Flankanw ye fɛn nafamaba ye izini suguya caman na, u bɛ kɛ fɛnw ye minnu bɛ pipew, pɔnpew, valvew ani minɛn wɛrɛw minɛ ɲɔgɔn fɛ. U jɔyɔrɔ min bɛ ji walima gaziw bɔli la cogo la min tɛ mɔgɔ tɔɔrɔ ani min bɛ kɛ ka ɲɛ, degun ni funteni cogoya caman na, o bɛ flansɛ sugandili kɛ ko kɔrɔba ye o sigida dafalen na. Ni suguya caman, hakɛ, ani fɛn minnu bɛ sɔrɔ, olu bɛ flansɛ ɲuman faamuya a kɛcogo ɲuman na, o nafa ka bon kosɛbɛ.

Nin barokun in bɛ fɛn dɔw don a kɔnɔ, u yɔrɔw, u kɔnɔfɛnw, ani u ɲinini minnu bɛ se k’aw dɛmɛ ka latigɛw kɛ ni kunnafoniw ye.

Flansɛw yɔrɔ kolomaw .

Flanges, hali ni u suguya tɛ kelen ye, u bɛ yɔrɔ koloma dɔw tila ɲɔgɔn na minnu bɛ u ka baara kɛcogo ɲɛfɔ .

ani baarakɛcogo. O yɔrɔw bɛ kɛ sababu ye ka flanw ka baarakɛcogo bɛɛ lajɛlen kɛ pibilikiw kɔnɔ.

Flange ɲɛda : flansɛ ni gazi min bɛ kɛ ka sigilan sirilen dilan, o yɔrɔ bɛ ɲɔgɔn sɔrɔ yɔrɔ min na. Flange ɲɛda suguya caman ye:

| flange ɲɛda suguya | jiracogo | yecogo | . | Nafaw nafa | tɛ |

| ɲɛda fla (FF) . | ka ɲɛsin degun dɔgɔman ma; gasi min bɛ kɛ ni ɲɛda bɛɛ ye, o wajibiyalen don. | Fla, yɔrɔ min ka nɔgɔn. | Jiko siratigɛ la, min tɛ tansiyɔn dɔgɔya, baarakɛminɛnw minnu tɛ kɔrɔfɔ ye. | Alignment nɔgɔn, a bɛ warping bali. | A ma bɛn tansiyɔnba ma. |

| Ɲɛda kɔrɔtalen (RF) . | Sigini barikama bɛ sɔrɔ tansiyɔn cɛmancɛ la ka se tansiyɔnba ma. | Yɔrɔ fitinin kɔrɔtalen Bore lamini na. | Refineries, chimique plantes, processus pipe. | Sealing (datugulan) min bɛ bonya ka ɲɛsin degun suguya caman ma. | A bɛ ɲɔgɔndan tigitigi de wajibiya. |

| Joli-suguya min bɛ kɛ ni bolo ye (RTJ) . | Nɛgɛ-ni-nɛgɛ-sigi-da-minɛn ka ɲɛsin cogoya juguw ma. | Deep groove for metal ring gasket. | Oil & Gas, kuran bɔli. | Sealing ɲuman, a bɛ yɛrɛyɛrɛ ani ka bonya. | A musaka ka bon, a bɛ sigili tigitigi de wajibiya. |

| Kan ni groove (T&G) . | Flangew minnu bɛ ɲɔgɔn cɛ, olu bɛ fanga kɔrɔsi fanga kɛlɛ. | kan kɔrɔtalen ani groove matching. | Tasaw ka bon, pɔnpe datugulanw. | Yɛrɛlabɛnni, taamasiyɛn barikama. | A bɛ fila-fila minnu bɛ bɛn ɲɔgɔn ma, olu de wajibiya. |

| Cɛ ni muso (M&F) . | Labɛnni tigitigi ni yɔrɔw kɔrɔtalenw/seginlenw. | Cɛ ɲɛda kɔrɔtalen, muso ɲɛda min bɛ don a kɔnɔ. | Funteni-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falen-falenw. | A bɛ ɲɔgɔndanbaliya bali, ka sigili ɲɛ. | Mako bɛ installation fila-fila la, machining precise. |

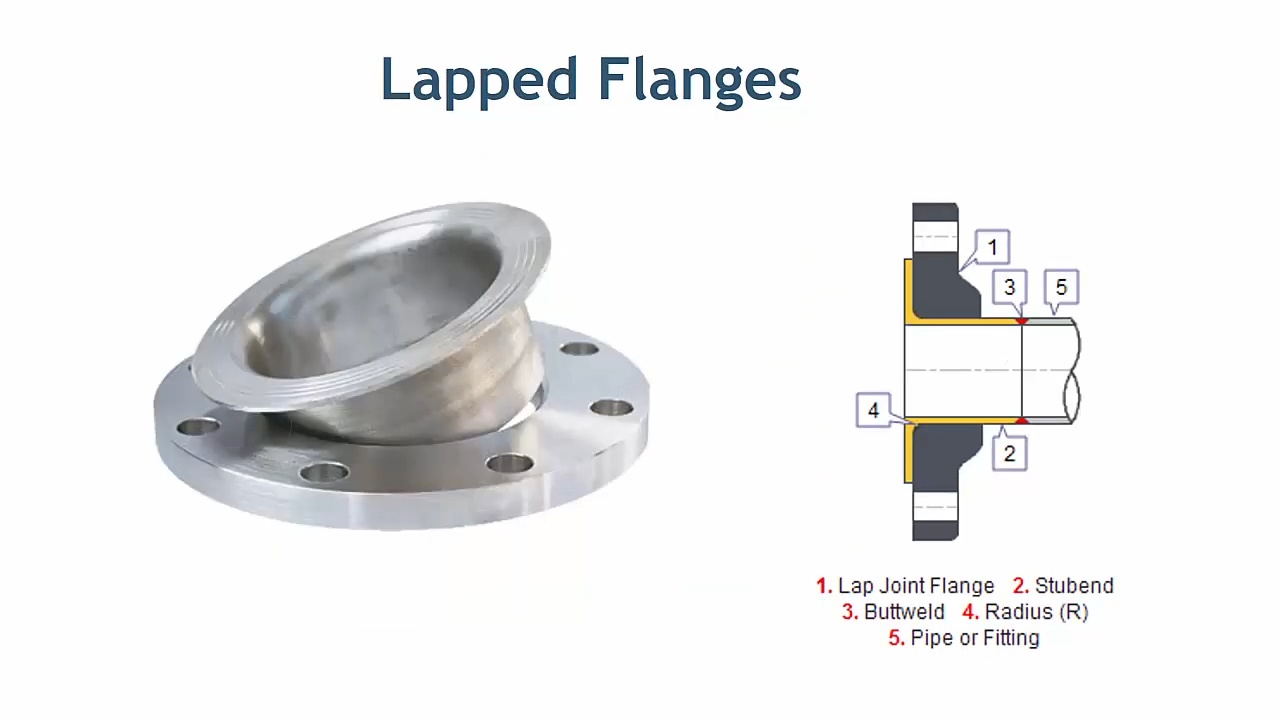

| Lap joint . | A bɛ se ka wuli ka bɔ a nɔ na, a ka nɔgɔn; Flange ye loose ye. | fila-fila, flansɛ min bɛ wuli ka bɔ a yɛrɛ la. | Dumuniko, pɔmpiw. | A ka nɔgɔn, a musaka ka dɔgɔ. | fanga dɔgɔyali, a tɛ kɛ degunba la. |

Flange Hub : Nin yɔrɔ in bɛ pipe ni flange cɛ, ka barika don ani ka dɛmɛ don ka degun tila ɲɔgɔn na.

Bore : pipe bɛ tɛmɛ cɛmancɛ dingɛ min fɛ. Bore hakɛ nafa ka bon bawo a bɛ nɔ bila ji bɔli ni tansiyɔn na k’a ɲɛsin a ma.

Neck (for weld neck flanges) : Neck bɛ fanga di ani ka dɛmɛ don ka pipew bɛn ɲɔgɔn ma u sigili senfɛ, kɛrɛnkɛrɛnnenya la tansiyɔnba la.

| Component | ɲɛfɔli . |

| flange ɲɛda . | yɔrɔ min na gasi bɛ sigi ka kɛ sigilan ye . |

| hub flange . | A bɛ fanga di ɲɔgɔndan ma . |

| Forazidingɛ | Cɛmancɛ dingɛ min bɛ kɛ ka ɲɛsin pipe jɛgɛn ma . |

| Kan | Walasa ka fanga ni pipe alignment fara a kan, kɛrɛnkɛrɛnnenya la welda kɔw la . |

Flansɛ suguya caman .

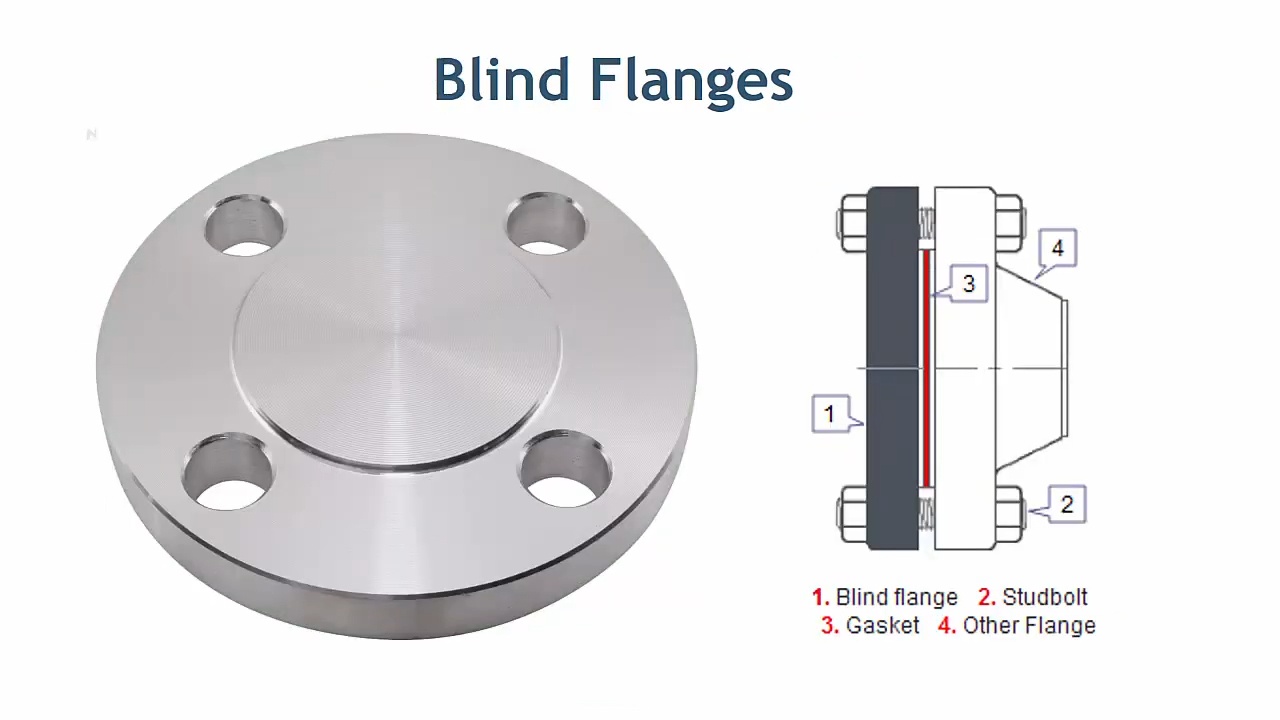

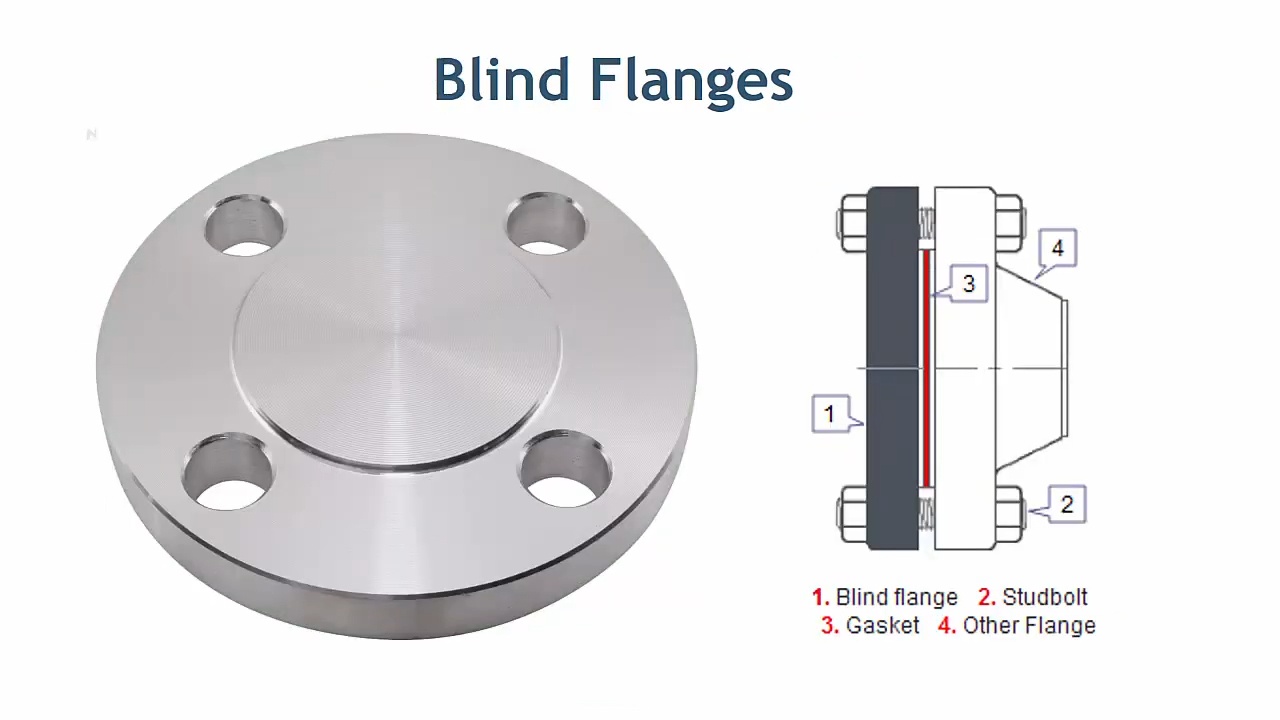

1. Fiyentɔw ka flansɛ .

dɔ Fiyentɔ flansɛ dabɔra ka pipe, valve, walima pressure minɛn laban datugu, ka baara kɛ i n’a fɔ a dawolo. A tɛ ni bore ye, o kɔrɔ ye ko da tɛ yen santiri kɔnɔ, o b’a to a ka ɲi kosɛbɛ sistɛmuw ma minnu bɛ se ka kɛ sababu ye ka dɔ fara u ka baara kan sini, ka u sɛgɛsɛgɛ, walima ka u ladon. Fiyentɔw nafa ka bon kɛrɛnkɛrɛnnenya la yɔrɔw la minnu bɛ tansiyɔnba la, bawo u bɛ degun muɲu kɔnɔna degunw ni fanga minnu bɛ kɛ ni bololanɛgɛ ye. U bɛ sɔrɔ ka caya iziniw kɔnɔ i n’a fɔ tulu & gazi ani kemikɛli, yɔrɔ minnu na pibiliki yɔrɔ dɔw bɛ bɔ ɲɔgɔn na tuma caman na walasa ka u ladon walima ka u sɛmɛntiya.

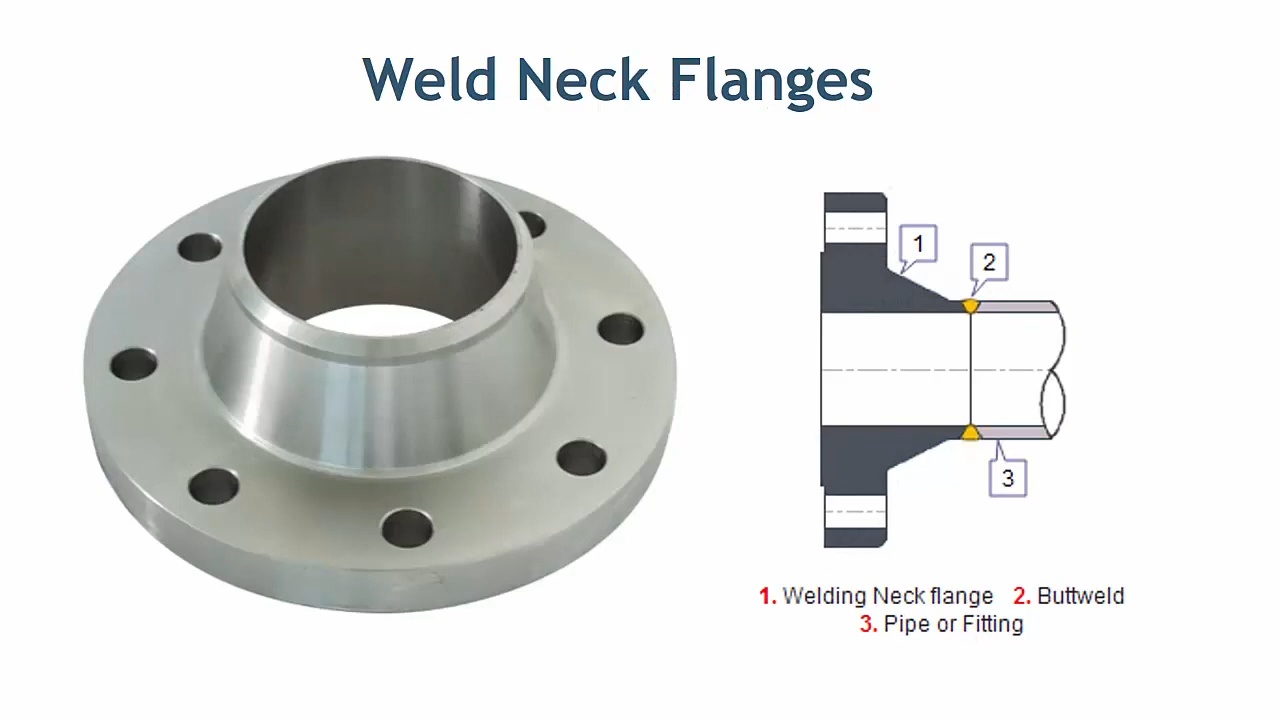

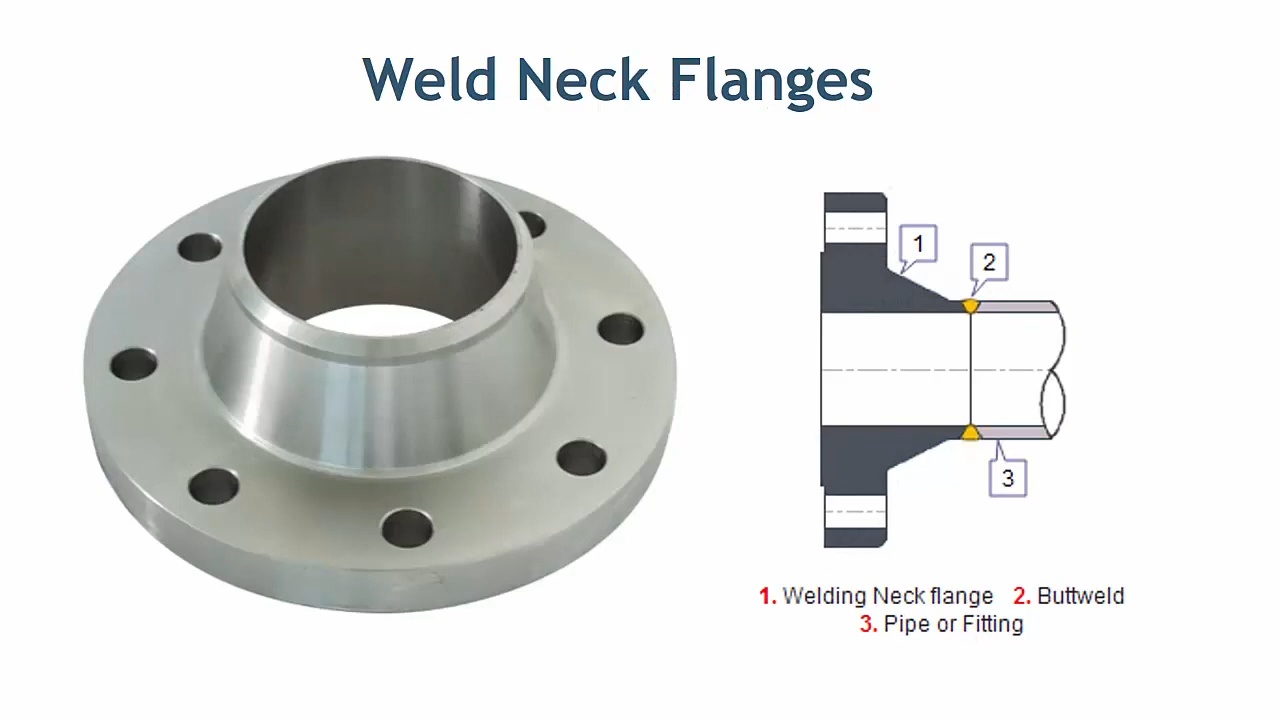

2. weld neck flange .

welda kɔkili bɛ dɔn a kɔ janyalen fɛ, o bɛ pipe fara ɲɔgɔn kan dɔɔni dɔɔni. Nin dilan in bɛ degunw hakɛ dɔgɔya, o b’a to a ka ɲi kosɛbɛ degunba ni funteni caman na. A kɔ bɛ bɛn ni pipe ye, ka ji bɔli nɔgɔya ani ka bɔgɔbɔli dɔgɔya. Nin flansɛ suguya in bɛ kɛ fɔlɔ baara nafamaw la i n’a fɔ petoroli sɛnɛyɔrɔw, kuran sɛnɛyɔrɔw, ani pibilikiw minnu bɛ fɛn nɔgɔlenw walima bagajiw ta. Pipe ni flange cɛ welda min bɛ kɛ ka fɛn bɛɛ kɛ, o bɛ a to a ka se ka sigicogo dafalen sɔrɔ, o min nafa ka bon kosɛbɛ sigidaw la minnu bɛ ko juguw ɲɛnabɔ.

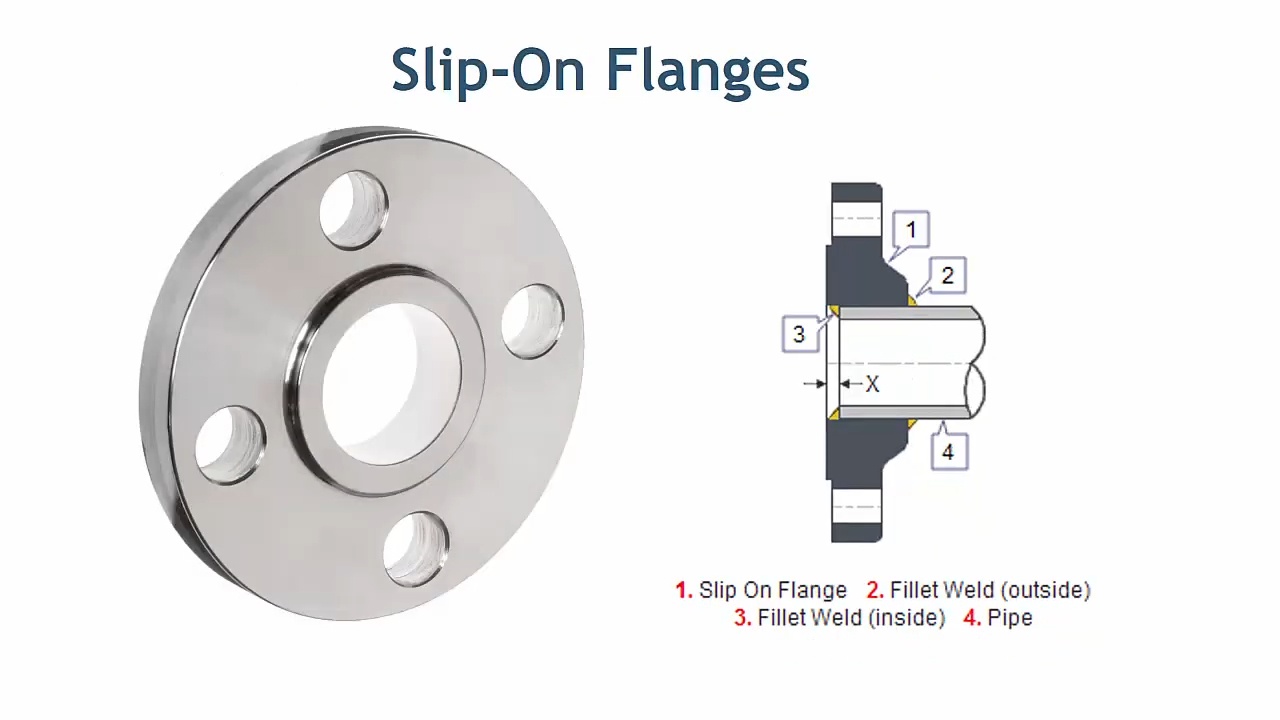

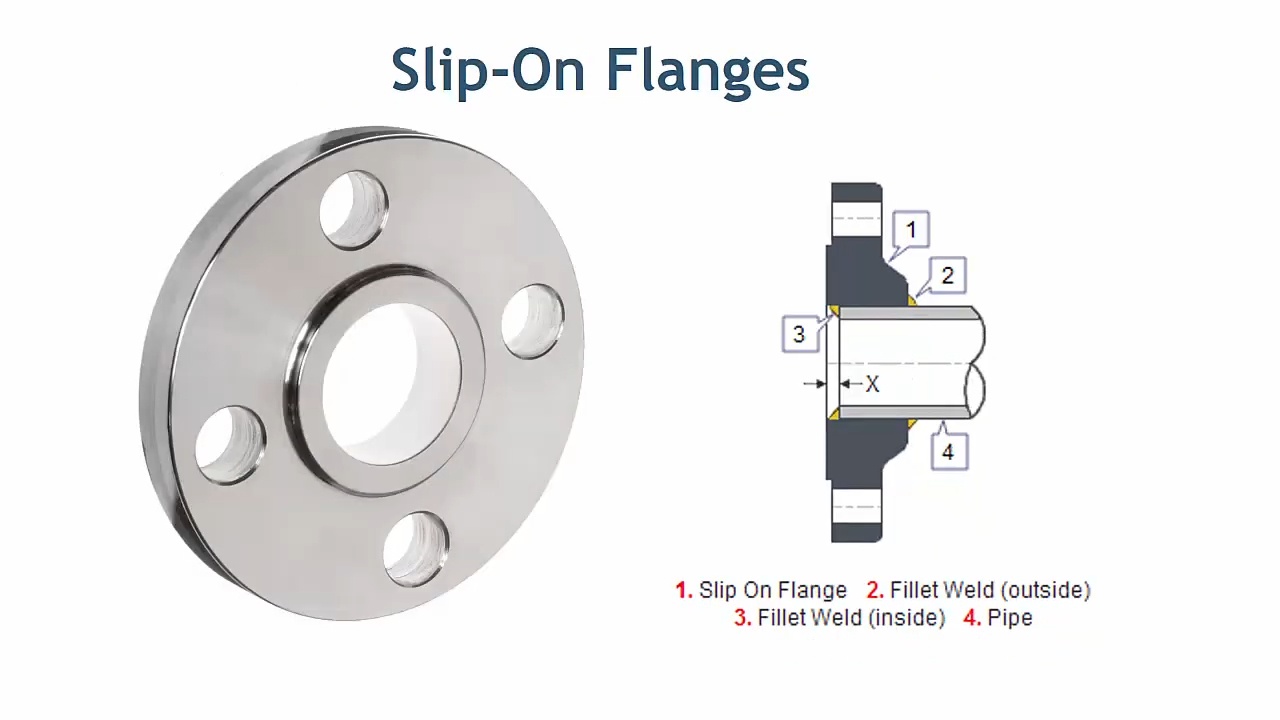

3. Slip-on flange .

Slip -on flange ye suguya nɔgɔman ye, min sigili ka nɔgɔn, min bɛ sɛgɛn pipe kan ani a bɛ welda kɔnɔna ni kɛnɛma fila bɛɛ la walasa ka jɛgɛnsira lakana. A dilanni tilennen b’a to a bɛ diya mɔgɔw ye minnu bɛ kɛ ni degun dɔgɔman ye, minnu tɛ kɔrɔfɔ ye, yɔrɔ minnu na sigili teliya nafa ka bon. Baara minnu bɛ kɛ tuma caman na, olu ye ji saniyacogo ye, fiɲɛbɔyɔrɔw, ani jibolisiraw. Hali ni a barika man bon i n’a fɔ welda kɔ flansɛ, a musaka ka dɔgɔ ani a ka ɲi kosɛbɛ ko minnu na degunba tɛ kɛ.

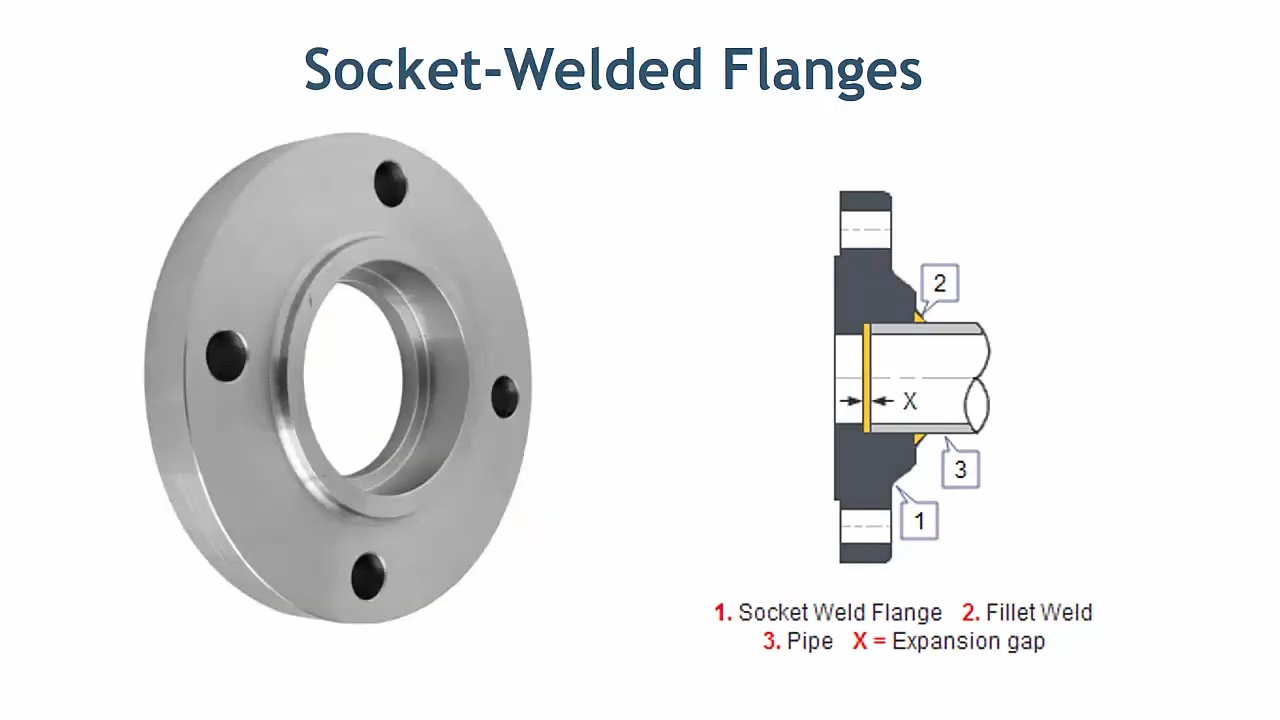

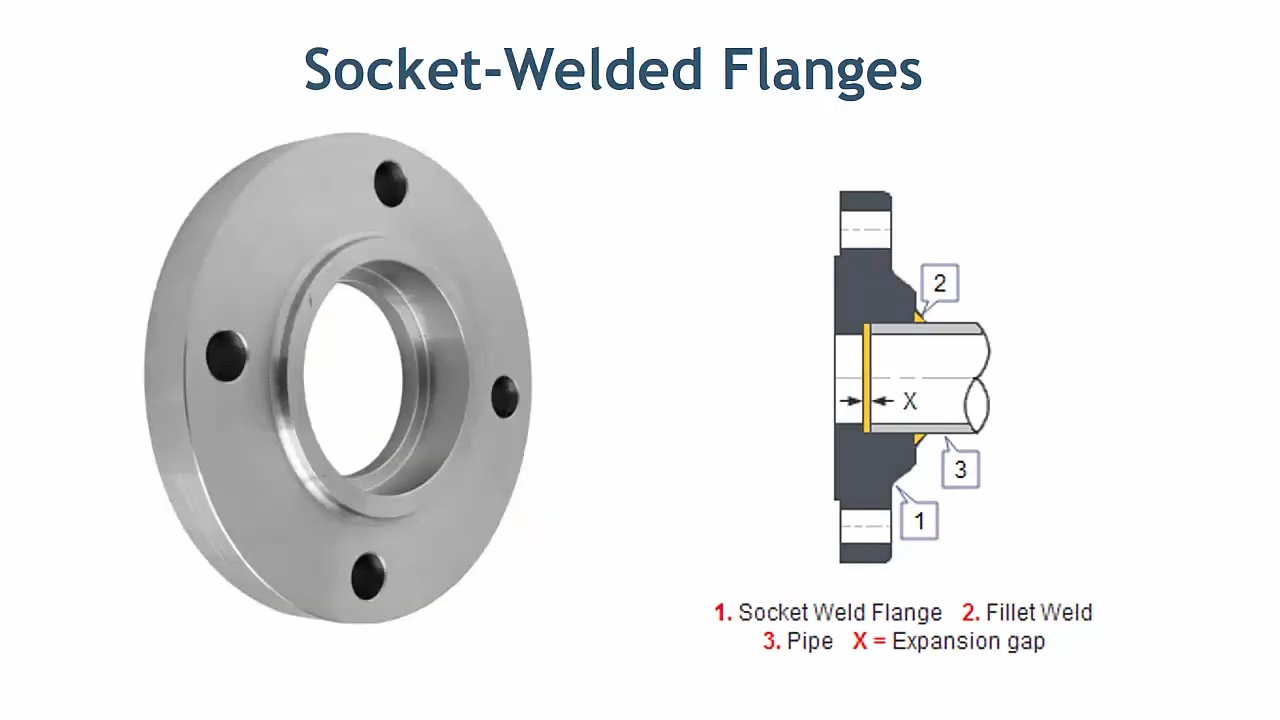

4. Socket weld flange .

Socket welda flange bɛ ni socket ye min na pipe bɛ bɛn, wa a bɛ welda kɛnɛma ka kɛ connection barikama ye. Nin flansɛ suguya in bɛ dɔn a ka ɲɔgɔndɛmɛ n’a sigili nɔgɔya fɛ, o b’a to a ka ɲi kosɛbɛ sigida la, min bɛ se ka kɛ fɛn ye min ka dɔgɔn, min bɛ se ka kɛ ni tansiyɔnba ye. A bɛ Kɛ ka caya ji ni wazi siraw la, kɛrɛnkɛrɛnnenya la yɔrɔ min na yɔrɔ ka dɔgɔ. Nka, a man kan ka kɛ baara gɛlɛnw na ka da a ka sɛgɛnbaliya kan ni a bɛ tali kɛ welda kɔkiliw la.

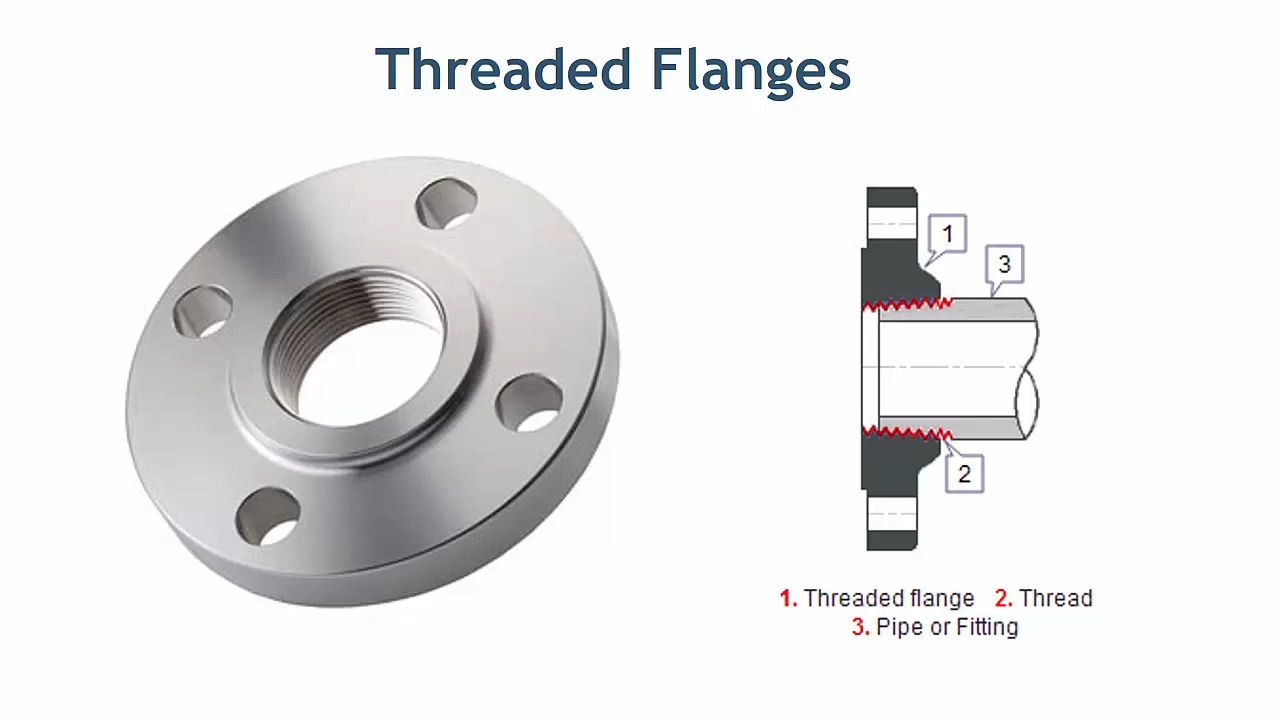

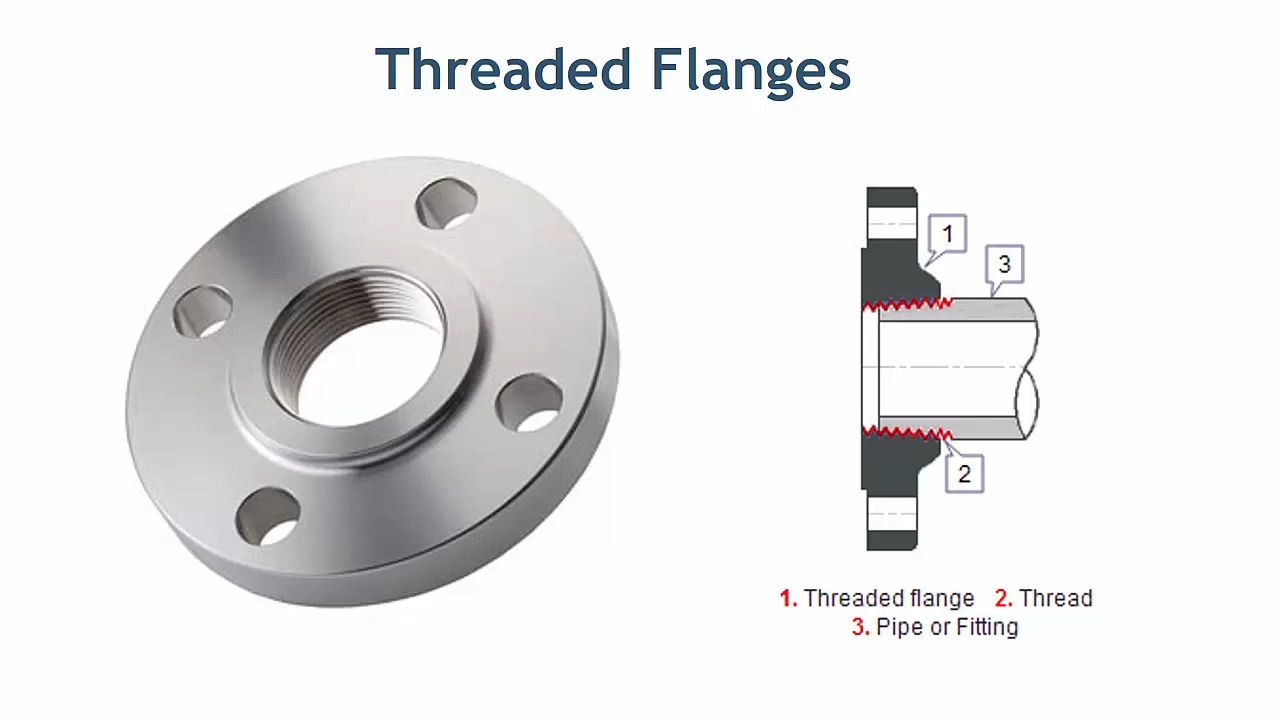

5. flansɛ min bɛ kɛ ni jiri ye .

o Filɛlikɛlan min bɛ kɛ ni jiri ye, kɔnɔna na, jiriw bɛ yen minnu b’a to a bɛ se ka siri pipe kan k’a sɔrɔ a mago tɛ welding na. O b’a to a nafa ka bon kɛrɛnkɛrɛnnenya la baarakɛcogo la, welding tɛ se ka kɛ yɔrɔ minnu na, i n’a fɔ fɛn minnu bɛ se ka tasuma don, olu bɛ se ka kɛ yɔrɔ minnu na, yɔrɔ minnu na, sɔgɔsɔgɔninjɛ farati ka kan ka dɔgɔya. Fɛn minnu bɛ kɛ ni jiri ye, olu bɛ kɛ cogoya la, u bɛ kɛ ni tasuma dɔgɔman ye, funteni ka dɔgɔn i n’a fɔ ji walima fiɲɛ siraw. U ka ɲi kosɛbɛ pibilikiw ma minnu bɛ kɛ yɔrɔw la minnu tɛ bɔgɔ ye.

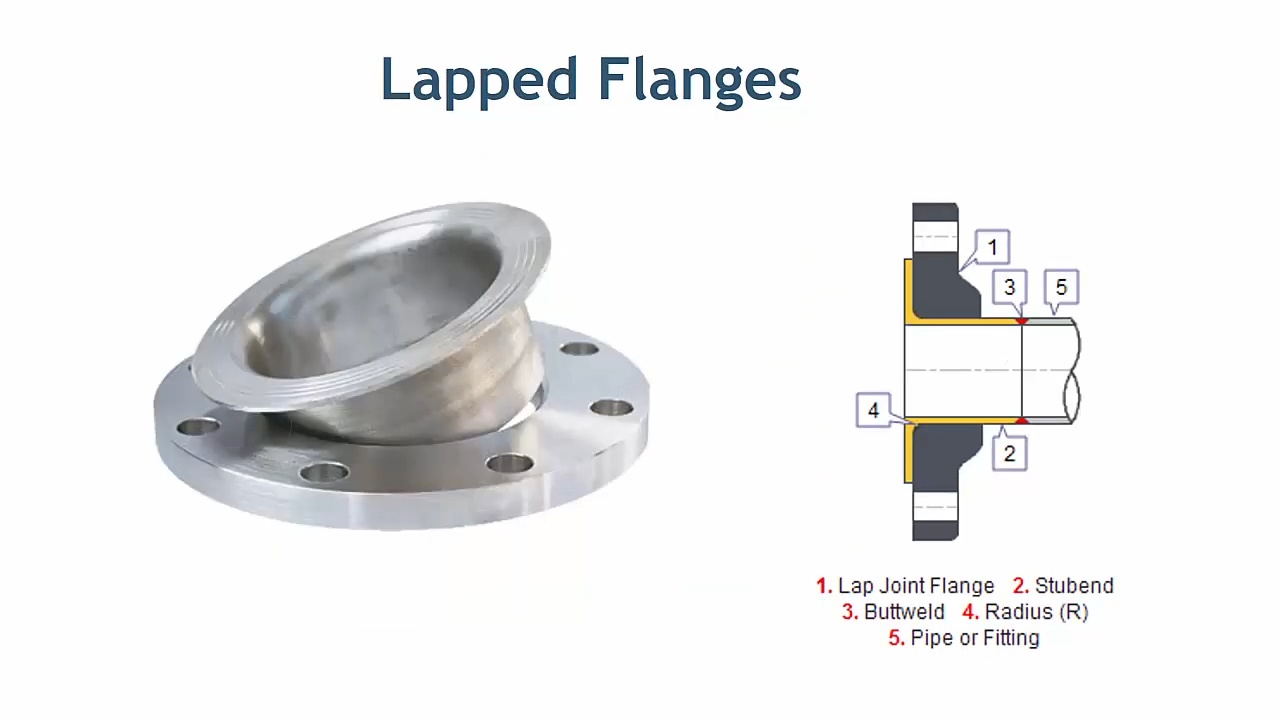

6. Lap flange joint .

Lap joint flange ye yɔrɔ fila ye min bɛ kɛ ni stub end ye ani backing flange lafiyalen ye. Flange lajɔlen bɛ a to bololanɛgɛ dingɛw ka ɲɔgɔn sɔrɔ nɔgɔya la, o b’a to a bɛ se ka wuli kosɛbɛ ani a ka ɲi kosɛbɛ sigida la min bɛ to ka wuli ka bɔ a la walasa ka a ladon walima ka a sɛgɛsɛgɛ. A nafa jɔnjɔn dɔ ye ko a bɛ se ka fara ɲɔgɔn kan ni nɛgɛ ye min sɔngɔ man gɛlɛn, n’a bɛ kɛ ni pibiliki fɛn sɔngɔ gɛlɛnw ye, minnu bɛ se ka sɔgɔ i n’a fɔ nɛgɛ min tɛ sɔgɔ. A ka teli ka kɛ dumuniw dilanni na, kemikɛli yɔrɔw la, ani baarakɛyɔrɔ wɛrɛw la, saniya ni sɔgɔli bɛ se ka kɛ yɔrɔ minnu na, olu nafa ka bon kosɛbɛ.

7. orifice flange .

Orifice flange kɔnɔ, orifice plate bɛ sɔrɔ, o bɛ kɛ ka ji, watara, walima gaziw ka jibɔ hakɛ suman pibiliki kɔnɔ. Nin flansɛ suguya in bɛ kɛ ka caya ni degunw ye walasa ka jibɔ hakɛw kɔlɔsi ni tansiyɔn danfaralen dɔ dabɔli ye. Orifice flanges bɛ sɔrɔ tuma caman na kemikɛli baara la, tulu labɛnni na, ani ji saniyacogo la, yɔrɔ minnu na jibɔ kɔlɔsili tigitigi nafa ka bon walasa ka baara kɛcogo ɲuman sabati.

8. welding neck flange .

bɛ welding neck flange jan i n’a fɔ welda kɔ flansɛ nka a kɔ janyalen don, o bɛ fanga wɛrɛ di a ma walasa ka baara kɛ yɔrɔ minnu na degunba ye haminanko ye. Nin flansɛ suguya in bɛ kɛ pibilikiw la minnu bɛ tansiyɔnba la, a ka c’a la, petoroli ni gazi baara la, walasa ka ɲɔgɔndan lakananenw ni dannayalenw sɔrɔ yɔrɔ janw na. A kɔ janyalen bɛ a to degunw tilatilali ka ɲɛ pibilikiw la minnu janya ka bon.

9. Flansɛ suguya kɛrɛnkɛrɛnnenw .

Nipoflange : welding neck flange ni nipolet faralen ɲɔgɔn kan, nin suguya in bɛ kɛ ka pibiliki bolofara dɔ bolofara 90-degree angle, o bɛ ɲɔgɔndan fitinin ni barikama di.

WELDO FLAnge : Nin flansɛ in dabɔra ka bɔli ɲɔgɔndan di, a ka c’a la, a bɛ kɛ bolofara pibilikiw ye. A bɛ welda ka ɲɛsin pipeba ma, ka ɲɔgɔndan dafalen ni leak-proof di.

Elbo flange : Ka kɔkili ni flansɛ baarakɛcogo fara ɲɔgɔn kan, nin flansɛ suguya in bɛ pibilikiw di u ka ɲɔgɔn sɔrɔ yɔrɔ dɔ la, ka dɔ bɔ u mago la kɔkili ni flansɛ yɔrɔw la.

Swivel flange : Flange swivel bɛ kɛnɛma-bololanɛgɛ lamaga-lamaga, o bɛ bololanɛgɛ dingɛ ɲɔgɔndɛmɛ nɔgɔya, kɛrɛnkɛrɛnnenya la, nafa bɛ min na kɔgɔjida la ani kɔgɔjida la, yɔrɔ minnu na ɲɔgɔndɛmɛ tigitigi bɛ se ka gɛlɛya.

Flansɛ dɔgɔyali : A bɛ kɛ ka pibiliki hakɛ dɔgɔya, flansɛ dɔgɔyali bɛ pibilikiw ni ɲɔgɔn cɛ minnu janya tɛ kelen ye, k’a sɔrɔ mago tɛ dɔgɔyalan wɛrɛ la, min bɛ kɛ tuma caman na sigidaw la, yɔrɔ dan bɛ yɔrɔ minnu na.

Flansing (flan) bonya : Flange (flan) min bɛ dɔgɔya, flange (flan) min bɛ bonya , o bɛ dɔ fara bore (bɔrɔ) hakɛ kan, o bɛ kɛ sababu ye ka pipeline (bolifɛn) dɔ don minɛnw na i n’a fɔ valve (dawolo) ani pɔnpew minnu dondaw ka bon.

O flansɛ suguya kelen-kelen bɛɛ bɛ ni fɛn kɛrɛnkɛrɛnnenw ye ani nafa minnu b’a to u bɛ bɛn izini baarakɛcogo wɛrɛw ma. Ni aw ye flansɛ suguya ɲuman sugandi sigida kɛrɛnkɛrɛnnen dɔ la, o bɛ bɔ sistɛmu ka tansiyɔn, a ka funteni ani a ka fɛnw bɛncogo la.

| Flange kunba | baarakɛcogo | ɲuman baarakɛcogo . |

| Fiyentɔw ka flansɛ . | Sealing off pipes or systèmes . | Tumu nafamayɔrɔw, tansiyɔn jiginni . |

| weld neck flange . | Pibiliki minnu bɛ kɛ ni tansiyɔnba ye, minnu bɛ funteni caman bɔ . | Fɛnɲɛnɛmaw, petoroli-sɛnɛfɛnw . |

| Slip-on flange . | Sisitɛmu minnu bɛ tansiyɔn dɔgɔya, olu bɛ ɲɔgɔn sɔrɔ nɔgɔya la . | Ji siraw, fiɲɛ minnu bɛ degun . |

| Socket weld flange . | Pibiliki minnu bɛ tansiyɔnba la, olu bɛ jolisira lakananenw de wajibiya . | hydraulique systèmes . |

| flansɛ min bɛ kɛ ni jiri ye . | Tansiyɔn dɔgɔman, funteni dɔgɔman sigida . | Jiko siratigɛ la, yɔrɔ min na welding tɛ se ka kɛ . |

| Lap flange joint . | Sitimɛ minnu bɛ to ka wuli ka caya . | Sigida minnu bɛ fɛnw tiɲɛ . |

| orifice flange . | Flow sumani . | kemikɛli baarakɛcogo, nafamafɛnw . |

Material Choices ka ɲɛsin flanw ma .

Fɛn ɲumanw sugandili flansɛ la, o nafa ka bon kosɛbɛ baarakɛcogo ni ɲɛnamaya jan fila bɛɛ la, ka kɛɲɛ ni baarakɛcogo ye. Nin ye fɛnw ye minnu bɛ kɛ ka caya: Fɛn minnu bɛ

Karɔbɔni nɛgɛ : Fɛn min bɛ kɛ ka caya flankɛw la ka da a fanga kan, a muɲuni, ani a musaka sɔrɔli. A ka ɲi kosɛbɛ baarakɛcogo bɛɛ lajɛlen na nka a bɛ se ka kɛ a tɛ baara kɛ ka ɲɛ sigidaw la minnu falen don fɛnw na.

Aloy Steel : Fɛn minnu bɛ sɔrɔ i n’a fɔ chromium, nickel, walima molybdenum, o bɛ a kɛ a bɛnnen don funteni ni tansiyɔnba cogoyaw ma, minnu bɛ kɛ ka caya sɛnɛfɛnw falenyɔrɔw ni kuran sɛnɛyɔrɔw la.

Inox : A bɛ dɔn a ka sɔgɔli kɛcogo ɲuman fɛ, nɛgɛ inox flanges ka ɲi sigidaw ma minnu ka nɛnɛ ka bon walima minnu bɛ kɛ ni kemikɛlifɛnw ye minnu bɛ se ka wuli.

Nɛgɛ min bɛ kɛ : A ka ca a la, a bɛ kɛ baarakɛyɔrɔw la, fanga ni masina nafa ka bon yɔrɔ minnu na, hali ni a tɛ sɔrɔ kosɛbɛ bi iziniw kɔnɔ k’a sababu kɛ a karicogo ye.

Aluminiyɔmu : Sugandili min ka nɔgɔn, min bɛ se ka nɔgɔ, o bɛ kɛ ka caya sigidaw la, girinya dɔgɔyali nafa ka bon yɔrɔ minnu na, i n’a fɔ aerospace baaraw la.

Brass : A ka ɲi kosɛbɛ funteni caman sɔrɔli la yɔrɔ minnu na, fɛnw tali ni u ka fɛnɲɛnamafagalanw nafa ka bon, a ka ca a la, u bɛ sɔrɔ kɔgɔji ni pɔmpiko siratigɛ la.

| cogoya | . | kɛ ka fɛnw |

| Karɔbɔni nɛgɛ . | fanga ka bon, a bɛ se ka kɛ . | Pibilikiw minnu bɛ kɛ fɛn bɛɛ ye, olu bɛ kɛ . |

| Alizɔn . | Tansiyɔnba, funteni caman bɛ se ka sɔrɔ min na . | Kuran jiriw, sɛnɛfɛnw feereyɔrɔw . |

| inox . | A bɛ se ka kɛ fɛn ye min bɛ se ka tiɲɛ, a bɛ mɛn . | kemikɛli baarakɛcogo, dumuni ani minfɛnw . |

| Nɛgɛ min bɛ kɛ ka fɛnw kɛ . | barikama nka brittle . | Tariku baarakɛcogo, baarakɛminɛnw minnu bɛ tansiyɔn dɔgɔya . |

| Aluminiyɔmu . | A ka nɔgɔn, a bɛ se ka fɛn dɔ tiɲɛ . | Aerospace, Transports Systems . |

| Brass . | Conductivité ni ductility . | Kɔgɔjida la, funteni caman bɛ sɔrɔ cogo min na . |

Fɛn minnu ka kan ka jateminɛ ni aw bɛ flansɛ sugandi .

Flange suguya .

Flange suguya ɲuman sugandili nafa ka bon walasa ka bɛn ni piping system ani baarakɛcogo ye. Misali la, weld neck flanges bɛnnen don ka ɲɛ ni tansiyɔnba ye, ka sɔrɔ slip-on flanges sigili ka nɔgɔn nka u tɛ mɛn.

Face suguya .

Flange ɲɛda ka kan ka kɛ sigilan ye min bɛ se ka da a kan. Ɲɛw kɔrɔtalenw ka fisa ni degun caman ye, ka sɔrɔ ɲɛda fla bɛ bɛn degun dɔgɔmanw ma.

Fɛn minnu bɛ kɛ ka ɲɛsin fɛnw ma .

Flankanw ka kan ka dilan ni fɛnw ye minnu bɛ bɛn ji walima gaziw ma minnu bɛ taa ni u ye ani u bɛ baara kɛ sigida min na, nɛgɛ min tɛ sɔgɔ, o bɛ se ka kɛ wajibi ye sigida nɔgɔlenw na, ka sɔrɔ nɛgɛ karɔbɔni bɛ se ka kɛ fɛn bɛɛ ye.

Hakɛw ni hakɛw .

Flange hakɛw, kɛnɛma cɛmancɛ ni bore hakɛ, olu ka kan ka bɛn piping system ma walasa a ka se ka bɛn ka ɲɛ ani ka a yɛrɛ tanga fɛnw bɔli ma.

Tansiyɔn ni funteni hakɛw .

Aw bɛ flanw sugandi tuma bɛɛ minnu bɛ sigida ka tansiyɔn ni funteni hakɛ camanba dafa walima ka tɛmɛ o kan walasa ka dɛsɛw bali.

musaka ni sɔrɔli .

Flanbaw minnu ka ɲi kosɛbɛ, olu bɛ se ka kɛ ni musaka fɔlɔ ye min ka bon nka u bɛ se ka wari bɔ waati kɔnɔ ni u ka baara jɔli ni u dilancogo dɔgɔyali ye. Ka fara o kan, aw bɛ a lajɛ ko flansɛ suguya ni fɛn sugandilenw bɛ sɔrɔ nɔgɔya la walasa ka u yɛrɛ tanga porozew ka waati latɛmɛni ma.

Fɛn dilanni fɛɛrɛw .

A dilanni taabolo bɛ nɔ bila flansɛ fanga ni a muɲuni na. Flanges forgés barika ka bon, k’a sɔrɔ flanges cast bɛ fɛn caman ɲɛfɔ ka ɲɛ, wa u dilanni ka nɔgɔn.

Fɛn dilanni fɛɛrɛw .

Flankanw dilanni fɛɛrɛ fɔlɔ fila bɛ yen:

Forging : flanw bɛ dilan ni fɛn in sumaya ni a cogoya ye degun kɔnɔ. Flange forgé (flanges forgés) barika ka bon ani u bɛ mɛn, o b’a to u ka ɲi kosɛbɛ ka baara kɛ ni degunba ye.

Casting : nɛgɛ mɔlen bɛ bɔn ka kɛ bɔgɔ ye walasa ka flansɛ kɛ. Casting bɛ sira di dilancogo gɛlɛnw ma, nka a ka c’a la, flanw fanga ka dɔgɔ ka tɛmɛ flanges forged kan. U bɛnnen don baarakɛcogo ma minnu bɛ kɛ ni tansiyɔn dɔgɔman ye, yɔrɔ minnu na tigitigi nafa ka bon.

Flangow ka baarakɛminɛnw ani u baarakɛcogo .

Flanbaw bɛ kɛ izini suguya caman kɔnɔ, u kelen-kelen bɛɛ bɛ ni wajibi kɛrɛnkɛrɛnnenw ye:

Manufacturing Industries : iziniw kɔnɔ, flangew bɛ kɛ ka minɛnw siri ɲɔgɔn na i n’a fɔ hydraulique ani pneumatic systems. U bɛ ɲɔgɔndɛmɛ tigitigi ani ka ɲɔgɔndanw lakana minnu bɛ kɛ ka ɲɛsin fɛnw dilanni masinw ma.

Kuranko : Ji-kuran ni funteni-sɛnɛyɔrɔw la, flanges bɛ turbinew, pɔnpew, ani minɛn wɛrɛw siri ɲɔgɔn na, ka joli barikamaw sabati, minnu tɛ se ka bɔ, minnu bɛ se ka ko juguw muɲu.

Ji ni jiko jugu furakɛli : Flankanw nafa ka bon kosɛbɛ pibilikiw, valves ani pɔnpew sirili la nɔgɔbɔlanw ni furakɛli yɔrɔw la, yɔrɔ minnu na ji bɔli bɛna kɛ nɔgɔ ye.

Petrokimika baarakɛyɔrɔ : Pibiliki minnu bɛ kɛ ni degunba ye kemikɛli jiriw la, olu bɛ u jigi da flanw kan minnu bɛ mɛn sen na walasa ka funteni jugumanba ni fɛn nɔgɔlenw muɲu.

Kɔgɔjida la : Flankanw nafa ka bon kurunbokari la, u bɛ jɛɲɔgɔnya lakananenw di fɛnɲɛnamafagalanw, nɛnɛbɔlanw, ani fɛn wɛrɛw cɛ.

Kuncɛli

Flankanw ye fɛn nafamaba ye izini caman kɔnɔ, minnu bɛ jɛɲɔgɔnya lakananenw di, minnu bɛ se ka da u kan, minnu bɛ degun, funteni ani sigida cogoyaw muɲu. Ni aw ye flansɛ ɲuman sugandi ka da a suguya kan, a kɛcogo kan, ani a kɛcogo kan, o bɛ sistɛmu dafalen sabati ani ka dɔ bɔ a jɔli waati la. Ni u ye flanw suguya wɛrɛw faamuya ani u baaracogo, iziniw bɛ se ka latigɛw kɛ minnu bɛ kɛ sababu ye ka baara kɛ ka ɲɛ, ka kɛ cogo la min tɛ mɔgɔ tɔɔrɔ, ani min bɛ mɛn.

Walasa ka ɲɛfɔli kɛ dɔnnikɛlaw fɛ aw ka fɛn dilanni porozɛ kan, aw bɛ se ka kuma an fɛ. An ka ɛntɛrinɛti injiniyɛri minnu bɛ se kosɛbɛ, olu bɛna aw dɛmɛ ka dilancogo, fɛnw sugandili, ani u dilanni taabolo lajɛ walasa ka ɲɛtaa ɲuman sɔrɔ. jɛɲɔgɔnya ni . Ekipu fmg ka ɲɛtaa. An bɛna aw ka sɛnɛfɛnw ta ka taa se hakɛ wɛrɛ ma ..

Faqs ko la flanges .

1. Fɛn min bɛ kɛ ka pibilikiw kɔnɔ, o ye mun ye?

Flange bɛ kɛ ka pipew, valves, pompes ani minɛn wɛrɛw siri pipe systems kɔnɔ. A bɛ se ka kɛ sababu ye ka sigida in lajɛ nɔgɔya la, k’a tiɲɛ, ani k’a ladon, ka sɔrɔ ka ɲɔgɔndan gɛlɛn di, min tɛ se ka bɔ, ka tɛmɛn bololanɛgɛ ni gazi sigilan fɛ. Flangew nafa ka bon kosɛbɛ yɔrɔw la minnu bɛ tansiyɔnba la walima minnu bɛ funteni caman na, yɔrɔ minnu na jɛɲɔgɔnya lakananen nafa ka bon.

2. Flankanw suguya jumɛnw de ka ca kosɛbɛ?

Flange suguya minnu ka ca kosɛbɛ olu ye:

weld neck flange : A bɛ dɔn fanga caman fɛ ani a bɛ kɛ ni tansiyɔnba ye.

Slip-on flange : a sigili ka nɔgɔn ani a bɛ baara kɛ ni a ye minnu bɛ kɛ ni tansiyɔn dɔgɔman ye.

Fiyentɔ flansɛ : A bɛ kɛ ka pibiliki dɔ laban datugu.

Socket weld flange : A ka ca a la, a bɛ kɛ pibiliki fitininw na, minnu bɛ tansiyɔnba la.

Filɛli min bɛ kɛ ni jiri ye : a bɛ siri pipew kan ni a tɛ sɔgɔ, a bɛ kɛ ni tansiyɔn dɔgɔman ye.

3. Face flange kɔrɔtalen kun ye mun ye?

Fasa kɔrɔtalen (RF) flansɛ bɛ yɔrɔ fitinin dɔ la min bɛ bore lamini walasa ka dasiri fanga kɛ yɔrɔ fitinin dɔ kan, ka gazi degun ɲɛ. O dilan in b’a to a bɛ se ka degunba kunbɛn ani k’a kɛ flansɛ ɲɛda ye min bɛ kɛ ka caya iziniw kɔnɔ, i n’a fɔ fɛnw nafamayɔrɔw ani kemikɛli jiriw.

4. Ne bɛ se ka flange material bɛnnen sugandi cogo di?

Fɛn ɲuman sugandili bɛ bɔ fɛnw na i n’a fɔ ji suguya min bɛ taa ni a ye, tansiyɔn, funteni, ani sɔgɔli kunbɛncogo. Fɛn minnu bɛ kɛ ɲɔgɔn fɛ, olu ye:

Karɔbɔni nɛgɛ : A ka ɲi kosɛbɛ baarakɛcogo bɛɛ lajɛlen na.

inox : bɛ sɔgɔli kɛ, a ka ca a la, a bɛ kɛ kemikali walima dumuni dilanni na.

Alloy Steel : A ka fisa sigida minnu bɛ tansiyɔnba la ani minnu bɛ funteni caman bɔ.

5. Danfara jumɛn bɛ slip-on flange ni weld neck flange cɛ?

Slip-on flange : slip bɛ pipe kan ani a bɛ welda kɔnɔna ni kɛnɛma fila bɛɛ kan. A sigili ka nɔgɔn nka a tɛ mɛn, o b’a to a bɛnnen don tansiyɔn dɔgɔmanw ma.

Weld neck flange : a bɛ ni kɔ jan ye min bɛ butt-welded to the pipe, o bɛ alignment ni stress distribution ɲuman di. A ka ɲi kosɛbɛ ka ɲɛsin tansiyɔnba ma, min bɛ kɛ ni funteni caman ye.

6. Bore ka baara ye mun ye flange kɔnɔ?

Bore ye cɛmancɛ dingɛ ye flange kɔnɔ pipe bɛ tɛmɛ yɔrɔ min na. A ka kan ka bɛn pibiliki cɛmancɛ ma walasa a ka se ka ɲɔgɔn sɔrɔ ka ɲɛ ani ka ji bɔli kɛ ka ɲɛ. welda kɔkiliw la, a ka ca a la, o bore bɛ sɛgɛn walasa ka degunw jɛnsɛn cogo kelen na ani ka dɔ bɔ fɛnw bɔli la walima u jɔcogo tiɲɛni farati la.

7. Flankanw bɛ se ka kɛ sababu ye cogo di ka ɲɔgɔndan sɔrɔ min tɛ se ka bɔ kɛnɛ kan?

flanges bɛ se ka ɲɔgɔndan sɔrɔ min tɛ se ka bɔn ka bɔ bolting ni baaracogo la gasiw . Bolow bɛ flansɛ fila ɲɛda siri ɲɔgɔn na, ka sɔrɔ gazi bɛ fɛn dɔ di min bɛ se ka degun, o bɛ yɔrɔ o yɔrɔ fa flansɛ ɲɛda ni ɲɔgɔn cɛ, o bɛ kɛ sababu ye ka sigilan sirilen siri. Tansiyɔnba la, nɛgɛ ni nɛgɛ sigilanw, i n’a fɔ ring-type joint (RTJ) gaziw, olu bɛ kɛ ka caya walasa ka lakana wɛrɛw sɔrɔ.