Pikirili ye fɛn dilanni fɛɛrɛ ye min bɛ kɛ ka caya, min bɛ tiɲɛni caman ɲini. Ni o tɛ, yɔrɔ dɔw tiɲɛniw ni jɔli musakabaw bɛ kɛ. Nin wale in yɔrɔ koloma dɔ ye Guide bushing ye, min bɛ kɛ sababu ye ka nɔgɔw labɛn ka ɲɛ, ka tiɲɛniw bali ani ka fɛn dilannenw cogoya sabati.

Nin sɛbɛn in kɔnɔ, an bɛna guide bushings jɔyɔrɔba sɛgɛsɛgɛ san 2019 kɔnɔ. Pikirili molida . Aw bɛna u ka baarakɛcogo, u ka fɛnw, u dilanni ani u ka dɛmɛ don u ka baara kɛcogo ɲuman na. Ni aw ye u nafa faamuya, aw bɛ se ka mɔni kɛcogo ɲɛ ani ka aw yɛrɛ tanga kow ma minnu bɛ kɛ ɲɔgɔn fɛ fɛn dilanni na.

Guide bush ye mun ye?

Guide bush, min bɛ wele fana ko guide pin bushing walima guide manche, o ye fɛn nafamaba ye pikiri kɛcogo la. O ye bolokɔni silinda ye min bɛ sigi pikirijikɛlan tilancɛ kelen na, a ka c’a la, a bɛ kɛ a tilancɛ jɔlen ye walima a 'a-side'. Guide bush kuntilenna fɔlɔ ye ka ɲɔgɔndɛmɛ tigitigi ni bilasirali kɛ ka ɲɛsin mouli tilancɛ ma min bɛ lamaga walima 'B-side' min bɛ kɛ ka mɔni da wuli ani ka a datugu.

Guide bushes jɔyɔrɔ pikirijikɛlanw na .

Guide bugunw bɛ baara fɔlɔ fila kɛ pikiri kɛcogo la:

Alignment : U bɛ moule mouvement tilancɛ (b-side) ɲɛminɛ, k’a lajɛ a bɛ bɛn dafalen ma ni tilancɛ jɔlen ye nɔgɔ dadon ni a dabɔli waati.

Dɛmɛn : Ni aw bɛ ɲɔgɔndɛmɛ ɲuman mara, ɲɛminɛlanw bɛ dɔ bɔ sɛgɛn na nɔgɔ la ani a yɔrɔw la, ka baarakɛminɛnw ɲɛnamaya bɛɛ lajɛlen caya.

Ni Guide Bush ka baara tigitigi tɛ, mɔbiliw bɛ se ka ɲɔgɔn kɛ cogo bɛnbali la, o bɛ na ni ko dɔw ye i n’a fɔ yɔrɔ dɔw tiɲɛni, u bɛ manamana, ani u tiɲɛni, o bɛ na ni jɔli musaka ye.

Jɛɲɔgɔnya min bɛ Guide Bushes ni Guide Pins cɛ .

Guide bushes and guide pins bɛ baara kɛ i n’a fɔ fila walasa ka pikirijikɛlanw baara ka ɲɛ. K’a sɔrɔ Guide Bush bɛ kanal di, guide pin bɛ don nin kanal in na, k’a lajɛ ko nɔgɔ tilayɔrɔ fila bɛɛ bɛ da ɲɔgɔn na cogo dafalen na. Jɛɲɔgɔnya min bɛ Guide Bush ni Guide PIN cɛ, o nafa ka bon kosɛbɛ teliya la, yɔrɔ minnu na hali fɛn misɛnniw bɛ se ka kɛ sababu ye ka fɛn dilanni nafabaliya sɔrɔ.

Nafa minnu bɛ sɔrɔ ka baara kɛ ni ɲɛminɛlanw ye pikiri kɛli la .

Guide bugunw jɔyɔrɔ ka bon kosɛbɛ pikiri kɛcogo ɲuman n’a kɛcogo ɲuman na. U waleyali bɛ nafa caman di, o bɛ nɔba bila sɛnɛfɛnw sɔrɔcogo la ani baarakɛcogo ɲuman na.

Yɔrɔ ɲuman ni a kɛcogo ɲuman .

Guide bushes bɛ dɛmɛba don a yɔrɔ dɔw la:

Aw bɛ a lajɛ ni nɔgɔ tilayɔrɔw bɛ bɛn ɲɔgɔn ma tigitigi .

Yɛlɛma minnu bɛ kɛ yɔrɔ hakɛw la .

Aw bɛ dɔ bɔ fiɲɛw sɔrɔli la i n’a fɔ flashing walima short shots .

Aw bɛ surface finish qualité de parts moldes .

Ni u bɛ ɲɔgɔndɛmɛ sabatilen mara molding cycle bɛɛ kɔnɔ, Guide bushes bɛ dɛmɛ ka yɔrɔw dilan ni u hakɛ tiɲɛni ye ka tɛmɛ ani ka u ɲɛnajɛ.

ka dɔ fara baarakɛcogo ɲuman kan ani ka dɔ bɔ cycle waatiw la .

Guide bushes minnu bɛ waleya ka ɲɛ, olu bɛ mɔli kɛcogo ɲɛ:

Aw bɛ nɔgɔya ka mɔli nɔgɔya ani ka da tugu .

ka baara bilali waati dɔgɔya k’a sababu kɛ ɲɔgɔndanbaliya koɲɛw ye .

Aw bɛ se ka baara teliya teliya la k’a sɔrɔ a ma jogo tiɲɛ .

Aw bɛ dɔ bɔ a la ko a ka kan ka ladilan tuma caman na a dilanni senfɛ .

O fɛnw bɛɛ lajɛlen bɛ kɛ sababu ye ka cycle waatiw surunya ani ka dɔ fara u ka baara bɛɛ kan.

Mold tiɲɛni min bɛ dɔgɔya ani mɔni ɲɛnamaya min bɛ mɛn sen na .

Guide bushes bɛ kɛ i n’a fɔ fɛnw lakanani fɛnw na:

Aw bɛ sɛgɛnbaliya bali ka sɛgɛn nɔgɔ yɔrɔw kan .

Aw bɛ degunw jɛnsɛn cogo kelen na nɔgɔ yɔrɔw cɛ .

Aw bɛ dɔ bɔ tiɲɛni farati la nɔgɔ bɔli senfɛ .

Aw bɛ yɛrɛyɛrɛli ni doni bɛnbali dɔgɔya mɔlifɛnw kan .

Ni an bɛ o tiɲɛniw nɔgɔya minnu bɛ se ka kɛ, ɲɛjiralanw bugunw bɛ nɔgɔw ka ɲɛnamaya janya kosɛbɛ ani ka dɔ bɔ ladonni wajibiyalenw na.

Baarakɛlaw ka lakana sabatili .

Guide bushes waleyali bɛ baarakɛyɔrɔ lakanani ɲɛ:

Aw bɛ dɔ bɔ nɔgɔw labɛncogo jugu farati la baarakɛtuma na .

Aw bɛ se ka fɛn minnu bɛ se ka kɛ sababu ye ka fɛnw lamaga walima ka fɛn caman wuli .

Dɔgɔyali yɔrɔ dɔw bɔli ko la .

Aw bɛ bololabaarakɛlaw ka fɛɛrɛw caya hakɛ dɔgɔya min wajibiyalen don .

O lakana yiriwaliw tɛ baarakɛlaw dɔrɔn de lakana, nka u bɛ dɛmɛ don fana ka fɛn dilanni sigida sabati min bɛ sabati ani min bɛ se ka fɔ ka ɲɛ.

Guide bushings dilanni ni u dilanni .

The design and manufacturing process of guide bushings is crucial for ensuring precision and reliability in injection molding. Nin yɔrɔ in bɛ yɔrɔ kolomaw sɛgɛsɛgɛ minnu bɛ sɔrɔ ka ɲɛsin bilasiralikanw dilanni ma minnu ka ɲi kosɛbɛ.

Material Selection .

Fɛn ɲuman sugandili nafa ka bon walasa ka busi kɛcogo ɲɛ:

Nɛgɛ gɛlɛn: A bɛ muɲuli ɲuman di ani a bɛ se ka sɛgɛn .

Baarakɛminɛnw nɛgɛw (D2, M2): Aw bɛ gɛlɛya ni hakɛ sabatiliba di .

inox: a bɛ resis corrosion in demand environments .

Bronze Alloys: Aw bɛ tulumafɛnw di u ma ani ka u don .

Fɛnw sugandili bɛ bɔ fɛnw na i n’a fɔ fɛn dilanni taabolo, doni makɔnɔnenw, ani funteni cogoyaw. Fɛn min sugandira, o ka kan ka baara kɛcogo segin-seginni muɲu ka sɔrɔ ka dimension (janya) tiɲɛni mara.

Siginiden ni a hakɛw .

Guide bushings bɛ ni silinda ye min kɔnɔna ni kɛnɛma janya tigitigiw bɛ yen. Jateminɛba minnu kɛra, olu ye:

Smooth Internal Bore for minimal friction ni guide pins .

Kɛnɛma yɔrɔ min dilanna walisa a ka se ka don nɔgɔ la .

busi ni pin cɛ, a bɛ se ka kɛ sababu ye ka ɲɔgɔn sɔrɔ tigitigi .

Dimensions (hakɛw) jatebɔlen don kosɛbɛ walasa ka guide pins walima postes bɛnninw sɔrɔ .

Lubrication features .

Lubrication ɲuman nafa ka bon kosɛbɛ walasa ka sɔgɔsɔgɔ ni a doncogo dɔgɔya:

Tuluw : masin bɛ don a kɔnɔna na walasa ka tulu minɛ .

Lubrifiant pockets: A dabɔra walasa ka a tilali nɔgɔya baara kɛtuma na .

Lubrication efficace: A bɛ funteni bɔli dɔgɔya ani ka bushing ɲɛnamaya janya .

Friction min bɛ dɔgɔya nin cogo la: A bɛ a to a ka baara kɛ ka ɲɛ ani ka a bali ka sɛgɛn ka kɔn a waati ɲɛ .

Surface furakɛli .

Surface furakɛli bɛ sɛgɛnbaliya fanga bonya ani ka ɲɔgɔnkanu dɔgɔya:

Funteni furakɛli:

Karɔti: A bɛ dɔ fara a ɲɛda gɛlɛya kan ka sɔrɔ ka a to a ka to gɛlɛya kɔnɔ .

Nitiriyali: A bɛ sɛgɛnbaliya kunbɛn ani ka dɔ bɔ ɲɔgɔnkanu na .

Induction Hardening: A bɛ sigida gɛlɛya di yɔrɔ kɛrɛnkɛrɛnnenw ma .

Surface coatings:

Tiɲɛni ni muɲuli .

Precision ye fɛnba ye Guide Bushing dilanni na:

Tolerances sirilenw: Aw bɛ a lajɛ ka ɲɛ ni ɲɛjiralanw ye ani ka a kɛ ka kɛɲɛ ni a kɛcogo ye .

A ka tiɲɛni hakɛ ka bon: a nafa ka bon kosɛbɛ walasa ka se ka mɔli tigitigiw labɛn .

Concentricity and straightness: Fɛnba minnu bɛ kɛ ka fɛnw bɛɛ lajɛlen tiɲɛni mara .

Tolerances constantes: A nafa ka bon ɲɔgɔn falen-falen na ani baara kuntaalajan na .

Masini ni finidoncogo .

Masina-fɛɛrɛw minnu bɛ taa ɲɛ, olu bɛ kɛ sababu ye ka dimension (janya) tiɲɛni ni surface (yɔrɔ) cogoya sabati:

Masini fɔlɔw:

Yɛlɛma: A bɛ silinda cogoya jɔnjɔn sigi sen kan .

Drilling: A bɛ kɔnɔna bore tigitigi dilan .

Grinding: A bɛ tolerances sirilenw sɔrɔ ani ka surfaces smooths sɔrɔ .

Finishing Operations:

Sɛgɛsɛgɛli ni jogoɲini .

Jogoɲumanya kɔlɔsili fɛɛrɛ gɛlɛnw b’a to Guide Bushing dannaya bɛ se ka kɛ:

Dimensions Measurements: Aw bɛ tolerance kofɔlenw labatoli sɛgɛsɛgɛ .

Surface quality checks: Aw ye a lajɛ ka ɲɛ walasa ka baara kɛcogo ɲuman sɔrɔ .

Gɛlɛya sɛgɛsɛgɛli: A bɛ fɛnw cogoyaw ni funteni furakɛli nafa dafa .

Sɛgɛsɛgɛli minnu bɛ kɛ ni ɲɛ ye: Aw bɛ a yɔrɔ fiɲɛ walima a dafabaliya fɛn o fɛn dɔn .

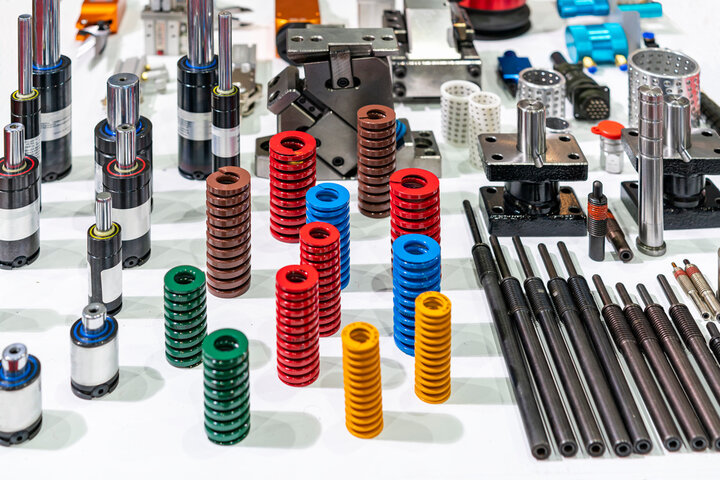

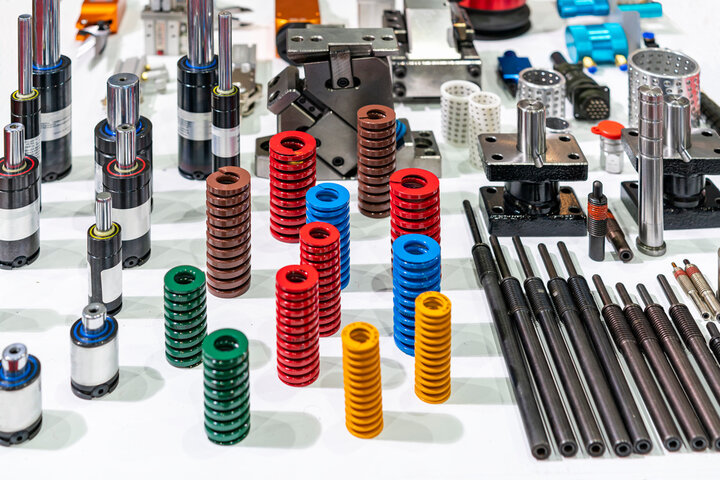

Bushing guide suguya wɛrɛw, fotoko nafolo . Prototool .

Ko minnu bɛ kɛ ni ɲɛminɛlanw ye minnu dilannen don koɲuman .

Guide bushings minnu dilannen don koɲuman, olu bɛ se ka gɛlɛyabaw lase pikiri kɛcogo ma. O ko ninnu tɛ nɔ bila yɔrɔ fanba dɔrɔn na, nka u bɛ fɛn dilanni nafa bɛɛ lajɛlen fana nɔ bila. Gɛlɛya minnu bɛ sɔrɔ, olu bɛ sɔrɔ jukɔrɔ, minnu bɛ tali kɛ ɲɛjiralanw na minnu tɛ sariya kɔnɔ.

Mold halves ka ɲɔgɔndanbaliya .

Ni bilasirali busiw ma dilan ni tiɲɛni ye, nɔgɔ tilayɔrɔw bɛ se ka ɲɔgɔn sɔrɔ cogo bɛnbali la. O ɲɔgɔndanbaliya in bɛ kɛ sababu ye ka:

Fɛnw tilatilali tɛ kelen ye : min bɛ na ni fiɲɛw ye i n’a fɔ flashw, short shots, ani cavity dafabaliya.

A sɛgɛnnen kojugu : Yɛlɛmabaliya bɛ dɔ fara sɛgɛn kan nɔgɔ la, o bɛ se ka tiɲɛni kuntaalajan kɛ.

Aw bɛ dɔ fara ɲɔgɔnkanu ni sɛgɛn kan .

Bushing min ma kɛ ka ɲɛ, o bɛ ɲɔgɔnkanu wɛrɛ lase mɔli yɔrɔw ni ɲɔgɔn cɛ. Nin ɲɔgɔndan in bɛ na ni nin ye:

Ɲɛnamaya dɔgɔyali : Ni sɛgɛn bɛ caya, o bɛ dɔ bɔ ɲɛjiralan bushing ni a lamini yɔrɔw bɛɛ ka muɲuli la.

Dimensionnel inaccuracies : Waati tɛmɛnen kɔfɛ, ɲɔgɔndan bɛ kɛ sababu ye ka deviations kɛ yɔrɔ dɔw la, o bɛ na ni fɛn dilanni ye min tɛ bɛn.

sirili walima nɔrɔli .

Guide bushings ni muɲuli juguw bɛ se ka siri walima ka nɔrɔ, o bɛ na ni:

Baarakɛcogo gɛlɛyaw : Mold tilancɛw bɛ kɛlɛ kɛ walasa ka da wuli ani ka u datugu, o min bɛ sɛnɛfɛnw bɔli taabolo tiɲɛ.

Sikili waati jan : nɔrɔli bɛ dɔ fara cycle waatiw kan, ka dɔ bɔ mouling kɛcogo bɛɛ la.

Yɔrɔ min bɛ bɔ a la ka tɛmɛ a dan kan .

Yɔrɔ min bɛ bɔ ɲɛjiralan pini ni ɲɛminɛlan cɛ, o bɛ bɔ kojugu, o bɛ basigibaliya lase mɔgɔ ma. O basigibaliya bɛ na ni nin ye:

Alignment jugu : min bɛ na ni mɔli dadonni ye min tɛ bɛn ɲɔgɔn ma ani fiɲɛ minnu bɛ se ka sɔrɔ a yɔrɔ labanw na.

Mɔli mankan ni yɛrɛyɛrɛli : Yɔrɔ lafiyalenw bɛ mankan ni yɛrɛyɛrɛli negelako tɛ, o bɛ nɔ bila nɔgɔ tiɲɛni na ka taa a fɛ.

A yɔrɔ cogoya min tɛ bɛn ɲɔgɔn ma .

Guide bushings tiɲɛnenw bɛ na ni fɛn caman ɲɔgɔnna ye a yɔrɔ ɲuman na. Ko fɔlɔw ye ninnu ye:

Dimension variations : Yɔrɔw bɛ se ka bɔ fɛn ɲɛfɔlenw na.

Aesthetics faantanw : Surface defects, finifini minnu tɛ kelen ye, walima dafabaliya yelenw bɛ se ka nɔ bila fɛn laban na cogoya la.

dɔ farala ladonni ni baarakɛbaliya kan .

Guide bushings minnu bɛ sɛgɛn joona kojugu walima minnu bɛ kɛ sababu ye ka baara koɲɛw caya, olu bɛ dɔ fara ladonni magow kan. O kɔlɔlɔw ye:

Yɛlɛma minnu bɛ kɛ tuma caman na ani dilanw : Bushings fililenw bɛ ladilanni kɛ tuma bɛɛ, ka dɔ fara baara musakaw kan.

Unplanned downtime : Ladonni walasa ka bushings dilan minnu ma dilan ka ɲɛ, o bɛ sɛnɛfɛnw bɔli waati bolodalenw tiɲɛ, ka sɔrɔw dɔgɔya.

Guide bush tiɲɛni sababuw .

Fɛn minnu bɛ kɛ sababu ye ka kungo tiɲɛni ɲɛminɛ, olu faamuyali nafa ka bon kosɛbɛ walasa ka pikiri kɛcogo ɲumanw mara. Nin yɔrɔ in bɛ Guide Bush ka tiɲɛni ni a ka dɛsɛ sababu suguya caman sɛgɛsɛgɛ.

Material qualité issues .

Fɛnw sugandili jugu bɛ nɔba bila Guide Bush ka baarakɛcogo la:

Substandard fɛnɲɛnamafagalanw bɛ se ka muɲu.

Fɛn minnu tɛ bɛn ɲɔgɔn ma, olu bɛ na ni sɛgɛn ye ka kɔn a waati ɲɛ .

Materiel fanga dafabali bɛ na ni deformation ye load jukɔrɔ .

Funteni furakɛli ni a gɛlɛya dɛsɛ .

Baara kɛcogo jugu bɛ se ka nɔba bila Guide Bush ka ɲɛnamaya janya la:

Funteni furakɛli protocoles minnu tɛ bɛn ɲɔgɔn ma, olu bɛ gɛlɛya lase mɔgɔ ma min tɛ bɛn ɲɔgɔn ma .

Surface gɛlɛya dafabaliya bɛ sɛgɛn teliya .

Furakɛli waati la, funteni bɛ se ka kɛ sababu ye ka tiɲɛni ni kari .

Fitini ni tulumafɛnw gɛlɛyaw .

Ni a ma ɲɛ ani tulumafɛnw tulumabaliya bɛ kɛ sababu ye ka tiɲɛni teliya:

Danfara min bɛ Guide Bush ni PIN cɛ, o ka ca kojugu:

Lubrication (ji bɔli) dafalen tɛ:

Design ani knife dingɛ jateminɛw .

Nafa minnu bɛ dilan na, olu bɛ se ka Guide Bush baarakɛcogo tiɲɛ:

Knife dingɛ bilali cogo bɛnbali bɛ dɔ bɔ dɛmɛ na .

degunw tilatilali jateminɛbaliya bɛ na ni dɛsɛ ye ka kɔn a waati ɲɛ .

Dilancogo jugu bɛ se ka ɲɛminɛlanw sɛmɛntiya ka kɛ jɔyɔrɔfalen fɛɛrɛw dɔrɔn ye .

sigili ni baarakɛcogo filiw .

Minɛcogo jugu sigili ni a baara kɛtuma na, o bɛ tiɲɛni kɛ:

Labɛnbaliya sigili senfɛ degunw yɔrɔw .

sirilanw minnu sirilen don kojugu, olu bɛ se ka fɛn dɔw tiɲɛni bila mɔgɔ la .

Numukɛ dadon teliya cogo bɛnbali bɛ se ka nɔ bila Guide Bush Lifespan na .

Ladonniko dɛsɛ .

Upkeepers guide bush degradation (Bugu tiɲɛni) sɔrɔbaliya:

Sɛgɛsɛgɛli minnu tɛ kɛ tuma caman na, olu b’a to ko misɛnninw bɛ se ka bonya .

Fɛn minnu sɛgɛnnen don, olu falenni waati latɛmɛni bɛ nɔ bila mɔli baara bɛɛ lajɛlen na .

Saniya ni tulumafɛnw waati bolodalenw ka teliya .

Fɛɛrɛ ɲumanw bɛ sɔrɔ Guide Bushing Maintenance la .

Guide bushings ladonni ɲuman nafa ka bon kosɛbɛ walasa u ka se ka u ka ɲɛnamaya janya ani ka pikiri kɛcogo ɲuman sabati. Ni aw ye nin wale ɲumanw ta, o bɛ se ka dɛmɛ don ka sɛgɛnbaliya bali, ka dɔ bɔ a jɔli waati la, ani ka a ka baara kɛcogo ɲuman sabati.

Sɛgɛsɛgɛli ni fɛn wɛrɛw bilali a nɔ na tuma bɛɛ .

Sɛgɛsɛgɛli kɛli tuma bɛɛ, o ye fɛnba ye walasa ka sɛgɛnw dɔgɔya ani ka ko minnu bɛ se ka kɛ joona. Ni aw ye sɛgɛsɛgɛli kɛ waati ni waati, aw bɛ se ka:

Aw bɛ sɛgɛncogo dɔn : Aw bɛ sɛgɛn taamasiɲɛ fɔlɔw ɲini sani u ka taa ni u ye nɔgɔ tiɲɛni na.

Fɛn minnu sɛgɛnnen don : Guide bushings sɛgɛnnenw falenni waati bɛnnen na, o bɛ baarakɛbaliya bali ani ka dɔ bɔ a jɔli waati la.

Sɛgɛsɛgɛliw bɛ kɛ tuma bɛɛ, o bɛ dɛmɛ ka nɔgɔ to a cogo la, ka a to a ka kɛ fɛn ye min tɛ tigɛ.

Lubrication management .

Lubrication ɲuman bɛ dɔ bɔ kosɛbɛ guide bush ni guide pin cɛ, o bɛ dɛmɛ ka tiɲɛni bali. Lubrication (jirisun) ɲɛnabɔli kɛcogo ɲumanw ye:

Baara kɛli ni tulumugu ye : Aw bɛ a lajɛ ni ɲɛjiralan bushing fɛnw bɛ sɔrɔ minnu bɛ se ka tulumafɛnw mara, ka u datugu cogo basigilen na baara kɛtuma na.

Aw bɛ tulumafɛnw kɛ tuma bɛɛ : Aw bɛ to ka tulumafɛnw kɛ bushings la walasa ka friction buildup ni u sɛgɛn bali.

Lubrication management effectif tɛ dɔrɔn ka guide bushing ka ɲɛnamaya janya, nka a bɛ a to a ka kɛ fana ko a bɛ baara kɛ ka ɲɛ.

Dimensional tiɲɛni sɛgɛsɛgɛliw .

Dimensional accuracy (hakɛ tiɲɛni) marali nafa ka bon walasa ka ɲɔgɔn sɔrɔ ani ka u labɛn ka ɲɛ. Dimensions régulières checks A b’a jira ko:

Tolerance Adherence : Ka sɛgɛsɛgɛli kɛ ko ɲɛminɛlan bushing bɛ to muɲuli kofɔlenw kɔnɔ walasa a kana kɛ cogo jugu la.

Nɔgɔ lamagacogo nɔgɔman : Aw bɛ a lajɛ ko nɔgɔ tilayɔrɔw bɛ da wuli ka u datugu ka ɲɛ, ka ko dɔw bali i n’a fɔ sirili walima nɔrɔli.

Ni aw bɛ sɛgɛsɛgɛli kɛ tuma bɛɛ dimensional accuracy kan, aw bɛ se ka aw yɛrɛ tanga fɛn dilanni koɲɛw ma minnu bɛ sɔrɔ ɲɔgɔndanbaliya fɛ walima ni u bɔli tɛmɛna.

Kuncɛli

Guide bushings jɔyɔrɔ ka bon kosɛbɛ pikiri kɛli la, ka a jira ko a bɛ kɛ ka ɲɛ ani ko a bɛ bɛn ɲɔgɔn ma. Dilancogo ɲuman ni a dilanni bɛ nɔba bila yɔrɔ jogo la kosɛbɛ ani ka mɔli ɲɛnamaya janya. U ka tiɲɛni bɛ nɔ bila fɛn dilannenw ka ɲɔgɔndɛmɛ na ani u ka baarakɛcogo ɲɛnamaya la.

Fɛn ɲumanw ladonni tuma bɛɛ ani u sugandili nafa ka bon walasa u dilanni ka ɲɛ. Ni aw bɛ bilasirali bushings to a cogo ɲuman na, o bɛ dɔ bɔ a jɔli waati la, ka a jira ko a bɛ se ka baara kɛ ka ɲɛ.

Kuma surun na, bilasirali bushingw minnu dilannen don koɲuman, olu ni ladonni kɛcogo kɔrɔlenw faralen ɲɔgɔn kan, olu ye fɛnba ye walasa ka fɛn dilanni ɲuman sabati ani ka baara musakaw dɔgɔya.