Have vos umquam admiratio quomodo manufacturers creare incredibiliter precise components in quibusdam durissima materiae notum est ipsum? Electrical missionem Machining (Edm) stat ad frontem de modern vestibulum technology, revolutioning quam nos figura metallum et PROLIXUS materiae.

Hoc provectus vestibulum processus loricas potestatem coerceri electrica obit ad consequi micron-gradu praecisione in machining universa geometries. Ex Aerospace Turbine components ad medicinae implantatorum, EDM scriptor capabilities extendunt per diverse industrias, offering solutions ubi traditional secans modos cadere.

Per explorandum processibus, types, et applications, nos unveil quomodo Edm transforms rudis materiae in praecisione, machinator components quod potestatem nostram nostram mundo.

Quid est EDM (electrica missionem Machining)?

Intellectus Edm fundamentum

Electrical missionem Machining (Edm) est praecisione vestibulum processus utilizing imperium electrica scintillas ad removendum materiam a PROLIXUS workpieces. Processus operates per electrica obit inter an electrode et workpiece, tum demergi in a dielectric fluidi . In in missionem gap of 0.01-0.5mm, millia scintillae per secundo creare localized zonas pervenire 8,000-12.000 ° C.

Et Dielectric fluidi serves multiple munera: providing electrica velit, refrigerationem machining area, rutilant awahing particulas et maintaining optimal gap conditionibus.

Principia scintilla exesa

In scintillam exesa processus sequitur a praecise sequence ubi ad ionization alveo develops in Pure Cannel of Superheated Gas. Material remotionem occurs per:

Melting et vaporization de materia

Ejectiontten ex electro copias

Formatio a recust iacuit per resolidification

Key processus parametri includit:

Historia evolutione Edm

Edm technology emerged in 1940s per Soviet scientists Boris et Natalya Lazarenko scriptor inventa de coercentur electrica exesa. In Evolution Progression ex basic Lazarenko circuits ad modern systems featuring cnc integration , filum-Edm technology, et provectus capabilities comprehendo Micro-Edm , Actyptive Imperium , et Ai-Pulcher Processus Aerospace et Medical Industria.

Quid est Edm amet in modern vestibulum?

Achieving praecisione vestibulum per EDM technology

Micron-gradu accurate et universa geometries characterise Edm scriptor praecisione elit in modern vestibulum. Processus Achieves dimensiva tolerances ut stricta quod ± 0.001mm dum machining intricate figuris in induratum materiae. Et non-contactus naturam Edm eliminat mechanica passiones et instrumentum induendum exitibus, quod typically modus conventional machining praecisione, enabling creaturae microscale features cum eximia superficies metam qualis.

Beneficia de Edm vestibulum in instrumentum et mori faciens

Mercatum materiae et profunda cavitates demonstrabo EDM scriptor crucial partes in tool et mori vestibulum. Et technology machines tool ferro components cum duritiam excedentem LX HRC sine dimensiva distortione consociata cum calor curatio processibus. Edm creates precise mori Cavitates cum profundum-ut-width rationibus major quam XX: I, incorporating intricate details et textured superficiebus, quod augendae in perficientur de iniectio coronam, et stampam operationes.

Impact in aerospace components

Calor-repugnans alloys et internum features showcase Edm est significationem in aerospace vestibulum. Processus excellit ad machining universa refrigerationem channels in Turbine components ex Nickel-fundatur superalloys, maintaining discrimine materiam proprietatibus per machining processus. Edm technology gignit praecisione-informibus diffundere foramina ut parva ut 0.3mm in diametrum ad cibus iniectio systems, directe contribuisset ad melius engine efficientiam et perficientur in modern elit.

Profacies et incommoda Edm technology

Commoda Edm Processing

Extraordinarios capability Edm apparatus complexu geometries seorsum a conventional modi. Processus excellit ad creando intricate figuras et internum features cum aspect rationes excedens XX: I, dum achieving acies internum angulos et denique singula quae esset impossibile per traditional machining aditus.

Material versatility represents alium significant utilitatem Edm technology. In processus efficiently machinis quis electrically PROLIXUS materia, pro duritia. Hoc facultatem probat praecipue valuable cum operantes cum ingravatum ferro usque ad LXX HRC, ut EDM eliminat periculum post-curatio distorsio et tractat exotic alloys cum otium.

In verbis praecisione et qualis , Edm demonstrat eximia elit. Et technology constanter Achieves tolerances ut stricta quod ± 0.001mm dum producendo optimum superficies finiatur usque ad 0,1. In absentia directum tool-ut-workpiece contactus eliminat mechanica accentus in delicata partes, unde in Burr-liberum components cum minimal calor-affectus zonis.

Incommoda Edm Processing

Prima limitatio Edm mendacium in processui celeritate . Comparari ad conventional machining modi, EDM exhibet tardius materia remotionem rates, ducens ad augeri productio tempore, praecipue pro simplex geometries. Hoc limitationem fit praesertim apparent in summus volumine productio missionibus quo exolvuntur tempore est crucial.

Operating sumptibus praesentem alium significant provocatione. In technology postulat substantial initial investment in apparatu et ongoing sustentationem expensis. Ordinarius electrode replacement debitum ad induendum et significant industria consummatio per operationem conferre ad altiorem productio costs comparari conventional machining modi.

Technical cohiberi inhaerens ad Edm processus requirere diligenter. Technology pendeat specialioribus dielectric liquor Management systems et petit iusto electrode sustentationem. Ceterum processum generat parva calor-affectus zone in machined superficie, et applicationem manet limited ad electrically PROLIXUS materiae.

Processus imperium complexitate adiungit aliud iacuit de provocatione. Achieving optimal praecessi requirit sophisticated modularis optimization et peritus operators, qui intelligere inlicacia processus. Systematis est scriptor sensitivity ad electrica conductivity variationes et opus ad iusto sustentacionem de Dielectric ratio demanda consistent operam ad ponere processus stabilitatem.

Quid facit in EDM opus?

Generating electrica obit

Dielectric fluidum , voltage potentiale , et electrode gap forma fundamental ex electrica missionem machining. Processus initiat cum intentione differentia applicantur inter tool Electrode et workpiece, typically a XX ad CXX volts. Et dielectric fluidum, plerumque hydrocarbon oleum aut deionized aqua implet parva gap (0.01-0.5mm) inter haec components. Sicut intentione crescit, quod gignit intensionem electrica agro quod ionizes in dielectric fluidi, formatam plasma alveo.

Et plasma alveo cursim expands, generating localized temperaturis ad 8,000 ad 12.000 ° c. Haec summa temperaturis causa workpiece materiam ad conflandum et vaporize instanti. Cum current est interrumpitur, in plasma alveo collapsa, creando implaciendo, quod fortiter eiecceat ad fusum materiam ex workpiece superficiem. Et Dielectric fluida tum rubet hos microscopic particulas parat superficie proximo missionem.

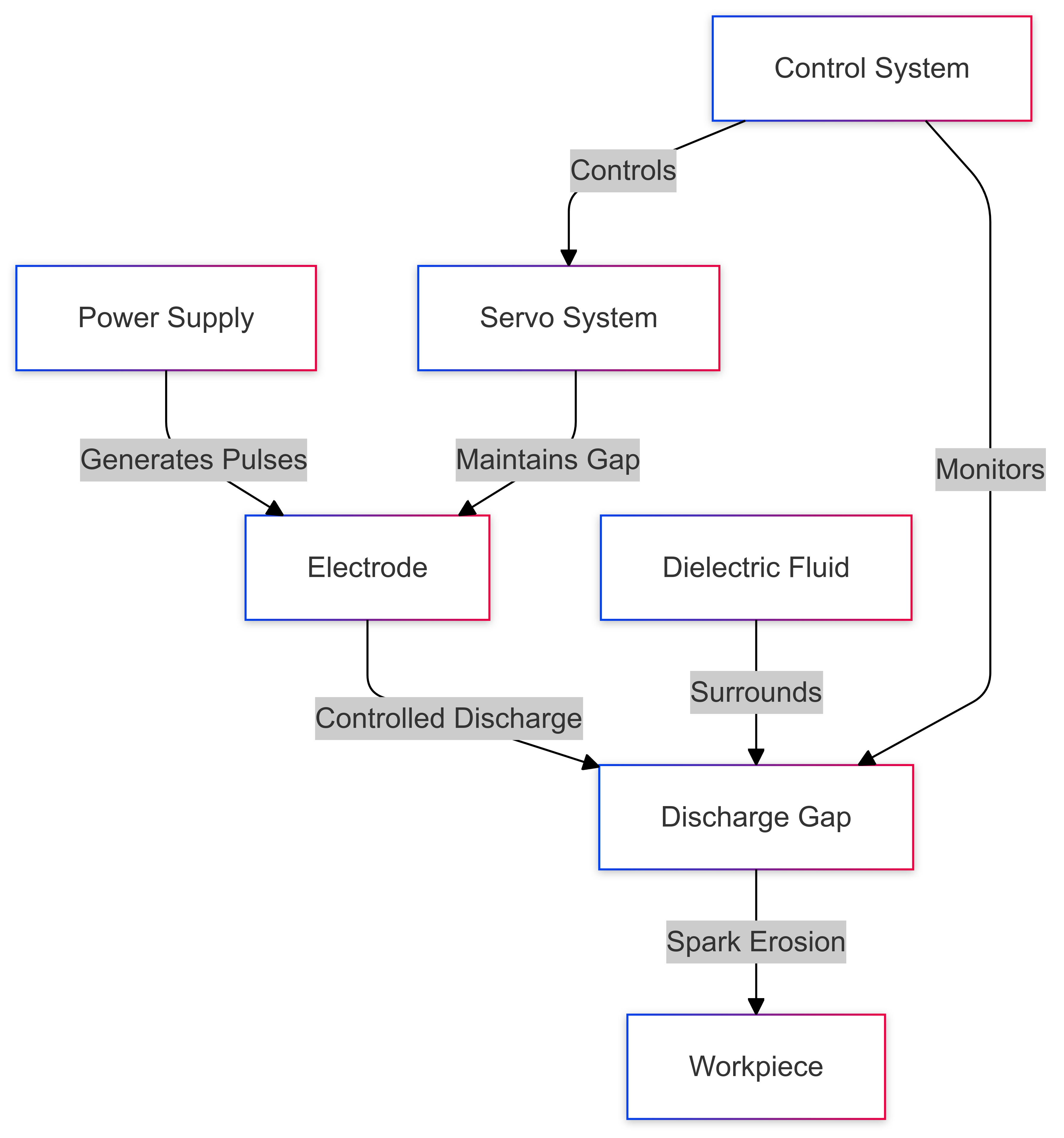

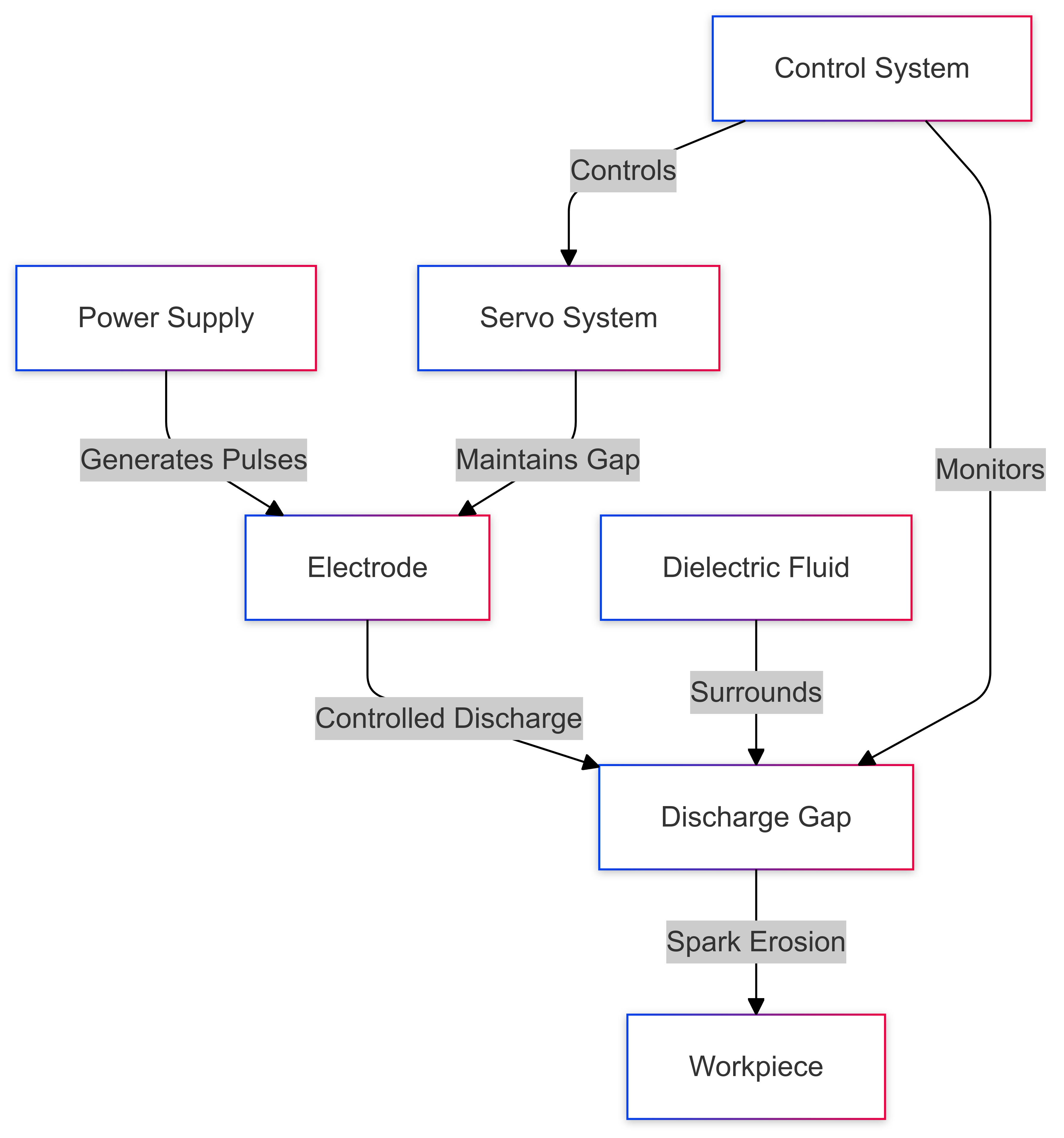

Components of Edm Systems

Vox copia unitas servit ut cor Edm operationes, tradens diligenter exerceri electrica pulsus. Moderni potestate utilitas sophisticated semiconductor cogitationes generate premise pulsus patterns, cum frequentiis vndique a 2,000 ad 500,000 HZ. Haec unitates modulatur et pulsus durationem et intensionem, permittens ad optimized materiam remotionem rates.

Dielectric ratio maintains in crucial operating environment. Constat ex adipiscing lacus, soleat, odio, et temperatus imperium unitates. In dielectric fluidi ira per complexu filtration system quod removet obstantia particulas ut parva ut 2-5 microns. Temperature stabilization in ± I ° C ensures consistent machining conditionibus et dimensional accurate.

Machina tool structuram praebet mechanica compage ad precise electrode positioning. High-praecisione servo systems control ad electrode motus cum resolutio usque ad 0,1 micrometris. Et structuram incorporat tremens, damping materiae et scelerisque ultricies systems ad ponere positioning accurate in extenditur machining operationes.

Monitoring et imperium in EDM

Verus-vicis gap magna sophisticated sensoriis ut metiretur electrica characteres cuiusque missionem. Advanced Systems analyze voltage et current waveforms ad microsecond intervals, detecting variationes ut indicant suboptimal machining conditionibus. Haec data feeds in Adaptive Imperium Algorithms quod continuouse optimize processus parametri.

Missionem stabilitatem control maintains consistent material remotionem rates per automated disparet machining parametri. Cum abnormal missionem exemplaria fieri, ratio potest modify pulsum parametri, rutilant pressura, aut electrode positus in milliseconds. Modern Edm machinarum incorporate artificialis intelligentia algorithms discere ex historical processus notitia ad praedicere et ne machining instabilities.

Superficies Quality magna Systems Track Evolution of Workpiece Superficies characteres in machining. Miscellam emission sensoriis deprehendere subtile mutationes in officio characteres ut afficit superficiem metam. Integration cum visione systems sino pro automated inspectionem superficiem texture et dimensional accurate, enabling clausa-loop imperium consummatione operationes.

Diversis genera Edm technology

Filum Edm

Filum electrica missionem machining (Wedm) utitur tenues metallicum filum, typice aes aut aeris, vndique a 0.3mm in diam. In filum acts ut continue movens electrode creando praecisis per electrica obit. A computatrum-continet ratio ducibus in filum scriptor iter dum maintaining constans gap inter filum et workpiece. Deionized aquam serves ut dielectric fluidi, providente superior refrigerationem et rutiusing capabilities in secare processus.

Filum subit continua continue pascit nova filum a copia spool, ne electrode gerunt afficiens cutting accurate. Provectus Wedm Systems consequi superficies finiatur ut bene sicut 0,1 micrometers ra et situ accuracies intra ± 0.001mm. Multi-axis control systems enable universa geometries, inter taperati et curvam superficierum, faciens Wedm praecipue valuable in tool et mori vestibulum.

Sinker EDM

Die-mergit Edm , etiam ut arietem Edm, utilitas a pressius informibus electrode quod plenunges in workpiece. Et electrode, communiter ex graphite aut aeris, maintains ejus figura dum creando in inversam cavitatem in workpiece. Hydrocarbon olei dielectric fluids ira per machining zona, maintaining meliorem fluxum fluxum condiciones et removere obstantia.

Moderni sinker Edm systemata incorporate orbitalis motus capabilities, permittens ad electrode movere in universa exemplaria in machining. Hoc orbitalis actio aucta rutilant efficientiam et amplio superficiem metam qualis. Automatic tool Changers accommodate multiple electrodes, enabling roughing et consummatione operationes cum diversis electrode geometries in unum setup.

More Details about Wire Edm vs. Sinker EDM.

EXERCITATIO EDM

Parvus foramen EXERCITATIO EDM specialitas in creando praecise foramina per tubulosam electrodes. Et electrodes, typice aes aut aeris, pluma internus rutilant rivos enim dielectric fluidi partus directe ad sectionem zone. Hoc technology facit foramina ut parva ut 0.1mm in diametrum cum profundum-ut-diameter componat nimis XX: I.

High-Rotatione Rotation de Electrode (500-2000 RPM) combines cum electrica obit ad consequi celeri materia remotionem rates. Rotating motu auget rutilant efficientiam et maintains foraminis. Advanced systems incorporate breakthrough deprehendatur ne electrode damnum cum completing per-foramina.

Micro Edm

Micro-scale EDM tendat ad terminos miniaturization, operantes cum pluma moles infra C micrometers. Ultra-denique filum electrodes, interdum ut tenuis ut 0.01mm, enable maxime praecisa secare operationes. Processus exigit specialized potentia commeatu capax generandi imperium obit cum vires humilis ut paucis microjoulales.

Precision positioning systems ponere sub-micron accurate in machining operationes. Advanced optical systems providere realis-vicis magna ex Micro-machining processus. In technology invenit extensive applicationem in vestibulum medicinae cogitationes, microscale formam, et praecisione electronic components.

Hybrid Edm Systems

EDM, molere hybrid machinis miscere metus molere cum electrica missionem machining in unum setup. Et molere rota incorporat fixa elementa quae generare electrica obit per operationem. Hoc compositum enhances materiam remotionem rates dum maintaining superior superficies metam qualitas. Hybrid accedunt praecipue beneficia machining provectus Ceramics et composita materiae.

Automated Tool Tractable Systems Seamless transitio inter alia machining modos. Sophisticated imperium systems optimize in statera inter mechanica molere et electrica missionem effectus secundum workpiece characteres et desideravit eventus. Integration multiple machining processus reduces setup et amplio altiore vestibulum efficientiam.

Applications of EDM Technology

Aerospace industria applications

High-temperatus Alloys et complexu Geometries faciunt EDM indispensable in aerospace vestibulum. Processus excellit ad machining Turbine laminis cum intricate refrigerationem channels, ubi traditum secans modos certamen cum calor, repugnant nickel-fundatur superalloys. Engine fabrica utilitas EDM ad creandum praecisione informibus diffusor pertusum quod parva ut 0.3mm in diametro, essentialis pro efficientis fuel iniectio systems. Et facultatem ad machina induravit materiae sine inducing scelerisque accentus conservat discrimine mechanica proprietatibus aerospace components.

Medical fabrica vestibulum

Biocappatible materiae et microscale features characterize Edm scriptor partes in Medical technology. Processus gignit detailed patterns in Titanium implantatorum, enhancing Oseoeointegration per pressius imperium superficiem texturing. Chirurgicam instrumentum fabrica utor micro-Edm ad producendum complexu cutting geometries in immaculatam ferro components cum tolerances ut stricta ut ± 0.005mm. Et non-contactus natura Edm prohibet materiam contaminationem, crucial ad maintaining biocompatibility of medicinae cogitationes.

Die et fingunt industria

Duratum instrumentum Steels et profunda cavis repraesentant prima applications in fingunt faciens. EDM dat creaturae de intricatus iniectio Fingunt features cum aspect rationes excedens XX: I, impossibile ad consequi per conventional machining. Processus machinis obduratum ferrum (usque ad LXX HRC) sine dimensional distortione consociata cum calor curatio, maintaining geometrica accurate in complexu progressivum perit. Filum-Edm technology secat praecise ferrum et mori components cum parva parva ut 0.01mm ad altus-precision Stamping operationes.

Electronics et semiconductor vestibulum

Microelectronic components et praecisione fixtures demonstrabo EDM scriptor capabilities in electronics productio. Et technology creates microscopic alignment features in Ceramic subiecta semiconductor packaging, cum positioning accuracies de ± 0.002mm. Edm processibus apparatus Beryllium aeris components ad summus frequency electronic iungo, maintaining discrimine electrica proprietatibus per imperium materia remotionem. Processus dat fabricam ex inlicitis calor submersus cum amplexurae superficiei regio exemplaria ad improved scelerisque administratione.

Automotive pars fabrica

PowerTrain components et cibus systematis partibus showcase Edm scriptor versatility in eget applications. Processus machinis precise valvae sedes in cylindrici capitibus facta est a offensione Alloy Steels, ensuring optimal combustione efficientiam. EDM technology creates complexu fuel injector nozzles cum multiple RAMULUS foramina ut parva ut 0.1mm in diametro, discrimine pro testimonii restrictius emissionem signa. Processus efficit fabricare de transmissione components cum intricatus spline profiles dum maintaining stricta geometric tolerances.

Research et Development Applications

Prototype Development et Material Testing Highlight Edm scriptor partes in scientificam. Processus creates precise test specimina pro mechanica proprietas iudicium, cum imperium superficies condiciones minimize experimentalem variables. Research facilities utilitas EDM ad fabricare consuetudinem fixtures et tooling ad specialized temptationis apparatu, saepe operantes cum exoticis materiae sicut Tungsten carbide vel Polycrystalline. In technology dat creaturae Microscale features in studeo fluidi dynamics et æstus translationis phaenomena in Engineering Applications.

Energy Sector Applications

Power generation components et nuclei applications demonstrabo Edm est significationem in industria productio. Processus machinis universa refrigerationem channels in Gas Turbine components, enhancing scelerisque efficientiam per optimized æstus translatio. Nuclear Power Facilities Miny pro Machining De Zirconium Alloy components, maintaining material integritas critica ad reactor salus. In technology gignit intricatum fluxus imperium features in valvae components oleum et Gas applications, cursus fidelibus operationem sub extremam conditionibus.

Quam eligere EM Equipment et parametri?

Lectio Edm Power Victualia

Power Rating et Pulsus Imperium Capabilities Forma fundamentum Edm potestate suppleret lectio. Modern Edm systemata requirere potestate supplet tradens precise current pules vndique a I ad CD amperes, cum voltage potentiae inter XX et CXX voltage, incorporandi technology pro firmum, rectangular pulsum waveforms.

Generator technology ludit a crucial munus in machining perficientur. Advanced ISO-pulsum generantibus providere iuris imperium of pulsus on-vicis et off-vicis a 0,1 ad MMM microseconds, cum adaptive imperium systems Monitor missionem condiciones et adjust parametri in real-vicis.

Arc praesidio systems curare processus stabilitatem et component salutem. Modern Power commeatus incorporate multiple tutela campester, inter brevi-circuitu deprehensio et adaptive gap imperium algorithms, respondens ad abnormes conditionibus in microseconds.

Tools et Electrodes in EDM

Electrode materiae significantly influere machining efficientiam et accurate. Aeris Electrodes providere optimum conductivity pro generali-ad applications, dum graphite electrodes Excel in aspera machining operationes, ubi maximum materiam remotionem rates sunt prioritas.

Electrode geometriam postulat diligenter consideratione rationem rationem et rutiusing conditionibus. Complex Electrodes requirere internum rutilant canales dum maintaining structural integritas sub scelerisque accentus, ratio pro scintilla gap varietates typically vndique a 0.01 ad 0.5mm.

Superficiem coating Technologies augendae electrode perficientur characteres. Titanium nitride coatings redigendum electrode induendum rates per usque ad XL%, dum Chrome-patella Aeris Electrodes demonstrabo superior resistentia ad hydrogenii embrittlement.

Optimization of machining parametri

Rates et eminent remotionem Rates et eminent remotionem Rates et superficies qualis. Pecco current occasus oportet statera productivity contra electrode gerunt, dum pulsum durationem occasus influentiam craterem magnitudine et calor, affectus zone profundum.

Dielectric conditionibus requirere precise imperium ad optimal perficientur. Pressura debet providere adaequatum rutilant non conturbant fluxum processum, dum temperatus imperium systems ponere consistency intra ± I ° c.

Servo potestate parametri ponere bene gap conditionibus per machining exolvuntur. Provectus Systems utilitas Algorithms secundum real-vicis vigilantia gap intentione et current waveforms, maintaining positioning accurate intra ± I micron.

Superficiem metam requisitis dux ultima parameter lectio. Roughing Operations uti altior industria campester Achieving remotionem rates ad CD mm³ / hora, dum consummatione operationes utilitas reducitur navitas campester, producendo superficiem utilitas ut humilis ut 0,1 ra.

Monitoring Strategies ut consistent machining results. Real-time analysis de missionem waveforms dat deprehensio processus instabilities, tracking multiple parametri eodem tempore comprehensive processus imperium.

Quid latest Edm progressionem?

Hybrid systems et multi-axis capabilities represent cutting-ora developments in EDM. Modern machinis combine Edm cum summus celeritas milling, enabling automated mutandi inter processiones ad optimal materiam remotionem et superficiem perfectis. Adaptive imperium systems nunc utilitas artificialis intelligentia praedicere et ne machining instabilitatum.

IOT connectivity et nubes-fundatur Cras Minering EDM Operations. Digital geminae technology dat realis-vicis simulatio, cum apparatus eruditione algorithms optimise parametri automatice secundum historical perficientur data.

Nano-scale praecisione pushes EDM capabilities amplius. Advanced Micro-Edm systems consequi pluma magnitudinum inferius V micromers per specialized RC-genus pulsus generantibus et ultra-precise positioning systems, aperiens novum applications in semiconductor et medicinae fabrica novum applications in siconductor et medicinae fabrica novi applications in siconductor et medicinae fabrica novi applications in siconductor et medicinae fabrica novi applications in siconductor et medicinae fabrica novum applications in siconductor et medicinae fabrica novi applications in siconductor et medicinae fabrica novum applications in siconductor et medicinae fabrica novum applications in siconductor et medicinae fabrica, et fabrica novi et medicinae et medicinae in arte.

COGITO

Promptus ad elevant vestibulum elit? In Team MFG, nos harundem secans-ore Edm technology ad transform vestri maxime provocans cogitationes in re. Noster publica-of-arte facilius domos in tardus in filum-Conscidisti et Sinker Edm systems, operated per industria, certified peritorum.

Contact Team MFG hodie ut reveles quomodo nostri EDM peritia potest adducere tua praecisione Engineering challenges ad vitam. Sit scriptor aedificare futurum de vestibulum simul.

Reference Sources

Electric missionem machining

Sinker EDM vs. filum EDM

Frequenter Interrogata Quaestiones (FAQs)

Q: Quid est fundamentalis principium post electrical missionem machining?

Edm operatur per generating imperium electrica scintillas inter an electrode et workpiece, cum quisque scintilla removere minima particulas de materia. Processus occurs in a dielectric fluidi environment, quae adjuvat control in scintillam scriptor intensionem et rubor obstantia.

Q: Quare si EGO Elige Edm super conventional machining modi?

Edm machinis complex figuris in induratum materiae sine mechanica contactus vel vi, achieving tolerances of ± 0.001mm. Hoc facit idealis pro delicata partes et durum materiae, ubi traditum secans instrumenta non deficient.

Q: Quid materiae potest efficaciter machined per EDM?

Quis electrically PROLIXUS materia est idoneam ad Edm, inter obduravit ferrum (usque ad LXX Hrc), Tungsten Carbide, Titanium Alloys et PROLIXUS Ceramics. In materia est duritia non afficit machinability.

Q: Quomodo ego eligere meliorem electrode materia mea application?

Considerans workpiece materia, desideravit superficies metam, et productio volumine. Aeris Electrodes offerre optimum gerunt resistentia ad praecisione opus, dum graphite praestat in aspera machining cum altius remotionem rates.

Q: Quid est typical machining parametri me monitor?

Clavis parametri includit missionem current (1-400 amperes), pulsus on-vicis (0.1-3000μs), gap intentione (20-120v) et dielectric fluido pressura (0.5-15 Bar). Haec directe affect machining celeritate et superficiem qualis.

Q: Quid causas electrode induendum et quomodo possum minuere eam?

Electrode gerunt consequitur ex scelerisque erosion durante sparking. Minimize est per eligendo oportet current density, usura orbitalis motus exemplaria, et exsequendam adaptive imperium systems quod optimize scintilla distribution.

Q: Quid faciam ponere consistent superficies metam qualis?

Monitor Dielectric liquidum munditiam, ponere stabile temperatus (± I ° C), et uti oportet perfectis parametri (reducitur industria, brevior pulsus). Ordinarius electrode rusticatio et gap magna sunt essentialis.

Q: Quid salus cautiones sequi cum operating EDM apparatu?

Uti propriis VENTILATIO for Delectric vapor, ponere electrica velit, iusto victum salus interlocks et sequi propriis fluidum tractantem ratio. Ignis praeventionis systems esse operational.

Q: Quomodo possum Troubleshoot instabiles machination conditionibus?

Reprehendo pro contaminari dielectric fluidi, inspicere electrode condicionem, quin potestatem copia occasus, et analyze emundare fluctus fluests. Effusus condiciones saepe manifesta ut arroganti vel irregularis superficiem patterns.

Q: Quid latest elit in EDM technology me scire?

Provectus Systems autem integrate AI-fundatur adaptive imperium, multi-axis capabilities cum in-processus mensurae, et Hybrid Machining optimis combining EDM cum summus celeritas ad optimized productionem.