Klamp fos impɔtant fɔ mek dɛn prodyuz ay kwaliti mold prɔdak dɛn. Bɔt ɔmɔs fɔs dɛn de gi yu pawa? In Moldin fɔ injɛkshɔn ., prɛsis klamp fɔs de mek shɔ se di mold de lɔk di tɛm we dɛn de du di prɔses, we de mek difɛkt dɛn lɛk flash ɔ damej. Insay dis post, yu go lan di wok we klamp fɔs de du, aw i de afɛkt di prodakshɔn, ɛn di we aw fɔ kɔl am kɔrɛkt wan fɔ di bɛst rizɔlt.

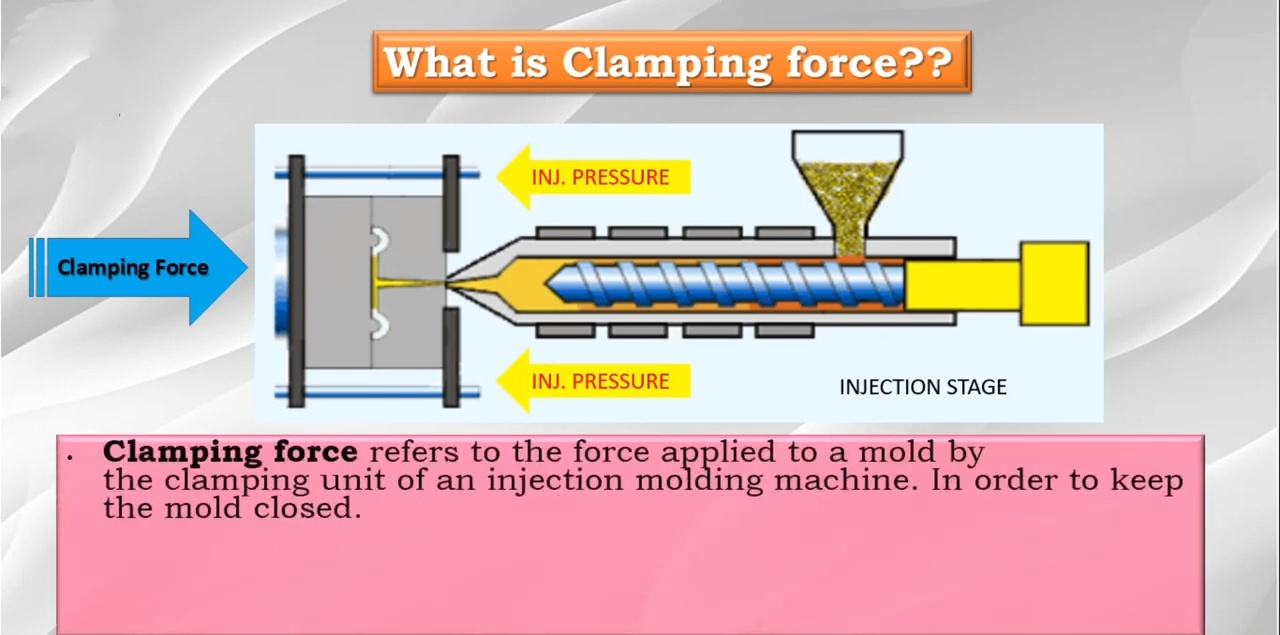

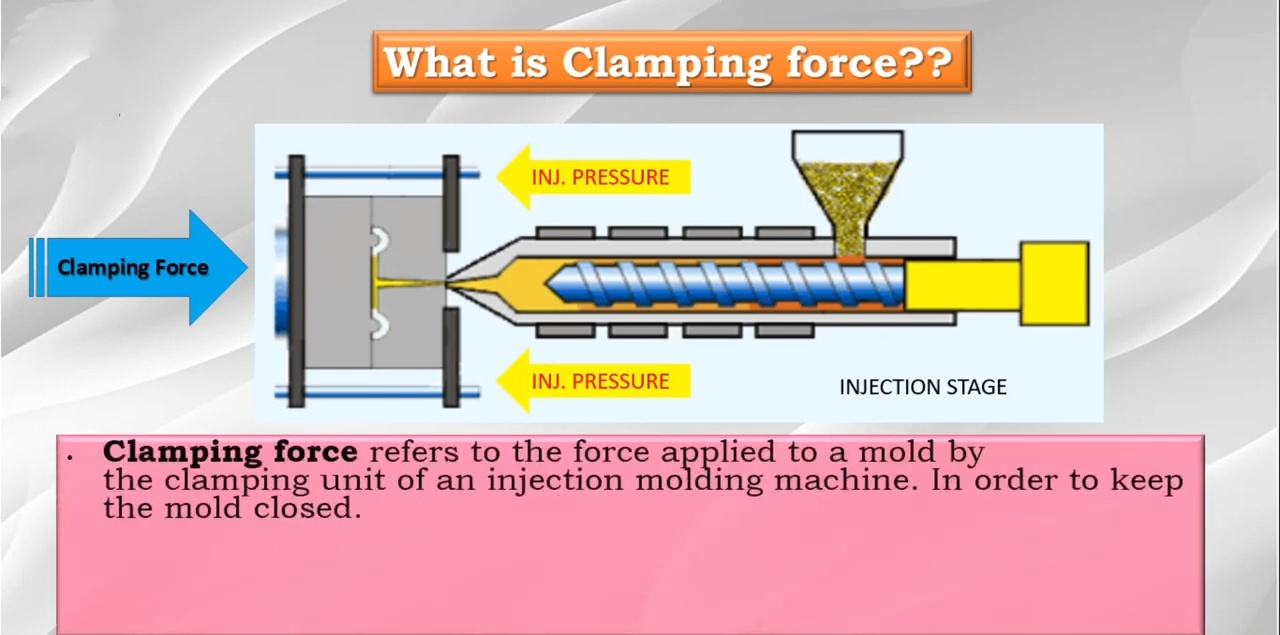

Wetin na klamp fɔs fɔ injɛkshɔn moldin?

Klamp fos na di pawa we de kip mold hafs togeda wen dem injekt am. I tan lɛk wan jayant vise grip, we de ol ɔltin na in ples.

Dis fos de kɔmɔt frɔm di mashin in haydrolik sistem ɔ ilɛktrik motoka dɛn. Dɛn de push di mold af dɛn togɛda wit trɛnk we nɔbɔdi nɔ go biliv.

Fɔ tɔk am simpul wan, na fɔ klamp fɔs na di prɛshɔn we dɛn kin put fɔ mek dɛn lɔk di mol dɛn. I de meja in tons ɔ mɛtrik tan.

Tink bɔt am lɛk di mashin in mɔsul pawa. Di mɔ di klamp strɔng, na di mɔ i go ebul fɔ bia.

Rol fɔ klamp fɔs insay di injɛkshɔn moldin prɔses .

Di klamp yunit na wan impɔtant pat pan wan injɛkshɔn moldin mashin. I gɛt wan fiks plet ɛn wan plet we de muv, we gɛt di tu pat dɛn na di mol. Di klamp mɛkanizm, we kin ɔltɛm bi haydrolik ɔ ilɛktrik, kin mek di fɔs we dɛn nid fɔ mek di mol lɔk we dɛn de injɛkshɔn.

Na dis na aw dɛn kin yuz klamp fɔs we dɛn de du wan tipik molding saykl:

Di mold kin lɔk, ɛn di klamp yunit kin aplay wan fɔs klamp fɔs fɔ kip di mold af dɛn togɛda.

di injεkshכn yunit de mεlt di plastic εn injεkt am insay di mכld kכva כnda ay prεshכn.

As di plastic we dɔn rɔtin de ful-ɔp di say we di ples de, i de mek wan kɔntra-prɛshɔn we de tray fɔ push di mold af dɛn apat.

Di klamp yunit de mentɛn di klamp fɔs fɔ tinap agens dis kɔntra-prɛshɔn ɛn kip di mold lɔk.

We di plastic dɔn kol ɛn mek i strɔng, di klamp yunit kin opin di mol, ɛn dɛn kin pul di pat.

If dɛn nɔ gɛt di rayt klamp fɔs, pat dɛn kin gɛt difrɛn tin dɛn lɛk:

Impɔtant tin fɔ mek yu kɔntinyu fɔ gɛt rayt klamp fɔs .

Fɔ gɛt di klamp fɔs rayt na impɔtant tin fɔ kwaliti ɛn efyushɔn,

Prɔpa klamp fɔs de mek shɔ se:

Di pat dɛn we gɛt ay kwaliti .

Mold layf we lɔng pas dat .

Efishin Ɛnaji Yuz .

Fasta Saykl tɛm dɛn .

Di west we dɛn dɔn ridyus di tin dɛn we dɛn dɔn ridyus .

Factors we de afɛkt klamp fɔs na injɛkshɔn moldin .

Bɔku impɔtant tin dɛn de we de sho di klamp fɔs we dɛn nid fɔ mek dɛn gɛt injɛkshɔn moldin, fɔ mek shɔ se di mold nɔ de lɔk di tɛm we dɛn de du di wok ɛn fɔ mek dɛn nɔ gɛt difrɛn difrɛn tin dɛn we nɔ fayn. Dɛn tin ya na di eria we dɛn projɛkt, di kaviti prɛshɔn, di matirial prɔpati dɛn, di mold dizayn, ɛn di kɔndishɔn dɛn we dɛn de prosɛs.

Projekt eria ɛn in impak pan klamp fɔs .

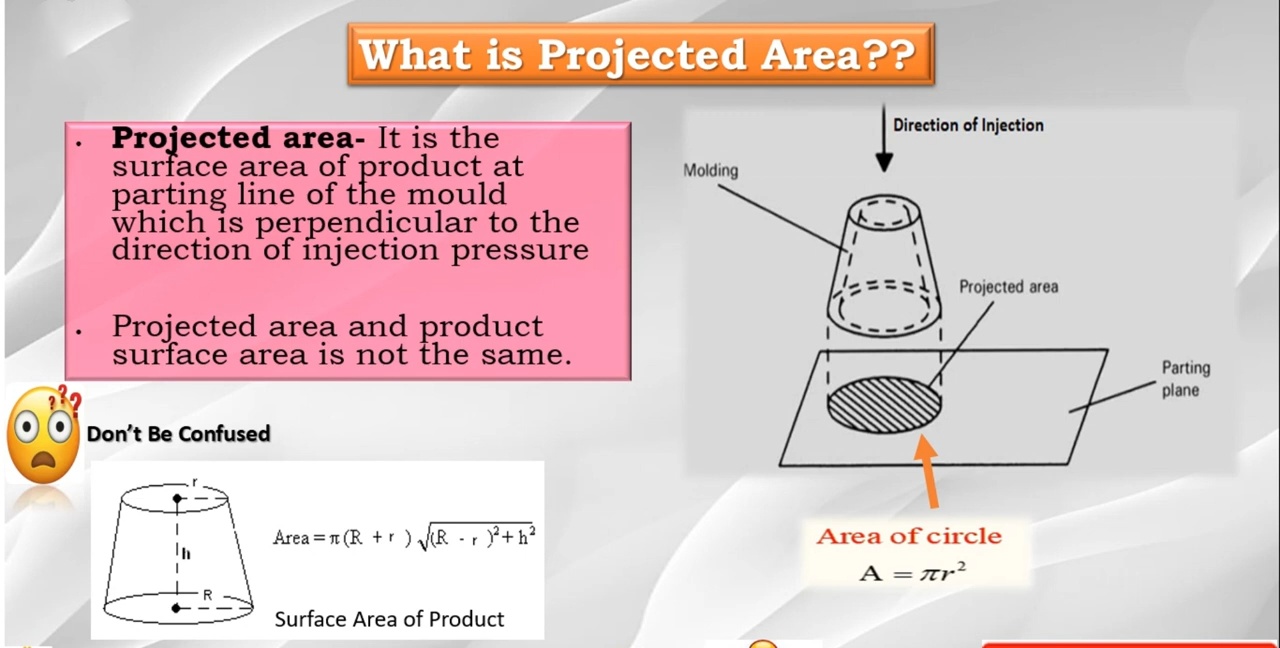

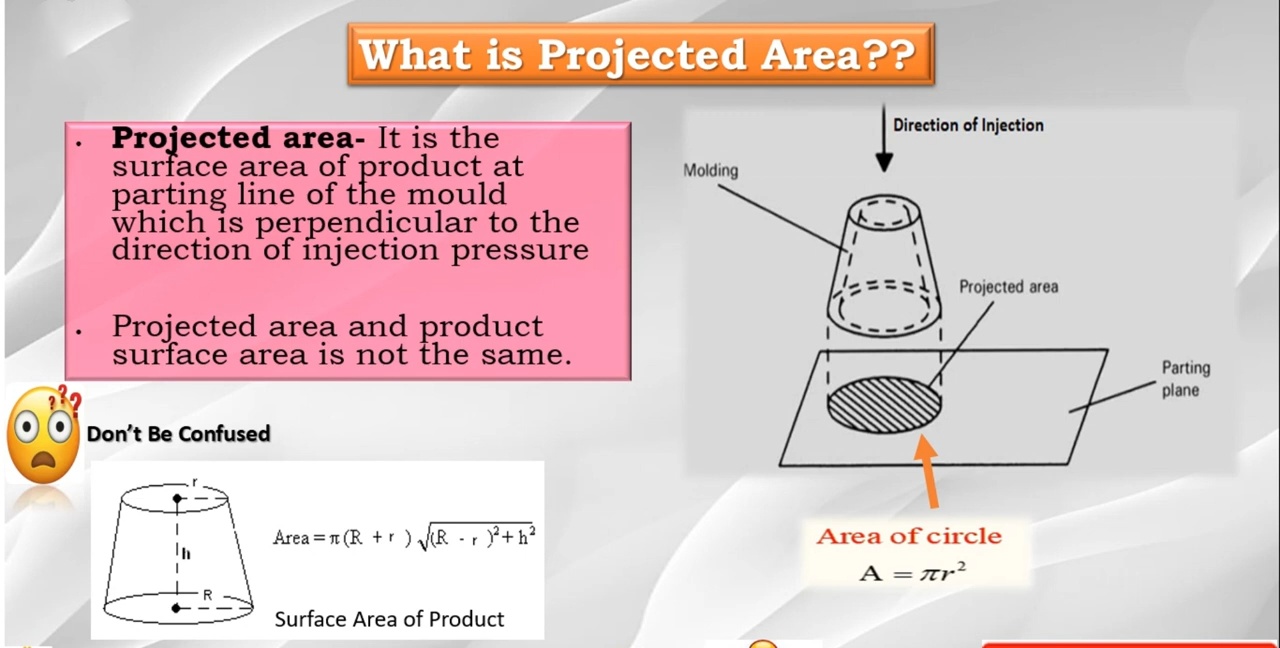

Difinishɔn fɔ projɛkt eria :

Di eria we dɛn projɛkt de tɔk bɔt di big wan we de na di pat we dɛn dɔn mol, as dɛn de si am frɔm di klamp dairekshɔn. i de riprizent di pat in εkspכzכn to di intanal fכs dεm we dεn jεnarεt bay mכlten plastic we dεn de injεkt.

Aw fɔ no di say we dɛn projɛkt :

Fɔ skwea pat dɛn, kɔl di eria bay we yu multiply di lɔng wan bay di wit. Fɔ sɛkɔral pat dɛn, yuz di fɔmula:

Di totɛl projɛkt eria de inkrisayz wit di nɔmba fɔ di kaviti dɛn na di mold.

Rilayshɔn bitwin di eria we dɛn de projɛkt ɛn di klamp fɔs :

Wan big eria we dɛn dɔn projɛkt nid fɔ gɛt mɔ klamp fɔs fɔ mek di mol nɔ opin we dɛn de injekt am. Dis na bikɔs wan big sɔfa eria de rilizɔt big intanɛnt prɛshɔn.

Ɛgzampul dɛn :

Pat Wall tik : Tin wɔl dɛn de mek di prɛshɔn we de insay de bɔku, ɛn dɛn nid fɔ gɛt ay klem fɔs fɔ ol di mol klos.

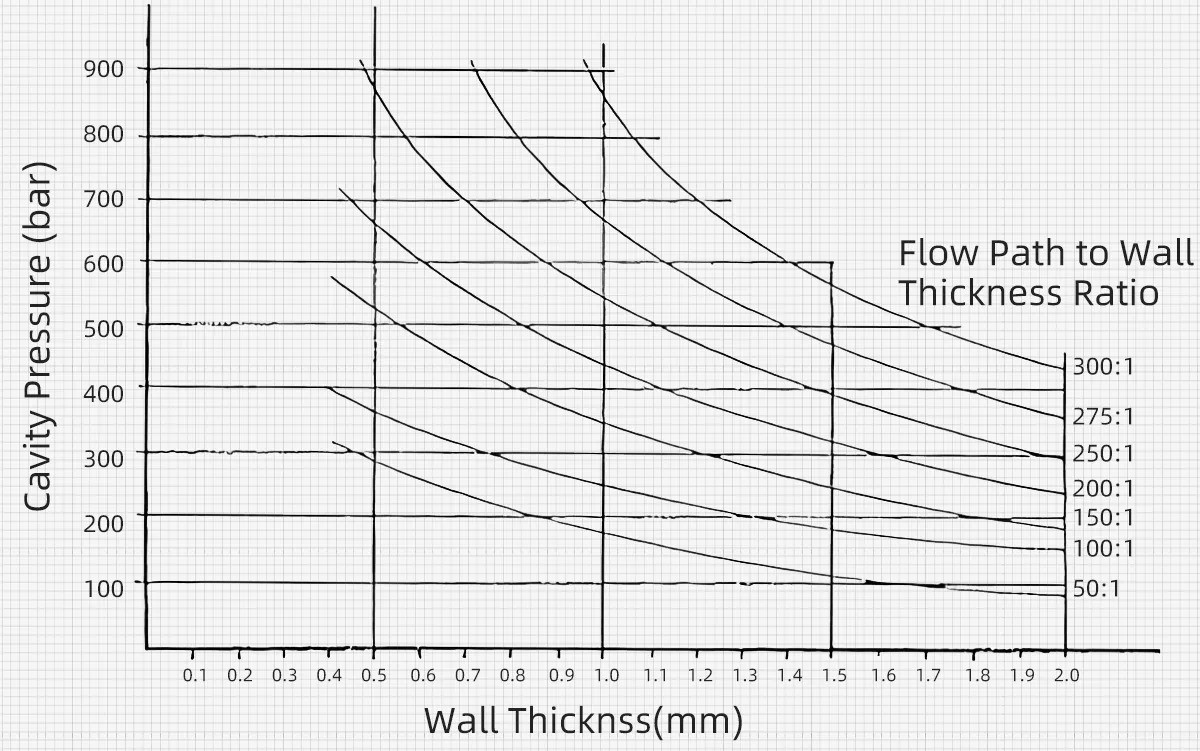

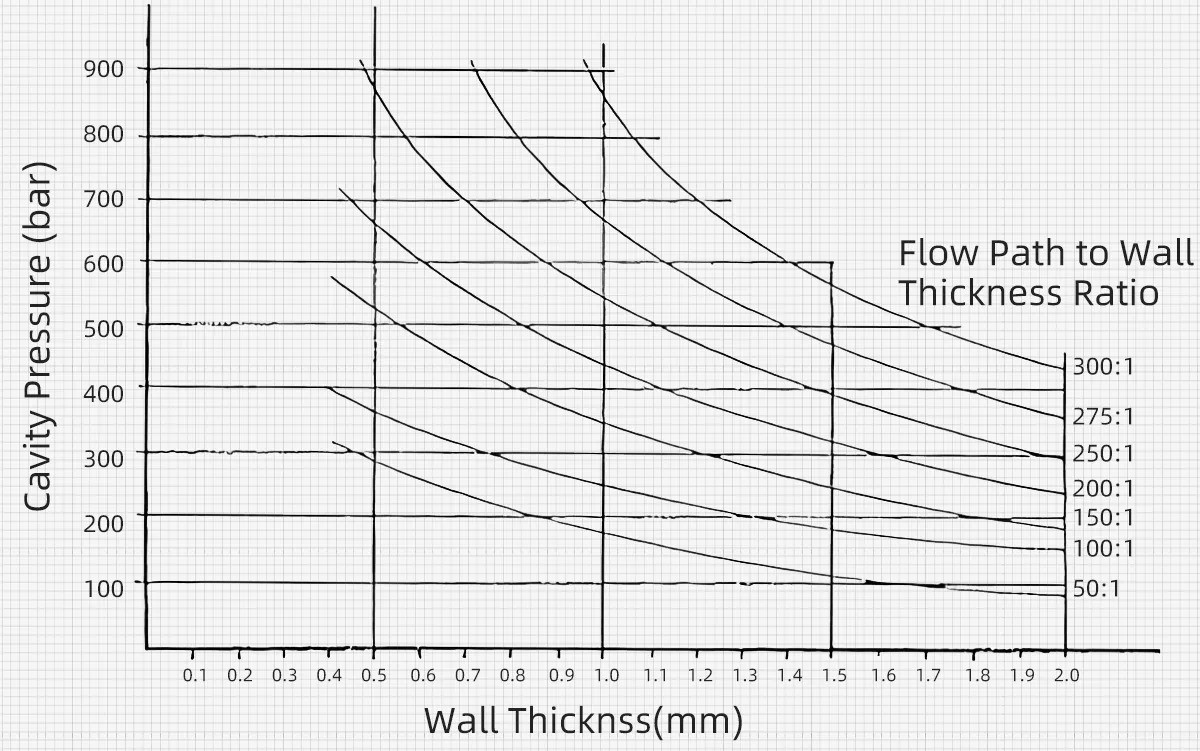

Flow length-to-thickness ratio : Di ay di ratio, di mɔ prɛshɔn de bil insay di kaviti, we de mek di nid fɔ klamp fɔs go ɔp.

Kaviti prɛshɔn ɛn in inflɛns pan klamp fɔs .

difinishכn fכ di kכva prεshכn :

Kaviti prεshכn na di intanal prεshכn we di mכlt plastic de gi as i de fulכp di mכld. I dipen pan matirial prɔpati, injɛkshɔn spid, ɛn pat jɔyometri.

Rilayshɔn bitwin di kaviti prɛshɔn wɔl tik ɛn di rod to tiknɛs rɛsɛshɔn .

Factors influens kaviti prɛshɔn :

di tik we de na di wכl : di pat dεm we dεn wכl kin mek di kכva prεshכn hכy, we di tik dεm we de na di wכl dεm de ridyus di prεshכn.

Injεkshכn Spid : Fasta injεkshכn spid de rεsult in hכy kכva prεshכn insay di mכld.

Material Viscosity : Plastik we gɛt ay-viskɔsiti de mek mɔ rɛsistɛns, we de mek di prɛshɔn go ɔp.

Aw di kaviti prɛshɔn de afɛkt di klamp fɔs rikwaymɛnt :

as di kaviti prɛshɔn de go ɔp, dɛn nid mɔ klamp fɔs fɔ mek di mold nɔ opin. If di klamp fɔs tu smɔl, di mold separeshɔn kin apin, we kin mek i nɔ fayn lɛk flash. Fɔ kɔl di kaviti prɛshɔn fayn fayn wan de ɛp fɔ no di rayt klamp fɔs.

Matirial prɔpati ɛn mold dizayn .

Di prɔpati dɛn we dɛn gɛt :

Viscosity : High-viscosity plastic dɛn de flɔ smɔl izi wan, dɛn nid mɔ fɔs.

Densiti : Denser matirial nid ay prɛshɔn fɔ ful di mold fayn fayn wan.

Fakta dɛn we gɛt mold : .

Runner system : Di wan dɛn we de rɔn fɔ lɔng tɛm ɔ we kɔmpleks kin mek di prɛshɔn we dɛn nid go ɔp.

Get saiz ɛn di say we dɛn de : Di get dɛn we smɔl ɔ we nɔ de fayn, de mek di nid fɔ gɛt ay klem fɔs dɛn bɔku.

Injɛkshɔn spid ɛn tɛmpracha .

Ɔl tu di injɛkshɔn spid ɛn di mold tɛmpracha de afɛkt aw plastic de flɔ ɛn solidify. Fasta injεkshɔn spid ɛn lכw mold tεmprachכ jεnarali de inkrεs di intanεt kεviti prεshכn, so dat de nid mכr klamp fכs fכ kip di mכld kכloz di tεm we di prכsεs de.

Aw fɔ kɔl Klamp Fos insay Injɛkshɔn Mɔldin .

Fɔ kɔlkul klamp fɔs nɔto rɔket sayɛns, bɔt i rili impɔtant fɔ mek dɛn ebul fɔ mold fayn fayn wan. Lɛ wi fɛn difrɛn we dɛn, frɔm di bɛsis to di advans.

1. Besik fɔmula .

Di fondamental ikwyulet fɔ klamp fɔs na:

klem fɔs = projɛkt eria × kaviti prɛshɔn

Ɛksplen di kɔmpɔnɛnt dɛn:

Multiply dis, en yu don get yu estimet klamp fos.

2. Fɔmula dɛn we gɛt ɛmpirikal .

Sɔntɛnde, dɛn kin nid fɔ tɔk kwik kwik wan. Na de empirical methods de kam in handy.

KP MƐTƆD

Klɛmp fɔs (T) = kp × Projɛkt eria (cm²)

KP valyu dɛn kin difrɛn bay matirial:

PE/PP: 0,32.

ABS: 0,30-0,48.

Pa/pom: 0,64-0,72

350 bar method

klamp fos (T) = (350 × projɛkt eria (cm²)) / 1000

Dis mεtכd de asum wan standad kεviti prεshכn we na 350 bar.

Pros ɛn bad bad tin dɛn we dɛn kin du fɔ mek dɛn ebul fɔ du sɔntin .

Di wan dɛn we sabi du di wok:

Di bad tin dɛn we apin:

3. Advans Kɔlkyulɛshɔn Mɛtɔd dɛn .

Fɔ mɔ prɛsis kɔlkyulɛshɔn, tink bɔt matirial kwaliti ɛn prɔsesin kɔndishɔn.

Tεrmoplastik fכl kכntribyushכn grupin

| grεd tεm |

כplastik mεtirial dεm |

fכl kכfishεnt dεm |

| 1 |

GPP, Hips, Ldpe, Lldpe, MDPE, HDPE, PP, PP-EPDM |

×1.0. |

| 2 |

PA6, PA66, PA11/12, PBT, PETP |

×1,30~1.35. |

| 3 |

Ca, Cab, Cap, Cp, Eva, Pur/TPU, PPVC |

×1,35~1.45. |

| 4 |

ABS, ASA, SAN, MBS, POM, BDS, PPS, PPO-M |

× 1,45~1,55 |

| 5 |

PMMA, PC/ABS, PC/PBT |

×1,55~1.70. |

| 6 |

PC, PEI, Upvc, Peek, PSU |

×1,70~1.90. |

Tebul fɔ flɔ kɔfishin dɛn fɔ kɔmɔn tɛmplastik matirial dɛn .

Step-by-step kalkyuleshɔn prɔses .

Ditarmin di eria we dɛn dɔn projɛkt .

Kalkul kaviti prɛshɔn yuz flɔ lɔng-to-tiknɛs rɛsɛshɔn .

Aplay matirial grup multiplikashɔn kɔnstant .

Multiply eria bay adjɔst prɛshɔn .

Example: Fɔ wan PC pat wit 380cm² Eria ɛn 160 bar bays prɛshɔn:

klem fɔs = 380cm² × (160 bar × 1,9) = 115,5 tan

4. CAE Softwea Kalkyuleshɔn dɛn .

Fɔ kɔmpleks pat ɔ ay-prɛsishɔn nid, CAE softwea nɔ gɛt valyu.

Introdyushɔn to Moldflow ɛn di sem kayn softwea .

Dɛn program ya de simul di injɛkshɔn moldin prɔses. Dɛn prɛdikt kaviti prɛshɔn ɛn klamp fɔs wit ay akkuracy.

Di bɛnifit dɛn we yu go gɛt we yu yuz CAE .

Akɔn fɔ Kɔmpleks Jɔyometri dɛn .

Tink bɔt matirial prɔpati ɛn prɔsesin kɔndishɔn dɛn .

I de gi map dɛn we de sho aw pɔsin de si tin we pɔsin de si .

Ɛp ɔptimayz mold dizayn ɛn prɔsesin paramita dɛn .

Example: Klamp fos kalkyuleshɔn fɔ wan polycarbonate lamp holda

Lɛ wi dayv insay wan rial-wɔl ɛgzampul. Wi go kɔl di klem fɔs fɔ wan polycarbonate lamp ɔlda.

Ɔndastand di ɛgzampul .

Wi lamp holda gɛt dɛn spɛsifikɛshɔn ya:

Di dayamita we de na do: 220mm

Di tik we de na di wɔl: 1.9-2.1mm

Material: Polikarbonat (PC)

Dizayn: Pin-shep sɛnta get

Di rod we lɔng pas ɔl: 200mm

Polycarbonate na wan we pipul sabi fɔ in ay viskɔsiti. Dis min se i go nid mɔ prɛshɔn fɔ ful di mol.

Step-by-step kalkyuleshɔn .

Lɛ wi brok di prɔses:

Kalkul di flɔ lɔng to di wɔl tiknɛs rɛsɛshɔn:

ratio = lɔngest flɔ pat / tint wɔl= 200mm / 1.9mm= 105:1.

Ditarmin di bays kaviti prɛshɔn:

Adjɔst fɔ di prɔpati dɛn we yu go gɛt:

PC de na Viskositi Grup 6 .

Faktɔ fɔ bɔku bɔku tin dɛn: 1.9 .

prɛshɔn adjɔstmɛnt = 160 bar * 1.9 = 304 bar

Kalkul Projekt Eria:

Eria = π * (dayamita/2)⊃2;= 3.14 * (22/2)⊃2; = 380 cm²

Kompyut Klamp Fos:

Fos = prɛshɔn * eria= 304 bar * 380 cm²= 115,520 kg= 115.5 tan

Adjɔstmɛnt fɔ Sef ɛn Efisiɛns .

Fɔ sef, wi de rawnd ɔp to di nɛks mashin saiz we de. Wan 120 tan mashin go fayn.

Tink bɔt dɛn tin ya fɔ mek dɛn ebul fɔ du di wok fayn fayn wan:

Start wit 115.5 tan ɛn ajɔst bays pan pat kwaliti

Monitor fɔ flash ɔ shɔt shot .

Smɔl smɔl ridyus fɔs if i pɔsibul witout kɔmprɔmis kwaliti .

Injekshɔn moldin mashin sɛlɛkshɔn ɛn klamp fɔs maching

Fɔ pik di rayt injɛkshɔn moldin mashin rili impɔtant fɔ mek yu gɛt sakrifays. I nɔ jɔs de bɔt klamp fɔs - sɔm tin dɛn kin kam insay.

Rilayshɔn bitwin klem fɔs ɛn mashin paramita dɛn .

Klamp fos nɔ de ayd. I tay klos to ɔda mashin spɛsifikɛshɔn dɛn:

Di kapasiti fɔ injɛkshɔn:

Skru saiz:

Stroke we de opin fɔ di mold:

Tie bar spacing: .

Rifrɛns rɛnj fɔ kɔmɔn plastic prɔdak dɛn .

Klamp fos nid fɔ difrɛn bad bad wan. Na dis na wan jenɛral gayd:

| Prodakt |

matirial |

we dɛn dɔn projɛkt fɔ projɛkt (cm²) |

we dɛn nid fɔ klamp fɔs (Tons) |

| Tin-wɔl kɔntena dɛn . |

Polipropilen (PP) . |

500 cm² |

150-200 tan dɛn |

| Awtomotiv Kɔmpɔnɛnt dɛn . |

ABS na ABS |

1,000 cm² |

300-350 tan dɛn |

| Ilɛktronik Hausin dɛn . |

Polikarbonɛt (PC) . |

700 cm² |

200-250 tan dɛn |

| Bɔtul Kap dɛn . |

HDPE we de na di . |

300 cm² |

90-120 tan dɛn |

Di tebul we de ɔp de gi wan rɔf gayd fɔ mach di prɔdak tayp dɛn wit di nid klamp fɔs. Dɛn figa dɛn ya kin difrɛn difrɛn wan bay pat kɔmplisiti, matirial prɔpati, ɛn mold dizayn.

Di tin dɛn we kin apin we pɔsin nɔ yuz di rayt fɔ klem .

Fɔ gɛt klamp fɔs rayt na impɔtant tin fɔ injɛkshɔn moldin. If yu tu smɔl ɔ tumɔs, dat kin mek yu gɛt siriɔs prɔblɛm dɛn. Lɛ wi fɛn di prɔblɛm dɛn we kin apin.

Insufisient klamp fɔs .

We yu nɔ aplay inof fɔs, sɔm prɔblɛm dɛn kin apin:

Flash fɔmɛshɔn .

Di tin dɛn we pasmak de siep bitwin di mold af dɛn .

I de mek tin dɛn we tan lɛk tin dɛn we nɔ want fɔ kɔmɔt na do pan pat dɛn .

I nid fɔ gɛt ɔda trim, inkris prodakshɔn kɔst .

po pat kwaliti kwaliti .

Dimensional inaccuracies bikɔs ɔf mold separeshɔn .

Filin we nɔ kɔmplit, mɔ na say dɛn we gɛt tint wɔl we gɛt tin dɛn .

Inkonsistent pat weit akɔdin to prodakshɔn rɔn dɛn .

Mold Damej .

Fɔs fɔ klamp fɔs .

Aplay tu moch fos no bi di ansa tu. I kin mek:

Mashin Wear .

Stret we nɔ nid fɔ de pan haydrolik kɔmpɔnɛnt dɛn .

Aksɛlɛrat Wear ɔf Tay Ba ɛn Plɛt dɛn .

Shortened mashin layfspan .

Energy west .

Mold Damej .

Difikulti fɔ rilis di kaviti prɛshɔn .

Impɔtant tin fɔ mek yu kɔntinyu fɔ gɛt di bɛst klamp fɔs .

Fɔ balans di klamp fɔs na di men tin fɔ mek yu ebul fɔ mold fayn fayn wan. Na dis mek i impɔtant:

Konsistent Pat Kwaliti .

Ekstend Ikwipmɛnt Layf .

Energy efficiency .

Fasta Saykl tɛm dɛn .

Ridyus di skrap ret dɛn .

Memba, optimal fos nɔ de statik. I kin nid fɔ ajɔst bay we yu yuz:

Monitoring ɛn fayn-tyunin fɔ klamp fɔs na impɔtant tin fɔ mek dɛn kɔntinyu fɔ mek ay kwaliti, efyushɔn prodakshɔn.

Di bɛst we fɔ mek shɔ se yu gɛt di bɛst klamp fɔs .

Fɔ ajɔst di pafɛkt klamp fɔs nɔto wan tɛm wok. I nid fɔ mek pipul dɛn pe atɛnshɔn to am ɛn ajɔst am ɔltɛm. Lɛ wi fɛn sɔm bɛst prɔsis fɔ kip yu injɛkshɔn moldin prɔses de rɔn fayn fayn wan.

Di rayt we aw fɔ mek di mold dizayn .

Gud mold dizayn na impɔtant tin fɔ optimal klamp fɔs:

Yuz balans rana sistem fɔ sheb prɛshɔn ivin wan .

Impliment prɔpa ventin fɔ ridyus trɔp ɛya ɛn prɛshɔn spayk dɛn .

Tink bɔt pat jɔyometri fɔ minimiz projɛkt eria usay i pɔsibul .

Disain wit yunifom wol tiknes fɔ protɛkt ivin prɛshɔn distribyushɔn

Material Selection ɛn di impak we i gɛt pan am .

Difrɛn matirial dɛn nid difrɛn klamp fɔs:

| matirial |

rilitiv klamp fɔs we dɛn nid |

| PE, PP |

Lo |

| ABS, PS . |

Lukin-grɔn uman |

| PC, Pom |

Ay |

Pik di tin dɛn we yu fɔ yuz wit sɛns. Tink bɔt ɔl tu di pat dɛn we dɛn nid ɛn di izi we fɔ prosɛs.

Mashin Mentɛnans ɛn Kalibreshɔn .

Rigyul mentenɛns de mek shɔ se dɛn gɛt kɔrɛkt klamp fɔs:

Chek haydrolik sistem fɔ lik ɔ wɛr .

Kalibrayt prɛshɔn sɛnsa dɛn ɛvri ia .

Inspek tie bar fɔ sayn dɛn we de sho se yu strɛs ɔ yu nɔ gɛt di rayt fɔ du wetin yu want .

Kip plet dɛn klin ɛn dɛn dɔn lɔs fayn fayn wan

Monitoring ɛn adjɔst di tɛm we dɛn de prodyuz .

Klamp fos nɔto sɛt-ɛn-fɔgɛt. Monito dɛn indikɛtɔ ya:

Adjɔst fɔs if yu notis di prɔblɛm dɛn. Smɔl chenj dɛn kin mek big big difrɛns.

Kwantitaytiv indikɛtɔ ɛn kɔntrol mɛtɔd dɛn .

Yuz data fɔ fayn-tyun yu prɔses:

Establish wan beslayn klamp fɔs .

Adjust in 5-10% inkrimɛnt bays pan pat kwaliti

Rikɔd di rizɔlt fɔ ɛni ajɔstmɛnt .

Krio wan database we de korelat fos to pat kwaliti .

Yuz dis data fɔ fiuja sɛtup ɛn trɔbulshut .

Example Control Chart:

| Klamp Fos (%) |

Flash |

shɔt shot dɛn |

wet kɔnsistɛns |

| 90 |

Nɔn |

Sɔm |

±0.5% |

| 95 |

Nɔn |

Nɔn |

±0.2% |

| 100 |

Smɔl smɔl . |

Nɔn |

±0.1% |

Fɛn di swit ples usay ɔl di kwaliti indikɛtɔ dɛn go fayn.

Dɔn

Fɔ ɔndastand ɛn kɔl di klamp fɔs impɔtant fɔ mek dɛn ebul fɔ mek di injɛkshɔn mɔld fayn fayn wan. I de mek shɔ se pat kwaliti, i nɔ de mek i nɔ gɛt ɛni prɔblɛm, ɛn i de mek di mold layf lɔng. Ki takeaways inklud di rol we projɛkt eria, matirial prɔpati, ɛn prɔsesin paramita dɛn de ple fɔ no di kɔrɛkt klamp fɔs. Aplay dis no insay yu prɔjek dɛm fɔ ajɔst bɛtɛ rizɔlt ɛn ɔptimayz prodakshɔn efyushɔn.