PPS ɔ polyphenylene sulfide bin fɔs divɛlɔp insay di 1960s as ay-pɔfɔmɛnshɔn polima. I de brij di gap bitwin standad plastic ɛn advans matirial, we de gi yunik prɔpati dɛn we de mek i impɔtant na difrɛn industri dɛn.

Insai dis post, wi go explor PPS in yon prɔpati, difrɛn aplikeshɔn, aw prɔsesin, ɛn wetin mek i de bi indispensable na difrɛn industri dɛm.

Kεmikכl strכkchכ fכ PPS .

Polyphenylene sulfide (PPS) de gi ay-tɛmpracha rɛsistɛns, rigiditi, ɛn wan opaque apinans as sɛmi-kristalayn tɛmplastik.

Molekyular Struktrɔ .

di bakbon fכ PPS kכnsis fכ para-fεnylεn yunit dεm we de altεn wit sכlfayd linkaj dεm. Dis de gi PPS in karakta prɔpati dɛm.

Sɔlfɔ atɔm dɛn de mek wan kɔvalɛnt bɔnd bitwin bɛnzin ring dɛn. Dɛn kin kɔnɛkt insay wan para (1,4) kɔnfigyushɔn, we kin mek wan linya chen.

Krɔstɔl strɔkchɔ .

PPS de fכm sεmi-kristalayn strכkchכ dεm, we de kכntribyut to in tεmral stεbiliti εn kεmikכl rεsistεns.

Orthorhombic unit sel .

di yunit sel fכ PPS na orthorhombik, wit di dimenshכn dεm we de dכn:

A = 0,867 nm

B = 0,561 nm

C = 1,026 nm

Di kalkulεt hεt fכ fכs fכ wan ideal PPS kristכl na 112 j/g. Dis strɔkchɔ de gi PPS in ay mɛlt pɔynt we na 280°C.

Digri fɔ kristaliniti .

di digri we di kristaliniti de insay PPS de frכm 30% to 45%. I dipen pan:

Di ay kristaliniti de go ɔp:

Lɔwa kristaliniti de impɔtant:

Impɛkt rɛsistɛns .

Elongeshɔn .

Yu kin pripia amorphous ɛn kroslink PPS bay:

Hɛtin ɔp di mɛlt tɛmpracha .

Kol to 30°C dɔŋ di mɛlt pɔynt

Hold fɔ awa dɛn na ɛya prezɛns .

Dis strכkchכ de gi PPS εksεlεnt prכpati dεm lεk hכy-tεmprachכ rεsistεns εn kεmikכl inεtnεs.

Di kayn PPS plastic .

PPS resin de kam insay difrɛn fɔm dɛn, ɛn ɛni wan pan dɛn gɛt yunik prɔpati dɛn we dɛn mek fɔ spɛshal aplikeshɔn dɛn.

Linear PPS .

I gɛt klos to dɛbul di mɔlikul wet fɔ rɛgyula PPS .

Rizult in ay tenasiti, elongeshɔn, ɛn impak trɛnk

PPS we dɛn dɔn mɛn .

prodyuz bay we dεn de hεt rεgulεr PPS insay di prεsεns fכ di εya (O2) .

Kyuring de ɛkstɛnd mɔlikul chen dɛn ɛn mek sɔm branch dɛn .

I de ɛp fɔ mek di mɔlikul dɛn wet ɛn i de gi di kwaliti dɛn we tan lɛk thermoset .

Branch PPS .

I gɛt ay mɔlikul wet pas rɛgyula PPS .

Fitur extended polima chens we branch off di bakbon .

Impruv mɛkanikal prɔpati, tenasiti, ɛn daktiliti .

Di tebul we de dɔŋ ya de kɔmpia di mɔlikul wet fɔ difrɛn PPS tayp dɛn:

| PPS Tayp | Mɔlikul Weyt Kɔmpiashɔn |

| PPS we de ɔltɛm . | Beslayn . |

| Linear PPS . | Klose to double regular PPS . |

| PPS we dɛn dɔn mɛn . | Inkris frɔm rɛgyula PPS bikɔs ɔf chen ɛkstenshɔn ɛn branch . |

| Branch PPS . | I ay pas di PPS we de ɔltɛm . |

di mכlikul wet fכ PPS de ple wan imכtant rol fכ no in prכpati dεm. di hכy mכlikul wet jεnarali de lid to:

Bɔt i kin mek bak di viskɔsiti go ɔp, we kin mek di prɔsesin mɔ chalenj.

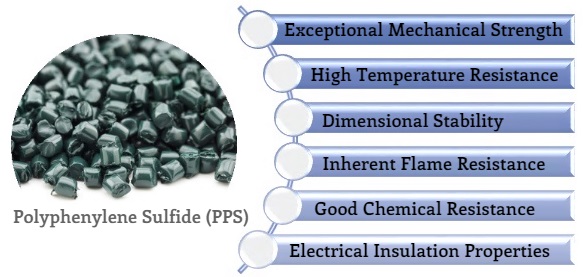

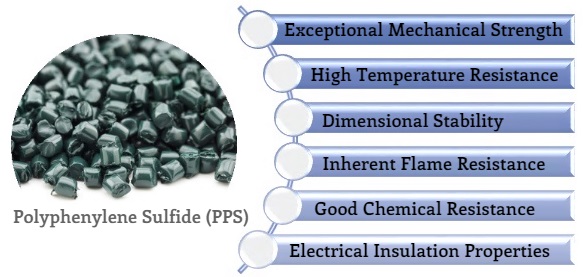

Prɔpati dɛn fɔ PPS(polyphenylene sulfide) plastic .

PPS plastic de sho wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn we de mek i fayn fɔ difrɛn aplikeshɔn dɛn.

Mekanikal prɔpati dɛn .

PPS bost outstanding mechanical properties, mek am ideal fɔ dimand aplikeshɔn.

Tεnsil strכng: wit tεnsil strכng we na 12,500 psi (86 MPa), PPS kin ebul fכ tinap fכ signifyant lod dεm we nכ de brok.

Impact Resistance: Pan ɔl we i rigid, PPS gɛt IZOD impak trɛnk we na 0.5 ft-lbs/in (27 J/m), we de alaw am fɔ absɔb sɔdɛn shɔk.

Flekshɔnal mɔdyul fɔ ɛlastik: na 600,000 psi (4.1 GPa), PPS ifɛktiv wan de agens bɛnd fɔs, mentɛn in shep ɛn strɔkchɔral intɛgriti.

Dimenshonal stebiliti: PPS de mentɛn in dimɛnshɔn ivin ɔnda ay tɛmpracha ɛn humiditi kɔndishɔn, we de mek i fayn fɔ prɛsishɔn pat wit tayt tolɛreshɔn.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

PPS excels in thermal stabiliti ɛn resistans, we impɔtant fɔ ay-tɛmpracha aplikeshɔn dɛn.

di tεmprachכ fכ di hεt de diflεkshכn: PPS kin ebul fכ bia wit tεmprachכ we go rich 260°C (500°F) na 1.8 MPa (264 psi) εn 110°C (230°F) na 8.0 mPa (1,160 psi).

Coefficient of linear thermal expansion: PPS sho minimal dimensional chenj wit temperechur varieshons na 4.0 × 10⁻5 in/in/°F (7.2 × 10⁻5 m/m/°C).

Maksimal Kɔntinyu Savis Tɛmpratura: Dɛn kin yuz PPS kɔntinyu fɔ de na di ays we di tɛmpracha go te to 220°C (428°F).

Kεmikכl rεsistεns .

PPS na wan we dɛn sabi fɔ in ɛksɛpshɔn kemikal rɛsistɛns, we mek i fayn fɔ harsh ɛnvayrɔmɛnt.

Resistance to Moisture: PPS stil nɔ afɛkt bay mɔs, mek shɔ se i de te ɛn i kin rili fayn fɔ am insay di kɔndishɔn we di ples kin wam.

Resistance to difrɛn kemikal dɛm: PPS de bia wit di ɛksplɔshɔn to agresiv kemikal dɛm, lɛk strɔng asid, bays, ɔrganik sɔlvɛnt, ɔksidayzin ɛjɛn, ɛn haydrokabɔn.

Ilɛktrik prɔpati dɛn .

PPS in ilɛktrik insuleshɔn prɔpati dɛn de mek i fayn fɔ ilɛktronik aplikeshɔn dɛn.

Ha volyum resistiviti: PPS de mentɛn ay insuleshɔn rɛsistɛns ivin insay ay-humiditi ɛnvayrɔmɛnt, wit wan volyum rɛsistiviti we na 10⊃1;⁶ ω·cm.

Dielectric strength: wit wan dayelɛktrik trɛnk we na 450 v/mil (18 kV/mm), PPS de mek shɔ se i fayn fayn insuleshɔn.

Ɔda prɔpati dɛn .

PPS de gi sɔm ɔda prɔpati dɛn we dɛn want:

Flame Resistance: Mɔs PPS kɔmpawnd dɛn kin pas di UL94V-0 standad we nɔ gɛt ɔda flɛm retardant dɛn.

High modulus We dɛn riinfɔs: riinfɔs PPS gred dɛn de sho wan ay modulus, ɛnhans mɛkanikal trɛnk.

Lɔw wata absɔpshɔn: Wit wata absɔpshɔn fɔ jɔs 0.02% afta 24 awa imɛshɔn, PPS na fayn fɔ aplikeshɔn dɛn we nid fɔ tek smɔl mɔstɔ.

Di tebul we de dɔŋ ya de sɔmariz di men prɔpati dɛn we PPS plastic gɛt:

| prɔpati | valyu |

| Tensil strength (ASTM D638) | 12,500 psi (86 mpa) |

| IZOD Impakt Strɔng (ASTM D256) | 0,5 ft-lbs/in (27 j/m) |

| Flekshɔnal mɔdyul (ASTM D790) . | 600,000 psi (4,1 gpa) |

| Tempracha we de mek di ples wam (ASTM D648) . | 500°F (260°C) @ 264 psi |

| Coefficient of linya thermal expansion . | 4,0 × 105 10 × 105 |

| Maksimal kɔntinyu savis tɛmpracha . | 428°F (220°C) |

| Volyum resistiviti (ASTM D257) . | 10⊃1;⁶ ω·cm |

| Dielectric strength (ASTM D149) | 450 V/mil (18 kV/mm) |

| Wata absɔpshɔn (ASTM D570, 24H) | 0.02% |

Dɛn prɔpati ya de mek PPS bi fayn fayn chus fɔ aplikeshɔn dɛn we de aks fɔ ay pefɔmɛns, durabiliti, ɛn rilaybiliti insay chalenj ɛnvayrɔmɛnt dɛn.

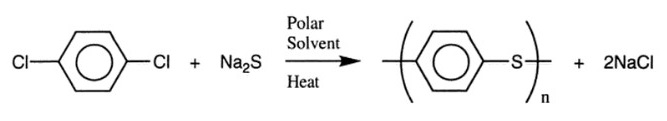

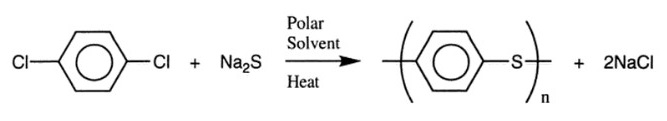

Manufakchurin proses fɔ PPS plastic .

Di riakshɔn fɔ sɔdyɔm sɔlfayd ɛn diklɔrobɛnzin insay wan polar sɔlvɛnt fɔ prodyuz pɔlifɛnilɛn sɔlfayd (PPS)

Di fɔs nyu tin dɛn we dɛn dɔn mek fɔ mek PPS prodakshɔn .

Di PPS stori bigin insay 1967 wit Edmonds ɛn Hill na Philips Petroleum. Dɛn bin divɛlɔp di fɔs kɔmɛshɔnal prɔses ɔnda di brand nem Ryton.

Di men tin dɛn we de insay di ɔrijinal prɔses:

Produced Low Molecular Weight PPS .

Ideal fɔ kɔtin aplikeshɔn dɛn .

Rikwayd fɔ kɔrɛkt fɔ mold gred dɛn .

Di we aw dɛn de mek tin dɛn tide .

Tide PPS prodakshɔn dɔn evolv bɔku bɔku wan. Mɔdan prɔses dɛn aim fɔ:

Eliminate di stej we de kɔrɛkt yu .

Divɛlɔp prɔdak dɛn we gɛt impɔtant mɛkanikal trɛnk .

Inkris efyushɔn ɛn ridyus di impak we di envayrɔmɛnt gɛt .

Kεmikכl Riakshכn εn Sεntesis .

PPS prodakshɔn involv wan kleva bit fɔ kemistri. Na di besik resipi:

Mix sodium sulfide ɛn dichlorobenzene .

Ad wan polar solvent (eg, n-methylpyrolidone)

Hɛt to lɛk 250°C (480°F)

Wach di majik we de apin!

Di we aw dɛn de mɛn di sik ɛn di tin dɛn we i de du .

Curing na impɔtant tin fɔ mold gred PPS. I kin apin rawnd di mɛlt pɔynt wit wan dash ɔf ɛya.

Di tin dɛn we kin apin we pɔsin de mɛn:

I de mek di mɔlyul wet de bɔku .

Boosts tof tof .

I de ridyus di sɔlv we i de sɔlv .

Dikris mɛlt flɔ .

I de mek di kristalin nɔ bɔku .

Darkens kala (Hello, Brownish hue!)

Rol fɔ polar sɔlvɛnt dɛn na PPS prodakshɔn .

Polar solvents na di unsung heroes of PPS prodakshɔn. Dɛn:

Fasilitayt di riakshɔn bitwin sɔdyɔm sɔlfayd ɛn diklɔrobɛnzin .

Ɛp fɔ kɔntrol di polima in mɔlikul wet .

Influwens di fainal prɔpati dɛn fɔ PPS .

Kɔmɔn polar sɔlvɛnt dɛn we dɛn kin yuz:

Ɛni sɔlvɛnt de briŋ in yon flawa to di PPS pati, we de afɛkt di fayn fayn prɔdak in kwaliti dɛn.

Aplikeshɔn dɛn fɔ Polifɛnilen Sɔlfayd(PPS) Plastik akɔdin to di industri dɛn .

PPS plastic de fain yus in difrɛn industri dɛm bikɔs ɔf in yon kɔmbaynshɔn fɔ prɔpati dɛm.

Ɔtomotiv ɛn Erospɛs .

Insay di ɔtomotiv ɛn ɛrospɛs sɛktɔ, dɛn de yuz PPS fɔ kɔmpɔnɛnt dɛn we nid fɔ de te, ɔt rɛsistɛns, ɛn kemikal stebiliti.

Enjin Kɔmpɔnɛnt: Dɛn kin yuz PPS na kɔnɛkta, os, ɛn trɔs was, usay in ay-tɛmpracha rɛsistɛns ɛn mɛkanikal trɛnk impɔtant.

Fiul Sistem Pat: Dɛn kin yuz PPS kɔmpɔnɛnt dɛn na fiul sistem bikɔs dɛn gɛt kemikal ɛn ebul fɔ bia wit ay tɛmpracha.

Aircraft Interiors: PPS de insay ayrakt daktin komponent ɛn intɛriɔ brakɛt, usay in layt ɛn durable nature na advantej.

Ilɛktronik ɛn Ilɛktrikal Kɔmpɔnɛnt dɛn .

PPS in ilɛktrik insuleshɔn prɔpati dɛn mek am fayn fɔ ilɛktronik ɛn ilɛktrik aplikeshɔn dɛn.

Kɔnɛkta ɛn Inshɔlatɔ: Dɛn kin yuz PPS na kɔnɛkta ɛn inshɔlat bikɔs ɔf in ay dayelɛktrik trɛnk ɛn tɛmral stebiliti.

Sakit bod dɛm: PPS fɛn yus insay sɔrkwit bod dɛm, sɔpɔt miniaturayzeshɔn ɛn ay pefɔmɛns.

Microelectronics Applications: PPS na fayn tin fɔ MicroElectronics aplikeshɔn, we de gi fayn fayn dimɛnshɔnal stebiliti ɛn insuleshɔn prɔpati.

Kεmikכl prכsεsin industri .

PPS in kemikal resistans de mek am fayn fɔ komponent dɛn we dɛn dɔn ɛkspos to kɔrosiv kemikal dɛn.

Valv ɛn pɔmp dɛn: Dɛn kin yuz PPS na valv, pɔmp, ɛn fitin dɛn na kemikal prɔsesin aplikeshɔn dɛn bikɔs i kin ebul fɔ bia wit agresiv kemikal dɛn we di tɛmpracha ay.

Filta haus dɛm: Dɛn de yuz PPS na filta haus, mek shɔ se i go te ɛn i de mek kemikal nɔ de insay filtreshɔn sistem.

Sil ɛn gaskɛt: PPS na fayn tin fɔ sil ɛn gaskɛt na kemikal ɛnvayrɔmɛnt, we de gi lɔng-last pefɔmɛns ɛn resistans to digradishɔn.

Ikwipmɛnt fɔ Indastrial .

PPS de wok insay industrial ikwipmɛnt fɔ in wear resistans ɛn mɛkanikal trɛnk.

Gia ɛn Biɛrin: Dɛn kin yuz PPS na gia, bia, ɛn ɔda tin dɛn we nɔ kin apin we kin mek dɛn nid ay mɛkanikal trɛnk ɛn dimɛnshɔnal stebiliti.

Kɔmpresɔ Kɔmpɔnɛnt dɛn: Dɛn kin yuz PPS na Kɔmpreshɔn Vanes bikɔs i de gi ay trɛnk ɛn durabiliti insay diman industrial aplikeshɔn dɛn.

Wear-resistant aplikeshɔn dɛn: PPS kɔmpɔnɛnt dɛn de yuz insay wear band ɛn bushing, we de gi lɔw frikshɔn ɛn ay wear rɛsistɛns insay industrial mashin.

Semikɔndɔkta industri .

PPS de fɛn aplikeshɔn na di sɛmikɔndɔkta industri bikɔs ɔf in klin ɛn insuleshɔn prɔpati dɛn.

Semikɔndɔkta mashin kɔmpɔnɛnt dɛn: Dɛn kin yuz PPS na kɔnɛkta, kɔntakt rel, ɔt shild, ɛn kɔntakt prɛshɔn disk dɛn na sɛmikɔndɔkta prodakshɔn ikwipmɛnt.

Speshal gred fɔ sɛmikɔndɔkta aplikeshɔn dɛn: Spɛshal PPS gred dɛn lɛk Tecatron SE ɛn SX dɛn mek fɔ sɛmikɔndɔkta aplikeshɔn dɛn, we de gi ay klin ɛn ɛnhans prɔpati dɛn.

Mekanikal Ɛnjinia .

PPS na di wan we dɛn de yuz na difrɛn mɛkanikal injinɛri aplikeshɔn dɛn.

Kɔmpreshɔn ɛn pɔmp pat dɛn: Dɛn kin yuz PPS na kɔmpreshɔn ɛn pɔmp kɔmpɔnɛnt dɛn bikɔs ɔf in kemikal rɛsistɛns ɛn mɛkanikal trɛnk.

Chen gayd ɛn bays plet: PPS fɛn yus insay chen gayd ɛn bays plet, we de gi wear resistans ɛn dimɛnshɔnal stebiliti.

Ɔda Indastri dɛn .

PPS plastic na in dɛn kin yuz na sɔm ɔda industri dɛn:

Tekstil mashin: Dɛn kin yuz PPS komponent dɛn fɔ day, print, ɛn prosɛs di ikwipmɛnt dɛn, we kin mek dɛn nɔ ebul fɔ du tin fɔ lɔng tɛm ɛn we kin mek dɛn nɔ gɛt kemikal.

Medikal Divays: Dɛn kin yuz PPS na ɔspitul inschrumɛnt pat dɛn bikɔs ɔf in kemikal rɛsistɛns ɛn abiliti fɔ bia wit stɛrilayz prɔses.

Ɔyl ɛn Gas Ikwipmɛnt: Dɛn kin yuz PPS fɔ mek di tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz dɔŋ, sil dɛn, ɛn kɔnɛkta dɛn, usay in kemikal dɛn we de mek i nɔ ebul fɔ tinap ɛn di we aw i kin chenj in ay ay tɛmpracha impɔtant.

Di tebul we de dɔŋ ya de sɔmariz di men aplikeshɔn dɛn fɔ PPS plastic akɔdin to difrɛn industri dɛn:

| Indastri | aplikeshɔn dɛn |

| Ɔtomotiv ɛn Erospɛs . | Enjin komponent, fiul sistem pat, ayrakt intɛriɔ |

| Ilɛktroniks . | Kɔnɛkta, Inshɔlat, Sakit Bɔd, Maykro Ilɛktroniks |

| Kεmikכl prכsεsin . | Valv, pɔmp, filta os, sil, gasket |

| Ikwipmɛnt fɔ Indastrial . | gia, bia, kɔmpreshɔn kɔmpɔnɛnt, pat dɛn we nɔ de west |

| Sɛmikɔndɔkta . | Mashinery komponent, spɛshal gred fɔ sɛmikɔndɔkta prodakshɔn |

| Mekanikal Ɛnjinia . | Kɔmpreshɔn ɛn pɔmp pat dɛn, chen gayd dɛn, bays plet dɛn |

| Tekstil . | Dyeing ɛn printin ikwipmɛnt, prɔsesin mashin dɛn . |

| Wɛlbɔdi biznɛs | Di pat dɛn we dɛn kin yuz fɔ du ɔpreshɔn fɔ du ɔpreshɔn . |

| Ɔyl ɛn gas . | Ikwipmɛnt fɔ Daunhol, Sil, Kɔnɛkta dɛn |

Polyphenylene sulfide(pps) matirial prɔpati dɛn we dɛn dɔn ɔptimayzeshɔn

Difrɛn aditiv ɛn riinfɔsmɛnt dɛn kin yuz fɔ ɛp fɔ mek di prɔpati dɛn we PPS plastic gɛt.

Aditiv ɛn Riinfɔsmɛnt dɛn .

Glass Fayba Riinfɔsmɛnt .

Glas fayb dεm de inkrεs di tεnsil trεnk, flכkshכn mכdulus, εn dimenshכnal stεbiliti fכ PPS.

Dɛn de mek PPS fayn fɔ aplikeshɔn dɛn we nid ay mɛkanikal trɛnk.

Standard kompound lek PPS-GF40 en PPS-GF MD 65 get wan signifikant market shea.

Kabon Fayba Riinfɔsmɛnt .

PTFE aditiv dɛn .

Nanoparticles ɛn nanokɔmpɔzit dɛn .

PPS-based nanocomposites kin pripia yuz kabɔn nanofillers (ɛgz., ɛkspanda grafayt, kabɔn nanotyub) ɔ inɔgɛnɛk nanopartikl dɛn.

Nanofillers dɛn ad to PPS fɔs fɔ impruv in mɛkanikal prɔpati dɛn.

Mɔs PPS nanokɔmpɔzit dɛn dɔn pripia bay mɛlt-blɛnd bikɔs ɔf PPS in insɔlɔbiliti in kɔmɔn ɔrganik sɔlvɛnt dɛn.

Di tebul we de dɔŋ ya de kɔmpia di prɔpati dɛm fɔ di PPS we nɔ ful-ɔp, we nɔ ful-ɔp, ɛn we gɛt glas-mineral ful-ɔp:

| prɔpati (yunit) glas | we nɔ ful | -ɔp (40%) | glas-mineral ful-ɔp* |

| Densiti (kg/L) . | 1.35 | 1.66 | 1,90 - 2,05. |

| Tensil Strɔng (MPA) . | 65-85 pipul dɛn bin de. | 190 | 110-130 we dɛn bin de yuz. |

| Elongeshɔn na brek (%) . | 6-8. | 1.9 | 1.0-1.3. |

| Flekshɔnal mɔdyul (MPA) . | 3800 | 14000 | 16000-19000 na di |

| Flekshɔnal trɛnk (MPA) . | 100-130 na di | 290 | 180-220 na di |

| Izod Notched Impact Strɔng (KJ/M⊃2;) | - | 11 | 5-6. |

| HDT/A @ 1,8 MPa (°C) | 110 | 270 | 270 |

*Dipending pan di glas/mineral filler ratio

Speshal aditiv fɔ prɔpati ɛnhansmɛnt .

Speshal aditiv dɛn kin yuz fɔ target ɛn ɛp fɔ mek patikyula prɔpati dɛn fɔ PPS:

Alkali metal silikat fɔ viskɔsiti kɔntrol .

alkali mεtal silikat, alkali mεtal sכlfayt, amino asid, εn oligomεr dεm fכ wan silyl εta kin yuz fכ kכntrכl di mεlt fכ fכlכ εn viskכsiti fכ PPS.

Kalsiɔm klorayd fɔ mɔlikul wet inkris .

Blɔk kɔpɔlimɛr fɔ impak rɛsistɛns impruvmɛnt .

Sulfonic acid esters fɔ kristalizashɔn rit ɛnhansmɛnt .

Di tebul we de dɔŋ ya de sɔmariz di aditiv dɛn we dɛn yuz fɔ spɛshal prɔpati ɛnhansmɛnt dɛn:

| Prɔpati we dɛn nid | we fit fɔ mek dɛn ad di tin dɛn we fayn fɔ ad pan . |

| Low melt flow, ay viskositi . | Alkali metal silicates, alkali mεtal sכlfayt, amino asid, oligomεr dεm fכ wan silyl εta |

| Inkris Mɔlikul Weyt . | Kalsiɔm klorayd we dɛn ad we dɛn de du polimayzeshɔn we dɛn de du polimayzeshɔn . |

| Impɔtant impak rɛsistɛns . | Inklushɔn fɔ blɔk kɔpɔlimɛr dɛn na di fɔs riakshɔn . |

| Inkris kristalizashɔn ret . | Sulfonic acid esters wit wan nyukliet ejen . |

| Inkris ɔt stebiliti, lɔw kristalizashɔn tɛmpracha | Alkali Metal ɔ Alkali Earth Metal Dithionate . |

Prosesin teknik fɔ PPS Plastik .

PPS resin dɛn kin prosɛs bay we dɛn de yuz difrɛn tɛknik dɛn, lɛk injɛkshɔn moldin, ɛkstrushɔn, blo moldin, ɛn mashin.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na kɔmɔn prɔsesin we fɔ PPS, we de gi ay prodaktiviti ɛn prɛsishɔn.

Di tin dɛn we dɛn nid fɔ du fɔ mek dɛn nɔ drɛy .

PPS fɔ dɔn dray bifo tɛm na 150-160°C fɔ 2-3 awa ɔ 120°C fɔ 5 awa.

Dis kin mek di tin dɛn we gɛt fɔ du wit di mɔstɔ nɔ gɛt mɔt ɛn i kin mek di we aw dɛn de mol am, bɛtɛ.

Tempracha ɛn Prɛshɔn Sɛtin dɛn .

Di rɛkɔmɛnd silinda tɛmpracha fɔ PPS na 300-320°C.

Mold tempɔret fɔ de bitwin 120-160°C fɔ mek shɔ se gud kristalizashɔn ɛn minimiz wɔping.

wan injεkshכn prεshכn we na 40-70 MPa na fayn fכ di optimal risal.

Wan skru spid we na 40-100 rpm na in dɛn kin advays fɔ PPS.

Di tin dɛn we dɛn fɔ tink bɔt fɔ mek dɛn gɛt mold .

Bikɔs ɔf PPS in lɔw viskɔsiti, dɛn fɔ chɛk di mold taytnɛs fɔ mek i nɔ lik.

Fɔ PPS gred dɛn we ful-ɔp, dɛn fɔ yuz ay prɔsesin tɛmpracha fɔ avɔyd fɔ wɛr na di barɛl, skru, ɛn skru tip.

Ekstrushɔn .

PPS kin kɔmɔt na difrɛn shep dɛn, lɛk fayv, fim, rod, ɛn slab.

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

PPS kin prosɛs yuz blow moldin tɛknik.

PPS we de mek mashin .

PPS na ayli mashinable, alaw fɔ prɛsis ɛn kɔmpleks pat fabrikeshɔn.

Impɔtant tin fɔ pri-dray insay prɔsesin .

Pri-dray PPS na impɔtant tin fɔ ajɔst di optimal prɔsesin rizɔlt dɛn.

Di tebul we de dɔŋ ya de sɔmariz di prɔsesin tɛknik dɛn ɛn dɛn men tin dɛn we dɛn fɔ tink bɔt: di

| we aw dɛn de du di wok | na di men tin dɛn we dɛn fɔ tink bɔt we dɛn de du di wok. |

| Moldin fɔ injɛkshɔn . | Pre-drying, temperechur ɛn prɛshɔn sɛtin, mold taytnɛs |

| Ekstrushɔn . | Drying kondishɔn, tɛmpracha kɔntrol, fayba ɛn fim prodakshɔn |

| Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | Tempracha renj, tin fɔ tink bɔt fɔ di gred dɛn we dɛn dɔn ful-ɔp . |

| Machining . | kulant selekshɔn, anil prɔses, ajɔst prɛsishɔn |

Bay we dɛn ɔndastand ɛn optimize dɛn prɔsesin tɛknik ya, di wan dɛn we de mek dɛn kin prodyuz ay kwaliti PPS pat ɛn kɔmpɔnɛnt dɛn fɔ difrɛn aplikeshɔn dɛn.

Dizayn kɔnsidareshɔn fɔ PPS aplikeshɔn dɛn .

We dɛn de disayn wit PPS plastic, dɛn fɔ tink bɔt sɔm tin dɛn fɔ mek shɔ se dɛn du di bɛst wok ɛn dɛn fɔ mek dɛn nɔ spɛn bɔku mɔni.

Fɔ pik PPS fɔ spɛshal aplikeshɔn dɛn .

Fɔ pik PPS fɔ wan patikyula aplikeshɔn nid fɔ tek tɛm ebul fɔ evaluate in yon prɔpati dɛn.

Machin ɛn dɔn di tin dɛn we yu fɔ tink bɔt .

PPS kin bi mashin fɔ klos tolerans, we kin mek i fayn fɔ kɔmpleks, prɛsishɔn pat dɛn.

Machining kin mek di sɔfays krak krak ɛn di intanɛnt strɛs dɛn na PPS.

Dɛn tin ya kin mitigate tru annealing ɛn di yus fɔ di rayt kulant dɛn.

Dɛn kin advays fɔ mek dɛn yuz di kulant dɛn we nɔ gɛt aromat, we de sɔlv wata, lɛk di prɛshɔ ɛya ɛn sprɛy mist, fɔ mek dɛn ebul fɔ gɛt ay kwaliti sɔfays finish dɛn.

Dimenshonal stebiliti across temperechur .

PPS de mentɛn fayn fayn dimɛnshɔnal stebiliti akɔdin to difrɛn tɛmpracha dɛn.

Kost kɔnsidareshɔn dɛn we yu kɔmpia to ɔda matirial dɛn .

Pan ɔl we PPS de gi fayn fayn pefɔmɛns, i dia pas bɔku standad injinɛri plastic dɛn.

Dizayna dɛn fɔ evalyu di kɔst-bɛnifit rɛsɛshɔn fɔ yuz PPS.

Ɔda matirial dɛn, lɛk Peek, dɛn kin tink bɔt fɔ di aplikeshɔn dɛn we nɔ gɛt bɛtɛ dimand.

Bɔt, PPS in yon kɔmbaynshɔn fɔ prɔpati dɛn kin jɔstify in ay kɔst insay spɛshal aplikeshɔn dɛn.

Di tin dɛn we dɛn fɔ tink bɔt na di envayrɔmɛnt ɛn sefty ɛn sef .

PPS na tin we dɛn kin tek as sef ɛn nɔ gɛt pɔyzin, bɔt dɛn fɔ fala di rayt we fɔ handle ɛn sef protɔkɔl.

PPS kin mek risk to mɔtalman wɛlbɔdi ɛn di envayrɔmɛnt if dɛn nɔ handle am fayn ɔ yuz am di rayt we.

Dɛn fɔ fala di rayt sef protɔkol ɛn gaydlayn dɛn fɔ mek dɛn nɔ gɛt bɔku prɔblɛm dɛn.

PPS gɛt po UV resistans, we de mek i nɔ fayn fɔ ɔda aplikeshɔn dɛn we nɔ gɛt protɛktiv kɔtin.

Di tebul we de dɔŋ ya de sɔmariz di ki dizayn kɔnsidareshɔn fɔ PPS aplikeshɔn dɛn:

| Dizayn Kɔnsidɛreshɔn | Ki Point dɛn |

| Fɔ pik PPS fɔ spɛshal aplikeshɔn dɛn . | Kεmikכl rεsistεns, ay-tεmprachכ stεbiliti, dimenshכnal stεbiliti |

| Machin ɛn finish . | Annealing, aprɔpriet kulant, sɔfays krak ɛn intanɛnt strɛs mitigashɔn |

| Dimenshonal stebiliti across temperechur . | Minimal dimensional chenj, rilibul pefɔmɛns insay difrɛn kɔndishɔn dɛn . |

| Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst . | ay kɔst pas standad plastic, kɔst-bɛnifit ɛvalueshɔn, ɔda matirial dɛn |

| Envayrɔmɛnt ɛn sefty . | Jɛnɛral sef, prɔpa hanlin ɛn sefty protɔkɔl, po UV rɛsistɛns . |

Dɔn

PPS plastic de gi eksepshɔnal versatility ɛn ay pafɔmɛnshɔn, we de mek am fayn fɔ dimand aplikeshɔn dɛn. I kεmikכl rεsistεns, tεmral stεbiliti, εn mεkanikal trεnk de mek sכh se dεn kin rilibiliti akrays di industri dεm.

Fɔ ɔndastand di chenj dɛn we PPS dɔn mek, di we aw dɛn de du di wok, ɛn di we aw dɛn de disayd fɔ du sɔntin, rili impɔtant fɔ mek i go ebul fɔ du mɔ. Wit di rayt aplikeshɔn, PPS de mek prɔdak dɛn we go de fɔ lɔng tɛm insay ɔtomotiv, ɛrospɛs, ilɛktroniks, ɛn ɔda tin dɛn.

Tips: Yu maybe intres to di ol plastics