Yala i delila k’i yɛrɛ ɲininka cogo min na plastiki yɔrɔ gɛlɛnw bɛ dilan ni kunnafoni gɛlɛnw ye wa? Jaabi bɛ sɔrɔ fɛɛrɛ hakilitigi dɔ la min bɛ wele ko . Pikiri molding bɛ fɛnw tiɲɛ. Nka, mun tigitigi de bɛ tiɲɛ, ani mun na u nafa ka bon kosɛbɛ?

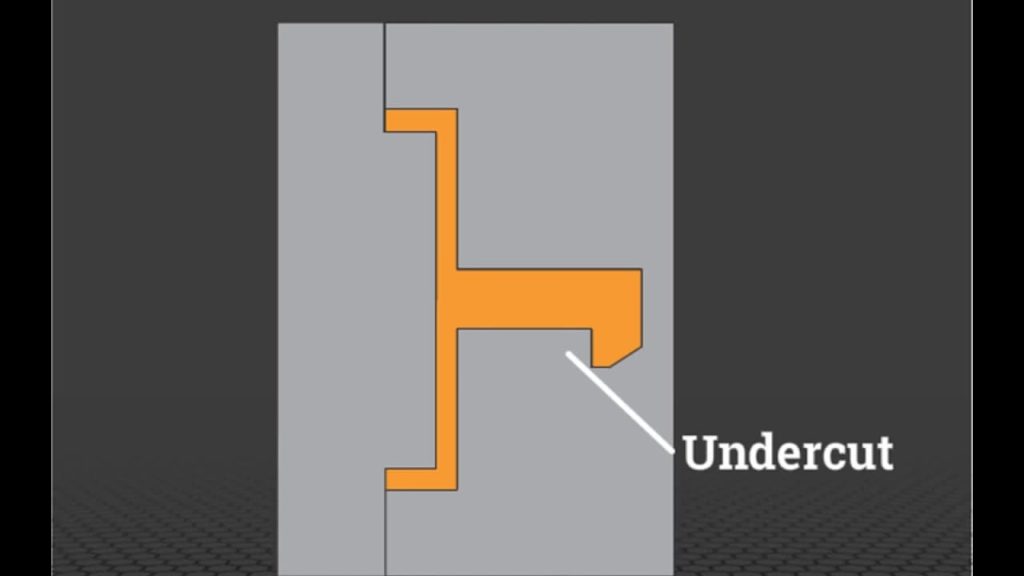

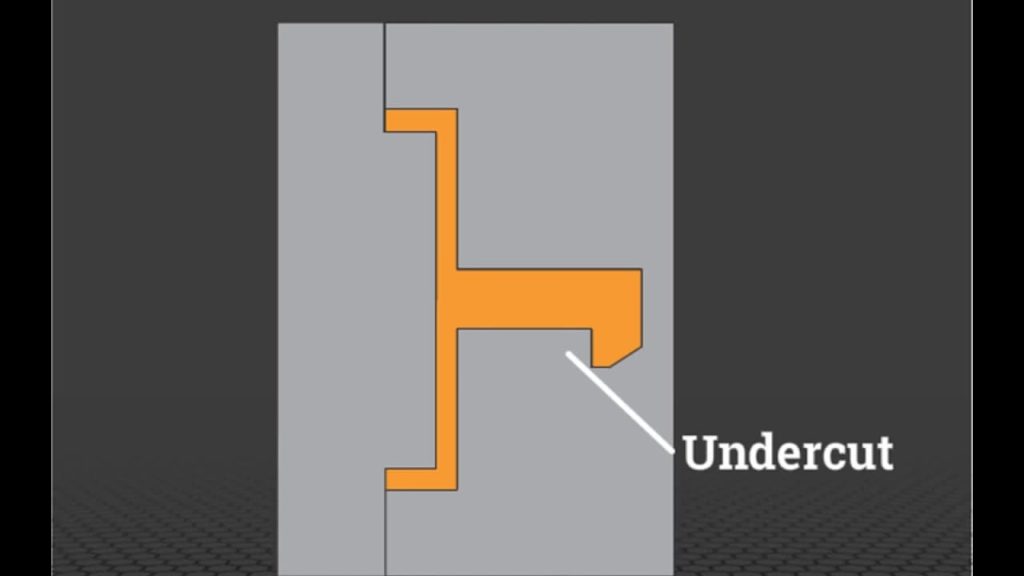

Undercuts ye fɛnw ye minnu bɛ a bali ka yɔrɔ dɔ bɔ a cogo la nɔgɔya la. U nafa ka bon kosɛbɛ yɔrɔw dabɔli la ni baarakɛcogo ɲuman ye, ni u lajɛcogo ɲɛ, ani mago bɛ baara filananw na. Nka, dilancogo ni molding undercuts bɛ na n’a yɛrɛ ka gɛlɛyaw ye.

Nin sɛbɛn in kɔnɔ, i bɛna a dɔn ko fɛn minnu bɛ tiɲɛni kɛ, olu ye fɛn minnu ye, mun na u nafa ka bon, ani u ka gɛlɛyaw ɲɛnabɔcogo ɲuman.

Pikiriw bɛ kɛ mun ye u bɛ fɛnw tiɲɛ?

Pikiri molding undercuts ye fɛnw ye minnu bɛ yɔrɔ dɔ bali ka bɔ nɔgɔya la a ka mɔli la. U bɛ i n'a fɔ hooks walima overhangs ko 'lock' yɔrɔ min bɛ a nɔ na. An k’u sɛgɛsɛgɛ k’a jɛya.

Ɲɛfɔli caman kɛra jukɔrɔlatigɛw kan .

Undercuts bɛ dilan cogoya la ni a yɔrɔ dɔ ye:

Protrusions .

dingɛw .

Cavities .

Yɔrɔ minnu bɛ don .

O fɛnw tɛ jɔ ka kɛɲɛ ni mɔli ka farali sira ye. O b’a to a ka gɛlɛn ka a yɔrɔ bɔ k’a sɔrɔ a ma a tiɲɛ.

Undercuts suguyaw .

Undercute suguya belebele fila bɛ yen:

Kɔnɔna jukɔrɔlatigɛw .

Kɛnɛma jukɔrɔla tigɛcogo .

A bɛ sɔrɔ kɛnɛma yɔrɔ la .

Misaliw: klipiw, jɛgɛw, flanw .

Aplikasi minnu bɛ kɛ tuma bɛɛ .

Undercuts bɛ baara kɛ ni industri suguya caman ye:

| Industry | Application | Benefit . |

| Elektroniki . | Butɔnw ka yɔrɔw . | Sɔrɔli ka nɔgɔn . |

| Furakɛli | Luer locks . | Jɛɲɔgɔnya lakananen . |

| Mobili . | Clips . | Assemblée teliya . |

Undercuts bɛ baarakɛcogo ni nɔgɔya lajɛ. U ye pikirijikɛlan dilanni fɛɛrɛ jɔnjɔn ye.

Nafa min bɛ a la ka a kɛ fɛn ye min bɛ kɛ ka fɛnw tigɛtigɛ Pikiriw la .

Kɔnɔnatumuw jɔyɔrɔ ka bon kosɛbɛ pikiri kɛlen yɔrɔw la. U bɛ nafa caman di minnu b’a to u nafa ka bon bi fɛn dilanni na.

Baarakɛcogo ɲuman ani dilancogo gɛlɛya .

Undercuts bɛ a to dilanbagaw ka yɔrɔw dilan ni:

O fɛnw bɛ yɔrɔ in baarakɛcogo ɲɛ. U fana bɛ se ka dilanw kɛ minnu ka gɛlɛn kosɛbɛ, minnu tun tɛ se ka kɛ ni u tun tɛ se ka kɛ.

A lajɛcogo ɲɛnabɔlen ani a jɛnsɛnni ɲɛ .

Dugukolo jukɔrɔla tigɛw bɛ yɔrɔw lajɛcogo nɔgɔya ani u bɔli nɔgɔya. U b’a to:

Snap-fit ɲɔgɔndan teliyalenw .

Mako minnu bɛ dɔgɔya ka ɲɛsin juruw ma walima nɛgɛw ma .

Fɛn minnu bɛ don walima minnu tiɲɛna, olu caman cili nɔgɔya .

O bɛ lajɛ kɛcogo ɲɛnabɔ ani ka ladonni kɛ fiɲɛ ye.

Baara filananw mago bɛ dɔgɔya .

Ni i ye jukɔrɔla-tigɛw don a yɔrɔ la min dilannen don, i bɛ se ka:

Aw bɛ aw mago bɔ fɛn dɔ la min bɛ wele ko drilling walima machining .

Aw bɛ dɔ bɔ a lajɛcogo hakɛ la .

Aw bɛ hadamadenw ka fili farati dɔgɔya .

O bɛ waati, cɛsiri ani nafolo mara fɛn dilanni na.

Musow ka musakabɔ ka bɔ jamana kɔnɔ .

Dugukolo jukɔrɔla tigɛw bɛ kɛ sababu ye ka musaka dɔgɔya, kɛrɛnkɛrɛnnenya la, fɛn dilanni boliw la minnu bɛ kɛ ni hakɛ caman ye. U bɛ se ka:

Waati tɛmɛnen kɔfɛ, o warimarataw bɛ fara ɲɔgɔn kan, o bɛ kɛ sababu ye ka fɛn dɔw kɛ minnu bɛ se ka kɛ sababu ye ka fɛn caman dilan.

| bɛ sɔrɔ a la . | Nafa min |

| Baarakɛcogo ɲɛtaa . | A bɛ se ka kɛ sababu ye ka fɛn dilanni gɛlɛnw kɛ . |

| Lajɛba ɲɛnabɔlen . | Streamlines Production . |

| OP filananw dɔgɔyali . | A bɛ waati ni nafolo mara . |

| musaka-nafa . | A bɛ musakaw bɛɛ lajɛlen dɔgɔya . |

Fɛɛrɛ minnu bɛ kɛ ka pikiri kɛcogo ɲɛ .

Kɔnɔbara basigilenw dilanni pikiri kɛli la, o bɛ fɛɛrɛ kɛrɛnkɛrɛnnenw de wajibiya. An ka fɛɛrɛw sɛgɛsɛgɛ minnu ka teli ka kɛ ani u dɛsɛ.

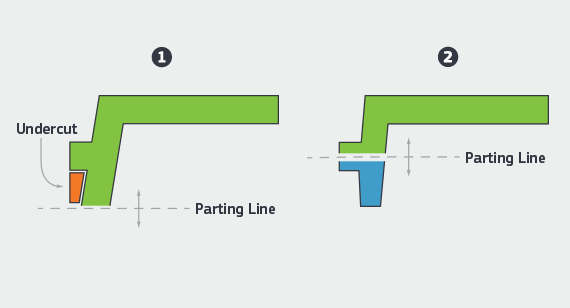

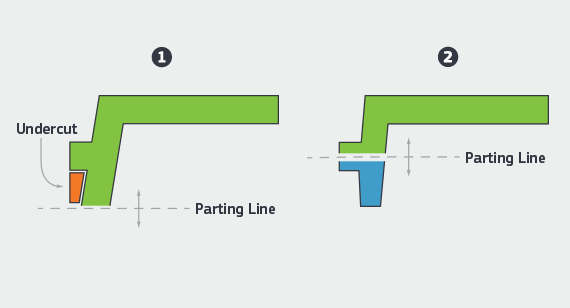

1. Ka fara ɲɔgɔn kan layini ladilanni .

Parting layini bilali nafa ka bon kosɛbɛ undercut dilancogo la. O bɛ tali kɛ:

O b’a To a yɔrɔ bɛ Bɔ ka Bɔ a la k’a sɔrɔ a ma Dòn a la.

Nafaw:

Dantigɛliw:

Ladilikanw ka ɲɛsin farali layini dilancogo ɲuman ma:

Aw ye a yɔrɔ dɔw baarakɛcogo ni a ɲɛnajɛcogo jateminɛ .

Aw bɛ farankanw hakɛ dɔgɔya .

Aw bɛ a lajɛ ni fiɲɛbɔlan ni nɛnɛ bɛ kɛ ka ɲɛ .

2. Kɛrɛfɛ-walew .

Side-actions ye movable mold components ye minnu bɛ undercuts dilan. U bɛ baara kɛ ni:

Kɛrɛfɛ-wale suguyaw:

Hydraulique - A bɛ baara kɛ ni ji tansiyɔn ye .

Mekaniki - min bɛ boli ka bɔ kaso la walima ka ɲɔgɔn sɔrɔ .

Pneumatique - Actuated by compressed air .

Dilancogo jateminɛw:

Aw ye aw jija ka a lajɛ ka ɲɛ ani ka a labɛn ka ɲɛ .

Aw bɛ a labɛn ka nɛnɛ ni fiɲɛ sama ka ɲɛ .

Aw ye fanga jateminɛ min ka kan ka kɛ walasa ka kɛrɛfɛwale kɛ .

Nafaw:

dɛsɛw: .

3. Bump-offs .

Bump-offs ye yɔrɔw ye minnu bɛ wuli mold kan minnu bɛ degun sɔrɔ bɔli senfɛ. U b’a To yɔrɔ in ka flex ani ka Bɔ jukɔrɔla-tigɛ la.

Fɛn minnu bɛnnen don bump-offs ma:

Dilancogo ɲɛfɔli:

Aw ye aw jija ka angles draft bɛrɛbɛn .

Aw bɛ baara kɛ ni yɔrɔ nɔgɔlenw ye minnu bɛ lamini .

Aw ye fɛn in ka degun dantigɛliw jateminɛ .

Nafaw:

Nafa minnu b’a la:

4. bolo-don-fɛnw doncogo .

Bololabaarakɛlaw bɛ don bolo la ka u bila nɔgɔ la ka sɔrɔ ka cycle kelen-kelen bɛɛ kɛ. U bɛ jukɔrɔla-tigɛw da:

Waati min na ka baara kɛ ni bolo-don-fɛnw ye:

Dilancogo ani fɛnw jateminɛcogo:

Nafa minnu bɛ yen:

Cons:

5. Sliding Shutoffs (Teleskoping Shutoffs) .

Sliding shutoffs ye mɔli yɔrɔw ye minnu bɛ taa ɲɔgɔn fɛ ni bɔli sira ye. U bɛ jukɔrɔla-tigɛw da:

Aplikasi:

Ladilikanw dicogo:

Aw ye aw jija ka ɲɔgɔn sɔrɔ ani ka u bɔ ɲɔgɔn na cogo bɛnnen na .

Aw bɛ baara kɛ ni fɛnw ye minnu bɛ se ka sɛgɛn, ka ɲɛsin da tugulenw ma .

Aw bɛ a labɛn ka nɛnɛ ni fiɲɛ sama ka ɲɛ .

Nafaw:

Dantigɛliw:

6. Kooriw minnu bɛ se ka bin .

Kooriw minnu bɛ se ka wuli, olu ye mɔli yɔrɔw ye minnu bɛ bin walima ka kɔsegin bɔli senfɛ. U b’a to yɔrɔ in ka bɔ kɔnɔna na.

Koori suguya minnu bɛ se ka wuli:

Mekaniki - min bɛ boli ka bɔ kaso la walima ka ɲɔgɔn sɔrɔ .

Hydraulique - Actuated by hydraulique pressure .

Dilancogo jateminɛw:

Aw ye aw jija ka ɲɔgɔndɛmɛ ni waati kɛcogo ɲuman sɔrɔ.

Aw bɛ a labɛn ka nɛnɛ ni fiɲɛ sama ka ɲɛ .

Aw ye fanga jateminɛ min ka kan ka kɛ walasa ka a kɔnɔna tiɲɛ .

Nafaw:

dɛsɛw: .

Fɛɛrɛ ɲuman sugandili bɛ bɔ fɛnw na i n’a fɔ:

Dilanko jateminɛw ka ɲɛsin jukɔrɔlatigɛw ma .

Ni yɔrɔ dɔw dilanni bɛ kɛ ni u jukɔrɔla tigɛlenw ye, fɛn jɔnjɔn caman bɛ yen minnu ka kan ka to an hakili la. An k’u sɛgɛsɛgɛ k’a jɛya.

Angles de draft .

Nafa min bɛ sɔrɔ draft angles .

Draft angles ye ko kɔrɔba ye ka ɲɛsin undercut design ma. U bɛ dɛmɛ don ka a lajɛ ko:

Ni a ma kɛ ni draft ɲuman ye, a yɔrɔw bɛ se ka nɔrɔ walima ka tiɲɛ bɔli waati.

Angles de draft recommended .

Angle de draft optimale bɛ bɔ a dilanni kɛrɛnkɛrɛnnen na. Nka, laadilikanw bɛɛ lajɛlen filɛ nin ye:

| Feature type | recommended draft . |

| Kɛnɛma kogow . | 1-2 degɛrɛ . |

| Kɔnɔna kogow . | 2-3 degɛrɛ . |

| Ribs ni Bosses . | 0,5-1 degɛrɛ fan kelen na . |

Ni dɔ farala draft angles kan, o bɛ se ka yɔrɔw bɔli ɲɛ ka ɲɛ nka a bɛ se ka nɔ bila ɲɛnajɛw la.

Kogo ka bon .

Ka kogo janya kelen mara .

Kogo janya basigilen nafa ka bon kosɛbɛ walasa ka u tigɛtigɛ. A b’a jira ko:

Hali a yɔrɔ nɛnɛni ni a dɔgɔyali .

Farati min bɛ a la ko a bɛ se ka kɛ ka a kɛ fɛn ye walima ko a bɛ se ka kɛ a ka sinji ye, o bɛ dɔgɔya .

Aw bɛ tugu tuma bɛɛ resin dilannikɛla ka laadilikanw na kogo janya kan.

A bɛ nɔ min bila yɔrɔ dɔ la min bɛ se ka kɛ fɛn ye .

Yɛlɛma minnu bɛ kɛ kogo janya la, olu bɛ se ka kɛ sababu ye ka:

Yɔrɔ barikamaw walima degunw hakɛ .

Material Flow ani Packing .

Nafa minnu bɛ ye a yɔrɔ la .

Aw bɛ a janya kelen mara a yɔrɔ bɛɛ la walasa ka ɲɛtaa ɲuman sɔrɔ.

Kɔnɔw ni radiyaliw .

Dɛmɛnanw bɛ sɔrɔ yɔrɔw la minnu dilannen don .

Kɔnɔbaraw ye fɛn finmanw ye, minnu bɛ i n’a fɔ kogo, minnu bɛ dɛmɛ don jɔli la. U bɛ dɛmɛ don:

Aw bɛ yɔrɔbaw barika bonya, minnu bɛ kɛ fla ye .

Aw bɛ sink taamasiɲɛw ni warping bali .

Aw bɛ yɔrɔ gɛlɛnw ni fanga yɔrɔw ɲɛ .

Baara kɛ ni kɔkiliw ye cogo ɲuman na walasa ka yɔrɔw tigɛcogo ɲɛ ka taa a fɛ.

Radiusing kɔnɔna kɔnɔnakow .

Kɔnɔnatumuw ka teli ka degun hakɛ sɔrɔ. Walasa ka nin ko in nɔgɔya:

Radiused nkɔniw bɛ degunw jɛnsɛn cogo kelen na, ka a yɔrɔ muɲuni ɲɛ.

Designing for Manufacturability (DFM) in undercut injection moulding .

DFM ye fɛn nafamaba ye min bɛ se ka kɛ sababu ye ka fɛnw tigɛ ka ɲɛ. An ka don a sariyakolow n’a nafaw la.

DFM sariyakolow lajɛlen .

DFM ye dilancogo ye min bɛ sinsin fɛn dilanni nɔgɔya kan. A sariyakolo jɔnjɔnw ye:

Ni DFM kɛra, dilanbagaw bɛ se ka yɔrɔw dilan minnu dilanni ka nɔgɔn ani minnu sɔngɔ ka nɔgɔn.

DFM nafa ka bon undercut design .

Undercuts bɛ gɛlɛya dɔ fara pikiri kɛcogo kan. DFM bɛ dɛmɛ ka nin gɛlɛya in ɲɛnabɔ ni:

Ka fɛn dilanni koɲɛw dɔn minnu bɛ se ka kɛ a dilanni daminɛ na .

Yɔrɔ jateminɛcogo ɲuman ka ɲɛsin fɛn kɛrɛnkɛrɛnnenw dilanni fɛɛrɛ ma .

Ka a lajɛ ko a dilanni bɛ bɛn ni fɛn sugandilenw ye .

ka dɔ bɔ fiɲɛw ni sɛnɛfɛnw bɔli la waati latɛmɛni na .

DFM donli nafa ka bon walasa ka se ka u ka fɛnw tigɛ ka ɲɛ.

DFM ka laadilikan minnu bɛ sɔrɔ fɛnw na minnu bɛ kɛ ka fɛnw tiɲɛ .

Nin ye DFM hakilina jɔnjɔn dɔw ye walasa ka jukɔrɔla-tigɛw dilan:

Min bɛ dɔ bɔ a jugumanba ni a gɛlɛya la .

Aw bɛ kogo janya basigilen kɛ a yɔrɔ bɛɛ la .

Aw bɛ draft angles bɛrɛbɛrɛw di walasa ka bɔli nɔgɔya .

Aw bɛ aw yɛrɛ tanga nkɔni ni dakunw ma .

Aw ye jateminɛ kɛ farali sira kan ani a bɛ nɔ min bila u ka tiɲɛni na .

Aw bɛ baara kɛ ni fɛnw ni muɲuli sariyalenw ye ni a bɛ se ka kɛ tuma o tuma .

Ni aw ye nin laadilikanw labato, o bɛ se ka dɛmɛ don ka fɛnw dilanni kɛcogo ɲɛ.

Nafa minnu bɛ DFM donli la .

DFM waleyali Undercut Design kɔnɔ, o bɛ nafa caman di:

dɔ bɔra sɛnɛfɛnw dilanni musakaw la ani u ka baara kɛwaatiw la .

Yɔrɔ ɲuman ni a kɛcogo ɲuman .

Baarakɛɲɔgɔnya min bɛ ka bonya dilancogo ni fɛn dilanni jɛkuluw cɛ .

Waati teliya ka taa sugu la fɛn kuraw kama .

Dɔ farala fɛn dilanni nafa bɛɛ kan .

| DFM nafa | nɔfɛko . |

| musakaw dɔgɔyali . | sɔngɔ caman wɛrɛw . |

| A dilanni teliya . | Ɲɛnamaya waati surunw . |

| A ka fisa ni jogo ye . | Kunnafoni minnu bɛ sɔrɔ kiliyanw fɛ sanfɛ . |

| Baarakɛcogo ɲuman min bɛ bonya . | Nafa sɔrɔli ka caya . |

Gɛlɛyaw ni furaw .

Dilancogo ni mɔli minnu bɛ kɛ ka fɛnw tiɲɛ, olu bɛ na n’a ka gɛlɛyaw hakɛ bɛnnen ye. An ka ko dɔw sɛgɛsɛgɛ minnu bɛ kɛ ɲɔgɔn fɛ ani u furakɛcogo.

Fɛnw ni dilancogo gɛlɛyaw .

Fɛn gɛlɛnw ni jateminɛ gɛlɛnw ɲɛnabɔli .

Fɛn gɛlɛnw i n’a fɔ polikarbonati ni ABS bɛ se ka gɛlɛya sɔrɔ u dilanni na. Olu:

Jateminɛ gɛlɛnw ni jukɔrɔla-yɔrɔw jugumanw walima minnu ka surun, olu bɛ taabolo gɛlɛya ka taa a fɛ.

Fɛn minnu bɛ kɛ ka ɲɛsin dilancogo koɲɛw ma minnu bɛ kɛ ɲɔgɔn fɛ .

Walasa ka se sɔrɔ o gɛlɛyaw kan, dilanbagaw bɛ se ka:

Aw bɛ baara kɛ ni fɛnw ye minnu bɛ se ka wuli ka bɔ u nɔ na i n’a fɔ TPE walima nilon .

Optimiser kogo janya ani draft angles .

Aw bɛ kɛrɛfɛ-walew walima koorilenw don a kɔnɔ walasa ka fɛn gɛlɛnw kɛ .

Baarakɛɲɔgɔnya min bɛ kɛ dilanbagaw ni fɛn dilannikɛlaw cɛ, o ye fɛnba ye walasa ka fura ɲumanw sɔrɔ.

Aesthétique ani baarakɛcogo jateminɛw .

Ka ɲɛsin farankanw ma minnu bɛ ye .

A ka c’a la, farali layiniw bɛ ye yɔrɔw kan minnu bɛ tigɛ ni u ye. U bɛ se ka:

Walasa k’u nɔfɛkow dɔgɔya, aw ye jateminɛ kɛ:

Ka farankan yɔrɔ ladilan .

Baara kɛ ni sɛbɛnni walima kulɛri ye walasa ka layiniw dogo .

baara kɛli ni sliding shooffs ye walasa ka yeli kɛ cogo la min tɛ fɛn tiɲɛ .

Ka baarakɛcogo dafalen sabati .

Undercuts fana bɛ se ka nɔ bila yɔrɔ in baarakɛcogo la. Walasa ka tilennenya sabati:

Aw bɛ dilancogo lajɛw ni simulatigɛw kɛ ka ɲɛ .

Kɔrɔbɔli prototypes (daɲɛ fɔlɔw sɛgɛsɛgɛli) diɲɛ cogoya lakikaw kɔnɔ .

Aw ye dilancogo ladilanni wajibiyalenw kɛ ka da hakilinaw kan .

Balannako ɲuman sɔrɔli baarakɛcogo ni fɛn dilanni cɛ, o nafa ka bon kosɛbɛ.

musaka minnu bɛ bɔ a la .

Balannako gɛlɛyaw ni a dilanni musakaw .

Undercuts complexes (daɲɛ kɔrɔma minnu ka gɛlɛn) caman na, olu kɔrɔ ye ko u dilanni musakaw ka bon. O bɛ bɔ:

Dɔ bɛ fara a ka nɔgɔw ni u ladonni kan .

Sikili waati janw ani fɛnw baaracogo sanfɛtaw .

Baara wɛrɛw kɛli bolo-don-fɛnw dontaw la walima baara filananw na .

Dilanbagaw ka kan ka u ka musaka dɔgɔyali nafaw jateminɛ ka kɛɲɛ ni u musaka nɔ ye.

A bɛ na ni nɔ minnu ye waati jan kɔnɔ, olu bɛ sɔrɔ wari bilali la .

Investissement upfront in a complexe mouth with undercuts bɛ se ka kɛ ko nafama ye. Nka, a nafa ka bon ka jateminɛ kɛ:

Undercut min dilannen don koɲuman, o bɛ se ka nafa sɔrɔ a laban na, hali ni musaka fɔlɔw bɛ se ka sɔrɔ.

| Gɛlɛya | ɲɛnabɔcogo . |

| Fɛn minnu ka gɛlɛn . | Baara kɛ ni fɛn wɛrɛw ye minnu bɛ se ka wuli ka bɔ u nɔ na . |

| Yɔrɔw tila-tilacogo yelenw . | Yɔrɔ ladilan walima ka baara kɛ ni sɛbɛnni ye . |

| Baarakɛcogo dafalen . | Aw bɛ sɛgɛsɛgɛli kɛ ka ɲɛ . |

| Sɛnɛ musakaw . | Balannako gɛlɛya ni a nafaw . |

Farankan

Kuma surun na, pikiri kɛli ni fɛn dɔw ye minnu bɛ se ka pikiri kɛ, o bɛ kɛ ni fɛɛrɛ jɔnjɔn caman ye. An ye farankanw, kɛrɛfɛ-walew, bugunw, bolo-don-yɔrɔw, ani teleskɔpi-da-yɔrɔw sɛgɛsɛgɛ. Fɛɛrɛ ɲuman sugandili nafa ka bon kosɛbɛ. Material Choice and Design for Manufacturability (DFM) fana nafa ka bon kosɛbɛ fɛnw dilanni na. Ka jɛ ka baara kɛ ni dɔnnikɛlaw ye, o bɛ a to a ka fisa ni tɔw bɛɛ ye. Undercut dilancogo ɲuman bɛ dɔnniya ni tiɲɛni fila bɛɛ de wajibiya.

Yala fɛn dɔ bɛ yen min bɛ se ka kɛ ka fɛnw tiɲɛ wa? Ekipu MFG ye dɔnniya sɔrɔ ka ɲɛnamaya sɔrɔ. Aw ka CAD filew ci bi . https://www.team-mfg.com ka teliya, fu. An ka dɔnnikɛlaw labɛnnen don k’aw dɛmɛ. Aw ka daminɛ sisan !