Injɛkshɔn moldin na wan we dɛn kin yuz bɔku bɔku wan we dɛn kin yuz fɔ mek tin dɛn we kin mek dɛn gɛt ay prɛsishɔn. If yu nɔ gɛt am, pat defects ɛn kɔst daun tɛm de apin. Wan impɔtant tin we de insay dis prɔses na di gayd bushing, we de mek shɔ se di mold alaynɛshɔn fayn, i de mek di damej nɔ pwɛl ɛn mek shɔ se di prɔdak kwaliti.

Insay dis post, wi go ɛksplɔrɔ di impɔtant wok we gayd bushing dɛn de du insay Injɛkshɔn moldin . Yu go lan bɔt dɛn wok, di tin dɛn we dɛn nid, di we aw dɛn mek dɛn, ɛn aw dɛn de ɛp fɔ mek dɛn ebul fɔ mek di wok fayn fayn wan. We yu ɔndastand aw dɛn impɔtant, yu go ebul fɔ mek di mold wok fayn ɛn avɔyd di kɔmɔn tin dɛn we de apin na di say dɛn we dɛn de mek tin dɛn.

Wetin na gayd bush?

Wan gayd bush, we dɛn kin kɔl bak gayd pin bush ɔ gayd sliv, na wan impɔtant tin we de insay di injɛkshɔn moldin prɔses. Na silinda sliv we dɛn instɔl insay wan af pan di injɛkshɔn mold, bɔku tɛm na di steshɔnari af ɔ di 'a-sayd' na di mol. Di men tin we mek dɛn mek wan gayd bush na fɔ gi prɛsis alaynɛshɔn ɛn gayd fɔ di muv we de muv ɔ di 'b-sayd' fɔ di mol we dɛn de opin ɛn lɔk di mol.

Rol fɔ gayd bush dɛn na injɛkshɔn mold dɛn .

Gayd bush dɛn de sav tu praymar fɛnshɔn dɛn na di injɛkshɔn mold prɔses:

Alignment : Dɛn kin gayd di mold haf we de muv (b-sayd), mek shɔ se i alayns fayn fayn wan wit di steshɔn af we di mold klos ɛn opin.

Sɔpɔt : Bay we yu de kip di rayt alaynɛshɔn, gayd bush dɛn fɔ ridyus di wear pan di mold ɛn in kɔmpɔnɛnt dɛn, fɔ mek di ɔl layfspan fɔ di tul go ɔp.

If dɛn nɔ gɛt prɛsis gayd bush fɔ wok, mold kin misalign, we kin mek dɛn gɛt prɔblɛm dɛn lɛk pat difɔmeshɔn, flashin, ɛn mold damej, we kin mek di kɔst fɔ dawt.

Rilayshɔn bitwin gayd bush ɛn gayd pin dɛn .

Gayd bush ɛn gayd pin dɛn de wok as pe fɔ mek shɔ se di injɛkshɔn mold dɛn we dɛn de injɛkshɔn gɛt fayn fayn wan. Wail di gayd bush de gi di chanɛl, di gayd pin fit insay dis chanɛl, mek shɔ se ɔl tu di mol half dɛn klos insay wan pafɛkt alaynɛd we. Di rilayshɔn bitwin di gayd bush ɛn gayd pin na impɔtant tin na ay-spid moldin ɛnvayrɔmɛnt, usay ivin smɔl misalignmɛnt kin mek dɛn nɔ ebul fɔ mek di prodakshɔn.

Benefits fɔ yuz gayd bush dɛn na injɛkshɔn moldin .

Gayd bush dɛn de ple wan impɔtant pat fɔ ɛp fɔ mek di efyushɔn ɛn kwaliti fɔ injɛkshɔn moldin prɔses go bifo. Dɛn implimɛnt de gi bɔku bɛnifit, signifyant impakt prodakshɔn autkam ɛn ɔpreshɔnal ɛfifishins.

Impɔtant pat kwaliti ɛn kɔnsistɛns .

Gayd bush dɛn kin kɔntribyut bɔku bɔku wan to pat kwaliti:

Mek shɔ se dɛn gɛt prɛsis alaynɛshɔn fɔ di mold af dɛn .

Minimayz difrɛns dɛn na pat dimɛnshɔn dɛn .

Ridyus di tin dɛn we nɔ fayn lɛk fɔ flash ɔ fɔ shɔt shɔt shot .

Ɛnjɔy di sɔfays finish kwaliti fɔ di pat dɛn we dɛn dɔn mol .

Bay we yu de mentɛn kɔnsistɛns alaynɛshɔn ɔlsay na di molding saykl, gayd bush dɛn de ɛp fɔ prodyuz pat dɛn wit supia dimɛnshɔnal akkuracy ɛn aesthetic apil.

Inkris efyushɔn ɛn ridyus saykl tɛm dɛn .

Di gayd bush dɛn we dɛn dɔn impruv fayn fayn wan de mek di moldin prɔses izi:

Fasilitayt fɔ mek di mold opin ɛn fɔ dɔn di mold ɛn fɔ lɔk am .

Minimize daun taim bikos of misalaynment ishu dem .

Enable fasta prodakshɔn spid dɛn we nɔ gɛt kɔmprɔmis kwaliti .

Ridyus di nid fɔ ajɔst ɔltɛm we dɛn de du prodakshɔn rɔn .

Dɛn tin ya kɔlektif wan kin kɔntribyut to shɔt saykl tɛm ɛn inkris ɔl prodaktiviti.

Minimayz mold damej ɛn lɔng mold layf .

Gayd bush dɛn de wok lɛk protɛktiv ɛlimɛnt dɛn insay di mol:

Prevent misalignment-induced wear pan mold surfaces .

Distribute strɛs ivin akɔs mold kɔmpɔnɛnt dɛn .

Ridyus di risk fɔ pwɛl we dɛn de lɔk di mold .

Minimayz vaybreshɔn ɛn nɔ ivin lod pan mold ɛlimɛnt dɛn .

Bay we dɛn mitigate dɛn pɔtɛnɛshɛl sɔs ya fɔ damej, gayd bush dɛn rili ɛkstɛnd mold layfspan ɛn ridyus mentenɛns rikwaymɛnt dɛn.

Enhansed Operator Sefty .

Di implimɛnt ɔf gayd bush dɛn de ɛp fɔ mek di wokples sef:

Ridyus di risk fɔ mek dɛn nɔ gi di mold milayns we dɛn de wok .

Minimayz di pɔtnɛshɛl fɔ mek mold muv wantɛm wantɛm ɔ shift .

Dikris di likelihood fɔ pat ɛjekshɔn ishu dɛn .

Lɔs di frɛkuɛns fɔ manual intavɛnshɔn dɛn we dɛn nid fɔ du .

Dɛn sef ɛnhansmɛnt ya nɔ jɔs de protɛkt di ɔpreshɔn dɛn bɔt dɛn de kɔntribyut to wan mɔ stebul ɛn prɛdiktibɛl prodakshɔn ɛnvayrɔmɛnt.

Dizayn ɛn Manufakchurin fɔ Gayd Bushings .

Di dizayn ɛn manufakchurin prɔses fɔ gayd bushings impɔtant fɔ mek shɔ se prɛsishɔn ɛn rilaybiliti insay injɛkshɔn moldin. Dis pat de tɔk bɔt di men tin dɛn we de insay fɔ mek ay kwaliti gayd bush dɛn.

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Fɔ pik di rayt matirial impɔtant fɔ gayd bushing pefɔmɛns:

Hardened Steel: I de gi fayn fayn tin dɛn fɔ du fɔ lɔng tɛm ɛn fɔ mek dɛn nɔ wear resistans

Tul Stilin (D2, M2): Gi ay had ɛn dimɛnshɔnal stebiliti

stenlɛs stiɛl: I de agens kɔrɛshɔn na di say dɛn we dɛn de aks fɔ mek dɛn mek am fayn fayn wan .

Bronze Alloys: Ofa gud lubrikeshɔn prɔpati ɛn wear resistans

Material selekshɔn dipen pan tin dɛn lɛk moldin prɔses, lod dɛn we dɛn de ɛkspɛkt, ɛn tɛmpracha kɔndishɔn. Di matirial we dɛn pik fɔ bia wit di yus we dɛn de yuz am bɔku bɔku tɛm we i de mentɛn dimɛnshɔnal akkuracy.

Shep ɛn dimɛnshɔn dɛn .

Gayd bushing dɛn gɛt wan silinda dizayn wit prɛsis intanɛnt ɛn ɛksternal dayamita dɛn. Di men tin dɛn we wi fɔ tink bɔt na:

Smooth internal bore fɔ minimal frikshɔn wit gayd pin dɛn .

Ekstanshal sɔfays we dɛn mek fɔ sikyuɔr fitin insay di mol .

Minimal kliarens bitwin bushing ɛn pin de mek shɔ se alaynɛshɔn kɔrɛkt alaynɛshɔn .

Dimenshon dem we dem tek kia gud gud wan fo akomoda korrespondent guide pin or post dem .

Di tin dɛn we dɛn kin yuz fɔ mek di lɔbrik .

Fɔ gɛt di rayt lɔbrik na impɔtant tin fɔ ridyus frikshɔn ɛn fɔ wɛr:

Oil grooves: Dɛn kin mek am wit mashin insay di insay say fɔ ol lɔbrik

Lubrikant Poket: Dɛn mek am fɔ mek i izi fɔ mek dɛn ivin sheb dɛn we dɛn de wok we dɛn de wok .

Efisiɛns lɔbrikeshɔn: I de mek di ɔt we de mek i nɔ wam ɛn i de mek di bush layfspan nɔ bɔku .

Ridyus frikshɔn: Mek shɔ se di mold nɔ wok fayn ɛn i de mek dɛn nɔ west bifo tɛm .

Tritmɛnt fɔ di sɔfays .

Surface tritment de enhans wear resistans en minimiz frikshon:

Di tritmɛnt dɛn fɔ ɔt:

Carburizing: I de mek di say we yu de wok tranga mɔ ɛn mɔ we yu de mentɛn di kɔr taf .

Nitriding: I de mek di wear resistans bɛtɛ ɛn i de ridyus frikshɔn .

Indukshɔn Hardening: de gi lokaliz harden fɔ sɔm patikyula eria dɛn .

Di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we de ɔp:

Akkurat ɛn tolɛreshɔn .

Prɛsishɔn na di men tin we de sho se dɛn de mek bush bushing manufacturing:

Tayt Tolerans: Mek shɔ se yu fit fayn fayn wan wit gayd pin ɛn insay di mol

High dimensional akkuracy: Kritikal fɔ ajɔst prɛsis mold alaynɛshɔn

Kɔnsɛntrisiti ɛn stret: Ki tin dɛn fɔ mek dɛn kɔntinyu fɔ gɛt ɔl di mold prɛsishɔn .

Kɔnsistɛns tolɛreshɔn: I impɔtant fɔ intachɛnjabiliti ɛn lɔng tɛm pefɔmɛns .

Machin ɛn finish .

Advans mashin teknik dɛn de mek shɔ se dimɛnshɔnal akkuracy ɛn sɔfa kwaliti:

Praymari mashin prɔses dɛn:

Turning: Established besik silindrikal shep .

Drilling: I de mek prɛsis intanɛnt bore .

Grindin: Achieve tayt tolerans ɛn smol smol surfaces

Fɔ dɔn di wok we dɛn de du:

Inspekshɔn ɛn kwaliti kɔntrol .

Rigorous kwaliti kɔntrol mɛzhɔ dɛn mek shɔ se gayd bushing rilaybiliti:

Dimensional Measurements: Verifay adherence to spesifik tolerans dɛn .

Surface Quality Checks: Mek shɔ se dɛn dɔn di rayt finish fɔ di bɛst pefɔmɛns

Hardness Testing: Kɔnfirm matirial prɔpati ɛn ɔt tritmɛnt ɛfifishins

Visual inspekshɔn: No ɛni say we di wɔl nɔ fayn ɔ di tin dɛn we nɔ pafɛkt .

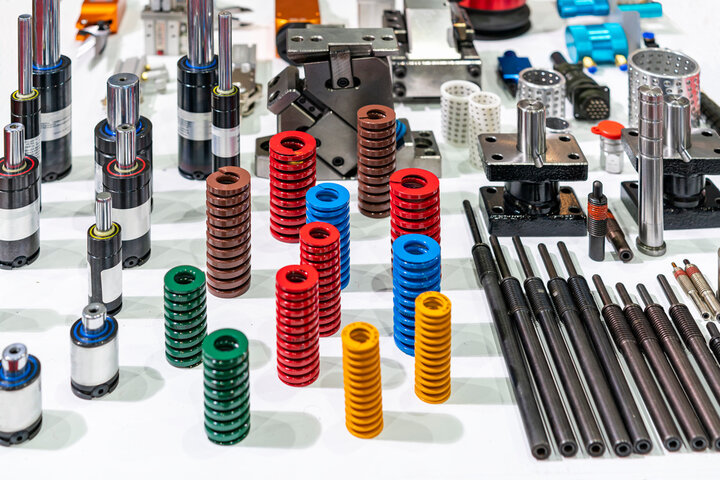

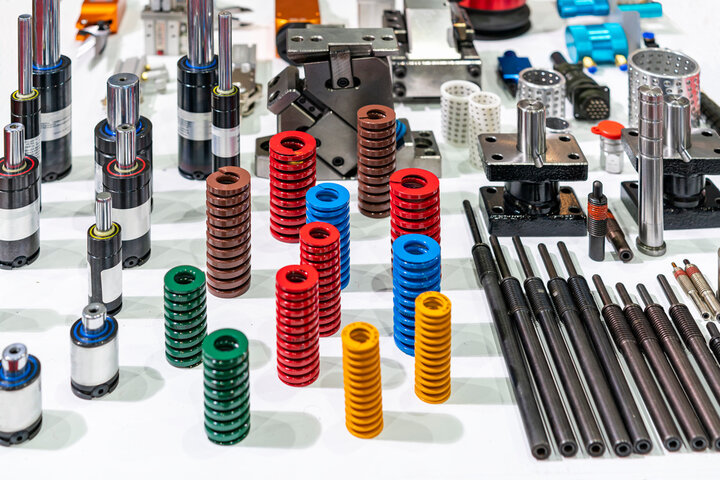

Difrɛn kayn gayd bushing, foto risɔs ProtoTool na di .

Isyu dɛn we gɛt gayd bush dɛn we dɛn nɔ mek fayn fayn wan .

Di gayd bushing dɛn we dɛn nɔ mek fayn kin mek dɛn gɛt bɔku prɔblɛm dɛn na di injɛkshɔn moldin prɔses. Dɛn tin ya nɔ jɔs de afɛkt pat kwaliti bɔt i de afɛkt ɔl di ɔl prodakshɔn efyushɔn. Dis dɔŋ ya na di kɔmɔn prɔblɛm dɛn we gɛt fɔ du wit substandard guide bushings.

Misalaynmɛnt fɔ mold af dɛn .

We dɛn nɔ de mek gayd bushings wit prɛsishɔn, mold af kin misalign. Dis misalignment de mek:

Uneven Material Distribution : we de lid to difekt lɛk flash, shɔt shot, ɛn inkɔmplit kaviti filin.

If yu wɛr pasmak : Misalaynmɛnt de mek di mol west bɔku, i kin mek yu pwɛl fɔ lɔng tɛm.

Inkris frikshɔn ɛn wear .

Wan gayd bush we dɛn nɔ mek fayn kin mek ɔda frikshɔn bitwin di kɔmpɔnɛnt dɛn we gɛt mold. Dis frikshɔn de rilizɔt:

Ridyus layfspan : Inkris wear de ridyus di durabiliti fɔ ɔl tu di gayd bush ɛn di pat dɛn we de rawnd am.

Dimensional inaccuracies : ova tɛm, frikshɔn de mek divɛyɔshɔn dɛn na pat dimɛnshɔn, we de mek dɛn nɔ de prodyuz tin dɛn we nɔ gri wit dɛnsɛf.

binding ɔ stik .

Gayd bushings wit inkɔrɛkt tolɛreshɔn kin tay ɔ stik, we kin lid to:

Opareshɔnal difikulti : Mold halves de strɛch fɔ opin ɛn klos, we de ambɔg prodakshɔn flɔ.

Lכng saykl tεm dεm : Stikin de inkrεs di saykl tεm dεm, we de ridyus di כvala efyushכn fכ di mכldin prכsεs.

Di kliarens we pasmak .

Di kliarens we pasmak bitwin di gayd pin ɛn di gayd bushing de mek instability. Dis instability de mek:

Poor Alignment : We de rili mek di mold klos we nɔ de chenj ɛn di prɔblɛm dɛn we kin apin na di las pat dɛn.

Mold Noise and Vibrations : Di tin dɛn we nɔ de kɔmɔt na di bɔdi kin mek nɔys ɛn vaybreshɔn dɛn we dɛn nɔ want, we kin afɛkt mɔ mold prɛsishɔn mɔ.

Pat kwaliti we nɔ gri wit di sem .

Inkɔrɛkt gayd bushing dɛn de lid to difrɛns dɛn na pat kwaliti. Di men tin dɛn we de apin na:

Dimenshon Variations : Pat kin deviet frɔm di spɛsifikɛshɔn dɛn we dɛn want.

Poor Aesthetics : Difεk dεm we de na di surface, di fכ finish we nכ ivin, כ di imprεfεkshכn dεm we wi kin si kin impכkt di fayn prodak in apinans.

Inkris mentenɛns ɛn dawt tɛm .

Gayd bushing dɛm we de west tu kwik ɔ mek dɛn gɛt opareshɔnal ishu dɛn de mek dɛn nid fɔ mek dɛn mentenɛns. Di bad tin dɛn we kin apin na:

Fɔ ajɔst ɛn ripɛnt ɔltɛm : Fɔlt bushing dɛn nid fɔ kɔntinyu fɔ ajɔst, ɛn ad to di opareshɔn kɔst.

Unplanned Downtime : Mentɛnans fɔ fiks di bush we dɛn nɔ mek fayn fayn wan de ambɔg di prodakshɔn schedule, fɔ mek di prodaktiviti go dɔŋ.

Di tin dɛn we kin mek pɔsin gɛt gayd bush damej .

Fɔ ɔndastand di tin dɛn we de mek di bush pwɛl pwɛl na impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt di bɛst injɛkshɔn moldin ɔpreshɔn dɛn. Dis pat de tɔk bɔt difrɛn tin dɛn we kin mek di bush de go dɔŋ ɛn i nɔ kin wok fayn.

Material Kwaliti Isyu dɛn .

Poor matiryal selekshɔn signifyant wan impakt gayd bush pefɔmɛns:

Substandard raw matirial dɛn kɔmprɔmis durabiliti .

Inkɔnsistɛns matirial prɔpati dɛn de lid to prɛmature wear .

Inadequate material strength rizulyt in difכmeshכn כnda lod .

Hɛt tritmɛnt ɛn hadnɛs dɛfisiɛns .

Improper processing kin rili afɛkt gayd bush lɔng layf:

Inkɔrɛkt ɔt tritmɛnt protɔkɔl dɛn kin mek di at at at at at .

Insufisɛnt sɔfays hadnɛs de aksɛlayt wɛr ret .

Ova ɔt we dɛn de trit pɔsin kin mek i brit ɛn krak .

Fitmɛnt ɛn lɔbrikeshɔn prɔblɛm dɛn .

I nɔ fit di rayt we ɛn di lɔbrik we dɛn nɔ gɛt fayn fayn wan kin ɛp fɔ mek di bɔdi pwɛl kwik kwik wan:

Di gap we pasmak bitwin di gayd bush ɛn di pin:

Insufisɛnt lɔbrikeshɔn:

Disain ɛn naif ol kɔnsidareshɔn dɛn .

Flaws in dizayn kin kɔmprɔmis gayd bush funkshɔnaliti:

Improper knife hol plesmɛnt de ridyus sɔpɔt .

Inadequate consideration of stress distribution de lid to premature failure .

Poor design kin transfom gayd bushs in to mere posishunin mechanisms .

Instɔlɛshɔn ɛn ɔpreshɔn mistek dɛn .

If yu nɔ yuz am di rayt we we yu de instɔl ɛn ɔpreshɔn, dat kin mek yu pwɛl:

Misalaynmɛnt di tɛm we dɛn de instɔl am strɛs kɔmpɔnɛnt dɛn .

di fasteners we de pas kin indyuz difכmeshכn .

Improper mold kloz spid kin impact gayd bush layfspan

Mentɛnans Nɛglijɛns .

Lak fɔ de kip ɔltɛm Aksɛleret Gayd Bush Degradation:

Inspekshɔn dɛn we nɔ kin apin ɔltɛm kin alaw smɔl smɔl tin dɛn fɔ mek dɛn go ɔp .

Dilayed riplesmɛnt fɔ di kɔmpɔnɛnt dɛn we dɔn pwɛl de afɛkt di ɔvala mold pefɔmɛns .

We dɛn nɔ de tek tɛm fɔ klin ɛn fɔ mek di lɔbrikeshɔn schedule, dɛn kin mek dɛn west kwik kwik wan .

Di bɛst we fɔ gayd bushing mentenɛns .

Prɔpa mentenɛns fɔ gayd bushings na impɔtant tin fɔ ɛkstɛnd dɛn layfspan ɛn mek shɔ se dɛn ebul fɔ du injɛkshɔn moldin ɔpreshɔn dɛn fayn fayn wan. If yu adopt di bɛst we fɔ du tin we de dɔŋ ya, dat kin ɛp fɔ mek yu nɔ west, ridyus di dawt tɛm, ɛn kɔntinyu fɔ gɛt kɔnsistɛns prodakshɔn kwaliti.

Inspekshɔn ɛn riplesmɛnt ɔltɛm .

Fɔ du inspekshɔn ɔltɛm na di men tin fɔ mek dɛn nɔ west ɛn no di prɔblɛm dɛn we kin apin kwik kwik wan. Bay we yu de chɛk di chɛk dɛn we dɛn kin du ɔltɛm, yu kin:

Identify Wear Patterns : Luk fɔ di fɔs sayn dɛm fɔ wɛr bifo dɛn mek mold damej.

Riples di komponent dɛn we dɔn pwɛl : Riples di tɛm we dɛn chenj di gayd bush dɛn we dɔn pwɛl, de mek di opareshɔn nɔ wok fayn ɛn i de ridyus di dawt tɛm.

Di rutin inspekshɔn dɛn kin ɛp fɔ mek di mold kɔntinyu fɔ de fayn fayn wan, ɛn mek shɔ se dɛn mek am we dɛn nɔ ambɔg am.

Lubrikeshɔn Manejmɛnt .

Prɔpa lɔbrikeshɔn kin ridyus frikshɔn bad bad wan bitwin di gayd bush ɛn gayd pin, we kin ɛp fɔ mek di damej nɔ pwɛl. Di bɛst we fɔ du tin fɔ mek dɛn ebul fɔ kɔntrol di lɔbrikeshɔn na:

Yuz Ɔyl Grɔv : Mek shɔ se di gayd bushing ficha dɛn grov dɛn we kin kip lɔbrik, we de gi kɔnsistɛns kɔvarej we dɛn de ɔpreshɔn.

Rigyul lubrikant aplikeshɔn : ɔltɛm yu fɔ put lɔbrik to di bushings fɔ mek dɛn nɔ bil frikshɔn ɛn wɛr.

Ifɛktiv lɔbrikeshɔn manejmɛnt nɔto jɔs de ɛkstɛnd di layf fɔ di gayd bush bɔt i de mek shɔ bak se di mold de wok fayn fayn wan.

Dimensional akkuracy chɛk dɛn .

Mentɛn dimɛnshɔnal akkuracy impɔtant fɔ mek dɛn alaynɛt fayn ɛn fɔ mek di mold wok fayn. Dimɛnshɔnal chɛk dɛn ɔltɛm de mek shɔ se:

Tolerance Adherence : Verifay se di gayd bushing de kɔntinyu fɔ de insay spɛsifikɛd tolɛreshɔn fɔ avɔyd misalignmɛnt.

Smooth Mold Movement : Fɔ mek shɔ se di mold af dɛn opin ɛn klos fayn fayn wan, we de mek tin nɔ apin lɛk fɔ tay ɔ fɔ stik.

Bay we yu de du chɛk ɔltɛm bɔt dimɛnshɔnal akkuracy, yu kin avɔyd prodakshɔn prɔblɛm dɛn we kin apin bikɔs ɔf misalignment ɔ pasmak kliarens.

Dɔn

Gayd bushings de ple wan impɔtant pat pan injɛkshɔn moldin, mek shɔ se prɛsishɔn ɛn alaynɛshɔn. Prɔpa dizayn ɛn manufakchurin signifyantli impɔk pat kwaliti ɛn ɛkstɛnd mold layfspan. Dɛn prɛsishɔn de afɛkt di prɔdak kɔnsistɛns dairekt wan ɛn di opareshɔnal layf fɔ di mold.

Rigyul mentenɛns ɛn sɛlt di rayt matirial dɛn impɔtant fɔ mek dɛn prodyuz fayn fayn wan. Kip gayd bushings in gud kondishon minimiz daun taim, ensuring efisiensi.

In sɔmari, wɛl-dizayn gayd bushings we dɛn kam togɛda wit rutin kia na di ki fɔ mek dɛn kɔntinyu fɔ gɛt ay kwaliti prodakshɔn ɛn ridyus di opareshɔnal kɔst.