Mun na plastiki yɔrɔ dɔw kulɛri tɛ kelen ye pikiri kɛlen kɔfɛ? O fiɲɛ in bɛ se ka kɛ musaka ye dilanbagaw ma. Kulɛri min tɛ bɛn ɲɔgɔn ma, o bɛ se ka dɔ bɔ fɛn dilanni na ani ka dɔ fara a tiɲɛni kan. Nin sɛbɛn in kɔnɔ, an bɛna kuma kulɛri basigilen nafa kan pikiri kɛli la, gɛlɛyaw bɛ izini minnu na, ani fura ɲumanw walasa ka ɲɛtaa ɲumanw sɔrɔ.

Kulɛri tiɲɛniw faamuyali .

Pikiriw dilanni siratigɛ la, kulɛriw cogoya jɔyɔrɔ ka bon kosɛbɛ fɛn dilannenw ka ɲumanya la. An ka don kulɛri nafama diɲɛ kɔnɔ ani k’u nɔfɛkow sɛgɛsɛgɛ fɛn dilanni taabolo la.

Kulɛri walima kulɛri danfara min tɛ kelen ye, o ɲɛfɔli .

Kulɛri min tɛ kelen ye, n’a bɛ fɔ fana ko kulɛri danfara, o bɛ tali kɛ:

A tɛ bɛn ɲɔgɔn ma ɲɛ, a juguya, ani a bonya yɔrɔw la minnu mɔlen don .

Yɛlɛma minnu bɛ bɔ kulɛri ɲɛfɔlenw na .

Pigment distribution non uniforme dans le matériel plastique .

O danfara ninnu bɛ se ka jira cogo nɔgɔlenw walima cogo nɔgɔlenw na, minnu bɛ nɔ bila:

Appel visuelle .

Product qualité .

Marka ka ɲɔgɔn sɔrɔ .

A taamasiɲɛw ka teli ka kɛ .

Kulɛri tiɲɛniw ka teli k’u yɛrɛ jira:

yecogo jiralanw .

Kulɛri ɲagaminenw: wulilanw walima u yɔrɔw minnu bɛ kɛ ni u ɲɛw ye .

Kuluw ɲɛnatɔmɔli: Yɛlɛma minnu ma labɛn ka ɲɛ, olu ɲɛ 10nan na .

marbling effects: streaks walima patterns bɛ i n'a fɔ marbre .

Spotting: Yɔrɔ minnu bɛ yɔrɔ la, u kulɛri ka di walima u ka nɔgɔn .

nɔ min bɛ sɔrɔ fɛn dilanni na .

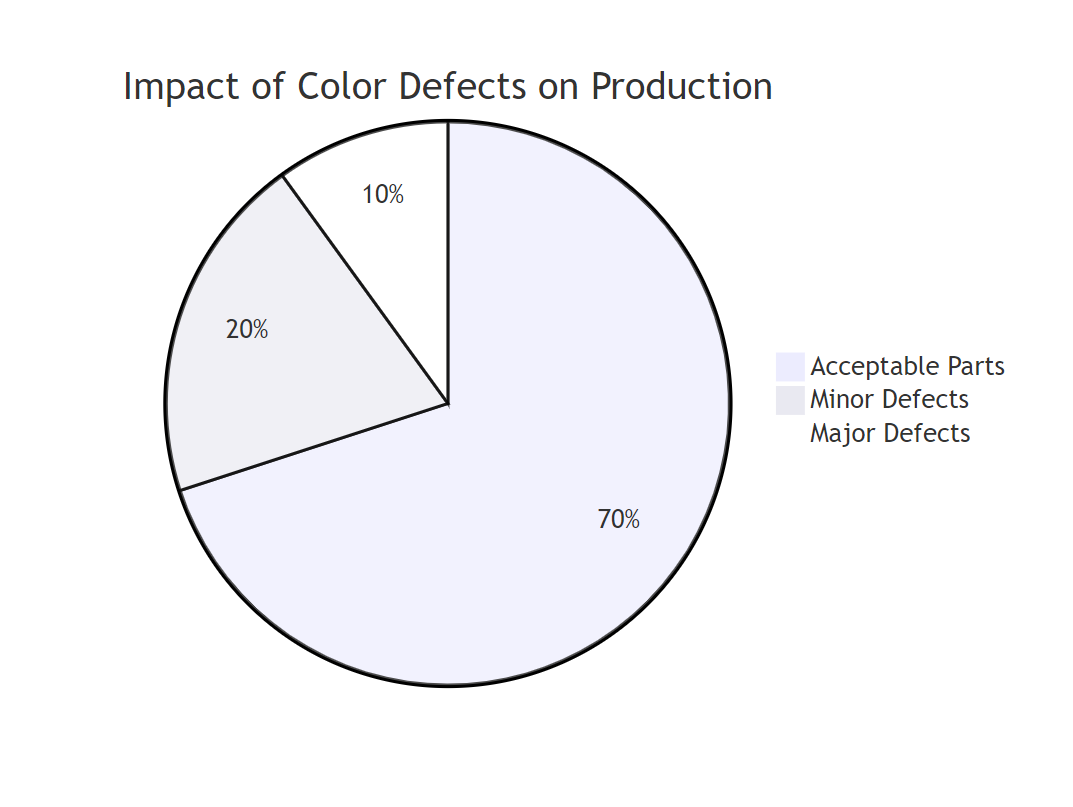

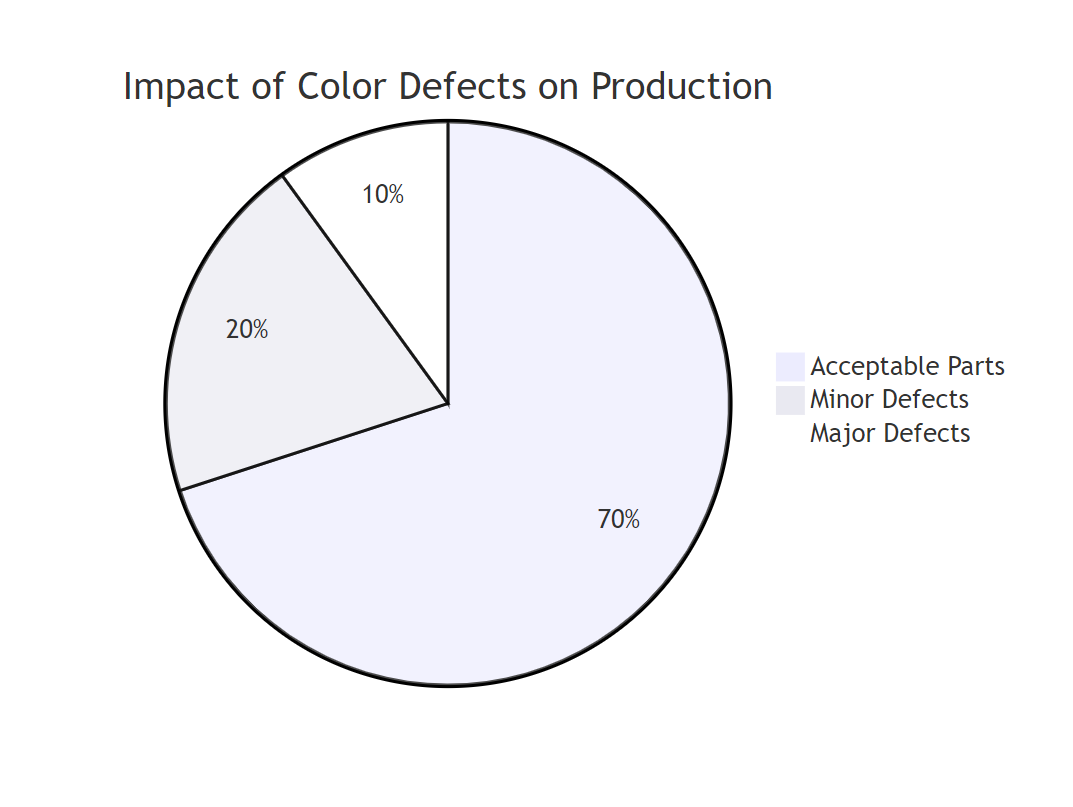

Kulɛri bɛnbaliya bɛ se ka kɛ sababu ye ka:

| koɲɛ |

kɔlɔlɔw . |

| Scrap hakɛ cayalenba . |

sɛnɛfɛnw musaka ka bon . |

| Gɛlɛya bɛ yɔrɔ minnu na . |

Lajɛba gɛlɛyaw . |

| Quality Control dɛsɛw . |

Layidu talenw . |

| Kunnafoni minnu bɛ sɔrɔ kiliyanw fɛ . |

Jagokɛlaw bɛ se ka bɔnɛ . |

Walasa ka kulɛriw ka juguya juguya jira, aw ye nin kunnafoniw jateminɛ:

Kulɛriw ka ɲɔgɔndɛmɛ koɲɛw tɛ nɔ bila ɲɛnajɛko dɔrɔn na. U bɛ se ka gɛlɛya basigilenw jira:

Ni aw ye nin taamasiɲɛ ninnu dɔn joona, olu bɛ a dilannikɛlaw dɛmɛ:

Ni u ye kulɛriw tiɲɛni faamuya, pikiri kɛcogo ɲɛnabɔbagaw bɛ se ka:

1.I ka jogoɲini taabolo yiriwa 2.Bɔgɔ bɛ dɔgɔya 3.Ka dɔ fara sɛnɛfɛnw bɛɛ lajɛlen nafa kan .

Kulɛri danfara dɔnni ni kiritigɛ .

Kulɛri bɛnbaliya dɔnni pikiri kɛli la, o bɛ kɔlɔsili ni sumani tigitigi de wajibiya. An ka fɛɛrɛw sɛgɛsɛgɛ minnu bɛ kɛ ka kulɛriw danfara dɔn ani k’u jateminɛ.

Ɲɛnajɛ sɛgɛsɛgɛli fɛɛrɛw .

Sɛgɛsɛgɛli yelen bɛ to sen fɔlɔ ye min nafa ka bon kosɛbɛ kulɛri jogoɲini na. A bɛ a jigi da hadamadenw ka faamuyali kan walasa ka danfara ye.

Yeelen ni sigida jɔyɔrɔ .

Yeelen cogoyaw bɛ nɔba bila kulɛri faamuyali la. Aw ye nin ko ninnu jateminɛ:

Yeelen sigicogo ɲuman b’a to:

Kulɛri jateminɛ basigilen .

Yɛlɛma misɛnninw dɔnni tigitigi .

Ɲɛw sɛgɛsɛgɛli min bɛ dɔgɔya sɛgɛsɛgɛlikɛlaw ma .

Dantigɛli hadamaden ɲɛ ni masin sɛgɛsɛgɛli .

Hadamaden ka yeli, hali ni a bɛ se ka ladamu, a nafa bɛ a la:

| hadamaden ɲɛ |

masina sɛgɛsɛgɛli . |

| Subjectif . |

Kuntilenna |

| A ka teli ka sɛgɛn . |

Baarakɛcogo basigilen . |

| Sensibilité limité . |

Kɔlɔsili min ka bon kosɛbɛ . |

| A bɛ nɔ bila ɲɛnayeli la . |

Sɛgɛsɛgɛli min bɛ kɛ ni kunnafoniw ye . |

Hali ni dantigɛliw bɛ yen, sɛgɛsɛgɛlikɛlaw minnu kalanna, olu bɛ se ka:

Kolorimɛtiri sɛgɛsɛgɛli .

Walasa ka kulɛri sumani tigitigi sɔrɔ, Kolorimɛtiriw bɛ kunnafoniw di minnu bɛ se ka jate. U bɛ sɛgɛsɛgɛli kuntilenna di ka tɛmɛ hadamaden ka faamuyali kan.

Faamuyali △e nafaw .

△E (Delta E) bɛ kulɛri danfara bɛɛ jira misali fila ni ɲɔgɔn cɛ. A jate bɛ kɛ ni:

△e = [(△L)⊃2 ye; + (△A)⊃2; + (△B)⊃2;]^(1/2)

Min:

sariyaw ka ɲɛsin kulɛri danfara minnu bɛ sɔn .

Industriw ka sariyaw bɛ to ka baara kɛ ni △e nafaw ye walasa ka kulɛri caman caman ɲɛfɔ minnu bɛ sɔn:

| △e Range |

Interpretation |

| 0 - 1 . |

Danfara min bɛ se ka ye kosɛbɛ . |

| 1 - 2 . |

Danfara fitinin . |

| 2 - 3,5 . |

Danfara min bɛ kɔlɔsi . |

| 3,5 - 5 . |

Danfaraba bɛ yen . |

| > 5 . |

Danfara min tɛ se ka sɔn . |

O yɔrɔw bɛ se ka ɲɔgɔn ta ka kɛɲɛ ni:

Ni u bɛ yeli ni kolorimɛtiri sɛgɛsɛgɛliw fara ɲɔgɔn kan, a dilannikɛlaw bɛ se ka:

Aw ye aw jija ka kulɛriw cogoya sabatilenw sɔrɔ .

Aw ye Industriw ka sariyaw dafa .

Aw ye kiliyanw ka ɲininiw wasa .

Mun bɛ kɛ sababu ye ka kulɛriw kɛ minnu tɛ kelen ye pikirijikɛlanw na?

Kulɛri min tɛ kelen ye pikiri kɛlen yɔrɔw la, o bɛ se ka bɔ fɛn suguya caman na. Nin sababu ninnu faamuyali bɛ dilanbagaw dɛmɛ ka kulɛriw ka bɛnbaliyakow ɲɛnabɔ ani ka u bali.

Fɛn minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye .

Fɛnɲɛnɛmaw jɔyɔrɔ ka bon kosɛbɛ kulɛriw cogoya la. Ko caman bɛ se ka kɛ sababu ye ka kulɛri bɛnbali kɛ:

Jogo ɲuman walima nɔgɔ min tɛ bɛn ɲɔgɔn ma .

Koumafɛnw ka ca .

Jali fɛɛrɛ bɛnbaliw .

Fiyew falenfɛnw tilatilali man ɲi .

Degun caman cili fɛn dɔw la .

Fɛn minnu bɛ kɛ i n’a fɔ polisitirini ni AB minnu bɛ se ka kɛ fɛn caman ye, olu ka teli ka fɛn caman Changements de couleur de couleur de stress. O bɛ kɛ ka da kɔnɔna degunw kan mɔli kɔfɛ.

Kulɛri jogo ani a kunbɛncogo .

Kulɛriw bɛ nɔba bila fura laban cogoya la. Gɛlɛyaw bɛ bɔ:

Pigments (pigments) jɛnsɛnni man ɲi .

Sumaya min bɛ kɛ ni funteni ye, o ka dɔgɔ .

Selection Colorant inapproprié .

Quality Control min tɛ se ka kɛ .

Aw ye nin ko ninnu jateminɛ ni aw bɛ kulɛriw sugandi:

Bɛn ni resin ye .

Taabolo funteni wajibiyalenw .

Dispersibilité dans le melt .

Sanfɛla kulɛriw bɛ se ka minɛnw ni nɔgɔw nɔgɔ. O bɛ na ni kulɛri caman ɲɔgɔnna ye minnu ma labɛn ka bɔ baara la minnu bɛ kɛ kɔfɛ.

Pikiri molding machine issues .

Gɛlɛya minnu bɛ sɔrɔ masin na, olu ka teli ka kɛ kulɛriw ka bɛnbaliya ye:

| ko bɛ |

nɔ bila kulɛri la . |

| Barili funteni tɛ bɛn ɲɔgɔn ma . |

Sumaya kojugu walima plastiki jugu . |

| component contamination walima wear . |

Qualité de melt inconsistent . |

| Masiniw ka ɲɛfɔli minnu ma bɛn . |

Baarakɛcogo ɲɛnabɔli min tɛ se ka kɛ . |

Ladonni tuma bɛɛ ani masin sugandili ɲuman nafa ka bon kosɛbɛ kulɛriw cogoya la.

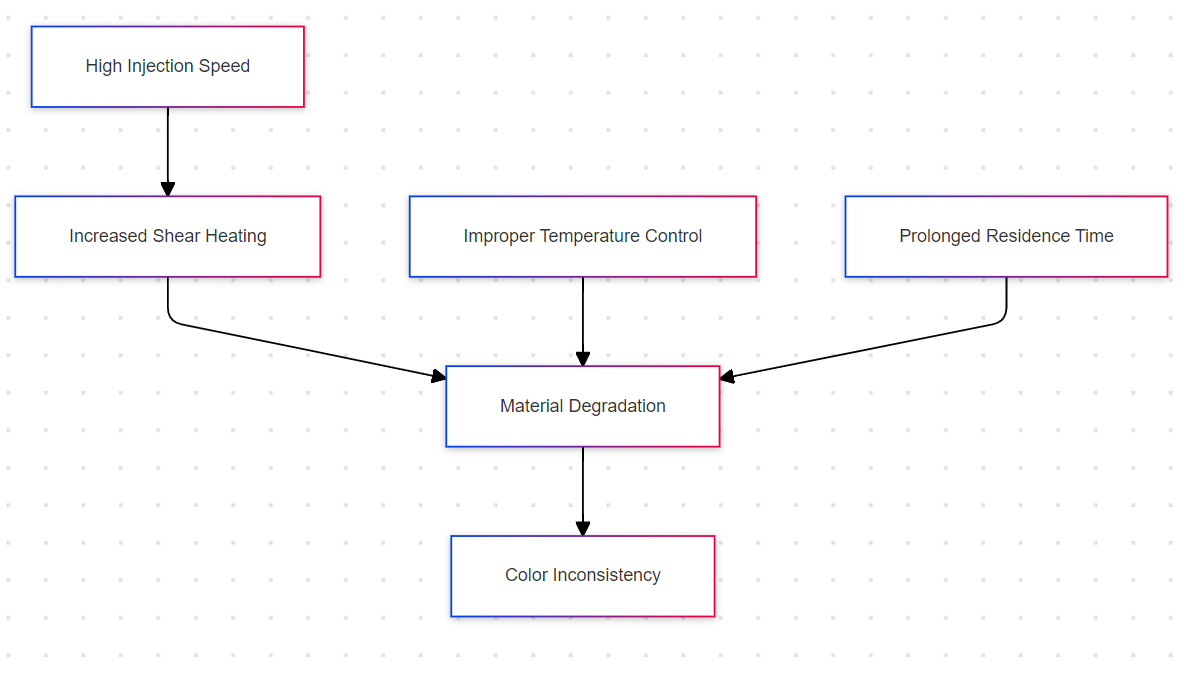

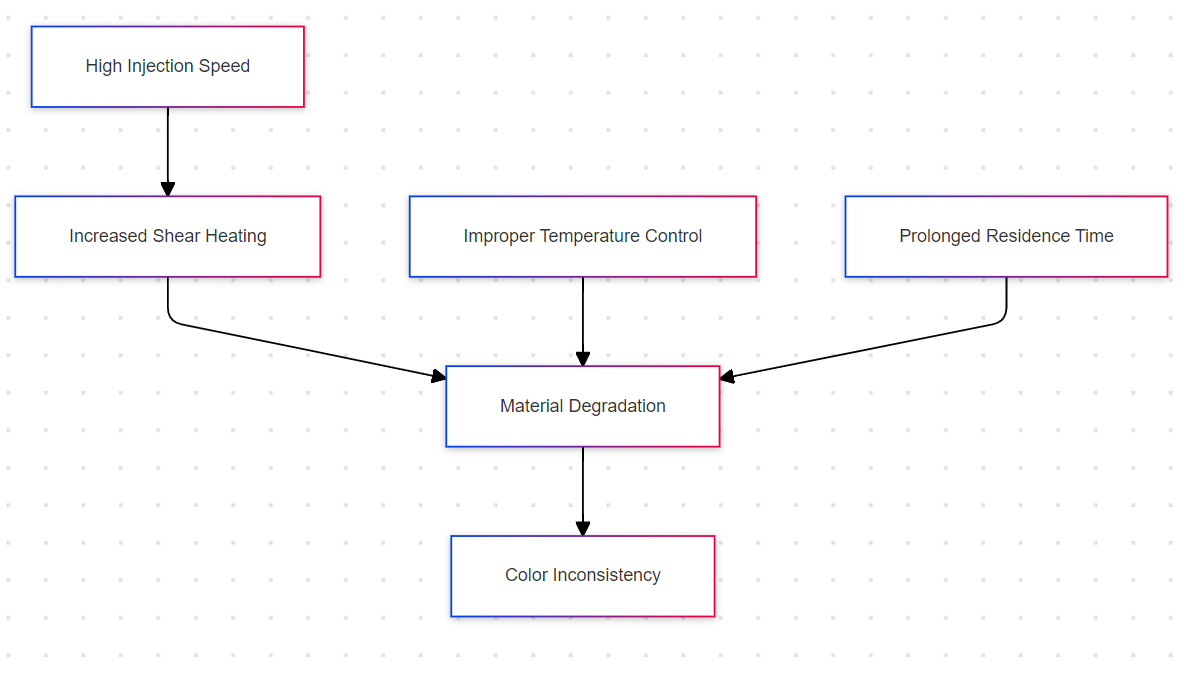

Molding Process Paramɛtɛrɛw .

Taabolow sigicogo bɛ nɔba bila kulɛriw la:

Pikiri teliya kojugu .

Tansiyɔn jiginni walima kɔ tansiyɔn .

Funteni hakɛ jateminɛcogo jugu .

Plastiki dafalen tɛ .

Residencement melt prolongée temps .

A tata hakɛ kulɛrilen walima a ɲagamini .

O paramɛtɛrɛw ɲɛnabɔli bɛ dɛmɛ ka kulɛriw cogoya sabati u dilanni bɛɛ la.

Mold Design ani a ladonni .

Fɛn minnu bɛ tali kɛ mɔli la, n’olu bɛ nɔ bila kulɛriw la, olu dɔw ye:

Nɛnɛ ni funteni tilacogo tɛ kelen ye .

Venting jugu min bɛ taa ni fiɲɛ ye .

Nɔgɔya ka bɔ a labɔlenw walima tulumafɛnw na .

Suboptimal gate yɔrɔ walima a dilanni .

Surface Roughness walima Polish Issues .

Nɔgɔ bɛ sɔrɔ nɔgɔw kan .

Nɔgɔ dilanni ɲuman ani a ladonni tuma bɛɛ nafa ka bon. U bɛ a to a ka wuli ka bɔ a nɔ na ani ka a nɛnɛ, ka kulɛri caman ɲɔgɔnna bali.

Kulɛri bɛnbaliya kunbɛncogo ani a gɛlɛyaw bɛ se ka ɲɛnabɔ cogo min na pikiri kɛli la .

Kulɛriw ka ɲɔgɔnbaliya pikiri kɛli la, o bɛ se ka kɛ gɛlɛyaba ye. A bɛ nɔ bila fɛn dilannenw ka ɲumanya la ani u ka kiliyanw wasako la. An ka fɛɛrɛ ɲumanw ɲini walasa ka nin ko in bali ani ka a gɛlɛyaw ɲɛnabɔ.

Quality Control de matériels rume et colorantes .

Ka da a la ko donnafɛn ɲumanw nafa ka bon kosɛbɛ kulɛri bɔli la min bɛ kɛ tuma bɛɛ:

Source Wisely : Aw bɛ fɛn dilanbagaw sugandi minnu bɛ se ka da u kan, walasa ka fɛnw sɔrɔ minnu bɛ bɛn ɲɔgɔn ma, minnu ka ɲi kosɛbɛ.

A maracogo ɲuman : Aw bɛ fɛnw minɛ ani ka u mara ka ɲɛ walasa u ka se ka u ka nafaw mara.

Jalabɔcogo : Aw bɛ jacogo ɲumanw waleya jilafɛnw na.

Kulɛri sugandili : Kulɛriw kɔrɔbɔ ka ɲɛ walasa u ka se ka baara kɛ ɲɔgɔn fɛ ani u ka baara kɛ.

Minɛnw ladonni : Aw bɛ to ka fɛnw tacogo minɛnw lajɛ ani ka u saniya.

Optimizing . Pikirili mɔli masinw sigicogo .

Masina sigicogo ɲuman nafa ka bon kulɛriw cogoya la:

Calibration : Aw bɛ to ka funteni hakɛ jateminɛcogo jateminɛ.

Paramɛtiriw kɔlɔsili : Aw bɛ baarakɛcogo paramɛtiriw ladilan i n’a fɔ pikiri teliya ani tansiyɔn.

Masina hakɛ : Aw ye aw jija ka mɔli masin bonya ka ɲɛ baara kama.

Saniya ka ɲɛ : Aw bɛ masin saniya ani ka a saniya ka ɲɛ kulɛri caman yeli cɛ.

Moli kɛcogo ɲuman .

Taabolo min bɛ se ka kunbɛn ka ɲɛ, o ye kulɛri basigilen jɔnjɔn ye:

Taabolow kɔlɔsili : Ka sigida barikama sigi senkan walasa ka paramɛtɛrɛw kɔlɔsi ani ka u ladilan.

Temperature optimization : Fine-tune melt temperature walasa ka kulɛriw jɛnsɛn cogo ɲuman na.

Pikiri profiling : Aw bɛ pikiri teliya ni degun kɛcogo ladilan walasa ka kulɛriw tilatilali kɛ cogo kelen na.

Sigida waati : Aw bɛ sigiyɔrɔw waati dɔgɔya barili kɔnɔ.

Scientific Molding : Ka sariyakolow sigi sen kan minnu bɛ se ka segin-ka-bɔ, minnu bɛ se ka fɔ ka ɲɛ.

Mold design jateminɛw hali kulɛri .

Mold design jɔyɔrɔ ka bon kosɛbɛ ka se ka kulɛri kelen sɔrɔ:

Nɛnɛ kelen : dilan mɔliw walasa ka funteni tilacogo balannen sɔrɔ.

Fiɲɛ bɛ don a la ka ɲɛ : Aw bɛ fiɲɛ minɛcogo ni jeninida taamasiɲɛw bali ka tɛmɛ fiɲɛbɔlan ɲuman fɛ.

Gate Optimization : Aw bɛ da yɔrɔw ni dilanw sugandi walasa ka balannen melt flow sɔrɔ.

Ladonni : Aw bɛ to ka nɔgɔ yɔrɔw saniya ani ka u furakɛ walasa u kana nɔgɔ.

Kulɛri fɛɛrɛw ni minɛnw optimisation .

Kulɛriw ka ɲɔgɔndɛmɛ ka ɲɛ ni kulɛriw ye minnu bɛ taa ɲɛ:

Quality Masterbatches : Baara kɛ ni kulɛriw ye minnu ka ɲi kosɛbɛ.

Pre-coloring : Aw bɛ fɛɛrɛw ta ka kɔn ka ɲɛ ni aw bɛ se ka a kunbɛn ka ɲɛ.

Dehumidifying dryers : Aw bɛ fɛnɲɛnamafagalanw ka nɔgɔko gɛlɛyaw bali ni jalenw ye minnu bɛ taa ɲɛ.

Nɛgɛ dɔnni : Aw bɛ detektɛriw sigi balocogo la walasa ka nɔgɔ bali.

Gɛlɛyaw ɲɛnabɔli fɛɛrɛw ka ɲɛsin kulɛri caman ɲɔgɔnnako ma .

Ni kulɛriko koɲɛw wulila, gɛlɛyaw ɲɛnabɔcogo sigilen nafa ka bon:

Gɛlɛyaw ɲɛnabɔcogo : Baara kɛ ni baarakɛminɛnw ye i n’a fɔ Ishikawa jatebɔw ani PDCA sɛrɛkiliw.

Root Cause Analysis : Isolate ani ka a jira ko kulɛri bɛnbaliya sɔrɔyɔrɔ fɔlɔw.

Adjustment incremental : Test processus paramètres cogo la min bɛ kɛ ka koɲɛw jira.

Ekipu ka jɛkafɔ : ka kumaɲɔgɔnya sabati dilancogo, fɛn dilanni, ani jogoɲini jɛkuluw cɛ.

Ni nin fɛɛrɛ ninnu waleyali ye, fɛn dilannikɛlaw bɛ se ka kulɛriw ka ɲɔgɔn sɔrɔli ɲɛ kosɛbɛ pikiri kɛli la. Kɔlɔsili kɛli tuma bɛɛ ani ɲɛtaa sabatili ye fɛnba ye min bɛ kɛ ka ɲɛgɛnɛsiraw mara minnu ka ɲi, minnu bɛ kɛ kelen ye.

Fura wɛrɛw ni wale ɲumanw .

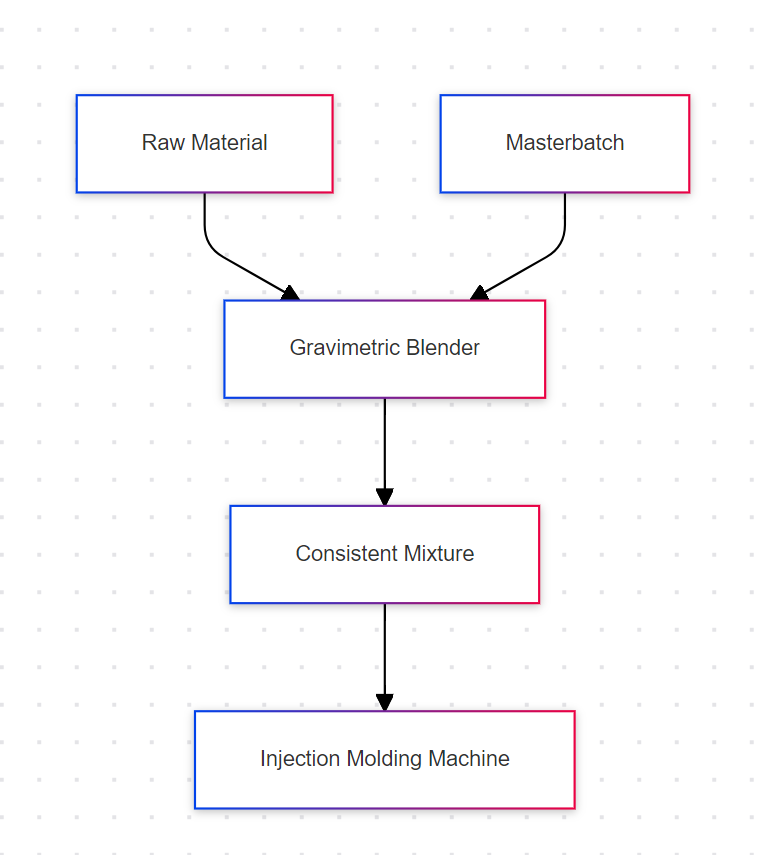

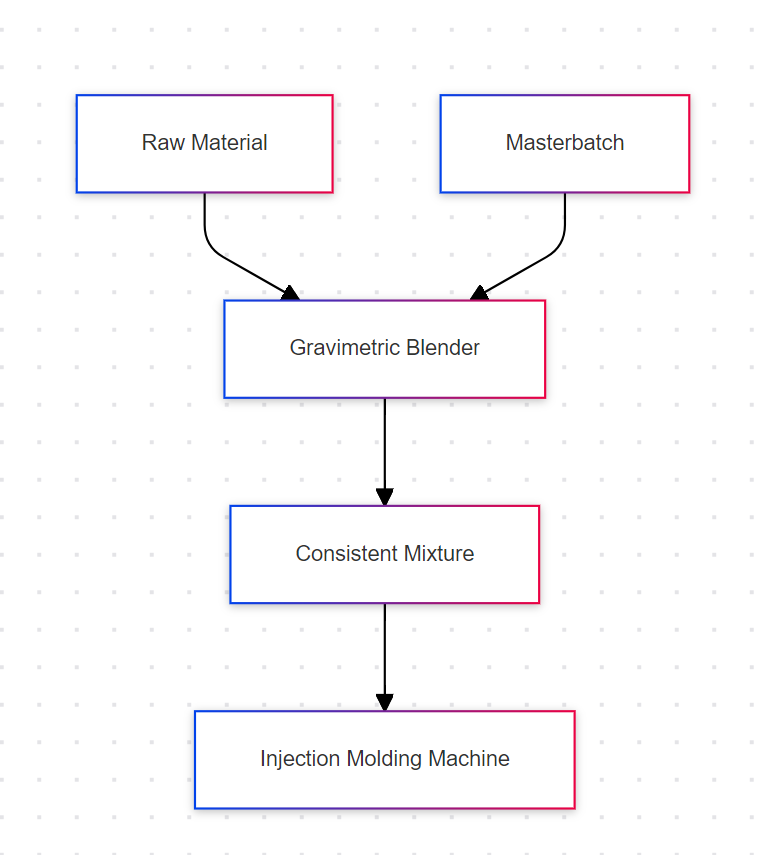

Baara kɛli ni gravimetric blenders ye .

Blender gravimétriquew bɛ kunnafoni tigitigi di fɛnw ɲagaminen kan. U bɛ masterbatch ni fɛnɲɛnamafagalanw hakɛ basigilenw sabati.

Nafa jɔnjɔnw ye ninnu ye:

Kulɛriw tata hakɛ tigitigi .

Blend ratios ladilanni waati yɛrɛ la .

Adamaden ka fili bɔli fɛnw labɛnni na .

O fɛɛrɛ in bɛ dɔ bɔ kosɛbɛ kulɛri caman ɲɔgɔnna na minnu bɛ sɔrɔ ɲagamini na min tɛ bɛn ɲɔgɔn ma.

Kuranko ɲɛnabɔli fɛɛrɛw sigilen .

Kuran jɔlen bɛ se ka kɛ sababu ye ka fɛnw fara ɲɔgɔn kan bolifɛnw waati. O bɛ na ni kulɛri tɛ kelen ye fura laban na.

Kɔrɔsili fɛɛrɛ jɔnjɔnw ye:

Ionizerw bɛ sɔrɔ fɛnw na minnu bɛ taa ni fɛnw ye .

Anti-statique faralifɛnw bɛ sɔrɔ fɛnɲɛnamafagalanw na .

Minɛnw ni bolifɛnw sigicogo dugukolo kan .

| yɔrɔ |

kɔlɔsili sumanikɛlan . |

| Hopper . |

Écran cone sigili . |

| Hoses transport . |

Ionizers walima ki blow static eliminators . |

| Molding Machine . |

Dugukolo kan sirilanw . |

O fɛɛrɛw bɛ fɛnw falenni bali ani ka kulɛriw tilatilali kɛ cogo kelen na.

Blenders de color de liquide .

Walasa ka mɔli kulɛri jɛmanw sɔrɔ, kulɛriw blenderw bɛ nafa kɛrɛnkɛrɛnnenw di:

Kulɛri jɛnsɛnni ɲɛnabɔlen .

A bɛ dɔgɔya ka ɲɛsin streaking walima marbling ma .

Kulɛri fanga ladilancogo nɔgɔman .

Kulɛri jilamaw bɛ don sen kan sanni fɛn ka don molding machine kɔnɔ. Nin waati in bɛ sira Di:

A ɲagaminen ni resin transparent ye .

Funteni tiɲɛni ka dɔgɔn .

Kulɛriw kɔlɔsili tigitigi waati yɛrɛ la .

Ni nin furakɛlicogo kɔrɔlen ninnu waleyali ye, fɛn dilannikɛlaw bɛ se ka:

Kulɛriw ka ɲɔgɔn sɔrɔcogo ɲɛ .

Aw bɛ tiɲɛniw dɔgɔya ka bɔ kulɛriw la .

Aw bɛ fɛn bɛɛ lajɛlen jogo ɲɛ .

Ko minnu kɛra .

Misali lakikaw bɛ hakilina nafamaw di kulɛri bɛnbaliya koɲɛw ɲɛnabɔli kan. An ka ko saba ni u furakɛcogo sɛgɛsɛgɛ.

Case 1: Selection Colorant improper .

Smartphone case dilannikɛla dɔ ɲɛda bɛ to ka kulɛri caman sɔrɔ u ka fɛn dilannenw na. Sɛgɛsɛgɛli y’a jira ko a jujɔ sababu: kulɛri sugandili bɛnbali.

Kunko:

Fɛɛrɛ:

A ye sɛgɛsɛgɛli kɛ funteni sabatili kan kulɛriw kan .

Pigments minnu bɛ se ka funteni kɛlɛ .

Baarakɛcogo paramɛtɛrɛw ladilanen ka ɲɛsin kulɛri kura ma .

Jaabi:

95% dɔgɔyali minnu bɛ sɔrɔ kulɛriw la .

Kunnafonidila ka ɲɛsin kiliyanw wasako ma .

sɛnɛfɛnw tiɲɛni dɔgɔyali .

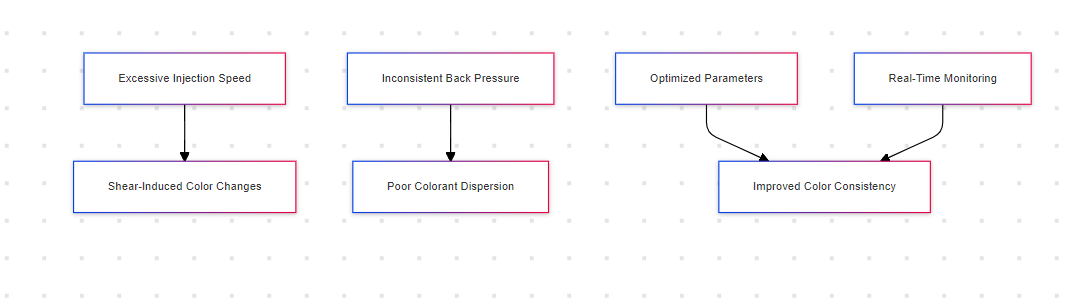

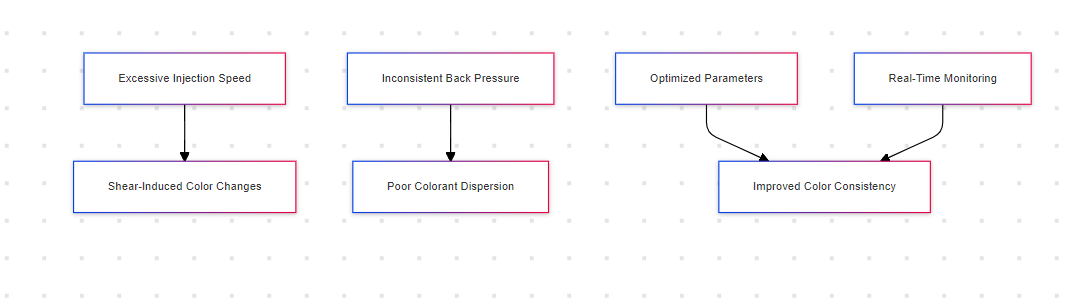

Ko 2nan : pikiri kɛcogo paramɛtiriw .

Mobili yɔrɔw feerela dɔ ye kulɛriw deviations sɔrɔ dashboard yɔrɔw la. Sɛgɛsɛgɛli y’a jira ko pikiri kɛcogo paramɛtiriw bɛnbaliw.

Kunko:

Pikiri teliya kojugu kɛra sababu ye ka kulɛri caman wuli shear-induite .

Kɔfɛ degun min tɛ bɛn ɲɔgɔn ma, o kɛra sababu ye ka kulɛriw jɛnsɛn cogo jugu la .

Fɛɛrɛ:

Pikiri teliya cogoya ɲuman .

Kɔfɛ tansiyɔn sigicogo ɲumanw .

A ye baara kɛcogo kɔlɔsili kɛ waati yɛrɛ la .

Jaabi:

Kulɛriw ka ɲɔgɔn sɔrɔli ɲɛnabɔra ni 80% ye .

Scrap hakɛ dɔgɔyara ka bɔ 7% na ka se 1,5% ma .

Sɛnɛfɛnw dilanni nafa cayara ni 12% ye .

Ko 3: Mɔbili funteni hakɛ jateminɛ .

Cosmetic packaging dilannikɛla dɔ ye sigida kulɛri danfara kɔlɔsi u ka fɛn dilannenw na. Sɛgɛsɛgɛli y’a jira ko nɔgɔ funteni hakɛ jateminɛcogo bɛnbali ye jalakibaga ye.

Kunko:

Nɛnɛ kɛcogo tɛ kelen ye, o sababu bɔra kristalɛ caman ɲɔgɔnna .

o kɛra sababu ye ka sigida kulɛri ni kɛnɛya koɲɛw jira .

Fɛnɲɛnɛma:

Moule de cooling channels minnu dilannen don kokura .

A ye funteni-sɛgɛsɛgɛlikɛlan wɛrɛw sigi sen kan .

A bɛ baara kɛ ni adaptive mold temperature control ye .

| Yɔrɔ min |

bɛ kɔn |

o ɲɛ . |

| Kulɛriw ka ɲɔgɔn sɔrɔli . |

75% . |

98% . |

| Sikili waati . |

Seginnkanni 28 . |

Seginnkanni 24 . |

| Scrap taux . |

5,5% . |

1,2% . |

Jaabi:

A ye kulɛri kelen sɔrɔ fɛn dilannenw bɛɛ la .

Dɔgɔyali cycle waati la ni 14% ye .

Fɛn bɛɛ lajɛlen ka jogo ɲɛnabɔlen .

Kuncɛli

Kulɛriw bɛ ɲɔgɔn sɔrɔ pikiri kɛli la fɛn suguya caman kan. Fɛnw, kulɛriw, masinko koɲɛw, ani baarakɛcogo paramɛtɛrɛw bɛɛ jɔyɔrɔ ka bon kosɛbɛ. A ladonni tuma bɛɛ, a sɛgɛsɛgɛliw, ani a ladilanni bɛ gɛlɛyaw bali sani u ka daminɛ. Ka jɛ ka baara kɛ ni feerekɛlaw ye, o bɛ fɛnw sabati minnu ka ɲi kosɛbɛ. Ni u ye o ko ninnu ɲɛnabɔ, fɛn dilannikɛlaw bɛ se ka fɛn kulɛrilenw sɔrɔ minnu bɛ bɛn ɲɔgɔn ma, minnu ka ɲi kosɛbɛ.