Insay di wɔl fɔ plastic prodakshɔn, dizayn fɔ manufakchurin (DFM) fɔ injɛkshɔn moldin stand dɛn as kɔna ston fɔ efyushɔn ɛn kwaliti. Dis kɔmprɛhɛnsif gayd de go insay di intrikas dɛm fɔ DFM, we de gi insayt fɔ in prinsipul dɛm, prɔses dɛm, ɛn di bɛst we fɔ du tin.

Introdyushɔn to Dizayn fɔ Manufakchurabiliti (DFM)

Wetin na DFM?

Disain fɔ Manufakchurabiliti (DFM) na di prɔses fɔ disayn prɔdak fɔ ajɔst di bɛst pɔsibul manufakchurin autkam. I involv fɔ tink bɔt difrɛn tin dɛn we de inflɔws manufakchurin di tɛm we dɛn de disayn di faz.

DFM de mek kɔmni dɛn ebul fɔ no ɛn adrɛs di prɔblɛm dɛn we kin apin kwik kwik wan. Dis kin ɛp fɔ mek di chenj dɛn we kin tek bɔku mɔni nɔ bɔku leta na di prodakshɔn prɔses.

Impɔtant DFM na Manufakchurin .

Implimentin DFM prinsipul dɛn de gi sɔm bɛnifit dɛn:

Kost sevings : Bay we dɛn de adrɛs di manufakchurabiliti kɔnsyans dɛn we dɛn de du dizayn, kɔmni dɛn kin ridyus di ɔl prodakshɔn kɔst. DFM de ɛp fɔ avɔyd dia dia modifyeshɔn dɛn dɔŋ di layn.

Improved quality : Disain wit manufakchurin in maynd de lid to ay kwaliti prodak. I de mek di prɔblɛm dɛn nɔ bɔku ɛn i de mek shɔ se di rizɔlt dɛn nɔ de chenj ɔltɛm.

Faster time-to-market : DFM de strimlayn di transishɔn frɔm dizayn to prodakshɔn. Dis kin mek kɔmni dɛn ebul fɔ briŋ prɔdak dɛn fɔ mek dɛn go na makit kwik kwik wan.

Enhanced Collaboration : DFM de promot kolaboreshɔn bitwin dizayn ɛn manufakchurin tim dɛn. I de fos wan shered ɔndastandin fɔ gol ɛn kɔnstrakshɔn.

DFM de aplikebul akɔdin to difrɛn industri dɛm, lɛk:

We dɛn ebul fɔ tek DFM, di kɔmni dɛn we de na dɛn sɛktɔ dɛn ya kin ebul fɔ mek dɛn wok fayn fayn wan. Dɛn kin gi ay kwaliti prɔdak dɛn we dɛn nɔ spɛn bɔku mɔni.

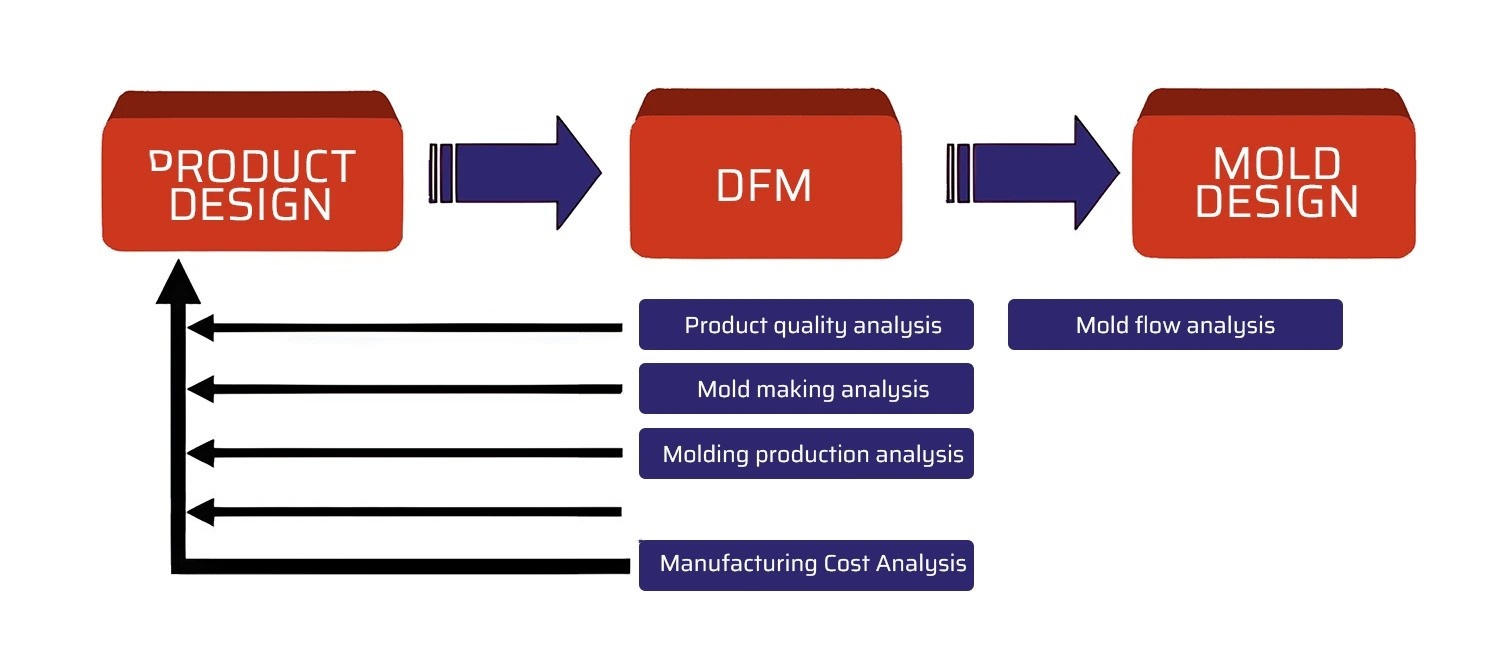

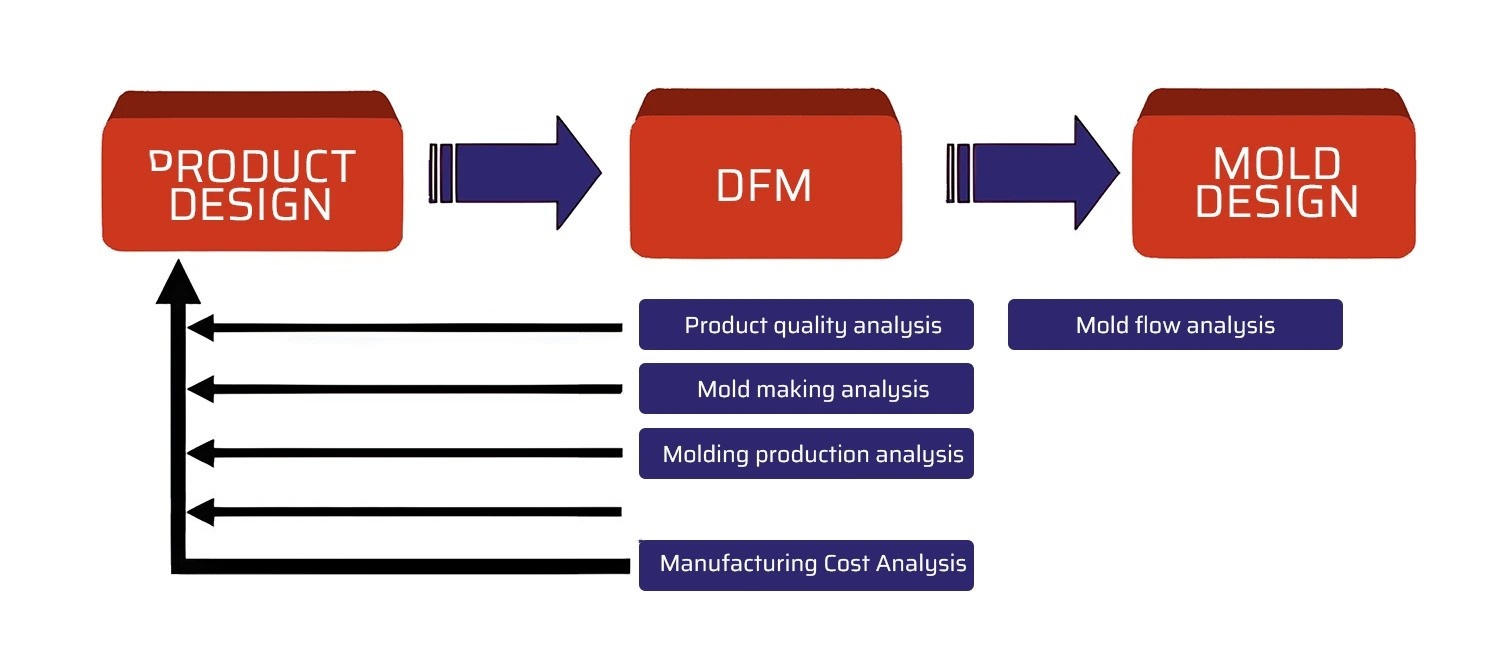

Faz dɛn fɔ di DFM prɔses .

Di dizayn fɔ manufakchurabiliti (DFM) prɔses insay plastic injɛkshɔn moldin involv sɔm ki faz dɛn. Dɛn step ya de mek shɔ se di prɔdak dɛn de ɔptimayz fɔ mek frɔm di biginin.

DFM analisis step .

Faz 1: Analysis of Plans and Concerns .

Di fɔs pat pan DFM bigin wit di ɔrijinal ikwipmɛnt manifakta (OEM) we de gi ditayl prɔjek plan ɛn dɔkyumentri to di kɔntrakt manifakta (CM). Dis inklud ɔl di infɔmeshɔn we gɛt fɔ du wit di prɔdak ɛn di we aw dɛn want am fɔ yuz am.

Dɔn di CM de rivyu dɛn matirial dɛn ya fɔ no ɛni prɔblɛm we go apin we dɛn go ebul fɔ mek di tin dɛn we dɛn want fɔ du. Dɛn kin tink bɔt tin dɛn lɛk Pat jɔyometri ., Material Selection , ɛn . Tolerances ..

Opin kɔmyunikeshɔn bitwin di OEM ɛn CM na impɔtant tin na dis stej. I de ɛp fɔ adrɛs di tin dɛn we de mɔna pipul dɛn kwik kwik wan.

Faz 2: DFM simulshɔn .

Insay di sɛkɔn pat, injinia dɛn de yuz advans mold flɔ simulshɔn softwe lɛk Sigmasoft fɔ analayz di injɛkshɔn moldin prɔses. Dɛn simulshɔn ya de gi valyu insayt dɛn fɔ no aw di matirial go biev we dɛn de mol.

Ki aspek dɛm we dɛn evalyu insay DFM simulshɔn dɛn inklud:

Bay we dɛn de rɔn dɛn simulshɔn ya, injinia dɛn kin prɛdikt ɛn protɛkt pɔtɛnɛshɔn . Di tin dɛn we nɔ fayn . Dɛn kin optimize di dizayn fɔ di bɛst pɔsibul manufakchurin autkam.

Faz 3: Prɛzɛnteshɔn fɔ di rizɔlt ɛn rɛkɛmɔndeshɔn dɛn .

Afta dɛn dɔn kɔmplit di simulshɔn dɛn, di CM kɔmpilayt wan ditayl ripɔt bɔt di rizɔlt dɛn. Dis ripɔt inklud spɛshal rɛkɛmɔndeshɔn fɔ adrɛs ɛni kwɛstyɔn we dɛn dɔn no di tɛm we dɛn de du di analisis.

Di DFM ripɔt tipikli kɔba:

Material Selection ɛn Mold Kɔndishɔn dɛn .

Di paramita dɛn we dɛn dɔn tɛst lɛk injɛkshɔn tɛmpracha, prɛshɔn, ɛn get saiz .

Komparetiv rizulyt fɔ difrɛn dizayn vayriɔnt dɛn .

Sajeshɔn fɔ protɔtayp ɛn tɛst .

Di CM prɛzɛnt dɛn fayndin ya to di OEM, wit dɛn prɔpɔz sɔlvishɔn dɛn. Dɛn de wok togɛda fɔ rifin di dizayn fɔ optimal manufacturability.

Faz 4: Protɔtayp, tɛst, ɛn kɔmplit

In di fainal faz fכ DFM, di fכkus shift fכ validet di optimized dizain tru fyzikal prototypes. 3D printin ɛn aditiv manufakchurin tɛknik dɛn kin yuz bɔku tɛm fɔ mek dɛn protɔtayp dɛn ya kwik kwik wan.

Di protɔtayp dɛn de du mɔ tɛst ɛn simulshɔn fɔ mek shɔ se dɛn mit ɔl di tin dɛn we dɛn nid. Ɛni ajɔstmɛnt we nid de, dɛn kin mek bay we dɛn yuz dɛn rizɔlt ya.

Wans dɛn dɔn dɔn di dizayn ɛn dɛn dɔn gri fɔ am, i kin muf go na ful-skel prodakshɔn. Di DFM prɔses de ɛp fɔ mek shɔ se wan smol transishɔn frɔm . Dizayn to Manufakchurin ..

Ki kɔnsidareshɔn dɛn na DFM fɔ injɛkshɔn moldin .

We dɛn de yuz dizayn fɔ manufakchurabiliti (DFM) prinsipul dɛn to plastic injɛkshɔn moldin, dɛn fɔ tink bɔt sɔm impɔtant tin dɛn. Dɛn tin ya na fɔ pik di tin dɛn we dɛn gɛt, fɔ mek di wɔl tik, fɔ mek di mold flɔ, fɔ mek di draft angul dɛn, fɔ shrink, ɛn fɔ ɔnda-kɔt.

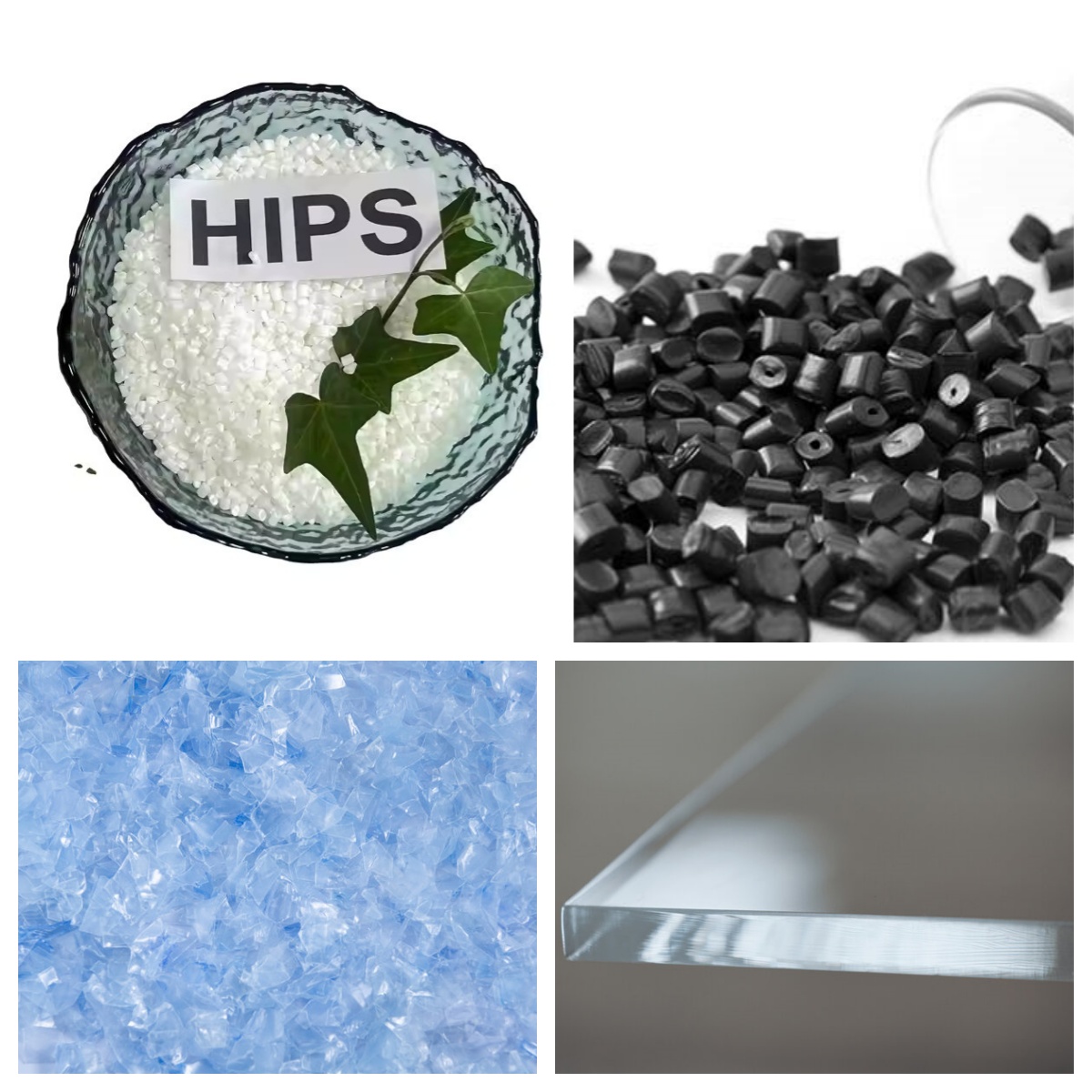

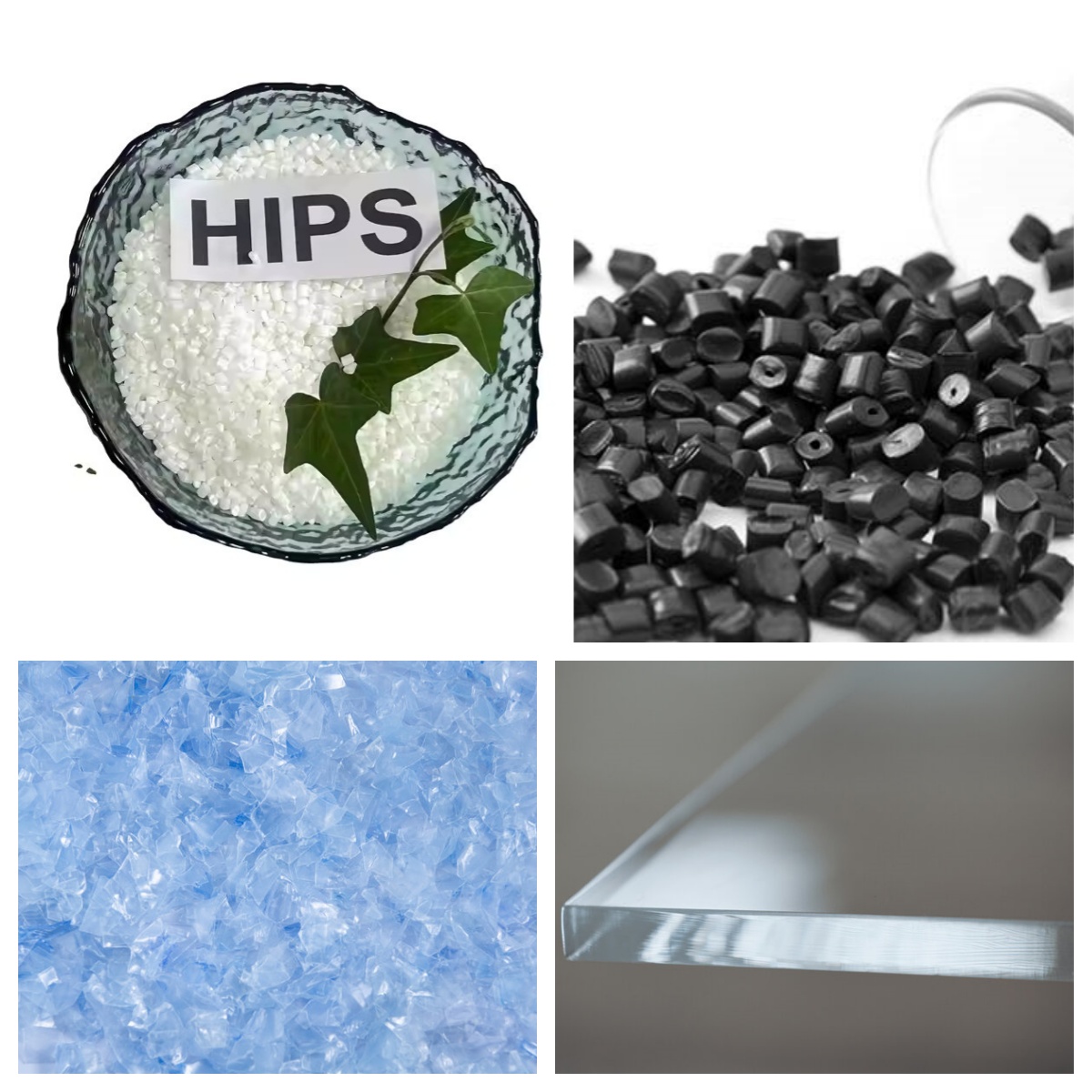

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Fɔ pik di rayt tin na impɔtant tin fɔ mek dɛn ebul fɔ mek di injɛkshɔn moldin fayn fayn wan. Dɛn kin yuz bɔku plastic dɛn, ɛn ɛni wan pan dɛn kin gi difrɛn prɔpati dɛn we kin afɛkt di we aw dɛn mek di dizayn.

Sɔm pan di tin dɛn we dɛn kin yuz mɔ na:

Ɛni matirial gɛt spɛshal prɔpati dɛn we de afɛkt aw i de biev we dɛn de mol. Fɔ ɛgzampul, naylon shrink mɔ pas PC , ɛn ABS nid fɔ gɛt lɔwa moldin tɛmpracha. Fɔ ɔndastand dɛn prɔpati ya rili impɔtant fɔ pik di tin dɛn we dɛn nid fɔ du we go mit ɔl tu di dizayn ɛn di tin dɛn we dɛn nid fɔ mek. Fɔ wan kɔmprɛhɛnsif gayd bɔt matirial sɛlɛkshɔn, chɛk ɔut Wetin dɛn kin yuz fɔ mek injɛkshɔn moldin ..

Tiknes optimizayshɔn fɔ di wɔl .

Optimizing wall tiknes de mek shɔ se pat dɛn kin kol ivin ɛn avɔyd difrɛn tin dɛn lɛk sink mak ɔ voyd . Dizayna dɛn fɔ fala di rɛkɔmɛnd wɔl tiknes gaydlayn fɔ difrɛn plastic dɛn.

| Di tik we dɛn kin yuz fɔ mek di tin dɛn | we dɛn dɔn rɛkɔmɛnd . |

| ABS na ABS | 1,5 to 4,5 mm |

| Polipropilen (PP) . | 0,8 to 3,8 mm |

| Naylon . | 2,0 to 3,0 mm |

| Polikarbonɛt (PC) . | 2,5 to 4,0 mm |

Yunifɔm wɔl tiknɛs na impɔtant tin fɔ avɔyd strɛs pɔynt dɛn. Insay kes dɛn we dɛn nid tin wɔl dɛn, tin-wɔl mol tɛknik dɛn. dɛn kin yuz Dis mεtכd de alaw fכ ridyus di wet we yu de mεnten pat trεnk.

Disain fɔ di rayt mold flɔ .

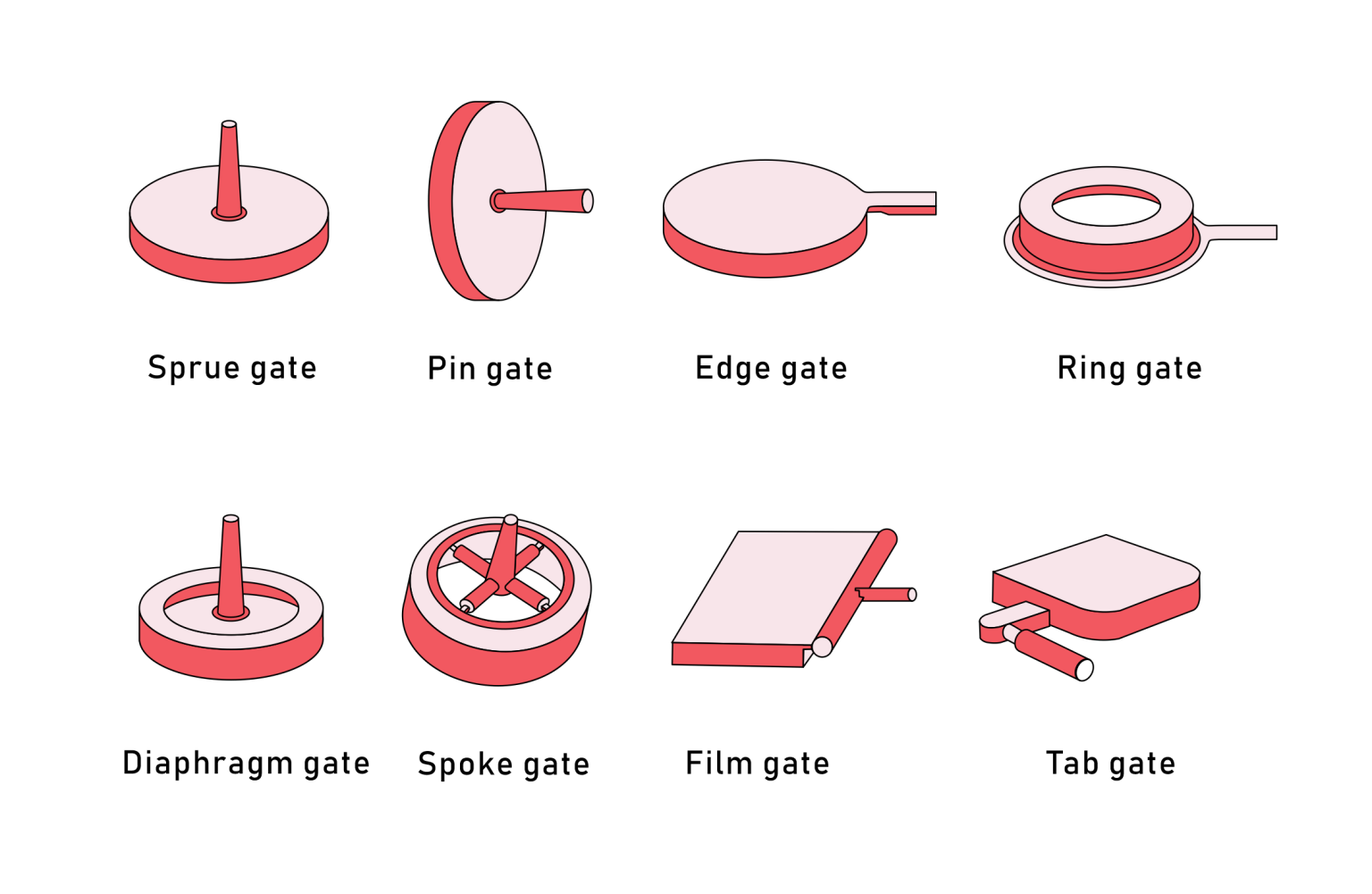

Fɔ mek shɔ se gud mold flɔ na ɔda impɔtant tin bɔt DFM. Prɔpa get ɛn rɔna sistɛm dizayn de ambɔg aw di plastic we dɔn rɔtin de ful di mol.

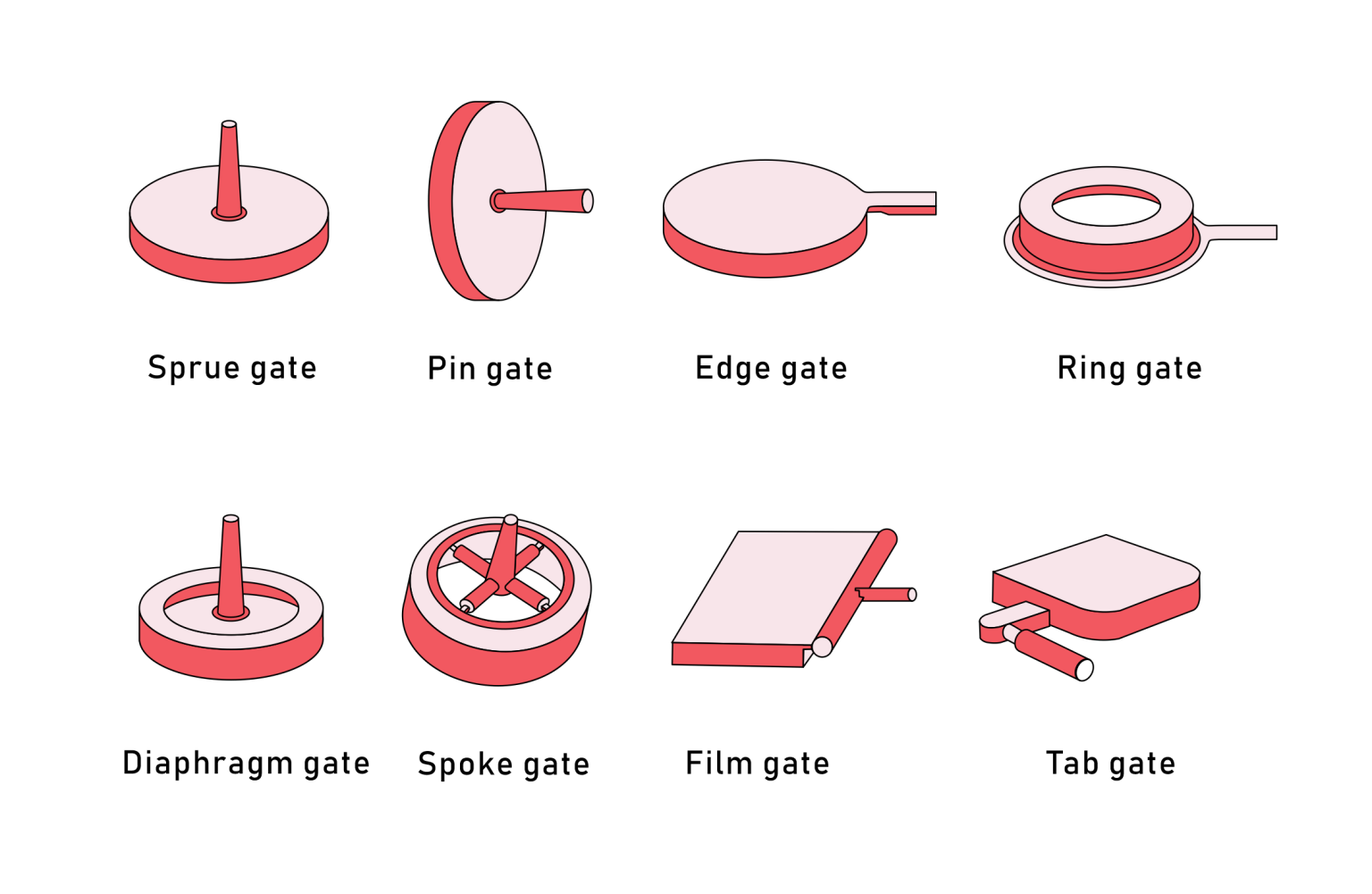

Get Tayp : Pik bitwin Edge Gates , Fan Gates , ɔ dairekt get dɛn bays pan pat jɔyometri ɛn matirial flɔ. Tayps of gets fo injekshon moldin .

Runner Systems : Yuz balans rana sistem fɔ mek shɔ se ivin distribyushɔn fɔ matirial.

Mold Cooling : Effective cooling de ɛp fɔ mek dimɛnshɔnal stebiliti kɔntinyu fɔ de ɛn i de mek wɔ nɔ de.

Dɛn fɔ mek di chanɛl dɛn we de mek di ples kol fayn fayn wan fɔ mek shɔ se dɛn ebul fɔ sheb ivin di tɛmpracha ɔlsay na di mol.

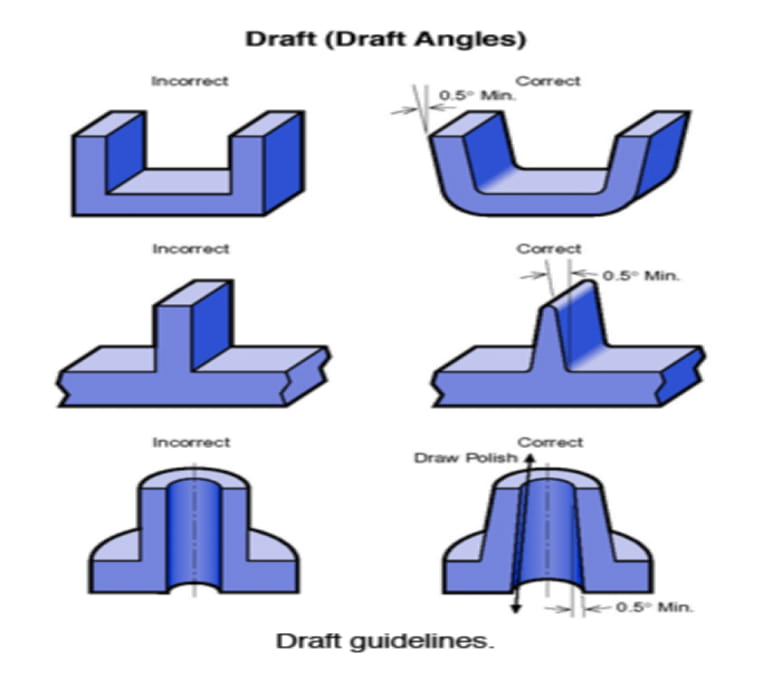

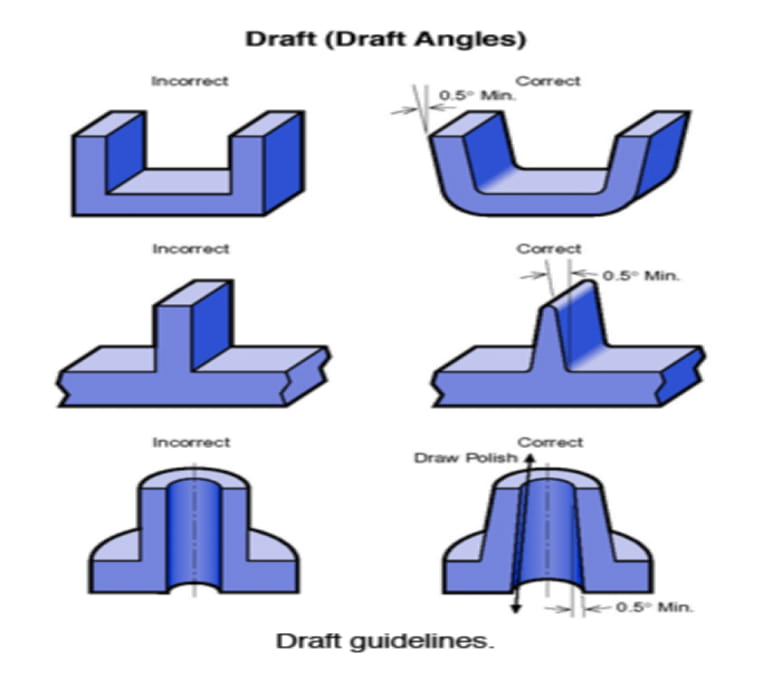

Draft angles ɛn sɔfays finish .

Draft angles na impɔtant tin fɔ mek di pat we de kɔmɔt na di mold kɔmɔt fayn fayn wan. If yu nɔ gɛt di rayt angul, di pat dɛn kin stik to di mol, ɛn dis kin mek yu pwɛl ɔ yu nɔ gɛt ɛni bad tin. Fɔ no mɔ, luk wi gayd bɔt Draft angle in injekshɔn moldin ..

Di draft angul dɛn we dɛn kin advays kin difrɛn bay di matirial ɛn di sɔfays tɛkstɔr. Fɔ mek di say dɛn we smɔl, yuz di minimum 0.5° to 1° . Fɔ di say dɛn we dɛn mek di tɛkstɔr, mek dis go ɔp to 3° to 5° fɔ mek dɛn nɔ skɔf ɔ fɔ stɔp.

Shrinkage ɛn wɔpej prɛvɛnshɔn .

Shrinkage ɛn wɔpej na kɔmɔn tin dɛn we de insay injɛkshɔn moldin. Disain fɔ yunifom shrinkage akɔdin to di pat de ridyus di chans fɔ mek dɛn prɔblɛm ya. tik eria dɛn kin shrink mɔ pas di wan dɛn we tan, so fɔ mek di wɔl tik na di sem we na di men tin. Lan mɔ bɔt dis . Warping in injekshɔn moldin .

Prɔpa ribbing ɛn gusseting kin bak minimiz wɔpej bay we dɛn de riinfɔs ay-stress eria ɛn distribyushɔn fɔs mɔ ivin.

ɔnda-kɔt ɛn sayd-akshɔn dɛn .

Ɔndakat ad kɔmplisiti to di mold dizayn ɛn i kin kɔmplikt pat ɛjekshɔn. Ɛnitɛm we i pɔsibul, pul ɔnda-kat bay we yu ajɔst di pat jɔyometri. If dɛn nɔ ebul fɔ avɔyd ɔnda-kɔt, sayd-akshɔn ɛn split kɔr fɔ mol kɔmpleks ficha dɛn. dɛn kin yuz Fɔ no mɔ bɔt aw fɔ dil wit ɔnda-kɔt, chɛk wi gayd pan Ways fɔ ajɔst injɛkshɔn moldin ɔndakat dɛn ..

sayd-akshכn dεm de alaw fכ izi fכ pul pat bay we dεn de shift pat dεm na di mold laterally bifo dεn kכl dεm, avכyd di nid fכ komplεks tul dεm.

Tuling kɔnsidareshɔn ɛn dɛn impak pan DFM .

Tooling de ple wan impɔtant pat pan manufakchurabiliti. Prɔses lɛk ilɛktrɔd mashin ɛn polishing de inflɔws pat kwaliti ɛn prɛsishɔn. Ha-kwaliti tul de mek yu gɛt mɔ kɔnsistɛns pat dɛn, bɛtɛ sɔfays finish, ɛn ridyus saykl tɛm.

Polishing de afɛkt di las pat in finish. Wan mold we dɛn dɔn polish bad bad wan kin mek say dɛn we gɛt glos, ɛn di mold dɛn we dɛn mek wit tɛkstɔr kin gi mat finish. We yu tink bɔt dɛn tin ya di tɛm we dɛn de disayn di dizayn faz, dat de mek shɔ se dɛn yuz di rayt tul prɔses.

Fɔ no mɔ bɔt di we aw dɛn de du injɛkshɔn fɔ mold ɛn aw fɔ tink bɔt, go na wi kɔmprɛhɛnsif gayd bɔt Wetin na injɛkshɔn moldin prɔses ..

Checklist fɔ DFM insay plastic injɛkshɔn moldin

| dfm chɛklist aytem | diskripshɔn |

| Maksimal prɛshɔn: filin . | Evaluate di prɛshɔn we dɛn nid fɔ ful-ɔp di mol. |

| Maksimal prɛshɔn: pak . | Asɛs di prɛshɔn we dɛn yuz di tɛm we dɛn de pak di stej fɔ mek shɔ se di matirial kɔnsistɛns. |

| Fil patɛn animɛshɔn . | Imajin aw di plastic we dɔn rɔtin de flɔ insay di mol. |

| Inlet prɛshɔn kɔv . | Monitor prɛshɔn na di matirial inlet fɔ mek shɔ se i flɔ fayn fayn wan. |

| Klamp Fos Ɛstimat . | Ɛstimat di fɔs we dɛn nid fɔ mek dɛn lɔk di mol we dɛn de injɛkshɔn. |

| Tempracha chenj we yu de fil . | Chek fɔ di tɛmpracha we de chenj we yu de fil fɔ fil fɔ avɔyd difrɛn difrɛn tin dɛn we nɔ fayn. |

| Frɔzɛn skin rizɔlt dɛn . | Analayz di ɔta layt fɔ di plastic we de solidify we yu de kol. |

| Shearing ret fɔ di rɛsin . | Mekɔp di rɛsin in shia rit fɔ evaluate flɔ prɔpati dɛn. |

| Flow Tracer animashɔn . | Trak di flɔ frɔnt fɔ di plastic we dɔn rɔtin fɔ no di prɔblɛm dɛn. |

| Trap dɛn we de na di ays . | fɔ no di say dɛn we di briz kin trɔp ɛn mek di ples nɔ gɛt natin ɔ di pat dɛn we nɔ kɔmplit. |

| Tempracha we de kɔmɔt na di briz . | Mek shɔ se dɛn gɛt fayn vent fɔ mek di tɛmpracha kɔntinyu fɔ de ɔlsay na di mol. |

| Weld layn dɛn . | Identify eria usay tu flɔ frɔnt mit, pɔtɛnɛshɛl kɔz wik spat. |

| Weld layn traysa animashɔn . | visualize weld line fomeshɔn fɔ prɛdikt usay matirial kin wik. |

| PVT chart analysis of weld lines . | Yuz di PVT chart fɔ asɛs di matirial in bihayvya na spɛshal kɔling stej dɛn. |

| Material Solidification During Part Cooling . | Monitor solidification fɔ mek yu nɔ gɛt kol kol ɛn pat dɛfekt. |

| Sink Maks dɛn . | Evaluate surface dipreshɔn dɛm wae kin kam wae pɔrsin nɔr de kol ɔr tik pasmak. |

| Hot Spots . | Identify eria dɛm na di pat wae kin gɛt ɔva ɔt wae dɛn de injekt. |

| VOIDS . | Ditekt intanɛnt ɛya poket dɛn we kin afɛkt pat trɛnk. |

| tik tik eria dɛn na di pat . | Chek fɔ si if i tik pasmak we kin mek yu gɛt sink mak ɔ voyd. |

| Tin eria dɛn na di pat . | Mek shɔ se di tin dɛn we de na di tin dɛn we dɔn pas, ful-ɔp fayn fayn wan fɔ mek dɛn nɔ gɛt pat dɛn we nɔ kɔmplit. |

| Yunifom fɔ mek di wɔl tik . | Disain fɔ ivin tik tik fɔ ridyus difɛkt lɛk sink mak ɛn wɔpej. |

| Material Flɔ Karakta dɛn . | Mek shɔ se di rɛsin we dɛn dɔn pik de flɔ fayn fayn wan ɛn dɛn kin ebul fɔ handel lɔng ɔ tin flɔ lɔng dɛn. |

| Di say we di get de . | Optimize di get lokeshɔn fɔ mek dɛn nɔ friz di get bifo tɛm ɛn di sink mak dɛn. |

| Bɔku bɔku get dɛn we dɛn nid fɔ gɛt . | Yuz bɔku bɔku get dɛn if nid de fɔ mek shɔ se dɛn ful-ɔp di kɔmpleks jɔyometri dɛn fayn fayn wan. |

| Gate impingement pan stɛl . | Mek shɔ se plastic de flɔ fayn fayn wan pan stɛl sɔfays fɔ mek i nɔ splay. |

| Pat Draft Angle . | Mek shɔ se dɛn gɛt adekwayt draft angul fɔ alaw fɔ izi pat ɛjekshɔn. |

| Tekstura rilis we nɔ gɛt skɔf . | Mek shɔ se draft na infεkt fɔ rilis tɛkstɔr pat dɛn we nɔ gɛt damej. |

| Tin stɛl kɔndishɔn dɛn na di tul . | Evaluate pat jɔyometri fɔ sɛkshɔn dɛn we kin mek tint stɛl kɔndishɔn. |

| Di simpul we aw dɛn kɔt am fɔ mek i izi fɔ ɔndastand . | Tink bɔt dizayn chenj dɛn fɔ pul ɔ simpul ɔnda-kat. |

| kristalizashɔn . | Chek fɔ ɛni kristalizashɔn ishu na di matirial we kin afɛkt pat kwaliti. |

| Fayba oriɛnteshɔn . | Asɛs aw fayba ɔriɛnteshɔn kin impɔk pat trɛnk ɛn pefɔmɛns. |

| Shrinkage na na na na na na na na na na na na na na na na na na | Evaluate di shrinkage bihayvya fɔ di matirial fɔ ridyus dimɛnshɔnal vɛryushɔn. |

| Warpage na di . | Asɛs di pɔtnɛshɛl fɔ wɔp ɛn aw fɔ mitigate am wit dizayn ajɔstmɛnt. |

Kɔmɔn difɛkt dɛn na plastic injɛkshɔn moldin we dɛn sɔlv bay DFM .

Plastik injɛkshɔn moldin na kɔmpleks prɔses. I involv bɔku vayriɔbul dɛn we kin lid to difrɛn difrɛn difrɛn tin dɛn na di fayn fayn prɔdak. Bɔt, bɔku pan dɛn tin ya kin apin tru di rayt dizayn fɔ manufakchurabiliti (DFM) prɔsis. Fɔ wan kɔmprɛhnsiv ɔvaviu fɔ kɔmɔn difrɛn difrɛn tin dɛn, yu kin rifer to wi gayd pan . Injɛkshɔn Moldin Difɛkt dɛn ..

Ki Difɛkt dɛn .

Flash : Flash de apin we di plastic we pasmak lik kɔmɔt na di mold kaviti, bɔku tɛm usay di tu af dɛn kin mit. I de mek wan tin layt we gɛt ɛkstra tin dɛn we dɛn fɔ trim. Flashing na bikɔs i nɔ gɛt bɛtɛ klamp fɔs ɔ po mold alaynɛshɔn. Lan mɔ bɔt dis . Injekshɔn moldin flash ..

Weld layn dɛn : Weld layn dɛn de apia usay tu difrɛn flɔ dɛn we dɛn dɔn mek wit plastic we dɔn rɔtin kin mit ɛn nɔ ebul fɔ fuz fayn fayn wan. Dis kin mek wik spat, we kin ridyus pat trɛnk ɔ chenj aw i luk. Fɔ no mɔ, luk wi gayd bɔt Injekshɔn moldin weld layn ..

Sink Mak : Sink mak na smɔl dipreshɔn ɔ dimples na di say we wan pat de. Dɛn kin apin we tik tik pat dɛn na di pat kin kol slo pas di say dɛn we tan lɛk tin, ɛn dis kin mek di say we de insay di pat kol. Lan aw fɔ mek yu nɔ gɛt dis sik . Sink mak in injekshɔn moldin ..

Short Shots : Short shot de apin we di mold cavity nɔ ful-ɔp wit molten plastic kɔmplit wan, we de rilizɔt wan pat we nɔ kɔmplit. Dis kin bi bikɔs ɔf di prɛshɔn we di injɛkshɔn gɛt smɔl, di tin dɛn we nɔ de flɔ we nɔ fayn, ɔ we nɔ gɛt bɛtɛ mold tɛmpracha. Diskɔba mɔ bɔt dis . Short shot in injekshɔn moldin ..

Burn Marks : mak dɛn we dɛn bɔn na dak ɔ dɛn nɔ gɛt kɔlɔ we di tin dɛn we dɛn kin yuz fɔ ɔt ɔ we kin mek di briz wam pasmak we dɛn de injekt dɛn. Dɛn kin afɛkt ɔl tu di pat in apinɛns ɛn strɔkchɔral intɛgriti.

Brittleness : Brittleness de tɔk bɔt pat dɛn we krak ɔ brok izi wan bikɔs dɛn nɔ gɛt bɛtɛ trɛnk. Dis difɛkt kin kɔmɔt frɔm di tin dɛn we nɔ fayn fɔ pik di tin dɛn we dɛn nɔ fɔ yuz, di kol we dɛn nɔ de kol, ɔ di wan dɛn we nɔ gɛt pat we wik.

Delamination : Delamination na we di say we wan pat de sho layers we pɔsin kin si we kin pul. dis kin apin we dεn yuz mεtirial dεm we dεn nכ kכmpatibl כ mכsich kin trכp insay di rεsin we dεn de injεkt.

Jetting : Jetting kin apin we di plastic de flɔ tu kwik kwik wan insay di mold cavity, we de mek wan patɛn we tan lɛk snek we de distɔrj di pat in apia ɛn ridyus in trɛnk. Lan mɔ bɔt dis . Jetting in injekshɔn moldin ..

Voids, splay, bubbles, and blistering : Voids na air poket we de fom insay di pat. Splay de rifer to streaks we di moisture de kam wit na di matiryal. Bɔbul ɛn blista dɛn kin apin we di briz we dɔn trɔp nɔ ebul fɔ rɔnawe pan di mol, ɛn dis kin mek di pat nɔ ebul fɔ du wetin i want ɛn aw i de luk. Fɔ no mɔ bɔt voyd, si wi atikul bɔt Vakum voids ..

Warping and Flow Lines : Warping rizulyt frɔm nɔ ivin kol, we de mek di pat bɛn ɔ twist. Flɔ layn dɛn na strek ɔ wev dɛn we pɔsin kin si na di pat pan di pat, we kin kɔmɔt frɔm di flɔ patɛn we nɔ de ɔltɛm we dɛn de injekt am. Lan mɔ bɔt dis . Warping in injekshɔn moldin ɛn . Flow lines defekt in injekshɔn moldin ..

Sɔlwɛshɔn dɛn tru DFM .

Fɔ sɔlv dɛn prɔblɛm ya, DFM (dizayn fɔ manufakchurabiliti) de gi targeted ajɔstmɛnt to pat ɛn mold dizayn. Na sɔm kɔmɔn sɔlv dɛm:

Pat dizayn ajɔstmɛnt dɛn : Modify di tik we de na di wɔl fɔ mek shɔ se yu kol yunifom. Ad rib ɔ gusset fɔ mek di say dɛn we gɛt ay strɛs strɔng ɛn mek wɔp nɔ wɔp.

Mold Design Optimization : Mek shɔ se dɛn put di get ɛn di sayz fayn fayn wan fɔ mek dɛn nɔ gɛt wɛl layn ɛn voyd. Disain kol chanel fɔ mek yu kɔntinyu fɔ gɛt yunifom tɛmpracha. Lan mɔ bɔt dis . Dizain fɔ mold ..

Injɛkshɔn prɛshɔn kɔntrol : Rigyul injɛkshɔn prɛshɔn fɔ avɔyd shɔt shot ɛn flash. Fɔ mek shɔ se di rayt prɛshɔn de ɛp fɔ ful-ɔp di mold kaviti ful wan ɛn nɔ ɔvapak.

Di tɛm we dɛn kin ajɔst di tɛm fɔ mek di ples kol : di tɛm we dɛn kin kol fayn fayn wan fɔ mek dɛn nɔ gɛt wɔpin, sink mak, ɛn nɔ gri fɔ mek dɛn strɔng. Fasta kol tεm na tik εria dεm de ridyus di chans fכ shrink.

Material Selection : Pik di matirial dɛn we gɛt di rayt shrinkage ret ɛn tɛmral prɔpati fɔ di pat dizayn. Material choice de impak ɔltin frɔm weld layn to ɔvala trɛnk. Wetin dɛn kin yuz fɔ mek injɛkshɔn moldin .

We dɛn mek dɛn ajɔstmɛnt ya tru DFM, di wan dɛn we de mek dɛn kin ridyus ɔ ivin pul dɛn kɔmɔn injɛkshɔn moldin dɛfɛkt dɛn ya bad bad wan.

Disain Gaydlain fɔ Kɔmɔn Ficha dɛn na Injɛkshɔn Mɔldin .

We yu de disayn pat fɔ plastic injɛkshɔn moldin, i rili impɔtant fɔ tink bɔt di manufakchurabiliti fɔ difrɛn ficha dɛn. Na sɔm gaydlain fɔ disayn kɔmɔn ɛlimɛnt dɛn insay wan we we go ɔptimayz prodakshɔn ɛn minimiz difrɛns. Fɔ si wan kɔmplit ɔvaviu, luk na wi gayd bɔt Wetin na dizayn gaydlayn fɔ injɛkshɔn moldin ..

1. Bos dɛn .

Bos na rayz ficha dɛm we de sav as atɛshmɛnt pɔynt ɔ strɔkchɔral sɔpɔt. Bɔku tɛm dɛn kin yuz dɛn fɔ skru, pin, ɔ ɔda tin dɛn we dɛn kin yuz fɔ fast.

Ki gaydlain fɔ disayn bɔs dɛn:

Ad wan rayus na di bays, saiz bitwin 25-50% pan di wɔl tik.

Limit di ayt to nɔ pas 3 tɛm di ɔdasay dayamita.

Yuz wan draft angle we de 0.5° to 1° na di ɔdasay fɔ mek i izi fɔ pul am kɔmɔt na do.

Ataya di bɔs to wan wɔl we de nia de yuz wan kɔnɛktin rib fɔ ad trɛnk.

Luk fɔ bɔku bɔku bɔs dɛn we nɔ de nia di wɔl pas tu tɛm di tik we di wɔl tik.

2. Ribs .

di rib dεm na tin, vεtikal wכl dεm we de inkrεs di stiffness fכ wan pat we dεn nכ ad signifyant mas. Dɛn kin yuz dɛn fɔ mek dɛn gɛt mɔ flat say dɛn ɔ fɔ mek dɛn gɛt lɔng span.

Dizayn Tips fɔ Ribs:

Kip di tik we nɔ rich 60% pan di men wɔl fɔ mek yu nɔ sink mak dɛn.

Limit di ayt to 3 tɛm di tik fɔ stebiliti.

Ad wan rayus na di bays, 25-50% pan di tik, fɔ ridyus di strɛs kɔnsɛntreshɔn.

Yuz wan draft angle we at le 0.5° pan wan sayd fɔ mek i izi fɔ pul pat.

3. Kɔna dɛn .

Shap kɔna na strɛs kɔnsɛntreta dɛn we kin mek pat nɔ wok. Dɛn kin mek i nɔ izi bak fɔ mek plastic flɔ fayn fayn wan we dɛn de injekt am.

Fɔ avɔyd dɛn tin ya:

Ad wan rayus to ɔl kɔna, insay ɛn autsay.

Mek di insay rayus at le 50% pan di wɔl tik.

Match di outsaid radius to di insaid radius plus di wol tiknes.

4. Draft angul dɛn .

Draft angles na smɔl tapers we dɛn ad to vertikal wɔl, pin, ɛn rib. Dɛn kin ɛp di pat fɔ fri klin wan frɔm di mol ɛn nɔ stik ɔ difɔm. Fɔ no mɔ, luk wi gayd bɔt Draft angle in injekshɔn moldin ..

Di amount of draft we dɛn nid de dipen pan sɔm tin dɛn:

Resin Type: Material wit ay shrinkage ret nid mɔ draft.

Tekstɔr: Rougher surfaces nid fɔ inkrisayz draft fɔ mek dɛn nɔ drɛg mak.

Dip: Tɔl ficha dɛn jɔs nid mɔ draft fɔ klin ejekshɔn.

As a rule of thumb, yuz wan minimum draft angle we na 1° fɔ smol smol surface ɛn 2-3° fɔ di wan dɛn we gɛt tɛkstɔr. Kɔnsul wit yu molding patna fɔ spɛshal kɔmɛnt dɛn bay yu dizayn.

5. Ejekta pins .

Ejector pins de yuz fɔ push di pat we dɔn dɔn kɔmɔt na di mold cavity. Di sayz, di shep, ɛn di say we dɛn de kin afɛkt di we aw di pat tan ɛn di we aw di pat fayn. Lan mɔ bɔt dis . Ejector pins in injekshɔn moldin ..

Kip dɛn pɔynt dɛn ya na yu maynd:

Put pin pan nɔ-kɔsmɛtik sɔfays ɛnitɛm we i pɔsibul.

Nɔ put pin pan tin ɔ fraylayz ficha dɛn we kin pwɛl we yu de kɔmɔt na do.

Yuz wan big pin fɔ sheb di ejekshɔn fɔs we yu nɔ lɛf mak we pɔsin kin si.

Tink bɔt ɔda we dɛn we dɛn kin yuz fɔ kɔmɔt na di wɔl, lɛk stripa plet dɛn, fɔ pat dɛn we gɛt kɔmpleks jɔyometri.

6. Get dɛn .

Get na di opin dɛn we dɛn kin yuz fɔ mek plastic we dɔn rɔtin go insay di mold kaviti. Prɔpa get dizayn impɔtant fɔ ajɔst kɔmplit, balans filin ɛn minimiz vishɔnal dɛfɛkt dɛn. Fɔ no mɔ, luk wi gayd bɔt Tayps of gets fo injekshon moldin ..

Sɔm impɔtant tin dɛn we wi fɔ tink bɔt:

Pik wan get tayp (ɛgz., tab, tanɛl, hot tip) we fit di pat jɔyometri ɛn rɛsin.

Sayz di get fɔ alaw fɔ mek di flɔ fayn fayn wan we nɔ go mek yu gɛt jet ɔ we yu de shea pasmak.

Luk fɔ gɛt get fɔ mek dɛn go ebul fɔ mek ivin ful-ɔp ɛn pak di say we di ples de.

Put di get dɛn we de fa frɔm di say dɛn we yu de si ɔ di tik say dɛn we kin mek yu sink ɛn we nɔ gɛt natin.

7. Di ol dɛn .

Dɛn kin mek ol dɛn we gɛt injɛkshɔn mold pat dɛn bay we dɛn de yuz kɔr pin dɛn na di mol. If dɛn nɔ mek am kɔrɛkt wan, ol dɛn kin difɔm ɔ nɔ gɛt di rayt saiz.

Fɔ fala dɛn gaydlayn ya:

Yuz wan yunifom wɔl tiknes rawnd di ol fɔ mek i nɔ distɔrshɔn.

Limit di dip we di . Blaynd ol fɔ nɔ pas 2-3 tɛm di dayamita.

Fɔ tru ol, sɔpɔt di kɔr pin na ɔl tu di ɛnd fɔ mek dɛn kɔntinyu fɔ alaynɛshɔn.

Ad smɔl taper ɔ draft to di ol fɔ mek i izi fɔ pul di pin.

8. Di layn dɛn we de pat .

Parting lines na di seams usay di tu haf dɛn na di mold kam togɛda. Bɔku tɛm dɛn kin si dɛn na di pat we dɔn dɔn ɛn dɛn kin afɛkt ɔl tu di aesthetic ɛn di funkshɔn. Lan mɔ bɔt dis . Parting line in injekshɔn moldin ..

Fɔ mek di impak we di layn dɛn we de pat pan di program gɛt nɔ bɔku:

Pozishɔn dɛn pan nɔ-kritikal sɔfays ɔ edj dɛn na di pat.

Yuz wan 'step' pat layn fɔ impɔtant alaynɛshɔn ɛn trɛnk.

Ad tɛkstɔr ɔ wan kɔba prɔfayl fɔ mek yu nɔ si aw di layn de apia.

Mek shɔ se dɛn draft ɛn klia fɔ mek dɛn nɔ flash ɔ nɔ gri wit di say we dɛn de sheb di layn.

9. Tɛkstɔr .

Tekstɔr sɔfays kin ɛp fɔ mek di pat we dɛn dɔn mol, fil, fil, ɛn wok. Bɔt dɛn kin nid bak fɔ gɛt spɛshal tin dɛn fɔ tink bɔt we dɛn de disayn ɛn yuz tul dɛn.

Kip dɛn pɔynt dɛn ya na yu maynd:

Yuz wan draft angle we at le 1-2° fɔ mek di tɛkstɔr nɔ inhibit pat ɛjekshɔn.

Avɔyd wantɛm wantɛm transishɔn ɔ shap edj dɛn na di tɛkstɔr patɛn.

Tink bɔt di dip ɛn di spɛshal we aw di tɛkstɔr de fɔ mek shɔ se di resin flɔ ɛn ful-ɔp fayn fayn wan.

Wok wit yu mold mek fɔ pik wan tɛkstɔr we yu kin mashin ɔ etch kɔrɛkt wan insay di tul.

10. Shrinkage .

Ɔl di plastic dɛn de shrink as dɛn de kol na di mol, ɛn dis shrinkage fɔ de na di pat ɛn di tul dizayn. Nɔ ivin ɔ pasmak shrinkage kin mek yu gɛt wɔpin, sink mak, ɛn dimensional inaccuracies.

Fɔ manej shrinkage:

Mentɛn wan kɔnsistɛns wɔl tiknes ɔlsay na di pat.

Avɔyd tik sɛkshɔn dɛn we kin gɛt sink ɛn insay voyd.

Yuz wan mold tempɔret we de ɛp fɔ mek di ples kol smɔl smɔl, yunifom.

Adjɔst di prɛshɔ we dɛn pak ɛn di tɛm fɔ kɔmpɛns fɔ di matirial shrinkage.

Modify di tul dimɛnshɔn dɛn bays pan di ɛkspɛkt shrinkage rɛt fɔ di rɛsin.

11. Weld layn dɛn .

Weld layn dɛn kin apin we tu ɔ mɔ flɔ frɔnt mit ɛn fiuz di tɛm we dɛn de mol di prɔses. Dɛn kin apia as mak dɛn we pɔsin kin si na di say we dɛn de ɛn kin ripresent wik pɔynt dɛn na di strɔkchɔ. Fɔ no mɔ, luk wi gayd bɔt Injekshɔn moldin weld layn ..

Fɔ mek di weld layn dɛn nɔ go afɛkt di we aw dɛn de du tin, di wan dɛn we de mek dizayn kin:

Optimize GATE lokeshɔn fɔ kɔntrol di flɔ ɛn mitin fɔ di mɛlt frɔnt dɛn.

Yuz wan mold tempɔret we de kip di flɔ frɔnt dɛn hot ɛn fluid as dɛn de kam togɛda.

Ad vent ɔ ɔvaflɔ wɛl fɔ pul trɔp ɛya ɛn impruv fushɔn na di wɛl layn.

Radius Di kɔna ɛn ed dɛn fɔ mek dɛn ebul fɔ flɔ bɛtɛ ɛn wan strɔng wɛl.

Tink bɔt aw fɔ yuz ay mɛlt tɛmpracha ɔ wan slo fil rit insay sɔm kes dɛn.

Wae dɛn nɔr kin ebul fɔ pul di wɛl layn dɛn ɔltɛm, dɛn strateji ya kin ɛp fɔ manej aw dɛn de luk ɛn aw dɛn kin afɛkt pan pat pefɔmɛns.

Na sɔm ɔda advays dɛn ɛn tin dɛn we dɛn fɔ tink bɔt fɔ disayn kɔmɔn tin dɛn na di pat dɛn we dɛn dɔn injɛkshɔn:

Fɔ di bɔs dɛn:

Riinfɔs lɔng ɔ slɛnd bɔs dɛn we gɛt gɔs ɔ rib fɔ mek dɛn nɔ deflɛshɔn ɔ brok we dɛn de yuz dɛn.

Fɔ di bɔs dɛm we go gɛt ɔt stak ɔ ultrasonically welded, fala di gaydlain dɛm we di ikwipmɛnt manifakta gi fɔ di bɛst rizɔlt.

Fɔ rib dɛn:

Spays rib at least tu taims di nominal wol tiknes apat fo mek shor se adekwat filin en minimiz sink maks pan di opozit safa.

Fɔ lɔng ɔ lɔng rib, tink bɔt fɔ ad flɔ chanɛl ɔ tiknes vɛryushɔn fɔ protɛkt ivin filin ɛn ridyus wɔp.

Fɔ kɔna dɛn:

Yuz wan big rayus na di kɔna dɛn we de na do we yu kɔmpia am wit di insay kɔna dɛn fɔ kɔmpɛns di natura thinnin fɔ di matirial na dɛn eria dɛn de.

Fɔ strɔkchɔral ɔ lod-bearing pat, avɔyd shap kɔna dɛn ɔltogɛda ɛn pik fɔ wan mɔ smɔl smɔl ɔ chamfered transishɔn.

Fɔ draft angul dɛn:

Apat frɔm di praymari draft na di wɔl dɛn, ad smɔl draft (0.25-0.5°) to ficha dɛn lɛk rib, bɔs, ɛn tɛks fɔ ɛp fɔ ejekshɔn.

Fɔ pat dɛn we gɛt ay aspek rɛsɛshɔn ɔ dip draw, tink bɔt fɔ yuz ay draft angul ɔ inkɔrpɔret wan slayd ɔ kam akshɔn insay di tul.

Fɔ Ejector Pin dɛn:

Yuz bɔku bɔku pin dɛn we gɛt balans layout fɔ sheb di ejektion fɔs ɛn mek di pat nɔ chenj ɔ pwɛl.

Fɔ rawnd ɔ silindrikal pat dɛn, tink bɔt fɔ yuz wan sliv ɛjɛkta ɔ wan stripa plet instead ɔf pin fɔ wan smol ɛn mɔ yunifom ejekshɔn.

Fɔ Get dɛn:

Nɔ put get dɛn na kɔna ɔ ed dɛn na di pat, bikɔs dis kin mek yu gɛt strɛs kɔnsɛntreshɔn ɛn get vestej kwɛstyɔn dɛn.

Fɔ big ɔ flat pat, tink bɔt fɔ yuz fan get ɔ wan kɔmbaynshɔn fɔ bɔku get fɔ ajɔst balans filin ɛn minimiz wɔp.

Fɔ ol dɛn:

Fɔ smɔl ol ɔ di wan dɛn we gɛt tayt tolɛreshɔn, tink bɔt fɔ yuz sɛpret drɔl ɔ riam ɔpreshɔn afta dɛn dɔn mol fɔ mek shɔ se dɛn kɔrɛkt ɛn kɔnsistɛns.

Fɔ di ol dɛn we gɛt trɛd, yuz wan insɛt we gɛt trɛd ɔ wan skru we de tap yusɛf fɔ mek di trɛd dɛn afta yu dɔn mol.

Fɔ di layn dɛn we de pat:

Avɔyd fɔ put pat layn dɛn akɔdin to di impɔtant dimɛnshɔn ɔ mating sɔfays ɛnitɛm we i pɔsibul.

Fɔ pat dɛn we gɛt ay kɔsmɛtik rikwaymɛnt, tink bɔt fɔ yuz wan tul wit 'shut-off' ɔ 'seamless' pating layn dizayn.

Fɔ tɛkstɔr:

Yuz wan kɔnsistɛns tɛkstɔr dip ɛn patɛn akɔdin to di pat fɔ mek shɔ se yu kol yunifom ɛn shrink.

Fɔ pat dɛn we gɛt bɔku tɛkstɔr ɔ wan kɔmbaynshɔn fɔ smol ɛn tɛkstɔr sɔfays, yuz wan smɔl smɔl transishɔn ɔ fizik brek fɔ separet di difrɛn eria dɛn.

Fɔ Shrinkage:

Yuz wan matirial we gɛt lɔwa shrinkage ret ɔ ay fil kɔntinyu fɔ minimiz dimɛnshɔnal chenj ɛn wɔpej.

Tink bɔt fɔ yuz wan mɔlti-kaviti tul wit balans rɔna sistɛm fɔ protɛkt ivin shrinkage ɛn kɔnsistɛns bitwin pat dɛn.

Fɔ wɛl layn dɛn:

Yuz wan matirial wit ay mɛlt flɔ indeks ɔ wan lɔwa viskɔsiti fɔ impɔtant di fushɔn ɛn trɛnk fɔ di wɛl layn.

Tink bɔt fɔ yuz gas-asist ɔ ɔvaflɔ wɛl tɛknik fɔ pul ɔ muf di wɛl layn to wan nɔ-kritikal eria na di pat.

Kes Stɔdi: Sɔlv Kwaliti Isyu dɛn na Mɛdikal Divays Manufakchurin

Prɔblɛm: Jɛtin ɛn po klia wan na mɛdikal divays winda dɛn

Wan mɛdikal divays manifakta bin gɛt impɔtant kwaliti kwɛstyɔn dɛn we dɛn bin de prodyuz. Di divays, we dɛn mek fɔ ɛp fɔ mɛn bon dɛn we dɛn de yuz ɔltrasɔund, bin gɛt wan transparent winda we nɔ bin ebul fɔ du inspekshɔn ɔltɛm. Di winda dɛn bin sho se dɛn gɛt jet ɛn dɛn nɔ bin klia, ɛn dis bin mek di divays nɔ fayn fɔ yuz fɔ mɛn pipul dɛn.

Di rut kɔz fɔ dis kwɛstyɔn na bin sabstret matirial we bin de ri-mɛlt ɛn miks wit di klia rɛsin . As di resin ful di mold, di tempɔret imbalans mek sɔm matirial ri-mɛlt ɛn afɛkt di klia we di winda klia. Di miks we dɛn miks di tin dɛn we dɛn nɔ gri wit we dɛn de yuz injɛkshɔn bin mek distɔshɔn dɛn, we mek dɛn nɔ bin ebul fɔ chɛk dɛn.

Solushɔn tru DFM .

Di kɔntrakt manifakta bin yuz dizayn fɔ manufakchurabiliti (DFM) prinsipul dɛn fɔ adrɛs dɛn kwaliti ishu dɛn ya. Na so DFM ɛp fɔ fiks di prɔblɛm:

Rivays Prodakt Dizayn ɛn Tul : Dɛn bin ajɔst di dizayn fɔ mek dɛn nɔ mek di matirial bak. Modifyeshɔn dɛn to di tul bin mek shɔ se bɛtɛ separeshɔn bitwin di klia rɛsin ɛn di sabstret matirial. Dis step bin impɔtant matirial flɔ, ridyus di chans fɔ jet ɛn ɔda tin dɛn we nɔ fayn fɔ si.

Yuz 3D printin fɔ protɔtayp ɛn tɛst : Bifo ful-skel prodakshɔn, di manifakta mek protɔtayp dɛn we de yuz 3D printin . Dis bin mek dɛn ebul fɔ tɛst ɛn validet di chenj dɛn we dɛn mek fɔ di dizayn we dɛn nɔ kɔmit to di kɔst fɔ ajɔst di tul dɛn. Bay we dɛn bin de protɔtayp fɔs, dɛn bin ebul fɔ si aw di chenj dɛn bin afɛkt di pat in klia ɛn trɛnk.

Introdyushɔn fɔ Ultrasonic Welding ɛn Value-Added Steps : Apat frɔm di dizayn improvements, di manufakchurin prɔses inkɔrpɔret ultrasonic weldding . Dɛn bin yuz dis prɔses fɔ jɔyn difrɛn pat dɛn na di divays, ɛn mek shɔ se di prɔdak intɛgriti bɛtɛ. Ɔda valyu-adɛd stɛp dɛn lɛk prodak printin ɛn adishɔnal kwaliti chɛk dɛn bin introdyus fɔ mek shɔ se kɔnsistɛns akɔdin to ɔl di yunit dɛn.

Visualizing di solushɔn

| ishu | kɔz | DFM sɔlvushɔn . |

| Jetting in windo . | Sabstret matiryal ri-meltin, miks wit resin | Impɔtant tul dɛn, separeshɔn fɔ di matirial dɛn . |

| Di tin dɛn we nɔ klia na di wɔl nɔ fayn . | Miks fɔ matirial, tɛmpracha imbalans . | Optimized dizayn ɛn bɛtɛ matirial flɔ . |

| Failed Product Inspekshɔn dɛn . | Difɛkt dɛn we pɔsin kin si, wik bɔnd dɛn . | Di ultrasonik welding, 3D prototyping |

Dɔn

Dizayn fɔ Manufakchurabiliti (DFM) impɔtant fɔ mek dɛn mol plastic injɛkshɔn. I de ɛp fɔ avɔyd di prɔblɛm dɛn we nɔ gɛt bɔku mɔni ɛn i de mek di prɔdak kwaliti bɛtɛ bay we i de adrɛs di prɔblɛm dɛn kwik kwik wan. Di men strateji dɛn na fɔ mek di wɔl tik fayn, fɔ yuz di rayt say dɛn fɔ gɛt di get, ɛn fɔ mek shɔ se di matirial go fayn fayn wan. We dɛn yuz dɛn DFM prinsipul dɛn ya, di wan dɛn we de mek dɛn kin mek di wok fayn, dɛn kin ridyus di kɔst fɔ di prodakshɔn, ɛn mek shɔ se dɛn gɛt di sem pat kwaliti.

Diskova aw Team MFG kin optimize yu injekshɔn moldin projɛkt dɛm. Kontakt wi tide fɔ wan fri kɔnsultɛshɔn ɛn kot. Lɛ wi wok togɛda fɔ mek yu dizayn dɛn gɛt layf, efyushɔn ɛn kɔst-ɛfɛktiv.

FAQs bɔt DFM fɔ injɛkshɔn moldin .

K: Wetin na di difrɛns bitwin DFM ɛn DFA pan injɛkshɔn moldin?

A: DFM de fos fɔ optimiz pat dizayn fɔ di injɛkshɔn moldin prɔses, we DFA de ɛmpɛsh fɔ disayn pat fɔ izi asɛmbli. DFM aim fɔ ridyus di manufakchurin kɔmplisiti ɛn kɔst, we DFA de strimlayn di asɛmbli prɔses.

K: Aw DFM de afɛkt di ɔvala kɔst fɔ wan injɛkshɔn mold prodak?

A: DFM de ɛp fɔ ridyus ɔl di prɔdak kɔst bay we dɛn de minimiz di kɔmplisiti we dɛn de mek, ridyus di matirial we dɛn de yuz, ɛn optimize di injɛkshɔn moldin prɔses. Dis kin mek di prɔdakshɔn kɔst smɔl, i nɔ kin gɛt bɔku difɛkt, ɛn i kin shɔt pasmak saykl tɛm.

K: Dɛn kin yuz DFM prinsipul dɛn fɔ di prɔdak dɛn we dɔn de?

A: Yes, DFM prinsipul dɛn kin aplay to di prɔdak dɛn we dɔn de tru wan prɔses we dɛn kɔl 'Design Optimization.' Dis involv fɔ analayz di dizayn we de naw, fɔ no di eria dɛn fɔ mek dɛn impruv, ɛn fɔ mek modifyeshɔn fɔ mek dɛn ebul fɔ mek di manufakchur.

K: Aw ɔltɛm dɛn fɔ du DFM analisis we dɛn de divɛlɔp di prɔdak?

A: DFM analisis fɔ bi ɔlsay na di prodak divɛlɔpmɛnt prɔses, frɔm di fɔs kɔnsɛpt to di las dizayn. Fɔ du di DFM rivyu dɛn we dɛn kin du ɔltɛm kin ɛp fɔ no ɛn adrɛs di prɔblɛm dɛn we kin apin kwik kwik wan, we kin mek dɛn nɔ nid fɔ chenj bɔku bɔku wan leta.

K: Wetin na di mɔs kɔmɔn DFM-rilayt ishu dɛn na injɛkshɔn moldin?

A: Kɔmɔn DFM ishu dɛn inklud inkɔnsistɛns wɔl tik, lɔk fɔ draft angul, nɔ fayn get ples, ɛn nɔ fayn kol. Ɔda tin dɛn kin gɛt fɔ du wit di we aw dɛn nɔ de pik di tin dɛn we dɛn nid, di shrinkage we nɔ ivin, ɛn di ɔnda-kat ɔ kɔmpleks jɔyometri dɛn we dɛn nɔ kɔt pasmak.