Plastik pat na di bakbon fɔ di mɔdan manufakchurin, we dɛn kin fɛn insay bɔku bɔku prɔdak dɛn we wi kin yuz ɛvride. Fɔ disayn dɛn pat dɛn ya, dɛn nid fɔ tek tɛm tink bɔt fɔ mek shɔ se dɛn ebul fɔ wok fayn ɛn gɛt kwaliti. Dis atikul de gi wan ditayl gayd bɔt di dizayn prɔses fɔ plastic pat dɛn, frɔm matirial sɛlɛkshɔn to fayn prodakshɔn. Insay dis post, yu go lan aw fɔ difayn rikwaymɛnt dɛn, pik matirial dɛn, ɛn ɔptimayz dizayn fɔ manufakchurabiliti.

Ovaviu fɔ di plastic pat dizayn prɔses .

Impɔtants fɔ Plastik Pat Dizayn fɔ Manufakchurabiliti .

Ifɛktiv plastic pat dizayn impɔtant fɔ mek shɔ se dɛn mek di manufakchurabiliti, kwaliti, ɛn kɔst-efyushɔn. Wan dizayn we dɛn dɔn mek fayn fayn wan, de mek di tɛm we dɛn de yuz fɔ west ɛn di tɛm we dɛn de mek di tin dɛn we dɛn de yuz, nɔ bɔku, ɛn dis kin mek dɛn gɛt mɔ prɔfit. Di wan dɛn we de mek di tin dɛn fɔ tek tɛm tink bɔt tin dɛn lɛk di we aw dɛn de pik di tin dɛn we dɛn de yuz, di dimɛnshɔnal akkuracy, ɛn di we aw dɛn de mek di tin dɛn fɔ mek dɛn ebul fɔ gɛt di bɛst rizɔlt.

Emphasis pan injɛkshɔn moldin prɔses dɛn .

Injɛkshɔn moldin na di mɔs kɔmɔn we dɛn kin yuz fɔ plastic pat prodakshɔn bikɔs ɔf in skɛlabiliti ɛn prɛsishɔn. Dis mεtכd de alaw fכ di mas prodakshכn fכ komplεks pat dεm we de mεnten tayt tכlerans εn ridyus west. Di rayt dizayn fɔ injɛkshɔn moldin inklud atɛnshɔn to di wɔl tik, draft angul, ɛn rib plesmɛnt fɔ mek i nɔ gɛt difrɛn difrɛn tin dɛn lɛk wɔp ɔ sink mak.

Ki stej dɛn na dizayn-to-prɔdakshɔn wokflɔ .

Di plastic pat dizayn prɔses involv sɔm intakɔnekt stej dɛn:

Difinishɔn fɔ di tin dɛn we yu nid .

Kɔnsɛpt Sketching .

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Ditayl dizayn .

strɔkchɔral analisis .

Faynal matirial sɛlɛkshɔn .

Modifying di dizayn fɔ mek (DFM) .

Protɔtaypin .

Tul ɛn Manufakchurin .

Dis wokflɔ de mek shɔ se dɛn gɛt wan sistamɛnt we dɛn de yuz fɔ divɛlɔp plastic pat. I de balans di wok we i de du, di we aw i de mek tin dɛn, ɛn di we aw i de spɛn bɔku mɔni.

Step 1: Difayn di tin dɛn we dɛn nid fɔ du .

Impɔtant tin fɔ kwantifay di tin dɛn we dɛn nid fɔ du .

Quantifying rikwaymɛnt dɛn de fɔm di kɔna ston fɔ saksesful plastic pat dizayn. I de gi:

Di tin dɛn we pɔsin fɔ du klia, we dɛn kin mɛzhɔ .

Ridyus di risk dɛn we dɛn kin gɛt we dɛn nɔ gɛt di rayt fɔ du wetin dɛn want .

Sɔlid fawndeshɔn fɔ dizayn disizhɔn dɛn .

Dizayna dɛn fɔ avɔyd vayg wɔd dɛn lɛk 'strong' ɔ 'transparent'. Bifo dat, dɛn fɔ tray fɔ spɛshal, kwantifayabl mɛtrik dɛn.

Factors fɔ tink bɔt .

Structural loading .

Structural loading analysis de mek shɔ se di pat dɛn tinap fɔ yuz di tin dɛn we dɛn want fɔ yuz ɛn di we aw dɛn kin yuz am di rɔŋ we:

Di kayn dɛn: Statik, dinamik, impak

Rate: Slow, moderate, kwik kwik wan

Frikyuɛnsi: Kɔntinyu, intamit, wan wan tɛm

Di tin dɛn we yu fɔ tink bɔt go go bifo pas di ɛnd-yuz:

Di Stres fɔ Asɛmbli .

Shipping Vibrations na di .

Di kɔndishɔn dɛn fɔ kip tin dɛn .

Worst-case scenarios .

Envayrɔmɛnt Kɔndishɔn dɛn .

Envairomɛnt Fakta dɛn Signifikɛnt impak plastic matirial prɔpati dɛn:

| Factor | kɔnsidareshɔn dɛn . |

| Tɛmprɛchɔ | Opareshɔn rɛnj, tɛmral sayklis . |

| Sok | Moisture absorpshɔn, dimɛnshɔnal stebiliti . |

| Kεmikכl εkspכzכn . | Resistance to solvents, oils, klin ejen dɛn . |

| Radieshɔn . | UV stebiliti, gama raytin tolerans . |

Worst-case scenario planning de ɛp fɔ mek shɔ se prodak rilibiliti ɔnda ekstrim kɔndishɔn.

Dimensional rikwaym ɛn tolerans .

Prɛsis dimɛnshɔnal spɛsifikɛshɔn dɛn rili impɔtant:

Fɔ balans tayt tolɛreshɔn wit di kɔst fɔ mek di tin dɛn we dɛn de mek, na impɔtant tin. Ova strikt tolerans kin rili inkrisayz di prodakshɔn ɛkspɛns.

Stɛndad ɛn Rigyuletɔri Rikwaymɛnt dɛn .

Fɔ fala di standad dɛn we gɛt fɔ du wit di tin dɛn we de apin de mek shɔ se dɛn de fala di prɔdak:

Dizayna dɛn fɔ no di standad dɛn we dɛn kin yuz fɔ du di wok kwik kwik wan we dɛn de du di wok. Dis we fɔ du tin kin mek dɛn nɔ ebul fɔ ridizayn dɛn bay kɔst leta.

Maketin ɛn Ikɔnomik Ristrikshɔn dɛn .

Di tin dɛn we pɔsin fɔ tink bɔt na di ikɔnomi de shep dizayn disizhɔn dɛn:

Antisiped Prodakshɔn Volyum dɛn .

Di savis layf we dɛn de ɛkspɛkt .

Target Kost fɔ wan Yunit .

Dɛn tin ya kin afɛkt di we aw dɛn de pik di tin dɛn we dɛn de yuz, di we aw dɛn de mek tin dɛn, ɛn di we aw dɛn mek di dizayn kɔmplisiti.

Step 2: Fɔ mek wan prɛliminari kɔnsɛpt skech .

Divɛlɔp di fɔs kɔnsɛpt sket dɛn .

Kɔnsɛpt Sketching de initiate di vijual ripreshɔn fɔ dizayn aydia dɛn. I de sav as wan impɔtant brij bitwin rikwaymɛnt ɛn tanjibul sɔlvishɔn.

Ki aspek dɛm fɔ ifɛktiv kɔnsɛpt skech:

Rapid Ideation: Jɛnɛret bɔku bɔku dizayn kɔnsɛpt dɛn kwik kwik wan.

Fokus pan funkshɔnaliti: prayoritayz kɔr ficha dɛn ova aesthetic ditel.

Adaptability: Alaw fɔ izi modifyeshɔn dɛn as di dizayn de evolv.

Fɔ sho di men tin dɛn we wi fɔ wɔri bɔt .

Dizayna dɛn fɔ ɛksplen di impɔtant rijyɔn dɛn na dɛn skech dɛn:

Stret kɔnsɛntreshɔn pɔynt dɛn .

Pɔtɛnɛshɛl wik spat dɛn .

Eria dɛn we nid spɛshal tin dɛn fɔ mek dɛn tink bɔt tin dɛn .

Dis we fɔ du tin kin mek am izi fɔ no di prɔblɛm kwik kwik wan ɛn fɔ mek dɛn ebul fɔ mek dizayn fayn fayn wan.

Fɔ no di fiks vs. vɛriɔbul fɛnshɔn dɛn .

Fɔ difrɛns bitwin fiks ɛn vɛriɔbul fɛnshɔn dɛn na impɔtant tin:

| Fiks fɛnshɔn dɛn | vɛriɔbul fɛnshɔn dɛn . |

| Dimenshon dem weh dey bi get big big ting dem weh dey bi get-am fo gova | Aesthetic elements fɔ mek di ples fayn . |

| Kritikal pefɔmɛns ficha dɛn . | Jɔyometri we nɔ gɛt ɛnitin fɔ du wit am . |

| Sef-rilayt komponent dɛn . | Ficha dɛn we pɔsin kin kɔstɔmayz . |

We dɛn no dɛn difrɛns ya, dat de mek dizayna dɛn ebul fɔ pe atɛnshɔn pan dɛn kriyaytiv ɛfɔt dɛn pan eria dɛn we gɛt mɔ dizayn fleksibiliti.

Kɔlabɔreshɔn wit Indastrial Dizayna dɛn .

Patnaship wit Indastrial Dizayna dɛn de ɛp fɔ mek di kɔnsɛpt sketin faz bɛtɛ:

Brings aesthetic ekspetiz to funkshɔnal dizayn dɛn .

I de mek shɔ se manufakchurabiliti fɔ kɔnsɛpt dɛn we de mek pɔsin fil fayn .

I de mek am izi fɔ divɛlɔp ɔlistik prodak .

Krieshɔn fɔ 3D skech ɔ rɛndɛrɛshɔn .

Mɔdan kɔnsɛpt skech kin involv 3D vijualizɛshɔn bɔku tɛm:

Dijital skech tul dɛn de mek dɛn ebul fɔ mek 3D kɔnsɛpt kwik kwik wan kwik kwik wan.

3D rεndεrεnt dεm de gi stekholda dεm wit klia dizayn vishכn.

Early 3D models fasilitet smol smol transishɔn to CAD divɛlɔpmɛnt.

Step 3: Initial Material Selekshɔn .

Kɔmpia di prɔpati dɛn we dɛn nid wit di tin dɛn we dɛn nid fɔ du wit di tin dɛn we dɛn nid .

Initial matirial sɛlɛkshɔn involv wan sistamat kɔmpiashɔn fɔ matirial prɔpati dɛn agens difayn rikwaymɛnt dɛn. Dis prɔses de mek shɔ se di bɛst matirial chus fɔ spɛshal aplikeshɔn dɛn.

Ki step dɛm fɔ dis kɔmpiashɔn:

Identify Kritikal Pɔfɔmɛnshɔn Paramita dɛn .

Evaluate Material Datasheets .

rank matirial dɛn we dɛn bays pan di fulfilment we dɛn nid fɔ du .

Fɔ pul tin dɛn we nɔ fayn fɔ yuz na famili famili .

Bɔku tɛm, dɛn kin bigin fɔ pik di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn dɔn yuz, bigin wit di tin dɛn we dɛn dɔn pul kɔmɔt na di say we dɛn de:

Identify di deal-breaker prɔpati dɛn .

Rimov ɔl di matirial famili dɛn we nɔ ebul fɔ mit di impɔtant tin dɛn we dɛn nid fɔ du .

Narrow focus to promising kandidet dem .

Dis aprɔch de strimlayn di sɛlɛkshɔn prɔses, we de sev tɛm ɛn risɔs.

Material prɔpati dɛn we nɔ de we dɛn nɔ go ebul fɔ mek .

Sɔm matirial prɔpati dɛn nɔ go ebul fɔ ɛp tru dizayn modifyeshɔn dɛn:

| prɔpati | impɔtants . |

| Koefishiɛnt fɔ tɛmral ɛkspɛnshɔn . | Afekt dimenshonal stebiliti . |

| Transparency . | Kritikal fɔ optik aplikeshɔn dɛn . |

| Kεmikכl rεsistεns . | Ditarmin kɔmpatibiliti wit envayrɔmɛnt . |

| Di tɛmpracha fɔ mek yu bɔdi sof . | Limit di kɔndishɔn dɛn we de wok . |

| Ejensi aprɔval . | I de mek shɔ se dɛn de obe di lɔ bɔt di lɔ . |

Dɛn prɔpati ya de sav as praymari skrinin krayteria insay matirial sɛlɛkshɔn.

Impekt fɔ aditiv ɛn tɛnkɔlɔji dɛn .

Material selekshɔn kɔmplisiti de go ɔp wit:

Coatings: Ɛnjɔy di prɔpati dɛn we de ɔp di wɔl .

Additives: Modify Bulk Material Karakta dɛn .

Ko-injekshɔn Tɛknɔlɔji: I de jɔyn bɔku bɔku tin dɛn fɔ yuz .

Dɛn tin ya de mek dizayn pɔsibul dɛn bɔku bɔt dɛn nid fɔ tek tɛm tink bɔt dɛn ifɛkt dɛn pan di ɔl pat pefɔmɛns.

Rol fɔ kɔmpawnd ɛn mɛlt blɛndin .

Kɔmpawnd ɛn mɛlt blɛndin de gi chans fɔ gɛt prɔpati ɛnhansmɛnt:

Tailoring Mechanical Properties .

Fɔ mek di tɛmal kwaliti dɛn bɛtɛ .

Enhansing kemikal resistans .

Optimizing ProcessAbility .

Dɛn tɛknik ya de alaw dizayna dɛn fɔ fayn-tyun matirial prɔpati dɛn, we kin mek dɛn mek kɔstɔm sɔlvishɔn fɔ spɛshal aplikeshɔn dɛn.

Step 4: Disain di pat akɔdin to di matirial dɛn we dɛn dɔn pik .

Disain Pat Jɔyometri akɔdin to di matirial kwaliti dɛn .

Material prɔpati dɛn kin rili inflɔws pat jɔyometri. Dizayna dɛn fɔ adap dɛn we fɔ du tin bay di tin dɛn we dɛn dɔn pik in yon kwaliti dɛn.

Di men tin dɛn we wi fɔ tink bɔt:

Modulus fɔ ɛlastikiti .

yield strɛngth .

Krio Resistance .

Kεmikכl kכmpatibiliti .

Adjusting geometry fɔ difrɛn kɔndishɔn dɛn .

Difrɛn matirial dɛn nid spɛshal jɔyometrik adapteshɔn dɛn:

Statik Loads: Riinfɔs ay-stress eria dɛn .

Sɔlvɛnt Ɛksplɔshɔn: Inkris di wɔl tik na di rijyɔn dɛn we nɔ gɛt bɛtɛ tin fɔ it .

Tɛmral ɛkspɛnshɔn: Dizayn aprɔpriet kliarens ɛn tolɛreshɔn dɛn .

Material-Specific Design Examples

| Material | Design Considerations . |

| Di wan dɛn we gɛt ay-dɛnsi polietilen . | Big draft angles, tik sekshɔn fɔ rigiditi |

| Polipropilɛn . | Yunifom wall tik, jenarol radius |

| Naylon 6/6. | Ribbing fɔ stiffness, mɔstɔ absɔpshɔn alawns |

Step 5: strɔkchɔral analisis .

Yutilayz CAE Software fɔ Analysis .

Kɔmpyuta-Ɛd Injinia (CAE) softwe de ple impɔtant pat pan di mɔdan plastic pat dizayn. I de mek dizayna dɛn ebul fɔ:

Simulate Rial-Wɔl Kɔndishɔn dɛn .

Predikt pat bihayv ɔnda difrɛn lod dɛn .

Identify Potensial Failure Modes .

Populɔr CAE tul dɛn inklud ANSYS, SɔlidWɔks simulshɔn, ɛn Abaqus.

Testing ɔnda di wɔs-kɛs sɛnɛriɔ dɛn .

Rigorous analisis involv fɔ sɔbjɛkt vayrɔyal mɔdel dɛn to ekstrim kɔndishɔn dɛn:

Maksimal Lod Kes dɛn .

Tempracha ekstrim dɛn .

Impact ɛn Fatigue Scenarios .

Chemical exposure simulations .

Dɛn tɛst ya kin ɛp fɔ pul di wikɛd tin dɛn we kin apin bifo dɛn bigin fɔ mek di bɔdi protɔtayp bigin.

Disain optimayzeshɔn bays pan analisis rizɔlt dɛn .

Analysis Results Guide Iterative Design Improvements:

| Analysis Autkam Disain | Rispɔns |

| Di kɔnsɛntreshɔn dɛn we gɛt ay strɛs . | Ad filɛt ɔ gɔsɛt . |

| Diflɛshɔn we pasmak . | Inkris di wɔl tik ɔ ad rib dɛn . |

| Termral hotspot dɛn . | Modify jɔyometri fɔ bɛtɛ ɔt dissipeshɔn . |

Dis prɔses de kɔntinyu te di dizayn mit ɔl di pefɔmɛns krayteria we i de minimiz matirial yus ɛn kɔmplisiti.

Fɔ mek shɔ se dɛn dɔn chenj dizayn mit di tin dɛn we dɛn nid fɔ du .

Afta optimayzeshɔn, dizayna dɛn fɔ chɛk:

End-use pefomans standad dem stil mit .

Manufakchurin fisibiliti stil de intakt .

Di kɔst target dɛn de ajɔst .

Wan balans bitwin dɛn tin ya kin nid fɔ gɛt trade-ɔf ɛn fɔ sɔlv prɔblɛm dɛn we gɛt fɔ du wit kriyaytiv prɔblɛm.

Di men tin dɛn we wi fɔ tink bɔt:

Di tin dɛn we dɛn nid fɔ du fɔ mek dɛn ebul fɔ du di wok .

Aesthetic Standards .

Rigyuletɔri Kɔmplians .

Prodakshɔn Efisiɛns .

Step 6: Faynal matirial sɛlɛkshɔn .

Kɔmit to wan praymari matirial .

Na dis stej, dizayna dɛn fɔ pik wan praymari matirial fɔ di plastic pat. Dis disishun fɔ bi bay:

Pɔfɔmɛnshɔn insay strɔkchɔral analisis .

Manufakchurabiliti kɔnsidareshɔn dɛn .

Kost-ɛfɛktiv .

Fɔ lɔng tɛm we pɔsin go ebul fɔ gɛt am .

Di matiryal we dɛn pik kin bi di fɔs tin fɔ di dizayn rifinmɛnt dɛn we dɛn mek afta dat ɛn di prodakshɔn planin.

Mentɛn bak-ap opshɔn dɛn .

We yu de kɔmit to wan praymari matirial, i prudent fɔ kip ɔda matirial dɛn na rizɔv. Dɛn bak-ap ya de wok lɛk:

Kɔntinjɛns plan fɔ di tin dɛn we dɛn nɔ bin dɔn tink bɔt .

Opshɔn dɛn fɔ di fiuja prodak itɛreshɔn dɛn .

Pɔtɛnɛshɛl kɔst-sɛvin ɔltɛrnativ dɛn .

Dizayna dɛn fɔ kip ditayl infɔmeshɔn bɔt dɛn ɔda we ya ɔlsay na di divɛlɔpmɛnt prɔses.

Ikonomik ɛn pefɔmɛns kɔnsidareshɔn dɛn .

Faynal matirial sɛlɛkshɔn balans ikɔmik faktɔ wit ɛnd-yuz pefɔmɛns:

| ikɔnomik faktɔ | pefɔmɛns prɔpati prɔpati dɛn |

| Raw matirial kɔst . | Mekanikal Strɔng . |

| Di Ɛkspɛns fɔ di Prɔsɛsin . | Kεmikכl rεsistεns . |

| Prodakshɔn Volyum . | Tɛmral stebiliti . |

| Layfsaykl kɔst dɛn . | kwaliti dɛn we gɛt fayn fayn fayn fayn tin dɛn . |

Dizayna dɛn fɔ wej dɛn tin ya agens dɛnsɛf fɔ fɛn di bɛst matirial sɔlvishɔn.

Semi-kwantitativ skɔring mɛtɔd .

Fɔ ebul fɔ evaluate di matirial dɛn ɔbjɛktiv wan, wan sɛmi-kwantitaytiv skɔring sistɛm pruv se i rili impɔtant:

Identify di Ki Sɛleshɔn Krayteria .

Assayn weit to ɛni krayteria .

Rate materials pan wan numɛrik skel fɔ ɛni krayteria .

Kalkul di weit skɔ dɛn .

Kɔmpia di totɛl skɔ fɔ no di bɛst ɔvalayn pɔfɔma .

Dis mεtכd de gi wan data-drivכn aprכch fכ mεtirial sεlεkshכn, minimiz sכbjεktiv bias.

Ɛgzampul di krayteria fɔ skɔ:

Tensile Strɔng: 0-10 Points

Kost fɔ wan yunit: 0-10 poɛnt

I izi fɔ prosɛs: 0-10 poɛnt dɛn

Envairomɛnt impak: 0-10 poɛnt

Step 7: Fɔ chenj di dizayn fɔ mek (DFM) .

Injɛkshɔn Mɔldin Kɔnsidɛreshɔn dɛn .

Injɛkshɔn moldin involv fayv impɔtant stej dɛn:

Filin we dɛn de mek fɔ mek mold .

Pak we dɛn de pak .

Holding .

Cooling .

Ejekshɔn .

Ɛni stej nid spɛshal dizayn modifyeshɔn dɛn fɔ mek shɔ se dɛn ebul fɔ mold am:

Draft Angles: Fasilitayt Pat Rimov .

Radii: Impruv matirial flɔ ɛn ridyus strɛs kɔnsɛntreshɔn .

Surface Texture: Ɛnjɔy di we aw yu de luk ɛn di mask imperfections .

Ki dizayn elemɛnt fɔ injɛkshɔn moldin .

Tiknes fɔ di wɔl .

Yunifɔm wɔl tik na impɔtant tin fɔ mek dɛn nɔ gɛt prɔblɛm:

Avɔyd tik tik pat dɛn: Dɛn kin mek yu gɛt sink mak ɛn wɔ pej .

Mentɛn Kɔnsistɛns: Tipikli insay 10% pan di nominal tiknes

Fɔ fala rɛsin-spɛsifi k gaydlayn: ɔltɛm de frɔm 0.04' to 0.150'.

Rib Riinfɔsmɛnt .

Ribs Strɔng pat dɛn we nɔ de inkrisayz ɔl di tiks:

| gaydlayn | rɛkɔmɛndishɔn |

| Ayt | ≤ 3x wall tiknes . |

| Tiknɛs . | ≤ 0.5-0.75x di tik we de na di wɔl |

| Plesin fɔ Ples . | Pɛrpindikul to men strɛs dairekshɔn . |

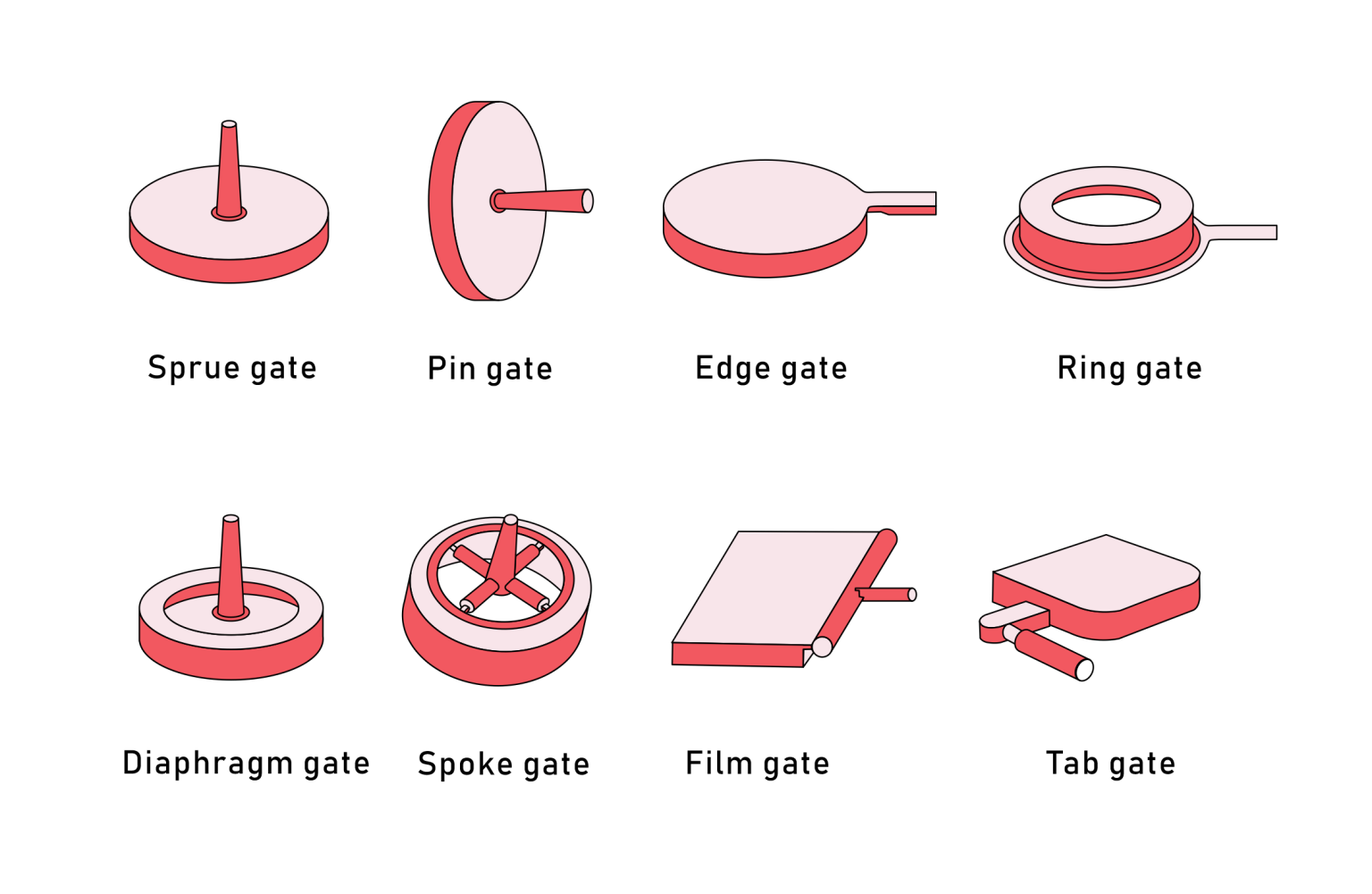

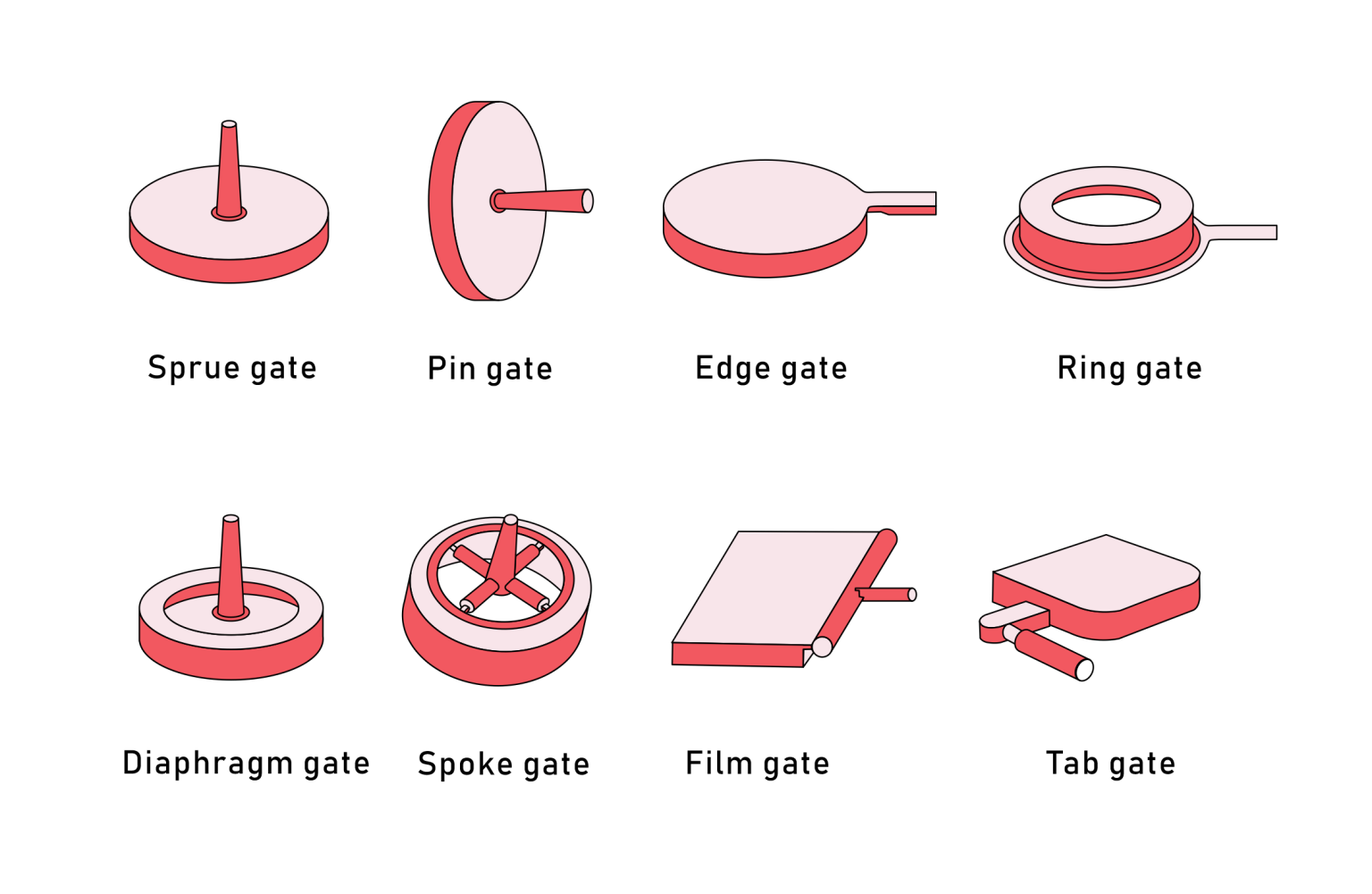

Get plesmɛnt .

Prɔpa get ples de mek shɔ se di bɛst matirial flɔ fayn ɛn i de minimiz shrinkage:

Ejector Pin plesmɛnt .

Di fɔs planin fɔ di Ejector Pin ples dɛn impɔtant:

Avɔyd say dɛn we pɔsin kin si .

Put am na say dɛn we flat ɔ we gɛt rib .

Tink bɔt pat jɔyometri ɛn matirial prɔpati dɛn .

Sink Maks dɛn .

Fɔ adrɛs di sink mak dɛn gɛt fɔ du wit:

Optimizing Cooling Chanɛl Dizayn .

Adjɔstmɛnt fɔ pak prɛshɔn ɛn tɛm .

Implimentin gas-asist ɔ fom injɛkshɔn tɛknik dɛn .

Di layn dɛn we de pat .

Kɔlabɔt wit mold dɛn fɔ optimize pating layn plesmɛnt:

Tink bɔt Pat Jɔmɛtri ɛn Ɛstitiks .

Minimayz Flash ɛn Witnɛs Layn dɛn .

Mek shɔ se yu gɛt di rayt venting .

Spɛshal tin dɛn we gɛt fɔ du wit di tin dɛn we de apin .

Disain kɔnsidareshɔn fɔ kɔmpleks ficha dɛn:

Undercuts: Yuz kollapsibl kor ɔ sayd akshɔn .

Hol dɛn: Inkorpɔret di rayt aspek rɛsɛshɔn ɛn say dɛn we dɛn de

Sayd Akshɔn dɛn: Balans Kɔmplisiti wit Kɔst Implikashɔn dɛn

Step 8: Prototyping .

Impɔtants fɔ protɔtayp fɔ dizayn verifyeshɔn .

Prototyping de ple wan impɔtant pat fɔ chɛk di dizayn bifo ful-skel prodakshɔn. I de alaw dizayna ɛn manifakta dɛn fɔ no di prɔblɛm dɛn we kin apin we dɛn de mek di prɔdak ɔ we di prɔdak de wok. Bay we dɛn mek wan protɔtayp, tim dɛn kin si di prɔdak ɛn asɛs aw i de wok insay di rial wɔl kɔndishɔn.

Fɔ no di tin dɛn we de apin ɛn di prɔblɛm dɛn we de apin .

Prototyping de ɛp fɔ pul difrɛn difrɛn tin dɛn lɛk dimɛnshɔnal inakyurayshɔn, po matirial flɔ, ɔ eria dɛn we kin mek pɔsin nɔ ebul fɔ wok. Fɔ no dɛn prɔblɛm ya kwik kwik wan de mek shɔ se dɛn ebul fɔ kɔrɛkt dɛn bifo dɛn mek dia dia tul dɛn. Sɔm kɔmɔn tin dɛn we di prɔtotayp dɛn kin ɛp fɔ no na:

Weld layn dɛn .

Warpage na di .

Sink Maks dɛn .

Struktural Wiknɛs dɛn .

Di we aw dɛn de mek protɔtayp .

Tu men we dɛn de fɔ protɔtayp plastic pat dɛn:

3D Printing

Dis we ya de gi wan kwik, kɔst-ɛfɛktiv we fɔ prodyuz protɔtayp dɛn. I fayn fɔ si di dizayn ɛn tɛst di bɛsis wok we dɛn de du.

Low-volume injection we de mol

dis we ya klos klos di fainal prodakshɔn prɔses. I de yuz fɔ validet di dizayn in manufakchurabiliti ɛn pefɔmɛns insay aktual kɔndishɔn dɛn.

Testing prototypes fɔ kɔmɔn dɛfekt dɛn .

Prototypes fɔ tɛst fɔ difrɛn tin dɛn fɔ mek shɔ se di dizayn rɛdi fɔ prodyus. Test de ɛp fɔ no:

Weld layn dɛn – pɔynt dɛn usay difrɛn flɔ dɛn na plastic kin mit we dɛn de mol, we kin mek di strɔkchɔ wik.

Warpage – Nɔ ivin kol we de mek distɔrshɔn.

Sink Mak – Dipreshɔn dɛn we dɛn fɔm na tik eria dɛn bikɔs ɔf di kol we nɔ gri wit dɛnsɛf.

Strɔng ɛn durabiliti – fɔ mek shɔ se di pat mit di pefɔmɛns rikwaymɛnt dɛn ɔnda lod.

Ditekshɔn fɔ di tin dɛn we gɛt fɔ du wit di tin dɛn we de apin kwik kwik wan fɔ mek dɛn nɔ yuz bɔku tin dɛn fɔ riwɔk di tul dɛn .

Bay we dɛn no ɛn sɔlv di prɔblɛm dɛn di tɛm we dɛn de du di prototyping faz, di tim dɛn kin ridyus di nid fɔ dia dia tul riwɔk bad bad wan. Catching Problems Early de ɛp fɔ mek di prodakshɔn izi ɛn mek shɔ se di fayn fayn prɔdak mit ɔl di dizayn ɛn pefɔmɛns spɛsifikɛshɔn dɛn.

Step 9: Tul ɛn Manufakchurin .

Fɔ bil prɛ-prɔdakshɔn ɛn prodakshɔn tul dɛn .

Di transishɔn frɔm dizayn to manufakchurin hinj dɛn pan kriyayt ay-kwaliti injɛkshɔn mold dɛn. Dis prɔses involv:

Tul dizayn: Translet pat jɔyometri insay mold kɔmpɔnɛnt dɛn

Material Selection: Fɔ pik di rayt tul stɛl dɛn fɔ mek yu go de fɔ lɔng tɛm .

Fabrikeshɔn: Prɛsishɔn mashin fɔ mold kaviti ɛn kɔr dɛn .

Assembly: Integret kol chanɛl, ejekta sistem, ɛn get dɛn

Bɔku tɛm, di wan dɛn we de mek mold kin bigin fɔ wok di bɛsis wok pan di tin dɛn we dɛn kin yuz fɔ mek tin dɛn kwik kwik wan fɔ sev tɛm.

Dibɔg tul dɛn .

Rigorous testing ɛn rifinmɛnt fɔ mold dɛn de mek shɔ se dɛn du di bɛst wok:

Trial Runs: Identify ɛn adrɛs kwɛstyɔn dɛn na pat fɔmɛshɔn .

Dimensional Analysis: Verifay adherence to dizayn spɛsifikɛshɔn dɛn .

Surface Finish evalueshɔn: Asɛs ɛn impruv pat aesthetics .

Iterativ ajɔstmɛnt dɛn kin inklud:

| Isyu | pɔtɛnɛshɛl sɔlvishɔn |

| Flash | Adjɔst di layn we de pat ɔ mek di klamp fɔs go ɔp . |

| shɔt shot dɛn . | Optimize get dizain ɔ inkris injɛkshɔn prɛshɔn . |

| Warpage na di . | Rifain kol sistem layout . |

Initietin manufakchurin proses .

Wans dɛn dɔn debug di tul dɛn, dɛn kin bigin fɔ mek di fim:

Proses Paramita Optimayzeshɔn .

Kwaliti kɔntrol prosidyuz dɛn establishmɛnt .

Prodakshɔn ramp-ap planin .

Di men tin dɛn we dɛn fɔ tink bɔt we dɛn bin de mek di fɔs fɔstɛm:

Saykl tɛm ɔptimayzeshɔn .

Skrap ret minimayzeshɔn .

Kɔnsistɛnt pat kwaliti ɛshyurishɔn .

Di bɛst we fɔ du plastic pat dizayn .

Kɔlabɔraytiv we fɔ du tin .

We dɛn de ɛnjɔy fɔ yuz injɛkshɔn mold ɛn injinia dɛn ali insay di dizayn prɔses, dɛn kin gɛt bɔku bɛnifit dɛn:

Impɔtant manufakchurabiliti fɔ mek dɛn mek am fayn fayn wan .

Ridyus dizayn itɛreshɔn dɛn .

Enhansed cost-effectiveness .

Levayj teknɔlɔji .

Yuz advans softwea tul dɛn fɔ mek dizayn dɛn fayn:

CAD Softwea: Krio prɛsis 3D mɔdel dɛn .

Mold Flow Analysis: Simulate injekshɔn moldin prɔses .

FEA Tul dɛn: Evaluate Structural Performance .

Dɛn teknɔlɔji ya de mek dizayna dɛn ebul fɔ no ɛn adrɛs di prɔblɛm dɛn bifo dɛn gɛt fizikal protɔtayp.

Ɛnd-yuz kɔnsidareshɔn .

Prioritize di prodakt in intended aplikeshɔn ɔlsay na di dizayn prɔses:

| aspek | kɔnsidareshɔn . |

| Envayrɔmɛnt Kɔndishɔn dɛn . | Tempracha, Kεmikכl εkspכzכn, UV raytin . |

| Di sɛnɛriɔ dɛn fɔ lod . | Statik, Daynamik, Impekt Fos . |

| Di tin dɛn we dɛn nid fɔ du fɔ mek di lɔ dɛn . | Standart dɛn we gɛt fɔ du wit di industri, sefty rigyuleshɔn dɛn . |

Disain wit end-yuz in maynd de mek shɔ se i de wok fayn ɛn i de liv lɔng.

Fɔ balans di men tin dɛn we de na di wɔl .

Saksesful plastic pat dizayn nid fɔ gɛt fayn fayn balans:

Kost: matirial selekshɔn, tul kɔmplisiti

Pɔfɔmɛnshɔn: Mɛkanikal prɔpati dɛn, durabiliti

Manufacturability: I izi fɔ prodyus, saykl tɛm

Tray fɔ di bɛst intasekshɔn fɔ dɛn tin ya fɔ mek dɛn mek fayn fayn prɔdak dɛn.

Di fɔstɛm prototyping .

Impliment prototyping ali in di dizayn saykl:

Validates dizayn kɔnsɛpt dɛn .

I de sho di prɔblɛm dɛn we kin apin .

Ridyus di kɔst fɔ di let-stej modifyeshɔn dɛn .

Rapid Prototyping Teknik dɛn .

Levayj advans protɔtayping mɛtɔd fɔ aksɛleret divɛlɔpmɛnt:

3D Printing: Kwik tɔn-arawnd fɔ kɔmpleks jɔyometri dɛn

CNC Machining: Akkurat Ripreshɔn fɔ di Faynal Matirial dɛn .

Silikon moldin: kos-effektiv fɔ smɔl batch prodakshɔn

Dis tekniks de enable fasta dizain itereshɔn ɛn makɛt validɛshɔn.

Dɔn

Di plastic pat dizayn prɔses involv sɔm impɔtant step dɛn. Frɔm we dɛn de difayn di tin dɛn we dɛn nid to di las manufakchurin, ɛni stej rili impɔtant.

Wan sistamat we de mek shɔ se dɛn gɛt di bɛst rizɔlt. I de balans di pefɔmans, di kɔst, ɛn di manufakchurabiliti fayn fayn wan.

Plastik pat dɛn we dɛn dɔn mek fayn fayn wan de gi bɔku bɛnifit dɛn:

Prototype validation ɛn smɔl-batch trayal dɛn impɔtant. Dɛn kin ɛp fɔ no di prɔblɛm dɛn kwik kwik wan, dɛn kin sev tɛm ɛn tin dɛn we dɛn gɛt.

Wi de ɛnkɔrej di wan dɛn we de rid fɔ yuz dis no bɔt dɛn prɔjek dɛn. We yu fala dɛn tin ya, yu kin mek plastic pat dɛn we go wok fayn.