Flɛnj na impɔtant pat pan difrɛn industri dɛn, we de wok lɛk di kɔnɛktin ɛlimɛnt dɛn we de ol paip, pɔmp, valv, ɛn ɔda ikwipmɛnt dɛn togɛda. Dɛn wok fɔ mek shɔ se di wata we de kɔmɔt na di wata ɔ di gas dɛn we de flɔ ɔnda difrɛn prɛshɔn ɛn tɛmpracha kɔndishɔn dɛn, sef ɛn efyushɔn, de mek di flɛnch sɛlɛkshɔn impɔtant to di intagriti fɔ di sistɛm. Wit bɔku kayn, saiz, ɛn matirial dɛn we de, fɔ ɔndastand di rayt flɛnch fɔ di rayt aplikeshɔn rili impɔtant.

Dis atikul de dayv dip insay di kayn flɛnch dɛn, dɛn kɔmpɔnɛnt dɛn, di tin dɛn we dɛn de yuz, ɛn di aplikeshɔn dɛn fɔ ɛp yu fɔ disayd fɔ du di rayt tin.

Ki komponent dɛn fɔ flɛnch dɛn .

Flanges, pan ɔl we dɛn difrɛn pan di kayn dɛn, sheb sɔm impɔtant kɔmpɔnɛnt dɛn we de difayn dɛn pefɔmɛns .

ɛn aplikeshɔn. Dis komponent dεm de kכntribyut to di כvala fכnshכnaliti fכ flang dεm na di paip sistεm dεm.

Flange Face : Di eria fɔ kɔntakt bitwin di flɛnch ɛn di gasket we dɛn yuz fɔ mek wan tayt sil. Di kɔmɔn kayn flɛnch fes dɛn na:

| Flange Face Type | Fitur | Apiarens Appearance | Applitions Applications | Advantages | Disadvantages |

| Flat fes (FF) . | fɔ lɔw-prɛshɔn; Ful-fes gasket we dɛn nid. | Flat, smɔl smɔl tin dɛn we de ɔp. | Lɔw-prɛshɔn wata sistɛm, nɔ-kritikal savis. | I izi fɔ alaynɛshɔn, i de mek pɔsin nɔ wɔp. | nɔ fit fɔ ay-prɛshɔn. |

| Fas we dɛn rayz (RF) . | Strɔng silin fɔ midul to ay prɛshɔn. | Smɔl rayz eria rawnd bor. | Rifainri, kemikal plant, proses paip. | Enhansed silin fɔ difrɛn prɛshɔn dɛn. | I nid fɔ gɛt prɛsis alaynɛshɔn. |

| Ring-tayp jɔyn (RTJ) . | Metal-to-metal silin fɔ ekstrim kɔndishɔn. | Dip grov fɔ mɛtal ring gasket. | Oil & Gas, pawa jenareshɔn. | Eksɛlɛnt silin, de agens vaybreshɔn ɛn ɛkspɛnshɔn. | Higher cost, nid fɔ instɔl prɛsis. |

| Tong ɛn grov (T&G) . | Intalɔk flɛnch dɛn nɔ de gri fɔ bɛn fɔs. | rayz tong ɛn maching groove. | ay-prɛshɔn stim, pɔmp kɔva. | Self-aligning, strɔng sil. | Rikways mached pairs. |

| Man ɛn uman (M&F) . | Prɛsis alaynɛshɔn wit rayz/rɛsis sɔfays. | Male rayz fes, uman recessed fes. | Hɛt ɛkschenja, prɛsishɔn aplikeshɔn dɛn. | I nɔ de mek pipul dɛn nɔ align, i de mek dɛn ebul fɔ sial fayn fayn wan. | Nid paired installation, prɛsis mashin. |

| Lap jɔyn . | Fleksibul, izi disassembly; Flange na loose. | Tu-pies, fri-rotating flange. | Food Processing, Plumbing Systems. | I izi fɔ alaynɛshɔn, i nɔ go tek bɔku mɔni. | Lɔwa trɛnk, nɔto fɔ ay prɛshɔn. |

Flange Hub : Dis pat de kɔnɛkt di paip to di flɛnch, we de gi riinfɔsmɛnt ɛn ɛp fɔ sheb prɛshɔn ivin.

Bore : Di sentral hol we di paip de pas tru. Bore saiz impɔtant as i de impɔk di fluid flɔ ɛn prɛshɔn dairekt wan.

Nek (fɔ weld nek flɛnch) : Di nɛk de gi riinfɔsmɛnt ɛn ɛp fɔ alaynɛd paip dɛn we dɛn de instɔl, mɔ na ay-prɛshɔn sistem.

| Komponent | diskripshon . |

| Flange fes . | Eria usay Gasket sidɔm fɔ mek wan sil . |

| Flange Hub na di . | I de gi riinfɔsmɛnt fɔ di kɔnɛkshɔn . |

| Dɔl | Sɛntral ol fɔ paip kɔnɛkshɔn . |

| Nɛk | Fɔ ad trɛnk ɛn paip alaynɛshɔn, patikyula na wɛld nɛk . |

Kɔmɔn kayn flɛnch dɛn .

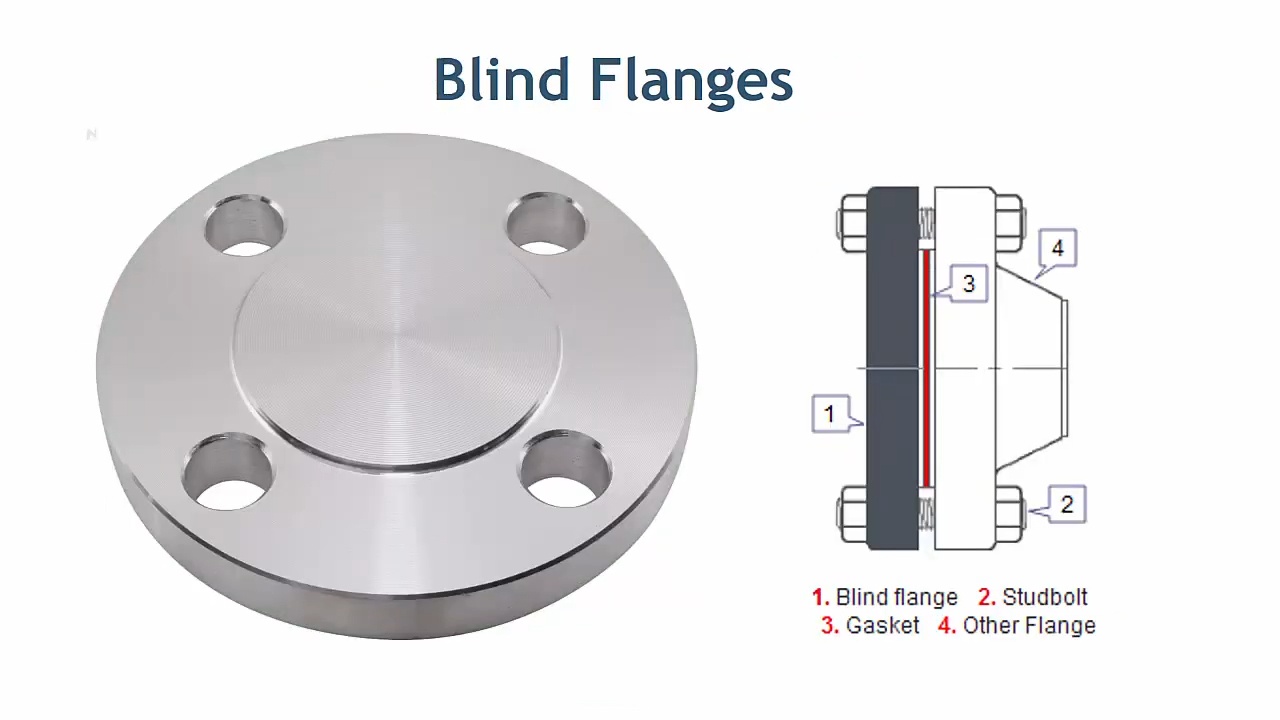

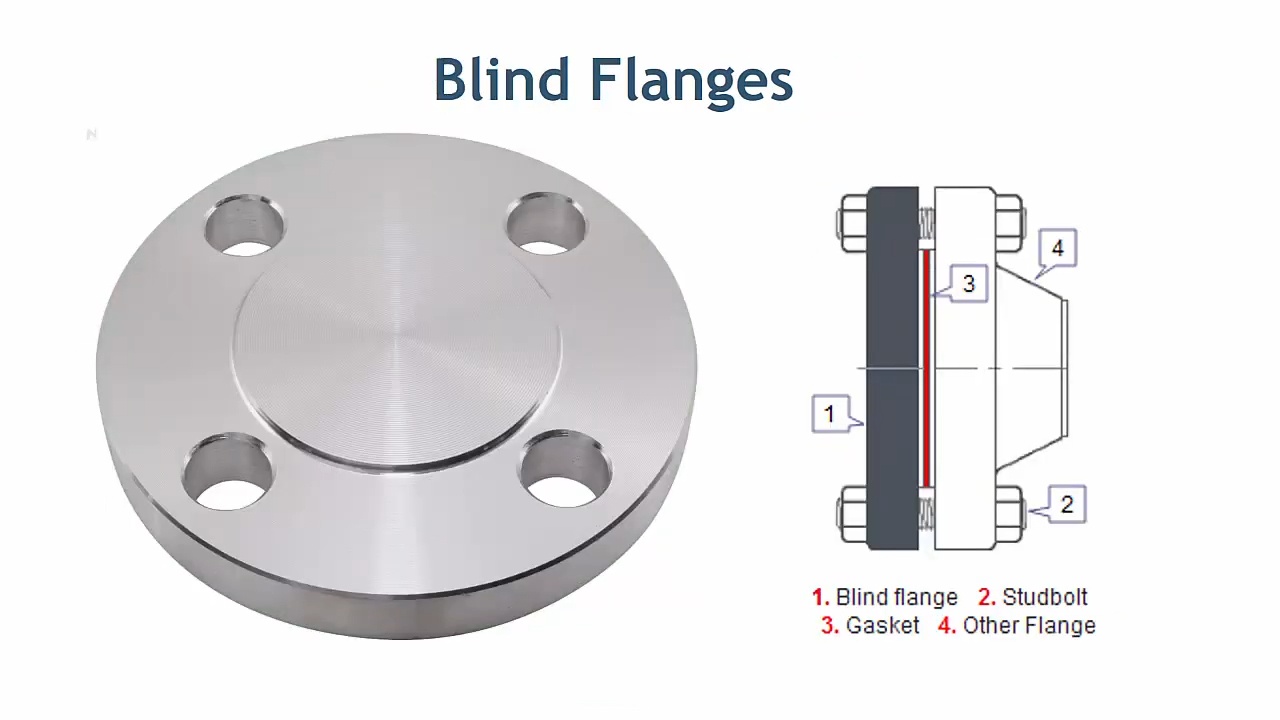

1. Blaynd flɛnch .

Dɛn mek wan blaynd flɛnch fɔ sial ɔf di ɛnd pan paip, valv, ɔ prɛshɔn vessel, we de wok lɛk kap. I nɔ gɛt ɛni bore, we min se nɔ opin nɔ de na di sɛnta, we de mek i fayn fɔ sistem dɛn we kin nid fɔ mek dɛn go ebul fɔ mek dɛn go bifo, fɔ mek dɛn go inspekshɔn, ɔ fɔ mek dɛn mentenɛns. Blaynd flɛnch dɛn kin rili yusful na ay-prɛshɔn ɛnvayrɔmɛnt, as dɛn kin ebul fɔ bia wit strɛs frɔm ɔl tu di intanɛnt prɛshɔn ɛn di fɔs dɛn we bolt de mek. Dɛn kin kɔmɔn fɔ si dɛn na industri dɛn lɛk ɔyl & gas ɛn kemikal prɔsesin, usay sɔm tɛm dɛn kin ayd sɔm pat dɛn pan paip fɔ mek dɛn mentenɛns ɔ ɔpgrɛd.

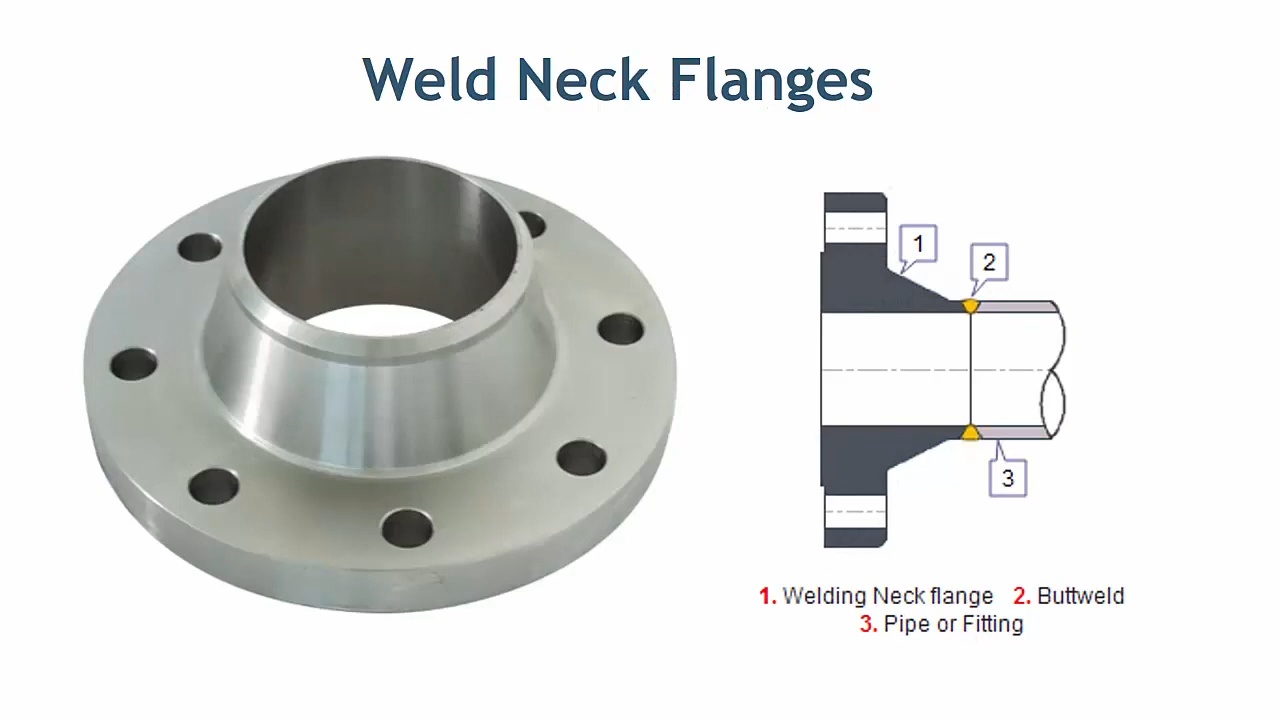

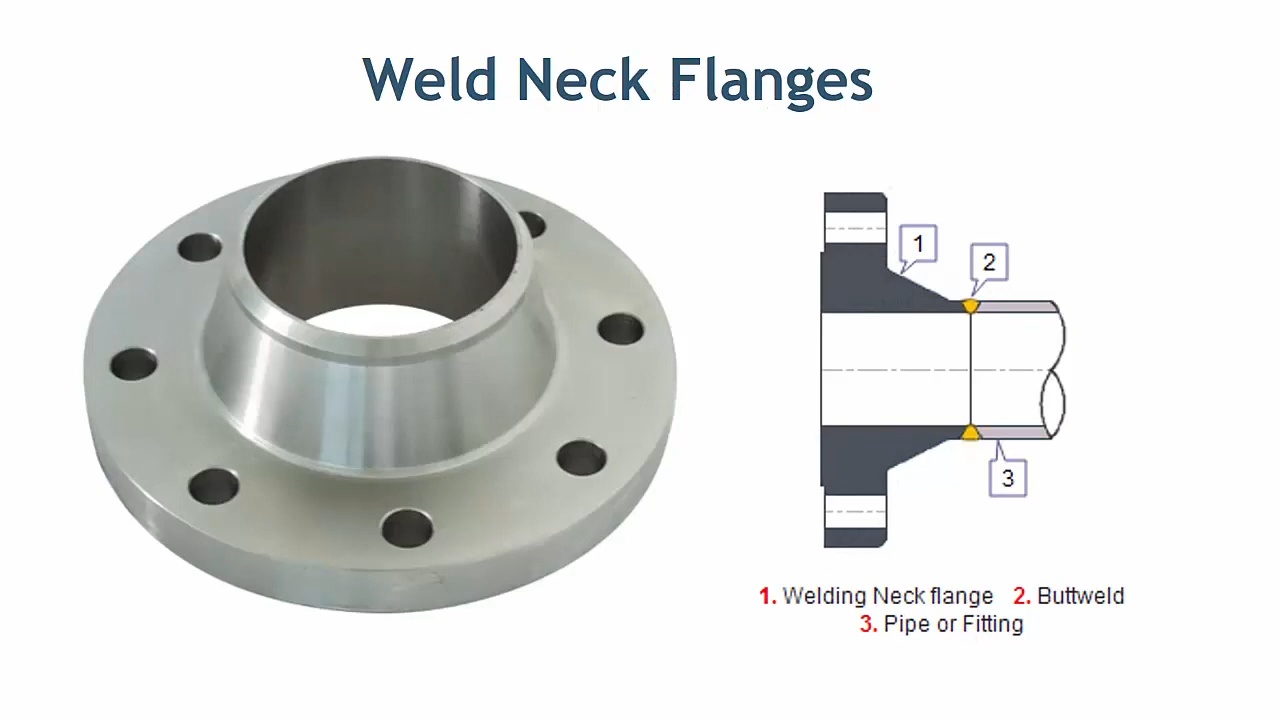

2. Weld nek flange .

Dɛn kin no wan wɛld nɛk flɛnch bay in lɔng tɛp nɛk, we kin jɔyn di paip smɔl smɔl. Dis dizayn de minimiz strɛs kɔnsɛntreshɔn, we de mek i fayn fɔ ay-prɛshɔn ɛn ay-tɛmpracha sistɛm. di nek de alayns wit di paip, mek shɔ se di wata we de kɔmɔt na di wata nɔ de flɔ fayn fayn wan ɛn i de ridyus di eroshɔn. Dis kayn flɛnch na in dɛn kin yuz mɔ na impɔtant aplikeshɔn dɛn lɛk petrolium rifinɛri, pawa plant, ɛn paip layn dɛn we de transpɔt kɔrosiv ɔ pɔyzin tin dɛn. Di ful-penetration weld bitwin di paip ɛn di flɛnch de mek shɔ se ay strɔkchɔral intɛgriti, we impɔtant fɔ sistem dɛn we de dil wit ekstrim kɔndishɔn.

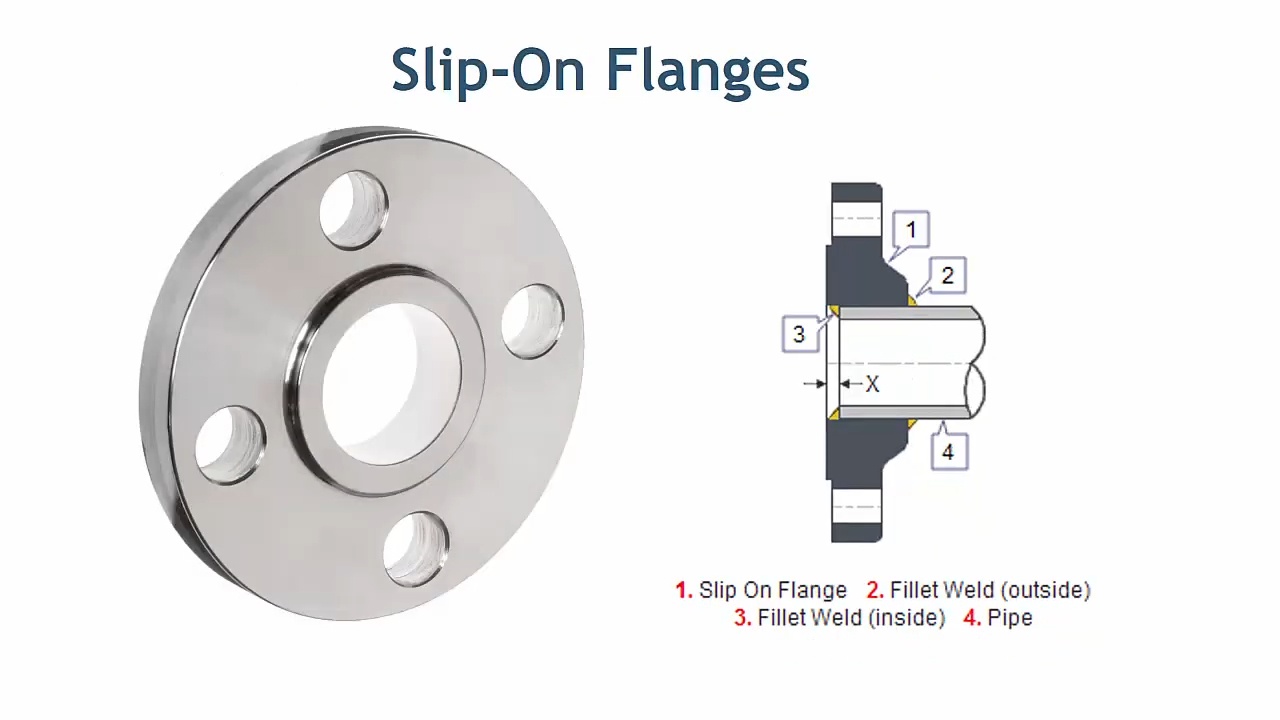

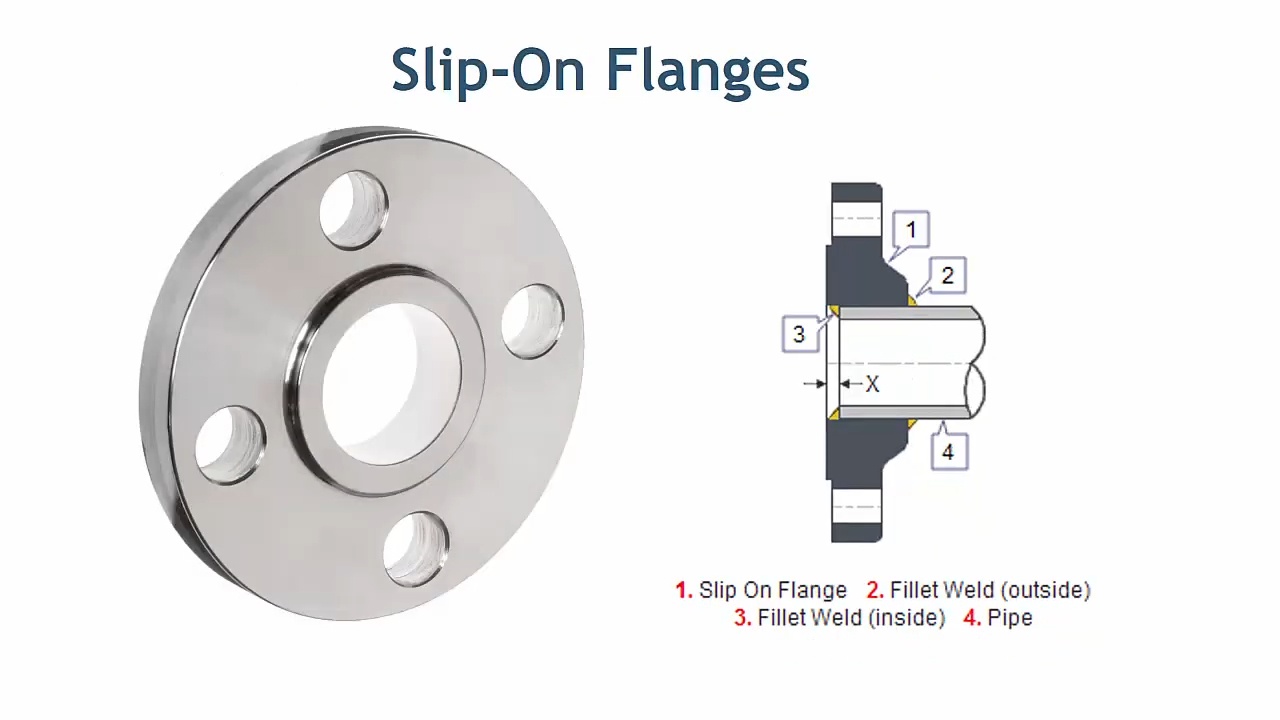

3. Slip-on flange .

Di slip-on flange na simpul, izi fɔ instɔl tayp we de slip oba di paip ɛn dɛn weld am insay ɛn ausayd fɔ mek di kɔnɛkshɔn sef. I stret dizayn mek am pɔpul na lɔw-prɛshɔn, nɔ-kritikal aplikeshɔn usay instɔleshɔn spid impɔtant. Di kɔmɔn tin dɛn we dɛn kin yuz na wata tritmɛnt sistem, ɛya paip, ɛn wata sɛrkyuyt dɛn we de mek dɛn kol. Pan ɔl we i nɔ strɔng lɛk wɛld nɛk flɛnch, i nɔ de tek bɔku mɔni ɛn i fayn fɔ di sityueshɔn dɛn usay ay-prɛshɔn pefɔmɛns nɔ nid fɔ de.

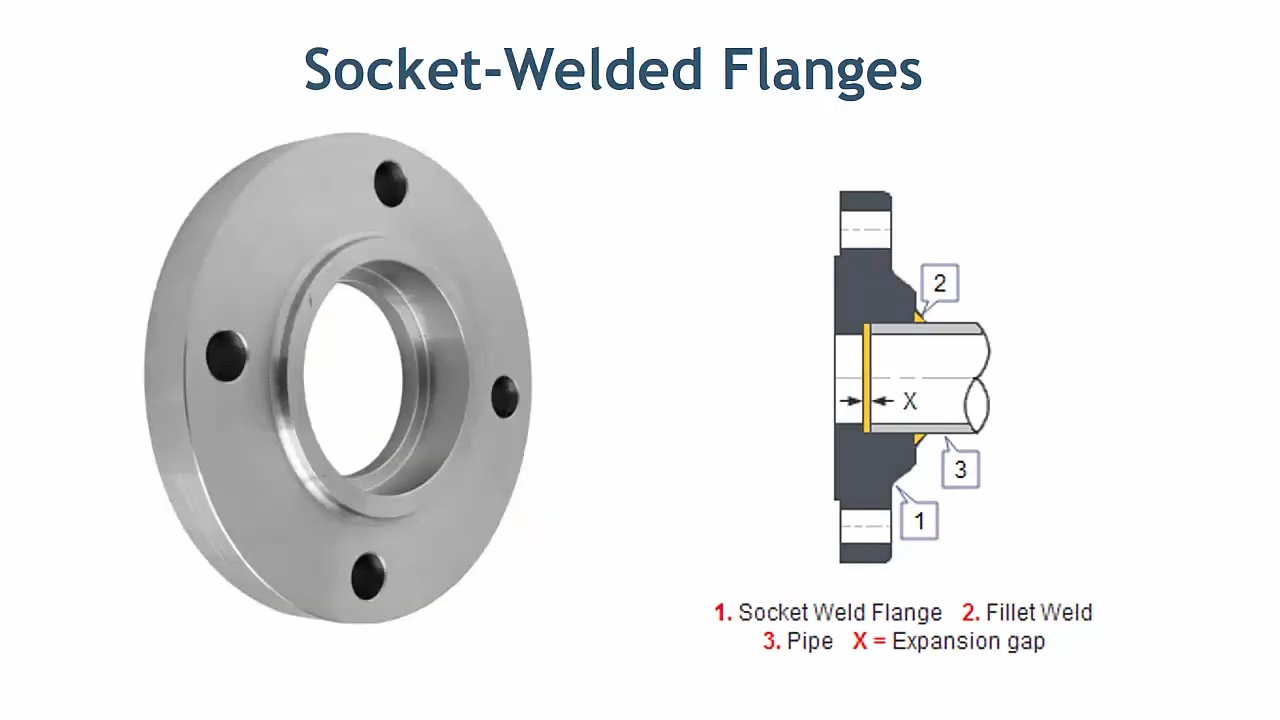

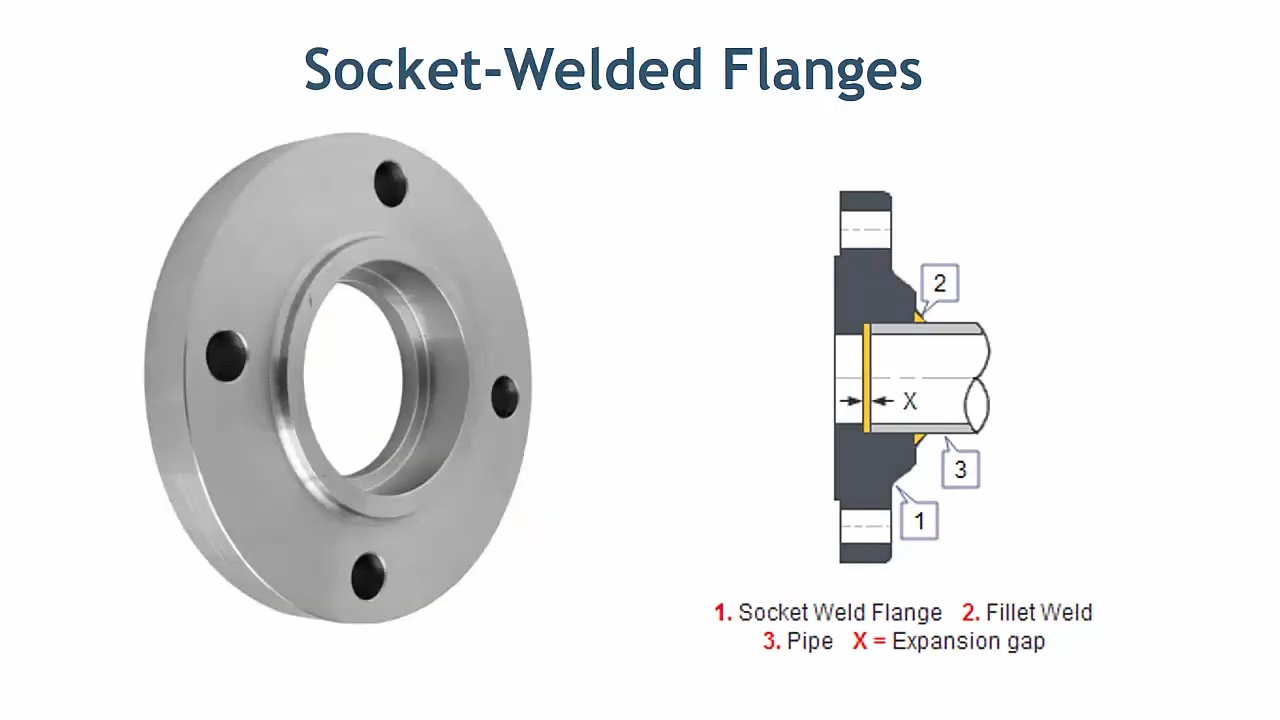

4. Soket weld flange .

Wan sɔkɛt wɛld flɛnch gɛt sɔkɛt usay di paip fit, ɛn dɛn kin wɛl am na do fɔ mek i gɛt strɔng kɔnɛkshɔn. Dis kayn flɛnch na pipul dɛn sabi am fɔ di izi we aw i izi fɔ alaynɛshɔn ɛn fɔ instɔl am, we mek i fayn fɔ smɔl dayamita, ay-prɛshɔn sistem dɛn. I kin yuz am na haydrolik ɛn stim layn, patikyula usay spɛs nɔ bɔku. Bɔt, i nɔ rɛkɛmand fɔ krichɔl savis aplikeshɔn bikɔs ɔf in lɔwa fatigue resistans kɔmpia to weld nɛk flɛnch.

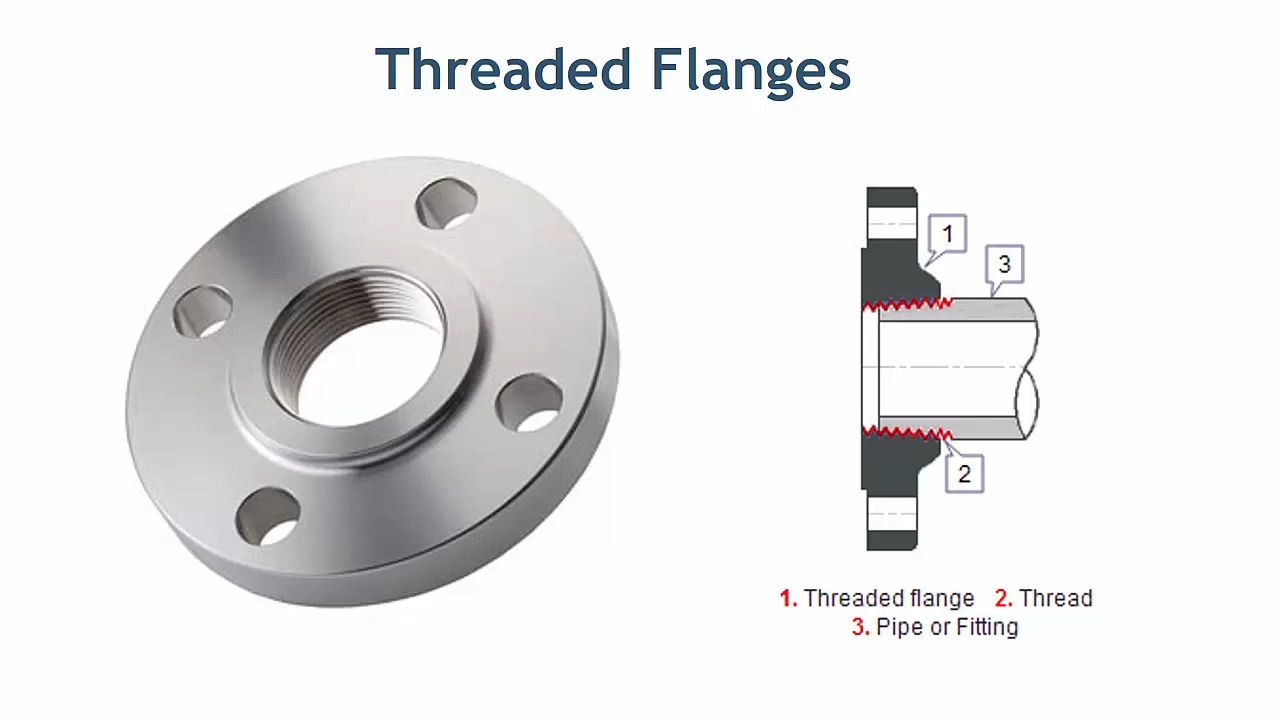

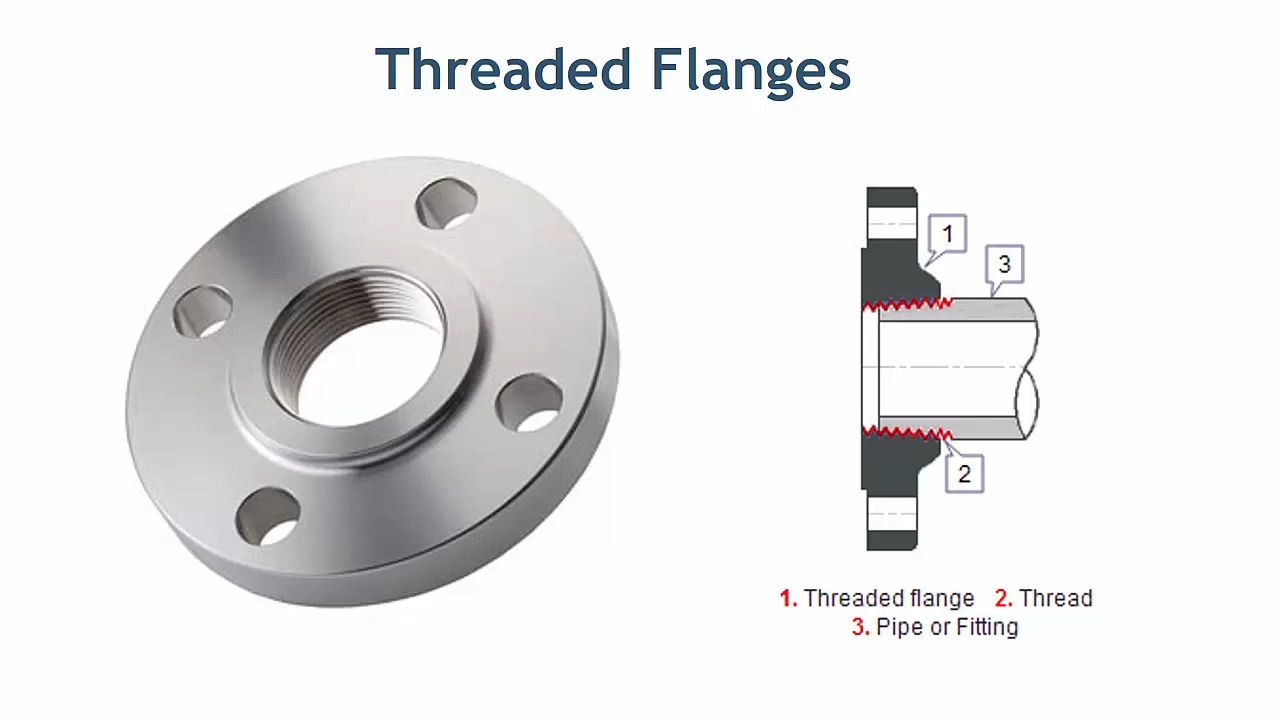

5. Flɛnj we gɛt trɛd .

Wan flɛnch we gɛt trɛd gɛt intɛnal trɛd dɛn we de alaw am fɔ skru pan di paip we nɔ nid fɔ wɛldin. Dis mek am patikyula yusful insay aplikeshɔn usay wɛldin nɔ pɔsibul, lɛk insay sistɛm dɛn we de kɛr tin dɛn we kin bɔn usay di risk fɔ spak fɔ smɔl. Dɛn kin yuz trɛd flɛnch dɛn we dɛn kin yuz na lɔw-prɛshɔn, lɔw-tɛmpracha sistɛm dɛn lɛk wata ɔ ay layn. Dɛn fayn fɔ smɔl-dayamita paip dɛn na say dɛn we nɔ de kɔrej.

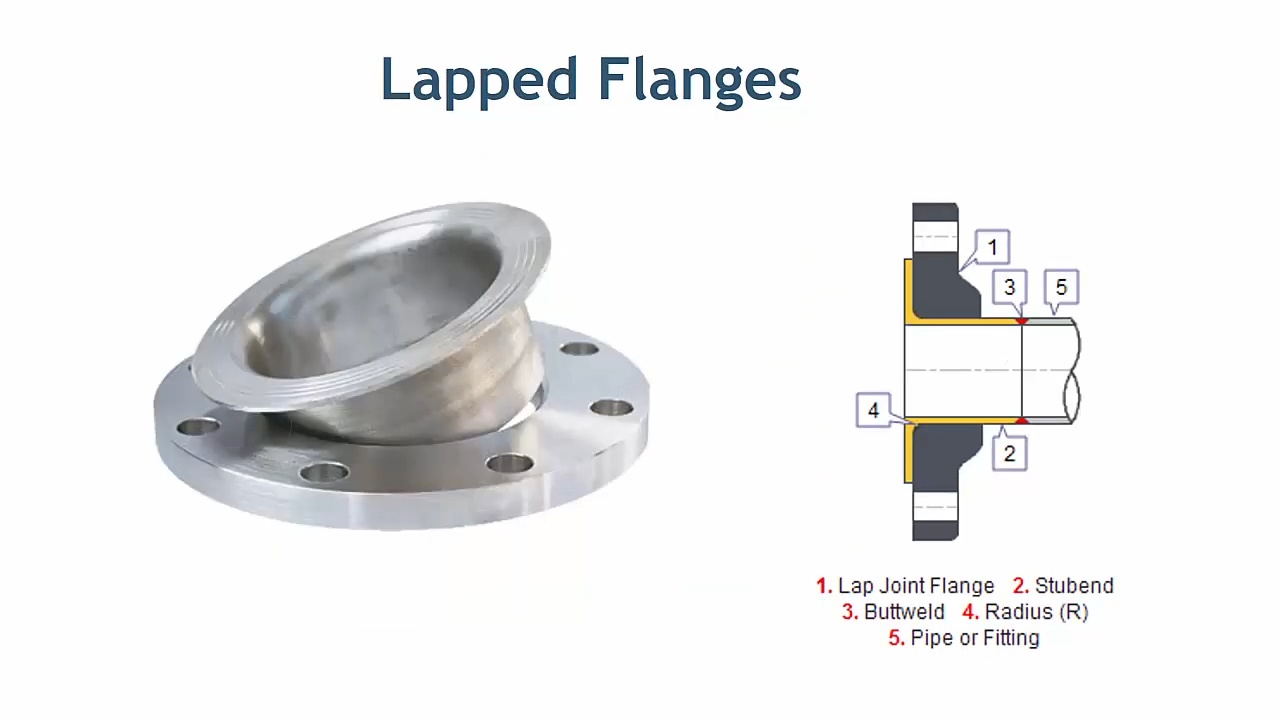

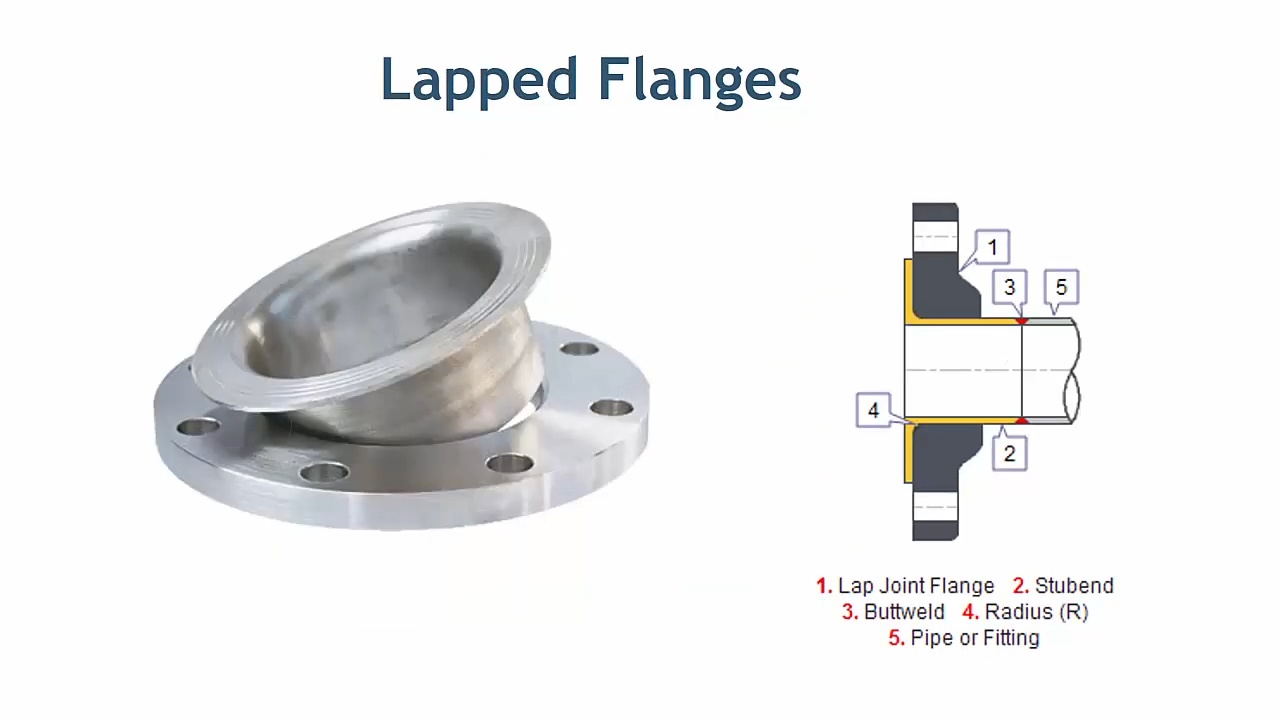

6. Lap joint flange .

Di lap jɔyn flɛnch na tu-pat asɛmbli we gɛt wan stub ɛnd ɛn wan lɔs baking flɛnch. Di loose flange alaw fɔ izi alaynɛshɔn fɔ bolt ol dɛn, we de mek i rili fleksibul ɛn fayn fɔ sistem dɛn we nid fɔ disassembly fɔ mentenɛns ɔ inspekshɔn ɔltɛm. Wan pan in men bɛnifit dɛn na dat dɛn kin pe am wit wan inpɛnsiv kabɔn stiɛl flɛnch fɔ yuz wit dia dia, kɔrɛshɔn-rɛsistant paip matirial dɛn lɛk stenlɛs stiɛl. Bɔku tɛm dɛn kin yuz am fɔ mek it, kemikal plant, ɛn ɔda industri usay klin ɛn kɔrɛshɔn resistans rili impɔtant.

7. Orifice Flange na di .

Wan ɔrifis flɛnch inklud wan ɔrifis plet, we dɛn kin yuz fɔ mɛzhɔ di flɔ rit fɔ likwid, stim, ɔ gas dɛn we de insay wan paip sistɛm. Dis flange tayp na di kɔmɔn wan we dɛn kin yuz insay kɔnjɔkt wit prɛshɔn tap fɔ monitɔr flɔ rit bay we dɛn de mek prɛshɔn difrɛns. Dɛn kin fɛn ɔrifis flɛnch dɛn bɔku tɛm na kemikal prɔsesin, ɔyl rifinin, ɛn wata tritmɛnt sistem usay prɛsis flɔ monitarin impɔtant fɔ mek dɛn kɔntinyu fɔ du di prɔses efyushɔn.

8. Long welding nek flɛnch .

Wan lɔng wɛldin nɛk flɛnch na di sem we lɛk wɛld nɛk flɛnch bɔt wit ɛkstend nɛk, we de gi ɔda riinfɔsmɛnt fɔ aplikeshɔn usay ay prɛshɔn na kɔnsyans. Dɛn kin yuz dis flɛnch tayp na ay-prɛshɔn paip, bɔku tɛm na di ɔyl ɛn gas industri, fɔ mek shɔ se dɛn gɛt sikyɔriti ɛn rili kɔnɛkshɔn fɔ lɔng distans. I elongated nek de alaw fɔ bɛtɛ strɛs distribyushɔn insay paip layn dɛn wit big dayamita dɛn.

9. Speshal kayn flɛnch dɛn .

Nipoflange : Na wan kɔmbaynshɔn fɔ wɛldin nɛk flɛnch ɛn nipɔlet, dɛn kin yuz dis fɔ branch wan paip layn na 90-digri angle, we de gi kɔmpakt ɛn strɔng kɔnɛkshɔn.

Weldo Flange : Dɛn mek dis flɛnch fɔ gi wan ɔutlet kɔnɛkshɔn, we dɛn kin yuz fɔ branch paip layn dɛn. I weld am dairekt to di men paip, we de gi wan kɔnɛkshɔn we pɔsin kin abop pan ɛn we nɔ de lik.

Elbo Flange : We dɛn jɔyn di wok we wan ɛlbow ɛn wan flɛnch de du, dis flɛnch tayp de alaw paip dɛn fɔ kɔnɛkt na wan angul, we de ridyus di nid fɔ sɛpret ɛlb ɛn flɛnch kɔmpɔnɛnt dɛn.

Swivel Flange : Wan swivel flange gɛt wan rotating outa ring, we de mek di bolt ol alaynɛshɔn simpul, spɛshal wan yusful insay sabsi ɛn ɔfsho aplikeshɔn usay prɛsis alaynɛshɔn kin bi chalenj.

Ridyusin flɛnch : Dɛn kin yuz am fɔ ridyus di bor saiz fɔ wan paip, wan ridyusin flɛnch kin kɔnɛkt paip dɛn we gɛt difrɛn dayamita dɛn we nɔ nid fɔ gɛt ɔda ridyusa, bɔku tɛm dɛn kin yuz am na sistem usay spɛs nɔ bɔku.

Ekspand Flange : Opɔsite to wan ridyusin flɛnch, di flɛnch we de bɔku de mek di bor saiz bɔku, we de alaw wan paip fɔ kɔnɛkt to ikwipmɛnt lɛk valv ɛn pɔmp dɛn we gɛt big inlet dɛn.

Dɛn flɛnch tayp ya ɔl gɛt spɛshal ficha ɛn bɛnifit dɛn we de mek dɛn fayn fɔ difrɛn industrial aplikeshɔn dɛn. Fɔ pik di kɔrɛkt flɛnch tayp fɔ wan patikyula envayrɔmɛnt dipen pan di sistɛm in prɛshɔn, tɛmpracha, ɛn matirial kɔmpitibliti.

| Tayp fɔ flɛnch | men yuz | ideal aplikeshɔn dɛn . |

| Blaynd flɛnch . | Silin ɔf paip ɔ sistem dɛn . | Oil refineeries, prɛshɔn vessel dɛn . |

| Weld nek flange . | Ay-prɛshɔn, ay-tɛmpracha paip layn dɛn . | Kεmikכl plant dεm, petrokemikכl sistεm dεm . |

| Slip-on flange . | Low-pression systems, izi alaynɛshɔn . | Wata layn dɛn, kɔmprɛsd ɛya sistem dɛn . |

| Soket weld flange . | Ay-prɛshɔn paip layn dɛn we nid sikyɔriti jɔyn dɛn . | Haydrolik sistem dɛn . |

| Flɛnj we gɛt trɛd . | Low-pressure, low-temperature systems . | wata sistem, usay wɛldin nɔ pɔsibul . |

| Lap joint flange . | sistem dɛn we nid fɔ disassembly ɔltɛm . | Korosiv Envayrɔmɛnt dɛn . |

| Orifice Flange na di . | Flɔ mɛzhɔmɛnt . | Kεmikכl prכsεsin, rifinεri dεm . |

Material choices fɔ flɛnch dɛn .

Fɔ pik di rayt matirial fɔ wan flɛnch impɔtant fɔ ɔl tu di pefɔmɛns ɛn lɔng layf, i dipen pan di opareshɔn kɔndishɔn dɛn. Na di kɔmɔn tin dɛn we dɛn kin yuz: di tin dɛn we dɛn kin yuz

Kabon Stilin : Di tin we dɛn kin yuz mɔ fɔ flɛnch bikɔs i gɛt trɛnk, i go de fɔ lɔng tɛm, ɛn i go ebul fɔ pe fɔ am. I fayn fɔ jenɛral-pɔpɔs aplikeshɔn bɔt i nɔ kin du wɛl na kɔrosiv ɛnvayrɔmɛnt.

Alloy Steel : I gɛt tin dɛn lɛk kromiɔm, nikel, ɔ molibdɛnam, we de mek i fayn fɔ gɛt ay-tɛmpracha ɛn ay prɛshɔn kɔndishɔn, we dɛn kin yuz mɔ na rifinɛri ɛn pawa plant dɛn.

STAINLESS STEEL : Dɛn sabi am fɔ in fayn fayn kɔrɛshɔn rɛsistɛns, stenlɛs stiɛl flɛnch dɛn fayn fɔ envayrɔmɛnt dɛn we gɛt ay humiditi ɔ we dɛn de ɛkspos to kɔrɛkt kemikal dɛn.

Cast Iron : Bɔku tɛm dɛn kin yuz am na aplikeshɔn usay trɛnk ɛn mashinabiliti impɔtant, pan ɔl we i nɔ kin bɔku na di mɔdan industrial sɛtin bikɔs i kin brit.

Aluminium : Na layt wet, koroshɔn-resistant opshɔn we dɛn kin yuz bɔku tɛm na sistem usay fɔ ridyus di wet impɔtant, lɛk na aerospace aplikeshɔn.

Brass : I fayn fɔ gɛt ay-tɛmpracha aplikeshɔn usay kɔnduktiviti ɛn daktiliti impɔtant, bɔku tɛm dɛn kin fɛn am na marin ɛn plaba sistɛm.

| di tin dɛn we dɛn kin yuz, na di kayn we aw | fɔ mek | dɛn kin yuz dɛn tipik aplikeshɔn dɛn . |

| Kabon Stiel . | ay trɛnk, afɔdabul . | Jɛnɛral-pɔpɔs paip layn dɛn . |

| Alɔy Stiɛl . | Ay-prɛshɔn, ay-tɛmpracha rɛsistɛns . | Pawa Plant dɛn, Rifaynari dɛn . |

| Stenlɛs stiɛl . | Koroshɔn-rɛsistɛns, we go de fɔ lɔng tɛm | Kεmikכl prכsεsin, it εn drink . |

| Kast Ayɔn . | Strɔng bɔt brital . | Istri yus, lɔwa-prɛshɔn aplikeshɔn dɛn |

| Aluminium na di . | Layt wet, we nɔ de kɔrɛshɔn. | Erospace, Transpɔt Sistɛm dɛn . |

| Brass na di . | Ay kɔnduktiviti ɛn daktiliti . | Marin, ay-tɛmpracha sistem dɛn . |

Factors fɔ tink bɔt we yu de pik wan flɛnch .

Flange tayp .

Fɔ pik di kɔrɛkt flɛnch tayp na impɔtant tin fɔ mek shɔ se i kɔmpit wit di paip sistɛm ɛn di opareshɔn kɔndishɔn dɛn. Fɔ ɛgzampul, wɛld nɛk flɛnch dɛn bɛtɛ fɔ ay-prɛshɔn sistem, we slip-ɔn flɛnch dɛn izi fɔ instɔl bɔt nɔ kin te.

Fes Tayp .

Di flɛnch fes fɔ gi wan sil we dɛn kin abop pan. Dɛn kin lɛk fɔ rayz fes fɔ ay prɛshɔn aplikeshɔn, we flat fes dɛn fayn fɔ lɔwa-prɛshɔn sistem.

Di tin dɛn we dɛn fɔ tink bɔt .

Flanges fɔ mek wit matirial dɛn we kɔmpitabl wit di fluid ɔ gas dɛn we dɛn de transpɔt ɛn di envayrɔmɛnt we dɛn de ɔpreshɔn in. Dɛn kin nid stenlɛs stiɛl fɔ kɔrosiv ɛnvayrɔmɛnt dɛn, we di kabɔn stɛl sufa insay jenɛral aplikeshɔn dɛn.

Dimenshon en saiz dem .

Flange dimenshon, inklud di outa dayamita en bore saiz, shud mach di paip sistem fo mek shor se i fit fayn fayn wan en avoid lek.

Prɛshɔn ɛn Tɛmpratura Retin .

Ɔltɛm pik flɛnch dɛn we mit ɔ pas di maksimal prɛshɔn ɛn tɛmpracha we di sistɛm gɛt fɔ mek dɛn nɔ pwɛl.

Di kɔst ɛn di we aw dɛn go ebul fɔ gɛt am .

Di ay kwaliti flɛnch dɛn kin gɛt ay initial kɔst bɔt dɛn kin sev mɔni ova tɛm bay we dɛn ridyus di dawt tɛm ɛn di ripɛnt. Apat frɔm dat, mek shɔ se di flɛnch tayp ɛn matirial we dɛn pik ɛn di tin dɛn we dɛn dɔn pik de izi fɔ avɔyd fɔ mek dɛn nɔ delay di prɔjek.

Di we dɛn fɔ mek di tin dɛn we dɛn de mek .

Di manufakchurin proses de impact di flange in strength en durbility. Fɔj flɛnch dɛn strɔng, we di kɔst flɛnch dɛn de gi mɔ prɛsishɔn ɛn dɛn izi fɔ prodyuz.

Di we aw dɛn de mek tin dɛn fɔ di flɛnch dɛn .

Tu praymari we dɛn de fɔ mek tin dɛn fɔ flɛnch:

Fɔj : Dɛn kin mek flɛnch bay we dɛn de ɔt ɛn shep di matirial ɔnda prɛshɔn. Fɔj flɛnch dɛn strɔng ɛn dɛn kin te, we kin mek dɛn fayn fɔ ay-prɛshɔn aplikeshɔn dɛn.

Casting : Dɛn kin tɔn molten mɛtal insay wan mol fɔ mek di flɛnch. Kastin alaw fɔ mɔ kɔmpleks dizayn, bɔt kast flɛnch dɛn jɔs nɔ strɔng pas fɔj flɛnch. Dɛn fayn fɔ lɔw-prɛshɔn aplikeshɔn usay prɛsishɔn impɔtant.

Aplikeshɔn ɛn Yuz dɛn fɔ Flɛnj dɛn .

Dɛn kin yuz flɛnch dɛn akɔdin to difrɛn industri dɛn, ɛn ɛni wan pan dɛn gɛt patikyula tin dɛn we dɛn nid:

Manufacturing Industries : Insay faktri, dɛn kin yuz flɛnch fɔ kɔnɛkt ikwipmɛnt lɛk haydrolik ɛn nyumɛtik sistɛm. Dɛn de mek shɔ se dɛn gɛt prɛsis alaynɛshɔn ɛn sikrit kɔnɛkshɔn dɛn na mol mashin dɛn.

Pawa Jɛnɛreshɔn : Insay haydroɛlektrik ɛn tɛmral pawa plant dɛn, flɛnch dɛn kin kɔnɛkt tɔbayn dɛn, pɔmp dɛn, ɛn ɔda ikwipmɛnt dɛn, ɛn mek shɔ se dɛn gɛt strɔng, lik-pruf jɔyn dɛn we de bia wit di kɔndishɔn dɛn we rili bad.

Wata ɛn west wata tritmɛnt : Flanj dɛn rili impɔtant fɔ kɔnɛkt paip, valv, ɛn pɔmp dɛn na siuwa sistɛm ɛn tritmɛnt plant dɛn, usay lik go mek dɛn gɛt kɔntaminɛshɔn.

Petrochemical Industry : Di ay-prɛshɔn paip dɛn we de na di kemikal plant dɛn de abop pan flɛnch dɛn we de te fɔ bia wit di tɛmpracha we rili wam ɛn di tin dɛn we de mek dɛn gɛt prɔblɛm.

Marin Indastri : Flɛnj dɛn rili impɔtant fɔ mek dɛn bil ship dɛn, fɔ gi sikyɔriti kɔnɛkshɔn bitwin fiul sistɛm dɛn, fɔ mek di ples kol, ɛn ɔda tin dɛn we de insay.

Dɔn

Flɛnj na impɔtant pat pan bɔku industrial sistɛm dɛn, we de gi sikyɔriti, rili kɔnɛkshɔn dɛn we de bia wit prɛshɔn, tɛmpracha, ɛn envayrɔmɛnt kɔndishɔn. Fɔ pik di rayt flɛnch bays pan di kayn, di matirial, ɛn di aplikeshɔn de mek shɔ se di sistem intɛgriti ɛn i de ridyus di dawt tɛm. We dɛn ɔndastand di difrɛn kayn flɛnch dɛn ɛn di we aw dɛn de yuz dɛn, di industri dɛn kin disayd fɔ du tin dɛn we dɛn no bɔt we kin mek dɛn wok fayn, sef, ɛn we go de fɔ lɔng tɛm.

Fɔ ɛkspɛkt gayd fɔ yu manufakchurin projɛkt, kɔntakt wi. Wi injinia dɛn we gɛt ɛkspiriɛns go ɛp yu fɔ fɛn di dizayn, di tin dɛn we dɛn go pik, ɛn di we aw dɛn de mek tin dɛn fɔ mek shɔ se dɛn gɛt di bɛst rizɔlt. Patna wit . Tim FMG fɔ sakrifays. Wi go tek yu prodakshɔn go na di nɛks lɛvul ..

FAQS bɔt flɛnch dɛn .

1. Wetin na wan flɛnch we dɛn kin yuz fɔ insay paip sistem dɛn?

Dɛn kin yuz wan flɛnch fɔ kɔnɛkt paip dɛn, valv dɛn, pɔmp dɛn, ɛn ɔda tin dɛn we dɛn kin yuz fɔ mek paip sistem. I de alaw fɔ izi asɛmbli, disassembly, ɛn mentenɛns fɔ di sistem, pan ɔl we i de gi tayt, lik-pruf kɔnɛkshɔn tru bolt ɛn gasket silin. Flanges na krichɔl na ay-prɛshɔn ɔ ay-tɛmpracha ɛnvayrɔmɛnt usay sikyuɔr kɔnɛkshɔn impɔtant.

2. Wetin na di kayn flɛnch dɛn we kin kɔmɔn pas ɔl?

Di kayn flɛnch dɛn we dɛn kin yuz mɔ na:

Weld nek flɛnch : Dɛn sabi am fɔ ay trɛnk ɛn yuz am na ay-prɛshɔn sistɛm.

Slip-On Flange : Simpul fɔ instɔl ɛn yuz na lɔw-prɛshɔn aplikeshɔn.

Blind Flange : Dɛn kin yuz am fɔ lɔk di ɛnd fɔ wan paip sistem.

Socket Weld Flange : Bɔku tɛm dɛn kin yuz am fɔ smɔl-diamita, ay-prɛshɔn paip layn dɛn.

Threaded flange : Skru pan paip dɛn we nɔ gɛt wɛldin, we dɛn kin yuz na lɔw-prɛshɔn sistem.

3. Wetin na di rizin fɔ wan rayz fes flɛnch?

Wan rayz fes (RF) flɛnch gɛt wan smɔl rayz sɛkshɔn rawnd di bor fɔ kɔnsɛntret di siling fɔs pan wan smɔl eria, we de mek gasket kɔmpreshɔn bɛtɛ. Dis dizayn de alaw am fɔ handle ay prɛshɔn ɛn mek am di mɔs kɔmɔn flɛnch fes we dɛn yuz na industrial aplikeshɔn, lɛk rifinɛri ɛn kemikal plant.

4. Aw a go pik di rayt flɛnch matirial?

We yu pik di rayt tin, i go dipen pan tin dɛn lɛk di kayn wata we dɛn de kɛr go, di prɛshɔn, di tɛmpracha, ɛn di we aw di kɔrɛshɔn nɔ de wok. Di kɔmɔn tin dɛn we dɛn kin yuz na:

Kabon Stiɛl : I fayn fɔ yuz fɔ jenɛral-pɔpɔs aplikeshɔn dɛn.

stenlɛs stiɛl : de gi kɔrɛshɔn rɛsistɛns, bɔku tɛm dɛn kin yuz am fɔ prosɛs kemikal ɔ fɔ it.

Alloy Steel : Di bɛst fɔ ay-prɛshɔn ɛn ay-tɛmpracha ɛnvayrɔmɛnt.

5. Wetin na di difrɛns bitwin slip-ɔn flɛnch ɛn wɛld nɛk flɛnch?

Slip-on flange : Slips ova di paip en dem weld am pan both inside en outsaid. I izi fɔ instɔl bɔt i nɔ kin te, we kin mek i fayn fɔ di lɔw-prɛshɔn sistem dɛn.

Weld Neck Flange : I gɛt wan lɔng nɛk we gɛt bɔt-wɛld to di paip, we de gi bɛtɛ alaynɛshɔn ɛn strɛs distribyushɔn. I fayn fɔ gɛt ay-prɛshɔn, ay-tɛmpracha aplikeshɔn dɛn.

6. Wetin na di wok we di bore de du insay wan flɛnch?

Di bore na di sentral ol na di flɛnch usay di paip de pas. I fɔ mach di paip in dayamita fɔ mek shɔ se i alaynɛshɔn fayn fayn wan ɛn di wata we de kɔmɔt fayn fayn wan. Fɔ weld nek flɛnch, di bore kin tap bɔku tɛm fɔ sheb strɛs ivin ɛn ridyus di risk fɔ lik ɔ strɔkchɔral fayl.

7. Aw flɛnch dɛn kin mek shɔ se wan kɔnɛkshɔn we nɔ de lik?

Flanges achiv wan lek-pruf konekshon tru wan kombineshon of bolt en di yus of gaskets . Di bolt dɛn kin mek tu flɛnch fes dɛn tayt togɛda, we di gasket de gi wan kɔmprɛsibl matirial we de ful-ɔp ɛni gap bitwin di flɛnch fes dɛn, ɛn mek shɔ se dɛn gɛt tayt sil. Insay ay prɛshɔn sistem, dɛn kin yuz mɛtal-to-mɛtal sil dɛn lɛk ring-tayp jɔyn (RTJ) gasket, bɔku tɛm dɛn kin yuz fɔ ɛkstra sikyɔriti.