Laser engraving ɔ laser etching: Us wan rayt fɔ yu prɔjek? Pan ɔl we ɔl tu di tɛknik dɛn de mek mak dɛn we go de sote go, dɛn difrɛn dip wan, dɛn go de fɔ lɔng tɛm, ɛn dɛn de yuz dɛn fɔ du am. We yu pik di kɔrɛkt we fɔ du tin, i go dipen pan di tin dɛn we yu gɛt, di tin dɛn we yu nid fɔ du fɔ lɔng tɛm, ɛn di mɔni we yu gɛt.

In dis post, wi go daiv insay laser engraving vs laser etching , we de kɔba ki difrɛns dɛn na di prɔses, matirial, ɛn kɔst. Yu go lan ustɛm fɔ pik ɛni wan pan dɛn, prɛktikal industri ɛgzampul dɛn, ɛn advays dɛn fɔ pik di bɛst we fɔ yu nid dɛn.

Wetin na laser engraving?

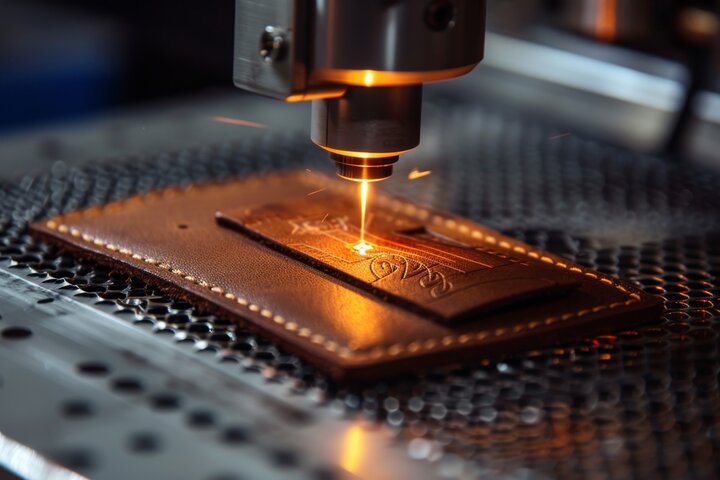

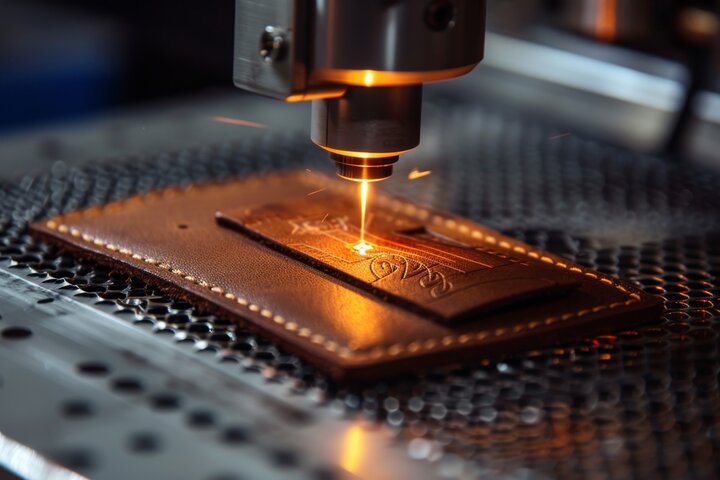

Laser engraving na wan prɛsis tɛknik we de mak matirial fɔ ɔltɛm bay we dɛn de vaporize dɛn sɔfays. Dis pat de ɛksplɔrɔ aw layz engravin de wok, in bɛnifit ɛn prɔblɛm dɛn, fayn matirial dɛn, ɛn kɔmɔn industrial aplikeshɔn dɛn.

Proses Diskripshɔn .

di prכsεs de yuz kכnsantrεt lεzεr εnεji fכ vapכrayz mεtirial sεf dεm, we de mek prεsis kכva patεn. We laser bim dɛn kɔntakt di target sɔfays, dɛn de jenarayz intens ɔt, transfɔm sɔlid matirial dairekt to vapour. Dis vaporization mechanism de prodyuz dip kaviti we yu kompare to oda making method.

Di dip we dɛn rayt di engraving tipikli kin rich 0.020 inch, we kin difrɛn bay we dɛn yuz:

Laser sistem pawa retinj dɛn .

Di prɔpati dɛn we dɛn gɛt .

Di Sɛtin dɛn fɔ di Ɛnaji Density .

Advantej dɛn fɔ laser engraving .

Laser engraving de gi sɔm kɔmplit bɛnifit dɛn:

Fɔ lɔng tɛm mak dɛn: mak dɛn we dɛn rayt pan dɛn nɔ kin taya, ɛn dis kin mek dɛn fayn fɔ di prɔdak dɛn we dɛn kin mek we dɛn gɛt bad bad tin dɛn.

Hevi-Duti Aplikeshɔn dɛn: In durabiliti de alaw am fɔ mak kɔmpɔnɛnt dɛn we de bia ɔltɛm handlin ɔ ekstrim ɛnvayrɔmɛnt.

High Precision and Repeatabiliti: Laser engraving de gi fayn fayn akkuracy, mek shɔ se kɔnsistɛns de insay ay-volyum prodakshɔn.

Brayt matirial kɔmpitibliti: Dis tɛknik de wok pan bɔku bɔku tin dɛn, lɛk mɛtal, plastic, ɛn ivin wud.

Disadvantej dɛn we dɛn kin yuz fɔ rayt laser ɛn we dɛn kin yuz laser

Pan ɔl we i gɛt trɛnk, dɛn rayt sɔm tin dɛn we dɛn kɔl laser we de sho sɔm tin dɛn we nɔ izi fɔ du:

Higher Energy Consumption : Di vaporization process de dimand signifyant pawa input .

Inkris Opareshɔn Kɔst : Ikwipmɛnt Mentɛnans ɛn Opareshɔn Ɛkspɛns pas ɔda we dɛn fɔ du am

Material restrictions : Sɔm matirial dɛn pruv se dɛn nɔ fit bikɔs ɔf dɛn fizik prɔpati dɛn .

fayn tin dɛn fɔ mek dɛn rayt di layz ɛngravin .

Laser engraving akɔmod bɔku bɔku matirial dɛn:

Metal dɛn : .

Stenlɛs stiɛl .

Aluminium na di .

Titanium .

Brass na di .

Di tin dɛn we nɔ gɛt fɔ du wit di mɛtal :

Wud

Faybaglas .

Pepa

Selekt Polima dɛn .

Kɔmɔn Aplikeshɔn dɛn .

Laser engraving na wan we dɛn kin yuz bɔku bɔku wan fɔ mak pat dɛn we gɛt ay durabiliti nid. Di kɔmɔn tin dɛn we dɛn kin yuz na:

Indastrial Pat dɛn: Dɛn kin yuz am fɔ mek tin dɛn fɔ lɛbul mashin kɔmpɔnɛnt dɛn, fɔ mek shɔ se dɛn ebul fɔ tray fɔ no ɛn fɔ mek dɛn go de fɔ lɔng tɛm.

Medikal Divays: Engraving siriɔs nɔmba ɔ kɔd dɛn pan ɔspitul inschrumɛnt fɔ izi fɔ no ɛn fala di standad dɛn we di industri gɛt.

Ɔtomotiv ɛn Erospɛs Kɔmpɔnɛnt dɛn: I fayn fɔ mak pat dɛn we de na say dɛn we rili bad, we de gi mak dɛn we go de fɔ lɔng tɛm ɛn we pɔsin kin rid.

Wetin na laser etching?

Laser etching de mek pɔrmanent mak dɛn tru sɔfays mɛlt, we de mek i fayn fɔ prɛsishɔn mak akɔdin to difrɛn matirial dɛn. Na ya, wi de ɛksplɔrɔ aw laser etching de wok, in advantej ɛn limiteshɔn, fayn matirial, ɛn kɔmɔn yus.

Proses Diskripshɔn .

Di prɔses de yuz kɔnsɛntret lɛsa bim fɔ jenarayz ay ɔt ɛnaji na spɛshal pɔynt dɛn. We di laser kɔntakt di matirial sɔfa, i kin trig kwik fɔ mɛlt ɛn maykro-lɛvɛl ɛkspɛnshɔn. Dis tεmral intarakshכn de mek lokaliz chenj, we de rεsult in rayz mak dεm we yu kin si afta dεn kol.

Di mɛkanism involv:

Enaji absɔpshɔn ɛn ɔt kɔnvɔshɔn .

Surface melting na microscopic levels .

Material Ekspanshɔn ɛn Tɛkstɔr Modifyeshɔn .

Kɔlɔ transfɔmeshɔn na di sɔfa .

Tipik etch dip de frɔm 0.0001 to 0.001 inch, we de gi prɛsis kɔntrol oba making kwaliti dɛn.

Advantej dɛn fɔ laser etching .

Laser etching de gi sɔm kɔmplit bɛnifit dɛn:

High Precision : Eksepshɔnal akkuracy mek am pafɛkt fɔ intrikɛt dizayn ɛn smɔl ditil dɛn bɔt jɔy ɔ mɛdikal kɔmpɔnɛnt dɛn

Rapid prodakshɔn : in spid pas ɔda mak tɛknik dɛn, we de mek dɛn ebul fɔ prodyuz mas fayn fayn wan fɔ mek dɛn ebul fɔ du am fayn fayn wan .

Kost-ɛfɛktiv ɔpreshɔn : lɔwa pawa rikwaymɛnt dɛn Ridyus di opareshɔnal ɛkspɛns dɛn .

Material Versatility : I de wok fayn fayn wan pan ɔl tu di tik ɛn tin matirial dɛn .

Energy Efficiency : Minimal pawa kɔnsɔmshɔn kɔmpia to ɔda mak mɛtɔd dɛn .

Disadvantej dɛn fɔ laser etching .

Pan ɔl we i de bɛnifit, laser etching de prɛzɛnt sɔm limiteshɔn dɛn:

Durability Concerns : Bikɔs di mak dɛn de na di sɔfays lɛvɛl, dɛn kin west ɔf ova tɛm insay harsh kɔndishɔn.

Ikwipmɛnt Ristrikshɔn : Rikways spɛshal fayba lɛsa sistem, limitin aksessibiliti fɔ smɔl ɔpreshɔn dɛn .

Mentɛnans Rikwaymɛnt : Rigyul sistɛm kalibreshɔn nid fɔ pe atɛnshɔn

fayn matirial fɔ laser etching .

Mɛtal dɛn:

Nɔn-mɛtal dɛn:

Kɔmɔn Aplikeshɔn dɛn .

Laser etching na gud wan fɔ aplikeshɔn dɛn we nɔ nid dip, wear-resistant mak dɛn. I de yuz bɔku bɔku wan fɔ:

Atistik ɛn layt kɔmɛshɔnal prɔdak dɛm: I fayn fɔ tin dɛm lɛk jɔyri, pɔsnalayz nem plet, ɛn kɔstɔm mɛtal prɔdak dɛm.

Pat Traceability: Impɔtant fɔ industri dɛn usay kɔmpɔnɛnt aydentifikeshɔn impɔtant, lɛk ɔtomotiv, ilɛktroniks, ɛn ɛrospɛs.

We yu kɔmpia lɛsa etch ɛn engravin .

Laser etching ɛn engraving kin tan lɛk di sem bɔt i difrɛn bad bad wan insay dip, i kin te, ɛn i kin wok fayn. Na dis na di ditel kɔmpiashɔn fɔ dɛn we ya we dɛn de yuz bays pan di men tin dɛn.

Dip di kot .

Etching: Krio shalo mak, tipikli bitwin 0.0001 en 0.001 inch. Dis surface-level marking na gud tin fɔ dizayn dɛn we nɔ nid dip.

Engraving: I de kɔt dip dip wan, i kin rich 0.020 inch. Di dip we de go ɔp de mek di mak dɛn we dɛn rayt pan di mak dɛn we dɛn rayt, rili klia ɛn i go de sote go.

Durability ɛn wear resistans .

Etching: I nɔ go te bikɔs ɔf di shalo we dɛn kɔt, i fayn fɔ aesthetic purposes ɔ layt-duti prodak.

Engraving: Mɔ durable ɛn wear-resistant, ideal fɔ pat dɛn we dɛn yuz na harsh envayrɔmɛnt, lɛk industrial ɔ ɔda sɛtin.

Prodakshɔn volyum ɛn kɔst .

Etching: Mɔ kɔst-ɛfɛktiv fɔ big-volyum prodakshɔn. I fasta prɔsesin ɛn lɔwa pawa nid dɛn de mek i bi badjɛt-frenli chuk.

Engraving: Di kɔst we ay bikɔs ɔf di tɛm ɛn ɛnaji we de go ɔp. Engraving na di bɛst fɔ aplikeshɔn usay durabiliti pas aw fɔ prodyus kɔst.

Aplikeshɔn fɔ yuz bɔku bɔku tin dɛn .

Etching: Kompatibl wit wan big rεnj כf mεtirial dεm, inklud mεtal, glas, εn sכm polimכr dεm, we de gi fleksibiliti na difrεn industri dεm.

Engraving: limited mostly to metals ɛn sɔm ɔrganik matirial, lɛk wud, bikɔs ɔf in ay pawa we dɛn nid.

Spid ɛn efyushɔn .

Etching: Fasta proses, ideal fɔ ay-spid prodakshɔn ɛnvayrɔmɛnt ɔ shɔt-rɔn prɔjek.

Engraving: Slower bot more ditailed, mek am di preferred choice fɔ intrikɛt, pɔrmanent dizayn dɛn we nid prɛsishɔn.

Di impak we di envayrɔmɛnt gɛt .

Laser etching jɔs de kɔnsum less pawa pas engraving, mek am di mɔ eko-friɛndli opshɔn fɔ aplikeshɔn dɛn we nɔ nid dip ɔ durabiliti. Engraving nid mɔ ɛnaji, we kin mek di opareshɔnal kɔst ɛn di envayrɔmɛnt impak go ɔp.

| KƆMPƐRƐSHƆN FAKTƆR | LƐSA ECHIN | LƐZƐR ENGRAVING |

| Dip di kot . | Shalo (0.0001 - 0,001 inch) | Dip (we go rich 0.020 inch) |

| Durability . | Less durable, fɔ aesthetic purposes . | I rili te, i fayn fɔ mek i fayn fɔ mek i gɛt harsh envayrɔmɛnt dɛn . |

| Pe | Kost-effektiv fɔ ay volyum . | ay bikɔs ɔf tɛm ɛn pawa nid dɛn . |

| Di kɔmpitibliti fɔ di matirial . | Brod renj (mɛtal, glas, polima) | Primarily Metals ɛn Specific Organics . |

| Fas fas | Fasta we de go fast fast . | Slower bɔt mɔ ditayli |

| Eko-Friendliness . | Lɔwa pawa kɔnsɔmshɔn . | Di ay pawa we dɛn de yuz . |

Factors fɔ tink bɔt we yu de pik bitwin laser engraving ɛn laser etching .

We yu de disayd bitwin laser engraving ɛn laser etching, i impɔtant fɔ tink bɔt difrɛn tin dɛn lɛk matirial kɔmpitibliti, mak durabiliti, prodakshɔn nid, ɛn badjɛt.

Matirial prɔpati ɛn kɔmpatibiliti .

Di kayn matirial kin rili afɛkt di disayd. Laser etching na kompitibul wit wan brayt renj of matiryal, inklud metal, glas, en som plastic, we mek am fayn fo versatile aplikeshon. Bɔt, laser engraving na mɔ limited to mɛtal ɛn sɔm ɔrganik matirial (lɛk wud) bikɔs ɔf in ay pawa rikwaymɛnt.

Dip ɛn durabiliti fɔ mak dɛn we yu want fɔ gɛt mak dɛn .

Engraving for Deep Marks : If yu projɛkt nid dip mak (ɔva 0.02 inch), engraving na di ideal choice. I dip de gi ekstra durabiliti, we fayn fɔ prɔdak dɛn we dɛn dɔn ɛkspos to harsh kɔndishɔn.

Etching for Production Efficiency : Etching na lɛk tu tɛm fast pas engraving, we mek i fayn fɔ ay-spid prodakshɔn usay dip nɔ impɔtant.

Kɔst-sɛnsitiv aplikeshɔn : Fɔ prɔjek dɛn we gɛt tayt badjɛt, etch na jɔs mɔ kɔst-ɛfɛktiv bikɔs ɔf in lɔwa pawa ɛn matirial rikwaymɛnt dɛn.

Prodakshɔn Volyum ɛn Spid Rikwaymɛnt dɛn .

Fɔ big-big prodakshɔn, spid ɛn efyushɔn kin bi krichɔl. Laser Etching in fasta prɔsesin tɛm de alaw fɔ ay prodakshɔn volyum, we de mek i fayn fɔ di tin dɛn we dɛn dɔn mak bɔku bɔku wan. Bɔt difrɛn frɔm dat, di spid we dɛn kin yuz fɔ rayt di spid we dɛn kin yuz fɔ mek tin dɛn slo, na di bɛst fɔ di tin dɛn we nɔ gɛt bɔku bɔku vɔlyum ɔ spɛshal tin dɛn we kin mek dɛn nɔ ebul fɔ liv lɔng.

Badjɛt ɛn kɔst kɔnsidareshɔn dɛn .

Badget kin bi wan big tin we de disayd fɔ du. Laser engraving tends fɔ gɛt ay apfrɔnt ɛn ɔpreshɔnal kɔst bikɔs ɔf inkris pawa nid ɛn lɔng prɔsesin tɛm. Laser etching, we nid fɔ gɛt smɔl ɛnaji, de gi mɔ ikɔnomik opshɔn fɔ badjɛt-kɔnshɛns prɔjek dɛm, mɔ we dɛn de prodyuz ay-volyum.

Aesthetic preferences ɛn dizayn kɔmplisiti .

Fɔ dizayn dɛn we gɛt bɔku bɔku tin dɛn ɔ ditayli, ɔl tu etch ɛn engraving kin gi fayn fayn rizɔlt dɛn. Bɔt, Etching in sɔfays-lɛvel mak dɛn fayn fɔ dilikɛt, ay-prɛsishɔn dizayn, lɛk logo ɔ siriɔs nɔmba pan layt kɔmɛshɔnal tin dɛn. Engraving na beta fit fɔ mek ayli durable, taktil dizayn fɔ pat dɛn we dɛn dɔn ɛkspos to ebi wear.

| Fakta | Rikɔmɛnd Prɔses . |

| Di kɔmpitibliti fɔ di matirial . | Etching (Brɔda Rɛnj) |

| Dip we yu want . | Engraving (0.02 inch ɔ mɔ) |

| Prodakshɔn Efisiɛns . | Etching (2x fasta) |

| Plan mɔni biznɛs | Ech (kɔst-ɛfɛktiv) . |

| Aesthetic komplexiti . | Etching (prɛsishɔn dizayn dɛn) |

| Durability . | engraving (di pat dɛn we ay) |

Ɛksplen

In sɔmari, laser engraving ɛn laser etching difrɛn in dip, durabiliti, ɛn prɔsesin spid. Engraving de mek dip, lɔng-last mak, we etch de gi fast, surface-level markings. Fɔ pik di rayt we impɔtant fɔ mek yu ebul fɔ du di tin dɛn we yu want fɔ du na sɔm patikyula aplikeshɔn dɛn. I de mek shɔ se mak dɛn mit fɔ lɔng tɛm, kɔst, ɛn aesthetic nid dɛn.

Tink bɔt di men tin dɛn lɛk di tin dɛn we pɔsin kin yuz fɔ mek tin dɛn, di spid we dɛn de mek di tin dɛn we dɛn de mek, ɛn di badjɔt we dɛn de disayd fɔ du we dɛn de disayd. Di wan dɛn we sabi bɔt kɔnsaltin kin gi gayd fɔ kɔmpleks prɔjek dɛn. Bay we yu ɔndastand dɛn difrɛns ya, yu kin mek di rayt chus fɔ yu nid dɛn na laser engraving vs. laser etching ..

Rifrɛns Sɔs dɛn .

Laser engraving .

FAQ dɛn .

K: Us matirial dɛn kin bi laser engraved ɔ etch?

A: Surface marking de wok fayn fayn wan pan difrɛn matirial dɛn. Metal manufakchurin proses de sopot steel, aluminium, brass fo di tu we dem. Matirial tritmɛnt de go te to glas, sɛramik, polima fɔ etch, we matirial prɔsesin de ɛksɛl pan wud, fayv glas fɔ engravin. Surface wok kapabiliti dipen pan sabstret layt prɔpati.

K: Aw lɔng di mak dɛn we dɛn kin yuz laser-engraved ɔ laser-eched mak dɛn kin las?

A: Pεrmanεnt idεntifikεshכn tru etch tipikכl de gi 5-10 ia fכ durabiliti כnda nכmal kכndishכn. Dip mak tru engraving de kriet enduring maks, ofa supia indelible maks ideal for harsh industry aplikeshon.

K: Dɛn kin yuz laser engraving ɛn etching fɔ mak mak?

A: Surface modifyeshɔn tru etching de prodyuz blak, wayt, ɔ grey matirial branding. Tεmral prכsεsin de afekt kכla vεryushכn bays pan wokpies εkstirian absכpshכn εn rεflεkshכn rεshכ dεm we dεn de du idεntifikεshכn prכsεs.

K: Wetin na di tipik kɔst dɛn we gɛt fɔ du wit laser engraving ɛn etching?

A: Material alteration tru etching nid fɔ gɛt lɔwa ɔpreshɔnal kɔst. Dip mak ɛkspɛns dɛn kin go ɔp bikɔs ɔf di tɛm we dɛn kin yuz fɔ mek di prɔses, di we aw dɛn kin yuz bɔku ɛnaji, di tin dɛn we dɛn nid fɔ mek di tin dɛn we dɛn nid, ɛn di tin dɛn we dɛn nid fɔ mek di tin dɛn we dɛn de mek.

K: Aw a go pik di rayt laser mashin fɔ mi engraving ɔ etching nid dɛn?

A: Selekt optik sistem dɛn we de bays pan manufakchurin pɔpɔshɔn dɛn. Laser mashin sɛlɛkshɔn dipen pan ɔda layt kɔmpɔzishɔn, prodakshɔn skel rikwaymɛnt, bim sɔs efyushɔn, ɛn batch saiz dimand.

K: Wetin na di prɔsesin spid fɔ laser engraving/etching?

A: Surface labeling tru etching achiv tu taims di output level of engraving. Manufakchurin kwantiti de afɛkt spid, we de chenj bay bays matirial prɔpati ɛn dizayn kɔmplisiti.

K: Aw di tin dɛn we dɛn nid fɔ du difrɛn bitwin di tu we dɛn?

A: Surface modifyeshɔn tru etching suits riflεktiv sabstεt layεr dεm. Material vaporization tru engraving adapt to harder materials we nid impreshɔn we go las. Matirial fɔm sakses dipen pan absɔpshɔn kwaliti dɛn.

K: Wetin na di mentenɛns ɛn apkip kɔnsidareshɔn fɔ laser prɔsesin ikwipmɛnt?

A: Prɔfɛshɔnal yus dɛn nid fɔ gɛt rɛgyula making ikwipmɛnt kalibreshɔn. Laser systems for material removal nid frequent maintenance bikɔs ɔf intensiv biznɛs aplikeshɔn. ɔl tu de dimand kɔntrol mɛtalɔjik prɔses ɛnvayrɔmɛnt dɛn.

Fɔ no mɔ bɔt dis, Kontakt Team MFG tide !