Welding de ple wan impɔtant pat pan industri dɛn lɛk ɔtomotiv, aerospace, ɛn kɔnstrɔkshɔn. Bɔt we i kam pan fɔ pik di rayt we, di dibɛt bitwin MIG ɛn TIG wɛldin kin apin bɔku tɛm. Ɛni tɛknik de gi difrɛn bɛnifit dɛn ɛn i de ɛp difrɛn tin dɛn fɔ du.

Insay dis post, wi go kɔmpia MIG ɛn TIG wɛldin, tu pan di wɛldin prɔses dɛn we dɛn kin yuz mɔ. Yu go lan bɔt dɛn prinsipul, gud ɛn bad tin dɛn, ɛn ustɛm fɔ yuz ɛni we fɔ du am. Ilɛksɛf yu na pɔsin we de bigin ɔ yu na wɛlda we gɛt ɛkspiriɛns, dis gayd go ɛp yu fɔ mek di rayt chuk fɔ yu prɔjek.

Wetin na MIG Welding?

MIG (mɛtal inɛt gas) wɛldin ripresent wan advans ak wɛldin tɛnkɔlɔji. I de mek strɔng mɛtal bɔnd dɛn tru wan sɛmi-ɔtomɛtik ɔ ɔtomɛtik prɔses. Prɔfɛshɔnal wɛlda dɛn kin kɔl am gas mɛtal ak wɛldin (GMAW) insay industrial aplikeshɔn dɛn.

Di MIG wɛldin prɔses .

Di prɔses de dipen pan tri ki kɔmpɔnɛnt dɛn we de wok insay wanwɔd:

Kɔntinyu waya ilɛktrɔd : Wan motoka sistem de fid waya ɔtomɛtik wan tru di wɛldin gɔn. Dis waya de sav ɔl tu as ilɛktrɔd ɛn filɛ matirial, we de mɛlt fɔ mek di wɛld bond.

Shielding Gas : Na miks we gɛt 75% argon ɛn 25% CO2 de flɔ tru di gɔn noz. Di gas shild de protɛkt di molten mɛtal frɔm atmosfɛrik kɔntaminɛshɔn we i de protɛkt di bɛst weld penɛtrɛshɔn.

Ilektrikal Kɔrɛnt : Dairekt kɔrɛnt (DC) de pas tru di waya ilɛktrɔd, we de mek wan ak. Di intens ɔt de mɛlt ɔl tu di waya ɛn bays mɛtal dɛn, we de mek wan sɔlid fushɔn jɔyn.

Wetin mek yu fɔ pik MIG Wɛldin?

MIG Welding de gi impɔtant bɛnifit dɛn akɔdin to difrɛn aplikeshɔn dɛn:

Spid ɛn efyushɔn .

Krio kɔntinyu wɛld dɛn we nɔ gɛt stɔp dɛn ɔltɛm we dɛn kin stɔp ɔltɛm .

Achieves higher deposition rates we yu kɔmpia to tradishɔnal we dɛn de yuz .

Ridyus prodakshɔn tɛm tru ɔtomatik waya fidin .

Yuz-frenli Opareshɔn

| Ficha | bɛnifit |

| Single-handed opareshon . | Bɛtɛ kɔntrol ɛn pozishɔn . |

| Semi-ɔtomɛtik fid . | Ridyus di ɔpreshɔn Fatigue . |

| Simpul Sɛtup . | Shorter Learning Curve . |

Material dɛn we dɛn kin yuz bɔku bɔku tin dɛn fɔ du .

MIG Welding Excels in Joining:

Aluminium sheets frɔm 26-gej to ebi plet .

Komponent dɛn we gɛt stenlɛs stiɛl .

Struktural Steel Assemblies .

Dissimilar mɛtal dɛn we nid strɔng bɔnd .

I adaptability de extend to multiple welding posishun - flat, horizontal, vertical, en ovahed. Dis fleksibiliti de mek am impɔtant fɔ ɔtomotiv, kɔnstrɔkshɔn, ɛn manufakchurin industri.

Wetin na TIG Welding?

TIG (Tungsten Inert Gas) Weldin, we dɛn kin kɔl bak GTAW (Gas Tungsten Arc Welding), de gi prɛsis, ay kwaliti wɛld dɛn. dis sofistikeyt prכsεs de mek εksepshכnal joyn dεm, patikyular pan tin mεtirial dεm we nid supεriכr finish kwaliti.

Di TIG wɛldin prɔses .

di prכsεs de intagret fכ imכtant kכmכpכnt dεm:

Nɔn-kɔnsumabl tungsten ilɛktrɔd : Wan spɛshal tungsten rod de jenarayz di ak we nɔ de mɛlt. I durabiliti de enable konsistent arc karakta truutout extended welding opareshons.

Pure Inert Gas Shield : Argon gas de flɔ tru di tɔch, protɛkt di weld pul frɔm atmosfɛrik kɔntaminɛshɔn. Sɔm aplikeshɔn dɛn de yuz ɛliyɔm ɔ argon-hɛliɔm miks fɔ ɛnhans pefɔmɛns.

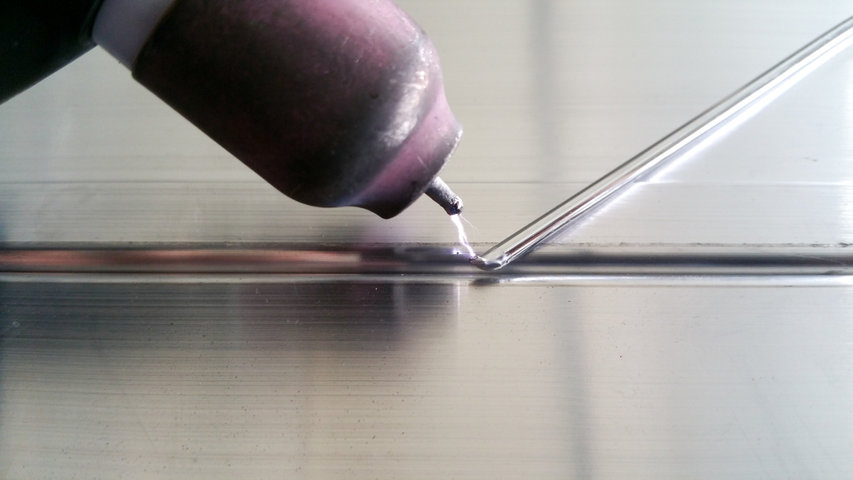

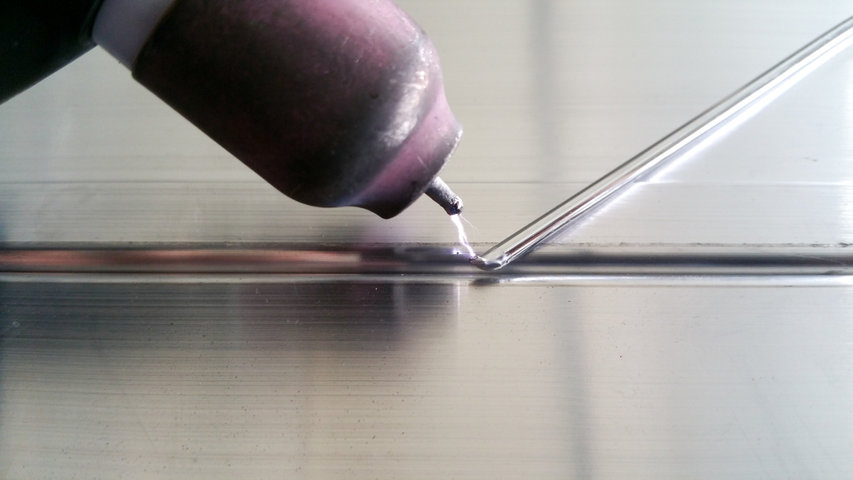

Optional Filler Metal : Welders manually fid seperet filler rods in di weld pul. Dis teknik de alaw prɛsis kɔntrol oba matirial adishɔn ɛn jɔyn kwaliti dɛn.

Pawa sɔs fleksibiliti : TIG sistem dɛn de wok pan ɔl tu di AC ɛn DC pawa. AC excels fɔ aluminium, we DC de gi supia rizulyt pan stɛl ɛn stenlɛs matirial.

Advantej dɛn fɔ TIG Wɛldin .

TIG Welding de gi sɔm bɛnifit dɛn, we mek i bi di we we dɛn kin lɛk fɔ du wok dɛn we nid ay prɛsishɔn:

Prɛsishɔn ɛn Kɔntrol : TIG Wɛldin de gi kɔntrol we nɔ gɛt wan kɔmpitishɔn oba di wɛldin prɔses, we de mek i fayn fɔ ditayli wok. Di wan dɛn we de wok kin fayn fayn wan tune di ɔt ɛn fil fɔ prɛsis, klin wɛld dɛn.

High-quality welds : Di weld dɛn we TIG wɛldin mek klin, strɔng, ɛn aesthetically pleasing, wit minimal spatter. Dis mek TIG fayn fɔ prɔjek dɛn we nid fɔ gɛt fayn fayn wɛl dɛn we pafɛkt fɔ si.

Versatility in Materials : TIG de wok fayn akɔdin to bɔku bɔku mɛtal dɛn, lɛk stenlɛs stiɛl, aluminiɔm, ɛn taytaniɔm. Di ebul we i ebul fɔ handle tin sɛkshɔn dɛn we nɔ gɛt wɔp na wan pan di big tin dɛn we i ebul fɔ du.

Ki difrɛns bitwin MIG ɛn TIG wɛldin .

Ɔndastand di difrɛn kwaliti dɛn bitwin MIG ɛn TIG Wɛldin de ɛp pɔshɔnal dɛn fɔ pik di bɛst prɔses fɔ spɛshal aplikeshɔn dɛn. Lɛ wi fɛn ɔl dɛn fawndeshɔnal difrɛns akɔdin to di men aspek dɛm.

Proses ɛn Tɛknik Kɔmpiashɔn

| Aspek | MIG Wɛldin | TIG Wɛldin |

| Ɔpreshɔn | Semi/Automatic . | Buk |

| Waya fid . | Kɔntinyu fɔ . | Dɛn kin gi dɛn an-fed . |

| Di we aw dɛn de kɔntrol . | Wan-an . | Tu-an + fut . |

| Learning Curve . | Soba | Ay |

Di tin dɛn we dɛn nid fɔ gɛt di tin dɛn we dɛn nid .

Mig Welding Setup .

Waya fid wɛldin gɔn Integretin ilɛktrɔd delivri ɛn gas flɔ

Otomatik waya fidin sistem we de mentɛn kɔnsistɛns matirial saplai .

Argon-CO2 miks (75/25) Shielding gas sistem .

DC pawa sos we de gi stebul ak karaktaiz .

TIG Welding Setup .

Specialized torch haus tungsten ilektrod .

Prɛsishɔn fut pedal kɔntrol amperaj .

pure argon shielding gas delivery sistem .

AC/DC pawa sɔs we de gi versatile ɔpreshɔn mɔd dɛn .

Pɔfɔmɛnshɔn Mɛtrik dɛn .

Spid ɛn efyushɔn .

MIG Welding excels in prodakshɔn ɛnvayrɔmɛnt:

Achieves 35-50 kubik fit per awa gas flow rates

Mentɛn kɔntinyu ɔpreshɔn fɔ ɛkstend tɛm dɛn .

Enables rapid komplitishon of long weld runs .

TIG Welding de prayoritɛt prɛsishɔn:

Opereyt na 15-25 kubik fit fɔ wan awa gas flɔ

I nid fɔ tek tɛm pe atɛnshɔn to di ditel dɛn .

I de prodyuz supia rizulyt pan krichɔl jɔyn dɛn .

Kwaliti Karakteristik

| Ficha | MiG Rizult | TIG Rizult |

| Weld apinans . | Gud, yunifom . | Eksɛlɛnt, aesthetic . |

| Spatter level . | Minimal to Modaret . | Klose to ziro . |

| Di klin we dɛn dɔn klin afta dɛn dɔn wɛl . | Sɔntɛnde, dɛn kin nid am . | nɔ kin rili nid . |

| Jɔyn Strɔng . | Strɔng | Big pas |

Kost Analysis .

Initial Invɛstmɛnt .

MIG sistem dɛn de gi kɔst-ɛfɛktiv ɛntrɛ insay wɛldin .

TIG ikwipmɛnt nid fɔ gɛt ay kapital invɛstmɛnt .

Ɔl tu di sistem dɛn nid fɔ gɛt di rayt sefty ikwipmɛnt .

Di ɛkspɛns fɔ di opareshɔn .

MiG consumables stil de ikonomik fɔ ay-volyum wok .

TIG opareshon inkur ay per-fut kos .

Material Preparation Impacts Overall expenses .

Materials we fit fɔ MIG ɛn TIG wɛldin .

Ɛni wɛldin prɔses de sho sɔm patikyula trɛnk dɛn we dɛn de jɔyn difrɛn matirial dɛn. Ɔndastand dɛn kapabiliti ya de ɛp fɔ ɔptimayz wɛldin autkam akɔdin to difrɛn aplikeshɔn dɛn.

Materials we fit fɔ MIG wɛldin .

MIG Welding na versatile, i de handle bɔku bɔku matirial dɛn, we inklud:

Carbon Steel : Dɛn kin yuz am bɔku bɔku wan na kɔnstrɔkshɔn ɛn ɔtomotiv industri, MiG wɛldin kin izi fɔ handel tik sɛkshɔn dɛn.

Stenless Steel : I fayn fɔ difrɛn strɔkchɔral aplikeshɔn dɛn, we de gi fɔ durabiliti ɛn kɔrɛshɔn rɛsistɛns.

Aluminium : Ideal fɔ big, tik sɛkshɔn dɛn, we dɛn kin yuz mɔ na di transpɔt ɛn aerospace industri.

MIG Welding de du di bɛst we yu de wok wit matirial dɛn we tik pas 1.2mm . I ay ɔt ɛn waya-fed sistem de mek am pafɛkt fɔ fast-paced prodakshɔn pan strɔng, tik mɛtal dɛn.

Materials we fit fɔ TIG wɛldin .

TIG Welding excels in prɛsishɔn, mɔ fɔ dilikɛt ɔ tin matirial, we mek i bi wan prɛferɛd chuk fɔ mɛtal dɛn lɛk:

Kabon Stiɛl : de gi klin, strɔng weld, ivin insay tin sheet, we de mek i pafɛkt fɔ fayn, ditayli wok.

Stainless Steel : Dɛn sabi am fɔ in smol finish ɛn minimal distɔshɔn, TIG na fayn tin fɔ kɔrɛshɔn-rɛsistant aplikeshɔn dɛn.

Aluminium : Di bɛst fɔ tin aluminium sɛkshɔn, i de gi prɛsis kɔntrol ɛn fayn fayn wɛld dɛn.

Magnesium, titanium, kɔpa : TIG de handle dɛn ɛkzotik mɛtal ya fayn fayn wan, we de gi wɛl trɛnk ɛn supia aesthetics.

TIG welding de shayn pan matirial bitwin 0.5mm ɛn 3mm . I fayn kɔntrol ɛn nɔ-kɔnsumabl ilɛktrɔd de mek am pafɛkt fɔ dilikɛt prɔjek dɛn we nid ay prɛsishɔn.

Kompareshon tebul: MiG vs Tig Material Kompatibiliti

| Matirial | we fit fɔ MIG | we fit fɔ TIG |

| Kabon Stiel . | Yɛs | Yɛs |

| Stenlɛs stiɛl . | Yɛs | Yɛs |

| Aluminium na di . | Yɛs | Yɛs |

| Magnɛsiɔm . | Nɔ | Yɛs |

| Titanium . | Nɔ | Yɛs |

| Kɔpa | Nɔ | Yɛs |

| MATERIAL TIKES . | 1.2mm ɛn ɔp | 0,5mm - 3mm |

Dis tebul de sho us matirial dɛn de wok fayn wit ɛni wɛldin we, i de sho di tik we ɛni prɔses de handel fayn fayn wan.

Weld kwaliti kɔmpiashɔn .

Di kwaliti dɛn we MIG wɛld dɛn gɛt .

MIG Welding de prodyuz strɔng ɛn rilibul wɛld, we de mek i fayn fɔ strɔkchɔral aplikeshɔn dɛn. Sɔm impɔtant kwaliti dɛn na:

Strɔng ɛn fulnɛs : Mig wɛld dɛn sabi fɔ bi robust, wit dip penɛtrɛshɔn. Dis kin mek dɛn fayn fɔ mek dɛn gɛt tik dɛn ɛn dɛn kin du bɔku bɔku tin dɛn.

Spatter : Wan bad tin na di we aw spat de apin. Pan ɔl we i nɔ afɛkt di weld in trɛnk, di weld eria kin nid fɔ klin ɔ grind fɔ mek i fayn fɔ luk.

Aesthetics : MiG welds de functional bɔt tipikli nɔ gɛt di rifin apinans fɔ TIG wɛld dɛn. Projekt dɛn we nid fɔ gɛt vishɔnal apil kin nid sɛkɔndari prɔses, lɛk fɔ sand ɔ polish.

Di kwaliti dɛn we TIG wɛld dɛn gɛt .

Tig weldin na rili rɛspɛkt fɔ prodyuz klin, prɛsis wɛld, mɔ we aesthetics impɔtant. Di men tin dɛn we di kwaliti dɛn gɛt na:

Smooth ɛn aesthetic finish : TIG weld dɛn smol, wit wan nit 'stacked dime' apinans, we de mek dɛn fayn fɔ dekɔretiv ɔ visible welds. Dis prɔses de mek wɛld dɛn we bɔku tɛm nɔ nid fɔ gɛt sɛkɔndari finish.

No spatter : TIG welds kriet virtually no spatter, ridyus di nid fɔ post-weld klinap ɛn kɔntribyut to di ɔvala neatness fɔ di fayn prodak.

Porositi : Wan pɔtɛnɛshɛl isyu na porositi na di wɛld rut. Fɔ klin di matirial ɛn di fil fayn fayn wan, i impɔtant fɔ mek dɛn nɔ gɛt gas pɔkit dɛn we go mek di weld wik.

Kompareshon Tebul: Mig vs Tig Weld Kwaliti

| Weld Kwaliti Aspek | Mig Welds | Tig Welds |

| Trɛnk | Strɔng, dɛn kin abop pan am fɔ tik matirial dɛn . | Strɔng bɔt bɛtɛ fɔ tin dɛn we tan lɛk tin dɛn . |

| Spatter na na na na na na na na na na na na na na . | Kɔmɔn, nid fɔ klin afta dɛn dɔn wɛl fɔ klin . | No spatter, minimal klinap nid fɔ de |

| Aesthetics . | funkshɔnal, nid fɔ dɔn . | Smɔl, polish, fayn fɔ yuz fɔ dekɔret |

| Di prɔblɛm dɛn we pɔsin kin gɛt . | Spatter, nɔ ivin finish | Prone to porositi, klinin na impɔtant tin . |

Skil Rikwaymɛnt fɔ Wɛlda dɛn .

MIG Welding: Lɔw skil rikwaymɛnt dɛn .

MiG Welding na wan pan di izi we fɔ wɛldin fɔ lan. I sɛmi-ɔtomɛtik nature mek am fayn fɔ biginin ɔ wɛlda dɛn we de wok pan ay-volyum prodakshɔn. Di men rizin dɛn we mek MIG izi fɔ masta inklud:

Simplified process : Di kɔntinyu waya fid ɛn sɛlf-rɛgyulayt ARC de mek MIG wɛldin stret, we nid fɔ gɛt smɔl manual intavɛnshɔn.

Minimal Coordination : Welda dɛn nɔmɔ nid fɔ handle di gɔn, lɛf smɔl rum fɔ mistek kɔmpia to mɔ kɔmpleks tɛknik dɛn.

Kwik Lanin Kɔv : Wit besik trenin, wɛlda dɛn kin prodyuz kwik kwik wan we dɛn kin akseptabl wɛld, we kin mek i fayn fɔ industri dɛn we nid fast rizɔlt.

TIG Welding: Dɛn nid fɔ gɛt ay skil lɛvɛl dɛn we dɛn nid

Difrɛn frɔm dat, TIG wɛldin de aks fɔ mɔ prɛsishɔn ɛn kɔntrol, we de mek i at fɔ masta. Di kɔmplisiti fɔ di prɔses nid fɔ mek wɛlda dɛn fɔ divɛlɔp wan rich spɛshal skil dɛn:

Molten Pool Control : TIG welda dɛn fɔ monitar ɛn ajɔst di molten pul ɔltɛm, mek shɔ se di wɛld dɛn we gɛt smol smol, klin.

Manual Wire Feeding : Di welda nid fɔ gi in an fɔ fid di filla rod insay di weld pul we i de handle di torch, we de ad to di chalenj.

Fut pedal kɔdineshɔn : TIG Wɛldin de yuz wan fut pedal fɔ kɔntrol ɔt. Di wan dɛn we de wɛl fɔ tek tɛm balans dis we dɛn de manej di ɔda tul dɛn, ɛn dis kin mek i nɔ izi fɔ di wan dɛn we de bigin.

Atɛnshɔn to ditiɛl : TIG wɛlda dɛn fɔ mentɛn klin, prɛsis wɛld, we kin nid bɔku ɛkspiriɛns fɔ pafɛkt.

Kompareshon tebul: MiG vs Tig Skil Rikwaymɛnt

| Skil Aspek | Mig Welding | TIG Wɛldin |

| Learning Curve . | Kwik, fayn fɔ di wan dɛn we de bigin . | Slow, nid fɔ gɛt bɔku trenin . |

| Proses Komplexiti . | Simpul, ɔtomatik waya fid . | Kɔmpleks, nid fɔ kɔntrol ɔl di pat dɛn wit yu an fɔ kɔntrol . |

| Han-ay Kɔdinɛshɔn . | Besik koordineshɔn wit wan an . | ay-lɛvɛl kɔdineshɔn, ɔl tu an ɛn fut kɔntrol . |

| Suitability fɔ di wan dɛn we de bigin . | Ideal fɔ nyu wɛlda dɛn . | Chalenj, Bɛst fɔ ɛkspiriɛns wɛlda dɛn . |

Aplikeshɔn Sɛnario dɛn Ɛgzampul dɛn .

MIG Welding Aplikeshɔn dɛn .

MIG Welding na fayn fayn tin fɔ big, ay-prɔdakshɔn wok dɛn usay spid ɛn efyushɔn impɔtant. Sɔm impɔtant ɛgzampul dɛn na:

Konstrɔkshɔn Stilin Strukchɔ dɛn : MiG wɛldin de handel tik matirial dɛn fayn fayn wan, we mek i fayn fɔ strɔkchɔ stɛl na bildin ɛn brij dɛn.

Automotive Manufacturing : Dɛn kin yuz am bɔku bɔku wan fɔ assemble motoka frem ɛn bɔdi panɛl, MiG Welding in spid ɛn adaptabiliti mek i go-to fɔ ay-volyum ɔtomotiv prodakshɔn.

Hevi Equipment : Frɔm agrikalchɔral mashin to industrial ikwipmɛnt, MiG wɛld dɛn strɔng ɛn dɛn kin te, dɛn fayn fɔ yuz ebi ebi.

TIG Welding Aplikeshɔn dɛn .

Tig weldin na di wan we dɛn kin lɛk fɔ wok dɛn we nid prɛsishɔn, klin, ɛn ay kwaliti wɛld dɛn. Sɔm aplikeshɔn ɛgzampul dɛn na:

Chemical Pipelines : TIG Welding in abiliti fɔ mek smol, klin weld dɛn de mek am pafɛkt fɔ paip layn dɛn we de kɛr sɛnsitiv matirial dɛn na kemikal plant dɛn.

Food equipment : Insay di fud industri, usay hajɛns impɔtant, TIG in klin weld dɛn fayn fɔ stenlɛs stiɛl ikwipmɛnt ɛn stɔrɔj tank dɛn.

Baysikul freym : TIG in prɛsishɔn de mek am fayn fɔ wɛldin laytwɛt matirial dɛn lɛk aluminiɔm ɛn taytaniɔm, we dɛn kin yuz bɔku tɛm na ay-pafɔmɛnshɔn baysikul freym dɛn.

Artworks : Fɔ skapul ɔ dɛkɔretiv mɛtal wok, TIG de gi di smol, aesthetically pleasing finish we dɛn nid fɔ atis projɛkt dɛn.

Kɔmpiashɔn Tebul: MIG vs TIG Aplikeshɔn Sɛnario

| Aplikeshɔn | MIG Wɛldin | TIG Wɛldin |

| Bil | Stilin strɔkchɔ dɛn, ay-volyum prɔjek dɛn . | prɛsis, klin wɛld fɔ spɛshal wok . |

| Ɔtomotiv . | Kar frem, bodi panels . | Speshal pat dɛn, ay-kwaliti finish dɛn |

| Indastrial . | Hevi ekwipmɛnt, mashin dɛn . | Kεmikכl paip, fכd-gεd ikwipmεnt |

| At ɛn Dizayn . | Big big mɛtal strɔkchɔ dɛn . | Skulpchɔ dɛn, baysikul frem dɛn, fayn fayn at wok dɛn |

Factors fɔ tink bɔt we yu de pik bitwin MIG ɛn TIG wɛldin .

We yu de disayd bitwin MIG ɛn TIG wɛldin, dɛn fɔ tink bɔt sɔm impɔtant tin dɛn fɔ mek shɔ se yu pik di bɛst we fɔ yu patikyula prɔjek.

Material tayp ɛn tik .

Wan pan di tin dɛn we impɔtant pas ɔl na di tin dɛn we de insay ɛn di tik we i tik. MiG Welding na bɛtɛ wan fɔ tik matirial , lɛk stɛl ɛn aluminiɔm, we mek i fayn fɔ wok dɛn we gɛt ebi ebi wok. Difrɛn frɔm dat, TIG wɛldin ɛksɛl fɔ handle tin matirial , lɛk stenlɛs stiɛl ɛn taytaniɔm, usay prɛsishɔn impɔtant.

Rikwayd weld kwaliti ɛn apia .

Di weld kwaliti ɛn apinans we dɛn want bak de ple impɔtant pat bak. If dɛn nid ay kwaliti, smol, ɛn fayn fayn wɛl dɛn we de mek pɔsin in yay fayn, TIG na di bɛst we fɔ du am. TIG Welds dɛn kin yuz bɔku tɛm fɔ dekɔretiv ɔ prɔjek dɛn we nid fɔ dɔn klin finish. MiG welds, though strong, kin nid post-prosεs fכ achy di sem lεvεl fכ aesthetic apil.

Prodakshɔn Spid ɛn Efisiɛns .

Fɔ prɔjek dɛn we nid ay prodakshɔn spid , MIG Wɛldin na di klia wina. I kɔntinyu waya fid de alaw fɔ wɛl kwik kwik wan, we de mek i fayn fɔ big-big industrial aplikeshɔn dɛn. Tig welding, na di ɔda say, de slo bikɔs ɔf in manual nature, we de mek i nɔ ebul fɔ wok fɔ big-volyum wok dɛn bɔt i fayn fɔ prɛsishɔn wok.

Skil levul fɔ di wɛlda .

Di wɛlda in skil lɛvɛl rili inflɔws di chukchuk. MiG Welding izi fɔ lan ɛn ɔpreshɔn, we mek i bi gud opshɔn fɔ biginin ɔ prodakshɔn ɛnvayrɔmɛnt wit less ɛkspiriɛns wɛlda. TIG Welding, bɔt, nid fɔ gɛt mɔ advans skil dɛn, lɛk molten pul kɔntrol , waya fidin, ɛn fut pedal kɔdineshɔn, we mek i bɛtɛ fɔ wɛlda dɛn we gɛt ɛkspiriɛns.

Badjɛt ɛn kɔst kɔnsidareshɔn dɛn .

Badget na ɔda impɔtant tin. MIG Welding jɔs de kam wit lɔwa ikwipmɛnt kɔst ɛn kɔnsumabl, we de mek am di mɔ kɔst-ɛfɛktiv opshɔn fɔ big prɔjek dɛm. TIG weldin, we de gi ay kwaliti weld, kin gɛt ay ikwipmɛnt ɛn ɔpreshɔnal kɔst bikɔs ɔf di prɛsishɔn we involv.

Sumari Tebul: Faktor dɛn we de inflɔws Mig vs Tig Choice

| Faktɔ | MIG Wɛldin | Tig Wɛldin |

| Material Type & Tiknes . | Tik tik matirial dɛn (stiɛl, aluminiɔm) . | Tin matirial dɛn (stɛnlɛs stiɛl, taytaniɔm) |

| Weld kwaliti & apinans . | Strɔng, kin nid fɔ gɛt post-prɔsɛsin . | Ay-kwaliti, klin finish |

| Produkshɔn spid . | Fast, we fit fɔ mek dɛn prodyuz big big wan . | Slower, ideal fɔ prɛsis wɛld dɛn . |

| Welder skill level . | I izi fɔ lan, gud fɔ di wan dɛn we de bigin fɔ lan | I nid fɔ gɛt advans skil dɛn . |

| Badget & Kost fɔ di . | Di ikwipmɛnt dɛn we de dɔŋ ɛn di kɔst fɔ wok . | ay kɔst bikɔs ɔf prɛsishɔn ɛn kɔmplisiti . |

Sefti prɛkoshɔn fɔ MIG ɛn TIG wɛldin .

Welding, ilɛksɛf na Mig ɔ TIG, involv impɔtant sef risk dɛn, we mek i impɔtant fɔ fala di rayt tin dɛn fɔ tek tɛm wit. Dis dɔŋ ya na di men tin dɛn we dɛn fɔ du fɔ mek shɔ se dɛn gɛt sef we fɔ wɛldin.

Di tin dɛn we pɔsin kin yuz fɔ protɛkt insɛf (PPE) .

Prɔpa PPE impɔtant fɔ protɛkt wɛlda dɛn frɔm bɔn, ilɛktrik shɔk, ɛn bad bad fyum. Di men tin dɛn na:

Welding Helmet and Face Shield : Wan ɛlmɛt de protɛkt yu yay ɛn fes frɔm di tranga layt ɛn spak dɛn we dɛn de mek we dɛn de wɛl. Fes shild dɛn de ad ɛkstra layt fɔ protɛkt.

Klos ɛn glɔv dɛn we nɔ de faya : Di wan dɛn we de wɛl fɔ wɛr jakit ɛn glɔv dɛn we nɔ de flay ɛn glɔv fɔ shild agens bɔn. Kɔtɔn ɔ lɛda matirial dɛn kin wok fayn fɔ mek spak nɔ kech faya.

Sefty Boots : Boots we nɔ de faya wit stɛl fut dɛn de protɛkt fut frɔm ebi ebi tin dɛn, spak, ɛn mɛtal we dɔn rɔtin.

Sef we de wok na di wokples .

Wan sef wokples impɔtant jɔs lɛk aw i impɔtant jɔs lɛk aw pɔsin fɔ protɛkt yusɛf. Di tin dɛn we de dɔŋ ya de ɛp fɔ mek shɔ se dɛn gɛt ples fɔ wɛldin we nɔ gɛt denja:

Prɔpa ventilashɔn : Weldin de mek pɔyzin fumy. Mek shɔ se yu wokples gɛt wɛl-ventilashɔn fɔ mek yu nɔ inhal fume, we kin mek yu gɛt siriɔs prɔblɛm fɔ blo.

Faya Prɛvenshɔn Mɛzhɔ : Kip faya ɛkstingyushɔn dɛn nia de ɛn klia di eria fɔ tin dɛn we kin bɔn. Welding sparks kin ignite faya kwik kwik wan if dɛn kam in kɔntakt wit tin dɛn we de mek pɔsin sik.

Ilektrikal sefty .

MiG ɛn TIG wɛldin de yuz ilɛktrik kɔrɛnt, we de prɛzɛnt di risk fɔ ilɛktrik shɔk if dɛn nɔ manej am fayn. Fɔ fala dɛn gaydlayn ya:

Grounding and Insulation : Ɔltɛm mek shɔ se di wɛldin mashin dɛn na grɔn fayn fayn wan ɛn ɔl di ilɛktrik kɔmpɔnɛnt dɛn gɛt wɛl-insuleshɔn fɔ avɔyd shɔt sɔrkwit dɛn.

Avoiding Electric Shock Hazards : Nɔ ɛva tɔch di ilɛktrɔd ɔ mɛtal pat dɛn na di wɛldin mashin we yu de wok. Apat frɔm dat, kip yu ikwipmɛnt dray ɛn avɔyd wɛldin insay wet kɔndishɔn fɔ ridyus di risk fɔ shɔk.

Rundown: MiG versus TIG welding

MiG ɛn TIG wɛldin ɛni wan gɛt wɔndaful kwaliti dɛn ɛn tin dɛn we de ambɔg dɛn. MiG Welding na kwik, rizin fɔ tik matirial, ɛn mɔ stret fɔ amatɔ. Tig welding, while more slo, ofa unrivaled akkuracy en fil for mo slendly matiral.

Ɔndastand di bɛnifit ɛn impɔtant tin dɛn fɔ ɛvri strateji de ɛp yu fɔ pik di rayt prosidur fɔ yu ɔndatak. Tink bɔt matirial kayn, want weld kwaliti, ɛn krieshɔn profisiɛns we yu de pik bitwin MIG ɛn TIG.

Rifrɛns Sɔs dɛn .

MIG weldin na di .

Gas tungsten arc welding .

China best CNC MACHINING SAVIS .