Wetin mek sɔm plastic pat dɛn gɛt kɔlɔ we nɔ ivin afta dɛn dɔn injɛkshɔn mol? Dis defekt kin kɔst fɔ di wan dɛn we de mek am. Di kɔlɔ we nɔ gri kin ridyus di kwaliti fɔ di prɔdak ɛn mek di west bɔku. Insay dis post, wi go tɔk bɔt di impɔtant tin we di kɔlɔ kɔnsistɛns gɛt fɔ du wit injɛkshɔn moldin, di prɔblɛm dɛn we di faktri dɛn de gɛt, ɛn di prɛktikal sɔlvishɔn dɛn fɔ mek shɔ se dɛn gɛt bɛtɛ rizɔlt.

Ɔndastand di difrɛn difrɛn kɔlɔ dɛn we nɔ fayn .

Insay di eria fɔ injɛkshɔn moldin, kɔlɔ kɔnsistɛns de ple wan impɔtant pat pan di prɔdak kwaliti. Lɛ wi dayv insay di wɔl fɔ kɔlɔ dɛfɛkt ɛn fɛn ɔl di impak we dɛn gɛt pan di we aw dɛn de mek tin dɛn.

Difinishɔn fɔ difrɛn kɔlɔ ɔ difrɛn kɔlɔ difrɛns .

Nɔ ivin kɔlɔ, we dɛn kin kɔl bak difrɛn kɔlɔ, de tɔk bɔt:

Inkɔnsistens dɛn na Hue, dip, ɛn shed akɔdin to di pat dɛn we dɛn dɔn mol .

Varieshɔn dɛn we de kɔmɔt frɔm di kɔlɔ spɛsifikɛshɔn dɛn we dɛn bin want fɔ gɛt .

Nɔn-yunifɔm pigmɛnt distribyushɔn insay di plastic matirial .

Dɛn difrɛns ya kin sho insɛf pan tin dɛn we nɔ klia ɔ we nɔ klia, we kin afɛkt:

Visual Apil .

Kwaliti fɔ di prɔdak .

Brand kɔnsistɛns .

Di kɔmɔn simptom dɛm .

Bɔku tɛm, di difrɛn difrɛn kɔlɔ dɛn kin sho dɛnsɛf tru:

Visual indikɛtɔ dɛn .

Miks kɔlɔ dɛn: swirl ɔ pat dɛn we gɛt difrɛn shed dɛn

Diskoloreshɔn: Shift dɛn we dɛn nɔ bin de ɛkspɛkt na hue ɔ intensiti

Marbling Effects: Streaks ɔ patɛns dɛn we tan lɛk mabul

Spɔtin: lokaliz eria dɛn we gɛt dak ɔ layt kɔlɔ

Impekt pan Manufakchurin .

Kɔlɔ inkɔnsistens kin mek:

| isyu |

kɔnsɛkshɔn . |

| Di skrap ret dɛn we de go ɔp . |

Di kɔst fɔ di prodakshɔn we ay pas ɔl . |

| Difikulti fɔ mach pat dɛn . |

Di Chalenj dɛn fɔ di Asɛmbli . |

| Kwaliti kɔntrol fayl dɛn . |

Dilay shipmɛnt dɛn . |

| Di we aw di kɔstɔma dɛn nɔ satisfay . |

Pɔtnɛshɛl fɔ lɔs biznɛs . |

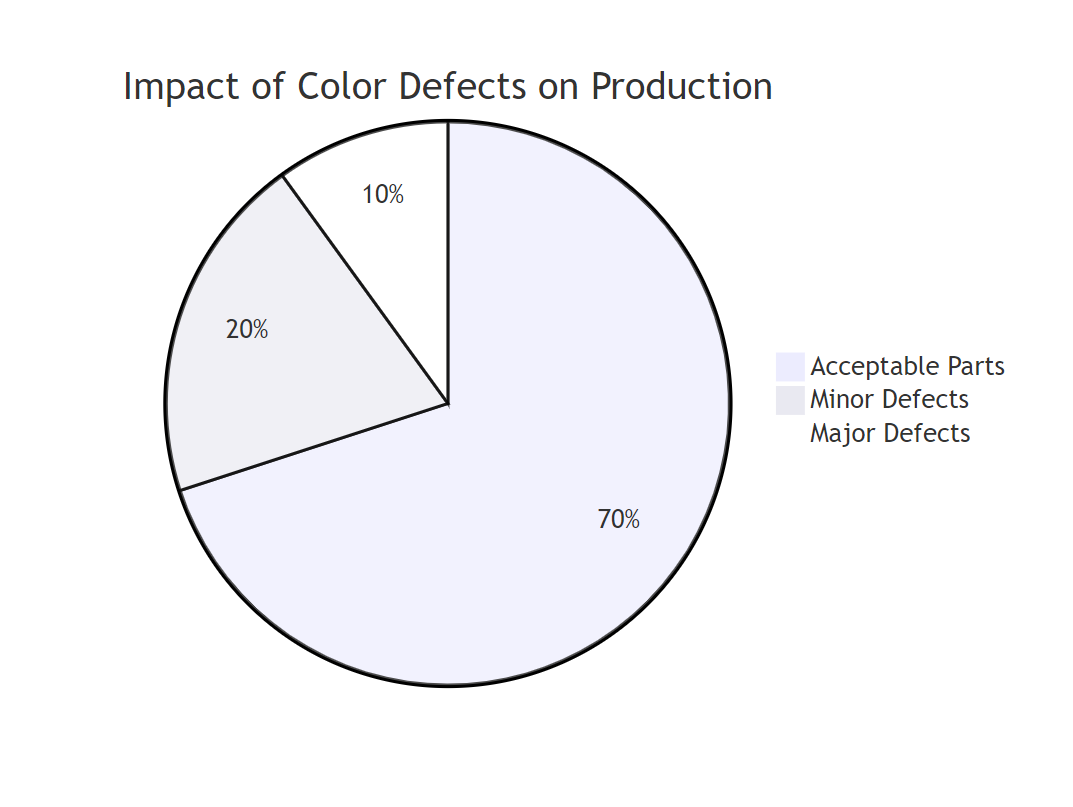

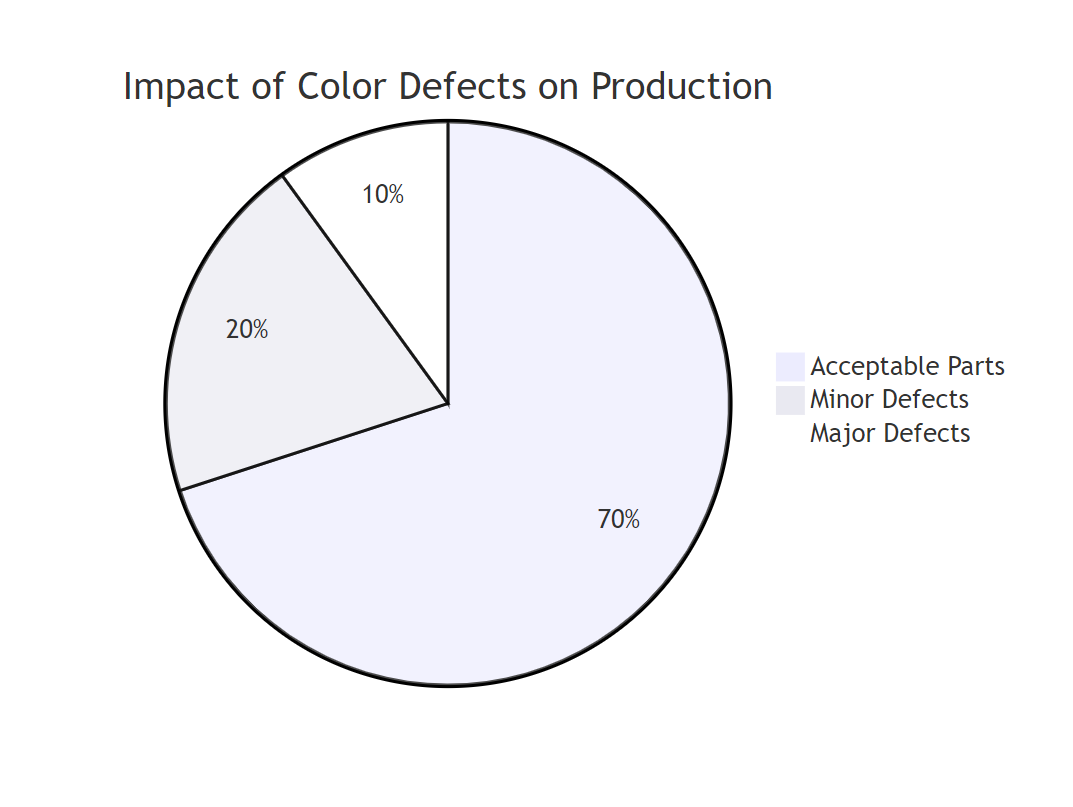

Fɔ sho di kayn we aw di kɔlɔ nɔ fayn, tink bɔt dis data:

Kɔlɔ kɔnsistɛns ishu dɛn nɔ jɔs afɛkt aesthetics. Dɛn kin sho se dɛn gɛt prɔblɛm dɛn we de ɔnda dɛn:

Mixing we nɔ fayn fɔ mek dɛn nɔ miks .

Di chenj chenj we de apin na di tɛmpracha .

Mold Design Flaws .

Di tin dɛn we gɛt fɔ du wit kɔntaminɛshɔn .

Fɔ no dɛn simptom ya kwik kwik wan kin ɛp di wan dɛn we de mek dɛn:

Bay we yu ɔndastand di difrɛn difrɛn kɔlɔ dɛn we nɔ fayn, di wan dɛn we sabi fɔ mold injɛkshɔn kin:

1.Impruv Kwaliti Kɔntrol Prɔses 2.Rɛdyuz west 3.Ɛnhans ɔvala prodakshɔn efyushɔn

Ditekshɔn fɔ di kɔlɔ ɛn jɔjmɛnt .

Fɔ no di kɔlɔ dɛn we nɔ gri wit injɛkshɔn moldin nid fɔ gɛt keen ɔbshɔbishɔn ɛn prɛsis mɛzhɔmɛnt. Lɛ wi fɛn ɔl di we dɛn we dɛn kin yuz fɔ no ɛn ebul fɔ no difrɛns bitwin difrɛn kɔlɔ dɛn.

Visual inspekshɔn tɛknik dɛn .

Visual inspekshɔn stil bi wan impɔtant fɔs step insay kɔlɔ kwaliti kɔntrol. I de abop pan mɔtalman sɛns fɔ si difrɛns.

Rol fɔ layt ɛn envayrɔmɛnt .

Layt kɔndishɔn dɛn kin rili ambɔg di we aw pipul dɛn de si di kɔlɔ. Tink bɔt dɛn tin ya:

Natural vs. artificial layt .

Kɔlɔ Tɛmpratura fɔ Layt Sɔs dɛn .

Di kɔlɔ dɛn we de rawnd ɛn di tin dɛn we de sho di tin dɛn we de apin .

Di rayt layt sɛtup de mek shɔ se:

Kɔnsistɛns kɔlɔ ɛvalueshɔn .

Akkurayt ditekshɔn fɔ di difrɛn difrɛn we dɛn we dɛn kin chenj di we aw dɛn nɔ de chenj .

Ridyus di ay strayn fɔ inspɛkta dɛn .

Limiteshɔn fɔ mɔtalman yay vs. mashin inspekshɔn .

Mɔtalman vishɔn, pan ɔl we dɛn kin ebul fɔ adap, i gɛt in prɔblɛm dɛn:

| Yuman ay |

mashin inspekshɔn |

| Subjective . |

Gol |

| Prone fɔ Fatigue . |

Kɔnsistɛns pefɔmɛns . |

| Limitɛd kɔlɔ sɛnsitiviti . |

Ditekshɔn fɔ ay-prɛsishɔn . |

| Influɛns bay optik ilyushɔn dɛn . |

Data-driven Analysis . |

Pan ɔl we dɛn nɔ ebul fɔ du natin, di inspɛkta dɛn we dɛn dɔn tren kin:

Inspekshɔn fɔ di Kolorimita .

Fɔ mek dɛn ebul fɔ mɛzhɔ di kɔlɔ klia wan, di kɔlorimita dɛn de gi dɛn data we dɛn kin kwantifay. Dɛn de gi ɔbjɛktiv analisis pas aw mɔtalman de si.

Ɔndastand △E Valyu dɛn .

△E (Delta E) riprizent di totכl kכla difrεns bitwin tu sεmpl. I de kɔlkul yuz:

△e = [(△L)⊃2; + (△A)⊃2; + (△B)⊃2;]^(1/2)

Usay:

Standards fɔ difrɛn kɔlɔ dɛn we dɛn kin gri wit .

Bɔku tɛm, di industri standad dɛn kin yuz △e valyu dɛn fɔ difayn akseptabl kɔlɔ chenj dɛn:

| △E rɛnj |

intapriteshɔn |

| 0 - 1 na di . |

Difrɛns we pɔsin kin si we i nɔ ebul fɔ ɔndastand . |

| 1 - 2. |

Smɔl difrɛns . |

| 2 - 3,5. |

Difrɛns dɛn we wi go notis difrɛns . |

| 3,5 - 5 |

signifyant difrɛns . |

| > 5 na di . |

Difrɛns we yu nɔ go gri wit . |

Dɛn rɛnj ya kin difrɛn difrɛn wan bay:

Di Spesifikasi Indastri .

Di tin dɛn we dɛn nid fɔ mek di prɔdak .

Di tin dɛn we di kɔstɔma dɛn de op fɔ .

Bay we dɛn jɔyn di inspekshɔn dɛn we dɛn kin si ɛn di wan dɛn we de na di kɔlorimɛta, di wan dɛn we de mek dɛn kin:

Mek shɔ se yu gɛt kɔnsistɛns kɔlɔ kwaliti .

Mit di Standart dɛn fɔ di Indastri .

Satisfy di dimand dɛn we di kɔstɔma dɛn gɛt .

Wetin kin mek di kɔlɔ we nɔ ivin gɛt injɛkshɔn mold pat dɛn?

Di kɔlɔ we nɔ ivin insay injɛkshɔn mold pat dɛn kin kɔmɔt frɔm difrɛn tin dɛn. We dɛn ɔndastand dɛn tin ya, dat kin ɛp di wan dɛn we de mek dɛn tin ya fɔ sɔlv prɔblɛm dɛn ɛn mek dɛn nɔ gɛt kɔlɔ we nɔ gri wit dɛnsɛf.

Raw Material Factors .

Raw matirial dɛn de ple impɔtant pat pan di kɔlɔ kɔnsistɛns. Bɔku tin dɛn kin mek dɛn gɛt kɔlɔ we nɔ ivin:

Kwaliti ɔ kɔntaminɛshɔn we nɔ gri wit wetin de apin .

Di tin dɛn we gɛt bɔku bɔku wata .

Di we aw dɛn nɔ de drɛy fayn fayn wan .

Poor distribushɔn fɔ fayv fil dɛn .

Stress Discoloration in sɔm matirial dɛn .

Matirial dεm lεk ay-impakt polistayn εn AB dεm kin pron to strεs-induse kכla chenj dεm. Dis kin apin bikɔs ɔf di strɛs dɛn we de insay afta dɛn dɔn mol am.

kwaliti ɛn kɔntrol we gɛt kɔlɔ .

Kɔlɔrant dɛn kin rili ambɔg di fayn fayn prɔdak in apia. Prɔblɛm dɛn kin kɔmɔt frɔm:

Poor dispersion of pigments .

Low tɛmal stebiliti .

Di kol we nɔ fayn fɔ di kɔlɔ we dɛn pik .

Inadequate kwaliti kɔntrol .

Tink bɔt dɛn tin ya we yu de pik di kɔlɔ dɛn:

Kompatibiliti wit di resin .

Prɔses Tɛmpratura Rikwaymɛnt dɛn .

dispersibility in di melt .

Di kɔlɔ dɛn we de na di ays kin kɔntamin di ikwipmɛnt ɛn mol dɛn. Dis kin mek di kɔlɔ chenj dɛn we dɛn nɔ bin de ɛkspɛkt na di prodakshɔn rɔn dɛn we kin kam afta dat.

Injekshɔn Molding Machine issues .

Bɔku tɛm, prɔblɛm dɛn we gɛt fɔ du wit mashin kin mek di kɔlɔ nɔ gri wit di kɔlɔ: Di impak we

| di prɔblɛm kin |

gɛt pan di kɔlɔ |

| Inkɔnsistɛns barɛl tɛmpracha . |

Ova ɔt ɔ po plasticizayshɔn . |

| Komponent kontamineshɔn ɔ wear . |

Kwaliti we nɔ gri wit di kɔrɛkt wan . |

| Mashin spesifikeshɔn dɛn we nɔ fayn fɔ yuz . |

Inadekwat prɔsesin kɔntrol . |

Rigyul mentenɛns ɛn di rayt mashin sɛlɛkshɔn na impɔtant tin fɔ mek di kɔlɔ kɔnsistɛns.

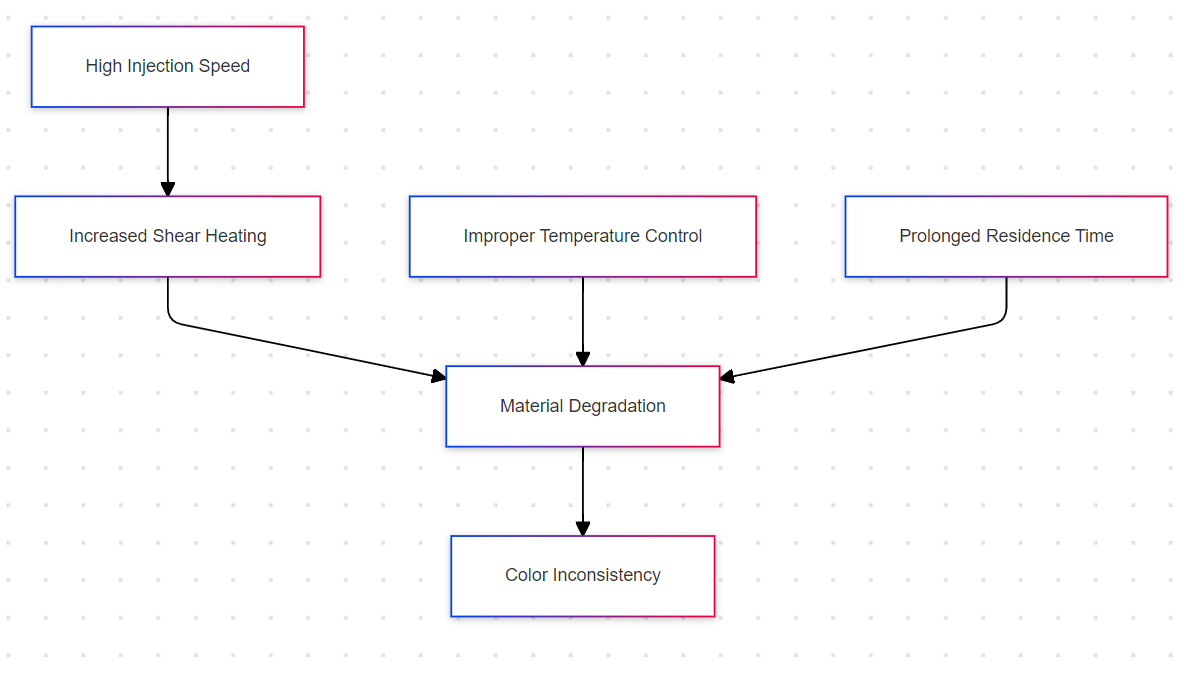

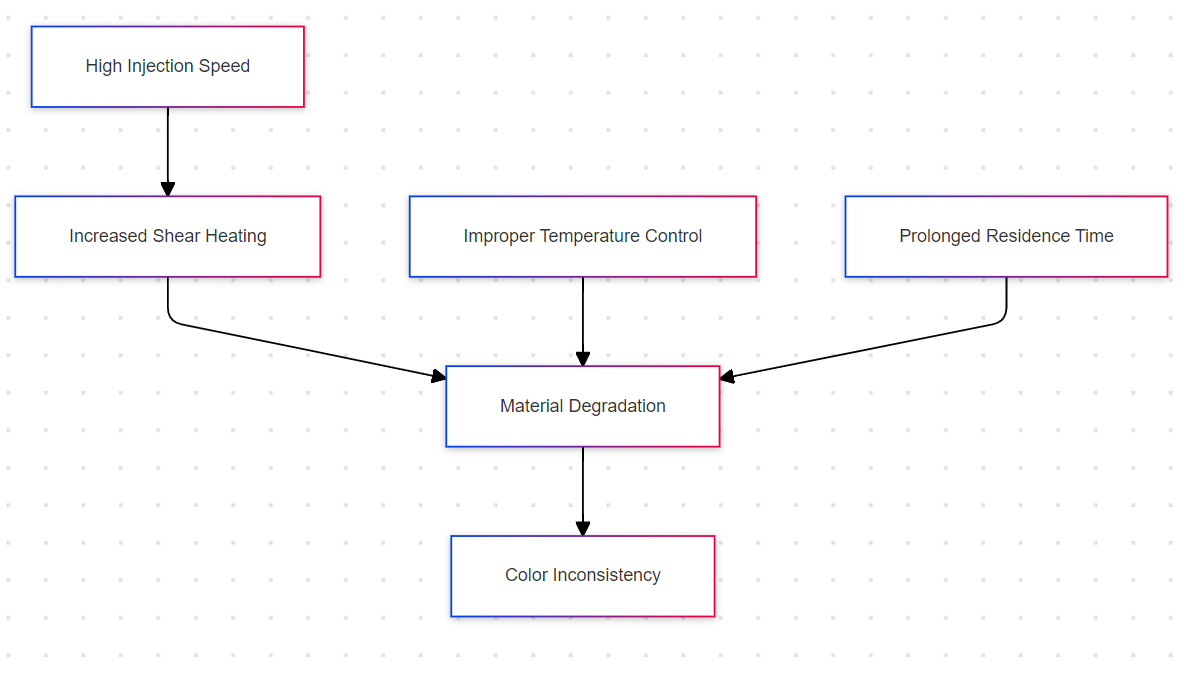

Molding proses paramita dɛn .

Prɔses sɛtin dɛn kin rili afɛkt di kɔlɔ yunifom:

Injɛkshɔn we pasmak spid .

Ay prɛshɔn ɔ bak prɛshɔn .

Improper melt temperechur kontr ɔ l .

Insufisɛnt plasticizayshɔn .

Fɔ lɔng tɛm fɔ mɛlt rɛsɛdans tɛm

Inkɔrɛkt Kɔlɔrant Dosing ɔ Mixing .

Optimizing dis paramita dεm de εp fכ mεnten kכla kכnsistεns tru di prodakshכn.

Mold dizayn ɛn mentenɛns .

Di tin dɛn we gɛt fɔ du wit mold we de afɛkt di kɔlɔ yunifom na:

Uneven cooling ɛn tempɔret distribushɔn .

Poor venting we de mek yu go ebul fɔ go na di ays ɛntrapmɛnt .

Kontamineshɔn frɔm rilis ɛjɛn ɔ lɔbrikɛn .

Suboptimal get lokeshɔn ɔ dizayn .

Surface roughness ɔ polish ishu dɛn .

Rust pan mold surfaces .

Fɔ mek di mold fayn ɛn fɔ mek dɛn kɔntinyu fɔ mek am fayn ɔltɛm na impɔtant tin. Dɛn de mek shɔ se dɛn de mek yunifom mɛlt flɔ ɛn kol, ɛn dis de mek di kɔlɔ chenj.

Aw fɔ mek yu nɔ gɛt ɛn sɔlv prɔblɛm dɛn we nɔ gɛt kɔlɔ we nɔ gri wit injɛkshɔn moldin .

Kɔlɔ inkɔnsistens insay injɛkshɔn moldin kin bi wan impɔtant chalenj. I de afɛkt di kwaliti fɔ di prɔdak ɛn di we aw di kɔstɔma dɛn satisfay. Lɛ wi fɛn ɔl di fayn fayn strateji dɛm fɔ mek wi nɔ gɛt dis prɔblɛm ɛn fɔ sɔlv dis prɔblɛm.

Kwaliti kɔntrol fɔ raw matirial ɛn kɔlɔrant dɛn .

Fɔ mek shɔ se dɛn put ay kwaliti input dɛn impɔtant fɔ kɔnsistɛns kɔlɔ autput:

Source Wisely : Pik rili fayn saplay dɛn fɔ kɔnsistɛns, ay-kwaliti raw matirial dɛn.

Prɔpa stɔrɔj : handel ɛn stɔ matirial dɛn kɔrɛkt wan fɔ mek dɛn kɔntinyu fɔ gɛt dɛn prɔpati dɛn.

Drying Protocols : Impliment di rayt drying prosidur fɔ hygroscopic matirial.

Colorant Selection : Tek tɛm tɛst di kɔla dɛn fɔ mek dɛn go ebul fɔ du am ɛn fɔ mek dɛn ebul fɔ du di wok fayn fayn wan.

Ikwipmɛnt Mentɛnans : Ɔltɛm inspɛkt ɛn klin di matirial hanlin ikwipmɛnt dɛn.

Optimizing we de mek yu ebul fɔ du di wok fayn fayn wan . Injekshɔn Molding Mashin Sɛtin dɛn .

Fayn-tyunin mashin sɛtin dɛn impɔtant fɔ mek yu gɛt kɔlɔ kɔnsistɛns:

Kalibreshɔn : ɔltɛm kalibrayt tɛmpracha kɔntrol sistɛm dɛn.

Paramita Monitoring : Adjɔst di ki prɔses paramita dɛn lɛk injɛkshɔn spid ɛn prɛshɔn.

Mashin Sizing : Mek shɔ se di mashin we dɛn de yuz fɔ mold gɛt di rayt sayz fɔ di wok.

Klin di mashin gud gud wan : Purge ɛn klin di mashin gud gud wan bitwin chenj dɛn na di kɔlɔ.

Fayn-tyunin di moldin proses .

Wan prɔses we dɛn kin kɔntrol fayn fayn wan na di men tin we kin mek pɔsin gɛt kɔlɔ ɔltɛm:

Proses Kontrol : Establish wan robust sistem fɔ monitar ɛn adjɔst paramita dɛn.

Tempracha optimayzeshɔn : Fayn-tyun mɛlt tɛmpracha fɔ optimal kɔlɔ dispershɔn.

Injekshɔn Profaylin : Adjɔst injɛkshɔn spid ɛn prɛshɔn profayl fɔ yunifom kɔlɔ distribyushɔn.

Residence Time : Minimize Material Residence Time in di Barrel.

Sayntis moldin : Impliment prinsipul fɔ ripit, prɛdiktibɛl rizɔlt.

Mold dizayn kɔnsidareshɔn fɔ ivin kɔlɔreshɔn .

Mold dizayn de ple wan impɔtant pat fɔ ajɔst yunifom kɔlɔ:

Yunifɔm kol : dizayn mold fɔ balans tɛmpracha distribyushɔn.

Adequate venting : Mek yu nɔ go insay di briz ɛn di mak dɛn we yu de bɔn ɛn bɔn mak dɛn tru di rayt vent.

Gate Optimization : Pik Get Locations ɛn Dizayn fɔ balans mɛlt flɔ.

Mentɛnans : Ɔltɛm klin ɛn trit mold sɔfays fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn.

Optimayzeshɔn fɔ di we aw dɛn de kɔla ɛn di ikwipmɛnt dɛn .

Impruv kala kɔnsistɛns tru advans kɔlɔ tɛknik:

Kwaliti Mastabatch : Yuz ay-kwaliti kala mastabatch dɛn prɛsis kɔntinyu.

Pre-coloring : Adopt pre-coloring methods wen i posibul fo beta kontrol.

Dehumidifying Dryers : Mek yu nɔ gɛt matirial mɔstɔ we yu de yuz advans drya.

Metal Detection : Instɔl ditektɔ dɛn na di fidin sistem fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn.

Trobulshut teknik fɔ chenj di kɔlɔ we de na di kɔlɔ .

We di tin dɛn we gɛt fɔ du wit kɔlɔ kam, dɛn impɔtant fɔ sɔlv di prɔblɛm dɛn we kin apin we dɛn de sɔlv prɔblɛm dɛn: dɛn rili impɔtant:

Prɔblɛm-sɔlv aprɔch : Yuz tul dɛn lɛk Ishikawa dayagram ɛn PDCA saykl dɛn.

ROOT KƆZ ANALYSIS : Ayzolayt ɛn no di praymar sɔs dɛm fɔ kɔlɔ inkɔnsistens.

Inkrimɛntal ajɔstmɛnt : Tɛst prɔses paramita dɛn sistamatically to pinpoint ishu dɛn.

Tim kolaboreshɔn : Foster kɔmyunikeshɔn bitwin dizayn, prodakshɔn, ɛn kwaliti kɔntrol tim dɛn.

Bay we dɛn de impruv dɛn strateji ya, di wan dɛn we de mek di tin dɛn kin rili ɛp fɔ mek di kɔlɔ kɔnsistɛns pan injɛkshɔn moldin. Fɔ wach ɔltɛm ɛn fɔ kɔntinyu fɔ impɔtant na di men tin fɔ mek dɛn kɔntinyu fɔ gɛt ay kwaliti, yunifom kɔlɔ.

Atikul dɛn we go ɛp fɔ sɔlv di prɔblɛm ɛn di bɛst we fɔ du am .

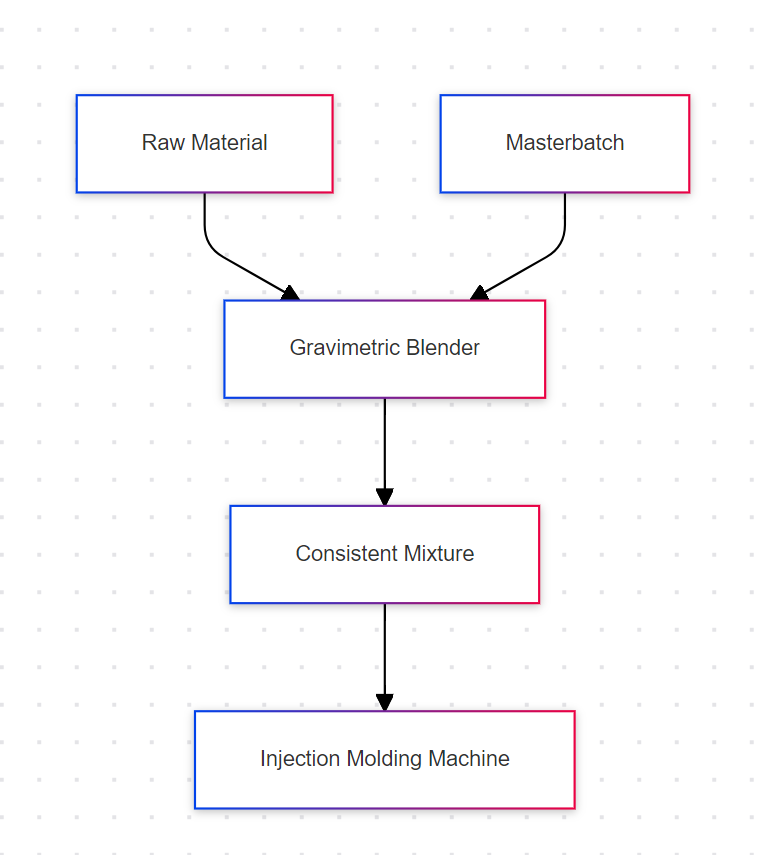

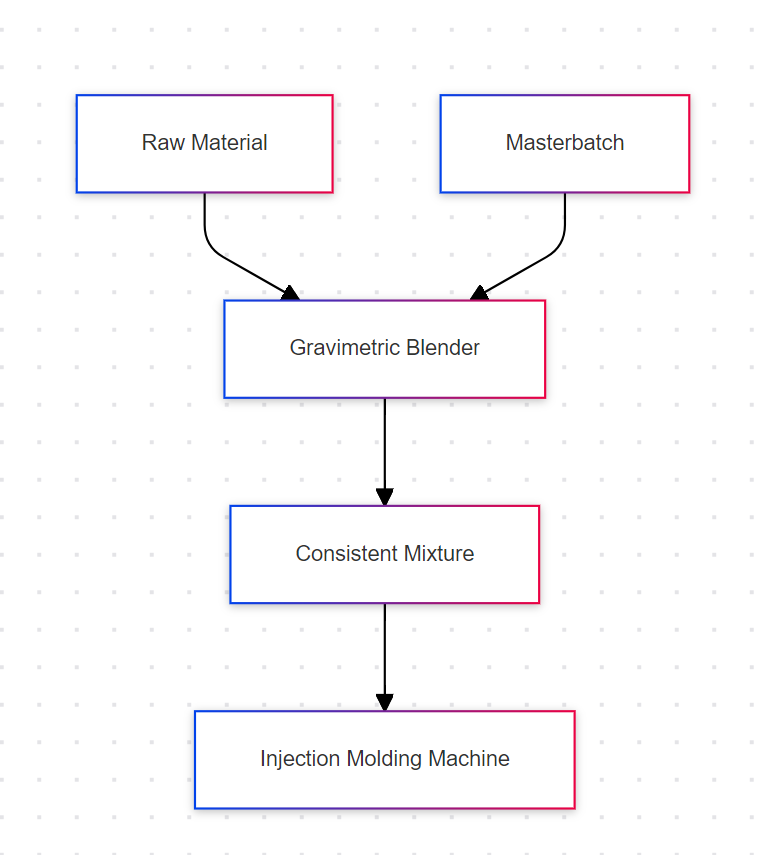

Yuz di Gravimetric Blenders .

Gravimetric blenders ofa prɛsis kɔntrol oba matirial miksin. Dɛn de mek shɔ se kɔnsistɛns rɛsɛshɔn dɛn fɔ mastabat ɛn raw matirial dɛn.

Di men bɛnifit dɛn na:

Akkurat dosin fɔ kɔlɔrant dɛn .

Rial-taym ajɔstmɛnt fɔ blɛnd rɛsɛshɔn dɛn .

Elimination of Human Error in Material Preparation .

Dis teknɔlɔji rili ridyus di difrɛn difrɛn kɔlɔ dɛn we kin apin bikɔs dɛn nɔ gri wit di miks we dɛn de miks.

Statik Ilɛktrishɔn Kɔntrol Mɛzhɔ .

Statik ilɛktrishɔn kin mek matirial separet we dɛn de transpɔt. Dis kin mek di kɔlɔ nɔ ivin na di las prɔdak.

Ifektiv statik kɔntrol mɛtɔd dɛn inklud:

ayɔniza dɛn na matirial transpɔt layn dɛn .

Anti-statik aditiv dɛn insay raw matirial dɛn .

Grɔndin fɔ di ikwipmɛnt ɛn transpɔt sistem dɛn .

| Location |

Control Measure |

| Hopper na di . |

Skrin Kɔn Instɔlɛshɔn . |

| Transpɔt hos dɛn . |

ayɔniza ɔ ki blo statik ɛliminɛtɔ . |

| Molding mashin . |

Grounding strap dɛn . |

Dɛn mɛzhɔ ya de mek dɛn nɔ gɛt matirial klɔmp ɛn mek shɔ se dɛn sheb di kɔla dɛn wan bay wan.

Liquid color blenders .

Fɔ transparent layt-kɔlɔ moldin, likwid kɔlɔ blɛnda dɛn de gi yunik advantej dɛn:

Impɔtant kɔlɔ dispershɔn .

Ridyus di risk fɔ streak ɔ marbling .

I izi fɔ ajɔst di kɔlɔ we di kɔlɔ gɛt .

Dɛn kin introduks likwid kɔla dɛn jɔs bifo di matirial go insay di mashin we dɛn kin yuz fɔ mol. Dis tɛm de alaw fɔ:

Yunifom miks wit transparent resin .

Minimal exposure to heat degradation .

Prɛsis kɔlɔ kɔntrol insay rial-taym .

We dɛn impruv dɛn advans sɔlvishɔn ya, di wan dɛn we de mek dɛn kin:

Impruv di kɔlɔ kɔnsistɛns .

Ridyus di west frɔm di kɔlɔ dɛn we nɔ fayn .

Ɛnjɔy di ɔl di prɔdak kwaliti .

Kes Stɔdi dɛn .

Rial-wɔl ɛgzampul dɛn de gi valyu tin dɛn fɔ no bɔt aw fɔ sɔlv di kɔlɔ inkɔnsistens kwɛstyɔn dɛn. Lɛ wi chɛk tri kes dɛn ɛn dɛn sɔlv dɛn.

Kes 1: Improper kolorant selekshɔn

Wan smart fon kes manifakta bin fes persistent kala varieshɔn na dɛn prodak. Investigeshɔn sho di rut kɔz: improper colorant selekshɔn.

Prɔblɛm:

Fɔ sɔlv:

kɔndɔkt tɛmal stebiliti tɛst dɛn pan kɔlɔrant dɛn .

Di pigmɛnt dɛn we dɛn dɔn pik we nɔ de ɔt .

Adjusted processing parameters fɔ nyu kɔlɔrant .

Rizɔlt:

95% ridyushɔn pan difɛkt dɛn we gɛt fɔ du wit kɔlɔ we gɛt fɔ du wit kɔlɔ .

Impɔtant tin dɛn we di kɔstɔma dɛn dɔn mek

Di west we dɛn dɔn mek we dɛn de mek di prodakshɔn dɔn go dɔŋ .

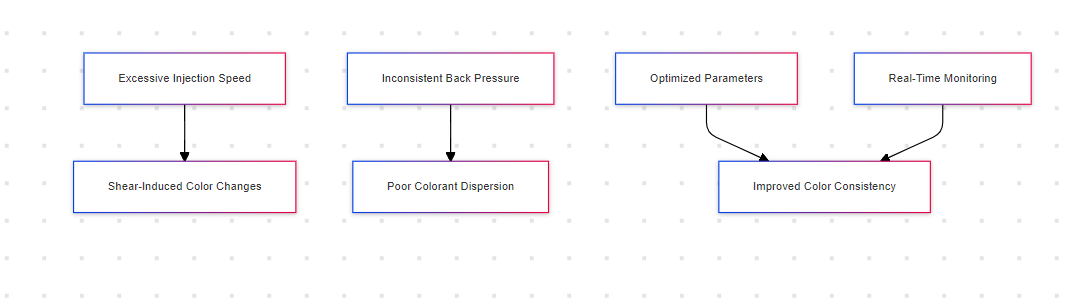

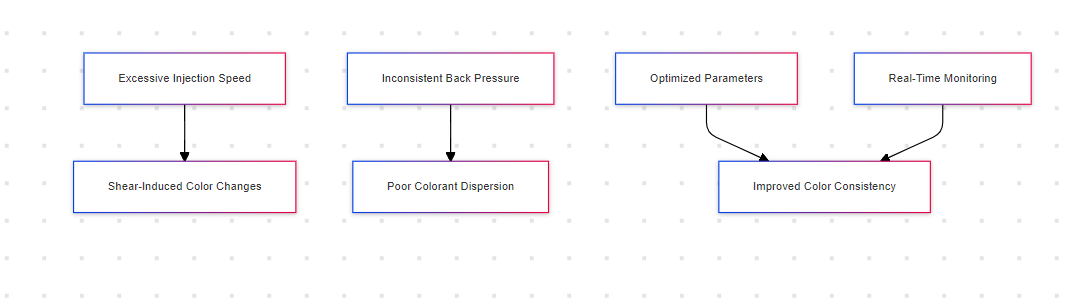

Kes 2: Injɛkshɔn Mɔldin Prɔses Paramita dɛn .

Wan ɔtomotiv pats saplayer bin ɛkspiriɛns kala dɛvyayshɔn insay dashbɔd kɔmpɔnɛnt dɛn. Analysis point to improper injection molding process parameters.

Prɔblɛm:

Fɔ sɔlv:

Optimized injekshɔn spid profayl .

Fayn-tun bak prɛshɔn sɛtin dɛn .

Implimented rial-taym prɔses monitɔrin .

Rizɔlt:

Kɔlɔ kɔnsistɛns impɔtant bay 80%

Skrap ret we dɛn ridyus frɔm 7% to 1.5% .

Prodakshɔn efyushɔn inkri bay 12% .

Kes 3: Mold tempɔret kɔntrol .

Wan kɔsmɛtik pak manifakta bin notis lokal kɔlɔ difrɛns dɛn na dɛn prɔdak. Investigeshɔn sho se di mold tɛmpracha kɔntrol nɔ fayn as di pɔsin we du di bad tin.

Prɔblɛm:

Sɔlv:

Mold cooling chanel dɛn we dɛn dɔn ridizayn .

Instɔl ɔda tɛmpracha sɛnsa dɛn .

Implimented adaptiv mold temperechur kontr ɔ l .

| Eria |

bifo |

afta . |

| Konsistensi fɔ kɔlɔ . |

75% |

98% |

| Saykl tɛm . |

28 sɛkɔn dɛn . |

24 sɛkɔn dɛn . |

| Skrap ret . |

5.5% |

1.2% |

Rizɔlt:

Achieved yunifom kala across ɔl di prodak eria dɛn .

Ridyus di saykl tɛm bay 14% .

Impɔtant ɔl di prɔdak kwaliti .

Dɔn

Kɔlɔ kɔnsistɛns insay injɛkshɔn moldin hinj pan difrɛn tin dɛn. Raw matirial, kolorant, mashin ishu, ɛn prɔses paramita ɔl de ple impɔtant rol dɛn. Fɔ mek dɛn mentenɛns, fɔ inspekshɔn ɔltɛm, ɛn fɔ ajɔst dɛn nɔ kin mek prɔblɛm nɔ de bifo dɛn bigin. We dɛn de wok togɛda wit di wan dɛn we de gi dɛn tin dɛn, dat de mek shɔ se dɛn gɛt ay kwaliti matirial dɛn. We dɛn de adrɛs dɛn aspek ya, di wan dɛn we de mek dɛn kin ebul fɔ gɛt kɔnsistɛns, ay kwaliti kɔlɔ prɔdak dɛn.