Plastic partes sunt backbone modern vestibulum, innumerabiles products utimur quotidie. Cogitans partes requirit diligenter consideranda efficaciam et qualitatem. Hoc articulum praebet detailed dux in consilium processus plastic partes ex materia selectio ad finalem productio. Hic post, youll 'discere quam ad define requisitis, eligere materiae, et optimize consilia ad manufacturabilitatem.

Maecenas Plastic pars consilium

Momentum plastic parte consilio manufacta

Efficens plastic parte consilio est essentialis ad ensuring manufacturrability, qualis, et sumptus-efficientiam. A bene optimized consilio minimizes materia vastum et productio tempore, ducens ad altius profitability. Manufacturers debet diligenter considerans factores sicut materia lectio, dimensional accurate, et productionem modi ad consequi meliorem results.

Emphasis iniectio CUMATIUM processibus

Iniectio CUMATIUM est maxime communiter processus pro plastic partim productio debitum ad scalability et praecisione. Hoc modus concedit ad massa productionem complexu partibus cum maintaining stricta tolerances et reducendo vastum. Proprium consilium iniectio coronam includit operam ad murum crassitudine, draft angulis et costa collocatione ne defectibus velut velut aut submersa marcas.

Key gradus in consilio, ad-productio workflow

Plastic Part Design processum involves aliquot internonected stationibus

Postulationem definition

Conceptum Sketching

Material Electio

Detailed consilio

Structural Analysis

Final Material Electio

Modifying consilio ad vestibulum (Dfm)

Prototyping

Tooling et vestibulum

Hoc workflow ensures systematicam aditus ad plastic parte progressionem. Hoc statera functionality, manufacturability et sumptus-efficaciam.

Gradus I: Defining Requisita

Momenti quantifying requisita

Quantifying requisitis format angularis prospere plastic parte consilio. Non providet:

Patet, measurable aliquip

Reducitur misinterpretation metus

Solidum fundamentum consilium decisionum

Designers ne incerta termini sicut 'fortis ' vel 'transparent '. Instead, quod oportet contendunt in specifica, metrics Quantifiable.

Factores considerans

Structural

Structural Loading Analysis ensures partes sustinere in animo usus et potentiale abutatur:

Genera: Static, Dynamic, Impact

Rate: tardus, moderari, celeri

Frequency: continua, intermittendi, occasional

Considerations ultra finem usum

Conventus accentus

Shipping vibrations

Conditions repono

Pessimum-casu missionibus

Environmental conditionibus

Environmental factores significantly impulsum plastic materia proprietatibus:

| factor | considerations |

| Temperamentum | Operating range, scelerisque cycling |

| Humor | Humorem effusio, dimensional stabilitatem |

| EXPOSITUM | Resistentia ad solvents, olea, Purgato agentibus |

| Radiatio | UV stabilitatem, gamma radiatio tolerantia |

Pessimum-casu missione planning adjuvat ut productum reliability in extrema condiciones.

Dimensional requisitis et tolerances

Dimensional specifications sunt crucial;

Stricta tolerances cum vestibulum sumptibus sumptibus est necessaria. Overly stricte tolerances potest significantly auget productio expensas.

Signa et regulatory requisitis

Adhaerere ad pertinet signa enses productum obsequium:

Designers oportet identify applicabilis signa mane in processus. Hoc approach prohibet pretiosi redesigns postea.

Venalicium et economic restrictiones

Oeconomica considerations figura consilium decisiones:

Hae factores influere materiam electionem vestibulum processus et consilio complexionem.

Gradus II: Partum A Primam conceptum Volume

Developing initial conceptum Historia

Conceptum Sketching initiat in visual repraesentatio consilio ideas. Serves ut crucial pontem inter requisita et tangibile solutions.

Key facies efficax conceptum Sketching:

Celeri ideation: Generare Multiple Design conceptus celeriter.

Focus in functionality: prioritize core features super aesthetic details.

Adaptability, patitur facile modifications ut consilio evolves.

Excitare clavem areas de

Designers debet commendandam discrimine regiones in sketches:

Accentus concentration punctorum

Potentiale infirma maculis

Areas requiring speciali vestibulum considerations

Hoc aditus facilitates mane forsit idem et targeted consilio improvements.

Identifying Fixarum variabilis munera

Distinguens inter fixum et variabilis munera est crucial:

| fixum munera | variabilis munera |

| Vexillum-gubernatur dimensiones | Aesthetic elementa |

| Critica perficientur features | Non-essential geometria |

| Salus-related components | Fusce features |

Cognoscere haec distinctiones enables designers ad focus eorum partum conatus in areas cum maioris Design flexibilitate.

Collaboration et industriae designers

Service cum Industrial Designs Enhances conceptum Sketching Phase:

Aesthetic peritia ad muneris consilia

Ensures manufacturability uisum appellans conceptibus

Faciliorem holistic productum progressionem

Creaturae 3D sketches et renderings

Moderni conceptum Sketching saepe involves 3D visualization:

Digital Sketching to to to to to to to to to years celeri 3D conceptum creaturae.

3D Renderings providere stakeholders cum clarius consilio vision.

Early 3D exempla facilitate levior transitus ad CAD Development.

Gradus III: Initial Material Electio

Comparet material proprietatibus cum requisitis

Initial materia selectio involves ratio proprietatibus contra defined requisita. Hoc processus ensures meliorem materia electiones ad propria applications.

Key gradus in hac comparatione:

COGNOSCO discrimine perficientur parametri

Evaluate Material Datasheets

Rank materiae secundum exigentiam complementum

Eliminatis unsuitable materia familias

Efficientis materia lectio saepe incipit cum eliminanda:

COGNOSCO paciscor-BREATER properties

Remove totum materia familias deficiente ad occursum discrimine requisita

Adspectum graciliorem focus ad promissum Candidati

Hoc adventu streamlins lectio processus salute et opibus.

Non-Designable Material Properties

Quidam materialium proprietatibus non potest auctus per Design Modifications:

| Property | momenti |

| Coefficientem scelerisque expansion | Afficit dimensional stabilitatem |

| Dialacritas | Critica ad optical applications |

| Chemical resistentia | Decernit compatibility amet |

| Mollientes temperatus | Limites operating conditionibus |

| Agency probat | Ensures regulatory obsequio |

Haec proprietatibus serve ut primaria protegendo criteria in materia lectio.

Impulsum additives et technologiae

Material Electio complexionem crescit:

Coatings: augendae superficies proprietatibus

EDICTIVES: Modify mole materiales

Co-iniectio Technology: Combines Multiple Materials

Haec factores expand consilio possibilities sed requirere diligenter consideratione eorum effectus in altiore parte perficientur.

Partes de compositione et conflandum

COMPOSITIO et conflandum Blending Offer Opportunities enim Property Enhancement:

Tailoring mechanica proprietatibus

Improving scelerisque characteres

Enhancing chemical resistentia

Optimizing processability

Haec artes patitur designers ad denique-tune material proprietatibus, in potentia creando mos solutions ad propria applications.

Gradus IV: Cogitans ex parte secundum electus materiae

Designing pars geometria secundum materiam characteres

Material proprietatibus significantly auctoritatem geometria. Designers oportet accommodare suum aditus secundum electi materia est unique attributa.

Key Consid:

Modulum elasticitatis

CEDITAS

Reperta resistentia

Chemical compatibility

Adjusting geometria pro variis conditionibus

Alia materiae eget specifica geometrica accommodationes:

Static Loads: Reinforce High-accentus Areas

Solvendo nuditate: auget murum crassitudine in vulnerable regionum

Thermal Expansion: Design oportet clearances et tolerances

Material-specifica consilio exempla

| materia | consilio considerations |

| Summus density polyethylene | Magna captura angulos, densissima sectiones ad rigiditatem |

| Polypropylene | Uniformis murum crassitudine, liberalis radii |

| Nylon 6/6 | Ribbing enim rigor, humorem effusio concedat |

Gradus V: Structural Analysis

Utique CAE Software ad Analysis

Computatrum -idided Engineering (CAE) Software ludit a crucial partes in modern plastic parte consilio. Eam dat designers;

Simulate real-mundi condiciones

Praedicere part mores sub variis onerat

COGNOSCO potential defectum modos

Popularibus cae instrumenta includit ansys, solidworks simulation et abaqus.

Testing sub pessimi-casu missionibus

Rigorous Analysis involves subiicit virtutis exempla ad extrema condiciones:

Maximam onus casibus

Temperature extrema

Impact et fatigandum missionibus

Chemical nuditate simulationes

Haec probat auxilium uncover potentiale infirmitatibus ante physica prototyping incipit.

Design Optimization secundum Analysis Results

Analysis Results Guide iteratesative Design improvements:

| Analysis Exitus | Design Response |

| Princeps accentus concentratione | Addere vittis vel Gussets |

| Nimia deflectionem | Auget murum crassitudine aut add costis |

| Scelerisque hotspots | Modify Geometria enim melius calor dissipatio |

Processus continues usque ad consilium occurrit omnibus perficientur criteria dum minimizing materiam usus et multiplicitate.

Cucumque modificatur consilio occurrat iudicium

Post Optimization, Designers debet cognoscere:

Finis-usus perficientur signa tamen occurrit

Manufacturing Feasibility manet integrum

Custus peltas sunt effectum

A statera inter haec factores saepe requirit commercia-offs et partum problema-solving.

Key Consid:

Eget elit

Aesthetic signa

Regulatory obsequio

Productio efficientiam

Gradus VI, Final Material Electio

Committing ad primaria materia

In hoc gradu, designers oportet eligere primaria materia ad plastic parte. Hoc consilium debet esse secundum:

Electus materia fit focus in subsequent Design et Lorem et productio planning.

Suscipio tergum options

Dum committing ad primaria materia, suus 'prudens ut alternative materiae in subsidiis. Haec tergum serve ut:

Contingency consilia ad improvisa exitibus

Options pro futuro productum iterations

Potential cost-salvis Alternatives

Designers potest ponere detailed notitia super his alternatives per progressionem processus.

Oeconomica et perficientur considerations

Final Material Electio statera economic factores cum finis-usus perficientur:

| Economic factors | Effectus Properties |

| Rudis materia pretio | Mechanica fortitudinem |

| Dispensando expensas | Chemical resistentia |

| Productio volumen | Scelerisque stabilitatem |

| Lifecycle costs | Aesthetic qualitates |

Designers debet ponderare haec factores adversus se invenire meliorem materiam solution.

Semi-quantitatis scoring modum

Ad obiective aestimare materiae, a semi-quantitatis scoring ratio probat invaluable:

COGNOSCO Key lectio criteria

Assignatis weightings ad invicem criterium

Rate materiae in numeralibus scale pro se criterium

Calculate ponderati scores

Compare summa ustulo determinare optimum altiore peragit

Methodo providet notitia-repulsi accedere ad materiam electionem, minimizing subiectiva præpositus.

Exemplum scoring criteria:

Tensile fortitudo: 0-10 punctorum

Cost per unit: 0-10 puncta

Processing otium: 0-10 Points

Environmental ictum: 0-10 Points

Gradus VII: Modifying consilio ad vestibulum (DFM)

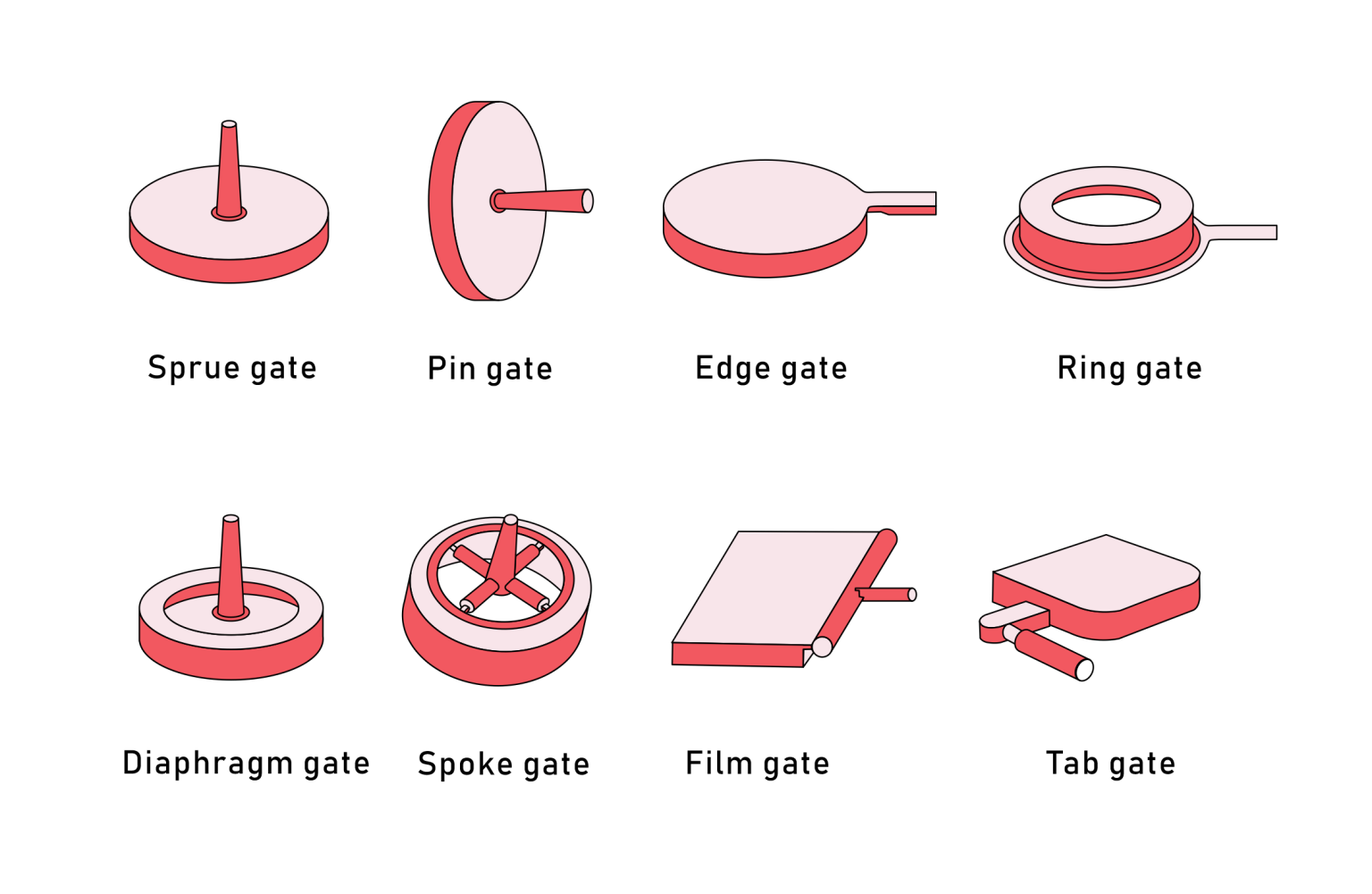

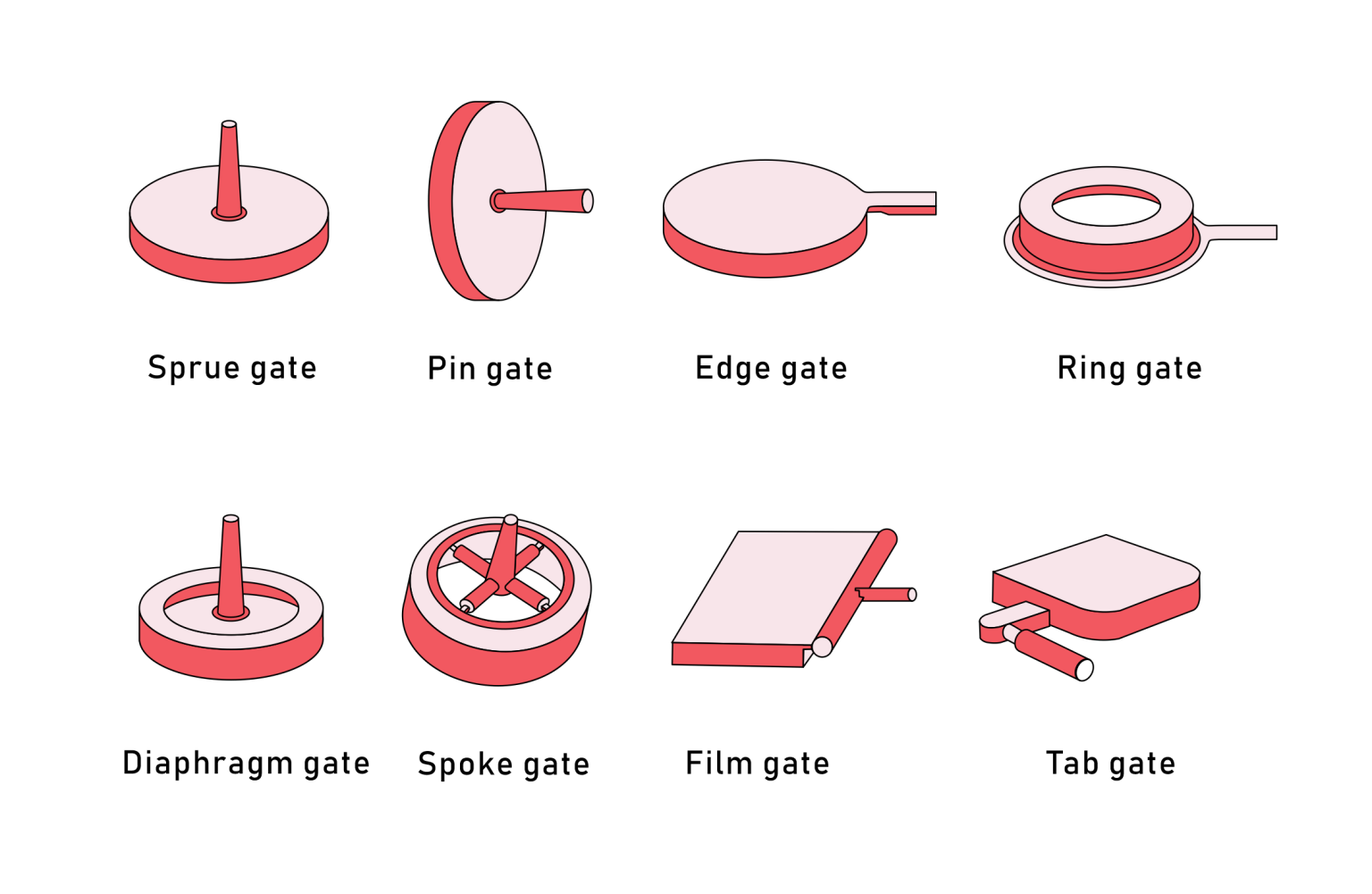

Iniectio CUMATIUM considerations

Iniectio CUMATIUM involves quinque discrimine:

Fingere implens

Stipare

Teneo

Refrigerium

Ejectio

Quisque scaena postulat specifica consilio modifications ut mirability:

Draft Angulis: facilitate parte remotionem

Radii, amplio material fluxus et reducere accentus concentratione

Superficiem texture: augendae species et larva imperfectionibus

Key Design elementa pro iniectio CUMATIUM

Muro crassitudine

Uniformis murum crassitudine est crucial pro prohibitione defectus:

Vitare densissima sectiones, possunt ducere mergit marcas et warpage

Ponere consistency: typice in X% of nomini crassitudine

Sequere resinae-specifica guidelines, plerumque vndique a 0,04 '0.150 '

Costa supplementum

Costas confirma partes absque augendae altiore crassitie:

| Guideline | commendaticiis |

| Altitudo | ≤ 3x Wall Crassitudo |

| Crassities | ≤ 0.5-0.75x Wall Crassitudo |

| Collocatio | Perpendicularis principalis accentus directionem |

Locement porta

Propriis porta locus optimal materiam fluxus et minimizes DECREMENTUM:

Ejector Pin collocatione

Early planning de ejector pin sita est essentialis:

Vitare visibilis superficiebus

Locus in plana vel costed locis

Considerans partem geometriam et materiam proprietatibus

Suspendisse marcas

Addressing submersa marcas involves:

Optimizing refrigerationem channel consilium

Adjusting sarcina pressura et tempore

Exacting Gas, adiuvaret et spumam iniectio artes

Lineas

Collaborate cum Pulvis ad optimize dividitur linea collocatione:

PRAECURSATIO

Consilio considerations ad universa Features:

Undercuts: Usus collapsible cororum aut latus actiones

Foramina, incorporate propriis aspect proportiones et locus

Side actiones: statera complexionem cum sumptus effectus

Gradus VIII: Prototyping

Momentum Prototyping Design verificationem

Prototyping ludit a crucial partes in uerificare consilio ante plenus-scale productio. Is sino designers et manufacturers ad identify potential proventus ut exsurgunt per vestibulum processus vel in productum est perficientur. Per creando a prototypum, teams potest visualize in productum et assess ad functionality in reality-mundi condiciones.

Identifying vestibulum et perficientur exitibus

Prototyping adjuvat discopere defectus ut dimensional inaccuracies, pauper materia fluxus, aut locis pronus ad defectum. Early identificatio horum problems ensures possunt corrigi ante pretiosa tooling est creatus. Quidam commune exitibus prototypes auxilium identify includit:

Modi prototyping

Sunt duo principalis modi ad prototyping plastic partes:

3D printing

hoc modum praebet a velox, cost-effective modus ad producendum prototypes. Est idealis pro visualizing consilio et temptationis basic functionality.

Minimum-volumine iniectio CUMATIUM

hoc modum propinqua simulat ad ultima productio processus. Suus 'solebat ad convalidandum consilium scriptor manufacturability et perficientur in ipsa conditionibus.

Prototypes testing ad defectus

Prototypes oportet probari variis proventus ut consilio parata productio. Testing adjuvat identify:

Weld lineae - puncta in diversis fluit plastic occursum durante coronam, in potentia infirmat structuram.

Warrage - inaequaliter refrigerationem quod causat distortionem.

Suspendisse marcas - Depressions formatae in densior locis ex repugnat refrigerationem.

Vires et diuturnitatem - cursus in partem obviam perficientur requisita sub onus.

Early Deprehensio exitibus ad minimize tooling rework

Per identifying et resolvente exitibus per prototyping tempus, teams potest significantly reducere opus ad pretiosa tooling rework. Capit problems mane adjuvat streamline productio et ensures in finalem uber occurrat omnia consilio et perficientur specifications.

Gradus IX: tooling et vestibulum

Aedificium edificium pre-productio et productionem instrumenta

Transitus a consilio ad vestibulum cardine in creando summus qualitas iniectio formae. Hoc processus involves:

Tool Design: Translating Pars Geometria in FORMA Components

Material Electio: eligens oportet instrumentum Steels pro diuturnitatem

Fabrication: praecisione machining et fingunt cavis et cors

Conventus: Refrigerant rivos, ejector systems et portas

Fingunt fabri saepe incipiunt basic opus in productionem tools mane ut salvum tempus.

Debugging Tooling

Vestibulum Testing et Refinement Fanges Ensure Optimal euismod:

Tentatio decurrit, identify et inscriptio exitibus in part formationem

Dimensional Analysis: Quin Adhaesione ad Design Specifications

Superficiem metam iudicium: AESTIONIBUS et amplio Part AESTHETICA

Augustments includit itative:

| exitus | potentiale solution |

| Mico | Adjust Discede linea vel auget FIGNUS Force |

| Breviter offa | Optimize porta consilio vel auget iniectio pressura |

| Warrage | Refine refrigerationem ratio layout |

Initiating vestibulum processus

Semel instrumenta sunt debugged, productio potest incipit:

Processus parameter Optimization

Quality imperium procedendi instauratione

Productio aggerem, usque planning

Key considerations durante initial productio:

Optimus exercitia plastic Design

Collaborative approach

Palles et engineers primis iniectio iniectio process cedat significant beneficia,

Leveraging technology

Utilitas Advanced Software Tools ad Optimize Designs:

CAD Software: Create Precise 3D Models

Fluxi fingunt analysis: simulare iniectio CUMATIUM processus

Fea Tools: Evaluate Structural Effectus

Haec technologies enable designers ad identify et inscriptio exitibus ante physica prototyping.

Finis-usu consideratione

Prioritize productum est in animo application per consilium processum:

| aspect | consideratione |

| Environmental conditionibus | Temperature, eget nuditate, UV radialis |

| Loading Scenarios | Static, dynamic, impulsum viribus |

| Regulatory Requirements | Industria-specifica signa, salus ordinationes |

Designing cum finis-usu in animo ensures bene perficientur et Vivacitas.

Blancing key factors

Prosperum plastic parte consilium requirit delicata statera:

Custus: Material Electio, Tooling Complexity

Euismod: mechanica proprietatibus, diuturnitatem

Manufacturrability: otium of productio, cycle tempore

Contendunt ad optimal intersection harum factores ad partum viable products.

Diluculo prototyping

Effectum EXEMPLAR sum cycle

Validates Design conceptus

Identifies potential exitibus

Reduces pretiosi nuper-gradu modifications

Celeri prototyping techniques

Leverage Advanced Prototyping modi ad accelerate Development:

3D printing: Velox Turnaround enim complexu Geometries

CNC Machining: Accurate Repraesentatio ultima materiae

Silicone CUMATIUM: Sumptus-Efficens enim Parvus Batch productio

Haec artes enable citius consilium iterations et forum sanatio.

Conclusio

Plastic pars consilium processum involves pluribus crucial gradus. Ex definiens requisitis ad ultima vestibulum, quisque scaena est vitalis.

A Systematica accedat ensures optimal results. Hoc statera perficientur, sumptus, et manufacturabilitate efficaciter.

Bene disposito plastic partes offerre numerosis beneficia:

Prototype convalidatio et parva-batch iudiciis sunt essential. Auxilium deprehendere exitibus mane, salute et resources.

Nos robora legentibus adhibere scientia in projects. Per haec gradus, vos can partum prospere plastic partes.