Sɔgɔsɔgɔ taamasiɲɛw, walima warijɛ sɛgɛsɛgɛli, olu ye fiɲɛ ye min bɛ sɔrɔ pikiri kɛli la tuma bɛɛ, nka a bɛ gɛlɛya. O sɔgɔli ninnu bɛ se ka plastiki yɔrɔw cogoya n’u fanga tiɲɛ. Sɔgɔli taamasiɲɛw ɲɛnabɔli nafa ka bon kosɛbɛ walasa ka fɛnw cogoya ni u muɲuni bɛɛ ɲɛ. Nin sɛbɛn in kɔnɔ, aw bɛna a dɔn fɛn min bɛ kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw kɛ, ka u bali cogo min na, ani ka aw ka pikiri kɛcogo ɲɛ ka ɲɛ walasa ka ninnu ban . fiɲɛw ..

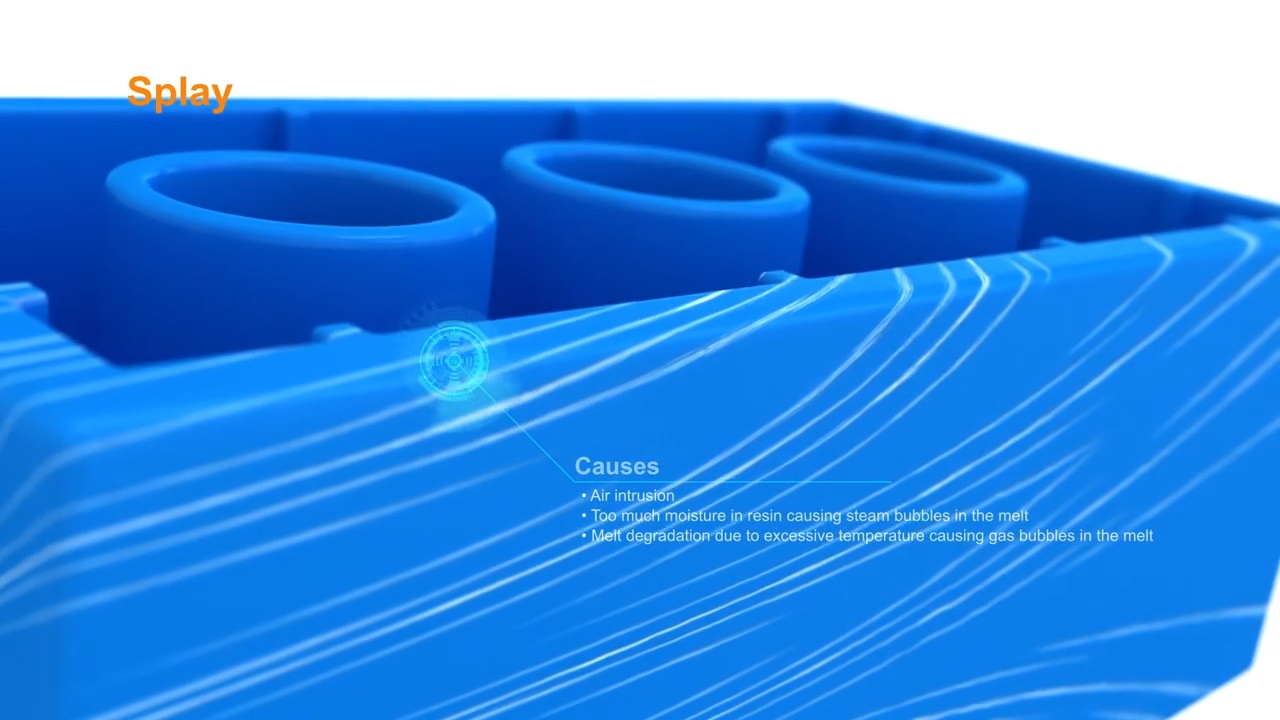

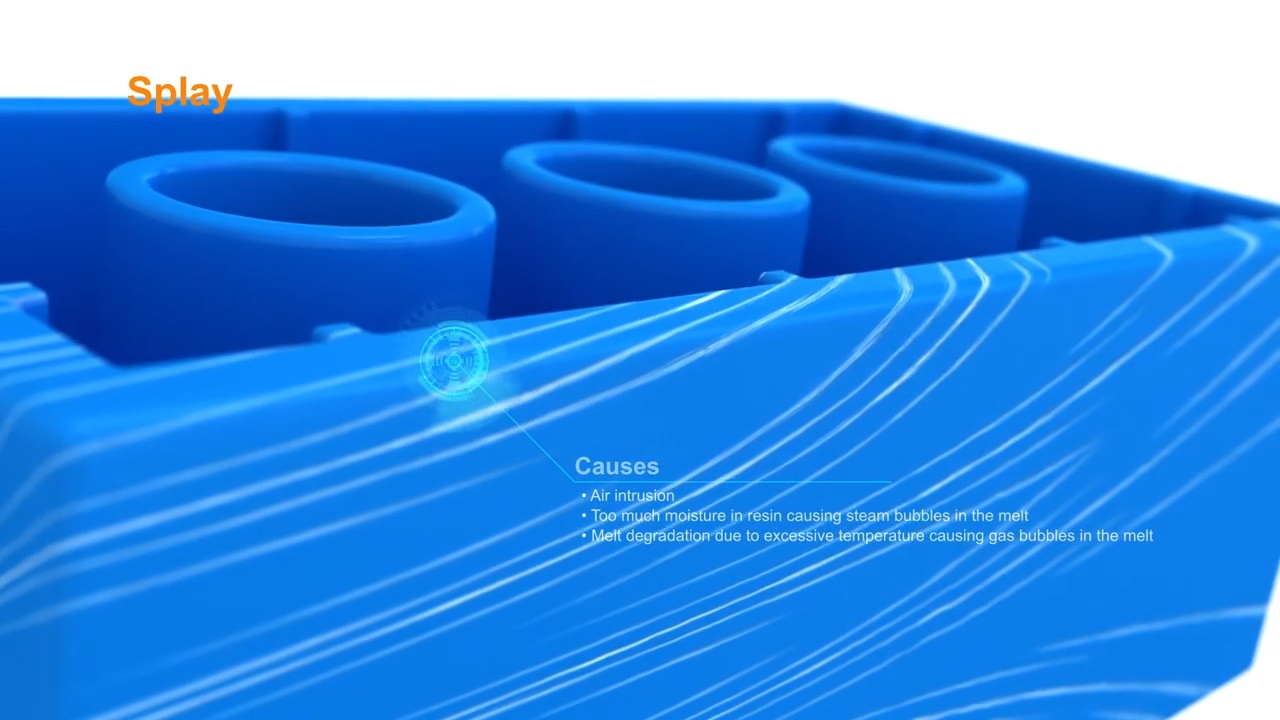

Splay marks ye mun ye?

splay marks, n’a bɛ fɔ fana ko warijɛ streaks, olu ye . ɲɛgɛnɛsiraw tiɲɛni min bɛ sɔrɔ pikirijikɛlanw kɔnɔ . O taamasiɲɛw bɛ ye i n’a fɔ warijɛ, min bɛ i n’a fɔ streak, o bɛ kɛ fɛn dilannen sanfɛ, tuma caman na, a bɛ tugu fɛnw bolicogo ɲɛ.

Ɲɛfɔli dafalen ani ɲɛjirali yecogo .

Sɔgɔli taamasiɲɛw bɛ dɔn u cogoya manamananan na, min ɲɛ ye warijɛ ye, min bɛ bɔ kɛnɛ kan yɔrɔ lamini na. U bɛ se ka u yɛrɛ jira i n’a fɔ layini finmanw, minnu janya ka bon walima minnu ka bon, minnu bɛ jɛnsɛn ka caya.

Tuma dɔw la, splay marks bɛ se ka kɛ i n’a fɔ . Flow lines walima surface dafabaliya wɛrɛw. Nka, u ka warijɛ kulɛri danfaralen n’u ka teli ka tugu fɛnw bolicogo sira la, olu bɛ u faranfasi.

A bɛ nɔ min bila a yɔrɔ cɛɲi ni a kɛcogo la .

Sɔgɔsɔgɔ taamasiɲɛw sɔrɔli bɛ se ka nɔba bila yɔrɔw la minnu dilannen don ni pikirijikɛlanw ye. U bɛ kɔlɔsi kɛrɛnkɛrɛnnenya la yɔrɔw la minnu bɛ yeelen bɔ, minnu bɛ manamana, wa u bɛ se ka dɔ bɔ fɛn dilannen cɛɲi bɛɛ lajɛlen na.

Ka fara u ka ɲɛnayeli kɛcogo kan, sɛgɛsɛgɛli taamasiɲɛw bɛ se ka nɔ bila fana yɔrɔ dilannen ka masina cogoyaw la. Yɔrɔ minnu bɛ ni sɛgɛsɛgɛli ye, olu bɛ se ka fanga dɔgɔya, ka tiɲɛni walima fɛn wɛrɛw jira fɛnw na minnu bɛ kɛ ni u bɛ tali kɛ u lamini na.

Sɔgɔsɔgɔ taamasiɲɛw danfara .

Sɔgɔli taamasiɲɛw bɛ se ka tila suguya caman na, u kelen-kelen bɛɛ ni u cogoya tɛ kelen ye:

Shear splay : bɛ ye i n’a fɔ sɛrɛw, linear streaks, tuma caman na da yɔrɔ kɛrɛfɛ. O streaks (sɛrɛw) bɛ Labɛn ni fɛnw ka woyo ye ani u bɛ Kɛ i n’a fɔ jaged walima uneven.

Sumaya Splay : A bɛ ye i n’a fɔ fɛn ɲumanw, minnu bɛ manamana, minnu bɛ i n’a fɔ filimu warijɛlama jɛnsɛnnen bɛ yɔrɔ bɛɛ la. A ka c’a la, o taamasiɲɛw bɛ jɛnsɛn ka caya ani u tɛ u ɲɛsin yɔrɔ kelen ma.

Nɔgɔ splay : A bɛ dɔn u ka sankaba, u ka sumaya fɛ, tuma caman na u bɛ kɛ streaks ye min tɛ kɛ tuma bɛɛ, min tɛ kɛ. A ka c’a la, o taamasiɲɛw bɛ kɛ ni ɲɛ ye min ka nɔgɔn ni a bɛ tali kɛ suguya wɛrɛw la.

Decompression splay ani air splay : A ka c’a la, u bɛ jira iko warijɛ layiniw walima bulonw, ka misali kɛ cogoya la min bɛ kɛ yɔrɔ in kan. U bɛ se ka kɛ fana i n’a fɔ yɔrɔ misɛnninw, minnu bɛ manamana, minnu jɛnsɛnnen don yɔrɔ lamini na.

Nɔgɔya splay : A bɛ jira i n’a fɔ dibi walima kulɛri caman, tuma dɔw la, a bɛ taa ni a ye sanfɛ gɛlɛya la. O fɛnw bɛ to ka yɔrɔ in kulɛri ni a laban cogoya tiɲɛ.

Banakisɛ minnu bɛ sɔrɔ pikiri kɛli la, olu sababuw ye .

Sɔgɔli taamasiɲɛw bɛ se ka bɔ fɛn suguya caman na minnu bɛ tali kɛ fɛnw na, u kɛcogo la, u dilanni na, ani u masin na. An ka sababuw sɛgɛsɛgɛ minnu bɛ sɔrɔ tuma caman na.

ji min bɛ kɛ plastiki kɔnɔ .

Nɔgɔ ye fɛn caman ye minnu bɛ kɛ sababu ye ka mɔgɔw sɛgɛn. Plastiki minnu bɛ ji la, i n’a fɔ nilon ani polikarbonati, olu ka teli ka ji minɛ ka bɔ sigida la.

O minɛcogo bɛ se ka kɛ a marali, a tacogo ani a minɛcogo la. Ni a ma ja ka ɲɛ sani a ka mɔ, nɔgɔ min bɛ plastiki kɔnɔ, o bɛna kɛ lafiɲɛbɔ ye funteni waati la, o bɛ na ni sɛgɛn taamasiɲɛw ye.

Plastiki fɛn in sumaya kojugu .

Funteni kojugu fana bɛ se ka kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw kɛ. O bɛ se ka bɔ:

Ni plastiki bɛ sumaya kojugu, a bɛ se ka gaziw tiɲɛ ani ka gaziw bɔ, minnu bɛ jira iko splay taamasiyɛnw yɔrɔ mɔlen kan. nin ye caman dɔ ye . Pikiriw dilanni tiɲɛni minnu bɛ se ka kɛ ka a sababu kɛ funteni hakɛ kunbɛncogo jugu ye.

shear-induite splay marks .

Degunba min bɛ sɔrɔ sɛgɛsɛgɛli la pikiri kɛtuma na, o bɛ se ka kɛ sababu ye ka mɔgɔw lamaga. O bɛ se ka sɔrɔ:

O sɔgɔli wale bɛ se ka plastiki fɛn tiɲɛ, o bɛ na ni warijɛ sɔgɔli ye. nin bɛ tali kɛ cogo min na . Flow layiniw bɛ se ka sɔrɔ ka da fɛnw bolicogo jugu kan.

Fiɲɛ bilali .

Fiɲɛ minɛlen min bɛ nɔgɔbɔlan kɔnɔ, o bɛ se ka kɛ sababu ye ka fɛnw sɔgɔsɔgɔ. Fiɲɛ bilali nɔgɔ la walima pikiri teliya cogo bɛnbali la, o bɛ se ka fiɲɛ bɔli bali, o bɛ na ni fiɲɛ minɛni ye ani o kɔfɛ sɛgɛn taamasiɲɛw. Nin ko in fana bɛ se ka kɛ sababu ye ka fiɲɛ wɛrɛw sɔrɔ i n’a fɔ . Shorts shots ..

Gate ni Runner Design koɲɛw .

Gating system dilanni bɛ se ka nɔ bila splay taamasiyɛnw sɔrɔli la. Ni da hakɛ ka dɔgɔ kojugu walima ni a balila, a bɛ se ka dan sigi fɛnw bɔli la ani ka kɛ sababu ye ka sɛgɛnlafiɲɛbɔlanw kɛ.

O cogo kelen na, da yɔrɔ walima a cogoya jugu bɛ se ka jibɔcogo tiɲɛ ani ka dɛmɛ don ka splay formation. Faamuyali . Da suguya minnu bɛ kɛ ka pikiri kɛ, olu nafa ka bon kosɛbɛ nin ko ninnu kunbɛnni na.

Nɔgɔya .

Plastiki fɛn nɔgɔli fana bɛ se ka kɛ sababu ye ka fɛnw sɔgɔsɔgɔ. O bɛ se ka kɛ ka da a kan:

O nɔgɔw bɛ se ka plastiki tiɲɛ walima ka a kulɛri wuli, ka bɔ i n’a fɔ warijɛ streaks yɔrɔ min dilannen don ni yɔrɔ dilannen ye. Nɔgɔya bɛ se ka kɛ sababu ye fana ka ko wɛrɛw kɛ i n' a fɔ . Flash walima . welda zana ..

Fɛn minnu bɛ sɔrɔ masinw fɛ .

E Pikiri mɔli masin yɛrɛ bɛ se ka kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw sɔrɔ. Masina in sumaya kojugu walima a saniyabaliya bɛ se ka kɛ sababu ye ka plastiki fɛn tiɲɛ.

Masina in ladonni jugu ni a saniyacogo jugu fana bɛ se ka nɔgɔw don a la minnu bɛ kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw kɛ. masinko koɲɛw fana bɛ se ka kɛ sababu ye ka fiɲɛ wɛrɛw sɔrɔ i n’a fɔ . Sink Marks walima . Warping ..

| Cause categorie | fɛn kɛrɛnkɛrɛnnenw . |

| Bugun | Plastikiw minnu bɛ ji la, u bɛ se ka minɛ u marali/minɛ waati la, u bɛ kɛ lafiɲɛbɔ ye u sumaya waati la . |

| Sumaya kojugu . | Barili funteni caman, sigiyɔrɔ waati jan, kɔ tansiyɔnba, funteni tiɲɛni . |

| Shear . | Pikiri teliya/tansiyɔn, juru teliyaba, da hakɛ bɛnbali . |

| Fiɲɛ bilali . | Mold venting man ɲi, pikiri teliya/tansiyɔn bɛnbali . |

| Gate ani Runner Design . | Da misɛn/obstructed, gate yɔrɔ/cogo jugu . |

| Nɔgɔya . | Regrind matériel nɔgɔ, dunanw ka fɛnɲɛnamafagalanw . |

| masin-ko-ɲɛnabɔli . | Sumaya kojugu, saniyabaliya, ladonni/saniya jugu . |

Sɔgɔli taamasiɲɛw balili pikiri kɛli la .

Sɔgɔli taamasiɲɛw balili bɛ taabolo bɛɛjɛfanga de wajibiya min bɛ fɛnw sugandili, masinw labɛncogo, mɔbili dilanni, ani nɔgɔya kɔlɔsili lamini. An ka don fɛɛrɛ jɔnjɔnw na.

Material Selection ani a labɛnni .

Plastiki ɲuman sugandili nafa ka bon kosɛbɛ. Plastiki minnu tɛ tansiyɔn ye, i n’a fɔ poliporopilini walima poliyetilɛni, olu man teli ka ji minɛ ani ka u lamaga.

Ni jilafɛnw ye minnu ka kan, ni u jalen don ani u marali ka ɲɛ. Dehumidifying jalenw bɛ se ka dɛmɛ don ka ji hakɛ kunbɛn ka tɛmɛ 0,03% kan, ka splay marks farati dɔgɔya.

Masina sigicogo ɲɛnabɔli .

Masina sigicogo ɲuman nafa ka bon kosɛbɛ walasa ka splay taamasiyɛnw bali. O ye:

ka barili funteni ladilan walasa a kana sumaya kojugu .

Kɔnɔna tansiyɔn kunbɛnni walasa ka funteni tiɲɛni dɔgɔya .

Optimizing screw speed ka dɔgɔya shear stress .

Pikiri teliya ni degun min bɛ kɛ ka ɲɛ walasa ka a bali ka wuli .

O paramɛtɛrɛw ka balansi ɲuman sɔrɔli ye yɔrɔw dilanni kunba ye minnu tɛ splay-free ye. Faamuyali . Jatebla minnu bɛ kɛ ka pikiri kɛ, olu bɛ se ka dɛmɛ don ka sigida ɲumanw sɔrɔ.

Mold design jateminɛw .

Mold design jɔyɔrɔ ka bon kosɛbɛ splay taamasiɲɛw balili la. Fiɲɛbɔyɔrɔ ɲuman ni gazi boli siraw nafa ka bon walasa fiɲɛ kana don a la.

Mold flow analysis bɛ se ka dɛmɛ don ka fiɲɛbɔlan dilancogo ɲɛ. Da hakɛ ni a sigiyɔrɔ fana bɛ nɔ bila splay formation na. Bololabaarakɛlaw ka tigɛyɔrɔw caya ani ka dacogo ɲɛ ka ɲɛ, o bɛ se ka kɛ sababu ye ka fɛnw bolicogo nɔgɔya.

Nɛnɛ ni mɔli funteni hakɛ jateminɛcogo kelen nafa ka bon walasa ka yɔrɔ funtenimaw bali minnu bɛ se ka kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw sɔrɔ. Funteni hakɛ kunbɛnni ɲuman fana bɛ dɛmɛ don . Pikirili Mulding Tolerances ..

Nɔgɔya dɔgɔyali .

Nɔgɔya kunbɛnni nafa ka bon kosɛbɛ walasa ka sɔgɔsɔgɔninjɛ taamasiɲɛw bali. O bɛ tali kɛ:

Aw bɛ to ka pikirijikɛlan ladon ani ka a saniya .

Regrind fɛnw tali kɔlɔsili la walasa ka u tanga tiɲɛni ma .

Filtration systems waleyali walasa ka jamana wɛrɛw ka fɛnɲɛnamafagalanw bɔ bɔgɔ la .

Ni aw ye masin ni fɛnw saniya ani ka u tanga nɔgɔw ma, o bɛ dɔ bɔ sɛgɛn taamasiɲɛw farati la.

| Banakunbɛn | fɛɛrɛ jɔnjɔnw . |

| Material Selection . | Aw bɛ plastiki minnu tɛ tansiyɔn ye, olu sugandi ni aw bɛ se ka . |

| Material labɛnni . | Aw bɛ a ja ani a maracogo ɲuman, aw bɛ dehumidifying jalenw kɛ . |

| Masina optimisation . | Aw bɛ barili funteni hakɛ ladilan, ka kɔ tansiyɔn kunbɛn, ka juru teliyacogo ɲuman sɔrɔ, ka pikiri kɛcogo ɲuman kɛ . |

| Mold design . | Aw bɛ a lajɛ ni fiɲɛbɔlan ni gazi boli siraw bɛnnen don, ka da hakɛ ni a sigiyɔrɔ ɲuman sɔrɔ, ka nɛnɛ kɛcogo kelen mara . |

| Nɔgɔya kunbɛnni . | Masina ladonni ni a saniya tuma bɛɛ, a bɛ baara kɛ ni regrind ye, ka filɛriw kɛ . |

Gɛlɛyaw ɲɛnabɔli sɔgɔsɔgɔninjɛ taamasiɲɛw: furaw ni furaw .

Ni splay taamasiɲɛw bɛ sɔrɔ pikirijikɛlanw kan, a nafa ka bon kosɛbɛ ka a jujɔ sababu dɔn ani ka latilenni kɛcogo bɛnnenw kɛ. An ka fɛɛrɛw sɛgɛsɛgɛ minnu bɛ kɛ ka sɛgɛnlafiɲɛbɔ taamasiɲɛw ɲɛnabɔ.

| ɲɛnabɔli senfɛwalew kunbabaw . | Gɛlɛyaw |

| Root sababu dɔnni . | Sɛgɛsɛgɛli kɛ splay taamasiyɛn yecogo n’a jɛnsɛnni kan, a kɛcogo ɲuman sɛgɛsɛgɛli, a ka masinw sigicogo, a sɛgɛsɛgɛli mɔli . |

| Taabolo paramɛtiri ladilanni . | Barili funteni finmanw, pikiri teliya ni tansiyɔn ɲuman, ka juru teliya ni kɔ tansiyɔn ladilan . |

| Modifications de mold . | Venting ni gazi boli siraw ɲɛ, ka da hakɛ ni a sigiyɔrɔ sɛmɛntiya, ka nɛnɛ kɛcogo ɲuman ni kelenya sabati . |

| Material jalen ni kondisiyɔn . | Aw bɛ jacogo ɲumanw waleya, ka baara kɛ ni dehumidifiers walima jalenw ye, ka a mara ani ka a mara sigida la . |

| Saniya ni saniya . | Aw bɛ to ka pikiri kɛ ni pikirijikɛlan ye, ka mɔli kɛ ka ɲɛ ani ka masinw yɔrɔw saniya ka ɲɛ . |

ka a sababu jugu dɔn .

Fɛn fɔlɔ min bɛ Kɛ o ye ka splay taamaʃyɛnw yecogo n’u jɛnsɛnni Sɛgɛsɛgɛ. u cogoya n’u sigiyɔrɔ kɔlɔsi yɔrɔ la.

O bɛ se ka taamasiyɛnw di a sababu jugu kan. Ni aw bɛ fɛnw ji hakɛ sɛgɛsɛgɛli kɛ ni infrarouge analyzers ye, o bɛ se ka dɛmɛ don ka a dɔn ni ji ye a jalakibaga ye.

Kɔlɔsili masinw sigicogo n’u kɛcogo paramɛtiriw fana nafa ka bon. Aw bɛ a lajɛ ni pikiri kɛcogo paramɛtiriw bɛnnen don fɛnw ni a yɔrɔ dilanni ma.

Ni aw ye nɔgɔw sɛgɛsɛgɛli kɛ ni degunw ye, ni jibolisiraw datugulen don, walima ni ko wɛrɛw ye, o bɛ se ka kɛ sababu ye ka fɛn dɔw jira minnu bɛ se ka kɛ sababu ye ka fɛnw sɛgɛsɛgɛ.

Baarakɛcogo paramɛtɛrɛw ladilanni .

Ni a jujɔ sababu dɔnna, baarakɛcogo paramɛtɛrɛw ladilanni bɛ se ka sɛgɛn taamasiɲɛw ɲɛnabɔ tuma caman na. O bɛ se ka kɛ:

Barili min bɛ kɛ ka ɲɛ ka ɲɛ walasa a kana sumaya kojugu .

Pikiri teliya ni degun ɲuman walasa ka sɛgɛn degun dɔgɔya .

Aw bɛ juru teliya ni kɔ tansiyɔn ladilan walasa ka fɛnw tiɲɛni dɔgɔya .

Yɛlɛma minnu bɛ kɛ ka caya ani ka jaabiw kɔlɔsi, o bɛ se ka dɛmɛ don ka yɔrɔ ɲumanw sɔrɔ yɔrɔw la minnu tɛ sɛgɛn.

Modifications de mold .

Ni mɔli dilanni bɛ ka dɛmɛ don splay marks la, fɛn dɔw bɛ se ka Changer. O bɛ se ka kɛ:

Fiɲɛbɔ ni gazi boli siraw ɲɛnabɔli walasa fiɲɛ kana don .

gate hakɛ ni a sigiyɔrɔ ladilanni walasa ka fɛnw bolicogo nɔgɔya .

ka nɛnɛ kɛcogo ɲuman sabati ani ka kɛ kelen ye walasa yɔrɔ funtenimaw kana kɛ .

Ni aw bɛ baara kɛ ɲɔgɔn fɛ ni mɔbili dilannikɛlaw ni baarakɛminɛnw dilannikɛlaw ye, o bɛ se ka dɛmɛ don ka o fɛn caman sɛmɛntiyalenw waleya ka ɲɛ.

Material jalen ni kondisiyɔn .

Fɛn minnu bɛ kɛ ka ji sɔrɔ, u jalen don ani u kocogo ɲuman, olu nafa ka bon kosɛbɛ. Aw bɛ jacogo barikama dɔ kɛ ni dehumidifiers walima jalenw ye minnu dabɔra kɛrɛnkɛrɛnnenya la plastikiw kama.

Aw bɛ fɛn dilannikɛla ka laadilikanw labato walasa ka a ja funteni, a waati ani a ji hakɛ maksimali. Ni aw bɛ sigida kɔlɔsilen mara a marali ni a tali waati la, o fana bɛ se ka ji minɛcogo bali.

Saniya ni saniya .

Pikiri dilanni masin saniya tuma bɛɛ bɛ se ka dɛmɛ don ka fɛn nɔgɔlenw ni nɔgɔw bɔ minnu bɛ kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw sɔrɔ. Aw bɛ baara kɛ ni saniya furaw ye minnu bɛnnen don ani ka tugu masin dilannikɛla ka laadilikanw na.

Nɔgɔ ni masin yɔrɔw saniyacogo ɲuman, i n’a fɔ fiɲɛbɔlanw, bariliw, ani juruw, o bɛ se ka tolenw caman sɔrɔli bali minnu bɛ se ka kɛ sababu ye ka sɔgɔsɔgɔninjɛ taamasiɲɛw kɛ.

Ko minnu kɛra: Splay taamasiyɛnw ɲɛnabɔli pikiri kɛli la .

Misali 1 : ka splay marks (sɔgɔli taamasiyɛnw) bɔ mobili kɔnɔna yɔrɔ dɔ la .

O cogo la, mobili dilanko tɔnba dɔ ye warijɛ streaks kunbɛn dashboard yɔrɔ dɔ kan. Splay taamasiyɛnw bɔra dakunw kɛrɛfɛ ani yɔrɔ kurulenw kan. Ekipu ye splay taamasiyɛnw cogoya n’u tilatilali sɛgɛsɛgɛ, k’u ka cogoya kɛrɛnkɛrɛnnenw kɔlɔsi sanfɛ.

Pikiriw dilanni paramɛtiriw lajɛ : Ekipu ye pikiri teliya ni funteni ladilan walasa ka fɛnw bolicogo nɔgɔya.

Sɛgɛsɛgɛli kɛ nɔgɔw kan ni fiɲɛ tɛ u la : U ye dafabaliya misɛnniw sɔrɔ fiɲɛbɔlan na minnu tun bɛ fiɲɛ minɛ.

Plastiki ji hakɛ sɛgɛsɛgɛli : Plastiki fɛn sɛgɛsɛgɛra ji la ani a sɔrɔla ko a bɛ se ka kɛ a hakɛ la min bɛ fɔ, o bɛ a to a ka jacogo ɲuman sɔrɔ.

Ni an ye yɔrɔ sanfɛla jogo suma ɲɔgɔn na ka kɔn ladilanni ɲɛ ani a kɔfɛ : a kɛcogo ɲuman kɔfɛ, streaks tununna, ani surface quality ɲɛnabɔra kosɛbɛ.

Misali 2: Sɔgɔli taamasiɲɛw ɲɛnabɔli furakɛli minɛnw yɔrɔ dɔ la .

Dɔgɔtɔrɔso minɛn dilannikɛla dɔ ye sɛgɛn taamasiɲɛw kɔlɔsi plastiki yɔrɔba dɔ kan min bɛ kɛ opereli minɛnw na. O warijɛ-taama ninnu ye nɔ bila a yɔrɔ cɛɲi n’a baarakɛcogo la, o min bɛ teliya ka wale kɛ.

Sɔgɔsɔgɔninjɛ taamasiɲɛw sɛgɛsɛgɛli : taamasiyɛnw tun bɛ sɔrɔ minɛn in dakun surunw kan kosɛbɛ.

Masina sigicogo ladilanni : Ekipu ye barili funteni dɔgɔya ani kɔ tansiyɔn ladilanen.

Mɔbili fiɲɛbɔlan ɲɛnabɔli : fiɲɛbɔlan wɛrɛ farala a kan walasa fiɲɛ minɛta ka se ka boli pikiri kɛtuma na.

O bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε b.

Misali 3nan : ka se sɔrɔ splay taamasiyɛnw kan minnu bɛ sɔrɔ mɔgɔw ka ɛntɛrinɛti so kɔnɔ .

Baarakɛda min bɛ plastiki so dilan telefɔni seleke naani na, o ye splay marks sɔrɔ a dakunw na ani screw boss kɛrɛfɛ. Streaks tun bɛ ye kosɛbɛ nɛnɛ kɔfɛ, o kɛra sababu ye ka ko dɔw kɛ ni ɲɔgɔnkanu ye.

Fɛn jalenw ɲɛnabɔli ɲuman : Ekipu ye ja waati caya walasa ka ji hakɛ dɔgɔya.

Dakunw dilanni kokura : Dabaw bonyalen don walasa ka fɛnw bolicogo ɲɛ ka don nɔgɔbɔlan kɔnɔ.

Pikiri teliya min bɛ kɛ ka ɲɛ : pikiri teliya dɔɔni kɛra walasa ka sɔgɔsɔgɔninjɛ bali.

O bεε la, mɔgɔw ka εlektroniki so ye jogo sariyaw dafa, ani ka bεnkanw bali.

Kuncɛli

Sɔgɔli taamasiɲɛw ɲɛnabɔli pikiri kɛli la, o nafa ka bon walasa ka fɛn ɲumanw sɔrɔ, minnu bɛ mɛn. Sɔgɔli taamasiɲɛw balili bɛ fɛn jacogo ɲuman de wajibiya, ka mɔli kɛcogo ɲuman sɔrɔ, ani ka masinw sigicogo tigitigiw de wajibiya. Gɛlɛyaw ɲɛnabɔcogo ɲuman bɛ waati ni nafolo mara. Baarakɛɲɔgɔnya min bɛ kɛ dilanbagaw ni fɛnw dilanbagaw cɛ, ani pikirikɛlaw cɛ, o ye fɛnba ye walasa ka o fiɲɛw ɲɛnabɔ ani ka fɛn dilanni bɛɛ lajɛlen nafa bonya.

Ɲininkaliw jaabiw .

J: Splay marks (sɔgɔli taamasiɲɛw) sababu jumɛnw de ka teli ka sɔrɔ pikiri kɛli la?

A: A sababu minnu ka ca, olu ye ji ye plastiki la, funteni kojugu, sɛgɛnba, fiɲɛ minɛni, ani nɔgɔ.

J: Ne bɛ se k’a dɔn cogo di ko ji bɛ ka splay marks (sɔgɔli taamasiɲɛw) bila ne ka yɔrɔw la?

A: Sɔgɔsɔgɔninjɛ taamasiɲɛw cogoya n’u tilatilali. Aw bɛ ji hakɛ sɛgɛsɛgɛli kɛ ni infrarouge sɛgɛsɛgɛlikɛlanw ye.

J: Plastiki minɛnw marali n’u jacogo ɲumanw ye jumɛnw ye?

A: Aw bɛ plastikiw mara sigida la min bɛ kɔrɔsi. Aw bɛ dehumidifying jalenw kɛ ka ji bɔ sani aw ka u mɔ.

J: Ne bɛ se ka n ka pikiri kɛcogo ɲɛ cogo di walasa ka splay marks bali?

A: Aw bɛ barili funteni hakɛ ladilan, ka kɔ tansiyɔn kunbɛn, ka juru teliyacogo ɲuman sɔrɔ, ani ka pikiri kɛcogo ɲuman kɛ. Aw bɛ aw jija ka nɔgɔ bɔn ka ɲɛ.

J: Yala splay taamasiɲɛw bɛ se ka ban pewu pikiri kɛlen yɔrɔw la wa?

A: Hali ni a bɛ se ka kɛ ko a tɛ se ka ban pewu, sɛgɛsɛgɛli bɛ se ka dɔgɔya kosɛbɛ bana kunbɛnni ni gɛlɛyaw ɲɛnabɔli fɛ.

J: Splay marks (splay marks) bɛ nɔ jumɛn bila part performance (yɔrɔ baarakɛcogo) la?

A: Sɔgɔli taamasiɲɛw bɛ se ka nɔ bila yɔrɔw cogoya cɛɲi na. U bɛ se ka fɛn dɔw fana jira fɛnw cogoyaw la ani masinw fanga dɔgɔyali la.

J: Yala splay marks bɛ jate fiɲɛw ye tuma bɛɛ wa? Yala dilanw bɛ yen minnu 'Utilize' splay marks?

A: Sɔgɔli taamasiɲɛw bɛ jate fɛn nafama ye caman na k’a sababu kɛ u bɛ se ka nɔ min bila ɲɛnajɛko la ani a bɛ se ka nɔ minnu bila yɔrɔ dɔw ka baarakɛcogo la. Labɛnw tɛ yen minnu bɛ kɛ ɲɔgɔn fɛ, minnu bɛ splay marks (sɔgɔli taamasiyɛnw) don u kɔnɔ ni laɲini ye.

J: Don o don ladonni ni a dilanni masinw ladonni ni u ladonni yɔrɔ kolomaw ye jumɛnw ye?

A: Nɔgɔw ni masinw yɔrɔw saniyacogo n’u sɛgɛsɛgɛli tuma bɛɛ. tulumafɛnw bɛ kɛ ka ɲɛ ani ka yɔrɔw falen waati bɛnnen na.

J: Cogo di ka balansi don jago ni splay taamasiyɛn nafama ni fɛn dilanni nafama cɛ?

A: Ka taabolo kɔlɔsili ni kɔlɔsili sira barikamaw waleya. Baara kɛ ni Statistical Process Control ye walasa ka koɲɛw dɔn ani ka u ɲɛnabɔ joona. Ka taa a fɛ ka taabolo paramɛtɛrɛw ɲɛnabɔ ka ɲɛ walasa ka jogo ɲuman ni baarakɛcogo ɲuman sɔrɔ.