Welding yana taka muhimmiyar rawa a cikin masana'antu kamar mota, aerospace, da gini. Amma idan ya zo ga zabar hanyar da ta dace, da muhawara tsakanin mig da Tig walda sau da yawa tasowa. Kowane dabarar tana ba da fa'idodi daban-daban kuma suna bauta wa dalilai daban-daban.

A cikin wannan post din, zamu kwatanta Mig da Tig Welding, biyu daga cikin mafi yawan ayyukan walda da aka yi amfani da shi. Za ku koya game da ka'idodinsu, ribobi da conta, kuma lokacin da amfani da kowace hanya. Ko kai ne mai farawa ko kuma gogaggen welder, wannan jagorar zai taimaka maka wajen sanya zabi da ya dace don aikin ka.

Menene Mig Welding?

MIG (Karfe Meterd Gash) Welding yana wakiltar fasahar Welding na Arc. Yana haifar da karfin karfe masu karfi ta hanyar tsarin atomatik ko tsari ta atomatik. Masu amfani da ƙwararrun ƙwararrun suna nufin shi sau da yawa suna nufin shi kamar yadda baka na iskar gas (Gmaw) a aikace-aikacen masana'antu.

Tsarin walda

Tsarin ya dogara da kayan haɗin mahaɗan uku da ke aiki a jituwa:

Cikakken waya na lantarki : Hanyar da aka ciyar da wayar ta atomatik ta hanyar walda bindiga. Wannan waya tana aiki a matsayin kayan lantarki da kayan filler, narkewa don samar da weld bond.

Gas na kare : cakuda argon 75% da 25% co2 yana gudana ta hanyar bututun bindiga. Hakkin mai yana kare ƙarfe mai narkewa daga gurɓataccen ATMOSPHERIC yayin inganta ayyukan ido na Weldalal.

Wutar lantarki : DAUTACH ACTUENT (DC) ya wuce ta hanyar lantarki, samar da ArC. A tsananin zafin zafi ya narke duka waya da karafa, ƙirƙirar haɗin gwiwa mai ƙarfi.

Me yasa Zabi Mig Welding?

Mig Welding yana ba da babban fa'idodi a kan aikace-aikace iri-iri:

Sauri da Inganci

Yana haifar da ci gaba da welds ba tare da tsayawa ba

Cimma matsara mafi girma idan aka kwatanta da hanyoyin gargajiya

Yana rage lokacin samarwa ta hanyar ciyar da waya ta atomatik

abokantaka mai amfani

| Amfani | da |

| Aiki mai kyau | Mafi kyawun kulawa da sakewa |

| Ciyarwar Automatik | Rage Fata na Better |

| Saiti mai sauƙi | Kwarewar koyon karatun |

Kayan aiki

Mig Welding Excels a cikin shiga:

Daidaitawa yana shimfiɗa zuwa matsayi mai yawa - lebur, a kwance, a tsaye, da sama da sama. Wannan sassauci ya sa ya dace da kayan aiki, gini, da masana'antu na masana'antu.

Menene walyan Tig?

Tig (Tiggten Gas) Welding, wanda kuma aka sani da GTAWA (Walden Gasgretten Welding), ya ba da cikakken bayani, ingancin welds. Wannan tsari na zamani yana haifar da abubuwan haɗin gwiwa na musamman, musamman akan kayan bakin ciki suna buƙatar ingancin gamsuwa mafi kyau.

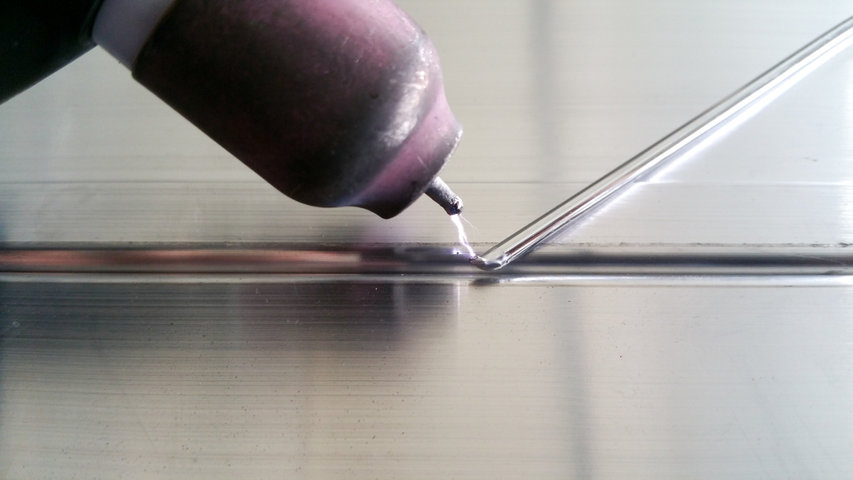

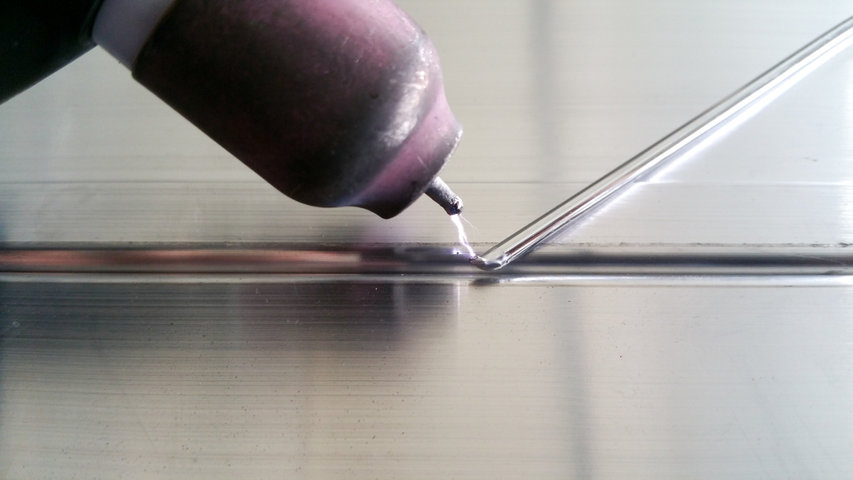

Tig walding tsari

Tsarin yana haɗa kayan haɗin guda huɗu masu mahimmanci:

Eldetwen mara amfani na Tasgagen : ƙwararrun Tung Trodsten yana haifar da Arc ba tare da narkewa ba. Karkatar da shi yana bawa halaye masu daidaituwa a cikin ayyukan walda.

Garkashin iskar gas na Tert : Argon yana gudana cikin wutar lantarki, yana kare wuraren shakatawa na Welmopheric. Wasu aikace-aikace suna amfani da Helium ko Argon-Helium gaurayawan don inganta aikin.

Zaɓin filaye na ƙarfe : welders da hannu City daban sander na daban a cikin gidan Weld tafkin. Wannan dabarar tana ba da cikakken iko akan ƙari da kuma halayen haɗin gwiwa.

Saurin Ikon wutar lantarki : Tig tsarin aiki a kan AC da DC Power. ACH EXCLs ga aluminum, yayin da DC ta samar da sakamako mafi girma akan karfe da kayan bakin ciki.

Abvantbuwan amfãni na Tig Welding

Tig Welding yana ba da fa'idodi da yawa, sanya hanyar da aka fi so don ayyuka don buƙatar babban daidai:

Daidaici da sarrafawa : Welding ɗin Tig yana ba da iko mai tsari game da tsarin waldi, yana sa ya dace da cikakken aiki. Masu aiki zasu iya tuni mai zafi da kuma filler don madaidaici, wallds masu tsabta.

Welds masu inganci : Welds Welding ne mai tsabta suna da tsabta, mai karfi, da kuma farantawa rai, tare da karancin karaya. Wannan yana sa tig ya dace da ayyukan da ke buƙatar cikakkun welds.

Falakawa a cikin kayan : Tig yana da tasiri a duk kewayon metals, ciki har da bakin karfe, aluminum, da titanium. Iyawarta na magance sassan bakin ciki ba tare da warke ba yana daya daga cikin ƙarfin sa.

Matsakaicin bambance-bambance tsakanin Mig da Tig Welding

Fahimtar halayen daban tsakanin Mig da Tig Welding yana taimaka kwararru na ƙwararrun tsari don ingantaccen tsari don takamaiman aikace-aikace. Bari mu bincika bambance-bambance na asali a cikin manyan fannoni.

Tsari da dabarun kwatancen

| selenting | tig | wal welding |

| Aiki | Semi / atomatik | Shugabanci |

| Ciyar Wire | M | Hannu-ciyar |

| Hanyar sarrafawa | Hannu daya | Hannun hannu guda biyu |

| Curning Curve | Matsakaici | M |

Abubuwan buƙatun kayan aiki

Mg walding saiti

Wire Ciyar da Gun Gun Haɗin Waya da Gasar Gas

Tsarin ciyar da kayan aiki na atomatik na kiyaye daidaitattun kayan aiki

Argon-CO2 Cakuda (75/25) Tsarin gas

Arc Worl Sourfin Hannu Arc Tallace-halaye

Tig Welding saiti

Musamman Torch na Torch Torch Tasgsten

Daidai gwargwado mai sarrafawa

Tsarin isar da gas na Argon

Haɗin kai mai ƙarfi na AC / DC

Ayyukan Aikin

Sauri da Inganci

Mig Welding Excels a cikin yanayin samarwa:

Cimma ƙafafu 35-50 cubic ƙafa na awa daya

Yana kiyaye aikin ci gaba don tsawan lokaci

Yana ba da damar cika ayyukan da sauri

Tig Welding fifikon Ka'idar:

Yana aiki a ƙafa 15-25 mai siffar sukari a awa ɗaya

Yana buƙatar kulawa sosai ga daki-daki

Yana samar da sakamako mafi girma a kan manyan gidajen abinci

Halaye masu inganci

| suna fasali | sakamako na MIG | sakamakon |

| Wel bayyanar | Mai kyau, uniform | Madalla da kyau, ado |

| Matsayi | Minimal zuwa matsakaici | Kusan Zero |

| Tsarin Weld-Weld | Wani lokacin ana buƙata | Da wuya ake buƙata |

| Hadin gwiwa | M | M |

Bincike na farashi

Zuba Jari

Mig tsarin yana ba da ingantaccen izinin shiga cikin waldi

Tigon kayan aiki yana buƙatar babban hannun jari

Dukkan tsarin suna buƙatar kayan aikin aminci da ya dace

Ayyukan aiki

Mig consumables ya ci gaba da tattalin arziki don aikin girma

Ayyukan Tig sun jawo sama da farashi mai ƙarfi

Tsarin kayan aiki yana tasirin kashe kuɗi gaba ɗaya

Kayan da suka dace da Mig da Tig Welding

Kowane tsari na walda yana nuna takamaiman ƙarfi lokacin shiga abubuwa daban-daban. Fahimtar wadannan damar na taimakawa inganta sakamakon sakamako a kan aikace-aikace daban-daban.

Kayan da suka dace da zane mai kyau

Mig Welding ne mai ma'ana, sarrafa ɗumbin kayan, gami da:

Carbon Carbon : Waloli sosai a cikin ginin da masana'antu na mota, Mig Welding a sauƙaƙe yana ɗaukar sassan Thicker.

Bakin karfe : Ya dace da aikace-aikacen tsarin tsari daban-daban, suna ba da tsauri da juriya da juriya.

Aluminium : Mafi dacewa ga mafi girma, sassan kauri, wanda aka saba amfani dasu a cikin sufuri da masana'antu Aerospace.

Mig Welding yana da kyau lokacin aiki tare da kayan ka kauri fiye da 1.2mm . Tsarin zafin rana da tsarin waya yana sa ya zama cikakke don haɓakar da aka tsara cikin sauri, lokacin farin ciki.

Kayan da suka dace da walƙumen Tig

Tig Welding Excells a cikin daidaici, musamman ga m ko bakin ciki kayan, sanya shi abin da aka fi so wa makirci kamar:

Carbon Karfe : Ba da tsabta, mai ƙarfi welds, har ma a cikin shinge na bakin ciki, yana sa cikakke ga mai kyau, cikakken aiki.

Bakin karfe : sananne don ƙarewarsa mai laushi da ƙarancin murdiya, Tig yana da kyau ga aikace-aikacen Corrosion-mai tsauri.

Aluminium : Mafi kyau ga na bakin ciki sassan, yana ba da iko daidai da kyawawan welds.

Magnesium, Titanium, sannu-sannu : Tig yana magance waɗannan motocin metals yadda yakamata, bayar da karfin Weldics.

Tig Welding yana haskakawa a tsakanin 0.5mm da 3mm . Kyakkyawan iko da kuma electrode mara rinjaye ya sa ya zama cikakke ga ayyukan da ke da alaƙa da ke buƙatar babban daidaito.

Kwatanta Table: Mig vs Tig kayan aiki

| ya | dace da Mig | ya dace da Tig |

| Bakin ƙarfe | I | I |

| Bakin karfe | I | I |

| Goron ruwa | I | I |

| Magnesium | A'a | I |

| Titanium | A'a | I |

| Jan ƙarfe | A'a | I |

| Kauri | 1.2mm kuma a sama | 0.5mm - 3mm |

Wannan tebur yana ba da tabbacin abin da kayan aiki suke aiki da kyau tare da duk hanyar walda, nuna kauri kowane tsari yana da inganci.

Weld mai inganci

Halaye na mg Welds

Mig Welding yana samar da masu ƙarfi da amintattun welds, yana sa ya dace da aikace-aikacen tsari. Wasu halaye masu mahimmanci sun haɗa da:

Stremara da cikawa : Mig Welds sananne ne don kasancewa da ƙarfi, tare da zurfin azanci. Wannan ya sa suka dace da kayan kauri da ayyukan nauyi.

Spatter : daya tilastawa shine abin da ya faru na spatter. Duk da yake bai shafi ƙarfin Weld, wurin Weld na iya buƙatar tsaftacewa ko nika don inganta bayyanar.

Aestentics : MIG Welds suna aiki amma yawanci ana rashin bayyanar tig welds. Ayyukan da ke buƙatar kira na gani na iya buƙatar sarrafa sakandare, kamar sanding ko polishing.

Halaye na welds

Ana ɗaukar walƙanci sosai don samar da tsabta, ainihin welds, musamman lokacin da Aestionics lamiri. Halayen maɓalli sun haɗa da:

M da kayan ado na ado : Tig Welds suna da santsi, tare da neat 'bayyanar dime ' bayyanar, sanya su ya dace da wannnai. Wannan tsari yana haifar da welds waɗanda galibi suna buƙatar ƙarshen ƙarshe.

Babu Spattter : Tig Welds Createirƙiri kusan kusan kusan babu mai tsiro, rage buƙatar tsabtatawa-Wel-Wel-Wel-Wel-Wel-Wel-Wel-Weldness na samfurin ƙarshe.

Pororla : Magana ta gaba ɗaya mai ban mamaki a tushen Weld. Tsabta da kyau da kyau na duka kayan kuma mai filler yana da mahimmanci don guje wa aljihunan gas wanda zai iya raunana Weld.

kwatancen

| Kwatancen | | |

| Ƙarfi | Mai ƙarfi, amintacce ga kayan lokacin farin ciki | Mai ƙarfi amma mafi kyau ga kayan kwalliya |

| Feser | Na kowa, yana buƙatar tsabtatawa-Weld tsaftacewa | Babu Spatter, Minimal Tsabtace da ake buƙata |

| Maganin ado | Aiki, yana buƙatar ƙarewa | Santsi, wanda aka goge, da kyau don amfani da kayan ado |

| M al'amurran | Spatter, UNNVEN Gama | Yalwa ga poronosos, tsabta yana da mahimmanci |

Bukatun Sentuta na Weelders

Mig Welding: Mai ƙarancin fasaha

Mig Welding ana ɗaukar ɗayan hanyoyin mafi sauƙin koya koya. Yanayin ta atomatik yana sa ya dace da sabon shiga ko masu ba da aiki suna aiki akan haɓaka girma girma. Mahimman mahimman dalilai da yasa miji mai sauki ne ga maigidan ya hada da:

Tsarin sauƙaƙe : Ci gaba da ciyar da waya da tsarin tsara kai suna yin migar walda madaidaiciya, yana buƙatar ƙasa da aikin hukuma.

Matsakaicin aiki : Weelders kawai suna buƙatar sarrafa bindiga, sun bar ƙasa don kuskure idan aka kwatanta da ƙarin rikitarwa.

Tsarin koyo mai sauri : Tare da horo na asali, walds suna iya hanzarta samar da welds da sauri, yana sa ya dace don masana'antu masu buƙatar sakamako mai sauri.

Tig Welding: Matakan kwarewar da ake buƙata

Sabanin haka, Tig Welding ya zama daidai da kuma iko, yana sa ya zama mafi wahala ga Master. Hadaddun tsarin yana buƙatar sannu masu kula da ƙwarewa don haɓaka kewayon ƙwarewa na musamman:

Gudanar da Moltten : Tig Welders dole su lura kuma daidaita tafkin Molten kullun, tabbatar da walwala mai tsabta, wallds masu tsabta.

Ciyarwar Waya ta Waya : Welder yana buƙatar ciyar da sandar filler da hannu cikin tafkin Weld yayin ɗaukar wutar lantarki, wanda ke ƙara kalubalen.

Yin hadin kai na ƙafa : Tig Welding yana amfani da ƙafar ƙafa don sarrafa zafi. WeLDers dole ne daidaita daidaiton wannan yayin gudanar da sauran kayan aikin, yana sa ya wahala ga masu farawa.

Hankali ga daki-daki : Tig Welders dole ne ya kiyaye tsabta, daidai welds, wanda sau da yawa na bukatar kwarewa mai mahimmanci ga cikakke.

Kwatancen Kwatanci: Mig vs Tig Direfin Kwarewa

| Schenting Scorst | Mig Welding | Tig Welding |

| Curning Curve | Da sauri, ya dace da sabon shiga | Jinkirin, yana buƙatar horo mai yawa |

| Tsarin Tsabtace | Mai sauki, ciyar da waya ta atomatik | Hadadden, yana buƙatar sarrafa jagora na duk fannoni |

| Daidaituwa na hannu | Daidaitawa tare da hannu daya | Gudanar da matakan aiki, hannayen biyu da kuma sarrafa ƙafa |

| Dace wa masu farawa | Mafi dacewa ga sababbin masu saki | Kalubale, mafi kyau ga gogewa |

Misalin aikin aikace-aikacen aikace-aikacen

Aikace-aikacen Welding Aikace-aikace

Mig Welding ya dace da mafi girma, ayyuka masu girma inda sauri da inganci suke da mahimmanci. Wasu misalai masu mahimmanci sun haɗa da:

Tsarin gini : MIG Welding Mindles Mindles munanan kayan aiki yadda ya kamata, yasa ya dace da tsarin ƙarfe a gine-gine da gadoji.

Masana'antu na mota : Waloli sosai don ɗaukar Frames da bangarori na jiki, saurin walda da daidaitawa suna sanya samarwa mai ƙarfi.

Kayan aiki mai nauyi : Daga kayan aikin gona zuwa kayan aiki na masana'antu, Mig Welds suna da ƙarfi da m, dace da amfani mai nauyi-nauyi.

Aikace-aikacen Welding Aikace-aikace

An fi son walda da ke buƙatar daidaito, tsabta, da walwala masu inganci. Wasu misalai na aikace-aikace sun haɗa da:

Abubuwan sunadarai : Ikon da ke da kyau don ƙirƙirar santsi, welds mai tsabta yana sa ya zama cikakke ga bututun mai dauke da kayan masarufi a cikin magungunan sunadarai.

Kayan aiki na abinci : A cikin masana'antar abinci, inda tsabta yana da mahimmanci, welds masu tsabta selds suna da kyau don kayan aikin bakin karfe da tankunan ajiya.

Dandalin keke : Daidaitaccen Tig yana da kyau don walwala kayan Lightweight da titanium, ana amfani da titanium a cikin fasahar keke.

Artworks : don zane-zane ko ƙarfe mai narkewa, tig yana ba da damar da aka samu mai santsi, a bayyane yake buƙatar ayyukan zane-zane.

Kwatancen Kwatawar Table: Mig vs Tig Aikace-aikace na Aikace-

| aikacen | Mig Welding | Tig Welding |

| Shiri | Tsarin karfe, ayyukan girma-girma | Madaidaici, walds masu tsabta don aikin musamman |

| Mayarwa | Furayoyin mota, bangarorin jiki | Fasali na musamman, ingancin ingancin |

| M | Kayan aiki, kayan aiki | Ansalon butanyenes, kayan aikin abinci |

| Art da zane | Babban ginin ƙarfe | Zane-zane, Frames na keke, kyawawan zane-zane |

Dalilai don la'akari da lokacin zabar kai tsaye tsakanin miji da Tig Welding

A lokacin da yanke shawara tsakanin Mig da Tig walda, dole ne a yi la'akari da dalilai masu yawa masu yawa don tabbatar da mafi kyawun zabi don takamaiman aikinku.

Nau'in kayan da kauri

Daya daga cikin mahimman abubuwan shine kayan da kauri. Mig Welding ya fi dacewa da kayan kauri , kamar karfe da aluminum, suna haifar da dacewa da ayyuka masu nauyi. Sabanin haka, Tig Welding Excels a lura da bakin ciki kayan , kamar bakin karfe da titanium, inda daidai yake da mahimmanci.

Da ake buƙata mai inganci da bayyanar

Ingancin da ake so Weld ingancin da bayyanar kuma suna taka muhimmiyar rawa. Idan mai inganci, mai santsi, ana buƙatar welds mai santsi mai dacewa, Tig shine babban zaɓi. Ana amfani da selds sau da yawa don dalilai na ado ko ayyukan da ke buƙatar tsabtatawa mai tsabta. Mig Welds, kodayake karfi, na iya buƙatar aiki-aiki don cimma wannan matakin na yau da kullun.

Girman samarwa da Inganci

Don ayyukan da ke buƙatar haɓaka haɓaka haɓaka , Mig Welding shine wanda ya faru. Ci gaba da ciyarwar waya yana ba da damar walwala mai sauri, sanya ya dace da aikace-aikacen masana'antu . Tig Welding, a gefe guda, yana da hankali saboda yanayin littafin sa, sanya shi ƙasa da mafi inganci don ayyukan girma-girma amma manufa don aikin daidai.

Matakin fasaha na welder

muhimmanci Matsayin kwarewar Welder muhimmanci da zabi. Mig Welding ya fi sauƙi a koya da aiki da kyakkyawan zaɓi don masu farawa ko mahalli samarwa da ƙarancin ƙwanƙwasa. Tig Welding, duk da haka, na bukatar karin kwarewar ci gaba, kamar su na PDTE POOL , ciyarwar waya, da hadin gwiwar ƙafa, wanda ya fi dacewa da gogewa.

Kasafin kuɗi da la'akari da kuɗi

Kasafin kuɗi wani abu ne mai mahimmanci. Mig Welding gaba ɗaya yana zuwa tare da ƙananan kayan aiki da abubuwan ci gaba, ya sa ya zama mafi tsada mai inganci don manyan ayyuka. Tig Welding, yayin bayar da mafi girma welds mai girma, yana da kayan aiki masu girma da farashi na aiki saboda daidaitaccen aiki.

Tebur

| Takaital | | |

| Nau'in kayan & kauri | Kayan kauri (karfe, alumini) | Kayan bakin ciki (bakin karfe, bakin karfe, titanium) |

| Weld qualid & bayyanar | Mai ƙarfi, na iya buƙatar aiki | Babban inganci, gama tsabta |

| Saurin samar | Da sauri, dace da manyan-sikelin samarwa | Sannu a hankali, daidai ne ga ainihin welds |

| Welder fasaha matakin | Mafi sauƙin koyo, mai kyau ga masu farawa | Yana buƙatar ƙwarewar ci gaba |

| Kasafin kudi & farashi | Ƙananan kayan aiki da farashin aiki | Mafi girman farashin saboda daidaitawa da rikitarwa |

Gwajin tsaro na Mig da Tig Welding

Welding, ko Mig, ya ƙunshi mahimmancin haɗari na aminci, yana sa yana da mahimmanci a bi matakan da suka dace. Da ke ƙasa akwai mahimman matakan aminci don tabbatar da ingantaccen yanayin walda.

Kayan kariya na mutum (PPE)

Pep ɗin da ya dace yana da mahimmanci don kare welds daga ƙonewa, girgiza wutar lantarki, da kuma lahani mai cutarwa. Abubuwan mabuɗin sun haɗa da:

Welding kwalkwali da garkuwa da fuska : kwalkwali yana kare idanunku da fuska daga tsananin haske da Sparks sun haifar da waldi. Garkan suna kara kara kariyar Layer.

Tufafi-resistant tufafi da safofin hannu : Weelds ya kamata suttura jaket na harshen jaket da safofin hannu don garkuwa da ƙonewa. Auduga ko kayan fata suna aiki mafi kyau don hana fannonin wuta daga wuta.

Takunan aminci : takalma masu tsayayya da wuta tare da yatsun karfe suna kare ƙafafu daga abubuwa masu nauyi, fells, da molten karfe.

Amincin aiki

Kyakkyawan wurin aiki yana da mahimmanci kamar kariya ta sirri. Matakan masu zuwa suna taimakawa wajen tabbatar da yanayin haɗari mai haɗari:

Samun iska mai kyau : walda yana haifar da turɓayar guba. Tabbatar da wuraren wasan kwaikwayonku da iska mai iska ne don hana shan inheration, wanda zai iya haifar da matsalolin numfashi.

Hanyoyin rigakafin kashe gobara : Kiyaye kashe wutar wuta kusa da kuma share fannin na kayan wuta. Welding Sparks na iya kunna wuta da sauri idan sun kasance tare da masu haɗari.

Tsaron lantarki

Dukkanin Mig da Tig Welding na lantarki, suna gabatar da haɗarin rawar jiki idan ba a gudanar da sarrafawa daidai ba. Bi waɗannan jagororin:

Groundinging da kuma rufi : Tabbatar da cewa a koyaushe tabbatar da wealing injina da yadda yakamata kuma duk abubuwan da aka gyara suna da matukar infored don guje wa gajerun da'irori.

Guji hadarin hadarin lantarki : Kada a taɓa wayoyin lantarki ko ƙarfe na injin walding yayin aiki. Ari, ci gaba da bushewar ku kuma ku guji walda a cikin yanayin rigar don rage haɗarin rawar jiki.

Rundown: Mig da Tig Welding

Mig da Tig walda kowannensu yana da halaye na ban mamaki da rashin kariya. Mig Welding yana da sauri, mai hankali don lokacin farin ciki kayan, da kuma madaidaiciyar madaidaiciyaform don yan koyo. Tig Welding, yayin da ya fi jinkirin, yana ba da daidaitaccen daidaitaccen abu da kuma jin ƙarin kayan aiki.

Fahimtar fa'idodi da matsalolin kowane dabarun taimaka muku da ɗaukar tsarin da ya dace don aiwatar da aikinku. Yi tunani game da juna, da ake son weld mai inganci, da ƙimar halitta yayin zabar tsakanin ƙaura da tig.

Takamatsu

Mig Welding

Gas ɗin Tretten Arc Welding

China mafi kyawun sabis na CNC