Welding joints jɔyɔrɔ ka bon kosɛbɛ fɛn dilanni walima jɔli baara o porozɛ ɲɛtaa la. O jɛɲɔgɔnyaw, minnu bɛ sɔrɔ nɛgɛ tilayɔrɔ fila walima u caman faralen ɲɔgɔn kan, olu bɛ fanga, muɲuli, ani fɛn bɛɛ lajɛlen cogoya jateminɛ.

Nin gafe in kɔnɔ, an bɛna an yɛrɛ su ji la, ka don welding joint suguya fɔlɔ duuru la: butt, tee, corner, lap, ani edge. Ni aw ye joginda suguya kelen-kelen bɛɛ jogo kɛrɛnkɛrɛnnenw n’u kɛcogo faamuya, aw bɛna se ka fɛɛrɛ ɲuman sugandi aw mago kɛrɛnkɛrɛnnenw kama. O la, i mana kɛ welda ye min bɛ kɛ waati kɔnɔ walima i bɛ daminɛ dɔrɔn, i ka fara an kan n’an bɛ welding joints diɲɛ sɛgɛsɛgɛ ani ka gundo da wuli walasa ka welda barikamaw dilan, minnu bɛ se ka da u kan tuma bɛɛ!

Welding joints ye mun ye ani mun na u nafa ka bon?

Welding joints ye ɲɔgɔndanw ye minnu bɛ sɔrɔ ni nɛgɛ fila walima a caman faralen ɲɔgɔn kan ɲɔgɔn fɛ welding fɛɛrɛ fɛ. O jogindaw nafa ka bon kosɛbɛ walasa ka fanga, jogo ani fɛn bɛɛ lajɛlen dafalen dɔn weldalen sigicogo la. An ka a lajɛ kosɛbɛ mun na welding joints nafa ka bon kosɛbɛ:

1. Fanga : welding joint suguya min bɛ kɛ ka ɲɛsin welda ɲɔgɔndan fanga ma. Joginda dilancogo bɛnnen sugandili b’a to weldalen sigicogo bɛ se ka fanga ni doni minnu bɛna di a ma a ka laɲini na, olu muɲu.

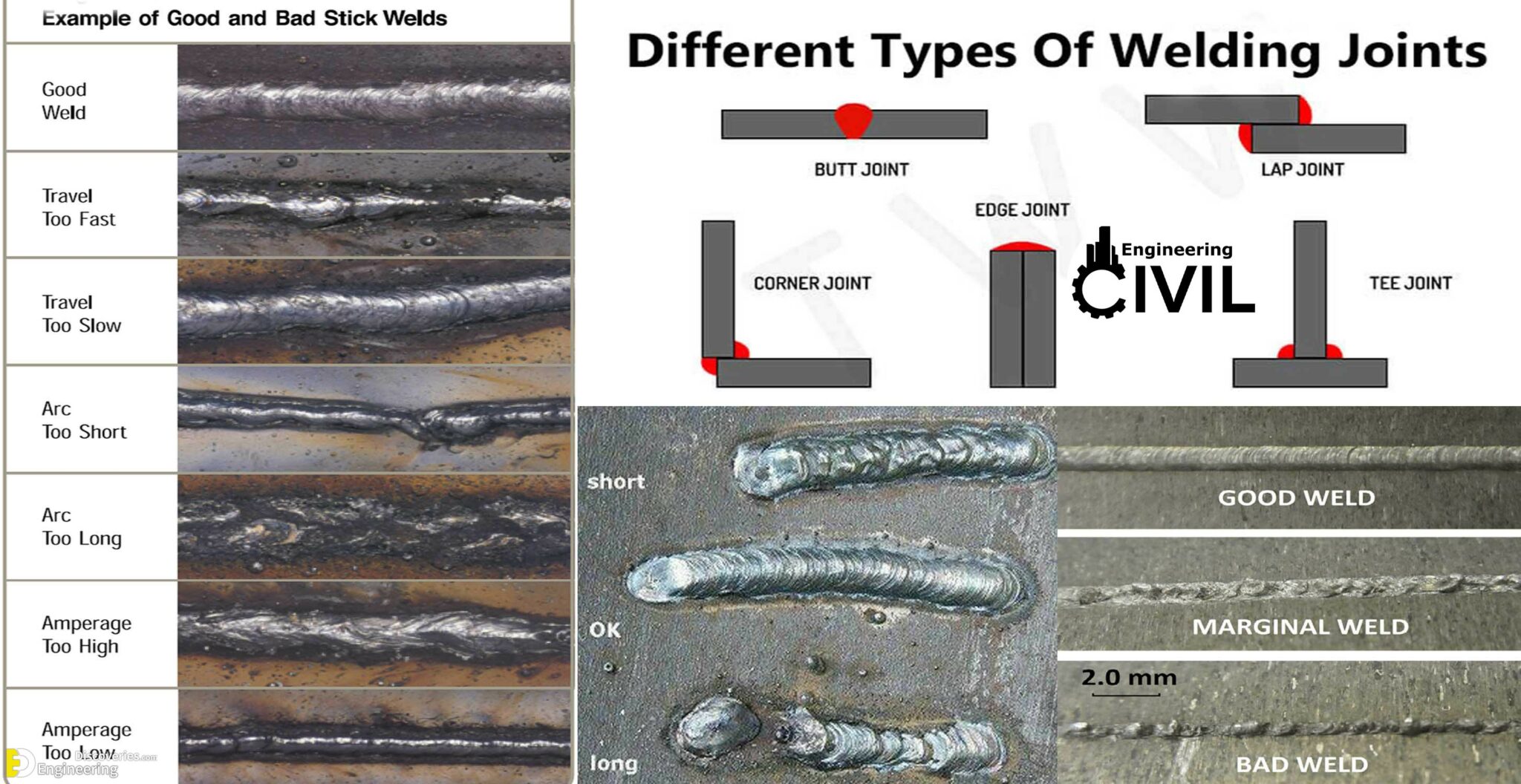

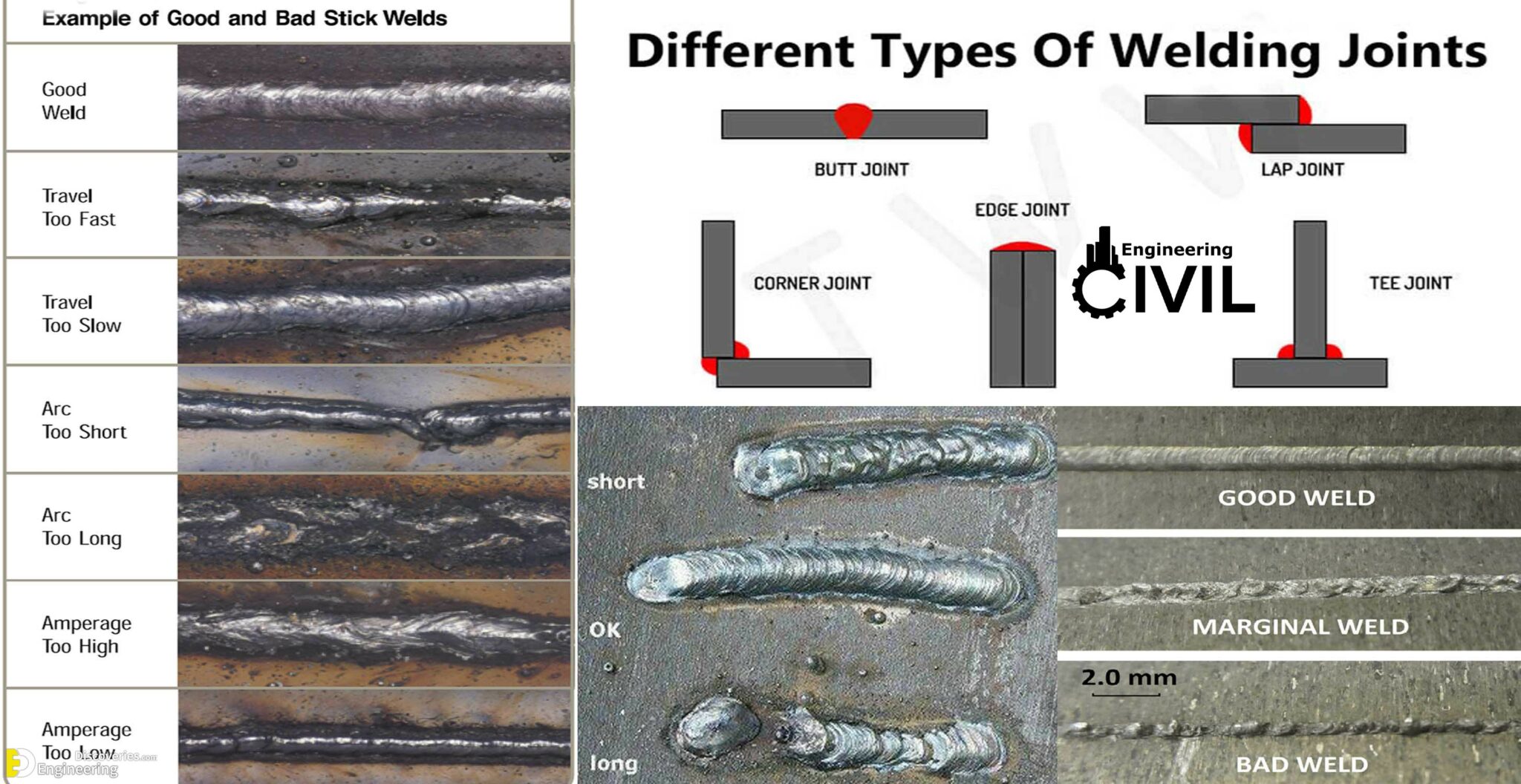

2. Quality : Joint design ani execution (Jɛkuluba) bɛ dɛmɛ don welda ka jogo bɛɛ la. Joli min dilannen don koɲuman ani min bɛ siri ka ɲɛ, o bɛna kɛ ni fiɲɛ hakɛ caman ye, ka ɲɔgɔn sɔrɔ ka ɲɛ, ani ka ɲɛnajɛ ɲɛ ka ɲɛ ni a bɛ tali kɛ joli la min ma labɛn ka ɲɛ walima min bɛ kɛ ka ɲɛ.

3. Durability : Joinding joint sugandili bɛ nɔ bila welded structure (sɔgɔsɔgɔninjɛ) ka muɲuli kuntaalajan na. Ni aw ye joginda suguya dɔ sugandi min bɛnnen don a kɛcogo kɛrɛnkɛrɛnnen ni a kɛcogo ma, aw bɛ se k’a lajɛ ko ɲɔgɔndan weldalen bɛ to fanga la ani ko a bɛ se ka da a kan waati kɔnɔ.

Ni aw bɛ welding joint type sugandi aw ka poroze kama, fɛn jɔnjɔn caman bɛ yen aw ka kan ka minnu jateminɛ:

l Material thickness : Fɛn minnu bɛ fara ɲɔgɔn kan, olu girinya bɛna nɔ bila joli suguya sugandili la. Fɛn minnu ka bon, olu bɛ se ka kɛ sababu ye ka jirisunw walima dondaw dafalen sɔrɔ, ka sɔrɔ fɛn minnu ka fin, olu bɛ se ka fara ɲɔgɔn kan ka ɲɛ ni filenw walima lapɔnw ye.

L Aplikasi : Aw ye jateminɛ kɛ baarakɛcogo ni doni wajibiyalenw na weldalen sigicogo la. Joli suguya dɔw bɛnnen don ka ɲɛ baara dɔw la, i n’a fɔ butt joints for pressure vessels or tee joints for structurel steel fabrication.

l Accessibilité (Sɔrɔli) : Joint Area (Jɛɲɔgɔnya yɔrɔ) sɔrɔli bɛ se ka nɔ bila jɛ-ka-baara sugandili la. Ni joginda sɔrɔli ka gɛlɛn walima ni a yɔrɔ ka dɔgɔn welding na, joli suguya dɔw, i n’a fɔ nkɔni walima dakun joliw, olu bɛ se ka kɛ ka ɲɛ ka tɛmɛ dɔw kan.

l musaka ni baarakɛcogo ɲuman : Jɛkulu ka dilancogo bɛ se ka nɔ bila welding baara musaka bɛɛ la ani a ka baarakɛcogo ɲuman na. Joli suguya dɔw bɛ labɛnni caman wajibiya, ka fasafɛn caman dun, walima ka waati jan ta ka welda ka tɛmɛ dɔw kan. Aw bɛ nin ko ninnu jateminɛ ni aw bɛ joli suguya dɔ sugandi walasa ka baarakɛcogo ɲuman ni musakabɔcogo ɲuman sɔrɔ.

5 fɔlɔ minnu bɛ kɛ ka welding joints .

Butt Joint .

Butt joint ye welding joints suguya dɔ ye min ka ca ani a ka nɔgɔn. A bɛ Sɔrɔ ni nɛgɛ fla bɛ Blà dakun-ni-da-kɔnɔ-yɔrɔ la k'u welda ɲɔgɔn na, ka ɲɔgɔndan Kɛ min tɛ 'sèn Bɔ ani min bɛ fla Kɛ. Butt joints bɛ kɛ ka caya baara suguya caman na, i n’a fɔ:

L pipe ni tube welding .

L structurel acier fabrication .

l feet métal fabrication .

l Degun-kurunba jɔli .

Butt joints bɛ se ka dabɔ ni groove cogoya caman ye, ka kɛɲɛ ni fɛnw girinya ye minnu bɛ fara ɲɔgɔn kan ani welda fanga ɲininen. Yɛlɛma minnu ka ca kosɛbɛ olu ye:

1. GROOVE Square .

2. V-Groove .

3. Bevel groove .

4. U-Groove .

5. J-Groove .

Walasa ka buteliw sɔrɔ minnu ka ɲi kosɛbɛ, aw ye nin laadilikan ninnu jateminɛ:

l Aw bɛ a lajɛ ni joli dakunw bɛ bɛn ɲɔgɔn ma ani ka u bɛn ɲɔgɔn ma walasa ka yɔrɔw ni ɲɔgɔn cɛbaliya dɔgɔya.

l groove configuration bɛnnen sugandi ka da fɛnw janya ni u fanga wajibiyalenw kan.

l Aw bɛ baara kɛ ni kɔkili walima fɛn min bɛ se ka tiɲɛ ni a mago bɛ o la walasa ka don dafalen sɔrɔ ani ka jeninida bali.

l Aw bɛ welding paramètres basigilenw mara, i n’a fɔ amperage, voltage, ani travel speed, welding kɛcogo bɛɛ la.

l Aw bɛ joli yɔrɔ saniya ka ɲɛ sani aw ka welding kɛ walasa ka nɔgɔ fɛn o fɛn bɔ a la min bɛ se ka nɔ bila welda cogoya la.

Tee Joint .

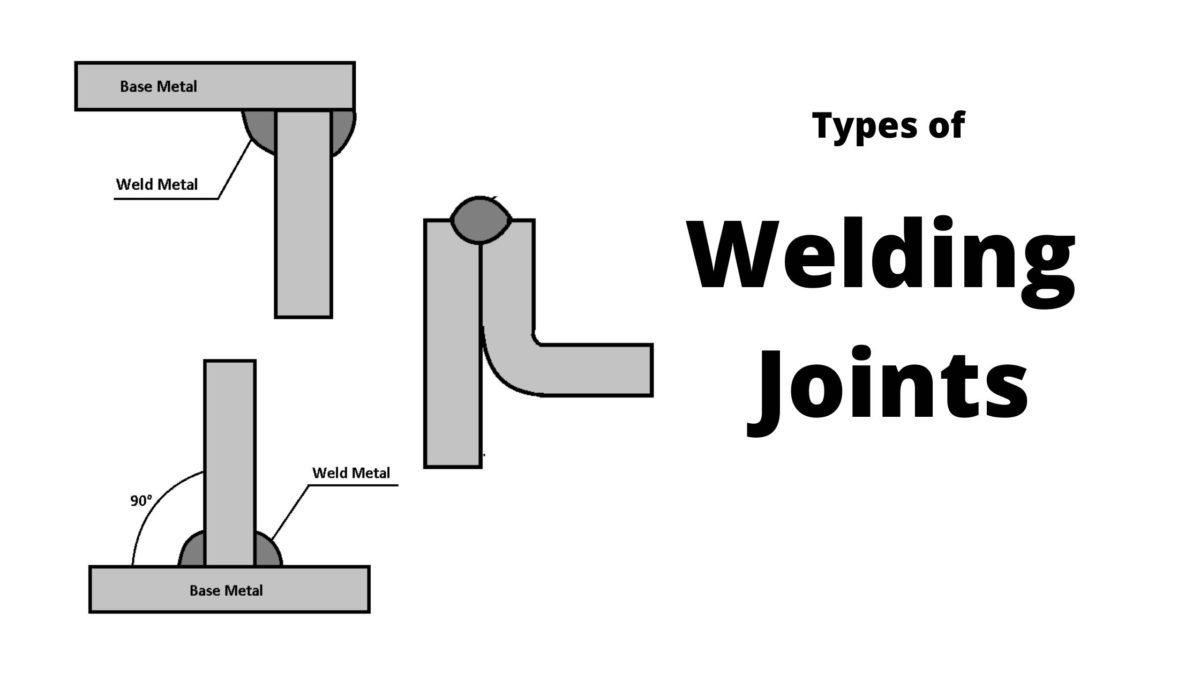

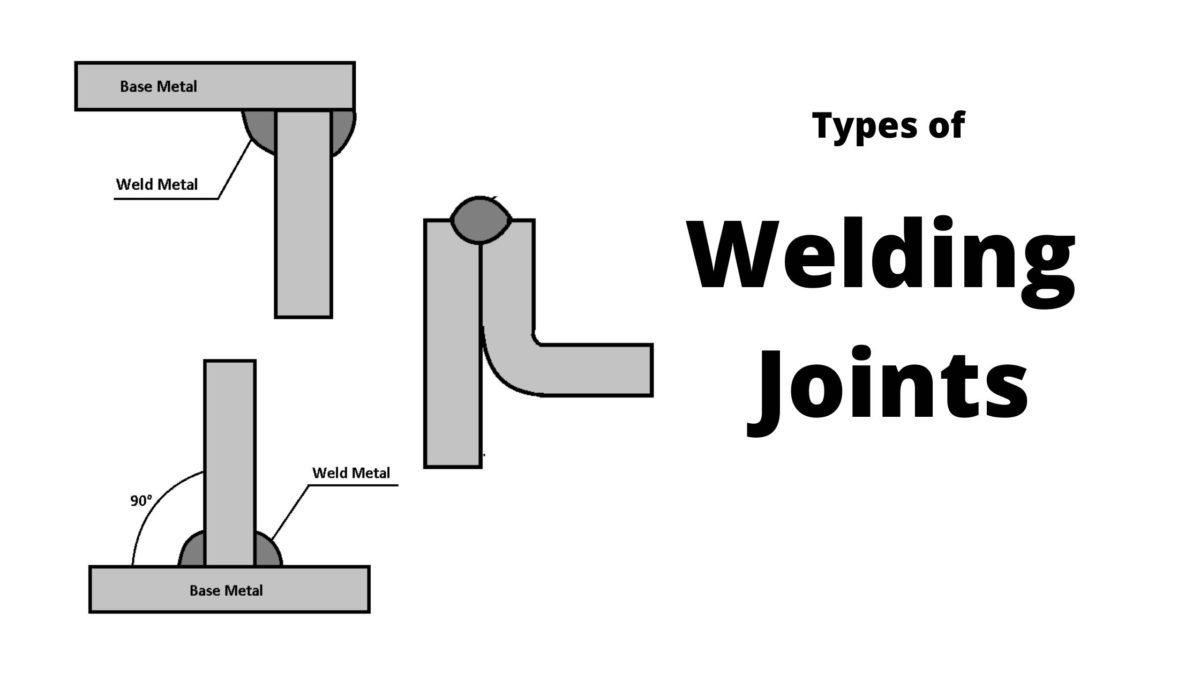

Tee joint, walima T-joint, bɛ da ni nɛgɛ kelen jɔlen bɛ dɔ wɛrɛ kan, ka kɛ 't' cogoya ye. Baarakɛminɛn kelen da bɛ siri ka taa tɔ kelen fan fla la. Tee jogindaw bɛ dɔn u ka masina fanga ɲuman fɛ, kɛrɛnkɛrɛnnenya la ni u sirilen don fan fila bɛɛ la. U bɛ baara kɛ kosɛbɛ baara suguya caman na, i n’a fɔ:

L structurel acier fabrication .

L Minɛnw dilanni .

L pipe ni tube welding .

A ka ca a la, tee joliw bɛ joli labɛnni fitinin de wajibiya, wa u sɔgɔli ka nɔgɔn kosɛbɛ ni u kɛcogo ɲuman ni u kɛcogo ɲumanw bɛ kɛ. Jogindaw dakunw bɛ se ka to u ma fɛn caman sɛmɛntiya, walima u bɛ se ka labɛn ni tigɛ ye, ni masinw ye, walima ni u sɔgɔra. Dilancogo jateminɛ minnu bɛ kɛ tee jogindaw kan, olu dɔw ye:

1. Baara kɛcogo : Ni aw bɛ tee joli 90 welding, a ka fisa aw ka baara kɛ ni 45 ye walasa ka doncogo ɲuman sɔrɔ baarakɛminɛn fila bɛɛ kan.

2. Material thickness: Ni welding dissimilar metal thicknesses, fore of the welda kan ka a bonya ka ɲɛ walasa ka fusion ɲuman sɔrɔ.

welda suguya caman ni a yɔrɔ fitinin caman bɛ se ka kɛ ka TEE jogindaw kɛ, i n’a fɔ:

L Fillet welds .

L bevel groove welds .

L J-Groove ka fɛnw .

L plug et slot welds .

L flare-bevel-groove welds .

L ka fɛnw falen-falen .

Ni tee joli bɛ welding, a nafa ka bon kosɛbɛ ka welda bila fan kelen na min bɛna degun walima ka doni ta. Joginda fan fila bɛɛ welding bɛ se ka fanga caman di ani ka dɛmɛ don ka dɛsɛ bali. Tee joints bɛ se ka kɛ fɛn caman ye wa u bɛ se ka welda cogo caman na, i n’a fɔ fla, horizontal, vertical, ani overhead.

Ko kelen min bɛ se ka kɛ ni tee joliw ye, o ye lamellar tearing ye, o bɛ se ka kɛ ka da a kan joli-sira-funu bɛ se ka kɛ. O bɛ se ka nɔgɔya ni baara kɛli ye ni welding fɛɛrɛ ɲumanw ye, ka sumaya ka kɔn, walima ka funteni furakɛli kɔfɛ ni a mago bɛ a la.

Lap joint .

Lap joint (lap) bɛ Sɔrɔ ni nɛgɛ fla bɛ ɲɔgɔn Da ɲɔgɔn kan, ka joli dɔ Dabɔ yɔrɔ min na weldalen bɛ yɔrɔ fla ninnu cɛ. Nin joli suguya in nafa ka bon kɛrɛnkɛrɛnnenya la ni fɛnw faralen don ɲɔgɔn kan minnu janya tɛ kelen ye, bawo u labɛncogo min bɛ ɲɔgɔn kan, o bɛ sira di jɛɲɔgɔnya barikama ma k’a sɔrɔ a ma kɛ ni joli labɛnni caman ye.

Lap jogindaw jogo ni u nafa jɔnjɔnw ye:

L Dafalen min bɛ ɲɔgɔn kan, o bɛ sira di ka fɛnw fara ɲɔgɔn kan minnu tɛ kelen ye .

l A bɛ tali kɛ jɛ-ka-baara la min ka dɔgɔn, waati ni nafolo bɛ bɔ a la .

L bɛ yɔrɔba dɔ di min ka bon kosɛbɛ welding, ka joli fanga bonya .

L bɛ sɛgɛsɛgɛli kɛ welding cogo ni a kɛcogo la .

LAP jogindaw bɛ kɛ ka caya izini suguya caman na, i n’a fɔ:

1. SHEET MEAL FACTIORTION .

2. Mobili farikolo panneau assemblée .

3. Dilanni ni a ladonni baarakɛminɛnw .

4. Remorque ani minɛnw dilanni .

Walasa ka lap joint (lap-joli) dilan, nɛgɛ fila ninnu bɛ jɔ walasa u ka se ka ɲɔgɔn sɔrɔ ni hakɛ kɛrɛnkɛrɛnnen ye, o min bɛ latigɛ ni fɛnw bonya ye minnu bɛ fara ɲɔgɔn kan. O yɔrɔw minnu bɛ ɲɔgɔn kan, olu ka kan ka saniya ani ka bɔ nɔgɔw la walasa ka welda fusili kɛcogo ɲuman sɔrɔ.

Welding styles caman bɛ se ka baara kɛ walasa ka lap joints dilan, ka kɛɲɛ ni u kɛcogo kɛrɛnkɛrɛnnen ye ani joli cogoya ɲininenw ye:

L Fillet welds .

L Plug welds .

L Spot welds .

L bevel groove welds .

Ni aw bɛ lap jogindaw labɛn ani ka u welding kɛ, a nafa ka bon kosɛbɛ ka a lajɛ ni yɔrɔw bɛ ɲɔgɔn kan ka ɲɛ ani ka u labɛn ka ɲɛ walasa ka yɔrɔw ni welda tiɲɛniw dɔgɔya. Aw bɛ jateminɛ kɛ ka ɲɛ, barisa ni aw tɛ se ka ɲɔgɔn sɔrɔ, o bɛ se ka kɛ sababu ye ka joli barikama sɔrɔ, ka sɔrɔ ni ɲɔgɔn falenni kojugu bɛ se ka kɛ sababu ye ka girinya ni fɛnw musakaw fara ɲɔgɔn kan.

Nkɔni jɛkulu .

Nkɔni jogindaw bɛ Sɔrɔ ni nɛgɛ fla bɛ Dòn ɲɔgɔn na ni 90-degree angle ye, ka L-shaped configuration (L-shaped configuration) Dabɔ. O jogindaw ni tee joliw bɔlen don ɲɔgɔn fɛ nka u tɛ kelen ye baarakɛminɛnw jɔyɔrɔ la. Nkɔni jogindaw bɛ kɛ ka caya karamɔgɔya la, kɛsu, ani nɛgɛdaga baara suguya caman dilanni na.

Nkɔni joli suguya belebele fila bɛ yen:

1. Open Corner Joint : Nin joli suguya in na, baarakɛminɛn fila in dakunw bɛ lajɛ ɲɔgɔn fɛ u nɔngɔnw na, ka kɛ V-cogo-yɔrɔ ye. O bɛ kɛ sababu ye ka se ka sɔrɔ ka ɲɛ ani ka welda nɔgɔya, kɛrɛnkɛrɛnnenya la ni baara bɛ kɛ ni fɛnw ye minnu ka bon.

2. Nkɔni dasirilen : nkɔni dasirilen dɔ bɛ dabɔ ni baarakɛminɛn kelen da bɛ na ni a kolen ye tɔ kelen ɲɛda la, ka kɛ nkɔni sirilen ye, min datugulen don. Nin joli suguya in bɛnnen don kosɛbɛ fɛn finmanw ma ani a bɛ kɛ cogo la min bɛ saniya, min bɛ diya ka ɲɛ.

Sugandili min bɛ kɛ nkɔni da wulilen ni datugulen cɛ, o bɛ bɔ fɛn caman na, i n’a fɔ fɛnw girinya, joli fanga ɲininen, ani a kɛcogo kɛrɛnkɛrɛnnenw.

Nkɔni jogindaw bɛ kɛ ka caya nin baara ninnu na:

l feet métal fabrication .

L HVAC ka kanali .

L Panneau de body de body .

L Kalansenw dilanni .

welda suguya caman bɛ se ka kɛ ka nkɔni jogindaw dilan, ka kɛɲɛ ni jogindaw cogoya ye ani fanga ɲininen ye:

L Fillet welds .

L V-Groove ka fɛnw .

L Edge ka fɛnw .

L Spot welds .

l corre-flanges de corps .

L J-Groove ka fɛnw .

L U-Groove ka fɛnw .

L Bevel-Groove welds .

L flare-v-groove welds .

L Square-Groove welds .

Ni welding corner joints, a nafa ka bon ka a lajɛ ni a bɛ bɛn ani ka a labɛn ka ɲɛ ani ka a labɛn ka ɲɛ ani ka a kɛ ka a yɔrɔ ɲininen mara. Sumaya ɲɛfɛ, funteni furakɛli kɔfɛ, ani welding fɛɛrɛ ɲumanw fana bɛ se ka dɛmɛ don ka ko dɔw bali i n’a fɔ kari walima ka kirin.

Edge Joint .

Edge joint ye welding joint suguya dɔ ye min bɛ sɔrɔ ni nɛgɛ fila dakunw bɛ ɲɔgɔn kan ani ka u siri ɲɔgɔn na. O joli suguya in bɛ dɔn ni baarakɛminɛnw bilali ye kɛrɛfɛ, n’u dakunw bɛ maga walima u faralen don ɲɔgɔn kan dɔɔnin, ka kɛɲɛ ni u kɛcogo kɛrɛnkɛrɛnnen ye ani u ka sɔgɔli kɛcogo ye min bɛ kɛ.

Edge joints (dakunw) bɛ kɛ ka caya fɛnw ni fɛn suguya caman dilanni na, i n’a fɔ:

1. Nɛgɛdaga finmanw .

2. Plate Girders ani Beams .

3. Kalansenw sigicogo .

4. Tanki ni kurunw sɔgɔli .

Edge joints (dakunw) ka fɛn caman bɛ sɔrɔ u seko la ka ladamu ni fɛnw janya ni u sɔgɔli wajibiyalenw ye dakun labɛncogo suguya caman kɛli fɛ. O labɛnw ye baarakɛminɛnw dakunw labɛnni ye walasa ka groove profile kɛrɛnkɛrɛnnen dɔ dilan, min bɛ se ka nɔ bila welda fanga, a doncogo ani a bɛɛ lajɛlen na.

Dakunw labɛnni minnu bɛ kɛ ɲɔgɔn na, olu ye:

l dakunw kɛnɛw : dakun jɛlen nɔgɔman, yɔrɔ min na baarakɛminɛnw dakunw bɛ to ka kɛ fla ye ani ka kɛ kɛrɛ ye. Nin labɛn in bɛ kɛ ka caya fɛn finmanw kama walima ni kɔfɛla bɛ baara kɛ.

L V-Groove: V-cogo dɔ bɛ dabɔ ni baarakɛminɛn fila bɛɛ dakunw ye, o bɛ sira di welda doncogo jugu ma ani ka joli fanga bonya.

L Bevel Groove: A bɛ tali kɛ V-Groove la, nka baarakɛminɛn dakun kelen dɔrɔn de bɛ chamfered, ka asymétrique groove profile dɔ dilan.

L J-Groove: J-cogo dɔ bɛ Sɔrɔ ni dakun kɛrɛnkɛrɛnnen dɔ ye baarakɛminɛn kelen kan ni dakun kurulen walima radiyali ye tɔ kelen kan. Nin labɛn in bɛ kɛ baara kɛrɛnkɛrɛnnenw na walima ni kɔkanna bara dɔ wajibiyalen don.

L U-Groove: U-shaped groove bɛ da ni chamfering fila bɛɛ ye baarakɛminɛn dakunw na ni curved walima radius profile ye, o bɛ welda doncogo ɲuman ni fanga di.

Edge labɛnni sugandili bɛ bɔ fɛnw na i n’a fɔ fɛnw janya, welda fanga ɲininen, ani welding kɛcogo kɛrɛnkɛrɛnnen min bɛ kɛ.

Welding fɛɛrɛ caman bɛ se ka kɛ walasa ka dakun joliw da, u kelen-kelen bɛɛ n’a nafaw n’u jateminɛcogo:

1. groove welds : Fɛɛrɛ min ka teli ka kɛ dakunw na, groove welda bɛ kɛ ka falan nɛgɛ bila ka don jirisunba labɛnni na baarakɛminɛnw ni ɲɔgɔn cɛ. Groove weld suguya kɛrɛnkɛrɛnnen (misali la, V-Groove, Bevel Groove, walima U-Groove) bɛ bɔ dakun labɛnni na min bɛ kɛ.

2. corner flange welds : O welda ninnu bɛ kɛ ni baarakɛminɛn kelen walima u fila bɛɛ ye flanged walima bent edge sɔrɔ, ka nkɔni ɲɔgɔnna cogoya dɔ da. Nkɔni flansɛw bɛ fanga ni gɛlɛya wɛrɛw di joli ma.

3. Edge flange welds: i n’a fɔ nkɔni flansɛw, dakun flansɛw bɛ kɛ ni baarakɛminɛnw dakunw bɛ jɛ walima u kɔrɔtalen don, nka flangew bɛ ɲɛsin sira kelen ma, ka jibolisira walima ɲɛda tolen dɔ da.

Ni welding edge joints, a nafa ka bon ka a jira ko baarakɛminɛnw bɛ bɛn ɲɔgɔn ma ani ka u labɛn ka ɲɛ walasa ka yɔrɔw dɔgɔya ani ka welda tiɲɛniw bali. Tack welds, clamping walima fixtures kɛrɛnkɛrɛnnenw tali bɛ se ka dɛmɛ don ka ɲɔgɔndɛmɛ ɲininen mara welding kɛcogo bɛɛ la.

Ladilikanw ka ɲɛsin welding joint dilancogo ɲuman sugandili ma .

Ka welding joint dilancogo ɲuman sugandi, o nafa ka bon kosɛbɛ walasa ka i ka welding poroze fanga, a muɲuni ani a bɛɛ lajɛlen ɲɛtaa sabati. Ni fɛn caman bɛ jateminɛ, a bɛ se ka kɛ fɛn ye min bɛ mɔgɔ caman degun ka joli suguya ɲuman dɔn i ka baara kɛrɛnkɛrɛnnen na.

Walasa ka dɛmɛ don ka latigɛ kɛcogo nɔgɔya, laadilikan nafama dɔw filɛ nin ye minnu ka kan ka to an hakili la ni aw bɛ welding joint design sugandi:

1. Aw bɛ fɛnw bonya ni u joli sɔrɔcogo jateminɛ : .

kelen. Fɛn minnu bɛ fara ɲɔgɔn kan, olu girinya jɔyɔrɔ ka bon joli suguya bɛnnenw dɔnni na.

B. Fɛn minnu ka bon, olu bɛ se ka kɛ welda walima dondaw dafalen ye, ka sɔrɔ fɛn minnu ka fin, olu bɛ se ka welda ka ɲɛ ni filenw walima lapɔnw ye.

C. Ka fara o kan, aw bɛ joli yɔrɔ sɔrɔli jateminɛ – joli suguya dɔw, i n’a fɔ nkɔni walima dakunw, a bɛ se ka nɔgɔya ka don yɔrɔ gɛlɛnw na walima yɔrɔ gɛlɛnw na.

2. Faamuyali fanga wajibiyalenw ani doni-ta-ko magow : .

kelen. Aw ye aw ka welda sigicogo kuntilenna ni doni tacogo laɲinitaw jateminɛ.

B. Yala a bɛna kɛ ni degun ye, walima ni a bɛ se ka a yɛrɛ minɛ wa?

C. Joli suguya dɔw, i n’a fɔ butt welda dafalenw, olu bɛ fanga ɲuman di ni tɔw ye.

D. Aw ye aw jija ka jɛ-ka-baara dɔ sugandi min bɛ se ka doni ni degun makɔnɔnenw muɲu sigida ka ɲɛnamaya kɔnɔ.

3. Aw ye jateminɛ laban ni ɲɛnajɛko ɲininenw jateminɛ :

kelen. Baara dɔw la, joli weldalen in yecogo nafa ka bon i n’a fɔ a fanga.

B. Ni ɲɛda saniyalen, min tɛ fɛn tiɲɛ, aw bɛ se ka buteli joli sugandi ni a dakun labɛncogo ɲuman ni a labancogo fɛɛrɛw ye.

C. Faan wɛrɛ fɛ, ni joli bɛna dogo walima ni a ɲɛda cogoya tɛ haminanko fɔlɔ ye, lap walima tee joli bɛ se ka kɛ ka ɲɛ.

4. Aw bɛ tugu welding codes (welding codes) la, sariyaw, ani kɛcogo ɲumanw na :

kelen. Ni aw bɛ welding joint design sugandi, a nafa ka bon ka tugu welding codes, standards, walima specifications minnu bɛ se ka kɛ aw ka industry walima projet ye.

B. Nin laadilikan ninnu ka teli ka ɲinini caman kɛ jɛ-ka-baara, labɛnni, ani welding fɛɛrɛw kan walasa ka welda-dafalenw lakana ani u dafalen.

C. Aw ye aw yɛrɛ dɔn sariyaw la minnu bɛ tali kɛ o ko la ani ka tugu u kɔ kosɛbɛ walasa aw kana aw yɛrɛ tanga ko dɔw ma minnu bɛ se ka kɛ walima ka baara kɛ kokura.

5. Aw ye lajɛ kɛ ni baarakɛlaw ye minnu bɛ se kosɛbɛ ni u dalen tɛ a la :

kelen. N’aw dalen tɛ a la ko aw ka sɛbɛn kɛrɛnkɛrɛnnen dicogo ɲuman bɛ se ka kɛ, aw kana siga ka ladilikan ɲini welding baarakɛlaw fɛ minnu bɛ se kosɛbɛ, i n’a fɔ welding inspectors (CWIS), welding injiniyɛriw, walima fɛn dilannikɛlaw minnu bɛ waati kɔnɔ, olu ka se ka sɛbɛn.

B. U bɛ se ka hakilina nafamaw ni ladilikanw di ka da u ka dɔnniya n’u ka ko kɛlenw kan, k’i dɛmɛ ka desizɔn ta ni kunnafoni ye ani ka i yɛrɛ tanga filiw ma minnu bɛ musaka caman bɔ.

Ni aw ye nin laadilikan ninnu labato ani ka aw ka welding poroze ka wajibi kɛrɛnkɛrɛnnenw jateminɛ kosɛbɛ, aw bɛ se ka jɛkulu ka dilancogo ɲuman sugandi min bɛ fanga, sɔrɔcogo, ɲɛnajɛko, ani sariyaw labato minnu bɛ tali kɛ o ko la. Aw ye aw hakili to a la, ka waati ta ka joli suguya ɲuman sugandi ka kɔn o ɲɛ, o bɛ se ka waati, cɛsiri, ani nafolo nafamaw kisi aw ma waati jan kɔnɔ, ka aw ka weldalen sigicogo ɲɛtaa n’a ɲɛnamaya sabati.

Fɛɛrɛ minnu bɛ kɛ ka jolilabanaw ka jogo ɲɛ .

Walasa ka joginda barikamaw sɔrɔ, minnu bɛ se ka da u kan, ani minnu ka ɲi, a nafa ka bon ka fɛɛrɛ ɲumanw kɛ welding kɛcogo bɛɛ la. Ni aw bɛ aw sinsin ko jɔnjɔnw kan i n’a fɔ dugukolo sanfɛla labɛnni, a labɛncogo, a sɔgɔli paramɛtiriw, ani a furakɛli kɔfɛ furakɛliw, aw bɛ se ka aw ka welda joliw bɛɛ lajɛlen cogoya n’u baara kɛcogo bɛɛ lajɛlen bonya kosɛbɛ. Fɛɛrɛ nafama dɔw filɛ nin ye minnu ka kan ka to an hakili la:

1. Saniya ni dugukolo labɛncogo ɲuman sani a ka kɛ welding ye :

kelen. Aw bɛ aw jija ka yɔrɔ minnu ka kan ka siri, olu tɛ nɔgɔw bɔ i n’a fɔ nɔgɔ, tulu, tulu walima penti.

B. Aw bɛ baara kɛ ni saniya fɛɛrɛ bɛnnenw ye, i n’a fɔ nɛgɛjuru, sɔgɔli, walima saniya kemikali, walasa ka nɔgɔw bɔ minnu bɛ se ka nɔ bila welda cogoya la.

C. Surface labɛnni ɲuman bɛ fusion ɲuman sabati ani ka welda tiɲɛniw farati dɔgɔya i n’a fɔ porosity walima fusion dɛsɛ.

2. Baarakɛminɛnw labɛncogo ɲuman ni u labɛncogo tigitigi marali :

kelen. Aw bɛ aw jija ka baarakɛminɛn minnu bɛna fara ɲɔgɔn kan, olu ka bɛn ɲɔgɔn ma ka ɲɛ ani ka u labɛn ɲɔgɔn fɛ ni yɔrɔ fitininw ye.

B. Aw bɛ baara kɛ ni sirilanw ye, ni fɛnw ye minnu bɛ se ka fɛnw siri, walima ni u bɛ siri walasa ka ɲɔgɔndɛmɛ ɲininen mara welding kɛcogo bɛɛ la.

C. Ni aw bɛ a labɛn ka ɲɛ ani ka a labɛn ka ɲɛ, o bɛ dɛmɛ ka welda doncogo kelen sɔrɔ, ka degunw hakɛ dɔgɔya, ani ka fɛnw tiɲɛni dɔgɔya.

3. welding paramètres ani consumables bɛnnenw sugandili : .

kelen. Aw bɛ welding kɛcogo ɲuman sugandi, ka nɛgɛ fa, ani ka gazi tanga fɛn kɛrɛnkɛrɛnnenw ma ani ka a kɛ.

B. Aw bɛ welding paramɛtiriw ladilan i n’a fɔ amperage, voltage, ani taama teliya walasa ka se ka welda doncogo ni biɲɛw cogoya ɲininen sɔrɔ.

C. Baara kɛli ni fɛnw ye minnu bɛ se ka tiɲɛ ani minnu bɛ kɛ ka fɛnw tiɲɛ, o bɛ welda tiɲɛni farati dɔgɔya, ka welda cogoya ɲɛ, ani ka dɔ fara baarakɛcogo kan.

4. Sumaya doncogo ni a waleyacogo ɲuman welding sequences :

kelen. Aw bɛ funteni doncogo ɲɛnabɔ ni welding paramɛtɛrɛw ladilanni ye ani ka baara kɛ ni welding fɛɛrɛ bɛnnenw ye, i n’a fɔ Stringer Beads walima Weaving.

B. Aw bɛ welding sequences bɛnnenw waleya, i n’a fɔ backstepping walima skip welding, walasa ka tiɲɛniw dɔgɔya ani ka degun tolenw dɔgɔya.

C. Funteni doncogo kɔlɔsili ani baara kɛli ni welding sequences bɛnnenw ye, o bɛ dɛmɛ ka basigifɛn ka masinko fɛɛrɛ ɲininenw mara ani ka dɔ bɔ welda ni ko minnu bɛ tali kɛ ɲɔgɔn na.

5. Aw bɛ baara kɛ ni furakɛli ni sɛgɛsɛgɛliw ye minnu kɛra kɔfɛ ni aw mago bɛ a la :

kelen. Aw bɛ furakɛli wajibiyalenw kɛ kɔfɛ, i n’a fɔ degunw kunbɛncogo, funteni furakɛli, walima ɲɛda fanidoncogo, walasa ka joli weldalen ka masina cogoyaw n’a cogoya ɲɛ.

B. Aw bɛ fɛɛrɛ bɛnnenw kɛ minnu tɛ tiɲɛni kɛ (NDT) fɛɛrɛ bɛnnenw na, i n’a fɔ sɛgɛsɛgɛli yelen, sɛgɛsɛgɛli min bɛ kɛ ni kɔnɔnajɛya ye, walima sɛgɛsɛgɛli min bɛ kɛ ni rezow ye, walasa ka welda tiɲɛni fɛn o fɛn bɛ se ka kɛ.

C. Ni aw bɛ baara kɛ ni furakɛliw ni sɛgɛsɛgɛliw ye minnu kɛra kɔfɛ, o bɛ dɛmɛ ka joli weldalen in dafalen ni a jogo ɲuman sabati ani ka ko dɔw jira minnu bɛ se ka kɛ dilan walima ka baara kɛ kokura.

Ni aw ye nin fɛɛrɛ ninnu waleya tuma bɛɛ ani ka aw janto kosɛbɛ fɛn fitininw na, aw bɛ se ka aw ka jogindaw weldalenw cogoya n’u kɛcogo ɲɛ kosɛbɛ. Aw k’aw hakili to a la ko ka waati ni cɛsiri kɛ welding kɛcogo ɲumanw na ka kɔn o ɲɛ, o bɛ se ka waati nafama, nafolo, ani kunkolodimi minnu bɛ se ka kɛ, olu kisi aw ma, laban na, o bɛ na ni welding porozɛ ye min bɛ ɲɛtaa sɔrɔ ani min bɛ se ka da a kan.

Kuncɛli

Nin gafe in kɔnɔ, an ye sɛgɛsɛgɛli kɛ welding joint suguya duuru kan: butt, tee, corner, lap, ani edge. Joli suguya kelen-kelen bɛɛ n’a ka jogo kɛrɛnkɛrɛnnenw, a ka baarakɛcogo ani a ka jateminɛw ye walasa ka welda jogo ɲuman ni fanga ɲuman sɔrɔ.

Welding joint bɛnnen sugandili nafa ka bon kosɛbɛ walasa ka i ka welda sigicogo dafalen n’a baara kɛcogo sabati. Ni aw ye fɛnw faamuya minnu bɛ sɔrɔ jɛ-ka-baara sugandili la, i n’a fɔ fɛnw janya, doni wajibiyalenw, ani sɔrɔli, aw bɛ se ka latigɛw kɛ ni kunnafoni ye minnu bɛ na ni welding porozew ɲɛtaa ye.

Ɲininkaliw jaabiw .

J: Welding defauts commun dɔw ye jumɛnw ye minnu ka kan ka kɔlɔsi ni joli suguya kelen-kelen bɛɛ ye?

A: Nafa minnu bɛ sɔrɔ tuma caman na, olu ye fusion dafabali ye, porosity ani cracking. Joli labɛnni ɲuman, welding fɛɛrɛ, ani paramɛtiriw sugandili bɛ se ka dɛmɛ don ka nin ko ninnu bali.

J: Yala welding joint suguya caman bɛ se ka fara ɲɔgɔn kan porozɛ kelen kɔnɔ wa?

A: Ɔwɔ, joli suguya caman bɛ se ka kɛ porozɛ kelen kɔnɔ. Sugandili bɛ bɔ ɲɔgɔndan kelen-kelen bɛɛ ka wajibi kɛrɛnkɛrɛnnenw na.

J: Fɛn jumɛnw de nafa ka bon kosɛbɛ ni i bɛ ka groove configurations suguya wɛrɛw sugandi?

A: Fɛnw janya, welda fanga ɲininen, ani welding kɛcogo ye fɛn nafamaw ye. Groove design bɛ nɔ bila doncogo la, fusion, ani joli bɛɛ lajɛlen baarakɛcogo la.

J: Ne bɛ se k’a dɔn cogo di ni ne mago bɛ don dafalen na walima a fan dɔ la?

A: Aw ye doni wajibiyalenw ni dilancogo ɲɛfɔcogo jateminɛ. Joli dafalen doncogo bɛ fanga caman di, ka sɔrɔ donni yɔrɔ dɔw bɛ se ka bɔ baara la min man kan ka kɛ kosɛbɛ.