Laser ja walima laser etching: jumɛn ka kan ka kɛ i ka poroze ye? Hali ni o fɛɛrɛ fila bɛɛ bɛ taamasiɲɛ banbaliw dilan, u juguman, u muɲuni, ani u kɛcogo tɛ kelen ye. Fɛɛrɛ ɲuman sugandili bɛ bɔ i ka fɛnw na, i ka muɲuli magow la, ani i ka baarakɛnafolo la.

Nin sɛbɛn in kɔnɔ, an bɛna don laser ja la vs. laser etching , ka danfara jɔnjɔnw datugu baarakɛcogo, fɛnw, ani musaka la. I bɛna a dɔn waati min na i bɛ se ka kelen-kelen bɛɛ sugandi, baarakɛcogo misaliw, ani laadilikanw walasa ka fɛɛrɛ ɲuman sugandi i magow kama.

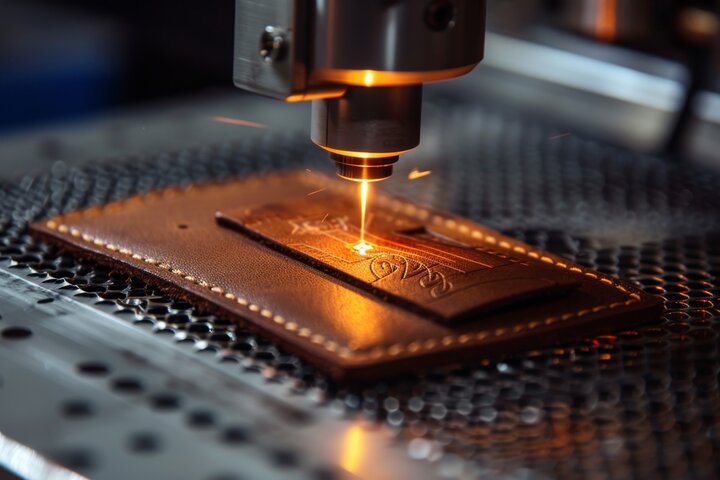

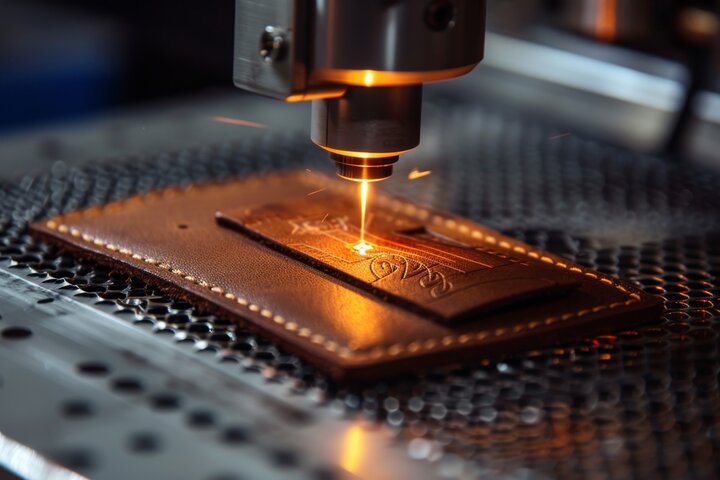

Laser ja ye mun ye?

Laser ja ye fɛɛrɛ tigitigi ye min bɛ fɛnw taamasiyɛn kudayi ni u ka yɔrɔ lafiɲɛ ye. Nin yɔrɔ in bɛ laser ja baara cogo sɛgɛsɛgɛ, a nafaw n’a dɛsɛw, fɛn bɛnnenw, ani izini baarakɛcogo minnu bɛ kɛ tuma bɛɛ.

Taabolo ɲɛfɔli .

O kɛcogo bɛ baara Kɛ ni laser fanga caman ye walasa ka fɛnw yɔrɔw Lajɔ, ka kɔnɔna-cogo tigitigiw Dabɔ. Ni laser-fiɲɛw bɛ ɲɔgɔn Sɔrɔ laɲini-yɔrɔ la, u bɛ funteniba Bɔ, ka fɛn gɛlɛnw Yɛlɛma k’u Kɛ 'yɔrɔ ye. O lafiɲɛbɔ-minɛn in bɛ kɔnɔnatumuw Bɔ minnu ka dun n’i y’a Jira ko taamaʃyɛn-fὲɛrɛ wɛrɛw bɛ Kɛ.

A ka c’a la, ja juguya bɛ se ka se santimɛtɛrɛ 0,020 ma, a bɛ ɲɔgɔn ta ka kɛɲɛ ni:

Nafa minnu bɛ sɔrɔ laser ja la .

Laser ja bɛ nafa caman lase mɔgɔ ma minnu bɛ mɔgɔ bila ka miiri:

Taamaʃyɛn minnu bɛ mɛn sen na: Taamaʃyɛn jalenw bɛ se ka sɛgɛn, o b’a to u bɛnnen don fɛnw ma minnu bɛ sɔrɔ cogoya gɛlɛnw na.

A ka baara gɛlɛnw: A ka muɲuli b’a to a bɛ se ka taamasiyɛn kɛ yɔrɔw la minnu bɛ muɲu tuma bɛɛ walima sigidaw la minnu ka jugu kosɛbɛ.

Laser ja min bɛ kɛ ka ɲɛ ani ka segin a kan: Laser ja bɛ tiɲɛni ɲuman di, o bɛ kɛ sababu ye ka bɛnkan sɔrɔ fɛn caman dilanni na.

Fɛn minnu bɛ bɛn ɲɔgɔn ma kosɛbɛ: Nin fɛɛrɛ in bɛ baara kɛ ni fɛn caman ye, i n’a fɔ nɛgɛw, plastikiw, ani hali jiri.

Nafa minnu bɛ sɔrɔ laser ja la .

Hali n’a fanga ka bon, laser ja bɛ dan dɔw jira:

Kuwame ka fanga bonya : Lafiya taabolo bɛ fanga doncogo caman ɲini .

Baara musakaw cayalen : Minɛnw ladonni ni u baara musakaw bɛ tɛmɛ fɛɛrɛ wɛrɛw kan .

Material Restrictions : Fɛn dɔw bɛ kɛ cogo bɛnnen na k’a sababu kɛ u farikolo cogoyaw ye .

Fɛn bɛnnenw ka ɲɛsin laser ja ma .

Laser ja bɛ se ka kɛ fɛn caman ye:

Nɛgɛw : .

inox .

Aluminiyɔmu .

Titanium .

Brass .

Fɛn minnu tɛ nɛgɛ ye : .

Yiri

Fibreglass .

Papiye

Polimɛriw sugandi .

Aplikasi minnu bɛ kɛ tuma bɛɛ .

Laser ja bɛ kɛ ka caya yɔrɔw taamasiyɛnni na minnu magow ka bon kosɛbɛ. Aplikasi minnu bɛ sɔrɔ tuma caman na, olu ye:

Industriw yɔrɔw : A bɛ kɛ ka fɛn dilanni kɛ walasa ka masinw yɔrɔw labeli, ka tugu ɲɔgɔn kɔ ani ka a muɲu.

Furakɛcogo minɛnw: Aw bɛ seriyali nimɔrɔw walima kodew ja opereli minɛnw kan walasa ka u dɔn nɔgɔya la ani ka u labato izini sariyaw la.

Mobili ni aerospace yɔrɔw: A ka ɲi taamasiyɛnw ma minnu bɛ sɔrɔ sigidaw la minnu ka jugu kosɛbɛ, ka taamasiyɛnw di minnu bɛ mɛn ani minnu bɛ se ka kalan.

Laser etching ye mun ye?

Laser etching bɛ taamasiɲɛ banbaliw dilan ni surface melting ye, o b’a to a ka ɲi kosɛbɛ taamasiyɛn tiɲɛni na fɛn suguya caman na. Yan, an bɛ sɛgɛsɛgɛli kɛ laser etching baara cogo kan, a nafaw n’a dantigɛliw, a ka fɛn bɛnnenw, ani a baarakɛcogo caman.

Taabolo ɲɛfɔli .

O kɛcogo bɛ laser-fiɲɛ caman Kɛ walasa ka funteni fanga caman Sɔrɔ yɔrɔ kɛrɛnkɛrɛnnenw na. Ni laser ye ɲɔgɔn Sɔrɔ ni fɛn ye, o bɛ wuli joona ani ka misɛnniw bonya. O funteni jɛɲɔgɔnya in bɛ na ni sigida caman yeli ye, o bɛ na ni taamasiyɛn wulilenw ye minnu bɛ ye nɛnɛ kɔfɛ.

Fɛɛrɛ in bɛ tali kɛ :

fanga minɛni ni funteni jiginni .

Surface melting (yɔrɔ min bɛ wuli) ni a hakɛw ye microscope ye .

Material expansion ani texture modification .

Kulɛri jiginni kan .

Etching juguman bɛ bɔ 0,0001 na ka se 0,001 ma, o bɛ se ka kɛ sababu ye ka taamasiyɛn kɛcogo tigitigi jira.

Nafa minnu bɛ sɔrɔ laser etching na .

Laser etching bɛ nafa caman lase mɔgɔ ma minnu bɛ se ka mɔgɔ bila ka miiri:

High Precision : Tiɲɛni nafama b’a to a dafalen don dilancogo gɛlɛnw kama ani kunnafoni misɛnninw biyew walima furakɛli yɔrɔw kan .

A dilanni teliya : A teliya bɛ tɛmɛ taamasiyɛn fɛɛrɛ wɛrɛw kan, o bɛ se ka kɛ sababu ye ka sɛnɛ kɛcogo ɲuman sɔrɔ .

Baara musaka dɔgɔyali : Kuranko wajibiyalenw dɔgɔyali bɛ dɔ bɔ baara musakaw la .

Material versatility : A bɛ baara kɛ ka ɲɛ fɛnmuguw ni fɛn finmanw bɛɛ kan .

Energy Efficiency : fanga dɔgɔyali min ka dɔgɔn ni taamasiyɛn kɛcogo wɛrɛw ye .

Nafa minnu bɛ sɔrɔ laser etching na .

Hali n’a nafa ka bon, laser etching bɛ dan dɔw jira:

Dunanw haminankow : Ikomi taamasiyɛnw bɛ sanfɛ, u bɛ se ka sɛgɛn waati tɛmɛnen kɔfɛ cogoya gɛlɛnw na.

Minɛnw dantigɛli : A bɛ fibre laser kɛrɛnkɛrɛnnenw de wajibiya, ka dan sigi baara misɛnninw sɔrɔli la .

Ladonni wajibiyalenw : Sisεmεti ka jateminɛ kɛli tuma bɛɛ mago bɛ jateminɛ na .

Fɛn bɛnnenw ka ɲɛsin laser etching ma .

Nɛgɛw:

Nɛgɛ minnu tɛ nɛgɛ ye:

Wɛɛrɛ

Seramiki .

Polimɛriw .

Acryliques sugandilenw .

Aplikasi minnu bɛ kɛ tuma bɛɛ .

Laser etching ka ɲi kosɛbɛ baarakɛcogo la minnu tɛ taamasiɲɛ jugumanw wajibiya, minnu bɛ se ka sɛgɛn. A bɛ kɛ ka caya:

Jagofɛn minnu bɛ kɛ ni seko ni dɔnko ye ani minnu ka nɔgɔn: A bɛnnen don fɛnw ma i n’a fɔ biyew, mɔgɔ yɛrɛ tɔgɔw, ani nɛgɛmafɛnw.

Yɔrɔw nɔfɛtaama: A nafa ka bon iziniw ma, yɔrɔ minnu na yɔrɔw dɔnni nafa ka bon kosɛbɛ, i n’a fɔ mobili, ɛntɛrinɛti, ani aerospace.

laser etching ni ja min bɛ tali kɛ ɲɔgɔn na .

Laser etching ni ja bɛ se ka kɛ i n’a fɔ a bɛ tali kɛ ɲɔgɔn na nka u bɛ danfaraba la u juguman na, u muɲuni na, ani u kɛcogo ɲuman na. Nin ye nin fɛɛrɛ ninnu sumacogo caman ye ka da fɛn jɔnjɔnw kan.

Tigɛ ka juguya .

Etching: A bɛ taamasiɲɛ minnu man bon, a ka c’a la, olu bɛ 0,0001 ni 0,001 inch cɛ. Nin yɔrɔ-ni-taama-taama in ka ɲi kosɛbɛ dilanw ma minnu mago tɛ juguya la.

Jalen: a bɛ tigɛ ka taa a fɛ, ka se 0,020 inch ma. O juguya min bɛ caya, o bɛ taamasiyɛnw jira minnu jalen don kosɛbɛ ani minnu bɛ to senna.

Durability ani wear resistance .

Etching: A man teli ka mɛn ka da a tigɛlenw kan minnu man dun, a bɛnnen don ka ɲɛsin ɲɛnajɛko ma walima fɛn nɔgɔmanw ma.

Jalabɔ: A bɛ mɛn ka tɛmɛ ani a bɛ se ka sɛgɛn, a ka ɲi yɔrɔw ma minnu bɛ kɛ sigida gɛlɛnw na, i n’a fɔ izini walima kɛnɛma sigidaw.

sɛnɛfɛnw bɔli hakɛ ani u musaka .

Etching: A musaka ka dɔgɔ kosɛbɛ ka ɲɛsin caman sɔrɔli ma. A ka baara teliya n’a fanga dɔgɔyali b’a kɛ sugandili ye min bɛ bɛn baarakɛnafolo ma.

Jalabɔ: musaka caman bɛ sɔrɔ waati ni fanga bonya kosɔn. Jaw bɛ bɛn kosɛbɛ baarakɛcogo ma yɔrɔ minnu na muɲuli ka bon ni u dilanni musaka ye.

Aplikasi versatility .

Etching: A bɛ bɛn ni fɛn caman ye, i n’a fɔ nɛgɛw, gilasi, ani polimɛri dɔw, minnu bɛ fɛn caman sɛgɛsɛgɛ izini suguya caman na.

Jalabɔ: A dan ye nɛgɛw ni fɛnɲɛnamafagalanw ye, i n’a fɔ jiri, k’a sababu kɛ a fanga ka bon kosɛbɛ.

Teliya ni baarakɛcogo ɲuman .

Etching: Taabolo teliya, min ka ɲi teliya la ka bɔ sigidaw la walima porozew la minnu bɛ kɛ waati kunkurunnin kɔnɔ.

Jalabɔ: A ka surun nka a ɲɛfɔlen don ka ɲɛ, o b’a to a ka fisa ni sugandili ye min ka gɛlɛn, min bɛ kɛ tuma bɛɛ, minnu bɛ ɲini ka ɲɛ.

Sigida laminiko gɛlɛya .

Laser etching bɛ fanga dɔgɔya caman na ka tɛmɛ ja kan, o b’a to a bɛ kɛ fɛɛrɛ ye min tɛ fɛn tiɲɛ kosɛbɛ baarakɛminɛnw na minnu tɛ kɛ ni juguya walima muɲuli ye. Jaw bɛ fanga caman de wajibiya, o bɛ se ka dɔ fara baara musakaw kan ani ka sigida laminiko gɛlɛya.

| Facteur comparaison | laser étching | laser ja . |

| Tigɛ ka juguya . | A ka dɔgɔn (0,0001 - 0,001 inch) . | Deep (fo ka se 0,020 inch ma) |

| A bɛ se ka muɲu . | A man teli ka mɛn, ka ɲɛsin ɲɛnajɛko ma . | A bɛ mɛn kosɛbɛ, a bɛnnen don sigida gɛlɛnw ma . |

| Sɔngɔ | A musaka ka dɔgɔ ka ɲɛsin hakɛ caman ma . | sanfɛ ka da waati ni fanga magow kan . |

| Material Compatibilité . | A ka bon (nɛgɛw, gilasi, polimɛriw) . | fɔlɔ nɛgɛw ni fɛnɲɛnamaw kɛrɛnkɛrɛnnenw . |

| Teliya | Teliya . | A ka surun nka a ɲɛfɔlen don ka ɲɛ . |

| Eco-friendliness . | Seko ni dɔnko dɔgɔyali . | Seko ni dɔnko caman sɔrɔli . |

Fɛn minnu ka kan ka jateminɛ ni aw bɛ sugandili kɛ laser ja ni laser etching cɛ .

Ni aw bɛ laser ja ni laser etching (laser ja) latigɛ, a nafa ka bon ka fɛn suguya caman jateminɛ i n’a fɔ fɛnw bɛ bɛn ɲɔgɔn ma cogo min na, taamasiyɛn muɲuni, fɛn dilanni magow, ani baarakɛnafolo.

Material Properties ani Compatibilité .

Fɛn suguya bɛ nɔba bila o latigɛ la. Laser etching bɛ bɛn ni fɛn caman ye, i n’a fɔ nɛgɛw, gilasi ani plastiki dɔw, o b’a to a ka ɲi kosɛbɛ baara caman na. Nka, laser ja bɛ dan nɛgɛw ni fɛnɲɛnamafagalanw ma (i n’a fɔ jiri) k’a sababu kɛ a fanga ka bon kosɛbɛ.

Taamasiɲɛw juguya ni u muɲuni ɲininenw .

Ja min bɛ kɛ ka taamasiyɛn juguw sɔrɔ : Ni i ka porozɛ bɛ taamasiyɛn juguw de wajibiya (sen 0,02 ni kɔ), ja ye sugandili ɲuman ye. A juguya bɛ muɲuli wɛrɛ di, min bɛnnen don fɛnw ma minnu bɛ sɔrɔ cogoya gɛlɛnw na.

Etching for production efficiency : Etching bɛ teliya ka tɛmɛ ja kan siɲɛ fila ɲɔgɔn, o b’a to a ka ɲi kosɛbɛ fɛn dilanni na yɔrɔ min na dunuya tɛ ko gɛlɛn ye.

Baara minnu bɛ kɛ ni musaka ye : Porozɛ minnu ka baarakɛnafolo ka gɛlɛn, a ka c’a la, etching bɛ musaka bɔ kosɛbɛ k’a sababu kɛ a ka fanga ni a ka fɛnw wajibiyalenw dɔgɔyali ye.

Production volume ani teliya wajibiyalenw .

Walasa ka fɛn caman dilan, teliya ni baarakɛcogo ɲuman bɛ kɛ ko kɔrɔba ye. Laser etching ka baarakɛwaati teliyalen bɛ se ka kɛ sababu ye ka fɛn dilanni hakɛ caman sɔrɔ, o b’a to a bɛnnen don fɛnw ma minnu bɛ taamasiyɛn kɛ. O ni ɲɔgɔn cɛ, Engraving ka teliya ka dɔgɔn kosɛbɛ fɛnw na minnu ka dɔgɔn walima minnu kɛrɛnkɛrɛnnen don, minnu bɛ ɲɛnamaya jan ɲini.

baarakɛnafolo ni musaka jateminɛw .

Budjet bɛ se ka kɛ koba ye min bɛ se ka kɛ. Laser ja bɛ teli ka kɛ ni musaka caman ye ka kɔn ani ka baara kɛ ka da fanga magow kan ani baarakɛwaati janw. Laser etching, min bɛ fanga dɔgɔya, o bɛ nafa caman di porozew ma minnu bɛ kɛ ni baarakɛnafolo ye, kɛrɛnkɛrɛnnenya la, fɛn caman dilanni na.

Aesthetic preferences ani dilancogo gɛlɛya .

Walasa ka fɛn dɔw dilan minnu ka gɛlɛn walima minnu ɲɛfɔlen don kosɛbɛ, etching ni ja fila bɛɛ bɛ se ka nɔ ɲumanw bɔ. However, etching's surface-level marks are ideal for delicate, high-precision designs, such as logos or serial numbers on light commercial items. Jaw bɛ bɛn kosɛbɛ walasa ka fɛnw dilan minnu bɛ mɛn kosɛbɛ, minnu bɛ se ka maga fɛnw na, yɔrɔ minnu bɛ don sɛgɛn gɛlɛnw na.

| Factor | recommended processus . |

| Material Compatibilité . | Etching (Broader range) . |

| Depite de ka kan ka kɛ . | Ja (0,02 inch walima ka tɛmɛ o kan) . |

| Sɛnɛfɛnw dilanni nafa . | Etching (2x ka telin) . |

| Baarakɛnafolo | Etching (nafolo musaka) . |

| Aesthetic complexité . | Etching (Diapsions précisions) . |

| A bɛ se ka muɲu . | Ja (Yɔrɔw) . |

Farankan

Kuma surun na, laser ja ni laser etching (laser ja) bɛ danfara Bɔ u juguya la, u muɲuni na, ani u baara teliya la. Jaw bɛ taamasiɲɛw dilan minnu ka dun, minnu bɛ mɛn, ka sɔrɔ etching bɛ taamasiyɛnw di teliya la, minnu bɛ dugukolo sanfɛ. Fɛɛrɛ ɲuman sugandili nafa ka bon kosɛbɛ walasa ka sɔrɔ ɲininenw sɔrɔ baara kɛrɛnkɛrɛnnenw na. A b’a to Marks ka se ka muɲu, ka musakaw kɛ, ani ka magoɲɛfɛnw ɲɛnabɔ.

Aw ye fɛn kolomaw jateminɛ i n’a fɔ fɛnw bɛ bɛn ɲɔgɔn ma cogo min na, u dilanni teliya, ani u ka baarakɛnafolo ni aw bɛ a latigɛ. Ladilikan dɔnbagaw bɛ se ka bilasirali kɛ porozɛ gɛlɛnw na. Ni aw ye o danfara ninnu faamuya, aw bɛ se ka sugandili kɛ aw magow la laser ja ni laser etching kɔnɔ ..

Reference sources .

Laser ja .

Ɲininkaliw jaabiw .

J: Fɛn jumɛnw bɛ se ka ja walima ka u sɔgɔ?

A: Surface marking bɛ baara kɛ ka ɲɛ fɛn suguya caman kan. Nɛgɛ dilanni taabolo bɛ nɛgɛ, aluminiyɔmu, nɛgɛdaga dɛmɛ o fɛɛrɛ fila bɛɛ la. Fɛnw furakɛli bɛ taa fo gilasi, seramiki, polimɛriw la walasa ka etching kɛ, ka sɔrɔ fɛnw dilanni bɛ tɛmɛ jiri kan, fibreglasi bɛ kɛ ja ye. Surface baarakɛcogo seko bɛ bɔ substrate layer properties (sɔgɔsɔgɔninjɛ) cogoyaw la.

J: Laser-engraved walima laser-etched marks bɛ mɛn waati joli kɔnɔ?

A: A ka c’a la, a ka c’a la, a bɛ se ka kɛ ko a bɛ se ka muɲu san 5-10 kɔnɔ cogo la min bɛ kɛ ka ɲɛ. Marka jugu kɛli ja fɛ, o bɛ taamasiyɛn banbaliw dilan, ka taamasiyɛn ɲumanw di minnu tɛ se ka bɔ, minnu ka ɲi kosɛbɛ izini baara gɛlɛnw kama.

J: Yala laser ja ni etching bɛ se ka kɛ kulɛri taamasiyɛn ye wa?

A: Surface modification through Etching bɛ fɛn nɛrɛma, finman, walima gri material branding dilan. Funteni baara bɛ nɔ bila kulɛri caman na ka da baarakɛminɛnw kɛnɛma minɛni kan ani hakilijakabɔ hakɛw dɔnni senfɛ.

J: musaka suguya jumɛnw bɛ tali kɛ laser ja ni etching na?

A: Fɛnw caman caman cili ni etching ye, o bɛ baara musakaw dɔgɔya. Marka musaka juguw bɛ caya ka da baarakɛwaati janw kan, fanga caman sɔrɔli, fɛnw gɛlɛya, ani fɛn dilanni seko wajibiyalenw.

J: Ne bɛ se ka laser-masin ɲuman sugandi cogo di ne ka ja walima ne ka etching magow kama?

A: Optical systems sugandi ka da a dilanni kuntilenna kan. Laser masinw sugandili bɛ bɔ kɛnɛma layiniw labɛncogo la, u dilanni sɛgɛsɛgɛli wajibiyalenw na, biɲɛw sɔrɔyɔrɔ ɲuman na, ani batch hakɛ ɲininiw na.

J: Laser ja/etching baarakɛcogo teliya ye mun ye?

A: Surface labeling through Etching bɛ ja bɔli hakɛ siɲɛ fila sɔrɔ. Fɛn dilanni hakɛ bɛ nɔ bila teliya la, a bɛ danfara don ni basigifɛnw nafaw ye ani a dilanni gɛlɛya ye.

J: Fɛn minnu bɛ kɛ ka ɲɛsin fɛnw ma, olu bɛ danfara jumɛn don o fɛɛrɛ fila ni ɲɔgɔn cɛ?

A: Surface modification through etching suits reflective substrate layers. Material vaporization through graving bɛ ladamu fɛn gɛlɛnw na minnu mago bɛ impressions banbaliw la. Fɛnw dilanni ɲɛtaa bɛ bɔ a minɛcogo la.

J: Laserw ka baarakɛminɛnw ladonni ni u ladonni jateminɛ ye mun ye?

A: Baarakɛlaw ka baarakɛcogo ɲuman bɛ kɛ ni taamasiyɛnw jateminɛcogo ye tuma bɛɛ. Laser sitɛmu minnu bɛ kɛ ka fɛnw bɔ, olu mago bɛ ladonni na tuma caman na ka da jagokɛlaw ka baarakɛcogobaw kan. U fila bɛɛ bɛ metallurgical process environmental contrôlés.

Ni aw b'a fɛ ka ɲininkali wɛrɛw kɛ, Contact Team MFG bi !