Welding jɔyɔrɔ ka bon kosɛbɛ iziniw kɔnɔ i n’a fɔ mobili, aerospace ani jɔli. Nka ni a bɛ tali kɛ fɛɛrɛ ɲuman sugandili la, sɔsɔli bɛ kɛ MIG ni TIG welding cɛ tuma caman na. Fɛɛrɛ kelen-kelen bɛɛ bɛ nafa danfaralenw di ani a bɛ baara kɛ ni kuntilenna wɛrɛw ye.

Nin sɛbɛn in kɔnɔ, an bɛna MIG ni TIG welding suma ɲɔgɔn na, o ye welding (sɔgɔli) kɛcogo fila ye minnu bɛ kɛ ka caya. Aw bɛna u ka sariyakolow, u ka nafaw ani u ka dɛsɛw dɔn, ani waati min na aw bɛ se ka baara kɛ ni fɛɛrɛ kelen-kelen bɛɛ ye. I kɛra mɔgɔ daminɛbaga ye wo, i kɛra welda ye wo, nin gafe in bɛna i dɛmɛ ka sugandili ɲuman kɛ i ka poroze la.

MIG welding ye mun ye?

MIG (gazi inɛri inɛri) sɔgɔli bɛ Arc welding fɛɛrɛ kɔrɔlen dɔ jira. A bɛ nɛgɛ siri barikamaw Dabɔ ni semi-automatique walima automatique ye. A ka c’a la, weldala ŋanaw b’a wele ko Gas Metal Arc Welding (GMAW) izini baara la.

MIG ka sɔgɔli kɛcogo .

O kɛcogo bɛ tali kɛ yɔrɔ koloma saba la minnu bɛ baara kɛ ɲɔgɔn fɛ:

Electrode continue de la wire : Moteur systeme bɛ fili a yɛrɛma ka tɛmɛ welding marifa fɛ. O nɛgɛ in bɛ Kɛ elekitorode ni fasafɛn fla bɛɛ ye, ka wuli ka Kɛ welda sirili ye.

Gazi lakanani : Argon 75% ni CO2 25% ɲagaminen bɛ tɛmɛ marifakisɛ fɛ. Gazi kala bɛ nɛgɛ wulilen tanga fiɲɛ nɔgɔlen ma ka sɔrɔ ka welda doncogo ɲuman sabati.

Kuranko : Kuran tilennen (DC) bɛ tɛmɛ ni kuran ye, ka arc dɔ bɔ. Funteni jugumanba bɛ nɛgɛ ni basi nɛgɛw bɛɛ wuli, ka fusion joint solide dilan.

Mun na aw bɛ Mig Welding sugandi?

MIG Welding bɛ nafa caman di baara suguya caman kɔnɔ:

Teliya ni baarakɛcogo ɲuman .

A bɛ weldaw da minnu bɛ to sen na k’a sɔrɔ u ma jɔ tuma caman .

A bɛ deposition hakɛ caman sɔrɔ ni i ye a suma ni laadala fɛɛrɛw ye .

A bɛ dɔ bɔ a dilanni waati la ni otomatiki filiw baloli ye .

Baarakɛcogo ɲuman baarakɛcogo

| nafa |

. |

| Bolo kelen-kelen baarakɛcogo . |

Kɔlɔsili ni jɔyɔrɔfalen ka ɲɛ . |

| Semi-otomatique feed . |

Operatɛri ka sɛgɛn dɔgɔyali . |

| Setup nɔgɔman . |

curve currté curve . |

Material versatility .

Mig welding ka fisa ni nin ye ka fara ɲɔgɔn kan:

Aluminiyɔmu sɛbɛnw bɛ bɔ 26-gauge la ka taa se tasa girinman ma .

inox yɔrɔw .

Assemblées de feres structurels .

Nɛgɛ minnu tɛ kelen ye, olu bɛ sirili barikamaw de wajibiya .

A ka ladamuni bɛ Taa fo welding jɔyɔrɔ caman na - fla, horizontal, vertical, ani overhead. O sɛgɛsɛgɛli in b’a to a nafa ka bon kosɛbɛ mobili, jɔli ani fɛn dilanni baarakɛyɔrɔw la.

Tig welding ye mun ye?

TIG (Gas inert inert) welding, a bɛ fɔ fana ko GTAW (Gas tungsten arc welding), o bɛ welda tigitigiw di, minnu ka ɲi kosɛbɛ. Nin wale camanba in bɛ joginda kɛrɛnkɛrɛnnenw dilan, kɛrɛnkɛrɛnnenya la, fɛn finmanw kan minnu bɛ fini laban cogoya ɲuman de wajibiya.

TIG ka sɔgɔli kɛcogo .

Taabolo bɛ yɔrɔ nafama naani fara ɲɔgɔn kan:

Tungsten elekitorode min tɛ sɔrɔ a la : tungsten bere kɛrɛnkɛrɛnnen dɔ bɛ arc sɔrɔ k’a sɔrɔ a ma wuli. A muɲuli bɛ se ka kɛ sababu ye ka arc jogo sabatilenw sɔrɔ welding baara janyalenw bɛɛ la.

Gazi min bɛ kɛ ni gazi ye, o saniyalen : argon gazi bɛ tɛmɛ tasuma fɛ, ka welda jidaga lakana ka bɔ fiɲɛ nɔgɔlen na. Baarakɛcogo dɔw bɛ baara kɛ ni heliyɔmu walima argon-helium ɲagaminenw ye walasa ka baara kɛcogo ɲɛ.

Optional Filler Metal : weldaw bɛ filɛriw balo ni bolo ye ka don welda jidaga kɔnɔ. O fɛɛrɛ in bɛ sira Di fɛnw farali ni u kolotugudaw cogoya ma tigitigi.

Power Source Flexibilité : TIG systems bɛ baara kɛ AC ni DC fanga fila bɛɛ kan. AC ka fisa ni aluminiyɔmu ye, ka sɔrɔ DC bɛ nɔ ɲumanw di nɛgɛ ni fɛnɲɛnamafagalanw kan.

Nafa minnu bɛ TIG welding na .

TIG welding bɛ nafa caman di, o b’a to a ye fɛɛrɛ ɲuman ye baara minnu bɛ kɛ ka ɲɛ kosɛbɛ:

Precision and Control : TIG welding bɛ kunnafoni di min tɛ se ka suma ni ɲɔgɔn ye welding kɛcogo kan, o b’a to a ka ɲi baara caman na. Baarakɛlaw bɛ se ka funteni ni fasa labɛn ka ɲɛ walasa ka welda saniyalenw ni saniyalenw labɛn.

Welda minnu ka bon kosɛbɛ : welda minnu bɛ bɔ TIG welding fɛ, olu saniyalen don, u barika ka bon, u bɛ diya, u bɛ diya, ni fɛn fitinin ye. O b’a to TIG bɛ bɛn porozɛw ma minnu bɛ welda dafalenw wajibiya.

Fɛn minnu bɛ kɛ fɛn caman na : TIG bɛ baara kɛ nɛgɛ suguya caman na, i n’a fɔ nɛgɛ, aliminiyɔmu, ani titaniyɔmu. A ka se ka dakun finmanw minɛ k’a sɔrɔ a ma kɛ ni warping ye, o ye a fanga belebele dɔ ye.

Danfaraba minnu bɛ MIG ni TIG welding cɛ .

MIG ni TIG welding cɛ jogo danfaralenw faamuyali bɛ baarakɛlaw dɛmɛ ka taabolo ɲuman sugandi baara kɛrɛnkɛrɛnnenw kama. An k’u ka danfara jɔnjɔnw Sɛgɛsɛgɛ ko jɔnjɔnw bɛɛ la.

Taabolo ni fɛɛrɛ sumayɔrɔ

| Aspect |

Mig Welding |

TIG welding . |

| Opereli |

Semi/automatique . |

Min bɛ fɛn bolo la |

| Wire Feed . |

Continuel . |

bolo-nafa . |

| Kɔlɔsili fɛɛrɛ . |

bolo kelen . |

bolo fila + sen . |

| curve kalan . |

Ka bɛrɛbɛn |

Teliman |

Minɛnw wajibiyalenw .

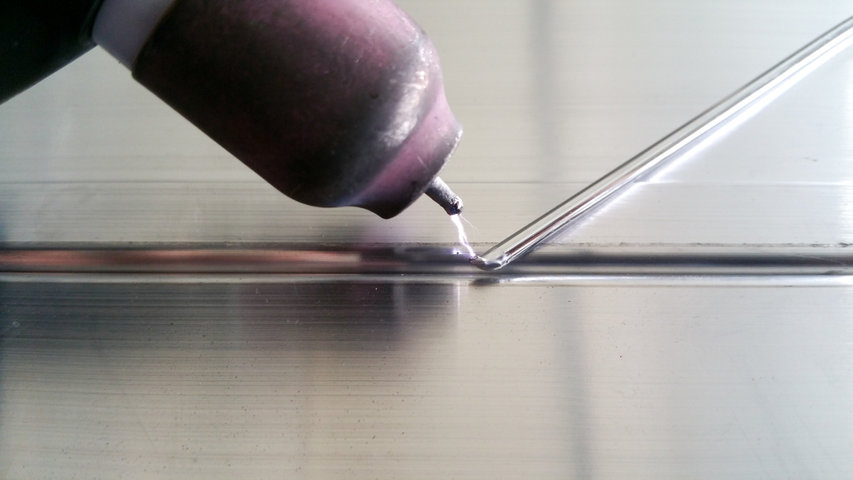

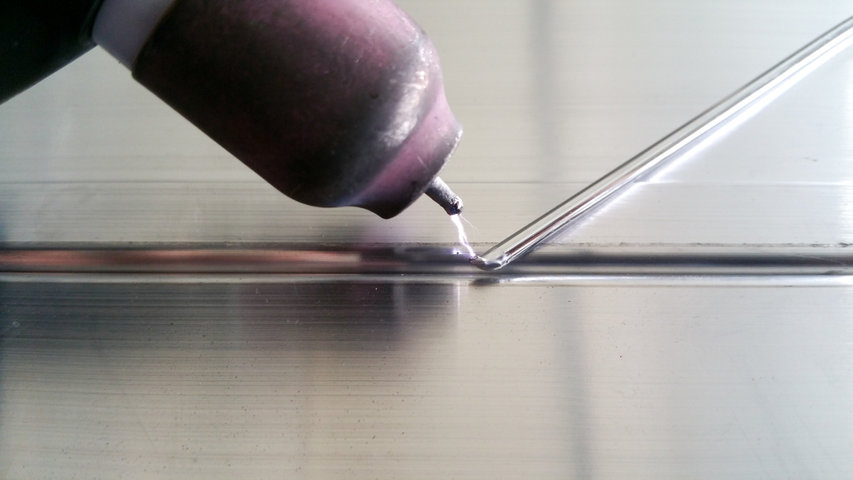

MIG ka welding setup .

Wire feed welding marifa integrating elekitorode lasecogo ani gazi bɔli .

Automatic Wire Feeding System ka fɛnw sɔrɔcogo basigilen mara .

ARGON-CO2 ɲagaminen (75/25) Gazi min bɛ mɔgɔ tanga .

DC fanga sɔrɔyɔrɔ min bɛ arc jogo sabatilenw di .

TIG ka welding setup .

Torch kɛrɛnkɛrɛnnen min bɛ tungsten elekitorode .

Precision Sen pedal Contrôle Amperage .

Gazi dilancogo saniyalen argon shielding .

AC/DC kuran sɔrɔyɔrɔ min bɛ baarakɛcogo caman di .

Baarakɛcogo jateminɛw .

Teliya ni baarakɛcogo ɲuman .

MIG welding ka fisa ni fɛn dilanni sigidaw ye:

A bɛ se ka 35-50 kubikɛmɛ kɛ lɛrɛ kelen kɔnɔ gazi bɔli hakɛ .

A bɛ baara kɛ ka taa a fɛ waati jan kɔnɔ .

A bɛ se ka kɛ sababu ye ka welda boli janw dafa joona .

TIG welding bɛ precision fɔlɔ:

A bɛ baara kɛ ni 15-25 kubik ye lɛrɛ kelen gazi bɔli la .

A bɛ ɲini ka jateminɛ kɛ kosɛbɛ fɛn fitininw na .

A bɛ jaabi ɲumanw dilan joli kɔrɔfɔlenw kan .

Jogoɲumanya

| jogo |

Mig Result |

TIG Result . |

| welda yecogo . |

Koɲuman, fini . |

A ka ɲi kosɛbɛ, a bɛ ɲɛnajɛ . |

| Nivo de spatter . |

Minimal ka se ka kɛ . |

zeru ka surun . |

| Saniya kɔfɛ saniya . |

Tuma dɔw la, a mago tun bɛ o la . |

A man teli ka kɛ wajibi ye . |

| Joli fanga . |

Fɔrɔlen |

A sanfɛ |

musaka sɛgɛsɛgɛli .

Investissement fɔlɔ .

MIG sitɛmuw bɛ don musaka la ka don welding kɔnɔ .

TIG minɛnw bɛ waribonba camanba de wajibiya .

O sigida fila bɛɛ mago bɛ lakana minɛn ɲumanw na .

Baara musakaw .

MIG Consumables tora sɔrɔko la baara caman na .

TIG baara bɛ sen kelen-kelen bɛɛ musaka caman bɔ .

Fɛnw labɛnni bɛ nɔ bila musakaw bɛɛ lajɛlen na .

Fɛn minnu bɛnnen don MIG ni TIG welding ma .

welding kɛcogo kelen-kelen bɛɛ bɛ fanga kɛrɛnkɛrɛnnenw jira ni u bɛ fɛnw fara ɲɔgɔn kan. O seko ninnu faamuyali bɛ dɛmɛ ka welding kɔlɔlɔw ɲɛ ka ɲɛ baarakɛminɛn suguya caman kɔnɔ.

Fɛn minnu bɛnnen don MIG welding ma .

MIG welding ye fɛn caman ye, a bɛ fɛn caman minɛ, i n’a fɔ:

Karɔbɔli nɛgɛ : A bɛ kɛ ka caya jɔli ni mobili baara la, MIG welding bɛ yɔrɔ minnu ka bon kosɛbɛ, olu minɛ nɔgɔya la.

inox : A bɛnnen don ka kɛ fɛn suguya caman ye, ka muɲuli ni sɔgɔli kɛcogo di.

Aluminiyɔmu : A ka ɲi dakun belebelebaw, minnu ka bon, minnu bɛ kɛ ka caya bolifɛnw ni aerospace baarakɛyɔrɔw la.

MIG welding bɛ baara kɛ ka ɲɛ ni a bɛ baara kɛ ni fɛnw ye minnu ka bon ni 1,2mm ye . A ka funteni ka bon ani a balocogo min bɛ balo ni nɛgɛ ye, o b’a to a dafalen don ka kɛ fɛn ye min bɛ se ka kɛ teliya la, nɛgɛ barikamaw kan, nɛgɛ minnu ka bon.

Fɛn minnu bɛnnen don TIG welding ma .

TIG welding bɛ tɛmɛ ni tiɲɛni ye, kɛrɛnkɛrɛnnenya la fɛn nɔgɔlenw walima fɛn finmanw na, o b’a to a ka fisa nɛgɛw ma i n’a fɔ:

Karɔbɔni nɛgɛ : A bɛ welda saniyalenw di, minnu barika ka bon, hali sɛbɛn finmanw kɔnɔ, o b’a to a dafalen don baara ɲumanw na, minnu ɲɛfɔlen don kosɛbɛ.

Inox : A bɛ dɔn a ka fini nɔgɔlen na ani a ka fɛn caman tigɛli la, TIG ye fɛn ɲuman ye min bɛ se ka kɛ ka fɛnw sɔgɔ.

Aluminiyɔmu : A ka fisa aluminiyɔmu yɔrɔ finmanw na, a bɛ kunnafoni tigitigi di ani welda cɛɲiw.

Magnesium, Titanium, Copper : TIG bɛ nin nɛgɛ wɛrɛw minɛ ka ɲɛ, ka fanga ni ɲɛnajɛko ɲuman di.

TIG welding bɛ yeelen bɔ fɛnw kan minnu bɛ 0,5mm ni 3mm cɛ . A ka kɔrɔsili ɲuman ani a ka elekitorode min tɛ se ka tiɲɛ, o b’a kɛ dafalen ye poroze nɔgɔlenw na minnu bɛ tiɲɛniba wajibiya.

Tabali sumalen: MIG vs TIG matériel compatibilité

| matériel |

bɛnnen don MIG ma |

min bɛnnen don TIG ma . |

| Karɔbɔni nɛgɛ . |

Awɔ |

Awɔ |

| inox . |

Awɔ |

Awɔ |

| Aluminiyɔmu . |

Awɔ |

Awɔ |

| Magnesium . |

Ayi |

Awɔ |

| Titanium . |

Ayi |

Awɔ |

| Nɛgɛ |

Ayi |

Awɔ |

| Materiel ka bon . |

1,2mm ani sanfɛ . |

0,5mm - 3mm . |

Nin ja in b’a jira fɛn minnu bɛ baara kɛ ka ɲɛ ni welding fɛɛrɛ kelen-kelen bɛɛ ye, ka taabolo kelen-kelen bɛɛ janya jira ka ɲɛ.

weld quality comparaison .

MIG welds ka jogo .

MIG welding bɛ welda barikamaw ni dannayalenw dilan, o b’a to a ka ɲi kosɛbɛ baarakɛcogo la. A jogo jɔnjɔn dɔw ye:

Fanga ni dafalen : MIG weldaw bɛ dɔn ko u barika ka bon, u doncogo jugu. O b’a to u bɛnnen don fɛnw ma minnu ka bon ani minnu ka baara ka gɛlɛn.

Spatter : A dɔgɔya kelen ye spatter sɔrɔli ye. Hali ni a tɛ nɔ bila welda fanga la, welda yɔrɔ bɛ se ka saniya walima ka a sɔgɔ walasa ka a yecogo ɲɛ.

Aesthetics : MIG welds ye baarakɛcogo ye nka a ka c’a la, TIG weldaw cogoya nɔgɔlen tɛ u la. Porozɛ minnu ka kan ka kɛ ni ɲɛ ye, olu bɛ se ka mago ɲɛ baarakɛcogo filanan na, i n’a fɔ sɔgɔli walima polisi.

TIG weldaw ka jogo .

TIG welding bɛ jate kosɛbɛ welda saniyalenw na minnu bɛ kɛ ka ɲɛ, kɛrɛnkɛrɛnnenya la ni ɲɛnajɛko nafa ka bon. A jogo jɔnjɔnw ye:

Finimugu nɔgɔlen ni cɛɲi : Tig weldaw bɛ nɔgɔya, u bɛ kɛ ni 'stacked dime' yecogo ɲuman ye, o b'a to u bɛnnen don welda masirilenw walima fɛn yetaw ma. O kɛcogo in bɛ weldaw Dabɔ minnu ka teli ka fini filanan si wajibiya.

No Spatter : TIG welds bɛ fɛn si da, ka dɔ bɔ a mago la ka ɲɛsin weld cleanup ma ani ka dɛmɛ don ka ɲɛsin fɛn laban bɛɛ lajɛlen labɛnni ma.

Porosity : Ko kelen min bɛ se ka kɛ, o ye porosity ye welda ju la. Fɛn ni fasa fila bɛɛ saniyacogo ɲuman nafa ka bon walasa gazi bɔrɛw kana kɛ minnu bɛ se ka welda fanga dɔgɔya.

Tabali sumalen: Mig vs TIG weld welda

| jogo ɲuman Aspect |

Mig welds |

TIG welds |

| Barika |

Fɛn barikamaw, dannaya bɛ se ka da minnu kan . |

A barika ka bon nka a ka fisa ni fɛn finmanw ye . |

| Spatter . |

A bɛ kɛ tuma bɛɛ, a bɛ kɛ ka ɲɛgɛnw saniya kɔfɛ . |

No spatter, minimal cleanup wajibiyalen don . |

| Aesthetics . |

functional, a bɛ finidoncogo de wajibiya . |

Smooth, polished, ideal ka baara kɛ ni dekoratif ye . |

| Ko minnu bɛ se ka kɛ . |

Spatter, fini tɛ kelen ye . |

A ka teli ka kɛ porosity ye, saniya ye ko gɛlɛn ye . |

Seko ni dɔnko wajibiyalenw weldaw kan .

MIG welding: seko ni dɔnko wajibiyalenw .

MIG welding bɛ jate welding fɛɛrɛ nɔgɔmanw dɔ ye ka kalan. A ka semi-otomatiki cogoya b’a to a ka ɲi daminɛbagaw ma walima weldalaw ma minnu bɛ baara kɛ ni fɛn caman dilanni ye. Kunba minnu b’a to MIG ka nɔgɔn ka se ka baara kɛ, olu dɔw ye:

Fɛɛrɛ nɔgɔman : nɛgɛ baloli basigilen ani yɛrɛlabɛnni arc bɛ MIG welding kɛ ka ɲɛ, o bɛ kɛ sababu ye ka bololabaara dɔgɔya.

Minimal coordination : weldalaw ka kan ka marifa minɛ dɔrɔn, ka yɔrɔ dɔgɔya fili la ni i y’a suma ni fɛɛrɛ gɛlɛnw ye.

Kalan teliya : Ni kalan jɔnjɔnw bɛ yen, welda bɛ se ka weldaw dilan joona minnu bɛ sɔn, o b’a to a ka ɲi kosɛbɛ iziniw ma minnu mago bɛ sɔrɔ teliya la.

TIG welding: Seko ni dɔnko hakɛ caman bɛ sɔrɔ .

O ni TIG welding tɛ kelen ye, o bɛ fɛn caman ɲini ka ɲɛ ani ka se ka a yɛrɛ minɛ, o bɛ a to a ka gɛlɛn ka se ka a dɔn kosɛbɛ. O baara in gɛlɛya bɛ weldalaw wajibiya u ka seko kɛrɛnkɛrɛnnen caman labɛn:

Molten Pool Control : TIG weldalaw ka kan ka molten pool kɔlɔsi ani ka a ladilan tuma bɛɛ, ka welda nɔgɔlenw ni saniyalenw sabati.

Bololabaarakɛlaw ka balo : welda ka kan ka falan bara balo ni bolo ye ka don sosɛti kɔnɔ ka a sɔrɔ a bɛ tasumamugu minɛ, o bɛ dɔ fara gɛlɛya kan.

Senna-pedal coordination : TIG welding bɛ senna-pedali kɛ ka funteni kunbɛn. Weldalaw ka kan k’o balansi koɲuman k’a sɔrɔ u bɛ baarakɛminɛn tɔw ɲɛnabɔ, o b’a to a ka gɛlɛn daminɛbagaw ma.

Attention to Detail : TIG weldaw ka kan ka welda saniyalenw mara, minnu bɛ kɛ tuma caman na, minnu bɛ dɔnniya nafama de wajibiya walasa ka dafa.

Tablo min bɛ tali kɛ ɲɔgɔn na: MIG vs TIG Seko ni dɔnko wajibiyalenw

| seko fan dɔ |

MIG welding |

TIG welding . |

| curve kalan . |

Teliya, min bɛnnen don daminɛbagaw ma . |

Slow, bɛ dege caman de wajibiya . |

| Taabolo ka gɛlɛya . |

Simple, automatique wire feed . |

complexe, bɛ a ɲini ka bolo di fan bɛɛ ma . |

| bolo-ɲini coordination . |

Basic coordination ni bolo kelen . |

Koordinasiyɔn sanfɛla la, bolo ni sen bɛɛ lajɛlen . |

| A bɛnnen don daminɛbagaw ma . |

Ideal ka ɲɛsin welda kura ma . |

Gɛlɛya, min ka fisa ni weldalaw ye minnu bɛ se kosɛbɛ . |

application scenarios misaliw .

MIG welding applications .

MIG welding bɛnnen don kosɛbɛ baarabaw ma minnu bɛ kɛ ni fɛn caman ye, teliya ni baarakɛcogo ɲuman nafa ka bon yɔrɔ minnu na. Misali jɔnjɔn dɔw ye:

Construction Steel Structures : MIG welding bɛ fɛnmugumuguw minɛ ka ɲɛ, o b’a to a ka ɲi kosɛbɛ jɔli nɛgɛ ma sow ni bɔrɔw kɔnɔ.

Automotive Manufacturing : A bɛ kɛ ka caya mobili karamɔgɔya ni farikolo pannew lajɛli kama, MIG Welding ka teliya n’a ka ladamuni b’a kɛ taa-ka-segin ye mobili dilanni na min ka bon kosɛbɛ.

Minɛn girinmanw : K’a ta sɛnɛ masinw na ka se izini minɛnw ma, MIG weldaw bɛ sabati ani u bɛ mɛn, u bɛnnen don baara gɛlɛnw ma.

TIG welding applications .

TIG welding ka fisa baara minnu na, minnu bɛ kɛ ka ɲɛ, ka saniya, ani ka welda minnu ka ɲi kosɛbɛ. Sɛbɛnni kɛcogo misali dɔw ye:

Pibilikiw : TIG Welding ka se ka welda nɔgɔlenw dilan minnu bɛ kɛ ka ɲɛ, o b’a to a dafalen don pibilikiw kama minnu bɛ fɛnw ta minnu bɛ se ka fɛn sɛgɛsɛgɛlenw ta kemikɛli jiriw la.

Dumunikɛminɛnw : Dumuniko siratigɛ la, yɔrɔ min na saniya nafa ka bon, TIG ka welda saniyalenw ka ɲi kosɛbɛ nɛgɛmafɛnw ni fɛnw marayɔrɔw la.

Bisikili karamɔgɔya : TIG ka tiɲɛni b’a kɛ fɛn ɲuman ye fɛn nɔgɔmanw na i n’a fɔ aliminiyɔmu ani titaniyɔmu, min bɛ kɛ ka caya bisikili karamɔgɔya la min bɛ se ka baara kɛ kosɛbɛ.

Seko ni dɔnko : Jaw walima nɛgɛko masirilenw kama, Tig bɛ fini nɔgɔlen, cɛɲi min ka di, o bɛ kɛ seko ni dɔnko porozɛw kama.

Tablo min bɛ tali kɛ ɲɔgɔn na: MIG ni TIG baarakɛcogo ɲɛfɔli

| kɛcogo |

MIG welding |

TIG welding . |

| Sojɔ |

Nɛgɛso jɔli, porozɛ minnu bɛ kɛ ni hakɛ caman ye . |

welda tigitigiw, saniyalenw baara kɛrɛnkɛrɛnnenw kama . |

| Mobili . |

Mobili karamɔgɔ, farikolo pannew . |

Yɔrɔ kɛrɛnkɛrɛnnenw, finiw minnu ka ɲi kosɛbɛ . |

| Industrie . |

Minɛn girinmanw, masinw . |

Pipelines kemikaliw, dumuni-sɛnɛ-minɛnw . |

| Seko ni dɔnko ani dilancogo . |

Nɛgɛdaga belebelebaw . |

Sculptures, cadres de bicyclettes, Artwork de cheveux |

Fɛn minnu ka kan ka jateminɛ ni aw bɛ sugandili kɛ MIG ni TIG welding cɛ .

Ni aw bɛ MIG ni TIG sɔgɔli latigɛ, fɛn jɔnjɔn caman ka kan ka jateminɛ walasa ka sugandili ɲuman kɛ aw ka poroze kɛrɛnkɛrɛnnen na.

Material suguya ani a janya .

Fɛn minnu nafa ka bon kosɛbɛ, olu dɔ ye fɛn ye ani a bonya. MIG welding bɛnnen don ka ɲɛ fɛnw na minnu ka bon , i n’a fɔ nɛgɛ ni aliminiyɔmu, o b’a to a ka ɲi baara gɛlɛnw na. O ni TIG welding tɛ kelen ye ka tɛmɛ fɛn finmanw minɛcogo kan , i n’a fɔ nɛgɛ ni titaniyɔmu, yɔrɔ min na tiɲɛni nafa ka bon kosɛbɛ.

A wajibiyalen don weld quality ani yecogo .

ɲininen Weld quality ni yecogo fana jɔyɔrɔ ka bon. Ni welda minnu ka ɲi, minnu bɛ nɔgɔya, ani minnu bɛ mɔgɔ ɲɛnajɛ, olu ka kan ka kɛ, TIG ye fɛɛrɛ ɲuman ye. Tig weldaw bɛ kɛ ka caya ka ɲɛsin finiw masirili ma walima porozɛw ma minnu bɛ fini saniyalen ɲini. MIG welds, hali ni u barika ka bon, a bɛ se ka kɛ ko a bɛ kɛ ni baara kɔfɛta ye walasa ka se ka ɲɛnajɛko sɛgɛsɛgɛli hakɛ kelen sɔrɔ.

Sɛnɛ teliya ni baarakɛcogo ɲuman .

Porozɛw kama minnu bɛ fɛn dilanni teliya la , MIG welding ye setigi jɛlen ye. A ka juru min bɛ to senna, o bɛ kɛ sababu ye ka welding teliya, o b’a to a bɛnnen don izinibaw ma . TIG welding kɔni bɛ teliya ka da a ka bololabaara kan, o b’a to a tɛ baara kɛ kosɛbɛ baara caman na nka a ka ɲi kosɛbɛ baara tigitigi la.

Seko ni dɔnko hakɛ min bɛ sɔrɔ welda la .

Welda ka seko hakɛ bɛ nɔba bila sugandili la. MIG welding kalanni n’a baara ka nɔgɔn, o b’a to a bɛ kɛ sugandi ɲuman ye daminɛbagaw fɛ walima fɛn dilanni sigidaw la minnu ka welda minnu tɛ ko dɔn kosɛbɛ. TIG welding, nka, a bɛ seko caman de wajibiya, i n’a fɔ molten pool control , wire feeding, ani senna pedal coordination, o b’a to a bɛnnen don kosɛbɛ weldalaw ko dɔnbagaw ma ..

baarakɛnafolo ni musaka jateminɛw .

Budjet ye ko kɔrɔba wɛrɛ ye. MIG welding caman bɛ na ni minɛnw musaka dɔgɔyali ye ani fɛn minnu bɛ se ka kɛ, o b’a to a bɛ kɛ fɛɛrɛ ye min musaka ka dɔgɔ porozɛbaw la. TIG welding, k’a sɔrɔ a bɛ welda ɲumanw di, a ka teli ka kɛ ni minɛnw ni baara musakaw ye minnu ka bon ka da a kan a bɛ se ka kɛ ko a bɛ se ka kɛ.

Tabali kuncɛlen: Fɛn minnu bɛ nɔ bila MIG ni TIG sugandili

| factor |

MIG welding |

welding . |

| Matériel suguya & a ka bon . |

Fɛn minnu ka bon (Steel, Aluminium) . |

Fɛn finmanw (nɛgɛ nɔgɔlen, titanium) . |

| Weld qualité & yecogo . |

Strong, bɛ se ka kɛ ni post-processing ye . |

Fini min ka bon, a saniyalen don . |

| Production Speed . |

Teliya, min bɛnnen don sɛnɛfɛnw dilanni ma . |

A ka surun, a ka ɲi kosɛbɛ welda tigitigiw kama . |

| Welder ka seko ni dɔnko hakɛ . |

A ka nɔgɔn ka kalan kɛ, a ka ɲi daminɛbagaw ma . |

A bɛ seko kɔrɔw de wajibiya . |

| Budjet & musaka . |

Minɛnw ni baara musakaw dɔgɔyali . |

musaka camanba ka da a kan a ka ɲi ani a ka gɛlɛn . |

Lakanali fɛɛrɛw MIG ni TIG welding .

welding, a kɛra MIG ye wo, a kɛra TIG ye wo, a bɛ faratiba lase mɔgɔ ma, o b’a to a nafa ka bon kosɛbɛ ka fɛɛrɛ ɲumanw tigɛ. Lakanali fɛɛrɛ jɔnjɔnw bɛ duguma walasa ka welding sigida lakanalen sɔrɔ.

Mɔgɔ yɛrɛ lakanani minɛnw (PPE) .

PPE ɲuman nafa ka bon walasa ka weldaw tanga jeninida ma, kuran sɔgɔli, ani sisi juguw ma. Fɛn minnu ye fɛnba ye, olu ye:

Welding kasɛti ni ɲɛda lakanani : Kasɛti bɛ i ɲɛw ni i ɲɛda tanga yeelenba ma min bɛ sɔrɔ welding waati la. Face Shields bɛ dɔ fara a lakanani kan.

Fini ni bolokɔniw bɛ se ka tasuma kunbɛn : weldaw ka kan ka jakitew ni bololanɛgɛw don minnu bɛ se ka tasuma bɔ walasa ka u yɛrɛ tanga jeninida ma. Koton walima jiribuluw bɛ baara kɛ ka ɲɛ walasa ka tasumamuguw bali ka tasuma minɛ.

Lakanali butikiw : Tasuma bɛ butiki minnu na ni nɛgɛ senkɔniw ye, olu bɛ senw tanga fɛn girinmanw ma, sɔgɔsɔgɔninjɛw, ani nɛgɛ wulilen.

Baarakɛyɔrɔ lakanani .

Baarakɛyɔrɔ lakananen nafa ka bon i n’a fɔ mɔgɔ yɛrɛ lakanani. Nin fɛɛrɛ ninnu bɛ dɛmɛ ka welding yɔrɔ dɔ labɛn min tɛ farati ye:

Fiɲɛ bilali ka ɲɛ : Welding bɛ bagajiw lawuli. Aw ye aw jija aw ka baarakɛyɔrɔ ka fiɲɛ bila ka ɲɛ walasa ka sisi fiyɛli bali, o bɛ se ka kɛ sababu ye ka ninakiliko gɛlɛyabaw lase aw ma.

Tasuma kunbɛnni fɛɛrɛw : Aw bɛ tasumafagalanw bila u kɛrɛfɛ ani ka fɛnw yɔrɔ jɛya minnu bɛ se ka tasuma bɔ. Sogow bɛ se ka tasuma don joona ni u donna fɛn faratilenw na.

Kuranko lakanani .

MIG ni TIG fila bɛɛ bɛ kuran kuranw kɛ, ka kuran sɔgɔli farati jira ni u ma ɲɛnabɔ ka ɲɛ. Aw ye nin laadilikanw labato:

Dugukolo ni a laminiko : Aw bɛ aw jija tuma bɛɛ ko welding masinw bɛ dugukolo kan ka ɲɛ ani ko kuran yɔrɔw bɛɛ lajɛlen don walasa u kana kurukuru.

Aw bɛ aw yɛrɛ tanga kuran sɔgɔli faratiw ma : Aw kana maga elekitorode walima nɛgɛ yɔrɔw la abada ni aw bɛ baara la. Ka fara o kan, aw bɛ aw ka minɛnw to u ka ja ani ka aw yɛrɛ tanga welding ma ji la walasa ka dɔ bɔ u ka sɛgɛn na.

Rundown: Mig ni TIG welding .

Mig ni TIG welding kelen-kelen bɛɛ bɛ ni jogo kabakomaw ni balilanw ye. MIG welding bɛ teliya, a bɛ bɛn fɛnw ma minnu ka bon, wa a bɛ ɲɛ kosɛbɛ amatɛriw fɛ. Tig welding, hali ni a ka surun, a bɛ tiɲɛni ni dusukunnata caman di minnu tɛ se ka suma ni ɲɔgɔn ye.

Fɛɛrɛ kelen-kelen bɛɛ nafaw n’a wajibiyalenw faamuyali b’i dɛmɛ ka fɛɛrɛ ɲuman ta i ka baara la. Miiri fɛnw suguya la, welda jogo ɲuman, ani dacogo dɔnniya la ka sɔrɔ ka sugandi MIG ni TIG cɛ.

Reference sources .

Mig welding .

Gazi tungsten arc welding .

China CNC Machining baarakɛlaw ka fisa .