Mun na yɔrɔ minnu bɛ pikiri kɛ, olu bɛ layini sɔrɔ u lamini na? Nin 'parting line' in ye ko kɔrɔba ye fɛn dilanni na. Faamuyali a bɛ se ka i ka dilanw ɲɛ ka taa a fɛ.

Nin sɛbɛn in kɔnɔ, i bɛna a dɔn farali sira ye min ye ani mun na a nafa ka bon. An bɛna kuma a nɔfɛkow kan fɛn dilannenw ka ɲumanya n’u baarakɛcogo kan.

Furakɛcogo min bɛ kɛ ka fɛnw fara ɲɔgɔn kan, o ye mun ye?

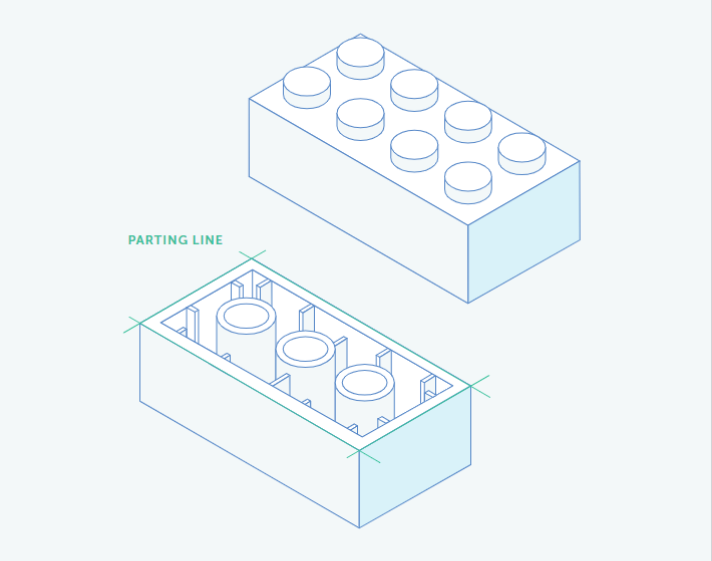

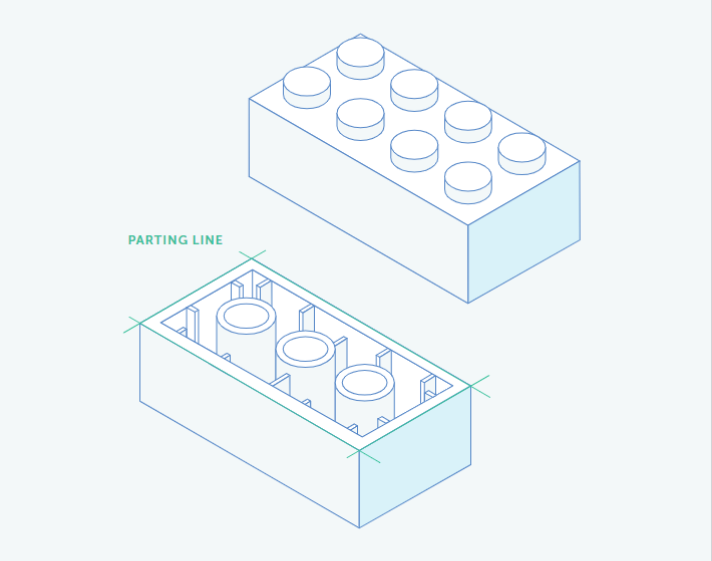

farali sira ye nɔgɔ tilayɔrɔba fila bɛ ɲɔgɔn sɔrɔ yɔrɔ min na. A bɛ ye i n’a fɔ layini finman min bɛ kɛ ni pikirijikɛlanw ye. Nin layini in tɛ se ka bali nka a bɛ se ka dɔgɔya walima ka dogo. A ka c’a la, dilanbagaw b’a bila yɔrɔw la minnu tɛ ye kosɛbɛ.

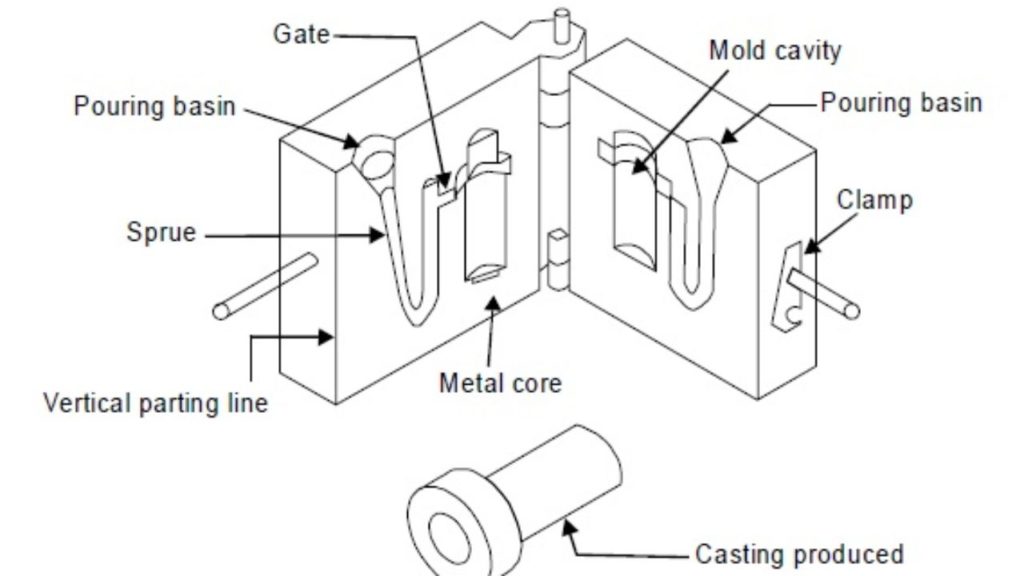

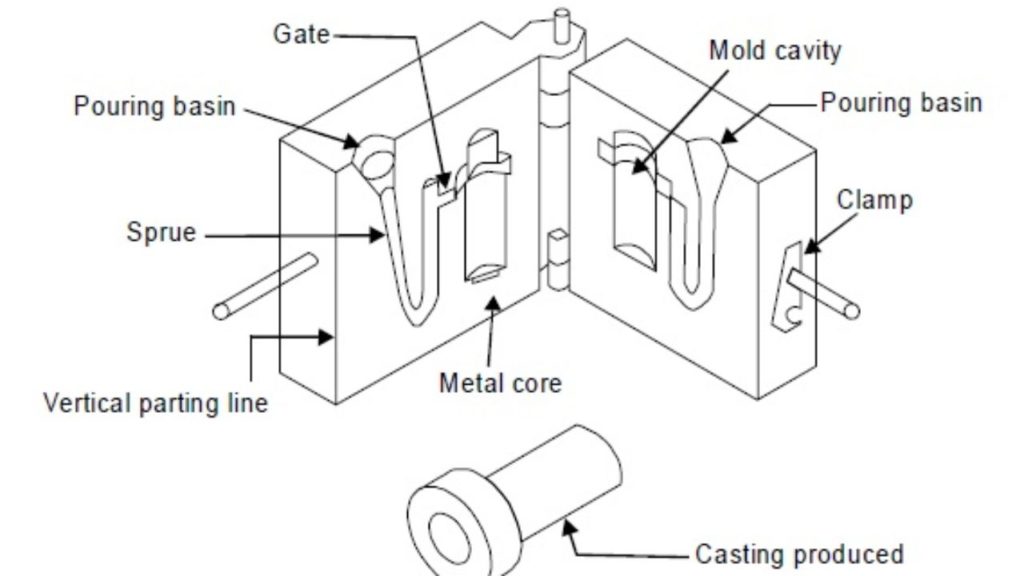

Jɛɲɔgɔnya layiniw bɛ dilan cogo min na .

Walasa k’a faamu ɲɔgɔndan sinsinniw bɛ kɛ cogo min na, an ka kan ka lajɛ kosɛbɛ . pikiri kɛcogo yɛrɛ. A bɛɛ bɛ daminɛ ni mɔni ye, min bɛ kɛ tilayɔrɔba fila ye: a kɔnɔna ni a kɔnɔna.

Moli tilayɔrɔba fila bɛ siri ɲɔgɔn na .

Plastiki wulilen bɛ pikiri kɛ nɔgɔbɔlan kɔnɔ tansiyɔnba jukɔrɔ .

Plastiki bɛ nɛnɛ ani ka gɛlɛya, ka nɔgɔ cogoya ta .

Moli bɛ da wuli, a yɔrɔ dafalen bɛ bɔ .

O baara in senfɛ de la, farali sira bɛ Sɔrɔ. Ni nɔgɔ tilayɔrɔba fila nana ɲɔgɔn fɛ, u bɛ ɲɔgɔn sɔrɔ layini walima awiyɔn kɛrɛnkɛrɛnnen dɔ kan. O bɛ Weele ko farali-yɔrɔ.

Jɛɲɔgɔnya min bɛ tilali layiniw ni nɔgɔw cɛ .

farankan yɔrɔ bɛ dɔn ni mɔli tilayɔrɔbaw dilanni ye. A kɔnɔna ni a kɔnɔna bɛ labɛn ka ɲɛ walasa ka yɔrɔ dafalen cogoya ɲininen dilan.

Nin tilayɔrɔba fila ninnu bɛ ɲɔgɔn sɔrɔ yɔrɔ min na, farali sira bɛ dabɔ. O ye 'fɛn ye min bɛ Kɛ 'sèn na min bɛ Taa yɔrɔ in lamini bɛɛ la.

| Mold tilancɛ | baarakɛcogo . |

| Kìsɛ | A bɛ kɛ kɔnɔnafɛnw ye . |

| cavité . | A bɛ kɛnɛmafɛnw labɛn . |

O farali sira bɛ se ka nɔba bila yɔrɔ dafalen cogoya n’a baarakɛcogo la. O de y’a to a nafa ka bon kosɛbɛ dilanbagaw ni ɛntɛrinɛti injiniyɛriw bolo ka layini bilali jateminɛ koɲuman dilancogo waati la.

farankan suguya minnu bɛ kɛ pikiri kɛli la .

Sisan, an ye farali layini jɔnjɔnw datugu, an ka suguya suguya minnu sɔrɔ pikiri kɛli la, an k’olu sɛgɛsɛgɛ. A suguya kelen-kelen bɛɛ n’a ka jogo ni a ka baarakɛcogo kɛrɛnkɛrɛnnenw don.

Lines verticals .

vertical partiting lines ye suguya ye min ka ca. U bɛ boli ka ɲɛsin nɔgɔ bɛ da wuli ani ka da tugu cogo min na. Aw bɛ to k’u sɔrɔ yɔrɔw kan minnu jateminɛcogo tilennen don, i n’a fɔ tasaw walima minɛnw.

Nafaw ni dɛsɛw

| Nafaw | . |

| A ka nɔgɔn ani a musaka ka dɔgɔ . | A bɛ se ka kɛ yecogo la . |

| A bɛnnen don yɔrɔ caman dilancogo ma . | A bɛ se ka kɛ ka fini wɛrɛw ɲini . |

Beveled Parting Lines .

Beveled partiting lines bɛ ni dakunw ye minnu bɛ ɲɔgɔn kɛrɛfɛ walima minnu bɛ wuli sanni u ka kɛ minnu bɛ tilennen. U bɛ Kɛ ka farali sira yecogo Dɔgɔya ani ka flash formation ( flash formation) Dɔgɔya.

Waati min na ka baara kɛ ni beveled parting lines ye .

Aw bɛ a lajɛ ka baara kɛ ni beveled partiting lines ye tuma min na:

Aesthetics ye ɲɛtaa kunba ye .

Aw ka kan ka flash dɔgɔya .

A yɔrɔ in bɛ ni kunnafoni gɛlɛnw ye farali sira kɛrɛfɛ .

Kurukuruw ka fara ɲɔgɔn kan .

I n’a fɔ a tɔgɔ b’a jira cogo min na, farankan kurulenw bɛ tugu yɔrɔ dɔ ka yɔrɔ kurulenw ka kontoronw kɔ. U ka gɛlɛn ka tɛmɛ farankan tilennenw kan ani u bɛ mɔli kɛrɛnkɛrɛnnenw de wajibiya.

Baarakɛcogo minnu bɛ kɛ ka ɲɛsin farankan kurulenw ma .

Kurukuru kurulenw ka ɲi kosɛbɛ:

Yɔrɔ minnu bɛ ni kurukuruw walima kontoronw ye .

Designs minnu bɛ ɲini ka kɛ cogo la min tɛ fɛn tiɲɛ .

Fɛn minnu bɛ kɛ ni ergonomi ye .

Senna-tɛgɛrɛw .

Senna-tigɛ layiniw bɛ ni nivo caman walima 'steps' ye farankan layini kan. U bɛ kɛ ka yɔrɔw ladon minnu kogo janya tɛ kelen ye walima ka u sirilan fanga balan foroko kan.

Kun minnu b’a jira ko baara bɛ kɛ ni senfɛ-seereya ye .

Aw bɛ se ka senna-tɛgɛrɛw sugandi ni:

A yɔrɔ in bɛ ni fɛn caman ye minnu bɛ ɲɔgɔn falen-falen kogow janya la .

Aw ka kan ka Clamping Force tila ɲɔgɔn na cogo kelen na .

A dilanni bɛ farankan caman de wajibiya .

farankanw bɛɛ lajɛlen .

farankan sinsinniw ye farankanw ye minnu bɛ jɔ, minnu bɛ kɛ ni biɲɛ ye, minnu bɛ kurukuru, ani minnu bɛ senna. U ye suguya ye min ka gɛlɛn kosɛbɛ wa u bɛ kɛ yɔrɔw la minnu ka jateminɛ ka gɛlɛn kosɛbɛ.

Yɔrɔ gɛlɛnw minnu bɛ fara ɲɔgɔn kan ka fara ɲɔgɔn kan .

Yɔrɔ minnu bɛ se ka kɛ sababu ye ka farankanw bɛɛ lajɛlen ɲini, olu misaliw ye:

Mobili kɔnɔfɛnw ni fɛn caman bɛ sɔrɔ .

furakɛli minɛnw ni muɲuli tigitigiw .

Mɔgɔ minnu bɛ fɛnw feere ni u cogoya ni u kunnafoni kunbabaw ye .

Designing ka ɲɛsin farali layiniw ma .

Ni a bɛ tali kɛ pikiri kɛli la, farali layini bilali ye daminɛ dɔrɔn de ye. Walasa ka yɔrɔ ɲumanw sɔrɔ, aw ka kan ka jateminɛ kɛ dilancogo caman na minnu bɛ se ka nɔ bila aw ka fɛn dilannen yecogo n’a kɛcogo la.

Mold design factors .

Aw ka nɔgɔ dilanni jɔyɔrɔ ka bon kosɛbɛ farali siraw sigiyɔrɔ n’u cogoya dɔnni na. Nin ye jateminɛ jɔnjɔn damadɔw ye:

Cavity and Core Alignment: Nɔgɔ tilayɔrɔ fila bɛ ɲɔgɔn sɔrɔ cogo min na, o bɛ se ka nɔ bila farali sira yecogo la. Labɛnni ɲuman nafa ka bon walasa ka flash dɔgɔya ani ka fini saniyalen, min tɛ fɛn tiɲɛ.

Surface Finish: I ka nɔgɔ surfaces texture ani u ka fini bɛ se ka dɛmɛ ka camouflage parting lines. A ka c’a la, fini minnu bɛ kɛ ni sɛbɛnni ye walima minnu bɛ kɛ ni matiriyali ye, olu ka teli ka farankanw jira ka tɛmɛ yɔrɔ nɔgɔlenw kan minnu bɛ yeelen bɔ.

Moli bolicogo: Plastiki wulilen bolicogo nɔgɔ kɔnɔ, o fana bɛ se ka nɔ bila farali sira cogoya la. gate bilali siratigɛ la ani jibɔ simulatigɛ bɛ se ka dɛmɛ don ka fɛnw tilatilali kɛ ka ɲɛ ani ka jibɔ siraw ye minnu bɛ ye.

| Factor | Impact on Parting Lines . |

| cavité ani core alignment . | A bɛ nɔ bila yecogo la ani flash formation . |

| Surface Finish . | bɛ se ka dɛmɛ don ka camouflage parting lines . |

| Moule flow . | A bɛ nɔ bila fɛnw tilatilali ni jibɔ siraw la . |

nɛnɛ ni sɔgɔli hakɛw .

I ka yɔrɔ bɛ nɛnɛ ani ka sabati cogo min na nɔgɔ kɔnɔ, o bɛ se ka nɔba bila a ka ɲumanya n’a ka muɲuli la. Aw ka kan ka min dɔn, o filɛ nin ye:

Nɛnɛ hakɛ: Nɛnɛ tɛ se ka kɛ sababu ye ka kirinni, ka dɔgɔya, ani ka fiɲɛ wɛrɛw sɔrɔ minnu bɛ se ka i yɔrɔ dafalen tiɲɛ. Fɔɲɔ-sɛnɛcogo ɲuman nafa ka bon walasa ka funteni hakɛ basigilen mara nɔgɔ bɛɛ kɔnɔ.

Shearing rate: Ni plastiki wulilen bɛ ka tɛmɛ nɔgɔ fɛ, a bɛ fanga sɔrɔ min bɛ se ka nɔ bila a ka nafaw la. Kɔrɔsili hakɛ caman bɛ se ka kɛ sababu ye ka tiɲɛni ni fanga dɔgɔya, kɛrɛnkɛrɛnnenya la, farali siraw kan. Ni aw bɛ jibɔ hakɛw ni da yɔrɔw labɛn ka ɲɛ, o bɛ se ka dɛmɛ don walasa ka o nɔw dɔgɔya.

Walasa ka nɛnɛ kɛcogo ɲɛ ani ka degunw dɔgɔya aw ka yɔrɔw la, aw bɛ nin fɛɛrɛ ninnu jateminɛ:

Aw bɛ nɛnɛ siraw don aw kɔnɔ minnu bɛ tugu aw ka kontoronw kɔ .

Aw bɛ baara kɛ ni fɛnw ye minnu ka bon i n’a fɔ Beryllium Copper walasa ka don a kɔnɔ ani ka a kɛ a kɔnɔna na .

Aw bɛ kogo janya fɛn caman ɲɔgɔnna caman dɔgɔya walasa ka nɛnɛ sabati hali .

Aw bɛ pikiri teliya ni tansiyɔn ladilan walasa ka sɛgɛsɛgɛli hakɛw kunbɛn .

Ejection processus .

Ni aw yɔrɔ nɛnɛna ani ni a y’a sabati, a ka kan ka bɔ nɔgɔ la. Nin yɔrɔ in de la ejector pins bɛ na baara la. Nka, ni u ma labɛn ka ɲɛ, u bɛ se ka taamasiyɛnw bila walima ka tiɲɛni kɛ u farali sira kan.

Walasa ka ejector pinw nɔfɛkow dɔgɔya aw ka farankan siraw kan, aw ye nin fɛɛrɛ ninnu jateminɛ:

Pin Placement: Aw bɛ ejector pinɛw bila yɔrɔ la min bɛ se ka kɛ walima ka fɛnw kɛ yɔrɔ minnu na ni aw bɛ se. O bɛ se ka dɛmɛ don walasa ka taamasiɲɛ yetaw dɔgɔya ani ka aw ka farali sira dafalen mara.

Pin dilanni: Aw bɛ baara kɛ ni ejector pins ye minnu cɛmancɛ ka dɔgɔn ani yɔrɔ jɛlen, min bɛ sɔgɔ walasa ka tiɲɛni walima flash sɔrɔli farati dɔgɔya. Pin dilanni kɛrɛnkɛrɛnnenw i n’a fɔ blade ejectors walima valve gate pins fana bɛ se ka kɛ ka baara kɛrɛnkɛrɛnnenw kɛ.

Moli bɔli: Aw bɛ mɔni bɔli fɛɛrɛ bɛnnen dɔ kɛ aw ka nɔgɔ la walasa ka a yɔrɔ bɔli nɔgɔya ani ka fanga dɔgɔya min ka kan ka bɔ. O bɛ se ka dɛmɛ don ka degunw dɔgɔya farali sira kan ani ka flash formation bali.

Gɛlɛyaw ni farali siraw .

Hali ni farali layiniw ye pikiri kɛcogo yɔrɔ wajibiyalen ye, u bɛ se ka gɛlɛya kɛrɛnkɛrɛnnen dɔw jira, kɛrɛnkɛrɛnnenya la ni u bɛ yɔrɔ gɛlɛnw ɲɛnabɔ walima ni u b’a ɲini ka fini dafalen sɔrɔ. An ka nin gɛlɛya dɔw lajɛ kosɛbɛ ani u bɛ se ka se sɔrɔ u kan cogo min na.

Ka siginiden gɛlɛnw minɛ .

Designs intricate ni curves, undercuts, walima fɛn caman bɛ se ka kɛ sababu ye ka farankan layini bilali kɛ fɛn ye min tɛ se ka kɛ. Fɛɛrɛ dɔw filɛ nin ye minnu bɛ kɛ ka ɲɛsin cogoya gɛlɛnw ma:

Fɛn caman farali ɲɔgɔn kan: Sani ka farankan tilennen kelen kɛ, i bɛ baara kɛ ni fɛɛrɛ caman ye min bɛ tugu yɔrɔ in ka kontoronw kɔ. O bɛ se ka dɛmɛ don walasa ka farali sira yecogo ɲɛnayeli dɔgɔya ani ka a to a ka kɛ cogo bɛnnen na.

Kɛrɛfɛ walew : Side actions walima sliding cores don moule design kɔnɔ walasa ka jukɔrɔla tigɛ walima ka fɛnw dilan minnu tɛ se ka kɛ ni moule nɔgɔman ye min bɛ kɛ yɔrɔ fila ye. Nin nɔgɔ yɔrɔ wɛrɛw bɛ se ka dɛmɛ don ka farankan sira saniyalenw, tigitigiw dilan yɔrɔ gɛlɛnw na.

3D sɛbɛnnenw doncogo: Walasa ka jateminɛ kɛ kɛrɛnkɛrɛnnenya la jateminɛ na, aw bɛ a lajɛ ka baara kɛ ni 3D sɛbɛnnenw ye walima kɔnɔna minnu bɛ se ka ɲɔgɔn falen nɔgɔya la walima ka fɛn wɛrɛw bila u nɔ na. O bɛ se ka kɛ sababu ye ka dilancogo caman kɛ ani ka sira di ka farankanw ɲɛfɔ cogo tigitigi la.

| fɛɛrɛ | nafa . |

| Fɛn caman farali ɲɔgɔn kan . | A bɛ tugu contours kɔ, a bɛ fɛn yetaw dɔgɔyali dɔgɔya . |

| Kɛrɛfɛ walew . | A bɛ fɛnw da minnu bɛ kɛ ka fɛnw tiɲɛ ani fɛn gɛlɛnw . |

| 3D sɛbɛnw donna . | A bɛ dilancogo sɛgɛsɛgɛli ni a tiɲɛni di . |

I mana fɛɛrɛ min sugandi, o mana kɛ fɛn o fɛn ye, o ye fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye. Hali ni ɲɔgɔndɛmɛn dɔɔni bɛ se ka kɛ sababu ye ka farankanw, flash walima fiɲɛ wɛrɛw ye minnu bɛ ye.

Walasa ka a lajɛ ka ɲɛ, aw bɛ nin wale ninnu jateminɛ:

Baara kɛ ni guide pins ni bushings ye walasa ka ɲɔgɔndɛmɛ tigitigi mara nɔgɔ tilayɔrɔw ni ɲɔgɔn cɛ .

Aw bɛ interlocks walima alignment features don moule design kɔnɔ .

Aw bɛ to ka nɔgɔ yɔrɔw lajɛ ani ka u mara walasa u kana sɛgɛn ani ka u kɛ cogo bɛnbali la .

Flash balili .

Flash, walima fɛn tɛmɛnen minnu bɛ dilan farankan sira kan, o ye gɛlɛya ye min bɛ sɔrɔ pikiri kɛli la. A tɛ dɔ bɔ a yɔrɔ cogoya dɔrɔn na, nka a bɛ se ka fitinin ni baarakɛcogo fana bali. O la, mun bɛ flash bila mɔgɔ la, ani i bɛ se k’a bali cogo di?

Flash formation sababuw ye:

Mold alignment walima a doncogo jugu .

Fanga min bɛ se ka kɛ fɛn ye min tɛ se ka kɛ .

Pikiri tansiyɔn walima a teliya kojugu .

Venting walima nɛnɛ tɛ se ka kɛ .

Walasa ka Flash dɔgɔya ani ka a bɔ, aw bɛ nin fɛɛrɛ ninnu lajɛ:

Nɔgɔ ladonni: Aw bɛ to ka aw ka nɔgɔw lajɛ ani ka u ladon walasa u ka se ka u labɛn ka ɲɛ ani ka u bali ka sɛgɛn. Aw bɛ a yɔrɔw falen ni aw mago bɛ a la ani ka yɔrɔw saniya ani ka u to u kana kɛ nɔgɔ ye.

Process Optimization: Aw bɛ pikirijikɛlan tansiyɔn, teliya ani baarakɛcogo wɛrɛw ladilan walasa ka flash formation dɔgɔya. Baara kɛ ni simulatigɛ porogaramuw ye walasa ka gɛlɛya yɔrɔw dɔn minnu bɛ se ka kɛ ani ka i ka baara kɛcogo ɲɛ ka kɛɲɛ ni o ye.

Flash Traps: Aw bɛ flash traps walima overflow kɔlɔnw don aw ka nɔgɔ dilanni na walasa ka fɛn tɛmɛnenw minɛ ani ka a bali ka jɛnsɛn ka kɛɲɛ ni farali sira ye. O fɛnw bɛ se ka dɛmɛ don ka flash kunbɛn ani ka a bɔli nɔgɔya a kɔfɛ.

Baara filananw : Ni flash kɛra, a ka ca a la a bɛ se ka bɔ baara filananw fɛ i n’a fɔ sɔgɔli, sɔgɔli, walima jiginni. Cryogenic deflashing, min bɛ baara kɛ ni nɛnɛba ye walasa ka flash in bɔ a la, o fana bɛ se ka kɛ nafama ye fɛn dɔw la.

Fɛɛrɛ minnu bɛ kɛ walasa ka dɔ bɔ farali siraw yecogo la .

Hali ni farali layiniw ye pikiri kɛcogo ye min tɛ se ka bali, u man kan ka kɛ ɲɛnayeli yelen ye. Fɛɛrɛ caman bɛ yen aw bɛ se ka minnu kɛ walasa ka u yecogo dɔgɔya ani ka fɛn dilannen dɔ dilan min tɛ fɛn tiɲɛ.

texture de surface camouflagage .

Fɛɛrɛ ɲuman dɔ min bɛ se ka kɛ sababu ye ka farankanw dogo, o ye ka baara kɛ ni surface textures ye minnu bɛ dɛmɛ ka layini yelen tɛmɛsira tiɲɛ. A bɛ baara kɛ cogo min na, o filɛ nin ye:

Texture Selection: Aw bɛ sɛbɛnni dɔ sugandi min bɛ aw ka yɔrɔ dilanni n’a baara dafa. Options bɛ daminɛ ni finiw ye minnu bɛ kɛ ni matte ye ka taa a bila fɛnw na minnu bɛ kɛ ni fɛnw ye minnu bɛ mɔgɔ bila ka wuli i n’a fɔ stipples walima grooves.

Mold texturing: A sɛbɛncogo sugandilen bɛ kɛ ka ɲɛsin mɔli sanfɛla ma, a bɛ kɛ ni etching ye, ni ja ye, walima ni fɛɛrɛ wɛrɛw ye. Ni plastiki wulilen ye mɔni fa, a bɛ kɛ ka mɔni kɛyɔrɔ cogoya ta.

Parting Line Placement: Partiction de la line de la line texturé dans le texture texture bɛ se ka dɛmɛ ka a yecogo sɛmɛntiya ka taa a fɛ. A kɛcogo bɛ dɛmɛ ka layini tiɲɛ ani ka a kɛ a tɛ kɔlɔsi kosɛbɛ.

Misaliw bɛ sɔrɔ texture applications effectives la:

texture cuir sur la parts intérieur automobile .

Brushed metal fini kan elekitoroniki so .

texture woodrain sur les components meubles .

| texture | application . |

| Suman min bɛ kɛ ni jiri ye . | Motomotive Interiors . |

| burusi nɛgɛma . | Elektronikiw ka so . |

| jiriforo . | Meubles components . |

Fɛɛrɛ filananw .

Hali ni a dilanni ni a mɔcogo ɲuman bɛ se ka kɛ, a bɛ se ka kɛ ko farankan dɔw bɛ ye walima ko a bɛ se ka kɛ ni fini wɛrɛw ye. O yɔrɔ de la, baarakɛcogo filananw bɛ na. sugandi damadɔw filɛ nin ye:

Yɛrɛyɛrɛli: Yɔrɔw bɛ bila tumbler kɔnɔ ni media abrasive ye ani ka yɛrɛyɛrɛ waati latigɛlen kɔnɔ. Abrasif wale bɛ dɛmɛ ka farankan siraw ni surface dafabaliya wɛrɛw nɔgɔya.

Deflashing cryogénique : A yɔrɔw bɛ kɛ funteni jugumanba la, a ka ca a la, a bɛ kɛ ni azote jilama ye. O bɛ kɛ sababu ye ka flash walima tɛmɛnen fɛn o fɛn kɛ farankan sira kan, o bɛ tiɲɛ ani ka bɔ nɔgɔya la.

Bolo tigɛcogo: Walasa ka boli misɛnniw walima yɔrɔ nɔgɔlenw, bolo tigɛ ni nɛgɛ walima sizo ye min ka nɔgɔn, o bɛ se ka kɛ sababu ye ka farankan bɔli daminɛ. O fɛɛrɛ in bɛ sira Di ka ɲɛ kosɛbɛ ani ka kɔrɔsi.

Media blasting: Yɔrɔw bɛ bɔn ni kunnafonidilanw ye minnu bɛ kɛ ka fɛnw sɔgɔ, i n’a fɔ cɛncɛn, gilasi biɲɛw, walima plastiki bɔgɔlanw. O bɛ dɛmɛ ka farankanw nɔgɔya ani ka surface finish (yɔrɔ min bɛ kɛ ka ɲɛ) di.

Segin-ka-bɔnye fɛɛrɛ sugandili bɛ bɔ fɛn caman na, i n’a fɔ:

Materiel suguya ani a muɲuni .

Yɔrɔ jateminɛ ni a gɛlɛya .

Surface Finish wajibiyalenw .

A dilanni hakɛ ani a musaka gɛlɛyaw .

Kuncɛli

Nin barokun in kɔnɔ, an ye ɲɔgɔndanw jɔyɔrɔba sɛgɛsɛgɛ pikiri kɛli la. Ka bɔ u ye fɛn minnu ye ani u bɛ dilan cogo min na walasa ka suguya ni dilancogo jateminɛ suguya caman sɛgɛsɛgɛ.

Ni aw ye danfaralanw jateminɛ u dilanni daminɛ na ani ka baara kɛ ɲɔgɔn fɛ ni aw ka pikiri kɛcogo jɛɲɔgɔn ye, aw bɛ se ka yɔrɔ ɲumanw dilan minnu bɛ aw ka baarakɛcogo n’aw ka ɲɛnajɛko wajibiyalenw dafa.

Aw mago bɛ dɛmɛ na ni pikiri kɛli ye ani ka fara ɲɔgɔn kan? Team MFG ka injiniyɛri ŋanaw labɛnnen don ka dɛmɛ don. An bɛ baara bɛɛ lajɛlen kɛ, k’a ta dilancogo ɲuman na ka se a dilanni n’a dilanni ma. Aw ye anw sɔrɔ bi walasa ka ladilikan sɔrɔ fu. A to Team MFG ka na ni i ka yeli ye ɲɛnamaya la!