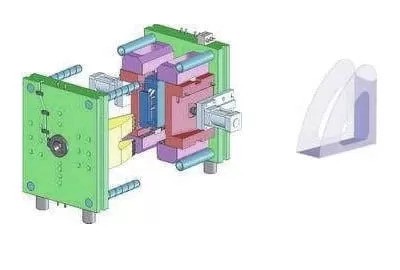

Yala i delila k’i yɛrɛ ɲininka cogo min na plastiki yɔrɔw ka gɛlɛn ni tigitigi ye wa? Pikiriw dilanni sɛgɛsɛgɛlikɛlanw de ye a kun ye. O yɔrɔ nafamaw bɛ dɛmɛ ka fɛn gɛlɛnw dilan fɛn dilannenw na, ka u dilanni nɔgɔya ani ka u kɛ ka ɲɛ. Nin sɛbɛn in kɔnɔ, aw bɛna a dɔn mun na sliderw nafa ka bon pikiri kɛcogo la ani u bɛ yɔrɔ gɛlɛnw kɛ cogo min na.

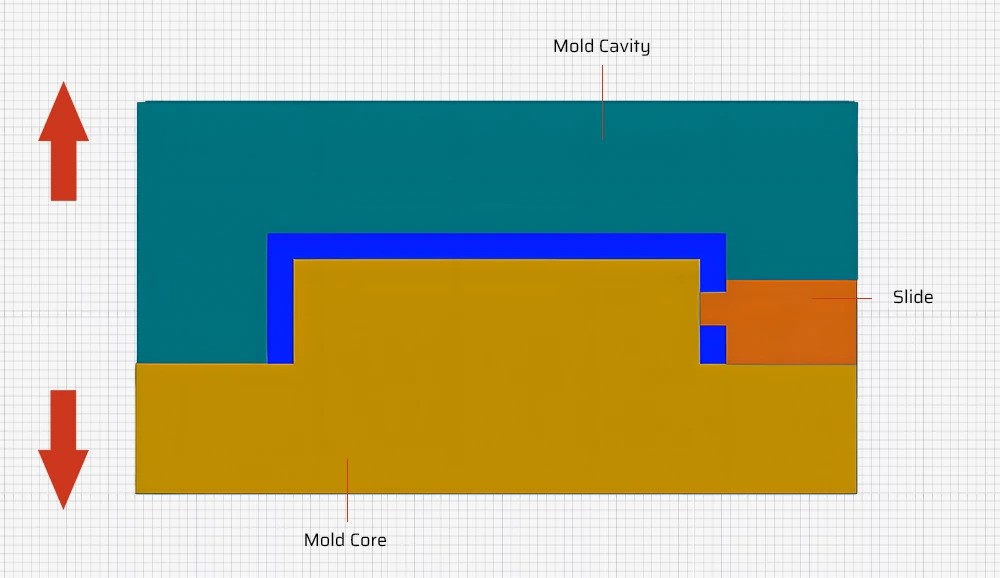

Injection molding slider ye mun ye?

Pikiri molding slider ye fɛn ye min bɛ se ka wuli ka bɔ a kɔnɔ. A bɛ sɛgɛn ka taa sira fɛ min bɛ jɔ walima ka kɛ kɛrɛ fɛ ka taa mɔli da wuli sira fɛ. O bɛ kɛ sababu ye ka dugukolo jukɔrɔla tigɛ, dingɛw, ani jirisunw da yɔrɔ la min dilannen don.

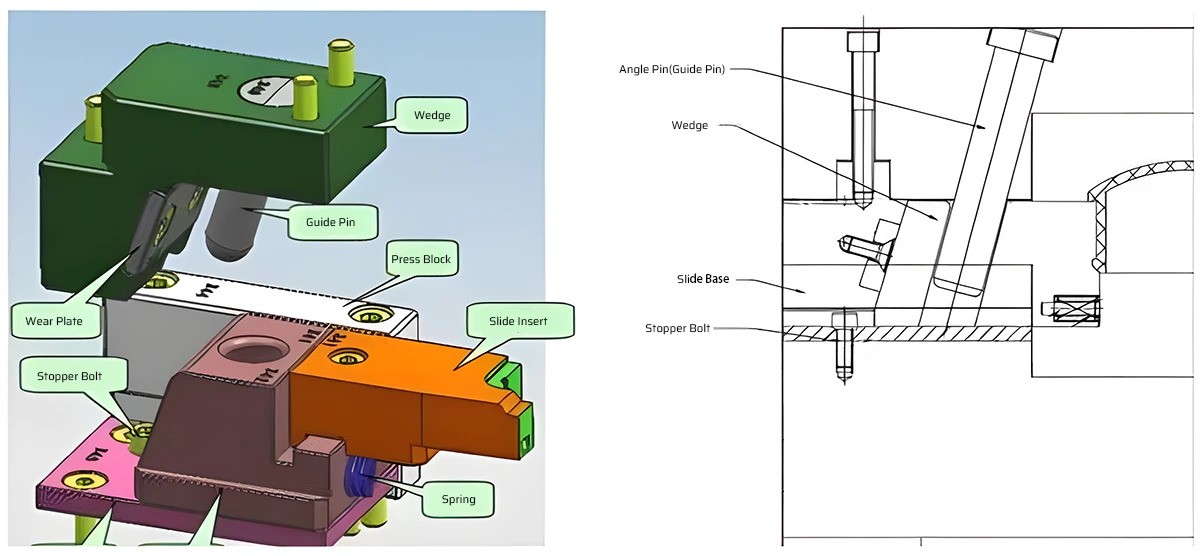

Slider (slider) sitɛmu yɔrɔ jɔnjɔnw ye:

Mun na sliderw bɛ kɛ pikiri kɛli la?

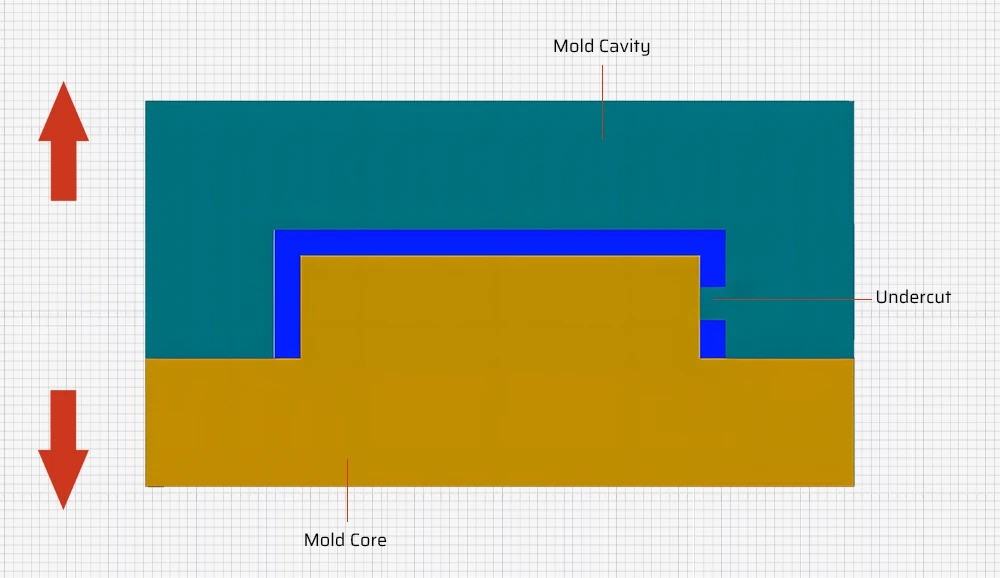

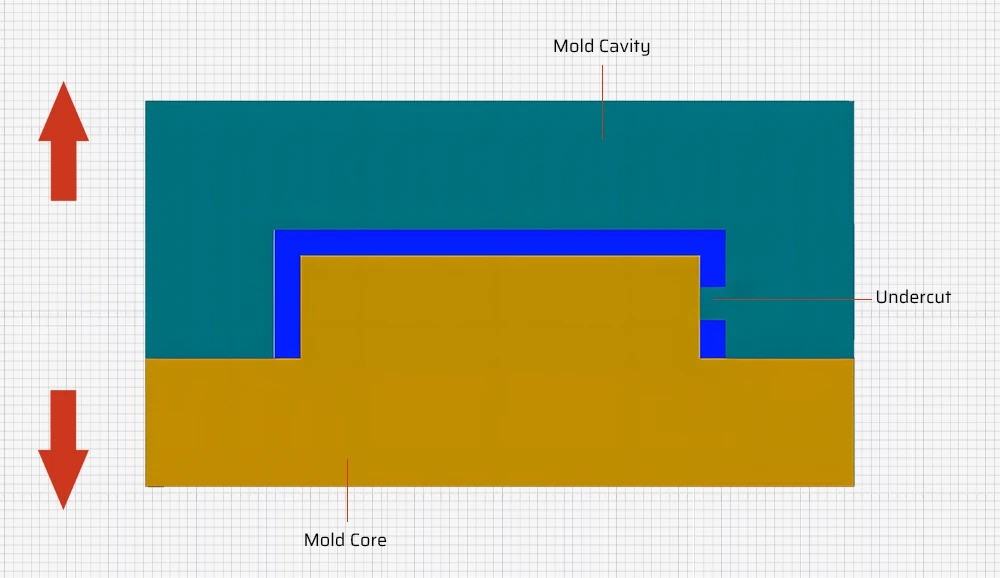

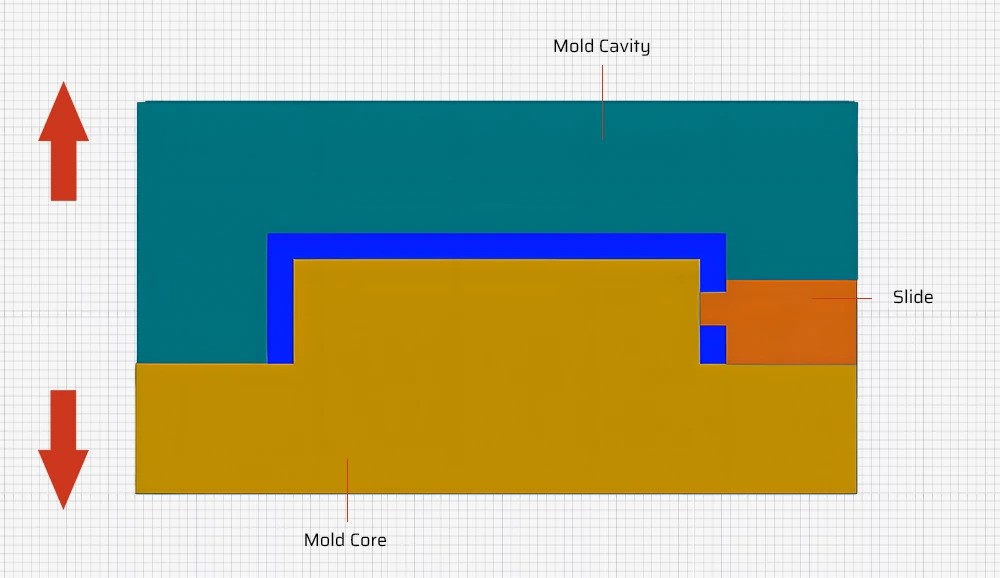

Sliders (sliders) nafa ka bon kosɛbɛ ni fɛn dilannen bɛ ni sigicogo ye min bɛ tiɲɛni kɛ ka ɲɛ k’a sɔrɔ u ma baara kɛ. u ka kan ka kɛ yɔrɔ minnu na . Undercuts ., dingɛw , walima jirisunw minnu tɛ se ka dilan ka ɲɛ nɔgɔbɔlan kɔnɔ.

Nin ye sliders nɔgɔya cogo ye ka ɲɛsin demolding smooth ma:

Mold da wuli waati la, guide angled pin bɛ slider (slider) bila.

O slider bɛ Taa kɛrɛfɛ, ka 'fɛn min bɛ 'kɔnɔna na walima min ka gɛlɛn, o Bɔ.

O b’a to yɔrɔ min dilannen don . A bɔra a la k’a sɔrɔ a ma tiɲɛni kɛ.

Ni sliderw tun tɛ yen, a tun tɛ se ka kɛ ka plastiki yɔrɔ gɛlɛn caman dilan fɛn kelen dilanni na. U bɛ mɔli jɔlen da wuli ka kɛ sɛgɛnlafiɲɛbɔ wale ye, o bɛ kɛ sababu ye ka dilancogo gɛlɛnw dilan.

Slider material ka kan ka gɛlɛya bɛnnen sɔrɔ ani ka a yɛrɛ tanga ka se ka lamaga-lamagali muɲu. A ka gɛlɛn walima a kɔnɔna yɔrɔ ka kan ka bɛn a tɔ ma . wugu.

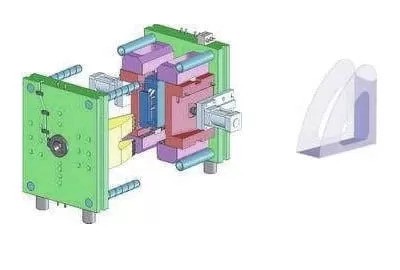

Slide sitɛmu yɔrɔw .

Pikiri mɔlikɛlanw bɛ kɛ fɛn jɔnjɔn caman ye. A yɔrɔ kelen-kelen bɛɛ jɔyɔrɔ ka bon kosɛbɛ walasa ka baara kɛ ka ɲɛ ani ka yɔrɔw labɛn minnu dilannen don ni fɛn dilannenw ye. An ka don o yɔrɔw la:

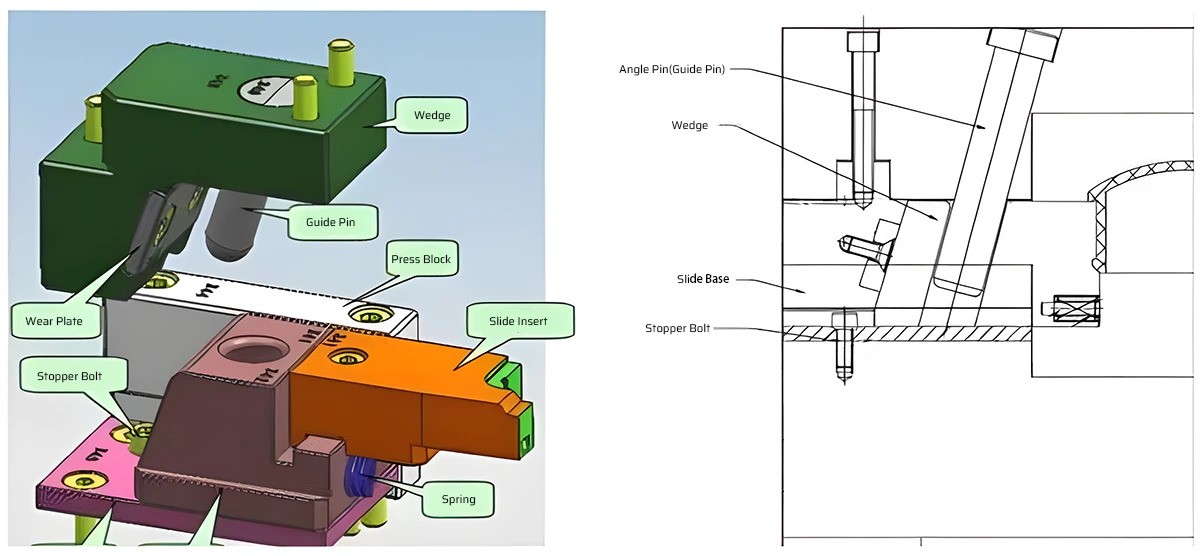

guide pin (pinɛ angle ou tron) .

Guide pin, n’a bɛ fɔ fana ko angle pin walima horn pin, o ye slide wale suguya ye min ka ca. A bɛ baara belebele fila de Kɛ:

A bɛ mold cavity kɔnɔna ni a kɛrɛ sɔrɔ .

ka dɛmɛ don ka ɲɛsin nɔgɔ ma .

Guide pin ka kan ka bila milimɛtɛrɛ 15 ni 25 cɛ fura sanfɛ. A bɛ lamaga nɔgɔya nɔgɔya mold system kɔnɔ.

Slide farikolo .

Slide farikolo ye slider mechanism dusukun ye. A bɛ yɔrɔ minnu bɛɛ Sɔrɔ sliding wale la, olu bɛɛ bɛ Sɔrɔ a kɔnɔ. Slide farikolo bɛ jɔli dɛmɛ di ani ka lamaga-lamagali jɛlen sabati.

Wear plate .

Wear plates dabɔra walasa ka dɔ bɔ ɲɔgɔn na ani ka u sɛgɛn yɔrɔw la minnu bɛ lamaga. U bɛ dɛmɛ don ka slider yɔrɔw ka ɲɛnamaya janya. O platiw bɛ baara kɛ ka ɲɛ mouding cycle caman kan.

Bloki digi .

Press block bɛ tansiyɔn ni fanga kɛ walasa ka slider baarakɛcogo ɲuman sɔrɔ. A bɛ slider sanfɛla tilancɛ dɛmɛ ani k’a ɲɛminɛ. Press block bɛ slide ni core cɛ janya mara.

Wedge .

Wedge bɛ slider (slider) degun, k’a bali ka kɔsegin pikiri kɛtuma na. O nafa ka bon kosɛbɛ k’a sababu kɛ degunba ye min bɛ sɔrɔ fɛn dilanni na. O wedge bɛ slider to a nɔ na.

Bolt de stop .

Dakun min bɛ kɛ ka sɛgɛsɛgɛli kɛ, o bɛ sɛgɛsɛgɛlikɛlan ka sɔgɔsɔgɔninjɛ kunbɛn a lamaga waati la. O ye screw component ye min sirilen bɛ slider kan. Stopper bolt bɛ taama walima lamaga kojugu bali ka tɛmɛ yɔrɔ latigɛlen kan.

Springs .

Springs bɛ dɛmɛ don slide jɔyɔrɔ la ani ka segin. U bɛ a lajɛ ko slider bɛ segin a jɔyɔrɔ ɲuman na mouding cycle kelen-kelen bɛɛ kɔfɛ. Springs jɔyɔrɔ ka bon kosɛbɛ bɛnkan sabatili la.

Pin guide suguyaw .

Guide pins ye pikirijikɛlanw ka fɛnw ye minnu nafa ka bon. U bɛ na suguya caman na, u kelen-kelen bɛɛ bɛnnen don baara kɛrɛnkɛrɛnnenw ma.

Moti finmanw walima tasa minnu sirilen don .

Nin ɲɛjiralan pinɛw ka ɲi kosɛbɛ nɔgɔbɔlanw na minnu ka fin, minnu bɛ se ka fara ɲɔgɔn kan. U bɛ nafa caman di:

Numumugu finmanw walima tasa minnu sirilen don, olu bɛ kɛ ka caya nɔgɔ misɛnniw na. U ye fura ye min musaka ka dɔgɔ, yɔrɔ dilanni nɔgɔmanw na.

Guide pins for 2 walima 3 plat plates ni plates thicks ani moule cavité belebelew .

Ni aw bɛ baara kɛ ni tasaw ye minnu ka bon ani ni u bɛ kɛ ni nɔgɔbɔlanw ye minnu ka bon, ɲɛjiralan pin dilanni kɛrɛnkɛrɛnnenw ka kan ka kɛ. Nin ɲɛjiralan pinɛw janya ni u cɛmancɛ hakɛ ye 1,5 ye walima ka tɛmɛ o kan.

Janya ni cɛmancɛ hakɛ ye ko kɔrɔba ye kun caman kosɔn:

A bɛ a lajɛ ko nɔgɔbɔlanw bɛ bɛn ɲɔgɔn ma ka ɲɛ .

A bɛ sirili walima nɔrɔli bali nɔgɔ bɔli ni a dadon waati la .

A bɛ gafe ɲɛ 10nan ka sigicogo dafalen mara .

Nka, ɲɛjiralan pinɛw ni u janya ni u cɛmancɛ hakɛ ka bon, olu bɛ se ka nafa dɔw jira:

Walasa ka nin ko ninnu nɔgɔya, u dilanni ni u dilanni nafama nafa ka bon. Ni aw bɛ baara kɛ ni fɛnw ye minnu ka ɲi kosɛbɛ ani ka guide pin jateminɛcogo ɲuman sɔrɔ, o bɛ se ka dɛmɛ don ka baara kɛ ka ɲɛ.

| Guide PIN suguya | baarakɛcogo | . |

| Moti finmanw walima tasa minnu sirilen don . | A sabatili ɲuman . Matte surface fini . | |

| Guide pins for 2 walima 3 plat plates ni plates thicks ani moule cavité belebelew . | Janya ni cɛmancɛ hakɛ ≥ 1,5 . A b’a to a ka bɛn ɲɔgɔn ma cogo bɛnnen na . A bɛ sirili walima a nɔrɔli bali . | |

Guide bloc (Slider) jɔyɔrɔ .

Guide bloc, n’a bɛ fɔ fana ko slider, o ye injection mold slider system yɔrɔ koloma ye. A bɛ baara kɛ ɲɔgɔn fɛ ni ɲɛminɛlan pinɛ ye walasa ka lamagacogo ɲuman ni tigitigi sɔrɔ.

Ka gafe ɲɛ pin ka baarakɛcogo dafa .

Guide block bɛ guide pin baara dafa. Hali ni Guide PIN bɛ yɔrɔ ni dɛmɛ di, Guide Block bɛ sɛgɛsɛgɛli nɔgɔya. O jɛɲɔgɔnya in nafa ka bon slider (slider) fɛɛrɛ baaracogo ɲuman na.

Fanga min bɛ mɔgɔ minɛ ka ɲɛ guide pin kan .

Guide bloc bɛ fanga dɔ lawuli guide pin kan. O fanga bɛ dɛmɛ ka ɲɛjiralan pinɛ to a nɔ na, hali pikiri kɛcogo degunba la. Ni Guide PIN jɔyɔrɔ bɛ mara, ɲɛminɛlan bɛ sɛgɛsɛgɛli kɛ sɛgɛsɛgɛlikɛlan ka lamagacogo tiɲɛni n’a kɛcogo ɲuman kan.

Guiding the motion of the guide pin .

Guide bloc fana bɛ baara kɛ walasa ka Guide Pin lamagacogo ɲɛminɛ. A bɛ sira ɲuman ni kɔrɔsilen di walasa ɲɛminɛlan pinɛ ka tugu o kɔ. Nin bilasirali in nafa ka bon kosɛbɛ walasa ka slider (slider) fɛɛrɛ sinsinni n’a tiɲɛni sabati.

A ka c’a la, ɲɛminɛlan bloki bɛ ni T-shaped guide slot ye. Nin slot design bɛ sira di bilasirali ɲuman ma ani ka dɛmɛ don guide pin na. Guide bloc ka kan ka dilan ni nɛgɛ gɛlɛn ye walasa ka se ka sɛgɛsɛgɛli kɛcogo segin-seginlen muɲu.

Lamaga-lamagali jɔlen ni a jiginni bɛɛ nɔgɔyali .

Guide bloc jɔyɔrɔba dɔ ye ka lamaga jɔlen ni lamaga-lamagali fila bɛɛ nɔgɔya. Pikiri kɛcogo la, slider ka kan ka taa sira fila fɛ:

Lamaga-lamagali jɔlen: Nin ye slider sanfɛla ni duguma lamaga ye, min bɛ boli ni guide pin ye.

Lamaga-lamagali horizontal (yɔrɔ lamagacogo): O ye slider (slider) lamini lamagacogo ye, o min bɛ sira Di jukɔrɔla-yɔrɔw ni fɛn gɛlɛnw dabɔli ma.

Guide block ka dilancogo bɛ se ka nin sira fila-fila lamagacogo in kɛ. A ka jɛɲɔgɔnya ni guide pin ni slider farikolo bɛ sira Di 'tɛmɛsira ma min tɛ 'sèn Bɔ lamaga-lamagali jɔlen ni lamaga-lamagali 'cɛ.

| Guide bloc baarakɛcogo | ɲɛfɔli . |

| PIN guide complementaire . | A bɛ baara kɛ ɲɔgɔn fɛ ni guide pin ye walasa ka lamagacogo ɲuman ni tigitigi kɛ . |

| Fanga min bɛ mɔgɔ minɛ . | A bɛ dɛmɛ ka ɲɛjiralan pinɛ to a nɔ na pikirijikɛlan caman degunw kɔrɔ . |

| Lamaga-lamagali . | A bɛ sira kɔlɔsilen di walasa ɲɛminɛlan ka tugu, ka ɲɔgɔndɛmɛ ni tiɲɛni mara . |

| Lamaga-lamagali jɔlen ni jiginni nɔgɔyalen . | A bɛ se ka kɛ sababu ye ka slider (slider) kɛ ka taa sanfɛ ani ka taa a fɛ . |

Pikirili molding sliders suguyaw .

Pikiriw dilanni sɛgɛsɛgɛlikɛlanw bɛ sɔrɔ suguya wɛrɛw la, u kelen-kelen bɛɛ bɛ ni jogo kɛrɛnkɛrɛnnenw ye ani u kɛcogo. An ka suguya fila sɛgɛsɛgɛ minnu bɛ kɛ tuma caman na: CAM pin slide ani hydraulique slides.

Cam Pin Slides (Pins angles) .

Cam pin slides, a bɛ fɔ fana ko angle pin, olu de ye slide wale suguya ye min ka ca. U bɛ ni guide pin ye min bɛ bɔ kɛrɛ fɛ min bɛ bɔ dingɛ kɛrɛ fɛ slider farikolo kɔnɔ. O nɛgɛdaga in bɛ sigi mɔni fan jɔlen na ani a bɛ baara kɛ ni angle bloc ye walasa ka slide datugu a nɔ na.

Cam pin slide nafa dɔw ye:

Nka, CAM PIN slides fana bɛ dan dɔw la:

Slide hydraulique .

Hydraulique slides bɛ kɛ ni a ka kan ka kɛ ni control ani précision ye. U nafa ka bon kɛrɛnkɛrɛnnenya la ko minnu na, masinw bɛ se ka degunba lase ɲɛjiralan bloki kan, o bɛ na ni sɛgɛn ni sɛgɛn ye.

Hydraulique slides bɛ nafa caman di:

Slide lamaga waati n’a kɛcogo kɔrɔ kunbɛn tigitigi .

Se ka pikirijikɛlan caman degun ka sɔrɔ a ma sɛgɛn kojugu .

Slide wale nɔgɔman ni basigilen .

Silindri hydrauliques locking bɛ se ka kɛ ka fɛnw jukɔrɔla tigɛ baarakɛminɛn kɔnɔ. U bɛ lakana ni tiɲɛni wɛrɛw Di o baarakɛcogo gɛlɛnw na.

| Slide suguya | jogo dɔw | . |

| Cam Pin Slides (Pins angles) . | Pin guide angle . Return automatique . A musaka ka dɔgɔ . | |

| Slide hydraulique . | Kunnafoni tigitigiw . A bɛ tansiyɔnba minɛ . Waleya nɔgɔman . | |

Injection moulding sliders bɛ baara kɛ cogo di?

Pikiriw dilanni sɛgɛsɛgɛlikɛlaw jɔyɔrɔ ka bon kosɛbɛ yɔrɔ gɛlɛnw dilanni na. Nka u bɛ baara kɛ cogo di tigitigi? An ka nin yɔrɔ hakilitigi ninnu baarakɛcogo n’u taabolo sɛgɛsɛgɛ.

Baarakɛcogo sariya min bɛ sliderw kan .

Sliderw tɛ ni circuits walima hydraulique silindaw ye. O la, u ka fanga bɛ bɔ min? Jaabi bɛ sɔrɔ ɲɛminɛlanw kɔnɔ minnu bɛ kɛ kɛrɛ fɛ.

Moli da wuli ni a dadon waati la, ɲɛjiralanw bɛ ɲɔgɔn sɔrɔ ni slider kɔnɔna kogo ye. O friction force bɛ slider system bɛɛ bila ka taa perpendicular to the demolding direction.

Slide angle pin sanfɛla ni duguma lamaga bɛ slider system bɛɛ boli. O ye fɛɛrɛ nɔgɔman ye, nka a bɛ nɔ bɔ, min bɛ mɔli ka lamaga-lamagali kɛ ka fɛn gɛlɛnw dilan.

Taabolo min bɛ kɛ senfɛ-senfɛ .

An ka slider baara tiɲɛ pikiri kɛcogo dɔ senfɛ:

Mold Closing:

Pikiri:

Plastiki min bɛ wuli, o bɛ mɔli kɔnɔna ni slider fa.

Wedge bɛ slider (slider) degun, ka kɔsegin bali ka da pikiri tansiyɔn kan.

A bɛ nɛnɛ:

Mold da wuli:

Mold bɛ da wuli, ani guide angled poste bɛ bɔ slider la.

O slider bɛ Taa kɛrɛfɛ, ka 'fɛn min bɛ 'kɔnɔna na walima min ka gɛlɛn, o Bɔ.

Ejection:

Ejector pins bɛ yɔrɔ mɔlen sama ka bɔ nɔgɔ la.

Slider bɛ segin a jɔyɔrɔ fɔlɔ la, a labɛnnen don cycle nata kama.

O baara in bɛɛ kɔnɔ, dakun min bɛ wele ko slider’s stroke, o bɛ dɛmɛ don ka a bila a jɔyɔrɔ la ani ka segin. O ye dɔnkili ye min bɛ Labɛn ka ɲɛ, min bɛ Nà ni yɔrɔw ye minnu dilannen don cogo dafalen na.

Gafe min bɛ kɛ ka pikirijikɛlan dɔ dilan, o ɲɛ kelen-kelen bɛɛ .

Pikiriw dilannikɛlan dilanni bɛ jateminɛ kɛ kosɛbɛ ani ka jateminɛ kɛ fɛn fitininw na. Aw bɛ nin gafe in labato min bɛ kɛ senfɛ-senfɛ walasa ka slide dilancogo ɲɛ.

1. Dilancogo fɔlɔ jateminɛw .

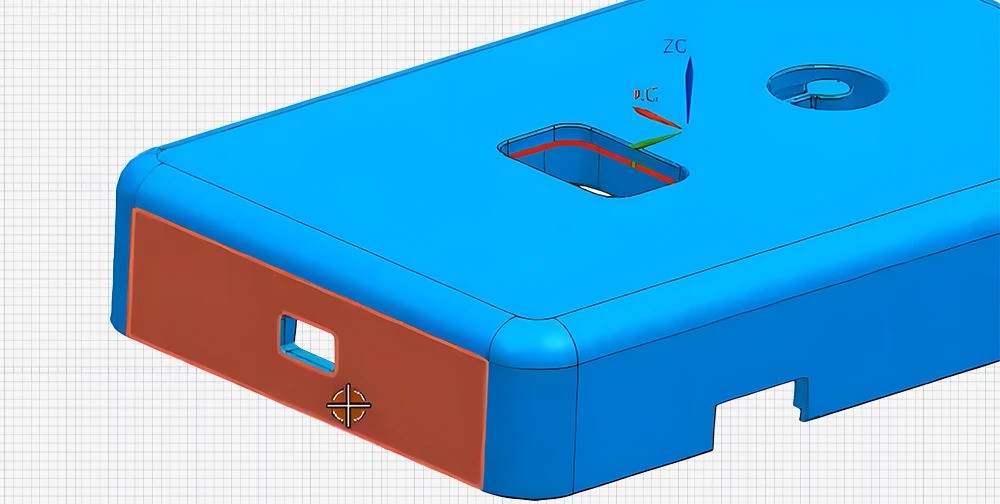

Aw bɛ a daminɛ ni a yɔrɔw labɛncogo lajɛli ye kosɛbɛ. Fɛn minnu bɛ kɛ ni slidew ye, olu dɔn, i n’a fɔ . undercuts , threads, walima shapes complexes. O fɛnw bɛna slide suguya ni u hakɛ fɔ.

2. Fɛnw sugandili .

Fɛn bɛnnenw sugandi slidew kama. Sugandili minnu bɛ kɛ tuma caman na, olu ye baarakɛminɛnw nɛgɛ, aluminiyɔmu ani Beryllium kuran ye. Aw bɛ aw jija fɛn sugandilenw ka se ka baara kɛ ni fɛn dilannen ye ani fɛn kɛrɛnkɛrɛnnen ye min bɛ kɛ ka fɛnw labɛn. Aw bɛ fɛnw jateminɛ i n’a fɔ gɛlɛya, sɛgɛnbaliya, ani funteni cogoyaw.

3. Ka slide suguya ni a nimɔrɔ dɔn .

Ka da fɛnw kan minnu dɔnna, i ka slide suguya bɛnnen sugandi. Aw bɛ slide hakɛ jateminɛ min ka kan walasa ka fɛn ɲininenw dilan ka ɲɛ. Yɔrɔ gɛlɛnw bɛ se ka kɛ ni slide caman ye minnu bɛ baara kɛ ɲɔgɔn fɛ.

4. Slide hakɛw jatebɔ .

Aw bɛ slidew hakɛw jateminɛ walasa ka lamagacogo ɲuman ni u bɔli kɛ nɔgɔbɔlan kɔnɔ. Aw ye a yɔrɔ dilancogo ani a ka slide suguya sugandilen jateminɛ. Slide ka kan ka yɔrɔ caman sɔrɔ walasa a ka se ka lamaga k’a sɔrɔ a ma fɛn wɛrɛw bali. Slider guide ka kan ka dilan ni 0,5mm clearance ye fan kelen fɛ.

5. Draft angle jateminɛw .

A bɛ don a kɔnɔ . Aw bɛ angles (yɔrɔw) kɛ slide (slide) dilancogo la walasa ka yɔrɔ tiɲɛni bali bɔli senfɛ. Draft angles bɛ yɔrɔ mɔlen bɔli nɔgɔya ka bɔ slide la. Aw bɛ a lajɛ ko angles draft bɛ bɛn fɛn kɛrɛnkɛrɛnnenw ma ani part geometry ma.

6. Interlocking fɛnw .

Design interlocking features walasa ka slidew lamagacogo laɲinibali bali u dilanni senfɛ. O fɛnw bɛ dɛmɛ ka slidew dafalen ni u tiɲɛni mara. U bɛ a lajɛ fana ko slidew bɛ segin u jɔyɔrɔ la ka ɲɛ mouling cycle kelen-kelen bɛɛ kɔfɛ. Aw ye aw hakili to a la ka jɔli bloki bila slider pinɛ janw laban na walasa a kana fɛn caman tiɲɛ.

7. Ka dilan ka ɲɛsin fɛnw dilanni ma .

Aw bɛ slide dilancogo ɲɛ ka ɲɛ walasa a dilanni, a lajɛcogo ani a ladonni nɔgɔya. Aw ye jateminɛ kɛ fɛn dilanni taabolo kɛrɛnkɛrɛnnenw ni minɛnw na minnu bɛ sɔrɔ. Aw bɛ a dilanni nɔgɔya walasa ka gɛlɛyaw dɔgɔya ani ka filiw seko dɔgɔya. Aw ye aw jija ka dilan min bɛ baara kɛ ani ka baara kɛ ka ɲɛ.

| Design Step | Key Considerations . |

| Fɔlɔ dilancogo jateminɛw . | |

| Material Selection . | |

| Slide suguya ni a nimɔrɔ latigɛ . | |

| Jatebɔ min bɛ kɛ ni slide dimensions ye . | |

| draft angle jateminɛw . | |

| Fɛn minnu bɛ ɲɔgɔn cɛ . | |

| Designing ka ɲɛsin manufacturability ma . | Optimide ka ɲɛsin fɛn dilanni, a lajɛli ani a ladonni nɔgɔya ma . Aw ye jateminɛ kɛ fɛn dilanni taabolo kɛrɛnkɛrɛnnenw ni a minɛnw kan . |

Walasa ka kunnafoni wɛrɛw sɔrɔ . pikirijikɛlanw yɔrɔw ani . Pikiri mɔli dilanni , aw bɛ taa an ka gafe bɛɛ lajɛlen na.

fili minnu bɛ kɛ tuma caman na walasa ka aw yɛrɛ tanga pikiri kɛli ma ni pikirijikɛlan ye .

Pikiriw dilannikɛlanw dilanni bɛ se ka kɛ fɛn gɛlɛnw ye. Ka i yɛrɛ tanga filiw ma minnu bɛ kɛ tuma caman na, o nafa ka bon kosɛbɛ walasa ka slide ɲumanw ni dannayalenw dilan. An ka jaan dɔw lajɛ walasa ka u kɔlɔsi.

draft angle jateminɛw mabɔ .

fili minnu ka jugu kosɛbɛ, olu dɔ ye ka ɲinɛ . Angles de draft . Angles de draft inadequate bɛ se ka kɛ sababu ye ka ko caman kɛ:

gɛlɛya bɛ yɔrɔ in bɔ nɔgɔ la .

Tiɲɛni min bɛ kɛ o yɔrɔ la bɔli senfɛ .

dɔ farala sɛgɛn kan slide ni moule surfaces kan .

Walasa ka o gɛlɛyaw bali, aw bɛ a lajɛ ni a yɔrɔ ni slide fila bɛɛ bɛ se ka sɛbɛn. Angle draft kɛrɛnkɛrɛnnen min bɛ ɲini, o bɛ bɔ fɛn ni yɔrɔ jateminɛ na. I n’a fɔ sariyaba dɔ, i ka 1° fo 2° minimuma draft angle (yɔrɔ min ka dɔgɔn kosɛbɛ) laɲini.

Materiel sugandili bɛnbaliw .

Ka fɛn jugu sugandi i ka slidew kama, o bɛ se ka kɔlɔlɔ juguw lase i ma. Fɛn minnu tɛ bɛn ɲɔgɔn ma, olu bɛ se ka kɛ sababu ye ka:

Ni aw bɛ fɛnw sugandi, aw bɛ u muɲuli ni u kɛcogo bɛn ni fɛnw dilanni ye ani u dilanni kɛcogo ye. Sugandili minnu bɛ kɛ tuma caman na, olu ye baarakɛminɛnw nɛgɛ, aluminiyɔmu ani Beryllium kuran ye. Aw bɛ fɛnw jateminɛ i n’a fɔ gɛlɛya, sɛgɛnbaliya, ani funteni cogoyaw.

Slide dilancogo gɛlɛnw kojugu .

Hali ni slidew bɛ se ka fɛn gɛlɛnw dilan, slide dilancogo gɛlɛnw bɛ se ka kɛ gɛlɛya ye. Nafa minnu bɛ sɔrɔ a la, olu nafa ka bon kosɛbɛ:

Dɔ farala fɛn dilanni ni a ladonni musakaw kan .

Faratiba min bɛ sɔrɔ a la ka a sɔrɔ a ma baara kɛ .

Gɛlɛya min bɛ sɔrɔ lajɛ ni a falenni na .

Walasa ka i yɛrɛ tanga nin ko ninnu ma, i ka nɔgɔya ni nafa bila jɔyɔrɔ fɔlɔ la i ka slide dilancogo la. Aw ye aw sinsin slidew dilanni kan minnu bɛ baara kɛ, minnu bɛ se ka da u kan, ani minnu dilanni ka nɔgɔn. Aw bɛ aw yɛrɛ tanga fɛnw ma minnu tɛ mako ɲɛ walima jateminɛ gɛlɛnw ye minnu bɛ gɛlɛya fara u kan k’a sɔrɔ nafa caman tɛ u la.

Omitting interlocking features .

Fɛn minnu bɛ ɲɔgɔn minɛ, olu nafa ka bon walasa ka slidew lamagacogo laɲinibali bali u dilanni senfɛ. Ni aw ye o fɛnw don a kɔnɔ, o bɛ se ka kɛ sababu ye ka:

Slidew ka ɲɔgɔndɛmɛbaliya .

A yɔrɔ cogoya min tɛ bɛn ɲɔgɔn ma .

Tiɲɛni bɛ kɛ ka ɲɛsin mɔli walima slidew ma .

Aw bɛ fɛnw don aw ka slide dilancogo la walasa ka slide integrité ni a tiɲɛni mara. O fɛnw b’a To slidew bɛ To u jɔyɔrɔ la molding cycle (boli-yɔrɔ) bɛɛ la.

| fili kɔlɔlɔ minnu bɛ sɔrɔ tuma caman na, olu | ɲɛnabɔcogo | . |

| Angles de draft (angles de draft) minnu bɛ u mabɔ olu la . | Ejection gɛlɛn . Yɔrɔ tiɲɛni . dɔ farala sɛgɛn kan . | |

| Materiel sugandili bɛnbaliw . | | Fɛn minnu bɛ mɛn ani minnu bɛ bɛn ɲɔgɔn ma, olu sugandi . Aw ye gɛlɛya jateminɛ, ka se ka a yɛrɛ tanga, ani ka funteni sɔrɔ . |

| Slide dilancogo gɛlɛnw kojugu . | | |

| Omitting interlocking features . | | |

Walasa ka kunnafoni wɛrɛw sɔrɔ pikiri kɛcogo ni fɛɛrɛw kan, aw ye an ka gafew lajɛ . pikiri kɛcogo jugu ani . Pikirili mɔli dilanni . Walasa ka kunnafoni caman sɔrɔ a yɔrɔ minnu bɛ o ko la, aw ye an ka barokun lajɛ . pikirijikɛlan yɔrɔ 10 ..

Pikiri molding slide vs lifter .

Pikiri mɔli slidew ni wulilanw fila bɛɛ bɛ kɛ ka jukɔrɔla tigɛw ni fɛn gɛlɛnw dilan yɔrɔw la minnu dilannen don. Nka, danfara bɛ u ni ɲɔgɔn cɛ u kɔrɔ, u kɛcogo ani u kɛcogo la.

kɔrɔ ni baarakɛcogo .

Lifter (lisan): O ye fɛn kɔrɔtalan ye min bɛ kɛ ka barajuru walima fɛn bɔlenw cogoya dilan fɛn kɔnɔ. A bɛnnen don ka barajuru nɔgɔmanw dilan wa a bɛ kɛ ka caya nin baara ninnu na:

Kuran dilanni minɛnw ka ɲɛsin muguw ma minnu bɛ sɔrɔ nɛgɛ ni nɛgɛ fɛ .

Lastikuw dilanni, i n'a fɔ pneu molds ani 'o' sigilan lastikuw .

Plastiki fɛnw ni thermosetting ani thermoplastique moulding .

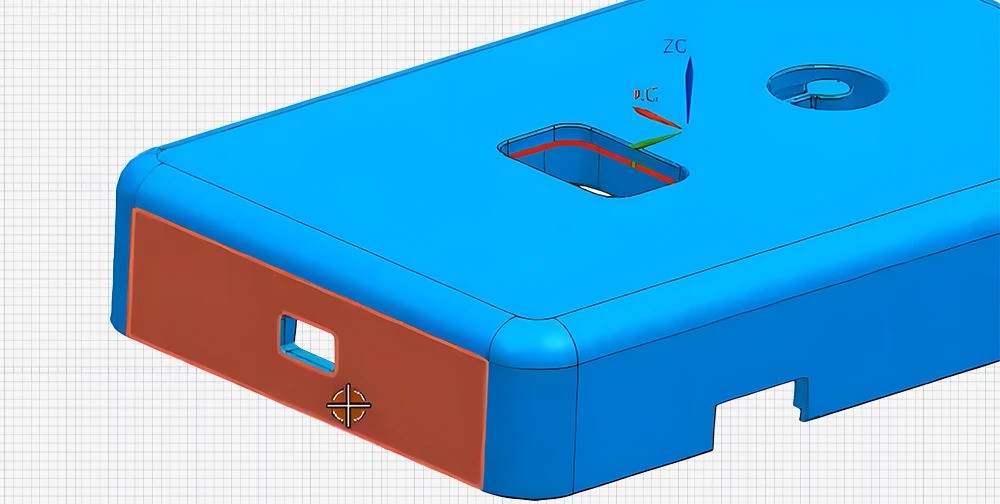

Slider: slider ye moule yɔrɔ ye min bɛ se ka slide kɛ moule da la walima ni a bɛ kɛ cogo dɔ la ka taa da wuli sira fɛ. A bɛ kɛ ni fɛn dilannenw jɔcogo b’a to a tɛ se ka bɔ yɔrɔ dilannen na ni slider tɛ baara kɛ. Sliderw bɛ baara kɛ kosɛbɛ yɔrɔ caman na, i n’a fɔ:

CNC masinw ni masinw ka yɔrɔw .

Mobili ni furakɛli minɛnw .

Elektroniki ni otomatiki masinw .

Pikiriw dilanni masinw ani mɔli da wulilanw .

Mekanikini min bɛ kɛ ni masin ye .

Lifter: Lifters bɛ baara kɛ ni ejecting mechanism suguya caman ye walasa ka barbs cogoya ani ka u bɔ fɛn dilannen kɔnɔ. O fɛɛrɛw dɔw ye:

Bloki bɔli fɛɛrɛ .

Molding parts ejecting mechanism .

Fiɲɛ tansiyɔn bɔli fɛɛrɛ .

Multi-component integrated ejecting mechanism .

Slanting slider ejecting mechanism .

Fɛɛrɛ kɛrɛnkɛrɛnnen min bɛ kɛ, o bɛ bɔ barajuru ka gɛlɛya la ani fɛn min bɛ dilan.

Slider: sliderw bɛ baara kɛ ni core samali fɛɛrɛ ye walasa ka yɔrɔ mɔlen bɔ ka bɔ mɔli la. Slider bɛ siri molding core la ani a bɛ boli ni guide column inclined ye. Mold da wuli waati la, slider bɛ taa kɛrɛfɛ, ka a kɔnɔna sama ani ka a ka fɛn tiɲɛnen walima a ka gɛlɛn bɔ.

Slider material yɛrɛ ka kan ka gɛlɛya bɛnnen sɔrɔ ani ka a yɛrɛ tanga ka se ka lamaga-lamagali muɲu. A ka gɛlɛn walima a kɔnɔna yɔrɔ min bɛ sɛgɛsɛgɛli kɛ, o ka kan ka bɛn mɔni tɔ ma.

| Fɛn minnu | bɛ kɛ ka | fɛnw wuli . |

| Kɔrɔ | Shapes Barbs kɔnɔ fɛn dilannen kɔnɔ . | Sliding component ka moule da wuli sira . |

| Waleyali | Barbs nɔgɔmanw, kuran baarakɛminɛnw, lastikuw dilanni . | Undercuts complexes, CNC masinw, mobili, furakɛli minɛnw . |

| Mekanikini min bɛ kɛ ni masin ye . | Bloki puse, mouling parts, fiɲɛ tansiyɔn bɔli . | core pulling mechanism driven by inclined guide column . |

| Materiel (Matɛriw ka wajibiyalenw) . | A bɛ bɔ a kɛcogo kɛrɛnkɛrɛnnen na . | Gɛlɛya bɛnnen ani ka resistance don ka friction muɲu . |

Kɔnɔna sɛgɛsɛgɛli fɛɛrɛ .

Ni kɛrɛfɛ-slider ni slant top mechanism tɛ Se ka Dabɔ, kɔnɔna-slider mechanism bɛ Nà baara la. O ye fura ye min ɲɔgɔn tɛ yen walasa ka fɛn dɔw ni fɛn gɛlɛnw dilan fɛn dilannen kɔnɔna fan fɛ.

Dilan jateminɛw ka ɲɛsin kɔnɔna slider farikolo ma .

Kɔnɔna slider farikolo ye kɔnɔna slider mechanism yɔrɔ koloma ye. Nin ye jateminɛ jɔnjɔn dɔw ye:

A bɛ taa ni a ye fɛn dilannen kɔnɔna fan fɛ: Kɔnɔna sɛgɛsɛgɛlikɛlan bɛ boli ka taa fɛn kɔnɔna fan fɛ, a tɛ i n’a fɔ sɛgɛsɛgɛli kɛcogo min bɛ kɛ ɲɔgɔn fɛ.

Backhoe Bit direction: Backhoe bitiki sira bɛ kɛrɛfɛ ni ɲɛminɛlan ye min bɛ wuli ka bɔ a nɔ na, o bɛ sɔrɔ sɛgɛsɛgɛli kɛcogo jɛlen na. O bɛ sira Di 'kɔnɔnafiliw dabɔli ma kɔnɔna fan fɛ.

Ressort-loaded walasa ka kɔfɛla lamaga bali: Kɔnɔna-slider bɛ resɔrɔn-don walasa a kana taa kɔfɛ k’a sɔrɔ a ma mɔli da tugu. O bɛ a to a jɔyɔrɔ ka ɲɛ ani ka tiɲɛni bali nɔgɔ la.

Bloki min bɛ se ka sɛgɛn ka ɲɛsin sɔgɔli ma ani koro bɔli ma: Bloki min bɛ se ka sɛgɛn, o bɛ kɛ ni kɔnɔna sɛgɛsɛgɛlikɛlan ye walasa ka sɔgɔli kɛ ani ka slider core extraction boli. Nin bloki in fana bɛ dɛmɛ don ka slider (slider) lasegin.

Angle caman pinɛw ani ɲɛminɛlanw ka ɲɛsin sliderw ma minnu ka bon .

Sliderw ka bon, dɛmɛ ni bilasirali wɛrɛw ka kan ka kɛ. Aw ka kan ka min jateminɛ, o filɛ nin ye:

Ni slider bonya tɛmɛna milimɛtɛrɛ 60 kan, a ka kan ka jateminɛ kɛ ni 2 ye.

Walasa ka sliderw bonya ka tɛmɛ milimɛtɛrɛ 80 kan, ɲɛminɛlan ka kan ka bila slider jukɔrɔ cɛmancɛ la.

O yɔrɔ wɛrɛw bɛ dɛmɛ ka fanga tila-tila ani ka kɔnɔna sɛgɛsɛgɛli fɛɛrɛ baara ka ɲɛ.

Jiginni angle pinɛ dingɛ daminɛyɔrɔ ye slider janw ye .

Slider janyalenw bɛ fɛn dɔ sɛmɛntiya ka kɛɲɛ ni angle pinɛ dingɛ jɔyɔrɔ ye. Ni slider (slider) ka bon kojugu, angle pinɛ dingɛ daminɛyɔrɔ ka kan ka jigin. O bεε bε sεnεkεcogo nɔgɔya ani ka bεnkan bεε bali ka bεn ni bεnkansεbεn wεrεw ye.

| Slider width | design considerations |

| < 60 mm . | Angle kelen pin . |

| 60-80 mm . | 2 angle pins . |

| > 80 mm . | 2 angle pins + guide bar slider jukɔrɔ . |

| slider janya | dilancogo jateminɛw . |

| Sariya | Yɛlɛma tɛ kɛ . |

| A ka bon kojugu . | Aw bɛ angle pinɛ dingɛ daminɛ yɔrɔ jigin . |

Kɔnɔna-slider fɛɛrɛ ye fura hakilitigi ye min bɛ kɛ ka fɛnw jukɔrɔla ni fɛn gɛlɛnw dilan fɛn dilannen kɔnɔna fan fɛ. Ni aw ye kɔnɔna slider farikolo dilanni jateminɛ koɲuman, ka angɛrɛ caman pinɛw ni ɲɛminɛlanw don a kɔnɔ walasa ka sɛgɛsɛgɛli kɛ ka ɲɛsin sɛgɛsɛgɛlikɛlanw ma minnu ka bon, ani ka angɛrɛ pinɛ dingɛ jɔyɔrɔ ladilan sɛgɛsɛgɛlikɛlan janw kama, aw bɛ se ka a lajɛ ni kɔnɔna sɛgɛsɛgɛlikɛlan baarakɛcogo ɲuman n’a nafa ye.

Bolo minnu bɛ kɛ pikiri kɛli la .

Bolo doni bɛ se ka kɛ fɛn wɛrɛ ye min bɛ se ka kɛ ka fɛnw sɛgɛsɛgɛ minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw sɛgɛsɛgɛ. U ye bololafɛnw ye minnu bɛ bila bolo la minnu bɛ jukɔrɔla-tigɛw ni fɛn gɛlɛnw dilan yɔrɔ dilannen na.

Alternative ka tɛmɛn sliders ani lifters kan ka sɔrɔ ka bɔ caman na .

Sliders ani lifters ye otomatiki fɛɛrɛw ye minnu bɛ dugumanaw ni fɛn gɛlɛnw bɔ pikiri kɛcogo yɔrɔw la. Nka, u bɛ se ka kɛ sɔngɔba ye ka ɲɛsin fɛn dilanni boliw ma minnu ka dɔgɔ. Nin yɔrɔ in de la bolola-donniw bɛ na tulonkɛ la.

Bololabaara ye fura ye min musaka ka dɔgɔ prototypes ni a bɔli hakɛ dɔgɔman na. U bɛ fɛɛrɛ sɔngɔ gɛlɛnw mago bɔ, o min b’a to u bɛ kɛ sugandili ye sɔrɔko siratigɛ la o baara ninnu kama.

Inserts minnu bɛ bila bolo la walasa ka jukɔrɔla tigɛw ni fɛn gɛlɛnw dilan .

Bololabaarakɛlaw bɛ don ni bolo ye minnu bɛ jukɔrɔla tigɛw ni fɛn gɛlɛnw dilan yɔrɔ dilannen na. Sani mɔni ka kɛ, baarakɛla dɔ bɛ don a kɔnɔ ni bolo ye. Nin bolo-don-yɔrɔ in bɛ Bɔ ni yɔrɔ dafalen ye k'a Bɔ walasa a ka Se ka Dòn kokura pikiri kɛlen nata waati la.

Bololabaara bɛ se ka fɛn caman dilan, i n’a fɔ:

Undercuts .

Fila .

Geometries complexe .

Kɛrɛfɛ dingɛw .

Kanalw ni jirisunw .

sɔrɔko siratigɛ la prototypes ani hakɛ dɔgɔmanw .

Hali ni bololafɛnw bɛ baara musakaw fara pikiri kɛcogo kan, u bɛ sɔrɔ hali bi sɔrɔko siratigɛ la ani fɛn caman dilanni na. O musaka dɔgɔyali ka bɔ fɛɛrɛ sɔngɔ gɛlɛnw na i n’a fɔ sliders ani lifters bɛ baara musaka faralenw kunbɛn.

Bololabaaraw bɛnnen don kɛrɛnkɛrɛnnenya la:

Prototyping ani kɔrɔbɔli kura dilancogo .

A bɛ boli hakɛ dɔgɔman na (a ka c’a la, a tilayɔrɔ 1000 bɛ tɛmɛ) .

Yɔrɔ minnu bɛ ni jateminɛ gɛlɛnw ye minnu bɛna gɛlɛya walima minnu dabɔli bɛna kɛ ni otomatiki fɛɛrɛw ye .

Jateminɛw kɛra wotoro kɔnɔ cogo basigilen na ani nɛnɛ kɛcogo ɲuman na .

I n’a fɔ pikirijikɛlan janya, bololafɛnw bɛ funteni tigitigiw de wajibiya walasa ka u cogoya ani u yɔrɔ kelen-kelen bɛɛ kɛ ɲɔgɔn fɛ. Nin ye jateminɛ jɔnjɔn dɔw ye:

Sikili basigilen: Ni yɔrɔ dɔ bɛ bolo-don-fɛn caman de wajibiya, wotoro basigilen bɛ se ka gɛlɛya. Walasa ka sɛnɛfɛnw bɔli waati bɛnnenw mara, a nafa ka bon ka bolo doni caman jɔ ani ka baara kɛ ni fɛn kɛrɛnkɛrɛnnenw ye walasa ka yɔrɔ gɛlɛnw bɔli nɔgɔya.

Nɛnɛ bɛnnen: Bolo doni ka kan ka dilan walasa ka nɛnɛ ɲuman dɛmɛ cycles ni ɲɔgɔn cɛ. U ka kan ka jɔ ni fɛnw ye minnu bɛ se ka pikiri kɛcogo nɔgɔyali muɲu. Nɛnɛ bɛnnen bɛ dɛmɛ ka yɔrɔ mɔlenw cogoya n’u kɛcogo ɲuman sabati.

Tansiyɔn dɔgɔyalen mɔli dadonni: A nafa ka bon kosɛbɛ ka mɔli kɛ ni degun dɔgɔman ye ka surunya walasa ka bolo doni tiɲɛni seko dɔgɔya. O bɛ dɛmɛ don ka bolokɔniw ka ɲɛnamaya janya ani ka yɔrɔ mɔlenw cogoya sabati.

| Bololabaarakɛlaw ka | sɛgɛsɛgɛlikɛlanw ni fɛnw wulilanw . |

| Inserts minnu bɛ bila bolo la . | Otomatiki fɛɛrɛw . |

| Sɔrɔko ka ɲɛsin sɛnɛfɛnw bɔli ma minnu ka dɔgɔ . | A musaka ka dɔgɔ ka ɲɛsin fɛn caman sɔrɔli ma . |

| A bɛnnen don prototypes ani geometries complexew ma . | A ka ɲi kosɛbɛ ka ɲɛsin fɛn dilanni bolibaw ma ani jateminɛ nɔgɔmanw . |

| Aw bɛ wotoroninw ɲini cogo basigilen na ani ka nɛnɛ jateminɛcogo ɲumanw kɛ . | A dabɔra otomatiki, baarakɛcogo basigilen kama . |

Kuncɛli

Pikiriw dilanni sɛgɛsɛgɛlikɛlanw faamuyali nafa ka bon kosɛbɛ walasa ka yɔrɔ gɛlɛnw dilan ni tigitigi ye. Sliderw bɛ a to u ka tiɲɛni kɛ ka ɲɛ ni u bɛ kuma u jukɔrɔla tigɛcogo kan, u ka jirisunw, ani u ka fɛn gɛlɛn wɛrɛw kan. An y’u ɲɛfɔli, u yɔrɔw, ani mun na u nafa ka bon moulding processus la.

An ye sɛgɛsɛgɛli kɛ slide sitɛmu yɔrɔ suguyaw la, guide pins suguyaw, ani baarakɛcogo sariya min bɛ sliderw kɔfɛ. Gafe min bɛ wele ko « guide de conception step » o ye sira dɔ di walasa ka sɛgɛsɛgɛli kɛcogo ɲumanw dilan ka sɔrɔ ka filiw kɛ minnu bɛ kɛ tuma caman na.

I n’a fɔ pikirikɛla, ka faamuyali jugu sɔrɔ sliderw kan, o nafa ka bon kosɛbɛ walasa ka yɔrɔ ɲumanw, yɔrɔ gɛlɛnw dilan ka ɲɛ. Ni aw ye dɔnniya sɔrɔ nin gafe in na, aw bɛ se ka aw ka pikiri kɛcogo ɲɛ ka ɲɛ ani ka hali dilancogo gɛlɛnw kunbɛn ni dannaya ye.