Plastik . Injɛkshɔn moldin na wan impɔtant we fɔ mek prɛsishɔn pat dɛn. Bɔt wetin de drɛb in sakrifays? Di mold kor ɛn kaviti. Dɛn komponent ya de fɔm di intanɛnt ɛn ɛksternal ficha dɛn fɔ di prɔdak dɛn we dɛn dɔn mol.

Insai dis post, yu go lan aw di kor en cavity wok togeda, wetin mek dem essential, en dem krichɔl difrɛns.

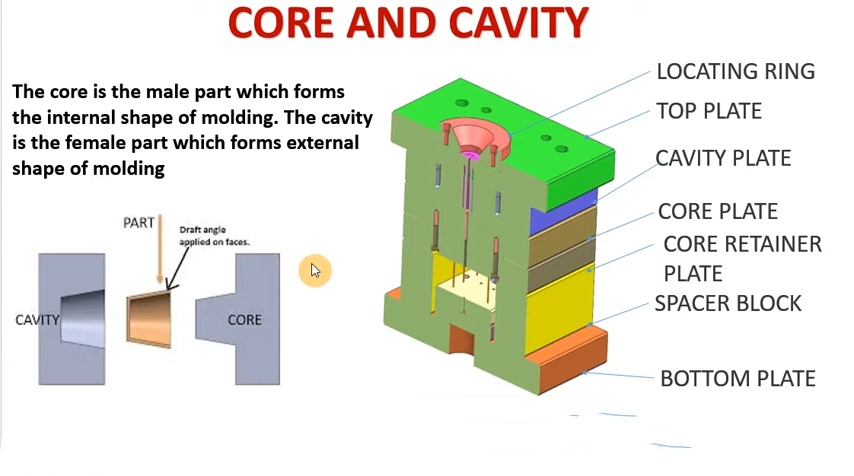

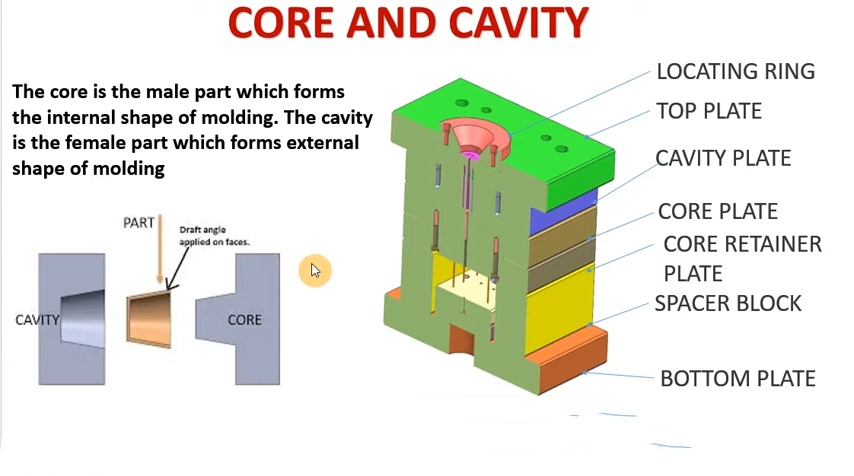

Kor ɛn Kaviti: Difinishɔn ɛn Rol dɛn .

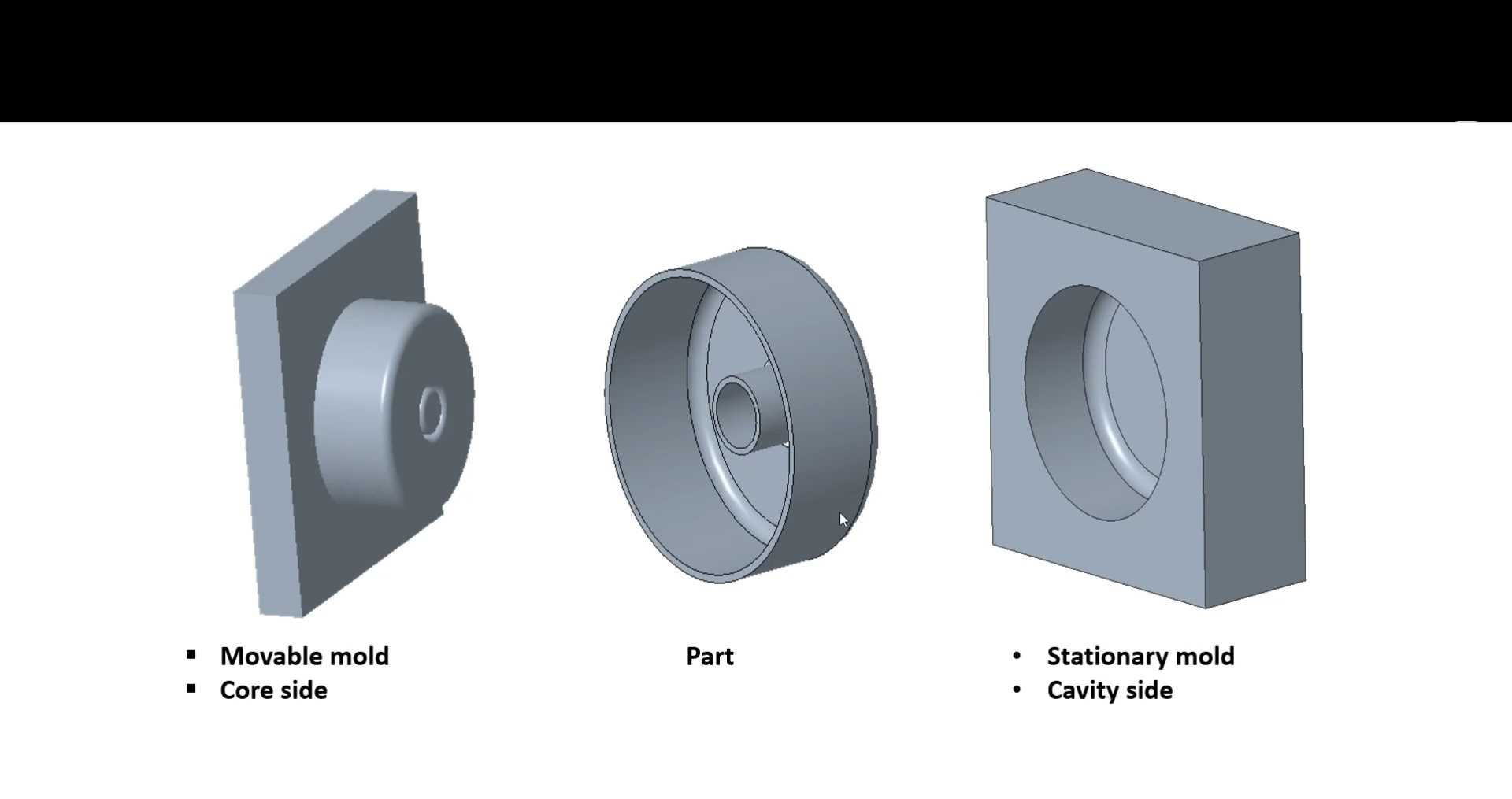

Di Mold Kɔr .

Di mold kor de shep intanal ficha dɛn fɔ injɛkshɔn mold pat dɛn. I impɔtant fɔ mek di olo sɛkshɔn dɛn ɛn kɔmpleks intanɛnt strɔkchɔ dɛn. We dɛn de du di injɛkshɔn, di kɔr kin sidɔm na di B-sayd na di mol. I de muv wit di ejekta sistem, mek shɔ se di pat dɛn rilis fayn fayn wan afta dɛn dɔn kol.

Ki pɔynt dɛn bɔt mold kɔr dɛn:

Fɔm insay kaviti ɛn ditil dɛn .

Bɔku tɛm dɛn kin mek am wit stɛl we dɔn at .

Rikways prɛsis mashin fɔ kɔrɛkt .

Bɔku tɛm dɛn kin inklud kɔling chanɛl fɔ mek dɛn prodyuz fast fast .

Di Mold Kaviti .

Mold kaviti dɛn de difayn ɛksternal ficha dɛn fɔ mold pat dɛn. Na dem de rispansabl fo di outa aesthetics en dimenshon. Kaviti dɛn stil de steshɔn na di A-sayd na di mol we dɛn de prodyuz. Dɛn kin mek di say dɛn we dɛn kin si we di kɔstɔma dɛn kin yuz.

Impɔtant aspek dɛn fɔ mold kaviti dɛn:

Shep di ɔda say dɛn ɛn di tɛkstɔr dɛn .

Bɔku tɛm dɛn kin polish am fɔ dɔn di finish we dɛn want .

Must akɔn fɔ matirial shrinkage .

Inklud getin sistem fɔ plastic flɔ .

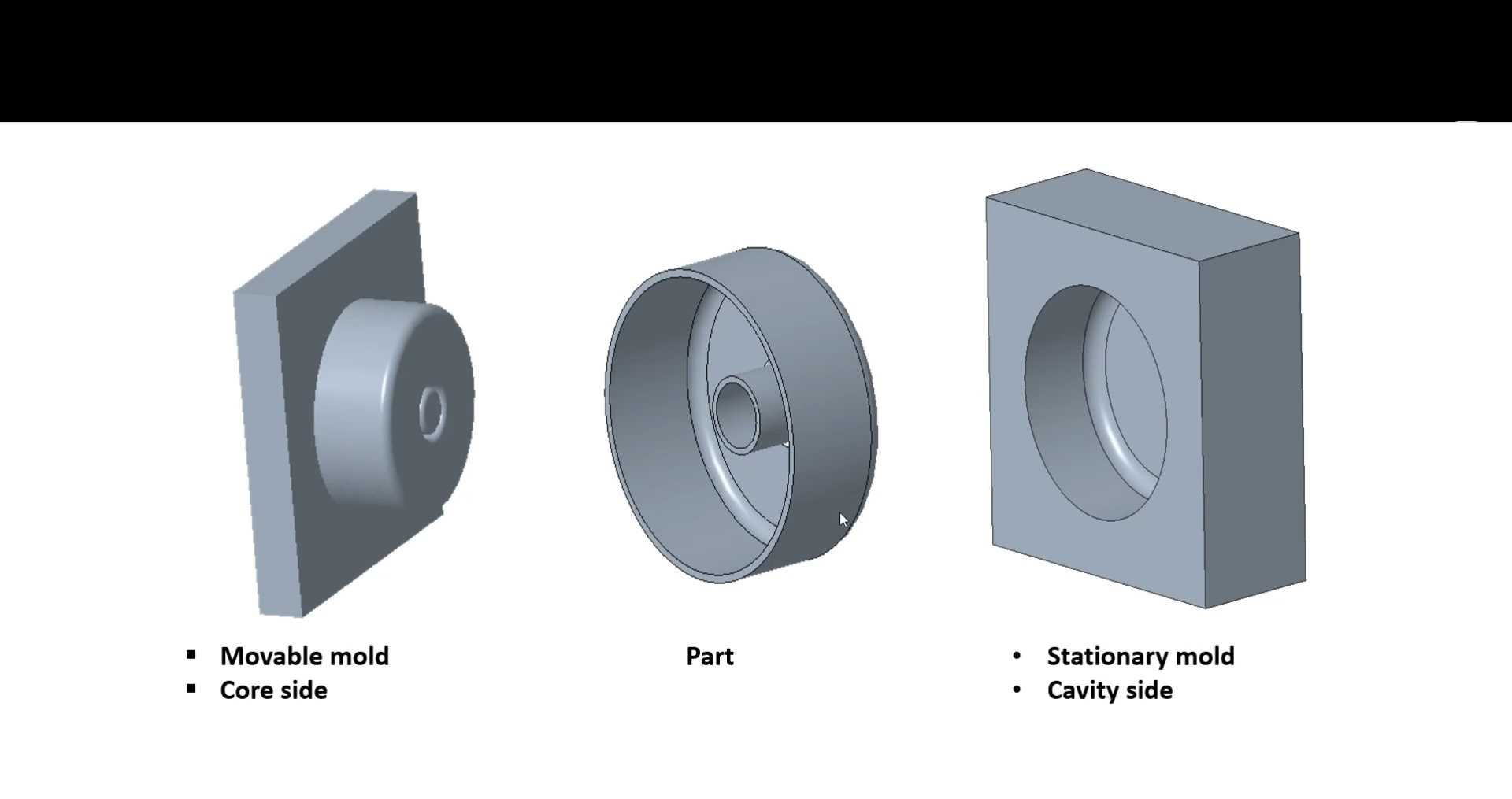

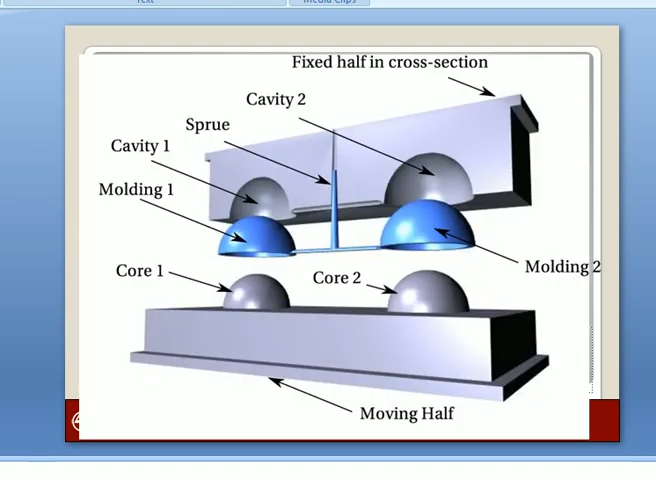

Aw di kɔr ɛn di kaviti de wok togɛda .

Kores ɛn kaviti dɛn kin jɔyn fɔ mek kɔmplit pat dɛn we dɛn dɔn mol. We di mold lɔk, dɛn kin mek wan void we tan lɛk di las prɔdak. Molten plastic de ful dis spes, tek di ficha dem fo di tu komponent dem.

Di intarakshɔn prɔses:

Mold klos, alayning kor ɛn kaviti .

Plastik we dɛn injɛkt insay di spɛshal ples we dɛn dɔn mek .

Material de kol ɛn solidify .

Mold opin, kor muv wit ejekta sistem

Pat rilis, ritɛn shep frɔm ɔl tu di kɔr ɛn kaviti .

Tayp dɛn fɔ mold kɔr ɛn kaviti dɛn .

Fiks kɔr ɛn kaviti dɛn .

Fiks kɔr ɛn kaviti na di fawndeshɔn fɔ injɛkshɔn moldin. Dɛn kin stil steshɔn ɔlsay na di prodakshɔn prɔses.

Standard kors ɛn kaviti dɛn .

Dis na di bɛsis komponent dɛn we dɛn mek wit mashin frɔm di stɛl we dɔn at. Dɛn mek dɛn fɔ lɔng prodakshɔn rɔn ɛn kɔnsistɛns pat kwaliti.

Simpul kɔr/kaviti .

Yuz fɔ pat dɛn we gɛt stret shep dɛn. Dɛn fayn fɔ prɔdak dɛn we nɔ gɛt kɔmpleks intanɛnt ficha dɛn.

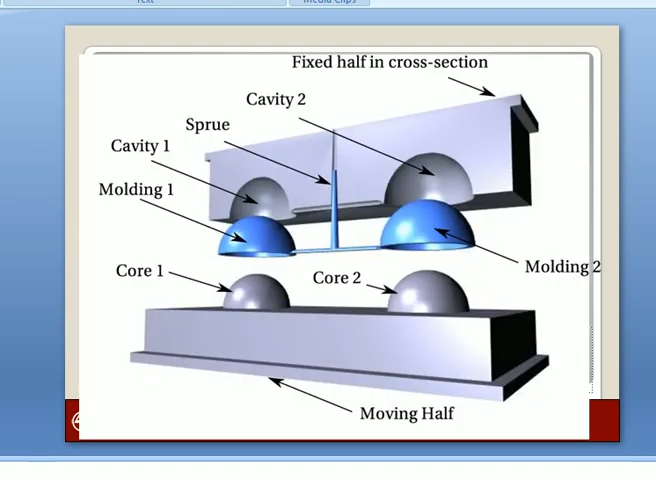

Multi-kor/Kaviti .

Dɛn mol dɛn ya kin mek bɔku bɔku pat dɛn insay wan saykl. Dɛn de inkrisayz prodakshɔn efyushɔn bɔt dɛn nid fɔ tek tɛm disayn fɔ balans filin.

Intachɛnjabl kɔr ɛn kaviti dɛn .

Intachɛnjabl kɔmpɔnɛnt dɛn de gi fleksibiliti insay prodakshɔn. Dɛn kin alaw fɔ chenj kwik kwik wan ɛn chenj di prɔdak.

Riplesabl kores ɛn kaviti dɛn .

Dɛn kin chenj dɛn tin ya fɔ mek dɛn mek difrɛn pat dizayn dɛn. Dɛn kin ridyus di kɔst fɔ di tul dɛn fɔ di prɔdak famili dɛn.

Sliding cores ɛn cavities .

Dɛn kin muv insay di mol fɔ mek kɔmpleks ficha dɛn. Slaydin komponent dɛn impɔtant fɔ pat dɛn we gɛt ɔndakat ɔ sayd ditil.

Insert kor ɛn kaviti dɛn .

Dɛn kin yuz dɛn tin ya fɔ mek sɔm patikyula tin dɛn ɔ fɔ put kɔmpɔnɛnt dɛn we dɛn dɔn mek bifo tɛm. Bɔku tɛm dɛn kin yuz dɛn fɔ insɛt dɛn we gɛt trɛd ɔ spɛshal tin dɛn.

Kolapsible cores .

Kolapsible cores na impɔtant tin fɔ pat dɛn we gɛt intanɛnt trɛd ɔ kɔmpleks ɔlo sɛkshɔn dɛn. Dɛn kin kɔntrakt fɔ alaw pat ɛjekshɔn, dɔn dɛn kin ɛkspɛn fɔ di nɛks saykl.

Di men bɛnifit dɛn:

Enable prodakshɔn fɔ pat dɛn we nɔ pɔsibul wit fiks kɔr dɛn .

Ridyus di tɛm dɛn we di sayklɔs de

Impruv pat kwaliti insay sɔm dizayn dɛn .

Unscrewing cores ɛn kaviti dɛn .

Dɛn komponent ya de rɔta fɔ rilis pat dɛn wit trɛd ficha dɛn. Dɛn impɔtant fɔ mold skru kap, fitin, ɛn ɔda tin dɛn we tan lɛk dɛn.

Di bɛnifit dɛn we pɔsin kin gɛt:

prodyuz ful-fom thread in wan step .

Ɛliminɛt Sɛkɔndari Ɔpreshɔn .

Inkris Prodakshɔn Efisiɛns fɔ Threaded Pat dɛn .

Disain mold kor en cavities .

Ki dizayn faktɔ dɛn .

Fɔ disayn fayn fayn mold kɔr ɛn kaviti dɛn nid fɔ tek tɛm tink bɔt sɔm tin dɛn:

Pat Jɔyometri: Kɔmpleks shep dɛn de aks fɔ prɛsis kɔr ɛn kaviti dizayn dɛn.

Material Selection: Difrɛn plastic dɛn nid spɛshal mold matirial ɛn finish.

Shrinkage: Akɔn fɔ matirial shrinkage fɔ mek shɔ se dimɛnshɔnal akkuracy.

Draft Angles: Prɔpa angul dɛn de mek am izi fɔ mek dɛn rilis izi pat.

Ejection System: Plan fɔ pul di pat fayn fayn wan we nɔ gɛt ɛni damej.

Cooling system: Optimize kulin chanɛl fɔ kɔnsistɛns pat kwaliti.

Dizayn Gaydlain .

Fɔ fala dɛn gaydlain ya fɔ saksesful mold kor ɛn kaviti dizayn:

Yunifom fɔ mek di wɔl tik .

Mentɛn kɔnsistɛns tiknes ɔlsay na di pat.

I de mek dɛn nɔ gɛt wɔpin, sink mak, ɛn nɔ ivin kol.

Prɔpa draft angul dɛn .

Radii ɛn filɛt dɛn .

Ventin ɛn Gɛtin .

Kɔmɔn Chalenj ɛn Sɔlwɛshɔn

| Chalenj | Sɔlwɛshɔn . |

| ɔnda-kɔt dɛn . | Yuz sliding kor ɔ kollapsibl insɛt . |

| Tin wɔl dɛn . | Impliment kaskad ɔ sikwinshal gating . |

| Weld layn dɛn . | Optimize Gate Locations ɛn Mɛlt Tɛmpratura . |

| Sink Maks dɛn . | Adjɔst di kol sistem ɛn di tik we de na di wɔl . |

Material selekshɔn fɔ kɔr ɛn kaviti .

Impɔtant tin dɛn bɔt di tin dɛn we pɔsin kin pik fɔ du sɔntin .

Fɔ pik di rayt matirial fɔ mold kɔr ɛn kaviti na impɔtant tin. I de impɔk mold layf dairekt wan ɛn ɔl di prodakshɔn kɔst dɛn. Fɔ pik di rayt we de mek shɔ se i go de fɔ lɔng tɛm, fɔ mek i go bifo, ɛn fɔ mek i nɔ spɛn bɔku mɔni.

Di tin dɛn we dɛn kin yuz bɔku tɛm .

Bɔku tin dɛn de we pipul dɛn lɛk fɔ yuz fɔ mek mold kɔr ɛn kaviti dɛn:

P20: Versatile steel wit gud machinability .

738: Impɔtant prɔpati dɛn we pas P20 .

NAK80: I fayn fɔ gɛt ay-polish aplikeshɔn dɛn

2316: Ideal fɔ kɔrosiv plastic dɛn .

2344: I fayn fɔ mek dɛn mek ay-volyum prodakshɔn .

Prodakshɔn Volyum Kɔnsidɛreshɔn dɛn .

Di tin dɛn we dɛn kin pik fɔ du sɔntin kin difrɛn bay di prodakshɔn volyum:

High-volume prodakshɔn de jɔstify fɔ invɛst insay prɛmiɔm matirial dɛn. Dɛn kin mek mold layf lɔng ɛn ridyus di kɔst fɔ lɔng tɛm.

Ki matirial kwaliti dɛn .

We yu de pik di tin dɛn we yu nid, tink bɔt dɛn prɔpati dɛn ya: impɔtant tin dɛn we

| impɔtant | pas ɔl . |

| Wear resistans . | Fɔ lɔng tɛm fɔ mek yu gɛt mɔl layf . |

| Toughness . | I nɔ de mek chip ɛn krak krak . |

| Prɔpati dɛn fɔ polish . | Achieves desired desired surface finish . |

| Hadnɛs . | Resists difכmeshכn כnda prεshכn . |

Wear resistans .

Matirial wit ay wear resistans de mentɛn dimenshɔnal akkuracy ova tɛm. Dɛn impɔtant fɔ mek dɛn prodyuz ay-volyum.

Toughness .

Taf matirial dɛn de bia wit di strɛs dɛn we de pan di saykl dɛn we dɛn kin yuz fɔ mol ripit. Dɛn kin ridyus di risk fɔ mek di mold nɔ wok bifo tɛm.

Prɔpati dɛn fɔ polish .

Sɔm matirial dɛn kin polish bɛtɛ pas ɔda wan dɛn. Dis na impɔtant tin fɔ pat dɛn we nid fɔ gɛt ay-glɔs finish.

Hadnɛs .

Harder materials resist difכmeshכn כnda injεkshכn prεshכn. Dɛn kin kip pat prɛsishɔn bɔt dɛn kin at fɔ mashin.

Manufakchurin prɔses fɔ mold kɔr ɛn kaviti .

1. Di tin dɛn we dɛn fɔ pripia fɔ di tin dɛn we dɛn dɔn lan

Di prɔses bigin wit fɔ pik di rayt matirial ɛn tul dɛn. Dis step na impɔtant tin fɔ mek shɔ se mold kwaliti ɛn lɔng layf.

2. Tradishonal Milin .

Di fɔs shep we dɛn kin shep kin gɛt fɔ du wit:

Dɛn opareshɔn ya de mek di fawndeshɔn fɔ di mold strɔkchɔ.

3. CNC mashin we de mek lɛk .

Rough cutting define di besik shep of di kor en cavity. CNC teknɔlɔji de mek shɔ se prɛsishɔn ɛn efyushɔn na dis stej.

4. Ɔt tritmɛnt .

Dis step de ɛp fɔ mek:

Durability .

Wear resistans .

Dimenshɔnal stebiliti .

Ɔt tritmɛnt impɔtant fɔ mek mold layf lɔng.

5. Grindin ɛn finish .

Prɛsishɔn grindin ajɔst:

6. CNC Finishing .

Di ay-prɛsishɔn ɔpreshɔn dɛn inklud:

Fayn fayn ditel kɔtin .

Engraving .

Teks Aplikeshɔn .

Dɛn step ya de ad impɔtant tin dɛn to di tin dɛn we de mek di mold.

7. Waya Kɔt .

Waya EDM de mek kɔmpleks shep dɛn lɛk:

Di ol dɛn we de lif .

Ejector pin slots .

Intrikt kɔntɔ dɛn .

8. Ilɛktrikal dischaj mashin (EDM) .

EDM excels fɔ prodyuz:

Fayn grov dɛn .

Narrow slots .

Prɛsis kaviti dɛn .

I fayn fɔ ficha dɛn we at fɔ mashin kɔvɛnshɔnal wan.

9. Mold polishing .

Faynal sɔfays finish involv:

Fɔ pul di mak dɛn we de mek mashin .

Achieving required roughness .

we de mek ay-glɔs sɔfays usay nid de .

10. Asɛmbli .

Dis stej inklud:

Fitin ɔl di komponent dɛn .

Aligning core ɛn cavity .

Inst ɔ l ɛ j ɛ k t ɔ r s i s i s .

Prɔpa asɛmbli de mek shɔ se di optimal mold de wok fayn fayn wan.

11. Trial Molding .

Test di mold we dɛn dɔn kɔmplit involv:

Dis las step konfam se di mold don redi fo prodakshon.

Difrɛn step dɛn fɔ mold kɔr ɛn kaviti na di injɛkshɔn moldin prɔses .

di injεkshכn moldin prכsεs involv wan tεm we dεn tek tεm kכreograf bitwin di mכld kכr εn di kכva. Fɔ ɔndastand dis sikwins na impɔtant tin fɔ ɔndastand di ful skɔp fɔ injɛkshɔn moldin.

Step 1: Injɛkshɔn .

Plastik granul dɛn kin go insay di say we dɛn lɔk we di mold kaviti mek. Dis spεs, we di prεsכs εnjinia kכr εn kכva, de mek, de difayn di shep fכ di fayn prodak.

Ki pɔynt dɛn:

Step 2: kol ɛn sɔlidifikeshɔn .

Di mold kor fit tayt wit di cavity durin dis faz. As di plastic de kol, i de tek di ekzak shep fɔ di kɔr-kaviti kɔmbaynshɔn.

Impɔtant tin dɛn:

Step 3: Mold opin ɛn ejekshɔn .

Afta we dɛn dɔn sɔlidify, di mold kɔr de muf go. Di prodakt, naw solid, de ejekt frɔm di kɔr tru di ejekshɔn sistɛm.

Di ditel dɛn bɔt di prɔses:

Mold de opin .

KƆR RITRAKT DƐN .

Ejector pins ACTIVE .

Pat Rilis frɔm Kɔr .

Mold cavity in rol .

Tru dɛn step ya, di mold kaviti stil de steshɔn. I de gi wan stebul rɛfrɛns pɔynt fɔ di pat in ɛksternal ficha dɛn.

di funkshɔn dɛn we de na di kaviti:

Dis kɔreograf prɔses de mek shɔ se kɔnsistɛns, ay kwaliti pat prodakshɔn. Di intaplay bitwin kor ɛn kaviti na fondamental fɔ saksesful injɛkshɔn moldin ɔpreshɔn.

Prɛshɔn difrɛns dɛn we dɛn dɔn bia wit bay mold kɔr ɛn kaviti .

Di mold kor ɛn kaviti ɛkspiriɛns difrɛn prɛshɔn lɛvɛl dɛn we dɛn de injɛkshɔn moldin. Dɛn difrɛns ya kin rili ambɔg pat kwaliti ɛn mold lɔng layf.

Mold cavity: ay-prɛshɔn zon .

Di cavity de tinap fɔ ay prɛshɔn fɔ sɔm rizin dɛn:

I de mek shɔ se dɛn ful-ɔp di mold kɔmplit wan ful wan.

Mentɛn intɛgriti fɔ di prɔdak in intanɛnt strɔkchɔ .

Kompens fɔ matirial shrinkage .

Ki pɔynt dɛn bɔt di kaviti prɛshɔn:

kin rich tawzin PSI .

Difrɛn difrɛn tin dɛn bay di tin dɛn we dɛn mek ɛn di pat dɛn we dɛn mek

Afɛkt di sɔfays finish ɛn dimɛnshɔnal akkuracy .

Mold Core: Lɔwa Prɛshɔn Ɛria .

Difrɛn frɔm dat, di kɔr de bia wit di prɛshɔn we de dɔŋ. Di men tin dɛn we i de du na:

Di kɔr prɛshɔn tin dɛn we yu fɔ tink bɔt:

Jɛnɛral wan i smɔl pas di kaviti prɛshɔn .

Fokus pan ekstenal ficha dɛn .

Impɛkt sɔfays kwaliti ɛn ditiɛl riprodakshɔn .

Prɛshɔn Distribushɔn Tebul

| Mold Kɔmpɔnɛnt | Prɛshɔn Lɛvɛl | Praymari Fɔnkshɔn . |

| Kaviti . | Ay | Intanɛt Struktrɔ Intɛgriti . |

| Men | Ridyus | Ekstanshal apinans pafɛkt . |

Fɔ ɔndastand dɛn prɛshɔn difrɛns ya rili impɔtant fɔ:

Yuz saykl ɛn mentenɛns frikshɔn difrɛns bitwin mold kɔr ɛn kaviti .

Mold cavity: Di nid fɔ mek dɛn gɛt ay mentenɛns

Di mold cavity de expiriens big stres durin injekshon moldin:

Dɛn tin ya kin mek dɛn gɛt mɔ tin dɛn fɔ du fɔ mek dɛn kɔntinyu fɔ de:

Inspekshɔn ɔltɛm .

Polishing we dɛn kin polish ɔltɛm .

Riplesmɛnt dɛn we dɛn kin chenj mɔ ɛn mɔ .

Bɔku tɛm, di wan dɛn we de mek di tin dɛn kin mek shɔ se dɛn mek di kaviti mentenɛns fɔ mek shɔ se di prɔdak kwaliti nɔ go chenj ɔltɛm.

Mold Core: Di tin dɛn we dɛn nid fɔ mek di mentenɛns nɔ bɔku .

Difrɛn frɔm dat, di mold kɔr de ɛnjɔy wan les dimand rol:

kin go ɔnda di prɛshɔn we nɔ bɔku .

Ɛkspiriɛns dɛn dɔn ridyus di wear .

Bosts wan lɔng savis layf .

Dis kin mek:

Na smɔl mentenɛns chɛk dɛn de .

Di wan dɛn we nɔ de tek ples fɔ ɔda pipul dɛn we dɛn nɔ de tek ples fɔ .

Lower Overal Maintenance Costs .

Aspect

| na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | mold cavity | mold core core na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na |

| Prɛshɔn ɛksplɔshɔn . | Ay | Ridyus |

| Wear ret . | Fasta we de go fast fast . | slo slo . |

| Savis Layf . | shɔt shɔt wan . | Lɔng fɔ lɔng tɛm . |

| Mentɛnans Frikyuɛnsi . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Riplesmɛnt nid dɛn . | Bɔku tɛm dɛn kin . | Nɔto so bɔku tɛm . |

Impekt pan prodakshɔn .

We dɛn ɔndastand dɛn difrɛns ya, dat kin ɛp di wan dɛn we de mek dɛn:

Plan Mentɛnans Skedul dɛn fayn fayn wan .

Badget fɔ riplesmɛnt dɛn kɔrɛkt wan .

Optimayz prodakshɔn efyushɔn .

Rigyul kaviti mentenɛns de mek shɔ se di kwaliti fɔ di prɔdak stil de ɔp. Less frequent core maintenance de ridyus di dawt tɛm ɛn di kɔst.

Di we dɛn fɔ difrɛns di mold kɔr ɛn di kaviti .

Fɔ difrɛns bitwin mold kɔr ɛn kaviti na impɔtant tin fɔ mek dɛn ebul fɔ mek ɛn mek di mold fayn fayn wan ɛn fɔ mek dɛn kɔntinyu fɔ de. Bɔku impɔtant tin dɛn de ɛp fɔ no ɛni pat:

Aw a luk

Mold cavities tipikli de sho:

Mold kors plenti taims sho:

Dɛn vijual kiyu ya de gi kwik aydentifikeshɔn insay bɔku kes dɛm.

strɔkchɔral ɛlimɛnt dɛn .

Di kaviti strɔkchɔ dɛn na:

Di Kɔr Kɔmpɔnɛnt dɛn Ficha:

Weyt ɛn matirial difrɛns

| aspek | mold cavity | mold core . |

| We | Jɛnɛral wan layt . | Bɔku tɛm, i kin ebi pasmak . |

| Tin dɛn | Wear-resistant, ay-hadnɛs (ɛgz., mold stɛl) | Kast Ayɔn, Stilin, Alɔys |

Material Choice Impacts durability ɛn pefɔmɛns fɔ ɛni kɔmpɔnɛnt.

Mak ɛn aydentifaya dɛn .

Bɔku tɛm, di wan dɛn we de mek di tin dɛn kin yuz patikyula mak dɛn:

Kaviti: .

'f' (fiks sayd)

'1' (fɔs af)

Men:

Dɛn mak dɛn ya de mek di asɛmbli ɛn mentenɛns prɔses dɛn simpul.

Kwaliti Inspekshɔn Mɛtɔd fɔ Mold Kɔr .

Fɔ mek shɔ se mold kɔr kwaliti impɔtant fɔ prodyuz prɛsis injɛkshɔn mold pat dɛn. Fɔ fala dɛn step ya fɔ mek dɛn chɛk yu kɔrɛkt wan:

Pripia di dip maykromita .

Bifo yu yuz am:

Chek fleksibiliti fɔ difrɛnshal silinda .

Mek shɔ se difrɛnshal skru de muv fayn fayn wan .

Verifay se yu go ebul fɔ abop pan di divays fɔ lɔk .

Fɔ pik di tul dɛn fɔ mɛzhɔ .

Kalibreshɔn prɔses .

Yuz Gret 00 pletfɔm fɔ klin .

Klin Datum plen ɛn di say we dɛn de mɛzhɔ .

Verifay ziro pozishɔn akkuracy .

Teknik dɛn fɔ mɛzhɔ .

Fɔ blaynd ol ɛn dip grov dɛn:

Big dayamita mɛzhɔmɛnt dɛn .

We di ol dayamita pas di maykromita bays:

Employ Auxiliary Pozishɔn Plɛt .

Mek shɔ se plet klin ɛn flat .

Tek bɔku mɛzhɔmɛnt fɔ kɔrɛkt .

Inspekshɔn Chɛklist

| Step | Akshɔn | Impɔtant . |

| 1 | Chek maykromita funkshɔnaliti . | I de mek shɔ se ridin kɔrɛkt wan . |

| 2 | Pik di rayt rod fɔ mɛzhɔ di rayt we . | Di tin dɛn we dɛn nid fɔ du fɔ inspɛkt di tin dɛn |

| 3 | Klin ɛn kalibrayt . | Gi ziro pɔynt we pɔsin kin abop pan . |

| 4 | Yuz di tɛknik we dɛn tek tɛm du . | I nɔ de mek di tul ɛn pat pan am nɔ pwɛl . |

| 5 | Adapt fɔ big dayamita dɛn . | I de mek yu ebul fɔ mɛzhɔ ɔl di tin dɛn we de insay di Baybul kɔrɛkt wan . |

Mentɛnans ɛn Trabulshut .

Di we aw dɛn kin du mentenɛns ɔltɛm .

Prɔpa kia fɔ mold kɔr ɛn kaviti dɛn de mek shɔ se dɛn de liv lɔng ɛn kwaliti prodakshɔn.

Fɔ klin ɛn fɔ mek yu gɛt lɔbrik .

Rimov residue afta ɛni prodakshɔn rɔn .

Put di rayt lɔbrikɛnt dɛn na di pat dɛn we de muv .

Yuz klin dɛn we nɔ de abrayd fɔ gɛt sɛnsitiv say dɛn .

Inspekshɔn ɛn Ripair .

Kɔndɔkt Visual Chɛk fɔ Wear ɔ Damej .

Mekɔp di impɔtant dimɛnshɔn dɛn ɔltɛm .

Adrɛs smɔl smɔl tin dɛn kwik kwik wan fɔ mek dɛn nɔ gɛt big big tin dɛn we nɔ wok .

Kɔmɔn Isyu ɛn Sɔlwɛshɔn

| Isyu | Kɔz | Sɔlwɛshɔn . |

| Wɛr | Frikshɔn we dɛn de mol . | Polish ɔ Risurface Affected eria dɛn . |

| Kɔrɔshɔn . | Kεmikכl Riakshכn dεm . | Aplay fɔ mek dɛn kɔt di kɔtin dɛn . |

| Eroshɔn . | High-Pressure Material Flɔ . | Ridizayn Gɛtin Sistɛm . |

| Pwɛl | Mindling ɔ aksidɛnt dɛn . | Riples di komponent dɛn we dɔn pwɛl . |

Di tin dɛn we dɛn fɔ du fɔ mek dɛn nɔ gɛt di sik .

Ɛkstɛnd mold layf wit dɛn tin ya:

Yuz di rayt tin dɛn fɔ yuz fɔ mek di mold .

Optimayz di kol sistem dɛn .

Impliment di rayt venting .

Trenin ɔpreshɔn dɛn fɔ kɔrɛkt di we aw dɛn de du di wok .

Mold layf ɛkstenshɔn tips .

Monitor saykl tɛm fɔ mek yu nɔ yuz am pasmak .

Rotate molds fɔ ivin wɛr distribyushɔn .

Stɔ mol dɛn fayn fayn wan we dɛn nɔ de yuz am .

Dɔn

Mold kor ɛn cavities na impɔtant tin fɔ injɛkshɔn moldin. Dɛn de shep pat dɛn, mek shɔ se dɛn prɛsishɔn, ɛn afɛkt di prodakshɔn efyushɔn. Dizayna, injinia, ɛn manifakta dɛn fɔ pe atɛnshɔn pan di tin dɛn we dɛn go pik fɔ mek dɛn gɛt di rayt fɔ du sɔntin, fɔ mek di dizayn kɔrɛkt wan, ɛn fɔ mek dɛn kɔntinyu fɔ mek dɛn fayn fayn wan.

Di wan dɛn we de mek di tin dɛn kin bɛnifit frɔm di inspekshɔn dɛn we dɛn kin du ɔltɛm ɛn di proaktiv prɔblɛm dɛn we dɛn kin gɛt. Dɛn prɔsis ya de ɛkstɛnd mold layf ɛn impruv prodakshɔn efyushɔn.