Yala i delila k’i yɛrɛ ɲininka cogo min na fɛn dilannikɛlaw bɛ fɛn tigitigiw dilan minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn gɛlɛnw ye minnu bɛ dɔn kosɛbɛ ɛntɛrinɛti fɛ wa? Kuran bɔli masin (EDM) jɔlen bɛ bi fɛn dilanni fɛɛrɛw ɲɛfɛ, a bɛ fɛn caman sɛmɛntiya an bɛ nɛgɛ ni fɛnw dilan cogo min na.

O fɛn dilanni taabolo kɔrɔlen in bɛ kuran bɔli fanga sɔrɔ walasa ka micron-level precision sɔrɔ masinw ka jateminɛ gɛlɛnw na. K’a ta aerospace turbine yɔrɔw la ka se furakɛli fɛnw ma, EDM ka sekow bɛ taa ɲɛ izini suguya caman na, ka fɛɛrɛw di yɔrɔ minnu na, laadala tigɛcogo bɛ dɔgɔya.

A ka baarakɛcogo, a suguyaw, ani a kɛcogo sɛgɛsɛgɛli fɛ, an bɛ EDM jira cogo min na, o bɛ fɛnw caman sɛmɛntiya ka kɛ fɛnw ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

EDM (kuran bɔli masin) ye mun ye ?

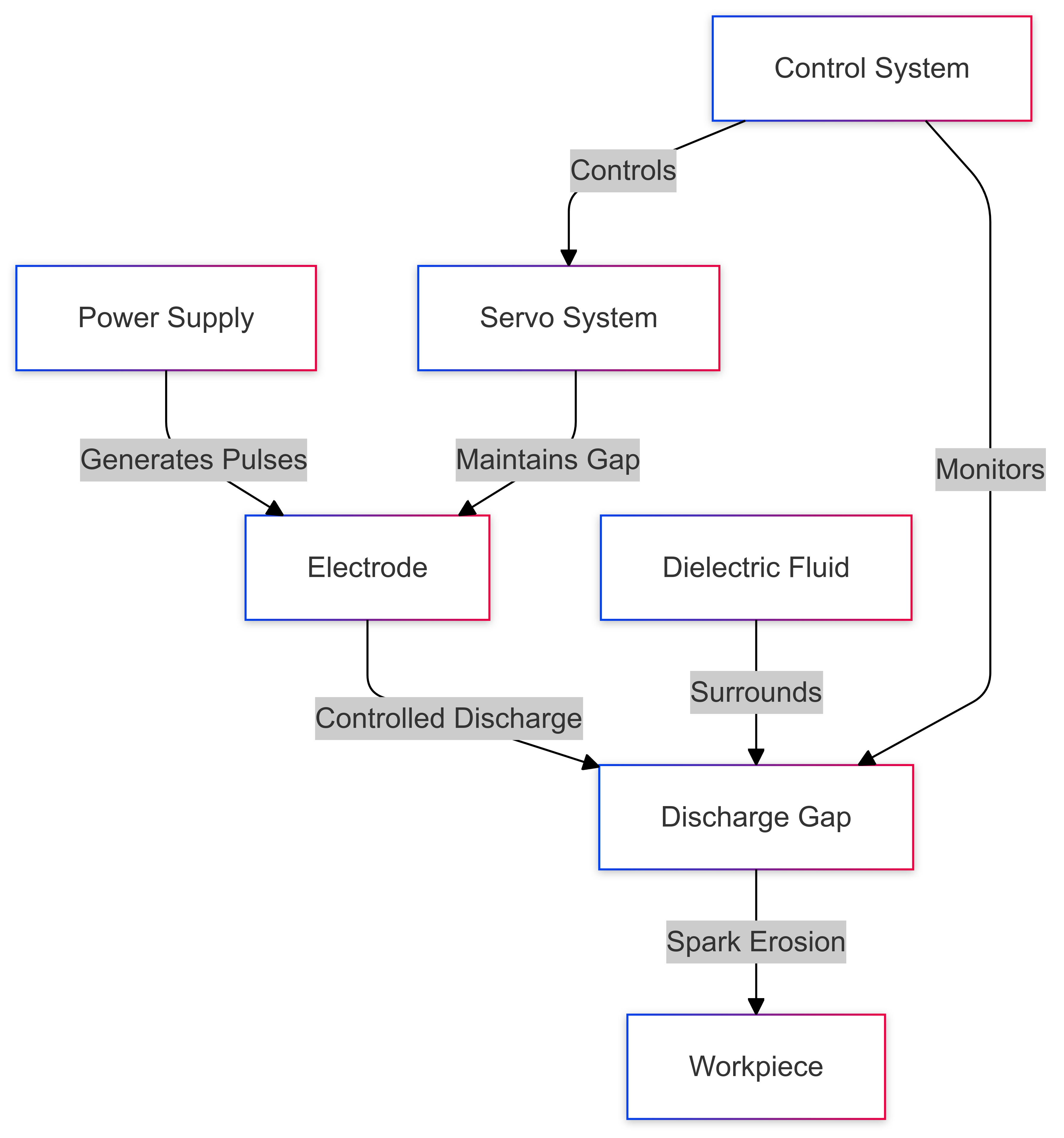

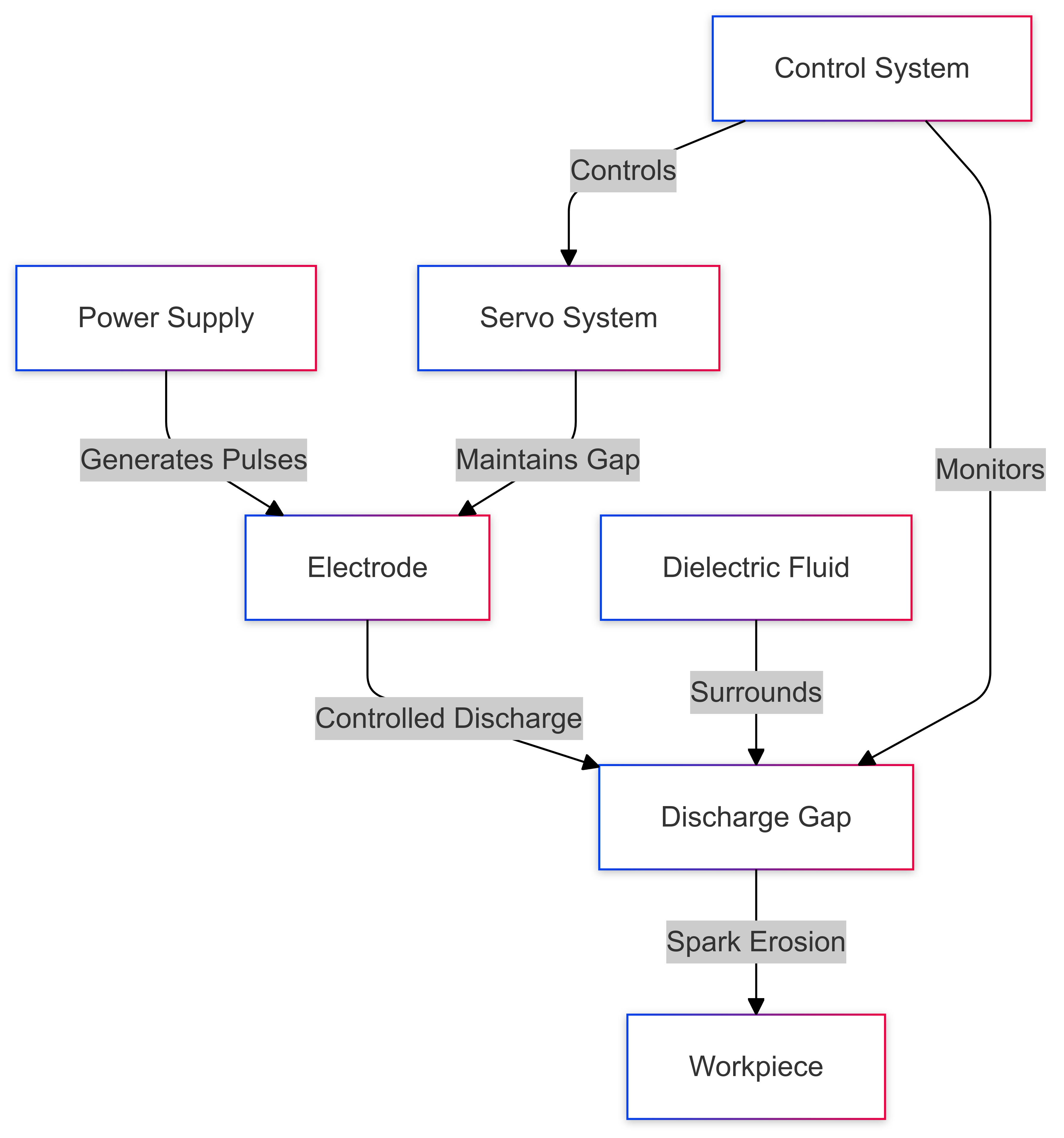

EDM jɔnjɔnw faamuyali .

Kuran bɔli masin (EDM) ye fɛn dilanni fɛɛrɛ ye min bɛ kɛ ni kuran ye walasa ka fɛnw bɔ baarakɛminɛnw na minnu bɛ se ka baara kɛ. O kɛcogo bɛ baara kɛ ni kuran bɔli ye elekitorode ni baarakɛminɛn cɛ, u fila bɛɛ bɛ ji la dielektriki ji la . kɔnɔ Discharge gap min ye 0,01-0.5mm ye, sparks ba caman bɛ sɔrɔ segin kɔnɔ ka sigida yɔrɔw dilan minnu bɛ se 8000-12.000°C ma ..

Dielektriki ji bɛ baara caman kɛ: kuran sɔgɔli, ka masina yɔrɔ nɛnɛ, ka fɛnɲɛnamafagalanw ci ka taa, ani ka danfara cogoya ɲumanw mara.

Sariyasenw ka ɲɛsin sɛgɛn ma .

Spark erosion process bɛ tugu ɲɔgɔn kɔ tigitigi yɔrɔ min na ionizasiyɔn sira bɛ yiriwa ka kɛ gazi ye min bɛ sumaya kosɛbɛ. Fɛnw bɔli bɛ sɔrɔ:

Materiel (fɛnw) wulicogo ni u lamagacogo .

ejection ni kuran fanga ye . Materiel molten

dɔ jɔli Layɛrɛ kura ka tɛmɛ Resolidification fɛ .

Taabolo jɔnjɔnw ye : .

EDM ka tariku ni a ka jiginni .

EDM ka fɛɛrɛbɔ bɔra san 1940w la Soviyetiki dɔnnikɛlaw fɛ Boris ani Natalya Lazarenko ka kuran sɛnɛcogo kɔrɔsilen sɔrɔli. O sɛgɛsɛgɛli in taara ɲɛ ka bɔ Lazarenko sɛrɛkili jɔnjɔnw na ka taa bi sigidaw la minnu bɛ CNC doncogo , fili-EDM fɛɛrɛw jira, ani seko kɔrɔlenw i n’a fɔ Micro-EDM , adaptive controls , ani AI-driven process optimization, revolutioning precision manufacturing aver aerospace ani medical industries.

Mun na EDM nafa ka bon bi fɛn dilanni na?

Ka se ka fɛn dilanni tigitigi sɔrɔ EDM fɛɛrɛ fɛ .

Micron-level accuracy ani jateminɛ gɛlɛnw bɛ EDM ka seko tigitigiw jira bi fɛn dilanni na. Taabolo bɛ se ka dimension tolerances sɔrɔ ka gɛlɛn i n’a fɔ ±0.001mm ka sɔrɔ ka shapes intricate (machining shapes) kɛ fɛn gɛlɛnw na. EDM ka ɲɔgɔndanbaliya bɛ masinw ka degunw ni baarakɛminɛnw sɛgɛnbaliya bɔ kɛnɛ kan minnu bɛ dan sigi masinw ka tiɲɛni kɔrɔlen na, o bɛ kɛ sababu ye ka mikroskala fɛnw dilan ni dugukolo sanfɛla laban cogoya ye min tɛ kelen ye.

EDM dilanni nafaw baarakɛminɛnw ni die dilanni na .

Fɛn minnu ka gɛlɛn ani minnu kɔnɔna ka dun, olu b’a jira ko EDM jɔyɔrɔba bɛ baarakɛminɛnw ni die dilanni na. Technology Machines Tool Steel yɔrɔw ni gɛlɛya bɛ tɛmɛ 60 HRC kan ni dimension distorsion tɛ min bɛ tali kɛ funteni furakɛli taabolo la. EDM bɛ die cavities tigitigiw dilan ni juguya ni bonya hakɛ ye min ka bon ni 20:1 ye, ka kunnafoni gɛlɛnw ni yɔrɔw don minnu bɛ kɛ ka pikiri kɛcogo ɲɛ ka ɲɛsin pikiri kɛcogo ma ani ka taamasiyɛnw kɛ.

A bɛ nɔ min bila aerospace yɔrɔw la .

Alloy minnu bɛ se ka funteni sɔrɔ ani kɔnɔnafɛnw bɛ EDM nafa jira aerospace dilanni na. O kɛcogo bɛ tɛmɛn nɛnɛ sira gɛlɛnw dilanni kan turbine yɔrɔw la minnu dilannen don ni nikɛri-based superalloys ye, ka fɛn nafamaw mara masinko baara bɛɛ kɔnɔ. EDM fɛɛrɛ bɛ difiyeli dingɛw dilan minnu bɛ i n’a fɔ fɛn minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ 0,3mm ye, u cɛmancɛ bɛ se 0,3mm ma, fɛnɲɛnamafagalanw pikiri kɛcogo la, o bɛ kɛ sababu ye ka motɛriw ka baarakɛcogo ɲuman n’u ka baarakɛcogo ɲɛ bi awiyɔnw kɔnɔ.

EDM fɛɛrɛbɔ nafaw ni a dɛsɛ .

EDM baarakɛcogo nafaw .

EDM ka seko danmadɔ ka ɲɛsin masinw ma minnu ka gɛlɛn, o b’a faranfasi ka bɔ fɛɛrɛ kɔrɔw la. O kɛcogo bɛ tɛmɛn cogoya gɛlɛnw ni kɔnɔnafɛnw dabɔli kan ni a ɲɛda hakɛ ye 20:1 ye, k’a sɔrɔ a kɔnɔna na, nkɔni nɔgɔlenw ni kunnafoni misɛnninw sɔrɔli tɛ se ka kɛ ni laadala masinw ye.

Material versatility bɛ nafa caman wɛrɛ jira EDM fɛɛrɛw la. O baara bɛ kɛ ni kuran fɛn o fɛn ye, o bɛ kɛ ni masin ye ka ɲɛ, a gɛlɛya mana kɛ min o min ye. O seko in nafa ka bon kɛrɛnkɛrɛnnenya la n’i bɛ baara kɛ ni nɛgɛ gɛlɛn ye fo ka se 70 HRC ma, bawo EDM bɛ farati ban furakɛli kɔfɛ tiɲɛni na, wa a bɛ fɛn wɛrɛw minɛ ni nɔgɔya ye.

siratigɛ la Tiɲɛni ni jogo ɲuman , EDM bɛ seko danfaralenw jira. Fɛɛrɛ in bɛ to ka muɲuli sɔrɔ ka gɛlɛn fo ±0,001mm ka sɔrɔ ka surface fini ɲumanw bɔ ka se 0,1 RA ma. Baarakɛminɛnw ni ɲɔgɔn cɛ jɛɲɔgɔnya tilennen tɛ yen, o bɛ degun bɔ masinw na yɔrɔ nɔgɔlenw kan, o bɛ na ni buruburuw ye minnu tɛ ni funteni ye, yɔrɔ minnu ka dɔgɔn.

EDM baarakɛcogo nafa .

EDM dantigɛli fɔlɔ bɛ sɔrɔ a baara teliya la . Ni an y’a suma ni masinw ka fɛɛrɛ kɔrɔw ye, EDM bɛ fɛnw bɔli hakɛ dɔgɔya, o bɛ na ni fɛn dilanni waati caya ye, kɛrɛnkɛrɛnnenya la, jateminɛ nɔgɔmanw na. O dantigɛli bɛ ye kɛrɛnkɛrɛnnenya la sɛnɛfɛnw dilanni cogoya caman na, yɔrɔ minnu na, cycle waati nafa ka bon kosɛbɛ.

Baara musakaw bɛ gɛlɛyaba wɛrɛ jira. O fɛɛrɛ in bɛ wari caman ɲini minɛnw na minnu bɛ sɔrɔ minɛnw na ani u ladonni musakaw la minnu bɛ senna. Elektɔri caman cili tuma bɛɛ ka da a sɛgɛnni kan ani fanga caman sɔrɔli baara senfɛ, o bɛ kɛ sababu ye ka fɛn dilanni musakaw caya ni i ye a suma ni masinw ye minnu bɛ kɛ cogo kɔrɔ la.

Fɛɛrɛko gɛlɛyaw minnu bɛ EDM taabolo la, olu bɛ jateminɛ kɛ kosɛbɛ. O fɛɛrɛ in bɛ bɔ dielektriki ji maracogo kɛrɛnkɛrɛnnenw na ani a bɛ elekitorode ladonni ɲini tuma bɛɛ. O tɛmɛnen 'kɔ, o kɛcogo bɛ yɔrɔ fitinin dɔ Bɔ min bɛ Kɛ ni funteni ye masinw kan, wa a baara bɛ To ka dan Kɛ kuran-minɛnw na.

Process Control Complexity bɛ gɛlɛya layini wɛrɛ fara a kan. Ka jaabi ɲumanw sɔrɔ, o bɛ paramɛtiriw ɲɛnabɔli caman ɲini ani baarakɛla ŋanaw minnu bɛ taabolo in ka gɛlɛyaw faamuya. Sitimɛ ka teli ka kuran taabolo caman ɲɔgɔnna sɔrɔ ani a mago bɛ dielektriki sitɛmu ɲinini na tuma bɛɛ, a bɛ jateminɛ kɛ tuma bɛɛ walasa ka taabolo sabatili sabati.

EDM taabolo bɛ baara kɛ cogo di?

Kuran bɔli minnu bɛ kɛ .

Dielektriki ji , voltage potentiel , ani elekitorode gap ye kuran bɔli masin basigilen jɔnjɔn ye. O baara bɛ daminɛ ni voltage danfara dɔ bɛ kɛ baarakɛminɛn elekitorode ni baarakɛminɛn cɛ, a ka c’a la, a bɛ daminɛ 20 na ka se 120 volt ma. Dielektriki ji, a ka c’a la, tulu idɔrɔsi walima ji deyonizelen, o bɛ yɔrɔ fitinin (0,01-0,5mm) fa o yɔrɔw ni ɲɔgɔn cɛ. Ni tension (volta) bɛ ka caya, a bɛ kuran-yɔrɔba dɔ Dabɔ min bɛ dielektriki ji ionize (ionize) Kɛ, ka plasma (plasma) sira Kɛ.

Plasma kanal bɛ bonya joona, ka yɔrɔ funteni sɔrɔ min bɛ se 8000 fo 12000°C ma. O funteni jugumanba ninnu bɛ kɛ sababu ye ka baarakɛminɛn in sɔgɔ ani k’a kɛ yɔrɔ ye min bɛ wuli yɔrɔnin kelen. Ni kuran tigɛra, plasma kanal bɛ bin, ka implosion dɔ da min bɛ fɛn wulilen bɔ ni fanga ye ka bɔ baarakɛminɛn sanfɛ. O kɔfɛ, dielektriki ji bɛ o fɛnɲɛnamafagalan ninnu bɔ, ka a sanfɛla labɛn ka bɔ a bɔli nata la.

EDM sitɛmuw yɔrɔw .

Kuranko yɔrɔ bɛ kɛ EDM baarakɛtaw dusukun ye, ka kuran wulilanw di minnu bɛ kɔlɔsi kosɛbɛ. Bi kuran dilanw bɛ baara kɛ ni semiconducteurs sophistiqués ye walasa ka pulse cogoya tigitigiw dilan, ni frequences bɛ daminɛ 2000 na ka se 500.000 Hz ma. O yɔrɔw bɛ se ka wuli-wuli waati ni fanga fila bɛɛ sɛmɛntiya, ka sira di fɛnw bɔli hakɛ ɲuman ma.

Dielektriki sitɛmu bɛ baarakɛyɔrɔ nafamaba mara. A bɛ Kɛ ni fɛnmarayɔrɔw ye, pɔnpew, filɛriw, ani funteni-minɛnw. Dielektriki ji bɛ yaala-yaala filɛri gɛlɛn dɔ fɛ min bɛ nɔgɔw bɔn ka dɔgɔn i n’a fɔ 2-5 mikron. Funteni sabatili ±1°C kɔnɔ, o bɛ kɛ sababu ye ka masinw cogoyaw ni u bonyacogo ɲuman sabati.

Masina baarakɛminɛnw jɔcogo bɛ masin-kalan-yɔrɔ di walasa ka elekitorode jɔyɔrɔ tigitigi sɔrɔ. Servo sitɛmuw minnu bɛ kɛ ni hakili ye kosɛbɛ, olu bɛ elekitorode lamagacogo ɲɛnabɔ ni a janya ye ka se mikoromɛtiri 0,1 ma. O jɔli in kɔnɔ, fɛn minnu bɛ se ka yɛrɛyɛrɛ, olu ni funteni musakabɔlanw bɛ don a kɔnɔ walasa ka jɔyɔrɔko tiɲɛni sabati masinko baara janyalenw senfɛ.

Kɔlɔsili ni kɔlɔsili EDM kɔnɔ .

Waati yɛrɛ la, danfara kɔlɔsili bɛ baara kɛ ni sensɛri caman ye walasa ka bɔli kelen-kelen bɛɛ ka kuran cogoya suman. Sitimɛw ɲɛtaa bɛ tension ni current waveforms sɛgɛsɛgɛ microsecond waatiw la, ka fɛn caman kɔlɔsi minnu bɛ se ka suboptimal machining cogoyaw jira. Nin kunnafoni in bɛ balo ka kɛ adaptive control algorithmes ye minnu bɛ to ka taabolo paramɛtɛrɛw ɲɛnabɔ.

Discharge Stability Control bɛ fɛnw bɔli hakɛ basigilenw mara ni masinw ka paramɛtɛrɛw ladilanni otomatiki ye. Ni bɔli kɛcogo juguw kɛra, o sitɛmu bɛ se ka wuli ka bɔ a nɔ na, a bɛ se ka fɛn caman sɛmɛntiya, walima a bɛ se ka fɛn caman sɛmɛntiya milisekɔndi kɔnɔ. Bi EDM masinw bɛ hakililata kɛcogo dɔw don u kɔnɔ minnu bɛ kalan tariku taabolo kunnafoniw na walasa ka masinw ka basigibaliya kofɔ ani k’a bali.

Surface quality monitoring systems bɛ baarakɛminɛnw sanfɛla cogoyaw jiginni lajɛ masinw senfɛ. Acoustic emission sensors bɛ fɛn misɛnninw ye minnu bɛ se ka fɛn caman yeli kɛ bɔli cogoyaw la minnu bɛ se ka nɔ bila dugukolo sanfɛla la. Intégration ni vision systems bɛ sira di ka automatique sɛgɛsɛgɛ surface texture ani dimensional accuracy kan, o bɛ kɛ sababu ye ka finitigiw ka baara kɛ ni dagalen ye.

EDM fɛɛrɛ suguya wɛrɛw .

EDM ka fili .

Kuran bɔli masin (WEDM) bɛ nɛgɛ nɛgɛ finman dɔ kɛ, a ka c’a la, nɛgɛ walima nɛgɛ, min bɛ bɔ milimɛtɛrɛ 0,02 na ka se 0,3mm ma. O nɛgɛ bɛ kɛ i n’a fɔ elekitorode min bɛ lamaga tuma bɛɛ, ka tigɛ tigitigiw da kuran bɔli fɛ. Ɔridinatɛri bɛ se ka nɛgɛ sira ɲɛminɛ ka sɔrɔ ka yɔrɔ to a ka to a cogo la nɛgɛ ni baarakɛminɛn cɛ. Ji deyonized bɛ kɛ dielektriki ji ye, a bɛ nɛnɛ ni flushing seko ɲuman di tigɛ waati la.

O nɛgɛ bɛ kuraya tuma bɛɛ ni nɛgɛ kura baloli ye tuma bɛɛ ka bɔ fɛn dɔ la min bɛ fɛnw dilan, o bɛ elekitorode sɛgɛn bali ka nɔ bila tigɛcogo ɲuman na. WEDM sitɛmuw ɲɛtaa bɛ se ka kɛ yɔrɔ ye min bɛ se ka kɛ 0,1 mikoromɛtiri RA ye ani jɔyɔrɔ tiɲɛniw ±0,001mm kɔnɔ. Axis multi-axis control systems bɛ se ka jateminɛ gɛlɛnw kɛ, i n’a fɔ surfaces tapered ani curved, o bɛ WEDM kɛ kɛrɛnkɛrɛnnenya la nafa ye baarakɛminɛnw ni die dilanni na.

Sinker EDM .

EDM die-sinking , n’a bɛ fɔ fana ko RAM EDM, o bɛ baara kɛ ni elekitorode ye min cogoya tigitigi bɛ don baarakɛminɛn kɔnɔ. Elektɔri, min bɛ dilan ni grafite walima nɛgɛ ye, o bɛ a cogoya mara ka sɔrɔ ka fɛn dɔ da min bɛ baara kɛ ni fɛn wɛrɛ ye baarakɛminɛn kɔnɔ. Hydrocarbune tulu dielektriki ji bɛ yaala-yaala masina yɔrɔ la, ka bɔli cogoya ɲumanw mara ani ka nɔgɔw bɔ.

Bi sinker EDM sitɛmuw bɛ orbital lamaga sekow don a la, o bɛ kɛ sababu ye ka elekitorode bila ka taa cogoya gɛlɛnw na masin dilanni waati. Nin orbital wale in bɛ flushing nafa bonya ani ka surface finish quality ɲɛ. Otomatiki baarakɛminɛnw caman cilikɛlaw bɛ se ka elekitorode caman sɔrɔ, ka kɛ sababu ye ka sɛgɛsɛgɛli ni finidon baara kɛ ni elekitorode jateminɛcogo wɛrɛw ye sigicogo kelen kɔnɔ.

kunnafoni wɛrɛw bɛ sɔrɔ o kan . Fila EDM vs. SINKER EDM ..

Dingɛ EDM .

Dingɛ fitinin EDM kɛrɛnkɛrɛnnen don dingɛ tigitigiw dilanni na ni elekitorode tubuluw ye. Elektɔriw, a ka c’a la, nɛgɛ walima nɛgɛw, kɔnɔna sɔgɔli siraw bɛ sɔrɔ dielektriki ji lasecogo la ka ɲɛsin tigɛyɔrɔ ma. O fɛɛrɛ in bɛ dingɛw Bɔ fo ka Se 0,1mm ma a cɛmancɛ la ni a juguya ni a cɛmancɛ hakɛ ye 20:1 ye.

Elektɔri jiginni teliya la (500-2000 rpm) bɛ fara ɲɔgɔn kan ni kuran bɔli ye walasa ka fɛnw bɔli teliya sɔrɔ. Lamaga min bɛ wuli ka wuli, o bɛ jibolisira nafa bonya ani ka dingɛ tilennen mara. Sitimɛw minnu bɛ taa ɲɛ, olu bɛ sɔrɔ ka fɛnw tiɲɛ walasa ka elekitorode tiɲɛni bali ni u bɛ tɛmɛn-yɔrɔw dafa.

EDM micro .

Micro-scale EDM bɛ miniaturization dancɛw gɛlɛya, ka baara kɛ ni feature hakɛw ye micromɛtɛrɛ 100 duguma. Ultra-fine wire electrodes, tuma dɔw la, u ka fin i n’a fɔ 0,01mm, olu bɛ se ka tigɛcogo tigitigiw kɛ. O kɛcogo bɛ kuran kɛrɛnkɛrɛnnenw de wajibiya minnu bɛ se ka jibɔw lawuli minnu bɛ kɔrɔsi ni fanga ye min ka dɔgɔ fo ka se mikrojoules damadɔw ma.

Jisigiyɔrɔ minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka fɛnw bila yɔrɔ la. Ɲɛnamaya kɛcogo ɲɛtaa bɛ mikro-masini kɛcogo kɔlɔsili waati yɛrɛ la. O fɛɛrɛ in bɛ baara caman sɔrɔ furakɛli minɛnw dilanni na, mikroskala mɔlifɛnw na, ani ɛntɛrinɛti yɔrɔw la minnu bɛ se ka tiɲɛ.

EDM systèmes hybrides .

EDM-grinding hybride masinw bɛ grinding conventionnelle ni kuran bɔli masinw fara ɲɔgɔn kan sigicogo kelen kɔnɔ. Grinding wheel bɛ fɛnw don a kɔnɔ minnu bɛ kuran bɔ baara kɛtuma na. O faralen ɲɔgɔn kan, o bɛ fɛnw bɔli hakɛw bonya ka sɔrɔ ka surface finish quality ɲuman mara. O fɛɛrɛ suguya in bɛ nafa sɔrɔ kɛrɛnkɛrɛnnenya la seramiki kɔrɔlenw ni fɛn dilannenw dilanni na.

Baarakɛminɛnw baarakɛcogo otomatikiw bɛ wuli ka bɔ masinw cogoya wɛrɛw ni ɲɔgɔn cɛ cogo nɔgɔman na. Kunnafoni-falen-falen-minɛn minnu ka ca, olu bɛ balansi ɲɛ ka ɲɛ masinw ka sɔgɔli ni kuran bɔli nɔw cɛ ka da baarakɛminɛnw cogoya kan ani u sɔrɔcogo ɲininenw kan. Masina-taamacogo caman ka ɲɔgɔnfaamu bɛ dɔ Bɔ sigili waati la ani ka fɛn dilanni bɛɛ lajɛlen nafa bonya.

EDM fɛɛrɛbɔ baarakɛcogo .

Aerospace industry applications .

Sumanmugu caman ani jateminɛ gɛlɛnw bɛ EDM kɛ fɛn ye min nafa ka bon kosɛbɛ aerospace dilanni na. O kɛcogo bɛ tɛmɛn masinw ka turbine blades kan ni nɛnɛ sira gɛlɛnw ye, yɔrɔ minnu na laadala tigɛcogo bɛ gɛlɛya ni nikɛri-based superalloys ye minnu bɛ funteni kɛlɛ. Motɛri dilannikɛlaw bɛ baara kɛ ni EDM ye walasa ka difilɛri dingɛw dilan minnu bɛ i n’a fɔ fɛn minnu ka dɔgɔn fo ka se milimɛtɛrɛ 0,3 ma, minnu nafa ka bon sɛnɛfɛnw pikiri kɛcogo ɲumanw na. Se min bɛ masinw gɛlɛyali masinw ye k’a sɔrɔ a ma sɛgɛnlafiɲɛbɔ degun bila mɔgɔ la, o bɛ aerospace yɔrɔw ka masinko nafama mara.

Dɔgɔtɔrɔso minɛnw dilanni .

Fɛn minnu bɛ se ka baara kɛ ɲɔgɔn fɛ ani mikroskala fɛnw bɛ EDM jɔyɔrɔ jira furakɛli fɛɛrɛw la. O kɛcogo bɛ misali caman dilan titaniyɔmu dontaw kan, ka osseointegration (osseointegration) bonya ni surface texturing (sɔgɔsɔgɔninjɛ) ye min bɛ kɔrɔsi tigitigi. Opereli minɛnw dilannikɛlaw bɛ baara kɛ ni micro-EDM ye walasa ka tigɛcogo gɛlɛnw dilan nɛgɛmafɛnw na minnu bɛ muɲu ni muɲuli ye fo ±0,005mm. EDM ka ɲɔgɔndanbaliya bɛ fɛnw nɔgɔli bali, o min nafa ka bon kosɛbɛ furakɛli minɛnw ka biyocompatibilité marali la.

Die ni moule industrie .

Baarakɛminɛn nɛgɛ gɛlɛnw ni kɔnɔna jugumanw bɛ baara fɔlɔw jira nɔgɔ dilanni na. EDM bɛ se ka pikirijikɛlanw ka fɛn gɛlɛnw dilan ni u ɲɛda hakɛw tɛmɛna 20:1 kan, u tɛ se ka sɔrɔ masinw fɛ minnu bɛ kɛ cogo kɔrɔ la. O baara masinw ye nɛgɛ gɛlɛya (fo ka se 70 HRC ma) k’a sɔrɔ a hakɛ tiɲɛni tɛ min bɛ tali kɛ funteni furakɛli la, ka jateminɛ kɛcogo ɲuman mara dies progressive complexe kɔnɔ. Wire-EDM fɛɛrɛ bɛ punch ni die yɔrɔw tigitigi tigɛ ni clearances ye minnu bɛ bɛn ɲɔgɔn ma fo 0,01mm ka ɲɛsin stamping operations ma kosɛbɛ.

Elektroniki ni Semikɔndukitɛri dilanni .

Microélectronique components ani precision fixtures bɛ EDM ka sekow jira ɛntɛrinɛti dilanni na. O fɛɛrɛ in bɛ fɛn misɛnninw dilan seramiki fɛnw na minnu bɛ kɛ ka semikɔndukiriw pake, ni u jɔyɔrɔ tiɲɛniw ye ±0,002mm ye. EDM bɛ masin Beryllium kuran yɔrɔw baara walasa ka elekitoroniki ɲɔgɔndan caman kɛ, ka kuran nafama mara ni fɛnw bɔli ye min bɛ kɔrɔsi. O kɛcogo bɛ se ka kɛ sababu ye ka funteni-minɛnw dilan minnu ka gɛlɛn ni dugukolo yɔrɔw cogoyaw ye minnu bɛ bonya walasa ka funteni maracogo ɲɛ.

Mobili yɔrɔ dilanni .

PowerTrain yɔrɔw ani fɛnɲɛnamafagalanw yɔrɔw bɛ EDM ka fɛn caman jira mobili baarakɛcogo la. O kɛcogo masinw valve sigilanw tigitigi silinda kunw na minnu dilannen don ni nɛgɛ gɛlɛnw ye minnu bɛ kɛ ni nɛgɛw ye minnu ka gɛlɛn, olu bɛ jeninida ɲuman sabati. EDM fɛɛrɛ bɛ fɛnɲɛnamafagalanw pikirikɛlanw dilan ni fiyɛlilan caman ye minnu janya bɛ se milimɛtɛrɛ 0,1 ma, minnu nafa ka bon kosɛbɛ fɛnɲɛnamafagalanw bɔli sariya gɛlɛnw kunbɛnni na. O kɛcogo bɛ se ka kɛ sababu ye ka transmission yɔrɔw dilan ni spline profiles intricate ye ka sɔrɔ ka jateminɛ tolerances sirilenw mara.

Sɛgɛsɛgɛli ni yiriwali baarakɛcogo .

Prototype yiriwali ni fɛnw sɛgɛsɛgɛli bɛ EDM jɔyɔrɔ jira dɔnniya ɲininiw na. O kɛcogo bɛ sɛgɛsɛgɛli kɛcogo tigitigiw dilan masinw ka nafolo jateminɛ kama, ni dugukolo sanfɛla cogoyaw ye minnu bɛ sɛgɛsɛgɛli fɛnw dɔgɔya. Ɲininikalan kɛyɔrɔw bɛ baara kɛ ni EDM ye walasa ka fɛnw dilan minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye ani baarakɛminɛnw ye sɛgɛsɛgɛlikɛminɛn kɛrɛnkɛrɛnnenw kama, tuma caman na, u bɛ baara kɛ ni fɛn wɛrɛw ye i n’a fɔ tungsten carbide walima polycrystalline diamant. O fɛɛrɛ in bɛ se ka kɛ sababu ye ka microscale (microscale) fɛnw dilan walasa ka fluid dynamics (jilamaw ka fɛnɲɛnamafagalanw) kalan ani ka funteni jiginni ko kɛlenw sɔrɔ ɛntɛrinɛti baarakɛcogo la.

Enerji ka baarakɛminɛnw .

Kuranko yɔrɔw ni nukiliya baarakɛminɛnw b’a jira ko EDM nafa ka bon fanga sɔrɔli la. O baarakɛcogo masinw nɛnɛ sira gɛlɛnw bɛ gazi turbine yɔrɔw la, ka funteni nafa bonya ni funteni jiginni ɲuman ye. Nukilila fanga baarakɛyɔrɔw bɛ EDM kɛ zirkoni fɛn dilannenw dilanni tigitigi ye, ka fɛnw dafalen mara min nafa ka bon kosɛbɛ reactor lakanani na. O fɛɛrɛ in bɛ jibolisiraw kunbɛncogo gɛlɛnw dilan valve yɔrɔw la tulu ni gazi baara kama, ka baara kɛ cogo la min bɛ se ka da a kan cogo juguw la.

EDM minɛnw ni paramɛtɛrɛw sugandi cogo di?

EDM ka kuran dilanyɔrɔw sugandili .

Se hakɛ ni Pulse control sekow de bɛ kɛ EDM kuran sugandili jusigilan ye. EDM bi sigidaw bɛ kuran dilanw wajibiya ka sisan pulses tigitigiw lase ampere 1 ma ka se 400 ma, ni tension potentiels bɛ 20 ni 120 volt cɛ, ka IGBT fɛɛrɛ don a kɔnɔ walasa ka pulse waveforms sabatilenw, rectangulairew don.

Jeneratɛri ka fɛɛrɛbɔ jɔyɔrɔ ka bon kosɛbɛ masinko baara la. ISO-Pulse generators (Iso-pulse generators) minnu bɛ taa ɲɛ, olu bɛ wuli-wuli yɛrɛmahɔrɔnyalen di waati kɔnɔ ani waati tɛmɛnen ma ka bɔ 0,1 na ka se 3000 ma, ka sɔrɔ adaptive control systems bɛ bɔli cogoyaw kɔlɔsi ani ka paramɛtiriw ladilan waati yɛrɛ la.

ARC lakanani fɛɛrɛw bɛ taabolo sabatili ni a yɔrɔw lakanani sabati. Bi kuran dilancogo bɛ lakana hakɛ caman don a kɔnɔ, i n’a fɔ fɛnɲɛnamafagalan surunw sɔrɔli ani adaptive gap control algorithms, ka jaabi di cogoya juguw ma mikrosekɔndi kɔnɔ.

Baarakɛminɛnw ni elekitorodew EDM kɔnɔ .

Elektɔri fɛnw bɛ nɔba bila masinw ka baarakɛcogo ɲuman na ani u ka tiɲɛni na. Kupu elektɔriw bɛ taabolo ɲuman di baarakɛcogo bɛɛ lajɛlen na, k’a sɔrɔ grafite elekitorode bɛ tɛmɛ masinw ka baara gɛlɛnw kan, yɔrɔ minnu na fɛnw bɔli hakɛ caman bɛ kɛ fɔlɔ ye.

Elektɔri jateminɛ bɛ a ɲini ka jateminɛ kɛ kosɛbɛ aspect ratios ni flushing cogoyaw kan. Elektɔri gɛlɛnw bɛ kɔnɔna sɔgɔli siraw de wajibiya ka sɔrɔ ka sigicogo dafalen mara funteni degun kɔrɔ, ka jatebɔ kɛ spark gap variations la cogoya la min bɛ daminɛ 0,01 na ka se 0,5mm ma.

Surface Coating Technologies bɛ elekitorode baarakɛcogo ɲɛ. Titanium nitride coatings bɛ dɔ bɔ elekitorode sɛgɛn hakɛ la fo ka se 40% ma, ka sɔrɔ chrome-plates kuran elektɔridiw bɛ se ka hidrɔzɛni sɔgɔli kunbɛncogo ɲuman jira.

Optimisation de paramètres machining .

Discharge energie hakɛw bɛ fɛnw bɔli hakɛw ni u sanfɛla cogoya de jira. Kurukuru hakɛ dantɛmɛnen ka kan ka balansi sɔrɔ ka kɛɲɛ ni elekitorode sɛgɛn ye, ka sɔrɔ pulse waati sigicogo bɛ nɔ bila crater hakɛ la ani funteni-ko-yɔrɔ juguya la.

Dielektriki cogoyaw bɛ kunbɛnni tigitigi de wajibiya walasa ka baara kɛcogo ɲuman sɔrɔ. Tansiyɔn ka kan ka kɛ fɛn ye min bɛ se ka wuli ka ɲɛ, k’a sɔrɔ a ma bɔli kɛcogo tiɲɛ, ka sɔrɔ funteni hakɛ jateminɛcogo bɛ bɛn ±1°C kɔnɔ.

Servo control paramètres bɛ gap conditions ɲumanw mara masinw ka sɛgɛsɛgɛli bɛɛ kɔnɔ. Sitimɛw ɲɛtaa bɛ baara kɛ ni algorisimuw ye minnu bɛ se ka kɛ ka kɛɲɛ ni waati yɛrɛ ye, minnu bɛ kɛ ka danfara don ni gap voltage ni current waveforms ye, ka jɔyɔrɔ tiɲɛni mara ±1 micron kɔnɔ.

Surface Finish Requirements Guide Final Parameter Selection. Baara gɛlɛnw bɛ kɛ ni fanga hakɛ caman ye minnu bɛ se ka bɔli hakɛw sɔrɔ fo ka se 400 mm³/lɛrɛ ma, k’a sɔrɔ finiko baara bɛ fanga hakɛ dɔgɔyali kɛ, ka dugukolo sanfɛla gɛlɛya hakɛw bɔ i n’a fɔ 0,1 RA.

Kɔlɔsili fɛɛrɛw bɛ kɛ sababu ye ka masinw ka jaabiw sɔrɔ minnu bɛ kɛ tuma bɛɛ. Discharge Waveforms sɛgɛsɛgɛli waati yɛrɛ la, o bɛ se ka kɛ sababu ye ka taabolo basigibaliya sɔrɔ, ka paramɛtɛrɛ caman nɔfɛtaama waati kelen na walasa ka taabolo kɔlɔsili bɛɛ lajɛlen kɛ.

EDM yiriwali labanw ye jumɛnw ye?

Sitimɛw ni ɲɔgɔn cɛ ani seko caman seko bɛ tigɛtigɛ yiriwaliw jira EDM kɔnɔ. Bi masinw bɛ EDM fara ɲɔgɔn kan ni teliyaba ye, o bɛ se ka kɛ sababu ye ka fɛnw caman wuli ka bɔ ɲɔgɔn na walasa ka fɛnw bɔ cogo ɲuman na ani ka u kɛ fini ye. Sisan, adaptive control systems bɛ baara kɛ ni hakililata ye walasa ka masinw ka basigibaliya kofɔ ani k’a bali.

IoT jɛɲɔgɔnya ani sankaba-sigi- kɔlɔsili EDM baarakɛcogo. Nizɛri filaninw ka fɛɛrɛbɔ bɛ se ka kɛ sababu ye ka baara kɛcogo simulatigɛ waati yɛrɛ la, k’a sɔrɔ masin kalanni algorisimuw bɛ paramɛtɛrɛw ɲɛnabɔ u yɛrɛma ka da tariku baarakɛcogo kunnafoniw kan.

nano-scale precision bɛ EDM sekow gɛlɛya ka taa a fɛ. Micro-EDM sitɛmuw ɲɛtaa bɛ se ka fɛnw hakɛ sɔrɔ mikromɛtiri 5 jukɔrɔ ni RC suguya pulsi jenitɛri kɛrɛnkɛrɛnnenw ye ani jɔyɔrɔfalen-falencogo ultra-précise, ka baarakɛminɛn kuraw da wuli semiconducteur ani furakɛli minɛnw dilanni na.

Aw ye wele kɛ ka wale kɛ .

Aw labɛnnen don ka aw ka fɛn dilanni sekow kɔrɔta wa? Team MFG la, an bɛ EDM fɛɛrɛ tigɛlenw baara walasa k’aw ka dilancogo gɛlɛnw sɛmɛntiya ka kɛ tiɲɛ ye. An ka yɔrɔ kura bɛ sɔrɔ yen, min bɛ wele ko EDM sitɛmuw, minnu bɛ baara kɛ ni telefɔni tigɛcogo ye ani minnu bɛ kɛ ni sinker ye, n’u bɛ baara kɛ ni dɔnnikɛlaw ye minnu ka seereya bɛ sɔrɔ iziniw fɛ.

Aw ye ɲɔgɔn sɔrɔ ekipu MFG la bi walasa k’a dɔn an ka EDM dɔnniya bɛ se ka aw ka precision engineering gɛlɛyaw lase ɲɛnamaya ma cogo min na. An ka fɛn dilanni nata jɔ ɲɔgɔn fɛ.

Reference sources .

Kuran bɔli masin .

SINKER EDM vs.

Ɲininkali minnu bɛ kɛ tuma caman na (FAQ) .

J: Kuran bɔli masinw ka sariya jɔnjɔn jumɛn bɛ yen?

EDM bɛ baara kɛ ni kuran sɔgɔlenw ye minnu bɛ kɔrɔsi elekitorode ni baarakɛminɛn cɛ, ni fɛn kelen-kelen bɛɛ bɛ fɛn misɛnninw bɔ fɛnw na. O kɛcogo bɛ kɛ dielektriki ji lamini na min bɛ dɛmɛ ka sɔgɔsɔgɔninjɛ fanga kunbɛn ani ka nɔgɔw bɔ.

J: Mun na ne ka kan ka EDM sugandi ka tɛmɛ masinw kan minnu bɛ kɛ ka caya?

EDM masinw cogoya gɛlɛnw bɛ sɔrɔ fɛn gɛlɛnw na ni masinw bɛ ɲɔgɔn sɔrɔ walima ni fanga ye, ka muɲuli sɔrɔ ±0.001mm. O b’a to a ka ɲi yɔrɔ nɔgɔlenw ni fɛn gɛlɛnw na, laadala tigɛminɛnw tun bɛna dɛsɛ yɔrɔ minnu na.

J: Fɛn jumɛnw bɛ se ka kɛ ni EDM ye ka ɲɛ?

Kuranko fɛn o fɛn bɛ se ka kɛ EDM ye, o bɛ se ka kɛ EDM ye, i n’a fɔ nɛgɛ gɛlɛn (fo ka se 70 HRC ma), tungsten carbide, titanium alloys ani conductif seramikiw. O fɛn in gɛlɛya tɛ nɔ bila masinw na.

J: Ne bɛ se ka fɛn ɲuman sugandi cogo di ne ka baarakɛcogo la?

Aw ye baarakɛminɛnw jateminɛ, ka dugukolo sanfɛla ɲini, ani ka baara kɛ ni u dilanni hakɛ ye. Kupu elektɔriw bɛ sɛgɛnbaliya ɲuman di baara la min bɛ kɛ ka ɲɛ, ka sɔrɔ grafite bɛ tɛmɛ masin gɛlɛnw kan minnu bɔli hakɛ ka ca.

J: N ka kan ka masina paramɛtiriw cogoya jumɛnw de kɔlɔsi?

Paramɛtiri jɔnjɔnw ye bɔli kuran ye (1-400 ampere), pulse on-time (0,1-3000μs), gap voltage (20-120V), ani dielektriki ji tansiyɔn (0,5-15 bar). Olu bɛ nɔ bila masinw teliya la ani u sanfɛla cogoya la.

J: Mun de bɛ kɛ sababu ye ka elekitorode sɛgɛn ani ne bɛ se k’a dɔgɔya cogo di?

Elektɔri sɛgɛn bɛ bɔ funteni jiginni na sɛgɛn waati. Aw bɛ a dɔgɔya ni sisan density bɛnnenw sugandili ye, ka baara kɛ ni orbital motion patterns ye, ani ka adaptive control systems (adaptive control systems) waleya minnu bɛ spark distribution (sɔgɔli) kɛcogo ɲɛ.

J: Ne bɛ se ka surface finish qualité constant mara cogo di?

Aw bɛ dielektriki ji saniyacogo kɔlɔsi, ka funteni sabatilen mara (±1°C), ani ka baara kɛ ni finidoncogo bɛnnenw ye ( fanga dɔgɔyali, pulses surunw). Electrode dressing (elektrɔdiw) kɛli tuma bɛɛ ani gap monitoring (yɔrɔ kɔlɔsili) nafa ka bon.

J: Lakanali fɛɛrɛ jumɛnw ka kan ka tugu EDM minɛnw baara la?

Aw bɛ fiɲɛbɔcogo ɲuman kɛ dielektriki lafiɲɛbɔ la, ka kuran tangalanw mara, ka lakana siraw ladon tuma bɛɛ, ani ka ji minɛcogo ɲumanw labato. Tasuma kunbɛnni fɛɛrɛw ka kan ka kɛ.

J: Ne bɛ se ka gɛlɛya sɔrɔ cogo di ka masinw cogoya sabatibaliw ɲɛnabɔ?

Aw bɛ a lajɛ ni dielektriki ji nɔgɔlen don, aw bɛ elekitorode cogoya sɛgɛsɛgɛ, ka kuran sɔrɔcogo sɛgɛsɛgɛ, ani ka bɔli jikuruw sɛgɛsɛgɛ. A ka c’a la, ko minnu tɛ sabati, olu bɛ jira i n’a fɔ arcing walima irregular surface patterns.

J: EDM fɛɛrɛ kuraw ye mun ye n ka kan ka minnu dɔn?

Sisan, sigida kɔrɔlenw bɛ AI-based adaptive control, multi-axis sekow don ɲɔgɔn na ni processus sumani ye, ani hybride machining options bɛ EDM ni teliyaba sɔgɔli fara ɲɔgɔn kan walasa ka se ka baara kɛ ka ɲɛ.