɛɛ ka sɛnɛfɛnw dilanni masinw bɛ se ka dɛmɛ don ka baara kɛcogo ɲɛ.

An b’aw jija aw ka sɛgɛsɛgɛli kɛ ka taa a fɛ ani ka o dɔnniya in waleya aw ka porozɛw kɔnɔ.