Plastiki . pikiri kɛli ye fɛɛrɛ jɔnjɔn ye walasa ka yɔrɔw dilan minnu bɛ se ka kɛ ka ɲɛ. Nka mun de b’a ka ɲɛtaa bila sen kan? Moule core ani cavité. O yɔrɔw bɛ kɛ fɛnw ye minnu dilannen don ni fɛn dilannenw ye.

Nin sɛbɛn in kɔnɔ, i bɛna a dɔn cogo min na, a kɔnɔna ni a kɔnɔna bɛ baara kɛ ɲɔgɔn fɛ, mun na u nafa ka bon, ani u ka danfara juguw.

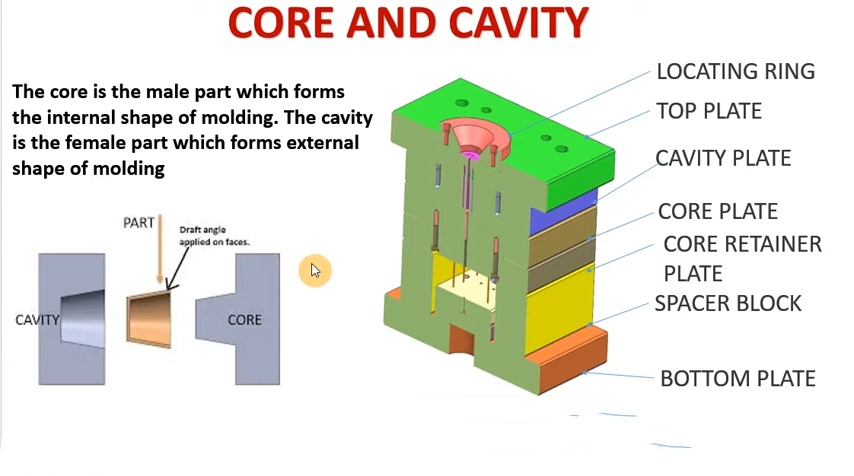

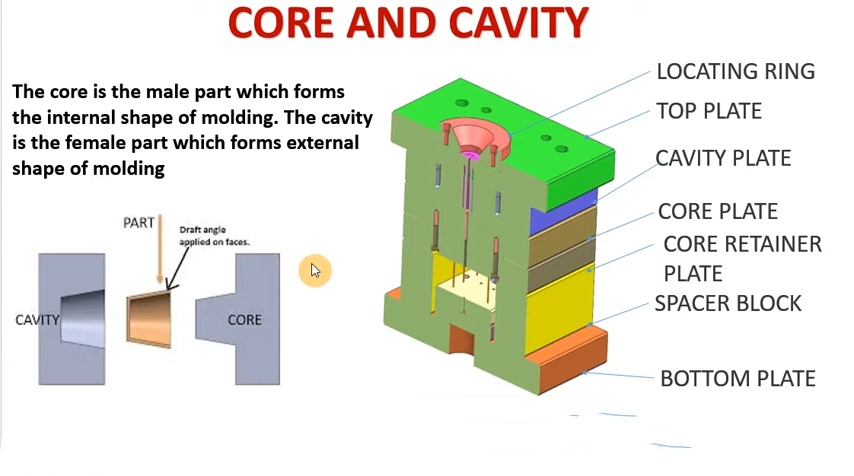

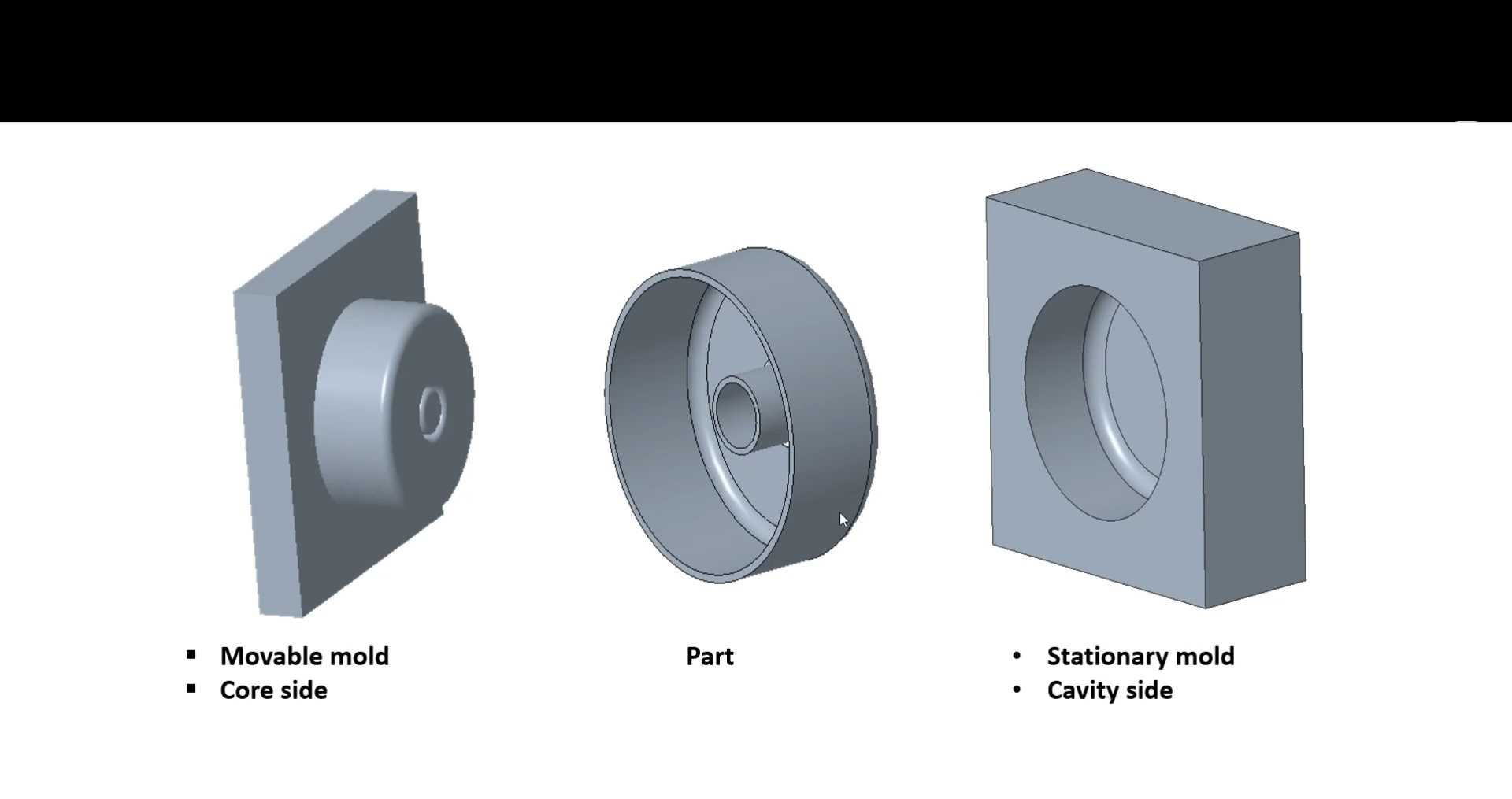

Core and Cavity: ɲɛfɔli ni jɔyɔrɔw .

A ka mold core .

Mold core bɛ pikiri kɛ yɔrɔ minnu na, olu kɔnɔna cogoyaw. A nafa ka bon kosɛbɛ dakunw ni kɔnɔna-jɔ-cogo gɛlɛnw dabɔli la. Pikiri kɛtuma na, a kɔnɔna bɛ sigi b-side of the mold kɔnɔ. A bɛ Taa ni ejector system ye, a bɛ a Jira ko yɔrɔw bɛ Bɔ ka ɲɛ nɛnɛ kɔfɛ.

Fɛn minnu bɛ sɔrɔ mɔli kɔnɔ, olu kan:

Foroko kɔnɔna ni a ɲɛfɔli .

A ka c’a la a bɛ dilan ni nɛgɛ gɛlɛn ye .

Aw bɛ masina tigitigi de wajibiya walasa ka tiɲɛni kɛ .

A ka ca a la, nɛnɛ siraw bɛ sɔrɔ a la walasa a dilanni ka teliya .

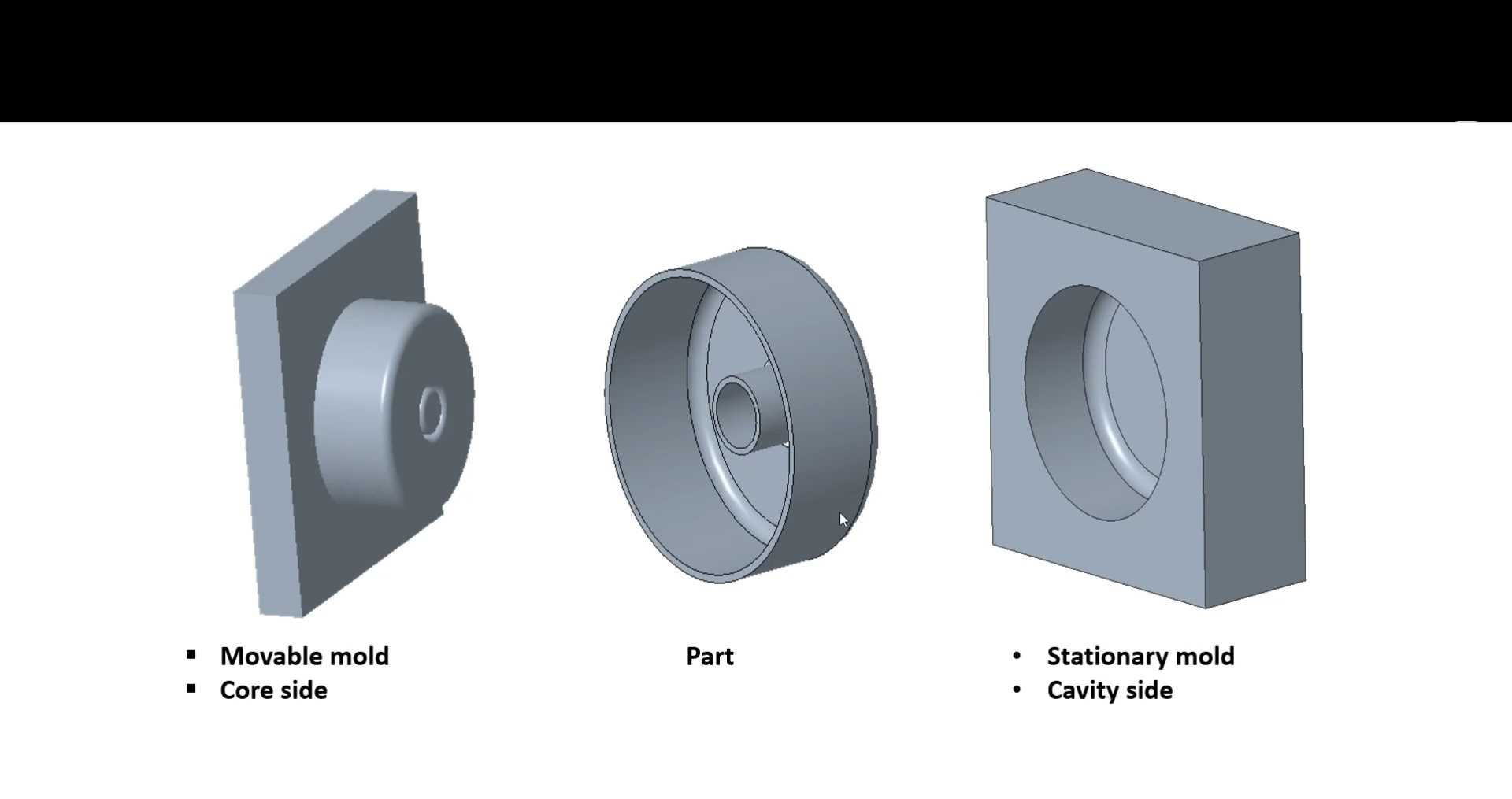

A ka mold cavity .

Mold cavities bɛ yɔrɔ mɔlenw kɛnɛmafɛnw ɲɛfɔ. U bɛ kɛnɛma ɲɛnajɛw ni u hakɛw ɲɛnabɔ. Kɔnɔnatumuw bɛ to u jɔyɔrɔ la A-kɛrɛ fɛ, u dilanni waati. U bɛ surfaces yelenw Dabɔ kiliyanw bɛ jɛɲɔgɔnya Kɛ ni minnu ye.

Ntumuw kɔnɔna nafamayɔrɔw:

Aw bɛ kɛnɛma yɔrɔw ni a kɛcogo ɲɛ .

A ka ca a la, a bɛ polisi ka kɛ fini ye min bɛ kɛ .

ka kan ka jate kɛ fɛnw dɔgɔyali la .

Aw ye gating systems (gating systems) don plastiki bolicogo la .

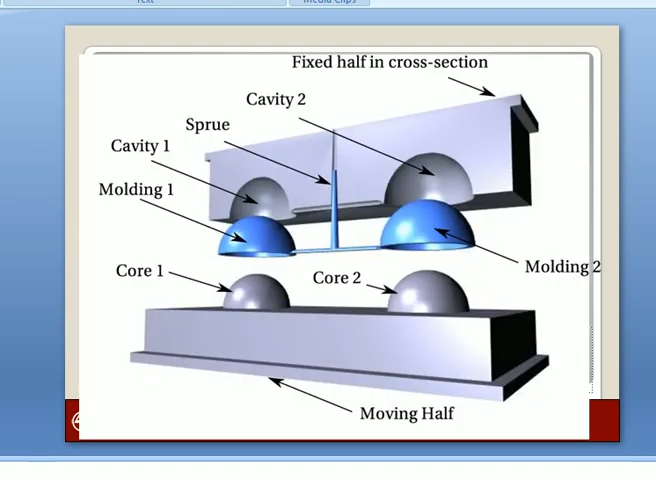

Core ni cavity bɛ baara kɛ ɲɔgɔn fɛ cogo min na .

Kooriw ni kɔnɔnatumuw bɛ fara ɲɔgɔn kan ka kɛ yɔrɔ dafalenw ye. Ni mɔni dafara, u bɛ yɔrɔ lakolon dɔ da a laban na. Plastiki mɔlen bɛ o yɔrɔ fa, ka a yɔrɔ fila bɛɛ ka fɛnw ta.

Jɛɲɔgɔnya taabolo:

Mold bɛ da tugu, ka core ni cavity bɛn .

Plastiki pikiri kɛra yɔrɔ min na .

Materiel bɛ nɛnɛ ani ka solidifies .

Mold bɛ da wuli, core bɛ lamaga ni ejector system ye .

A yɔrɔ dɔw bɛ bɔ, ka cogoyaw mara ka bɔ core ni cavity fila bɛɛ la .

Moulu ni a kɔnɔnatumu suguyaw .

Cores ni cavities fixes .

Kɔnɔw ni kɔnɔnatumuw jɔlenw ye pikirijikɛlanw jɔli jusigilan ye. U bɛ To u jɔyɔrɔ la sɛnɛfɛnw dilanni taabolo bɛɛ la.

Standard cores ani cavities .

Olu ye fɛn jɔnjɔnw ye minnu dilannen don ni nɛgɛ gɛlɛn ye. U dabɔra ka ɲɛsin fɛn dilanni boli janw ma ani a yɔrɔ cogoya basigilen.

Core/cavité nɔgɔman .

A bɛ kɛ yɔrɔw ye minnu cogoya tilennen don. U ka ɲi kosɛbɛ fɛnw ma minnu kɔnɔna na, fɛn gɛlɛnw tɛ u la.

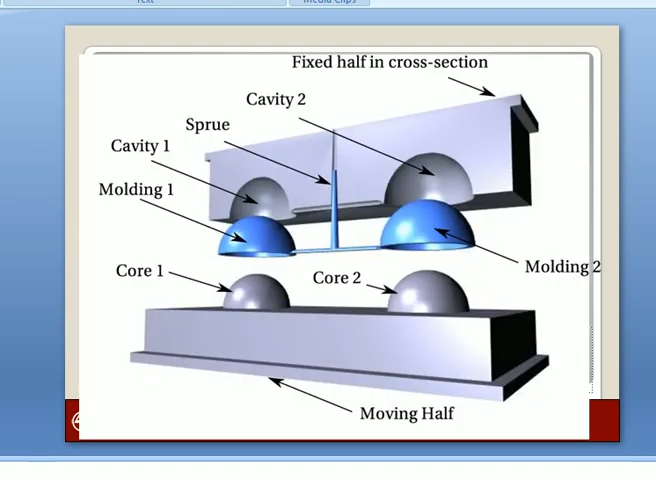

Multi-Core/Cavité .

O mɔli ninnu bɛ yɔrɔ caman Bɔ 'sèn kelen na. U bɛ dɔ fara sɛnɛfɛnw dilanni nafa kan nka u bɛ dilancogo ɲuman de wajibiya walasa ka facogo ɲuman sɔrɔ.

Kooriw ni kɔnɔnatumuw bɛ se ka ɲɔgɔn falen .

Fɛn minnu bɛ se ka ɲɔgɔn falen-falen, olu bɛ fɛn caman sɛgɛsɛgɛ u dilanni na. U bɛ sira di fɛn caman Changements rapides ma ani fɛn dilannenw caman ɲɔgɔnna.

Kooriw ni kɔnɔnafɛnw minnu bɛ se ka falen .

Olu bɛ se ka ɲɔgɔn falen-falen walasa ka yɔrɔw dilanni suguya wɛrɛw dilan. U bɛ dɔ bɔ baarakɛminɛnw musakaw la fɛn dilannenw denbayaw ye.

Sliding cores ani cavities .

U bɛ Taa-ka-segin mɔli kɔnɔ walasa ka fɛn gɛlɛnw Dabɔ. Sliding components nafa ka bon yɔrɔw la minnu bɛ ni undercuts walima side details ye.

Aw bɛ kooriw ni kɔnɔnatumuw don .

Olu bɛ kɛ ka fɛn kɛrɛnkɛrɛnnenw dilan walima ka fɛnw don u kɔnɔ minnu dilannen don ka kɔn. U bɛ kɛ ka caya ka kɛ fɛnw ye minnu bɛ don walima ka kɛ fɛn kɛrɛnkɛrɛnnenw ye.

collapsible cores .

Kooriw minnu bɛ se ka wuli, olu nafa ka bon kosɛbɛ yɔrɔw la minnu kɔnɔna bɛ kɛ ni kɔnɔnafɛnw ye walima yɔrɔ gɛlɛnw ye minnu kɔnɔna ka gɛlɛn. U bɛ 'kontra Kɛ k'a To yɔrɔ dɔ ka Bɔ yen, o kɔ fɛ u bɛ Fàra ɲɔgɔn kan 'sènfɛ-sɛbɛnni nata kama.

Nafa jɔnjɔnw:

A bɛ se ka kɛ sababu ye ka yɔrɔw dilan minnu tɛ se ka kɛ ni koro jɔlenw ye .

Aw bɛ jiginni waatiw dɔgɔya .

Yɔrɔw cogoya ɲɛ ka ɲɛ dilancogo dɔw la .

Kooriw ni kɔnɔnatumuw bɔli kɛnɛ kan .

O yɔrɔw bɛ Yɛlɛma ka yɔrɔw Bɔ ni fɛnw ye minnu bɛ Kɛ ni jiri ye. U nafa ka bon walasa ka juruw, fɛnw, ani o ɲɔgɔnna fɛnw dilan.

Nafaw:

Designing moule cores ani cavities .

Fɛn minnu bɛ kɛ ka fɛnw dilan .

Moule cores ni cavities ɲumanw dilanni bɛ fɛn caman jateminɛ kosɛbɛ:

Part geometry (Jimɛtiri): Siginiden gɛlɛnw bɛ core (koro) tigitigi ni cavity (kɔnɔw) dilancogo de wajibiya.

Fɛnw sugandili: Plastiki suguya wɛrɛw bɛ fɛn kɛrɛnkɛrɛnnenw ni finiw de wajibiya.

Shrinkage: Jatebɔ kɛ fɛnw dɔgɔyali kan walasa ka u hakɛ jateminɛ.

Angles de draft: Angles proprées bɛ nɔgɔya yɔrɔ bɔli nɔgɔya.

Ejection system: Labɛnni ka ɲɛsin yɔrɔw bɔli ma ka ɲɛ ni tiɲɛni tɛ.

Cooling System: Optimiser cooling channels for constant part quality.

Dilancogo ɲɛfɔli .

Aw ye nin laadilikan ninnu labato walasa ka mɔli core ni cavity dilancogo ɲɛnabɔ:

Uniform mur thickness .

Aw bɛ a janya basigilen mara a yɔrɔ bɛɛ la.

A bɛ warping, sink marks, ani cooling (nɛnɛma) bali.

Angles de draft propre .

Radii ni Fillets .

Venting ni gating .

Gɛlɛyaw ni furakɛlicogo

| minnu bɛ | kɛ ɲɔgɔn fɛ . |

| Undercuts . | Aw bɛ baara kɛ ni sliding cores ye walima inserts collapsibles . |

| Kogo finmanw . | Kaskade walima gating sequentiel waleyali . |

| welda zana . | Aw bɛ da yɔrɔw ɲɛnabɔ ani ka funteni wuli . |

| Sink marks . | Aw bɛ nɛnɛbɔlan ni kogo janya ladilan . |

Materiel sugandili ka ɲɛsin core ani cavity ma .

Nafa min bɛ sɔrɔ fɛnw sugandili la .

Fɛn minnu bɛ se ka kɛ ka mɔli kɔnɔna ni kɔnɔnatumuw sɔrɔ, olu sugandili nafa ka bon kosɛbɛ. A bɛ nɔ bila fɛn dilanni ɲɛnamaya la ani a dilanni musakaw bɛɛ lajɛlen na. Sugandili ɲuman bɛ a to a bɛ se ka muɲu, ka a tiɲɛ, ani ka musaka bɔ.

Fɛn minnu bɛ kɛ ka caya .

Fɛn caman ka di mouli kɔnɔna ni a kɔnɔna na:

P20: nɛgɛ suguya caman ni masina ɲuman .

738 : Nafolo minnu ɲɛnabɔra P20 kan .

Nak80: A ka ɲi kosɛbɛ ka ɲɛsin politiki caman ma .

2316: A ka ɲi kosɛbɛ plastiki nɔgɔlenw na .

2344: A bɛnnen don ka kɛ fɛn caman dilanni ye .

Production volume jateminɛw .

Fɛnw sugandili bɛ danfara ka kɛɲɛ ni u dilanni hakɛ ye:

Sɛnɛfɛnw dilanni hakɛ caman bɛ jo di wari bilali ma fɛn sɔngɔ gɛlɛnw na. U bɛ mɔni ɲɛnamaya janya ani ka musaka kuntaalajanw dɔgɔya.

Fɛn minnu bɛ kɛ ni fɛnw ye minnu bɛ se ka kɛ .

Ni aw bɛ fɛnw sugandi, aw ye nin jogo ninnu jateminɛ:

| jogo | nafama . |

| Aw bɛ resistance don . | prolongs moule ɲɛnamaya . |

| Toughness . | A bɛ chipping ni cracking bali . |

| Polishing properties . | A bɛ se ka surface finish ɲininen sɔrɔ . |

| gɛlɛya . | A bɛ deformation kɛlɛ degun kɔrɔ . |

Aw bɛ resistance don .

Fɛn minnu bɛ ni sɛgɛnba ye, olu bɛ hakɛ tiɲɛni mara waati kɔnɔ. U nafa ka bon kosɛbɛ sɛnɛfɛnw dilanni na.

Toughness .

Fɛn gɛlɛnw bɛ se ka degunw muɲu minnu bɛ kɛ ka segin-ka-bɔnyew kɛ. U bɛ dɔ bɔ nɔgɔ bɔli la ka kɔn a waati ɲɛ.

Polishing properties .

Fɛn dɔw bɛ polisi ka ɲɛ ka tɛmɛ dɔw kan. O nafa ka bon kosɛbɛ yɔrɔw la minnu bɛ finiw ɲini minnu bɛ kɛnɛya kosɛbɛ.

gɛlɛya .

Fɛn minnu ka gɛlɛn, olu bɛ se ka fɛn dɔw tiɲɛ pikirijikɛlan degun na. U bɛ yɔrɔ jɛlen mara nka u bɛ se ka gɛlɛya ka tɛmɛ masin kan.

Mold Core ani Cavity ka fɛn dilanni taabolo .

1. Fɛnw labɛnni .

O baara bɛ daminɛ ni fɛnw ni baarakɛminɛnw ye minnu bɛnnen don. Nin sen in nafa ka bon kosɛbɛ walasa ka nɔgɔw cogoya ni u ɲɛnamaya janya.

2. Laadalata ka sɛnɛfɛnw sɛnɛcogo .

Fɔlɔ cogoya bɛ tali kɛ:

O baara ninnu de ye mɔli jɔcogo jusigilan ye.

3. CNC masinw .

Tigɛ gɛlɛn bɛ kɔnɔna ni kɔnɔna cogoya jɔnjɔn ɲɛfɔ. CNC fɛɛrɛ bɛ tiɲɛni ni baarakɛcogo ɲuman sabati nin waati in na.

4. Funteni furakɛli .

Nin sen in bɛ dɔ fara a ka baara kan:

A bɛ se ka muɲu .

Aw bɛ resistance don .

Dimensions sabatili .

Funteni furakɛli nafa ka bon walasa ka nɔgɔw ka ɲɛnamaya janya.

5. Grinding and Finishing .

Precision grinding bɛ se ka kɛ:

6. CNC ka finiw .

Baara minnu ka ɲi kosɛbɛ, olu dɔw ye:

Fine detail tigɛ .

Ja min bɛ kɛ .

Text application .

O fɛɛrɛ ninnu bɛ fɛn nafamaw fara ɲɔgɔn kan ka ɲɛsin nɔgɔ yɔrɔw ma.

7. Fila tigɛ .

Wire EDM bɛ cogoya gɛlɛnw dilan i n’a fɔ:

Lifter Holes .

Ejector Pin Slots .

Contours intricates .

8. Kuran bɔli masin (EDM) .

EDM ka fisa ni a dilanni ye:

Fine grooves .

Slots fitininw .

Cavities tigitigiw .

A ka ɲi kosɛbɛ fɛnw na minnu ka gɛlɛn ka masina kɛ cogo la.

9. Mold Polishing .

Surface fini laban bɛ tali kɛ:

10. Lajɛba .

Nin yɔrɔ in na, nin yɔrɔ in ye:

A lajɛcogo ɲuman bɛ mɔli baara ɲuman sabati.

11. Kɔrɔbɔli Molding .

Moli dafalen kɔrɔbɔli bɛ kɛ ni nin ye:

Nin sen laban in b’a jira ko mɔni labɛnnen don ka bɔ.

Mold core ni cavité (dawolo) kɛcogo wɛrɛw pikiri kɛcogo la .

Pikiri kɛcogo bɛ kɛ ni jɛɲɔgɔnya ye min bɛ kɛ ka ɲɛ, min bɛ kɛ ka ɲɛsin fɛn dilannen kɔnɔna ni a kɔnɔna cɛ. Nin ɲɔgɔndan in faamuyali nafa ka bon kosɛbɛ walasa ka pikiri kɛcogo dafalen minɛ.

Taabolo fɔlɔ : pikiri .

Plastiki granules bɛ don yɔrɔ datugulen na min bɛ dilan ni mold cavity ye. Nin yɔrɔ in, n’o ye koro ni kɔnɔna tigitigi ye, o bɛ fɛn laban cogoya ɲɛfɔ.

Fɛn minnu ye nin ye:

Taabolo 2nan : nɛnɛ ni sodification .

Mold core bɛ bɛn kosɛbɛ ni kɔnɔna ye nin waati in na. Ni plastiki bɛ ka nɛnɛ, a bɛ core-cavity faralen ɲɔgɔn kan cogo tigitigi ta.

Fɛn nafamaw:

funteni jiginni ka bɔ plastiki la ka taa foroko la .

Material bɛ dɔgɔya dɔɔni .

A yɔrɔ bɛ daminɛ ka gɛlɛya .

Taabolo 3nan : Moli dacogo ni a bɔli .

Solidifié kɔfɛ, mold core bɛ taa ka taa. Fɛn min bɛ sɔrɔ, sisan a jɔlen don, o bɛ bɔ a kɔnɔna na ka tɛmɛ bɔli sira fɛ.

Taabolo kunnafoni:

Mold opens .

core retracts .

Ejector pins active .

Yɔrɔ dɔw bɔra Core .

Mold Cavity ka jɔyɔrɔ .

O senfɛ-seereyaw bɛɛ la, nɔgɔ-yɔrɔ bɛ to jɔyɔrɔ la. A bɛ yɔrɔ in ka kɛnɛmafɛnw ɲɛfɔli yɔrɔ sabatilen Di.

Cavity baarakɛcogo:

Nin dɔnkilidacogo in bɛ yɔrɔw dilanni sabati cogo basigilen na, min ka ɲi kosɛbɛ. Koori ni kɔnɔna cɛ jɛɲɔgɔnya ye fɛnba ye pikiri kɛcogo ɲɛnabɔli la.

Degun danfara minnu bɛ muɲu ni u kɔnɔna ni u kɔnɔna ye .

Moli kɔnɔna ni a kɔnɔna bɛ degun hakɛ caman sɔrɔ pikiri kɛli waati la. O danfara ninnu bɛ nɔba bila yɔrɔ jogo ni mɔni janya la kosɛbɛ.

Moule cavité: zone de présure haute .

O yɔrɔ bɛ degunba muɲu kun caman kosɔn:

Aw bɛ a lajɛ ka mɔli dafa ka ɲɛ .

A bɛ fɛn dilannenw kɔnɔna sigicogo dafalen mara .

A bɛ fɛnw tiɲɛni musaka bɔ .

Fɛn minnu bɛ sɔrɔ cavity pressure kan:

Ka se PSI ba caman ma .

A bɛ danfara ka kɛɲɛ ni fɛnw ye ani a yɔrɔ dilanni .

A bɛ nɔ bila Surface Finish ani Dimensional Accuracy .

Mold Core: Degun dɔgɔya yɔrɔ .

O ni ɲɔgɔn cɛ, a kɔnɔna bɛ degunw muɲu. A ka baara fɔlɔw ye :

Fɛn min bɛ kɛ ka fura in bɔ kɛnɛ kan .

Ka a jira ko a yecogo dafalen don .

Facilitating part release .

Degun jɔnjɔnw jateminɛ:

A ka ca a la a ka dɔgɔn ka tɛmɛ cavity pressure kan .

A sinsinnen bɛ kɛnɛmafɛnw kan .

A bɛ nɔ bila surface quality ani detail reproduction .

Tansiyɔn jatebɔ tabali

| mɔli yɔrɔ | tansiyɔn hakɛ | baara fɔlɔ . |

| cavité . | Jamanjan | Kɔnɔna sigicogo dafalen . |

| Kìsɛ | Ka lajigin | Kɛnɛma yecogo dafalen . |

O degun danfara ninnu faamuyali nafa ka bon kosɛbɛ:

Mold design propré .

Material Selection .

Ladonni bolodacogo .

Baarakɛcogo sɛrɛkili ni ladonni kɛcogo danfara bɛ sɔrɔ nɔgɔw kɔnɔna ni u kɔnɔna cɛ .

Mold Cavity: Ladonni magow ka bon .

Nɔgɔ bɛ degunba la pikiri kɛli waati la:

O kow bɛ na ni ladonni wajibiyalenw ye ka caya:

Sɛgɛsɛgɛliw bɛ kɛ tuma bɛɛ .

Polishing waati ni waati .

A ka ca a la a bɛ se ka kɛ a nɔnabila ye .

A ka ca a la, fɛn dilannikɛlaw bɛ kɔnɔw ladonni boloda walasa ka fɛn dilannenw cogoya sabati.

Mold Core: Ladonni wajibiyalenw dɔgɔyali .

O ni ɲɔgɔn cɛ, Mold Core bɛ jɔyɔrɔ sɔrɔ min tɛ fɛn caman ɲini:

O bɛ na ni nin ye:

Ladonni sɛgɛsɛgɛliw ka dɔgɔn .

A nɔnabila ka dɔgɔn .

Ladonni musakaw bɛɛ lajɛlen bɛ dɔgɔya .

Tabali min bɛ tali kɛ ɲɔgɔn na

| , | o ye moule cavité | moule core ye . |

| Degun jirali . | Jamanjan | Ka lajigin |

| wear rate . | Teliya . | Slower . |

| Baarakɛyɔrɔ ɲɛnamaya . | A ka surun . | A ka jan . |

| Ladonni frequency . | sanfɛ . | Ka lajigin |

| A ka kan ka kɛ fɛn ye min bɛ se ka kɛ a nɔ na . | A ka ca a la . | A ka ca a la . |

nɔ min bɛ sɔrɔ sɛnɛfɛnw dilanni na .

O danfara ninnu faamuyali bɛ dilanbagaw dɛmɛ:

Labɛnni bolodacogo ɲumanw .

Budjet ka ɲɛsin fɛnw falenni ma tigitigi .

Optimiser production efficientique .

Kɔnɔnatumuw ladonni basigilen bɛ a to fura ɲumanw ka to ka caya. Ni aw tɛ to ka ladonni kolomaw kɛ, o bɛ dɔ bɔ jɔli ni musakaw la.

Fɛɛrɛ minnu bɛ kɛ ka nɔgɔw ni kɔnɔnafɛnw danfara .

Danfara min bɛ mɔni kɔnɔna ni a kɔnɔna cɛ, o nafa ka bon kosɛbɛ nɔgɔ dilanni n’a ladonni nafama na. Fɛn jɔnjɔn damadɔ bɛ dɛmɛ ka yɔrɔ kelen-kelen bɛɛ dɔn:

Yecogo

Modèle cavities bɛ jira cogoya la:

Mold cores bɛ to ka a jira ko:

Textures gɛlɛnw .

Dingɛ yelenw .

Tigɛ taamasiyɛnw .

O taamasiyɛn yetaw bɛ teliya ka dɔn a ka ca a la.

Fɛn minnu bɛ kɛ ka fɛnw jɔ .

Cavité (dadon) jɔcogo dɔw ye:

Koorilenw ka baarakɛcogo:

Parting surfaces .

Manches de moule .

Ejector Pin Holes .

girinya ni fɛnw danfara

| aspect | moule cavité | moule core . |

| Girinya | Jɛnkulu ka nɔgɔn . | A ka c’a la, a ka gɛlɛn . |

| Minɛ | A bɛ se ka sɛgɛn, a ka gɛlɛn kosɛbɛ (misali la, a bɛ kɛ ni nɛgɛ ye) . | Nɛgɛ min bɛ kɛ ka fɛnw kɛ, nɛgɛ, alifini . |

Material Choice bɛ nɔ bila a yɔrɔ kelen-kelen bɛɛ ka muɲuli n’a ka baarakɛcogo la.

taamasiyɛnw ni taamasiyɛnw .

A ka ca a la, a dilannikɛlaw bɛ baara kɛ ni taamasiɲɛ kɛrɛnkɛrɛnnenw ye:

Cavité:

'f' (kɛrɛfɛ-yɔrɔ) .

'1' (a tilancɛ fɔlɔ) .

Kìsɛ:

O taamaʃyɛnw bɛ ɲɔgɔn dalajɛ ni u ladonni taabolo nɔgɔya.

Jogoɲumanya sɛgɛsɛgɛli fɛɛrɛw mɔli kɔnɔ .

Ka a lajɛ ko mɔli kɔnɔna jogo ka bon kosɛbɛ walasa ka pikirijikɛlanw dilan minnu dilannen don tigitigi. Aw bɛ nin fɛɛrɛ ninnu tigɛ walasa ka sɛgɛsɛgɛli tigitigiw kɛ:

Mikoromɛtiri min bɛ dunuya la, o labɛnni .

Sani aw ka baara kɛ ni a ye:

Aw ye silinda danfaralen ka sɛgɛsɛgɛli lajɛ .

Aw bɛ a lajɛ ni diferential screw lamagacogo ɲuman .

Aw ye a sɛgɛsɛgɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

Sumanikɛlanw sugandili .

Calibration processus .

Aw bɛ baara kɛ ni Grade 00 plateforme ye walasa ka saniya .

Datum plane saniyalen ani sumanikɛlan .

Aw bɛ zeru jɔyɔrɔ tiɲɛni sɛgɛsɛgɛ .

Sumanikɛcogo fɛɛrɛw .

Fiyentɔw ka dingɛw ni jirisunw jugumanw kama:

Aw bɛ aw janto farikoloɲɛnajɛ la opereli waati .

Aw bɛ aw yɛrɛ tanga fanga kojugu ma .

Aw bɛ baara kɛ ni lamaga-lamagali nɔgɔmanw ye, minnu bɛ kɔlɔsi .

Sumanikɛlanw ka bon .

Ni dingɛ cɛmancɛ tɛmɛna mikromɛtiri basigilen kan:

Baara kɛ ni dɛmɛnan ye min bɛ kɛ ka mɔgɔw bila u jɔyɔrɔ la .

Aw ye aw jija ka plati saniya ani ka a kɛ fla ye .

Aw bɛ sumanikɛlan caman ta walasa ka tiɲɛni kɛ .

Sɛgɛsɛgɛli sɛgɛsɛgɛli sɛbɛn

| senfɛ | wale | nafama . |

| 1 | Aw bɛ mikromɛtiri baarakɛcogo lajɛ . | A bɛ kalan tigitigiw lajɛ . |

| 2 | Sumanikɛlan ɲuman sugandi . | Matches Sɛgɛsɛgɛli magow . |

| 3 | Saniya ani ka a jateminɛ . | A bɛ zeru point dannamɔgɔ di . |

| 4 | Aw bɛ baara kɛ ni fɛɛrɛ ɲuman ye . | A bɛ tiɲɛni bali baarakɛminɛn na ani a yɔrɔ dɔ . |

| 5 | Adapt ka ɲɛsin diamètres belebelew ma . | A bɛ se ka kɛ sababu ye ka fɛn bɛɛ suman tigitigi . |

Ladonni ni gɛlɛyaw ɲɛnabɔli .

Ladonni kɛcogo minnu bɛ kɛ tuma bɛɛ .

Mold cores ni cavities ladonni ɲuman bɛ a to a ka mɛn ani a bɛ kɛ ka ɲɛ.

Saniya ni tulumafɛnw .

Aw bɛ tolenw bɔ u dilanni boli kelen-kelen bɛɛ kɔfɛ .

Aw bɛ tulumafɛn bɛnnenw kɛ yɔrɔ lamagannenw na .

Aw bɛ saniyalanw kɛ minnu tɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye .

Sɛgɛsɛgɛli ni dilan .

Aw bɛ ɲɛnayeli lajɛ ni aw bɛ a sɛgɛn walima ni aw bɛ a tiɲɛ .

Aw bɛ hakɛw suman tuma bɛɛ .

Ko misɛnw ɲɛnabɔ joona walasa ka dɛsɛbaw bali .

Ko minnu bɛ kɛ tuma caman na ani furakɛli

| kow | ɲɛnabɔli | . |

| Ka don | Friction waati la molding . | Pologne walima yɔrɔ minnu tɔɔrɔla kokura . |

| Corrosion . | kemikorow ka waleyaw . | Aw bɛ a tangalanw kɛ . |

| Erosion . | Fɛn min bɛ kɛ ni degunba ye . | GATING SYSTEM . |

| Ka tiɲɛ | Handling walima kasaara . | A yɔrɔ tiɲɛnenw falen . |

Banakunbɛn fɛɛrɛw .

Aw bɛ mɔni ɲɛnamaya janya ni nin wale ninnu ye:

Aw bɛ baara kɛ ni fɛn bɛnnenw ye .

Optimiser cooling systems .

Venting propre (Bɔcogo ɲuman) waleyali .

Tɛrɛn baarakɛlaw ka baarakɛcogo ɲumanw na .

Mold Life Extension Tips .

Aw bɛ cycle waatiw kɔlɔsi walasa ka baara kɛcogo jugu bali .

Aw bɛ mɔlikɛlanw wuli walasa u ka se ka don u kɔnɔ hali .

Aw bɛ mɔni kɛ ka ɲɛ ni aw tɛ baara kɛ ni a ye .

Kuncɛli

Moli kɔnɔna ni a kɔnɔna nafa ka bon pikiri kɛli la. U bɛ yɔrɔw cogoya, ka u ɲɛfɔ ka ɲɛ, ka nɔ bila u dilanni na. Dilanbagaw, injiniyɛriw ani fɛn dilannikɛlaw ka kan k’u sinsin fɛnw sugandili kan, u dilanni tigitigi, ani u ladonni kan.

Dilanbagaw bɛ nafa sɔrɔ sɛgɛsɛgɛliw la tuma bɛɛ ani gɛlɛyaw ɲɛnabɔcogo minnu bɛ kɛ ka ɲɛ. O walew bɛ mɔni ɲɛnamaya janya ani ka fɛn dilanni nafa bonya.