Mil mashin dɛn na mashin tul dɛn we dɛn kin yuz fɔ du bɔku tin dɛn we dɛn mek fɔ shep sɔlid tin dɛn bay we dɛn de pul di tin dɛn we pasmak. Dɛn de yuz rotary cutters fɔ mek prɛsis pat ɛn kɔmpɔnɛnt dɛn. Dɛn mashin dɛn ya kin du difrɛn wok dɛn lɛk fɔ kɔt, drɔ, ɛn shep pan mɛtal, plastic, wud, ɛn ɔda tin dɛn.

Brif istri bɔt mashin dɛn we dɛn kin yuz fɔ mil .

Di evolushɔn fɔ mil mashin dɛn de frɔm di fɔs pat pan di 19t sɛntinari:

1818: Ɛli Witni bin mek di fɔs mil mashin na Nyu Ayvin, Kɔnɛktik.

Bifo dis invinshɔn: wokman dɛn bin de abop pan fayl dɛn na dɛn an, we na bin wan prɔses we bin de tek bɔku tɛm ɛn we bin de dipen pan dɛn skil.

Di fɔs tɛm we dɛn kin yuz am: Dɛn kin yuz am mɔ fɔ gɔvmɛnt kɔntrakt dɛn, lɛk fɔ mek rayf pat dɛn.

Divεlכpmεnt dεm we bin kam afta dat: bin lid to inkrεs prεsishכn, efyushכn, εn vεrsatiliti in mεnεjmεnt prכsεs dεm.

Impɔtant tin fɔ mil mashin dɛn na manufakchurin industri dɛn .

Milin mashin dɛn de ple impɔtant pat pan di mɔdan manufakchurin:

Versatility: Dɛn kin mek difrɛn shep dɛn, frɔm simpul flat sɔfays to kɔmpleks 3D kɔnto.

Prɛsishɔn: we ebul fɔ prodyuz pat dɛn wit tayt tolɛreshɔn, impɔtant fɔ industri dɛn lɛk aerospace ɛn ɔtomotiv.

Efisiɛns: CNC mil mashin dɛn de ɔtomayz prɔses, inkris prodakshɔn rɛt ɛn ridyus mɔtalman mistek.

Material Flexibility: I kin wok wit bɔku bɔku tin dɛn, lɛk mɛtal, plastic, ɛn kɔmpɔzit.

Kɔst-ɛfɛktiv: Pan ɔl we dɛn bin dɔn put dɛn fɔs, dɛn de gi lɔng tɛm sevings tru impɔtant prodaktiviti ɛn ridyus west.

Di industri dɛn we de bɛnifit frɔm di mil mashin dɛn na:

Bay we dɛn de gi prɛsis, efishɔnal, ɛn versatile matirial rimɔv kapabiliti, mil mashin dɛn dɔn bi indispɛnsabl insay mɔdan manufakchurin prɔses akɔdin to bɔku bɔku industri dɛn.

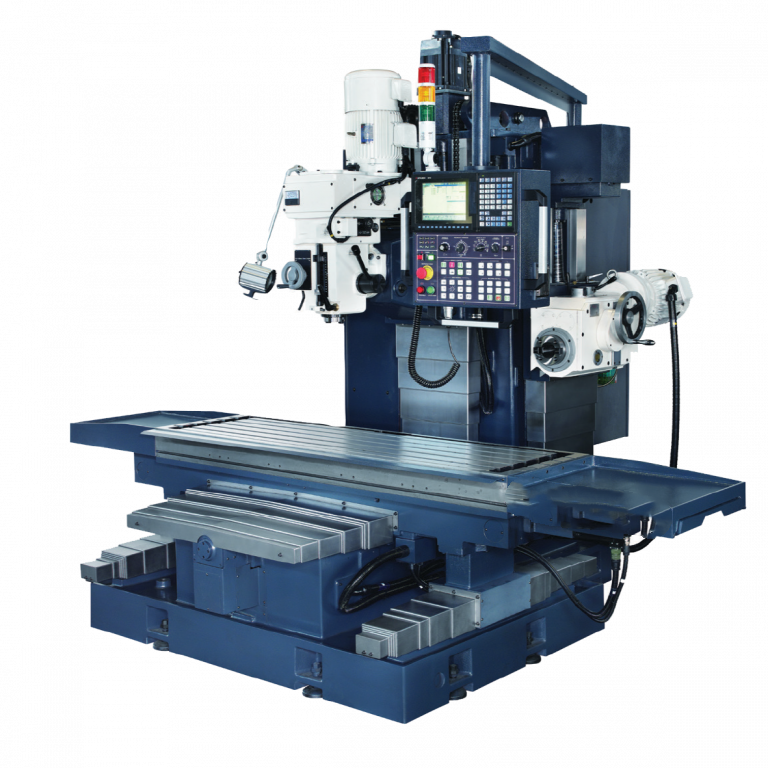

Struktrɔ ɛn Ki Kɔmpɔnɛnt dɛn fɔ Milin Masin dɛn .

Milin mashin dɛn gɛt sɔm impɔtant tin dɛn we de wok insay wanwɔd fɔ mek shɔ se dɛn gɛt prɛsis ɛn efishɔnal mashin ɔpreshɔn.

Bɔt

Di bays de fɔm di fawndeshɔn fɔ wan mil mashin:

Fɔnkshɔn: I de gi stebiliti ɛn absɔb vaybreshɔn dɛn we dɛn de ɔpreshɔn .

Material: tipikli cast iron, ofa durability ɛn rigidity

Dizayn: Bɔku tɛm dɛn kin put wan kɔlant rizɔva fɔ mek dɛn ebul fɔ kɔntrol di ɔt fayn fayn wan .

Pila

As di bakbon fɔ di mil mashin, di kɔlɔm:

Sɔpɔt di wan ol strɔkchɔ .

Haus di spindle en motor .

I gɛt drayv sistem fɔ kɔntrol spindle muvmɛnt .

Ni

Di knee na wan kritikal adjustable komponent:

Sɔpɔt ɔl tu di sadul ɛn wok tebul .

Fit wan vertikal fid skru fɔ prɛsis dip kɔntrol .

I de mek yu ebul fɔ muv vertikal wan along di kɔlɔm fɔ mek yu ebul fɔ put am kɔrɛkt wan .

Sadul we dɛn mek

Dis komponent de mek am izi fɔ mek dɛn muv mɔlti-dayrɛkshɔn:

Slayd dɛn along di knee in di y-aks .

Alaw wok tebul muvmɛnt na di x-aks .

I de ɛp fɔ mek ɔl di pozishɔn dɛn we de na di pozishɔn we dɛn de yuz fɔ mek di ples fayn .

wok tebul .

Di wok tebul na di praymar wokpies sɔpɔt:

Muv along x en y aks via sadul en knee

Fitur T-slots fɔ sikyuɔr wokpies ɛn klamp atɛshɔn

Gi wan stebul pletfɔm fɔ difrɛn mashin ɔpreshɔn dɛn .

Spindle we de na di .

As di sentral komponent, di spindle:

Hol ɛn Rotates Cutting Tools .

kin bi ɔriɛnted vertikal ɔ ɔrizɔntal bays pan mashin tayp .

Ofa adjustable fid ret fɔ difrɛn mashin rikwaymɛnt dɛn .

Ovaarm, Arbor, ɛn Kwil .

Dɛn tin ya kin difrɛn bay di kayn mashin we dɛn kin yuz:

Horizontal Machines: Yuz Ovaarm ɛn Arbor fɔ kɔt tul sɔpɔt .

Vɛtikal Masin dɛn: Employ wan Kwil fɔ Gayd Tul Up-ɛn-dɔwn Muvmɛnt

Ɔl tu de ɛp fɔ mek di prɛsishɔn we dɛn de kɔt ɛn fɔ mek dɛn ebul fɔ du bɔku tin .

Atikul dɛn we gɛt fɔ du wit dis .

Bɔku ɔda pat dɛn kin ɛp fɔ mek di mil mashin wok fayn fayn wan:

spindle ed: os di spindle ɛn kin swivel fɔ angul muvmɛnt dɛn

Tul ɔlda dɛn: Sikyu difrɛn kɔtin tul dɛn to di spindle

Divayd ed: Ɛnables prɛsis wokpies roteshɔn fɔ kɔmpleks ɔpreshɔn

Wok prinsipul fɔ mil mashin dɛn .

Milin mashin dɛn de wok pan wan fawndeshɔnal prinsipul fɔ rimɔv matirial we dɛn de yuz rotary kɔta. Dɛn de gi prɛsishɔn ɛn versatility fɔ shep difrɛn matirial dɛn fɔ manufakchurin aplikeshɔn dɛn.

Di we aw dɛn de pul di tin dɛn we dɛn dɔn yuz

Di men wok we di mil mashin dɛn de du involv:

Rotating multi-point cutters na ay spid .

Advans dis kɔta dɛn insay wan steshɔn wokpies .

Selektivli pul matirial fɔ ajɔst di shep ɛn dimɛnshɔn dɛn we yu want .

Ki Paramita dɛn .

Saksesful mil ɔpreshɔn dɛn de dipen pan tek tɛm ajɔstmɛnt fɔ sɔm paramita dɛn:

Prɛshɔn: I de kɔntrol di fɔs we di pɔsin we de kɔt de yuz na di wokpies .

Cutter Head Speed: de disayd di ret we dɛn de pul di matirial .

Fid dairekshɔn: Influɛns di kwaliti fɔ di say we dɛn dɔn dɔn .

Kritikal Opareshɔnal Fakta dɛn .

Fɔ mek shɔ se di wok we dɛn de du fɔ mek di mashin dɛn fayn fayn wan, di wan dɛn we de wok de fɔ tink bɔt:

Spindle Speed: Afɛkt di kɔt efyushɔn ɛn sɔfays finish kwaliti

Tebul Fid Rɛt: Impɛkt Material Rimov Rɛt ɛn Tul Layf ɛn Tul Layf .

Dip fɔ Kɔt: I de sho di kayn we aw dɛn pul di tin dɛn we dɛn pul na ɛni pas .

Kɔta roteshɔn dairekshɔn: Influɛns chip fɔmɛshɔn ɛn sɔfays kwaliti .

Di kwaliti fɔ di mashin ɛn di efyushɔn .

Bɔku tin dɛn kin rili afɛkt di ɔl kwaliti ɛn di efyushɔn we di mil ɔpreshɔn dɛn gɛt:

Di tin dɛn we dɛn kin yuz fɔ pik di tul dɛn .

Material: Fɔ mek i mach ɔ pas di wok we dɛn fɔ du fɔ wok.

Jɔyometri: Influɛns chip fɔmɛshɔn ɛn ɛvakyushɔn

Kotin: I de mek di tul layf bɛtɛ ɛn i de ridyus frikshɔn .

Cutting Parameters Optimization

| Paramita | Efεkt pan Kwaliti | Efεkt pan Efisiensi |

| Fas fas | Surface Finish . | Di ret fɔ pul di matirial dɛn . |

| It | Dimenshonal akkuracy . | Tul Wear . |

| Dip | Pat Intɛgriti . | Di tɛm fɔ prosɛs . |

Kul ɛn lɔbrik .

Prɔpa kol ɛn lɔbrikeshɔn sistem dɛn:

Ridyus frikshɔn bitwin tul ɛn wokpies .

Dissipate heat we dɛn de mek we dɛn de kɔt .

Ekstend tul layf ɛn impruv sɔfays finish .

Di kayn mashin dɛn we dɛn kin yuz fɔ mil .

Vɛtikal mil mashin dɛn .

Vɛtikal mil mashin dɛn gɛt spindle ɔriɛnted vertikal along di z-aks. Di spindle de muv ɔp ɛn dɔŋ, we de mek dɛn mashin dɛn ya fayn fɔ kɔt ɛn drɔ ɛn drɔ. Dɛn ɛksɛl insay ɔpreshɔn dɛn we nid prɛsishɔn pozishɔn, patikyula fɔ mek kɔmpleks pat dɛn. Dɛn versatility de alaw dɛn fɔ du shep, kɔt, ɛn drɔl wok wit ay akkuracy, we de mek dɛn pɔpul na industri lɛk aerospace ɛn ɔtomotiv.

Ki ficha dɛn fɔ vertikal mil mashin dɛn:

Spindle orientation : vertikal alayned spindle along di z-aks.

Suitability : Best fɔ plunge kɔt, drɔl, ɛn prɛsishɔn shep.

Versatility : kin ebul fɔ handle kɔmpleks pat dɛn akɔdin to difrɛn matirial dɛn.

Mashion dɛn we de mek fɔ mil ɔrizɔntal mil .

Di ɔrizɔntal mil mashin dɛn gɛt spindle we paralel to di wok tebul, we de mek dɛn ebul fɔ handle big ɛn tik matirial dɛn fayn fayn wan. Dɛn kin yuz dɛn fɔ aplikeshɔn dɛn lɛk fɔ slot, fɔ grov, ɛn fɔ plan flat say dɛn. Ɔrizɔntal mil dɛn de gi inkris rigiditi, we de mek dɛn fayn fɔ roughing prɔses dɛn we nid pawaful kɔt tul dɛn.

Advantej dɛn fɔ ɔrizɔntal mil mashin dɛn:

Spindle orientation : paralel to di wok tebul, inkris stebiliti.

Aplikeshɔn dɛn : Dɛn kin yuz am fɔ slɔt, grov, ɛn plan fɔ gɛt flat say dɛn.

Material Handling : Efficient fɔ big, tik wokpies ɛn ay-spid ɔpreshɔn.

Yu kin gɛt di no bak bɔt . Di kɔmparayshɔn bitwin ɔrizɔntal ɛn vertikal mil mashin dɛn ..

CNC milling mashin dɛn .

CNC mil mashin dɛn de intagret Kɔmpyuta Nyumɛrik Kɔntrol (CNC) tɛnkɔlɔji, we de alaw prɛsis kɔntrol oba mashin prɔses dɛn. Dɛn mashin dɛn ya kin yuz kɔmpyuta instrɔkshɔn dɛn we dɛn dɔn program bifo tɛm fɔ mek dɛn ebul fɔ kɔt, drɔ, ɛn shep di wok dɛn we dɛn fɔ du fɔ mek dɛn ebul fɔ kɔt dɛn. CNC mil dɛn sabi fɔ dɛn ay akkuracy ɛn abiliti fɔ prodyuz kɔmpleks kɔmpɔnɛnt dɛn wit kɔnsistɛns rizɔlt, we mek dɛn indispɛnsabl insay industri dɛn we nid prɛsishɔn, lɛk aerospace ɛn mɛdikal divays dɛn.

Notabl aspek dɛm fɔ CNC mil mashin dɛm:

CNC Teknɔlɔji : Ɔtomɛtik prɔses dɛn we kɔmpyuta program dɛn de drɛb.

Prɛsishɔn : Ay akkuracy in kriet kɔmpleks ɛn dilikɛt kɔmpɔnɛnt dɛn.

Efisiensi : we ebul fɔ rɔn 24/7, inkris prodaktiviti.

Yunivasal mil mashin dɛn .

Yunivasal mil mashin dɛn kin jɔyn di tin dɛn we ɔl tu di vertikal ɛn ɔrizɔntal mil mashin dɛn kin ebul fɔ du. Dɛn gɛt wan swiveling wok tebul we de alaw angul mil ɔpreshɔn, we de mek dɛn rili versatil fɔ difrɛn wok dɛn. Bɔku tɛm dɛn kin yuz dɛn mashin dɛn ya na tul rum, ripa shɔp, ɛn wokshɔp usay dɛn nid fɔ du bɔku bɔku opareshɔn dɛn na wan mashin.

Di men tin dɛn we de na di yunivasal mil mashin dɛn:

Kɔmbaynshɔn fɔ di kapabiliti dɛn : Sɔpɔt ɔl tu di vertikal ɛn ɔrizɔntal mil.

Swiveling Worktable : I de mek angul mil fɔ kɔmpleks shep dɛn.

Aplikeshɔn dɛn : I fayn fɔ yuz fɔ tul rum, fɔ mek shɔp, ɛn fɔ yuz wokshɔp.

Bed mil mashin dɛn .

Dɛn mek bed mil mashin dɛn fɔ mek dɛn ebul fɔ du ebi ebi wok. Dɛn gɛt wan fiks wok tebul, ɛn di spindle de muv along di z-aks fɔ du di kɔt. Dɛn mashin dɛn ya kin gɛt big big strɔng ɛn trɛnk, we kin mek dɛn fayn fɔ wok pan big, ebi pat dɛn, lɛk di wan dɛn we de na di ɔtomotiv, aerospace, ɛn kɔnstrɔkshɔn industri.

Men kwaliti dɛn fɔ bed mil mashin dɛn:

Fiks tebul : de gi stebiliti fɔ ebi-duti mil ɔpreshɔn.

Spindle Movement : de muv vertikal along di z-aks fɔ dip kɔt.

Aplikeshɔn dɛn : Dɛn kin yuz am bɔku bɔku wan na ɔtomotiv, ɛrospɛs, ɛn kɔnstrɔkshɔn industri.

Special Purpose Milling Machines .

Disain fɔ spɛshal mil rikwaymɛnt dɛn:

Rotary tebul mil mashin dɛn .

Sikɔral tebul de rɔn pan vertikal aks .

Bɔku bɔku kɔta dɛn na difrɛn ayt dɛn .

Kɔntinyu fɔ lod/ɔnlod di tɛm we dɛn de wok .

Gantry milling mashin dɛn .

Big bed we de sɔpɔt wan mavable gantri .

Multiple cutters we dɛn dɔn mont pan gantri freym .

Ideal fɔ mashinin ovasayz pat dɛn .

5-aks mil mashin dɛn .

Ofa muvment in tri linear en tu rotary axes

I de mek kɔmpleks shep ɛn kɔnto .

I de mek prɛsishɔn bɛtɛ ɛn i de ridyus di tɛm we dɛn de sɛtup

Mil mashin opareshɔn ɛn tɛknik dɛn .

Fes mil .

Fes mil de mek flat surface we de pependikul to di tul aks:

Yuz dɛn fes mil kɔta dɛn wit bɔku bɔku kɔt ed dɛn .

Dip fɔ kɔt adjɔst via kros-fid skru na di tebul

I de mek ay kwaliti sɔfays finish dɛn na big eria dɛn .

Aplikeshɔn dɛn: Injin blɔk sɔfays, mold bays, strɔkchɔral kɔmpɔnɛnt dɛn

Plɛnti mil (slab mil)

Dis opareshɔn de mek di say dɛn we dɛn de du tin fayn ɛn ɔrizɔntal:

Kɔta aks paralel to di mashin we dɛn mek wit mashin .

Dɛn kin yuz am fɔ ridyus di tik we de wok .

Jɛnɛret flat sɔfays wit gud dimɛnshɔnal akkuracy .

Aplikeshɔn dɛn: Kiwes, slot, flat besplet sɔfays dɛn

Angular mil di .

Angular mil de jenarayz sɔfays dɛn na spɛshal angul dɛn:

Employs angled cutters ɔ tilt wok tebul dɛn .

Krio prɛsis angul ficha dɛn pan wokpies dɛn .

Widely yuz in V-block manufacturing ɛn chamfering .

Aplikeshɔn dɛn: Dovetail jɔyn dɛn, angul brakɛt dɛn, gia tit dɛn

Fɔm Milin .

Fɔm mil de prodyuz irɛgyula shep dɛn we de yuz spɛshal kɔta dɛn:

Yuz fɔm kɔta dɛn we dɛn mek fɔ spɛshal prɔfayl dɛn .

Slower cutting rates we yu kɔmpia to plain milling .

I de mek kɔmpleks kɔnto dɛn insay wan pas .

Aplikeshɔn dɛn: Akitekchɔral moldin dɛn, kɔstɔm mashin pat dɛn

Straddle milling .

Dis teknik wan tɛm de mil tu paralel sɔfays dɛn:

Yuz tu sayd mil kɔta dɛn we dɛn dɔn mont pan di sem arbor .

Spays bitwin kɔta dɛn we dɛn kin ajɔst wit kɔla dɛn .

Efishin fɔ prodyuz bɔku paralel sɔfays dɛn .

Aplikeshɔn dɛn: T-Slot Milling, Hexagonal/Square Surface Generation

Gang miling .

Gang miling employs multiple cutters pan wan singl arbor:

| Advantej | diskripshɔn |

| Prodaktiviti . | I de du bɔku ɔpreshɔn dɛn na wan pas . |

| Ɔganayz | I de ridyus di tɛm we dɛn de sɛtup ɛn i de mek di akkuracy bɛtɛ . |

| Versatility na di . | Kɔmbayn Roughing ɛn Finishing Opareshɔn dɛn . |

Aplikeshɔn dɛn: Ɔtomotiv Kɔmpɔnɛnt dɛn, Mas-prɔdyuz Pat dɛn

Profayl mil .

Profile Milling Riplikɛt Kɔmpleks Shep dɛn pan Wokpies dɛn:

Yuz Hɛlikal Plɛn Kɔta ɔ Ɛnd Mil Kɔta .

Fɔ fala wan tɛmplat ɔ CNC program fɔ prɛsis riplikishɔn .

I fayn fɔ ɔl tu di 2D ɛn 3D profayl ɔpreshɔn dɛn .

Aplikeshɔn dɛn: Day Mek, Aerospace Kɔmpɔnɛnt dɛn, Kɔstɔm Pat dɛn

Atikul dɛn we dɛn kin yuz fɔ mil .

Advans mil strateji dɛn de ɛp fɔ mek di wok fayn ɛn kwaliti:

Ramping: smɔl smɔl tul ɛnjɔymɛnt fɔ impɔtant tul layf .

Hɛlikal Milin: I de mek prɛsis ol ɛn trɛd dɛn .

Trochoidal Milling: Ridyus di tul wear insay had matirial

High-speed machining ɛn optimized chip kɔntrol strateji dɛn de impruv prodaktiviti ɛn sɔfays kwaliti akɔdin to difrɛn mil ɔpreshɔn dɛn.

Advantej ɛn aplikeshɔn dɛn fɔ mil mashin dɛn .

Milin mashin dɛn de gi bɔku bɛnifit dɛn akɔdin to difrɛn industri dɛn, we de mek dɛn nɔ gɛt ɛnitin fɔ du wit di we aw dɛn de mek tin dɛn tide.

Di bɛnifit dɛn we pɔsin kin gɛt .

Ay prɛsishɔn ɛn akkuracy .

we ebul fɔ ajɔst tayt tolɛreshɔn, bɔku tɛm insay maykron .

Kɔnsistɛnt rizɔlt, mɔ wit mashin dɛn we CNC kin kɔntrol .

Ripitabl prɔses fɔ ay-volyum prodakshɔn .

Versatility na di .

Handles difrɛn matirial dɛn: mɛtal, plastic, kɔmpɔzit, ɛn wud

I de du difrɛn opareshɔn dɛn: fɔ kɔt, drɔ, boring, ɛn shep

Adaptable to difrɛn pat saiz ɛn kɔmplisiti dɛn .

Impruv Surface Finish .

I de prodyuz ay kwaliti sɔfays finish dɛn .

Ridyus nid fɔ sɛkɔndari finish ɔpreshɔn .

I de ɛp fɔ mek di prɔdak fayn ɛn i de wok fayn ɛn i de wok fayn fayn wan .

Inkris efyushɔn wit CNC teknɔlɔji .

Awtomat dɛn Kɔmpleks Machining prɔses dɛn .

I de ridyus mɔtalman mistek ɛn i de mek di prɔdaktiviti go ɔp .

Enables 24/7 opereshɔn fɔ ay-volyum manufakchurin .

Aplikeshɔn dɛn .

Milin mashin dɛn kin fɛn bɔku yus akɔdin to bɔku bɔku industri dɛn:

Ɔtomotiv Indastri .

I de mek injin blɔk, silinda ed, ɛn transmishɔn kɔmpɔnɛnt dɛn .

I de prodyuz kɔmpleks pat dɛn wit ay prɛsishɔn ɛn ripitabiliti .

Enables rapid prototyping ɛn tul fɔ nyu motoka mɔdel dɛn .

Indastri fɔ Erospɛs .

mashin dɛn laytwɛt yet strɔng komponent fɔ ayrakt ɛn spɛshɔl ship .

I de mek intrɛst tɔbayn bled dɛn ɛn strɔkchɔral pat dɛn .

Mek shɔ se dɛn fala di strɛng industri standad dɛn .

Ilɛktronik Indastri .

fabriket sɔrkwit bod dɛn wit prɛsis patɛn ɛn ol dɛn .

I de mek os ɛn ɔt sink fɔ ilɛktronik tin dɛn .

Enables miniaturization of komponents tru ay-prɛsishɔn milling .

Indastri fɔ wok wit mɛtal .

Krio mold ɛn day fɔ difrɛn manufakchurin prɔses .

Prodyuz kɔstɔm tul kɔmpɔnɛnt ɛn fiks dɛn .

Enables rapid prototyping ɛn smɔl-batch prodakshɔn .

Medikal ɛn Dɛnt Indastri .

Manufakchɔ dɛn implant ɛn prostɛtiks wit bayɔkɔmpatibl matirial dɛn .

Prodyuz ɔspitul inschrumɛnt dɛn wit kɔmpleks jɔyometri dɛn .

Krio kɔstɔm dɛnt krawn ɛn brij dɛn .

Speshal Aplikeshɔn Ɛgzampul dɛn

| Aplikeshɔn | Diskripshɔn | Ki bɛnifit dɛn . |

| Mold ɛn day mek . | Krio komplex mold fɔ injɛkshɔn moldin ɛn day-kast | ay prɛsishɔn, fayn fayn sɔfays finish . |

| Gia Manufakchurin . | I de prodyuz difrɛn kayn gia dɛn wit prɛsis tut profayl dɛn . | Konsistent kwaliti, ay prodakshɔn ret . |

| Komplex sɔfays mashin . | Jɛnɛret intrikɛt 3D sɔfays fɔ ɛrospɛs ɛn ɔtomotiv pat dɛn . | Abiliti fɔ mek yunik jɔyometri, tayt tolɛreshɔn dɛn . |

Sɛlɛkshɔn ɛn mentenɛns fɔ mil mashin dɛn .

Prɔpa sɛlɛkshɔn ɛn mentenɛns fɔ mil mashin dɛn de mek shɔ se di bɛst pefɔmɛns, lɔng layf, ɛn kɔst-ɛfɛktiv insay di manufakchurin ɔpreshɔn dɛn.

Selekt di rayt mil mashin .

Pik wan mil mashin we dɛn bayz pan spɛshal mashin dɛn we dɛn nid:

wokpies saiz ɛn matirial .

Rikwayd prɛsishɔn ɛn sɔfays finish .

Prodakshɔn volyum ɛn fleksibiliti nid dɛn .

Di ples we de na di flɔ ɛn di badjɔt kɔnstrakshɔn dɛn we de de .

Ki factors fɔ mek mashin sɛlɛkshɔn .

Tink bɔt dɛn impɔtant tin dɛn ya we yu de pik wan mashin fɔ mil:

Spindle spid renj ɛn pawa .

Adekwat pawa fɔ intended matirial ɛn kɔt dip .

sufayf spid renj fɔ difrɛn opareshɔn dɛn .

Torque Karakteristik dɛn we de mach di tipik woklɔd dɛn .

Tebul saiz ɛn travul

| faktɔ | impɔtant . |

| tebul saiz . | Ditarmin maksimal wokpies dimɛnshɔn dɛn . |

| X-Aksis Travul . | Afεkt lכngitudinal machin kεpabiliti . |

| Y-Aksis Travel . | Influwens transvas kɔtin rɛnj . |

| Z-Aksis Travul . | Ditarmin vertikal mashin kapasiti . |

Kontrol sistem ɛn ɔtomɛshɔn lɛvɛl .

Manual Controls fɔ simpul opareshɔn ɛn lɔw volyum dɛn .

CNC sistem fɔ kɔmpleks pat ɛn ay-volyum prodakshɔn .

Kɔnsidɛreshɔn fɔ di ɔpreshɔn skil lɛvɛl ɛn trenin rikwaymɛnt dɛn .

Mentɛnans ɛn Trabulshut .

Prɔpa mentenɛns de mek shɔ se dɛn rili ebul fɔ wok ɛn i de ɛkstɛnd mashin layf.

Klin ɛn lɔbrik ɔltɛm .

Di klin we dɛn de klin di chips ɛn di kɔlant rɛsɛdyu .

Wik Lubrikeshɔn fɔ Muv Pat ɛn Gayd Ways

Inspekshɔn ɛvri mɔnt fɔ di kɔlant kwaliti ɛn filtreshɔn sistem dɛn .

Inspekshɔn ɛn Riplesmɛnt fɔ di pat dɛn we dɛn dɔn wɛr .

Chek ɛn chenj di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɔn pwɛl ɔltɛm ɔltɛm .

Inspek spindle bearings fɔ nɔys ɔ vaybreshɔn we nɔ kɔmɔn ɔ vaybreshɔn .

Monitor ɛn ajɔst bɛlt tɛnsiɔn as nid de

Kɔmɔn tin dɛn ɛn sɔlv dɛn .

Poor surface finish .

Di Vaybreshɔn we pasmak .

Dimenshɔn dɛn we nɔ kɔrɛkt .

Nɔys dɛn we nɔ kɔmɔn .

Bay we dɛn tek tɛm pik di aprɔpriet mil mashin ɛn impruv wan strɔng mentenɛns program, di wan dɛn we de mek dɛn kin maksimayz prodaktiviti, kwaliti, ɛn ikwipmɛnt lɔng layf insay dɛn opareshɔn.

Di ɛndnot dɛn .

Mil mashin dɛn de ple impɔtant pat pan di mɔdan manufakchurin. Dɛn de gi prɛsishɔn, versatility, ɛn efyushɔn fɔ difrɛn industri dɛn.

Dis atikul bin sho di men tin dɛn we dɛn kin du fɔ mil mashin dɛn, lɛk di kayn we aw dɛn tan, di wok we dɛn de du, ɛn di we aw dɛn de yuz dɛn. Ɔndastand vertikal, ɔrizɔntal, CNC, ɛn yunivasal mil mashin dɛn kin ɛp fɔ mek di prodakshɔn prɔses dɛn wok fayn.

Wi de ɛnkɔrej yu fɔ fɛn ɔda tin dɛn ɛn yuz dis no bɔt yu prɔjek dɛn.