Yala aw delila k’aw yɛrɛ ɲininka cogo min na plastiki fɛnw dilannen don ni o ɲɔgɔnna tiɲɛni ni ɲɔgɔndɛmɛ ye wa? Jaabi bɛ sɔrɔ pikiri kɛcogo la, yɔrɔ min na, plastiki wulilen bɛ pikiri kɛ bɔgɔmugu kɔnɔ walasa ka cogoya ɲininen dilan. Nka, o wale in ɲɛtaa bɛ da kosɛbɛ daaw dilanni n’u bilali cogo bɛnnen na.

Dabaw ye dakun misɛnninw ye minnu bɛ kɛ ka plastiki wulilen don nɔgɔbɔlan kɔnɔ, wa u dilanni bɛ se ka fɛn laban in ka jogo dilan walima k’a tiɲɛ.Nin sɛbɛn in kɔnɔ, i bɛna da suguya wɛrɛw dɔn minnu bɛ kɛ pikirijikɛlan na ani u kelen-kelen bɛɛ bɛ nɔ bila u dilanni na cogo min na.

Pikiri molding gate ye mun ye?

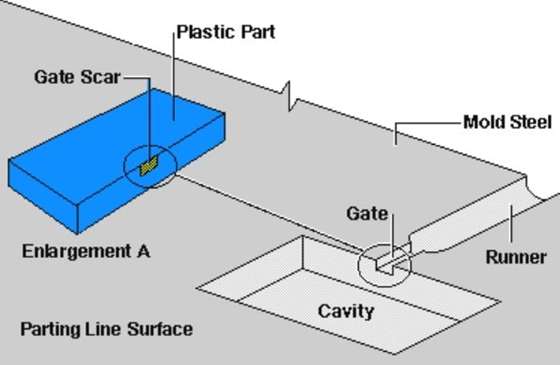

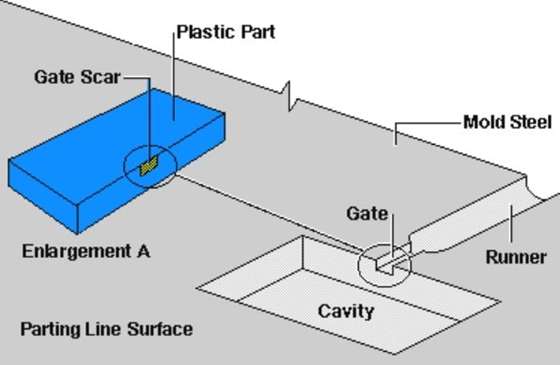

Pikiri molida da ye da fitinin ye min bɛ a to plastiki wulilen ka don nɔgɔbɔlan kɔnɔ. A bɛ Kɛ i n'a fɔ tɛmɛsira, ka bolibaga-sistɛm ni yɔrɔ min bɛ ka Kɛ, o siri ɲɔgɔn na.

Dabaw jɔyɔrɔ ka bon kosɛbɛ pikiri kɛcogo la. U bɛ plastiki wulilen ka jibɔ hakɛ, a degun ani a ɲɛsincogo kɔlɔsi ni a bɛ kɔnɔna fa. Dacogo ɲuman b’a to kɔnɔboli ka fa cogo kelen na ani cogo ɲuman na, o bɛ na ni yɔrɔw ye minnu ka ɲi kosɛbɛ ni fiɲɛ fitininw tɛ.

Dabaw suguya, u bonya ani u sigiyɔrɔ bɛ se ka nɔba bila yɔrɔw la minnu dilannen don ni fɛn dilannenw ye. U bɛ nɔ bila:

Flow Patterns ani Fali kɛcogo .

Fɔɲɔ hakɛ ni dɔgɔyali .

weld line formation .

Surface yecogo ani aesthetics .

Yɔrɔ fanga ni masinw ka jogo .

Dakun dilancogo ɲuman sugandili nafa ka bon walasa ka pikiri kɛcogo ɲɛ. A bɛ ɲini ka jateminɛ kɛ kosɛbɛ fɛnw kan i n’a fɔ yɔrɔ jateminɛcogo, fɛnw cogoyaw, ani fɛn dilanni wajibiyalenw.

Ja nɔgɔman min bɛ pikirijikɛlan da dɔ baara jira.

Mun na da dilanni nafa ka bon pikiri kɛli la?

Gate design ye pikiri kɛcogo ye min nafa ka bon kosɛbɛ. A bɛ nɔ bila fɛn laban ka jogo la k’a ɲɛsin a yɛrɛ ma. Da min dilannen don koɲuman, o b’a to plastiki wulilen bɛ woyo ka ɲɛ ani ka kɛ cogo kelen na ka don nɔgɔbɔlan kɔnɔ. O bɛ na ni yɔrɔw ye minnu hakɛw bɛ bɛn ɲɔgɔn ma, u cogoya ani u kɛcogo masinw na.

Faan wɛrɛ fɛ, dakun dilanni jugu bɛ se ka kɛ sababu ye ka fiɲɛ ni ko suguya caman sɔrɔ:

Short shots : Moule cavité dafabali .

Layini welda : Layini yetaw yɔrɔ minnu na jibɔ ɲɛfɛ bɛ ɲɔgɔn sɔrɔ .

Sinsin taamasiɲɛw : dugukolo kan degun minnu bɛ sɔrɔ nɛnɛbaliya fɛ .

Warpage: Yɔrɔ in tiɲɛni ka da a kan a bɛ dɔgɔya cogo kelen na .

Jeni taamasiɲɛw: Aw bɛ kulɛri caman wuli ka bɔ plastiki sumaya kojugu .

O fiɲɛw tɛ nɔ bila yɔrɔ cɛɲi dɔrɔn na, nka a baarakɛcogo n’a muɲuni fana. U bɛ se ka kɛ sababu ye ka fɛn tiɲɛnenw hakɛ caya, ka baara kɛ kokura, ani ka kiliyanw ka ɲininkaliw kɛ.

O ni da minnu dilannen don koɲuman, olu bɛ nafa caman lase u ma:

Yɔrɔ ɲuman ni a kɛcogo ɲuman .

jiginni waatiw dɔgɔyali ani ka dɔ fara baarakɛcogo kan .

Fɛnw tiɲɛni ni u tiɲɛnenw dɔgɔyali .

Mekaniki fanga ni a baarakɛcogo bonyalen .

A ka nɔgɔn ka bɔ baara la min bɛ kɛ ni fɛnɲɛnamafagalanw ye (misali la, da bɔli) .

Ni u bɛ da dilancogo ɲɛ, a dilannikɛlaw bɛ se k’u ka pikiri kɛcogo ɲɛ. U bɛ se ka yɔrɔ ɲumanw dilan ka ɲɛ ani ka musaka bɔ.

Jateminɛ jɔnjɔnw dakunw dilanni na .

Ni aw bɛ daaw dilan pikiri kɛli kama, fɛn nafama caman bɛ yen aw ka kan ka minnu to aw hakili la. O jateminɛw bɛ se ka i ka yɔrɔ mɔlenw ka ɲɛtaa kɛ walima k’u tiɲɛ. An ka u kelen-kelen bɛɛ lajɛ kosɛbɛ.

Gate Placement .

I bɛ da bila yɔrɔ min na i fan fɛ, o nafa ka bon kosɛbɛ. A bɛ a jira cogo min na plastiki wulilen bɛ woyo ka don nɔgɔbɔlan kɔnɔ. A ka fisa, i b’a fɛ ka da sɔrɔ:

a yɔrɔ in yɔrɔ min ka bon kosɛbɛ .

Yɔrɔ janw ni fɛnw ye minnu bɛ ye .

cogo la min bɛ jibɔ yɔrɔjan ni a kɛlɛli dɔgɔya .

Dadoncogo ɲuman bɛ dɛmɛ ka hali fa, ka welda layiniw dɔgɔya, ani ka da taamasiyɛn yetaw dɔgɔya.

Gate taille .

Da in bonya fana jɔyɔrɔ ka bon. A bɛ nɔ bila pikiri teliya la, degun na, ani jibɔ kɛcogo bɛɛ lajɛlen na. Da min ka dɔgɔ kojugu, o bɛ se ka kɛ sababu ye:

Fali dafalen (shot shots) .

Degunba min bɛ sɔrɔ sɛgɛsɛgɛli la ani fɛnw tiɲɛni .

cycle waatiw ka jan ani ka dɔ bɔ baarakɛcogo la .

Faan wɛrɛ fɛ, da min ka bon kojugu, o bɛ se ka kɛ sababu ye ka baara kɛ ni fɛnw ye ka tɛmɛ ani ka da wuli waati jan kɔnɔ. Dakun hakɛ ɲuman sɔrɔli ye fɛnba ye walasa ka balansi sɔrɔ a yɔrɔ ɲuman ni a dilanni nafa cɛ.

Yɔrɔ cogoya ani fini .

I ka geometri ani i ka surface fini ɲininen bɛ nɔ bila gate sugandili la. Siginiden gɛlɛnw, kogo finmanw, ani ɲɛnajɛko wajibiyalenw bɛ se ka da suguya kɛrɛnkɛrɛnnenw dɔn. I n'a fo:

Edge gates for flat, yɔrɔ janw .

Pin Gates ka ɲɛsin fɛn misɛnninw ma minnu bɛ kɛ silinda ye .

Tip gates hot gates for pièces ni surface quality ɲininiw ka bon .

Ka dacogo bɛn yɔrɔ cogoyaw ma, o bɛ a to a bɛ se ka kɛ ka ɲɛ ani ka fiɲɛw farati dɔgɔya.

Da minnu ka kan ka kɛ .

Ka kɛɲɛ ni i yɔrɔ bonya n’a gɛlɛya ye, i bɛ se ka da caman sɔrɔ. O bɛ kɛ kɛrɛnkɛrɛnnenya la, yɔrɔbaw, yɔrɔ fla walima yɔrɔ minnu ka fɛn gɛlɛnw bɛ yen. Baara kɛ ni da caman ye minnu bɛ se ka:

Aw bɛ mɔli kɔnɔna facogo ni a pakeli ɲɛ ka ɲɛ .

Aw bɛ welda layiniw ni jibɔcogo nafama wɛrɛw dɔgɔya .

Aw bɛ cycle waatiw surunya ni aw bɛ a to nɛnɛ ka teliya .

Nka, ka da caman fara a kan, o fana bɛ dɔ fara baarakɛminɛnw musakaw kan ani u ka gɛlɛya kan. A nafa ka bon ka balansi ɲuman sɔrɔ ka da i ka baarakɛcogo kɛrɛnkɛrɛnnen n’i ka ɲininiw kan.

| Jateminɛ |

nɔfɛta . |

| Gate Placement . |

Flow behavior, weld lines, gate marks . |

| Gate taille . |

Fali, sɛgɛn degun, cycle waati . |

| Yɔrɔ cogoya ani fini . |

Mololabilité, defauts, surface qualité . |

| Dabaw hakɛ . |

Fa, pake, cycle waati, baarakɛminɛnw musaka . |

Dakun dilanni jateminɛ kunbabaw kuncɛlen ani u nɔfɛkow pikiri kɛli la.

Pikiriw dilanni dakun suguyaw .

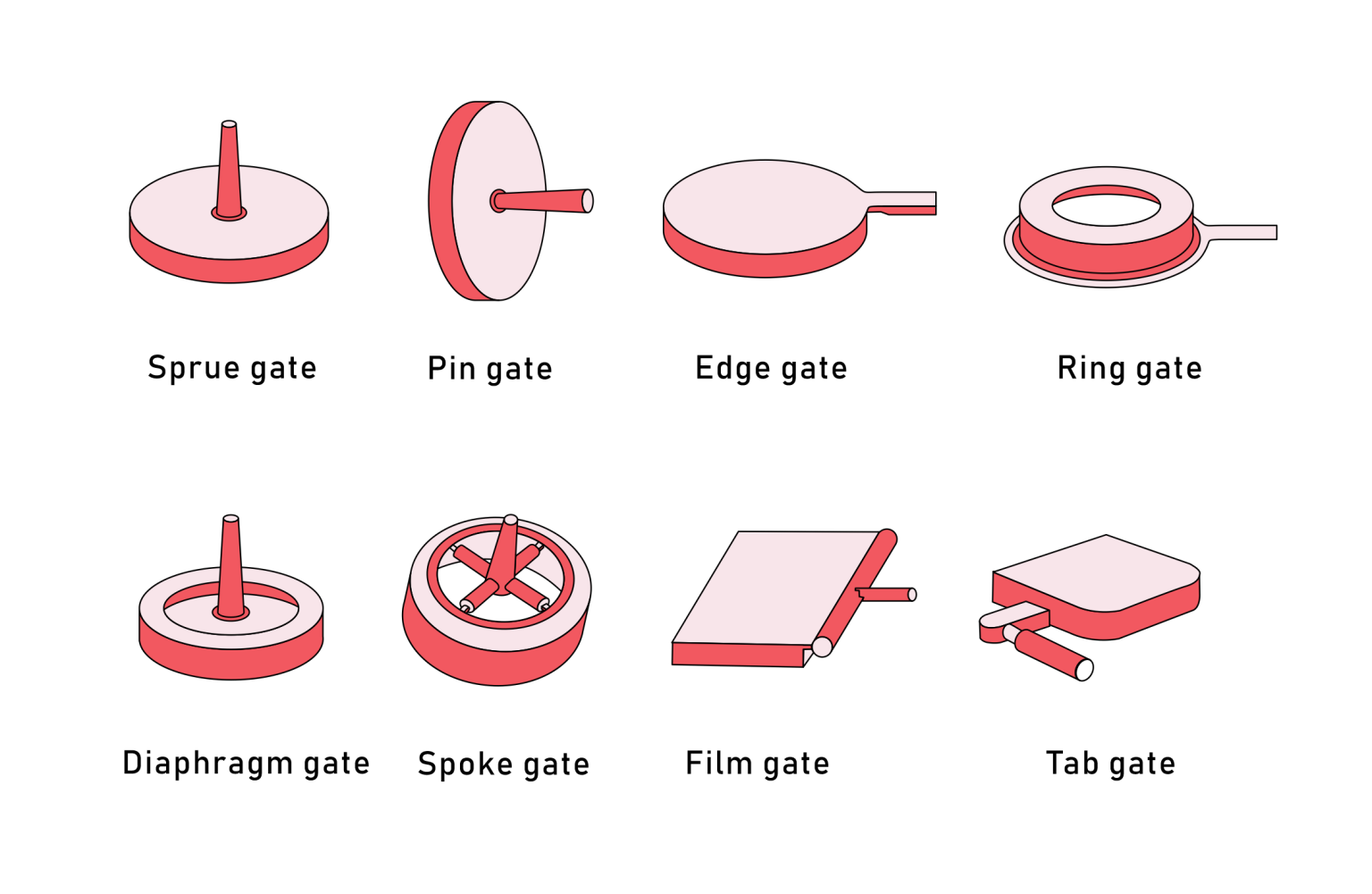

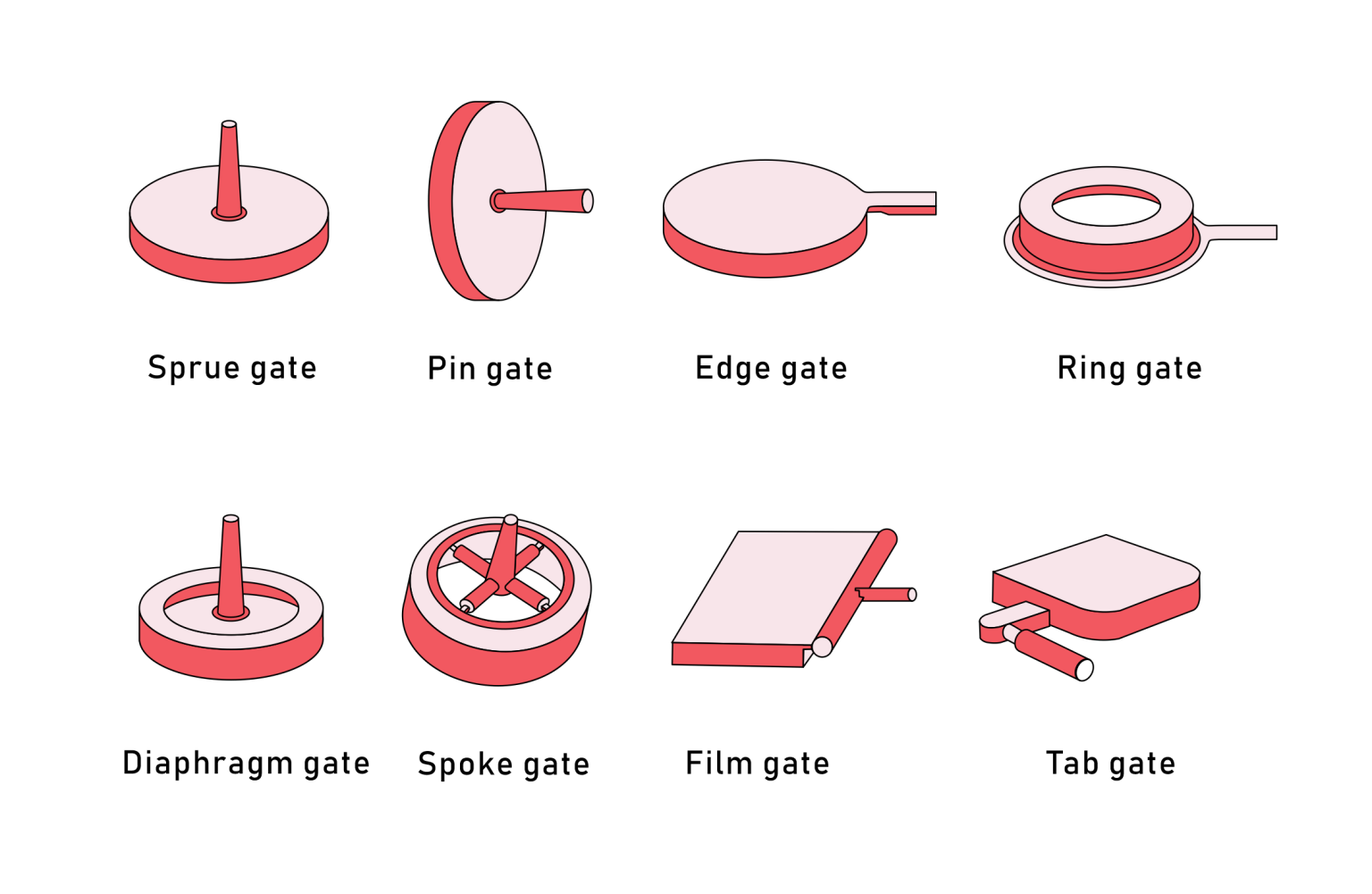

Pikiriw dilanni daaw bɛ sɔrɔ cogoya ni hakɛ suguya caman na, u kelen-kelen bɛɛ n’u ka jogo n’u ka baarakɛcogo kɛrɛnkɛrɛnnenw. An ka da suguya dɔw sɛgɛsɛgɛ minnu bɛ kɛ ka caya o baara in na.

1. Dakunw ɲɛsinnen walima u falen .

Dakun tilennenw walima dakunw ye pikirijikɛlan dacogo nɔgɔman ye ani a jɔnjɔn ye. U bɛ kɛ ni kanal tilennen ye, min bɛ kɛ ni sɛgɛn ye, min bɛ nozzle siri ɲɔgɔn na ka ɲɛsin mold cavity ma.

Kɛcogow:

A dilanni nɔgɔman ani a dilanni ka nɔgɔn .

Daba bonya bɛ sira di jibɔ hakɛ caman ma .

A bɛnnen don yɔrɔw ma minnu ka bon ani minnu ka bon kosɛbɛ .

Nafaw:

Baarakɛminɛnw musaka dɔgɔyali ani ɲɛtaa waati kunkurunninw .

A bɛ se ka yɔrɔbaw fa minnu ka nɔgɔn joona .

Degun min ka dɔgɔn ni sɛgɛn ye ani fɛnw tiɲɛni .

Nafa minnu b’a la:

A bɛ da taamasiyɛnba dɔ to a yɔrɔ la min bɛ ye .

A bɛ se ka kɛ ko bolo bɔli ni a laban bɛ kɛ ni bolo ye .

A man ɲi yɔrɔw ma minnu kogow ka fin walima u ka fɛn gɛlɛnw .

Aplikasi:

Fɛn minnu ka bon, minnu kogo ka bon .

Yɔrɔ minnu tɛ kɔrɔfɔ kɛ yɔrɔ minnu na ɲɛnajɛko tɛ ɲɛtaa ye .

prototyping ani low-volume production runs .

2. Edge Gates .

Edge daaw bɛ sɔrɔ yɔrɔ da la, a ka c’a la, farankan sira kan. U bɛ fura nɔgɔman ni nafama di pikiri kɛcogo caman na.

Kɛcogow:

Rectangulaire cross-section min bɛ taper ka bɔ bolibaga la ka taa a yɔrɔ la .

A bɛ se ka tigɛ nɔgɔya la walima ka bɔ a kɔfɛ.

A bɛnnen don yɔrɔw ma minnu bɛ kɛ fla ye, minnu kogow ka fin .

Nafaw:

A ka kan ka fa ani ka a pake ka kɛ mold cavity ye .

Minimal flow resistance ani shear stress .

welda layiniw ni jibɔli nafama wɛrɛw farati dɔgɔyali .

Nafa minnu b’a la:

A bɛ da taamasiyɛn yelen to a yɔrɔ da la .

A bɛ se ka kɛ ko bolo bɔli ni a laban bɛ kɛ ni bolo ye .

dan bɛ yɔrɔw la minnu bɛ ni jateminɛ nɔgɔmanw ye ani kogo janya kelen .

Aplikasi:

Fɛn minnu bɛ kɛ fla ye, minnu kogow ka fin (misali la, tasaw, datugulanw, panɛriw)

Yɔrɔ minnu bɛ ni yecogo wajibiyalenw ye minnu tɛ kɔrɔfɔ ye .

sɛnɛfɛnw bɔli hakɛ caman bɛ boli .

3. Submarine gates .

A bɛ fɔ fana ko tunnel daaw walima sub gates, submarine gates bɛ sɔrɔ farali sira jukɔrɔ. U bɛ dakun dogolen ɲɛnabɔcogo dɔ Di yɔrɔw la minnu ka ɲi kosɛbɛ.

Kɛcogow:

kanal angle walima kurulen min bɛ don yɔrɔ la min bɛ sanfɛ .

Gate bɛ tigɛ a yɛrɛma bɔli senfɛ .

A bɛnnen don yɔrɔ misɛnniw ma, minnu bɛ kɛ silinda la walima minnu bɛ ni jukɔrɔla ye .

Nafaw:

A bɛ da taamasiyɛn yebali to a yɔrɔ la .

Otomatiki da bɔli bɛ dɔgɔya ka bɔ fɛnw na minnu bɛ kɛ ka fɛnw bɔ .

Yɔrɔw cogoya ni u jogo ɲɛnabɔlen .

Nafa minnu b’a la:

Baarakɛminɛnw ka gɛlɛn ani u sɔngɔ ka gɛlɛn ni da suguya tɔw ye .

Dadon hakɛ danma ani jibɔ hakɛ .

A bɛ se ka kɛ sababu ye ka fa walima ka a pake cogo dɔw la .

Aplikasi:

A yɔrɔ fitininw, silindaw (misali la, pinɛw, busi, fiɲɛw) .

Yɔrɔ minnu ka ɲɛnajɛko ka bon .

furakɛli walima kunmabɔfɛnw yɔrɔ minnu na da taamasiyɛnw tɛ sɔn .

4. Kafeda daaw .

Kafedaw, minnu tɔgɔ dara u ni kafeminkutu bɔlen kan, olu ye ji jukɔrɔla da caman caman ɲɔgɔnna ye. U bɛ Kɛ yɔrɔw ye minnu ka flow walima gating wajibiyalenw kɛrɛnkɛrɛnnenw bɛ u la.

Kɛcogow:

kanal kurulen walima s-s-cogo min bɛ don a yɔrɔ la angle dɔ la .

Gate bɛ tigɛ a yɛrɛma bɔli senfɛ .

A bɛnnen don yɔrɔw ma minnu bɛ ni jibɔ siraw ye minnu tɛ sinsinni ye .

Nafaw:

A bɛ sira di gating ma yɔrɔw la minnu bɛ se ka sɔrɔ walima yɔrɔ dɔ la .

Otomatiki da bɔli bɛ dɔgɔya ka bɔ fɛnw na minnu bɛ kɛ ka fɛnw bɔ .

Yɔrɔw cogoya ni u jogo ɲɛnabɔlen .

Nafa minnu b’a la:

Baarakɛminɛn gɛlɛnw ni sɔngɔ gɛlɛnw bɛ tali kɛ da suguya wɛrɛw la .

Dadon hakɛ danma ani jibɔ hakɛ .

A bɛ se ka kɛ sababu ye ka fa walima ka a pake cogo dɔw la .

Aplikasi:

Yɔrɔ minnu bɛ ni jateminɛ gɛlɛnw ye walima jibɔ siraw minnu tɛ sinsinni ye .

Yɔrɔ minnu bɛ ni gating wajibiyalen kɛrɛnkɛrɛnnenw ye walima minnu bɛ dan .

Yɔrɔ minnu ka bon kosɛbɛ, dakun taamasiyɛnw ka kan ka dogo yɔrɔ minnu na .

5. Diaphragme daaw .

Diaphragme gates, n’a bɛ fɔ fana ko da laminiw, olu bɛ kɛ yɔrɔw ye minnu cogoya ye silinda ye walima ni u cogoya ye. U bɛ fɛnw ka jibɔcogo kelen di, min bɛ kɛ ni radiyali ye ka don nɔgɔbɔlan kɔnɔ.

Kɛcogow:

da lamini min bɛ yɔrɔ lamini walima min bɛ sɔrɔ cɛmancɛ la .

A bɛ fɛnw ka jibɔ balannen, radiyali di .

A bɛnnen don yɔrɔw ma minnu bɛ kɛ silinda la walima minnu bɛ kɛ ni kon ye .

Nafaw:

A ka kan ka fa ani ka a pake ka kɛ mold cavity ye .

welda layiniw ni jibɔli nafama wɛrɛw farati dɔgɔyali .

A yɔrɔ fanga ni a cogoya ɲɛnabɔlen .

Nafa minnu b’a la:

bɛ se ka da taamasiyɛn yelen to a yɔrɔ kan .

A bɛ manuel gate bɔli ni a labanko de wajibiya .

A dan ye yɔrɔw ye minnu bɛ ni jateminɛ kɛrɛnkɛrɛnnenw ye .

Aplikasi:

Silindriw walima komini yɔrɔw (misali la, tasaw, minɛnw, funteniw) .

Yɔrɔ minnu bɛ ni balannako ye, ni radiyali flow wajibiyalen don .

Fɛn minnu na da bilali cɛmancɛ la walima periferi la .

6. Bololabaarakɛlaw ka da minnu bɛ kɛ ni funteni ye .

Bololabaarakɛlaw ka valve gatew bɛ kɛ ka fara Runner Systems hot kan. U bɛ kunnafoni tigitigi di fɛnw bolicogo kan ani u bɛ yɔrɔ saniyalenw di, minnu tɛ da.

Kɛcogow:

Valve pin min bɛ fɛnw bolicogo ɲɛnabɔ ka don mouli kɔnɔ .

A bɛ yɔrɔ saniyalen, da tɛ yɔrɔ min na .

A bɛnnen don ka kɛ fɛn caman dilanni ye ani ka kɛ fɛn caman ye .

Nafaw:

Fɛn minnu bɛ kɛ ka fɛnw bolicogo ni u pikiri kɛ .

A bɛ da a la ko a mago bɛ da bɔli la ani a laban na .

Sikili waatiw dɔgɔyali ani sɛnɛfɛnw dilanni nafa ka bon .

Nafa minnu b’a la:

Investissement fɔlɔw ni ladonni musakaw ka ca .

Setup ni control systems complexe wajibiyalen .

A bɛ se ka kɛ ko a man kan ka kɛ fɛnw bɛɛ la walima a yɔrɔ jateminɛtaw la .

Aplikasi:

caman sɔrɔli bɛ boli ni jogoɲini gɛlɛnw ye .

Multi-cavity molds ka ɲɛsin yɔrɔ misɛnninw ma minnu bɛ tiɲɛ .

Furakɛcogo, mobili, walima fɛn minnu bɛ kɛ ka fɛnw feere, ni da taamasiyɛn yetaw tɛ yen .

7. Bololabaarakɛlaw ka funtenibɔlanw .

Bololabaarakɛlaw ka funteni-da-yɔrɔw ye da sugu wɛrɛ ye min bɛ Kɛ ni boli-minɛnw ye minnu bɛ Kɛ ni funteni ye. U bɛ jibɔcogo ɲɛ ani ka jiginni waatiw dɔgɔya ni i ye a suma ni laadala boli nɛnɛma siraw ye.

Kɛcogow:

Nozzle funteni min bɛ fɛnw funteni ni u jibɔ mara .

A bɛ yɔrɔ saniyalen, da tɛ yɔrɔ min na .

A bɛnnen don ka kɛ fɛn caman dilanni ye ani ka kɛ fɛn caman ye .

Nafaw:

Fɛnw bolicogo ɲɛnabɔlen ani tansiyɔn jiginni dɔgɔyali .

A bɛ da a la ko a mago bɛ da bɔli la ani a laban na .

Sikili waatiw dɔgɔyali ani sɛnɛfɛnw dilanni nafa ka bon .

Nafa minnu b’a la:

Investissement fɔlɔw ni ladonni musakaw ka ca .

Setup ni control systems complexe wajibiyalen .

A bɛ se ka kɛ ko a man kan ka kɛ fɛnw bɛɛ la walima a yɔrɔ jateminɛtaw la .

Aplikasi:

caman sɔrɔli bɛ boli ni jogoɲini gɛlɛnw ye .

Multi-cavity molds ka ɲɛsin yɔrɔ misɛnninw ma minnu bɛ tiɲɛ .

Furakɛcogo, mobili, walima fɛn minnu bɛ kɛ ka fɛnw feere, ni da taamasiyɛn yetaw tɛ yen .

8. Fan Gates .

Fan da ye dakun da suguya ye min da bɛ bonya, min bɛ i n’a fɔ fan. U bɛ kɛ yɔrɔw ye minnu bɛ fa teliya la ani fɛnw tilatilali cogo kelen na.

Kɛcogow:

da belebeleba, min bɛ i n’a fɔ fan min bɛ taper ka bɔ bolibaga la ka taa a yɔrɔ la .

A bɛ fɛnw falen teliya la ani ka fɛnw tilatilali kɛ cogo kelen na .

A bɛnnen don yɔrɔw ma minnu ye fla ye, minnu kogow ka fin, yɔrɔbaw bɛ minnu na .

Nafaw:

A ka kan ka fa ani ka a pake ka kɛ mold cavity ye .

welda layiniw ni jibɔli nafama wɛrɛw farati dɔgɔyali .

A yɔrɔ fanga ni a cogoya ɲɛnabɔlen .

Nafa minnu b’a la:

A bɛ da taamasiyɛn yelen to a yɔrɔ da la .

A bɛ se ka kɛ ko bolo bɔli ni a laban bɛ kɛ ni bolo ye .

dan bɛ yɔrɔw la minnu bɛ ni jateminɛ nɔgɔmanw ye ani kogo janya kelen .

Aplikasi:

Fɛn minnu bɛ kɛ fla ye, minnu kogow ka fin, ni u yɔrɔ ka bon (misali la, panɛriw, dakunw, sanubɔlanw)

Yɔrɔ minnu bɛ ni yecogo wajibiyalenw ye minnu tɛ kɔrɔfɔ ye .

sɛnɛfɛnw bɔli hakɛ caman bɛ boli .

9. Pin daaw .

Pinɛ da ye da misɛnninw ye, da minnu bɛ kɛ silinda ye, minnu bɛ kɛ yɔrɔw ye minnu kogow ka bon walima minnu bɛ tigɛtigɛ. U bɛ fɛn camanba di ka don nɔgɔbɔlan kɔnɔ.

Kɛcogow:

Da fitinin, silinda min bɛ bɔ bolibaga la ka taa a bila yɔrɔ la .

A bɛ fɛn camanba di ka kɛ yɔrɔbaw ye walima yɔrɔbaw .

A bɛnnen don yɔrɔw ma minnu ɲɛda cogoya wajibiyalenw tɛ kɔrɔfɔ ye .

Nafaw:

A yɔrɔ ka bon walima a yɔrɔbaw facogo ɲuman .

Farati min bɛ a la ka a kɛ a ka marifaw ye, o bɛ dɔgɔya walima ka a fa cogo dafalen na .

Degun min ka dɔgɔn ni sɛgɛn ye ani fɛnw tiɲɛni .

Nafa minnu b’a la:

A bɛ da yelen dɔ to yɔrɔ in sanfɛ .

A bɛ se ka kɛ ko bolo bɔli ni a laban bɛ kɛ ni bolo ye .

A dan ye yɔrɔw ye minnu kogow ka bon walima u tigɛtigɛyɔrɔbaw .

Aplikasi:

Kogow ka bon walima u yɔrɔbaw (misali la, u jɔyɔrɔw, u ka so, u ka brackets)

Yɔrɔ minnu bɛ ni yecogo wajibiyalenw ye minnu tɛ kɔrɔfɔ ye .

sɛnɛfɛnw bɔli hakɛ dɔgɔman fo ka se hakɛ cɛmancɛ ma .

Fɛn minnu bɛ tali kɛ da sugandili la .

Ka da ɲuman sugandi i ka pikiri kɛli porozɛ kama, o tɛ ko ye min bɛ kɛ ni fɛn kelen ye. Fɛn caman bɛ na baara la ni i bɛ da suguya ɲuman ni yɔrɔ sugandi. An ka nin jateminɛw sɛgɛsɛgɛ ka ɲɛ.

Material Properties ani Flow cogoyaw .

I bɛ baara kɛ ni plastiki fɛn suguya min ye, o bɛ nɔba bila da sugandili la. Fɛn suguya caman bɛ ni jibɔcogo caman ye, i n’a fɔ sɔgɔli, sɔgɔli sɛgɛsɛgɛli, ani funteni sabatili. O jogo ninnu bɛ nɔ bila cogo min na plastiki wulilen bɛ don a kɔnɔ ani ka nɔgɔbɔlan fa.

Misali la, fɛn minnu bɛ ji caman bɔ i n’a fɔ poliyetilɛni (PE) ani poliporopilini (PP) bɛ se ka kɛ dabaw ye minnu ka bon walasa k’u ka jibɔ teliya hakɛ sɔrɔ. Faan wɛrɛ fɛ, ɛntɛrinɛti plastikiw i n’a fɔ polikarbonati (PC) ani akirilonitirili butadiyɛni stirireni (ABS) bɛ se ka nafa sɔrɔ da misɛnninw na minnu bɛ se ka u ka jibɔ kunbɛn ani ka sɛgɛn degunw dɔgɔya.

| Material |

Flow jogo bɛnnenw |

Da suguya bɛnnenw . |

| PE, PP . |

Flow sanfɛ, viscosité dɔgɔman . |

Dabaw (misali la, Sprue, Edge) |

| PC, ABS |

Flow moderate, shear sensitive . |

da misɛnninw (misali la, pinɛ, valve) . |

| Nylon, pom |

Flow dɔgɔman, viscosité sanfɛ . |

da cɛmancɛw (misali la, fan, ji-kɔnɔ-yɔrɔ) |

Tablo 1 : Fɛnw bolicogo cogoyaw ani da suguya bɛnnenw.

Yɔrɔ jateminɛ ani kogo janya .

I ka yɔrɔ cogoya n’a hakɛw fana jɔyɔrɔ ka bon da sugandili la. Yɔrɔ minnu ka jateminɛ ka gɛlɛn, kogo finmanw, walima u janya tɛ kelen ye, olu bɛ se ka da suguya kɛrɛnkɛrɛnnenw de wajibiya walasa ka u fa ka ɲɛ ani ka fiɲɛw dɔgɔya.

Misali la, yɔrɔ minnu kogow ka fin, olu bɛ se ka nafa sɔrɔ dakun da la walima fiɲɛbɔlan da la, minnu bɛ jibɔ sira jan, min man bon, walasa ka yɔrɔ fa joona ani cogo kelen na. Faan wɛrɛ fɛ, yɔrɔ minnu kogow ka bon, olu bɛ se ka kɛ ni pinɛ da walima jirisunw daaw ye walasa ka fɛn caman wuli ka don nɔgɔ yɔrɔ jugumanw na.

Jaa 1 : Jɛɲɔgɔnya min bɛ yɔrɔ jateminɛ ni da sugandili cɛ.

Mold design and Construction .

Aw ka pikirijikɛlan dilanni n’a jɔli bɛ se ka dan sigi walima ka se ka da suguya dɔw sɔrɔ. Parting line yɔrɔ, ejector pin placement, ani cooling channel layout bɛɛ bɛ nɔ bila da la yɔrɔ ni cogo min na bɛ se ka don foroko kɔnɔ.

Da suguya dɔw, i n’a fɔ ji jukɔrɔla da walima kafedaw, olu bɛ mɔli kɛcogo kɛrɛnkɛrɛnnenw walima masin wɛrɛw de wajibiya walasa k’u cogoya n’u dondaw kɛrɛnkɛrɛnnenw ladon. Dɔw fana, i n’a fɔ bolibagaw ka da minnu ka suma, olu bɛ se ka kɛ wajibi ye ka nɔgɔ dilan minnu ka gɛlɛn ani minnu sɔngɔ ka gɛlɛn walasa ka manifold ni nozzle yɔrɔw fara ɲɔgɔn kan.

A nafa ka bon kosɛbɛ ka jateminɛ kɛ nɔgɔ dilanni na a daminɛ na ani ka jɛ ka baara kɛ ni baarakɛminɛnw dilannikɛlaw ye minnu bɛ se kosɛbɛ walasa ka a dɔn ko da suguya sugandilen bɛ se ka kɛ ani ko a ka ɲi i ka baara kɛrɛnkɛrɛnnen na.

Sɛnɛfɛnw hakɛ ni u ka baarakɛcogo ɲuman wajibiyalenw .

Aw ka sɛnɛfɛnw bɔli hakɛ ni u ka baarakɛcogo ɲuman kuntilenna fana bɛ nɔ bila da sugandili la. Da suguya wɛrɛw bɛ baarakɛcogo hakɛ caman di, cycle waatiw, ani prop-molding wajibiyalenw.

Ni aw bɛ baara kɛ ni fɛn caman ye, aw bɛ se ka da suguyaw sugandi minnu bɛ cycle waatiw dɔgɔya ani ka se ka bɔ teliya la, i n’a fɔ valve gates walima thermal gates. O dakun suguyaw fana bɛ dɔ Bɔ bololabaara da bɔli ni a labanko la, o bɛ dɔ Fàra a dilanni taabolo kan.

Nka, nin dakun kɔrɔlenw bɛ na ni musaka fɔlɔw ni gɛlɛya caman ye n’i y’a suma ni dakun suguya nɔgɔmanw ye i n’a fɔ da walima dakunw. Ni boliw ka dɔgɔn fo ka se hakɛ cɛmancɛ ma, o dakun suguya jɔnjɔnw bɛ se ka kɛ musakabɔ ye ka sɔrɔ ka i ka jogo ɲuman ni i ka baarakɛcogo ɲuman wajibiyalenw dafa hali bi.

| Production Volume |

Efficiency Laɲiniw |

Da suguya bɛnnenw . |

| Jamanjan |

Sikili waati fitininw, otomatiki trimming . |

Valve gates, gate thermal . |

| Hakɛ |

A ka baara kɛcogo ɲuman ani a musaka . |

Fan daaw, ji-kɔnɔ-yɔrɔw . |

| Fɛ́gɛn |

A musaka ka dɔgɔ, a bɛ kɛ ni bolo ye . |

daaw da, dabaw . |

Tablo 2 : Sɛnɛ hakɛ, baarakɛcogo ɲuman kuntilenna, ani da suguya bɛnnenw.

Ni aw ye o kow jateminɛ koɲuman ani ka lajɛ ni pikiri kɛcogo dɔnbagaw ye, aw bɛ se ka da suguya ɲuman sugandi aw ka baara kɛrɛnkɛrɛnnen kama. Dakun sugandili ɲuman bɛ se ka dɔ fara kosɛbɛ i ka pikiri kɛcogo porozɛ ɲuman kan, a kɛcogo ɲuman ani a nafa sɔrɔli kan.

Kuncɛli

Da suguya ɲuman sugandili nafa ka bon kosɛbɛ pikiri kɛli la. A bɛ nɔ bila fɛn laban ka jogo n’a ka baarakɛcogo ɲuman na. Aw bɛ da suguya ni a bilali lajɛ aw ka dilanw kɔnɔ. O desizɔn bɛ se ka fiɲɛw bali ani ka fɛn dilanni kɔlɔlɔw ɲɛ. Aw ye lajɛ kɛ ni baarakɛlaw ye minnu bɛ se kosɛbɛ walasa u ka bilasirali sɔrɔ. U bɛ se ka dɛmɛ don ka aw ka da dilanni kɛcogo ɲuman sɔrɔ ani ka a jira ko a bɛ se ka kɛ cogo ɲuman na.

Team MFG ye aw ka jɛɲɔgɔn dannamɔgɔ ye ka ɲɛsin furakɛli kɛcogo ma min bɛ kɛ ka ɲɛ. Aw ye anw sɔrɔ bi, ka an ka dɔnnikɛlaw bila ka aw ka poroze kɛ ka ɲɛ walasa ka ɲɛtaa sɔrɔ.