Polymethyl methacrylate, ɔ PMMA, na wan versatile sintetik polima. Dɛn sabi am as akrilik, pleksiglas, ɔ ɔrganik glas, i de rivɔlɔshɔn difrɛn industri dɛm.

Frɔm ɔtomotiv to kɔnstrɔkshɔn, PMMA in yon prɔpati dɛn de mek i rili impɔtant. Insai dis post, wi go explor PMMA in kwaliti, aplikeshon, en wai e bi impotant fo modna manufakchurin.

Wetin na PMMA?

PMMA, ɔ polymethyl methacrylate, na wan versatile sintetik polima. I sabi fɔ in remarkabl klia ɛn di tɛm we i go de fɔ lɔng tɛm. Dis transparent, rigid thermoplastic de sav as wan ekselent alternativ to glass en Polikabɔnɛt ..

Bɔku tɛm dɛn kin kɔl am Acrylic ɔ Plexiglas, PMMA bost impɔtant prɔpati dɛn:

Layt wet (40% layt pas glas)

Shatter-resistant (10 tɛm strɔng pas rɛgyula glas)

High layt transmishɔn (92% layt pas tru)

UV ɛn wɛda-rɛsistɛns .

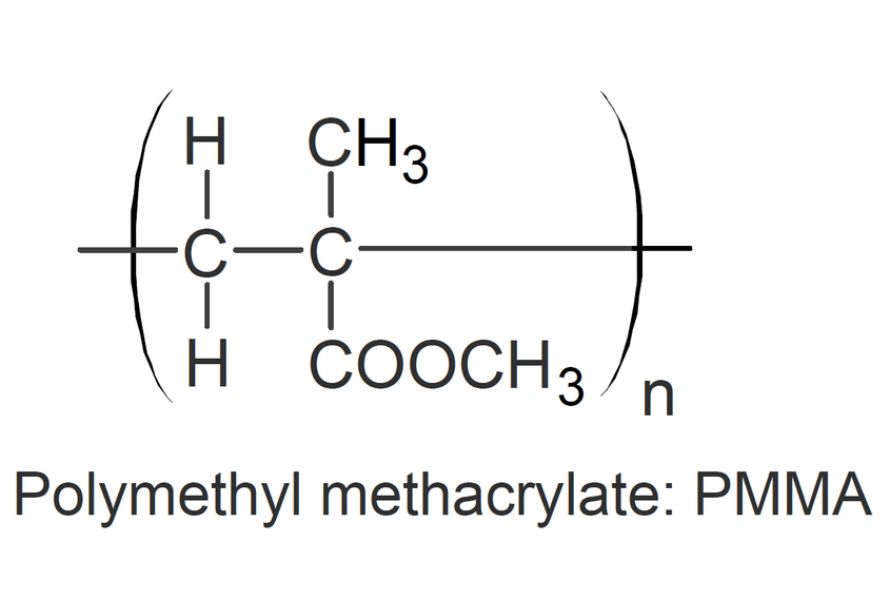

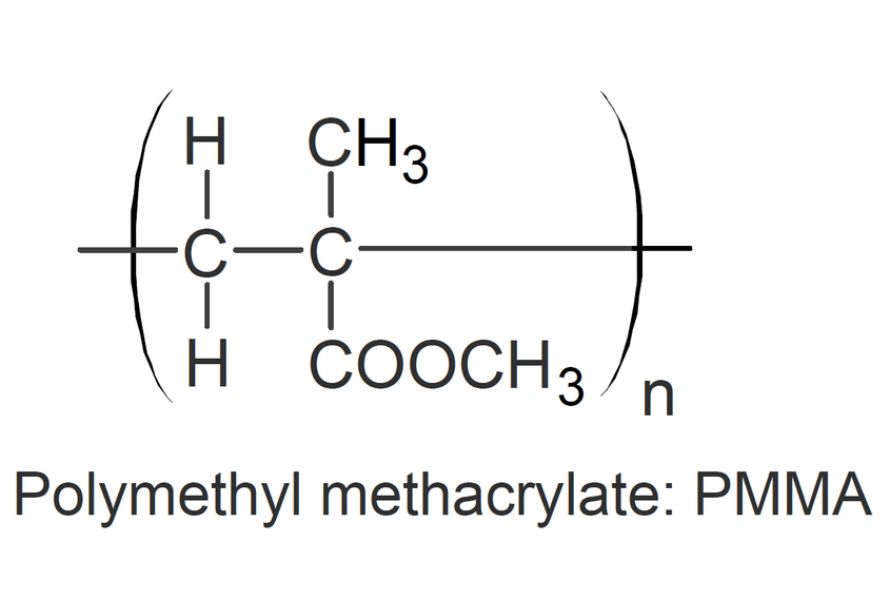

Molekyular Struktrɔ .

na in kכr, PMMA de fכm frכm mεtil mεtakrilet (MMA) mכnomεr dεm. Di molkyular fomula fɔ MMA na C5H8O2 ɔ CH2=CCH3COOCH3.

Struktrɔ fɔ PMMA Plastik .

PMMA in strɔkchɔ de kɔntribyut to in yon kwaliti dɛn:

Faybrɔs mɔlikul arenjmɛnt .

Spatial netwok konfigyushɔn .

Linear polimer wit ester bonds .

PMMA de sheb sɔm tin dɛn we fiba wit ɔda plastic dɛn lɛk Pet ɛn . PS in terms of transparency ɛn versatility. Bɔt i gɛt in yon spɛshal prɔpati dɛn we de mek i fayn fɔ sɔm patikyula aplikeshɔn dɛn. Fɔ no mɔ bɔt aw dɛn kin prosɛs PMMA, yu go want fɔ lan bɔt Akrilik injɛkshɔn moldin ..

Prɔpati dɛn fɔ PMMA (Akrilik) .

Fizik prɔpati dɛn fɔ PMMA

| prɔpati | valyu/diskripshɔn |

| Tik | 1.17-1.20 g/cm³ |

| Optik Klarity . | 92% layt transmitans . |

| Surface Hardness . | Ay |

| skrach resistans . | Gud (bɛtɛ pas ɔda transparent polimɛr dɛn lɛk polycarbonate, bɔt smɔl pas glas) |

| We | 40% layt pas glas . |

| UV resistans . | Eksɛlɛnt rɛsistɛns to UV raytin . |

| Wettering resistans . | Ay resistans fɔ wɛda . |

| Transparency . | I fayn (we nɔ gɛt kɔlɔ ɛn we nɔ gɛt kɔlɔ ɛn we klia) |

| Rifrakt indeks . | 1.49 |

Mekanikal prɔpati dɛn fɔ PMMA

| Mɛkanikal Prɔpati | Diskripshɔn . |

| Tensile Strɔng . | 65 MPa / 9400 psi |

| Flekshɔnal trɛnk . | 90 MPa / 13000 psi |

| Tensile modulus na na na na na na na na na na na na na na na na na na . | 2300-3300 MPA |

| Surface Hardness . | Ay |

| Impɛkt rɛsistɛns . | Lɔwa we yu kɔmpia am to sɔm plastic dɛn, bɔt i ay pas glas . |

| skrach resistans . | Gud (bɛtɛ pas ɔda transparent polimɛr dɛn lɛk polycarbonate, bɔt smɔl pas glas) |

| Dimenshɔnal stebiliti . | Gud (bikɔs ɔf di lɔw mɔstɔ absɔpshɔn) |

| Toughness . | Modaret (homopolymers na brital, copolymers na tof) |

| Stifnɛs . | Ay |

| Fatigue Biɛvhɔ . | kin obsכv frכm di Wöhler kεrv כf flכkshכn strכng versus nכmba כf saykl dεm . |

| Brittleness . | de kɔntinyu fɔ brit ivin we di ples ay pasmak . |

Tɛmral prɔpati dɛn fɔ PMMA

| Tɛmral prɔpati | valyu/diskripshɔn |

| Glas transishɔn tɛmpracha . | 106°C (we go rich 115°C fɔ di kɔst blank dɛn) |

| Tempracha we de sof (Vicat B) . | 84-111°C (dipen pan min molar mas) |

| Tempracha we de mek di ples wam . | 95°C / 203°F (@ 0,46 mpa/66 psi) |

| Maksimal fɔ yuz di tɛmpracha fɔ lɔng tɛm . | i go rich 70°C . |

| Oto-ignishɔn tɛmpracha . | 400-465°C na di |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | 60-80°C (Jɛnɛral Rɛnj) |

| Tɛmral ɛkspɛnshɔn . | ay pas glas ɔ mɛtal . |

| Flamabiliti fɔ mek yu bɔdi bɔn . | I izi fɔ bɔn (UL 94 HB klasifikeshɔn) |

| Tempracha we de mɛlt (fɔ prosɛs) . | 200-250°C (injekshɔn moldin) |

| Tempracha fɔ ɛkstrushɔn . | 180-250 ° C . |

| Tɛmpratura we dɛn kin gɛt we dɛn de yuz tɛmfɔm . | 150-180°C (we go rich 200°C fɔ ay molar mas tayp) |

Kεmikכl rεsistεns כf PMMA

| Kεmikכl rεsistεns | diskripshכn . |

| Resistant to . | |

| nɔ de agens . | |

| Speshal vulnerabilities . | Susceptible to strɛs kɔrɛshɔn krak krak . I kin pwɛl bay sɔm sɔlvɛnt dɛn lɛk H2O2, asɛtɔn, alkol . |

| Weta nɔ de . | Eksɛlɛnt rɛsistɛns to wɛda ɛn ɔltra vayolɛt raytin . |

| Wata absɔpshɔn . | Lɔw mɔstɔ ɛn wata absɔpshɔn . |

| Salt Wata Resistance . | We Saltwater nɔ afɛkt am . |

Ilektrikal prɔpati dɛn fɔ PMMA

| Ilɛktrik Prɔpati | Diskripshɔn . |

| Ilektrikal insuleshɔn . | Gud ilektrikal insulator, espeshali na low frequencies . |

| Ay Frikyuɛnsi Pɛfɔmɛns . | Dis dɔŋ ya polietilen ɛn polistayn insay insulin kapabiliti dɛn . |

| Loss Factor . | I de kɔntinyu fɔ stebul we dɛn de yuz am nɔmal wan . |

| Surface resistans . | I de kɔntinyu fɔ stebul we dɛn de yuz am nɔmal wan . |

| Suitabli we yu go fit fɔ . | Advantej fɔ prodyuz pat dɛn na di ilɛktrik industri . |

| Statik chaj . | Prone to surface chaj krieshɔn . |

| Antistatik prɔpati dɛn . | Bɔku tɛm dɛn kin nid fɔ ad antistatik aditiv dɛn . |

| Dielectric strength . | Ay |

| Dissipeshɔn faktɔ . | Lo |

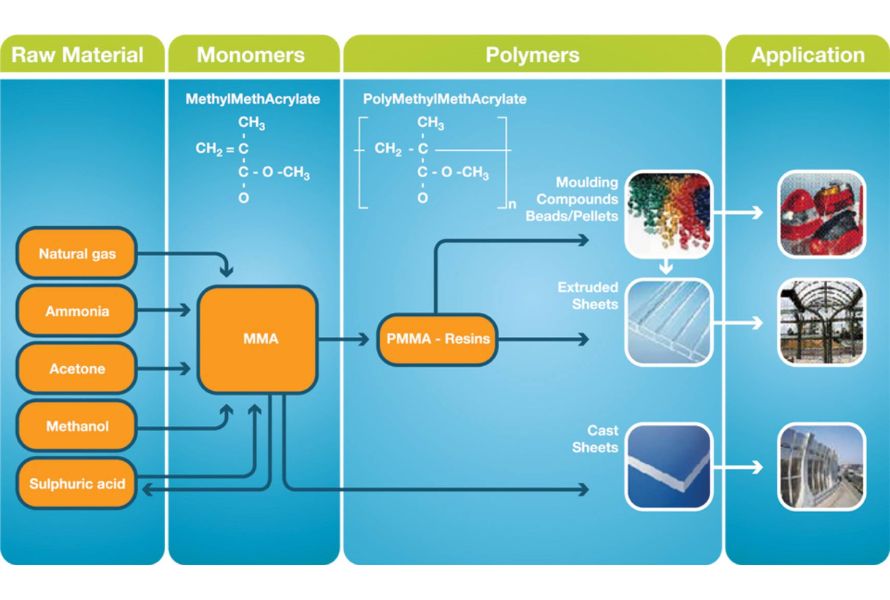

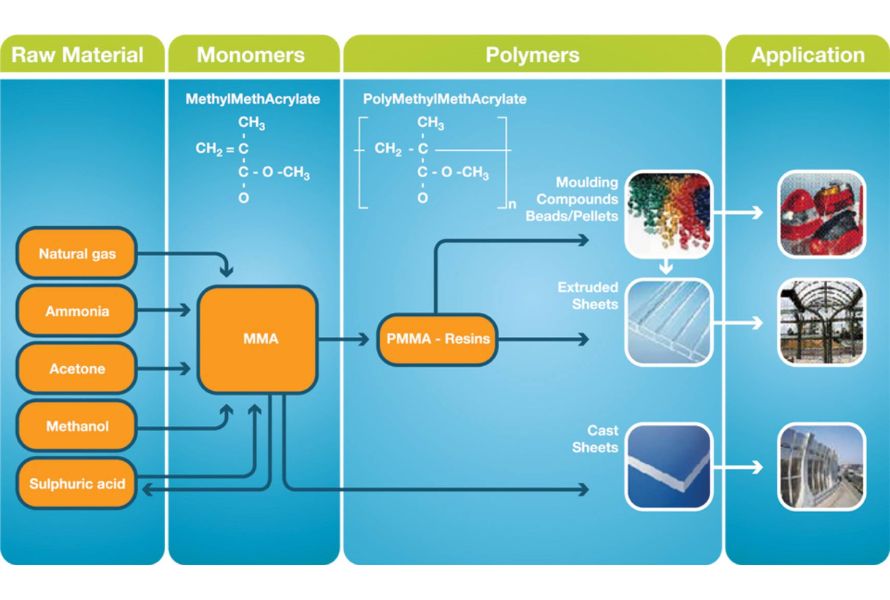

Prodakshɔn fɔ PMMA .

PMMA, ɔ akrilik, dɛn kin mek am bay we dɛn de polimayz mɛtil mɛtakrilɛt (MMA). MMA na wan ɔrganik kɔmpawnd wit di fɔmula CH2=C(CH3)COOCH3. Na wan likwid we nɔ gɛt kɔlɔ, we nɔ gɛt smel.

Polimerizayshɔn fɔ MMA .

Di polimayzayshɔn fɔ MMA kin bi bay we dɛn yuz difrɛn we dɛn:

Tɛmral polimɛrayzeshɔn .

Mɔs kɔmɔn we fɔ PMMA prodakshɔn .

MMA de hot to 100-150°C .

Na dis tempɔret, MMA mɔlyul dɛn kin jɔyn fɔ mek polima chen dɛn .

Katalytik polim i s i s i s .

Radieshɔn polimɛrayzeshɔn .

Di choice of polimayzayshɔn mɛtɔd dipen pan di prɔpati dɛn we dɛn want ɛn ɛnd-yuz aplikeshɔn dɛn fɔ di PMMA.

Sos frɔm Europlas .

Fɔmeshɔn fɔ PMMA Prodakt dɛn .

afta polimεrayzeshn, PMMA kin fכm insay difrεnt shep dεm:

Shit ɛn blɔk dɛn .

Na sɛl kastin ɔ ɛkstrushɔn de prodyuz am .

Dɛn kin yuz am fɔ aplikeshɔn dɛn lɛk sayn dɛn, akwariɔm dɛn, ɛn glazing .

Bid dɛn .

Resin dɛn .

Di fɔmɛshɔn prɔses de inflɔws di fayn fayn prɔpati dɛn fɔ di PMMA prodak. fכ egzampl, sεl-kכst shit dεm gεt supεriכr optik klia wan we yu kכmpεr to εkstrud wan dεm.

MMA na di kכpכlimεrayzeshn fכ akrilכyl klorayd wit mεtanכl de prodyuz am. Dis prכsεs de mek sכh se wan hכy-puriti monomכr fכ PMMA prodakshכn.

Di thermal ɛn katalytik polimayzayshɔn mɛtɔd dɛn na di wan dɛn we dɛn kin yuz mɔ na di industri. Dɛn de gi gud balans fɔ prodakshɔn efyushɔn ɛn prodak kwaliti.

Radieshɔn polimayzayshɔn, pan ɔl we nɔto kɔmɔn, de gi yunik advantej dɛn. I alaw fɔ prɛsis kɔntrol oba di polimayzayshɔn prɔses ɛn i kin prodyuz PMMA wit spɛshal prɔpati dɛn.

Di we aw dɛn de du di wok fɔ PMMA plastic .

PMMA kin prosɛs yuz difrɛn we dɛn, i dipen pan di shep ɛn prɔpati dɛn we dɛn want fɔ di fayn prodak.

Moldin fɔ injɛkshɔn .

Melt PMMA na injekt insay wan mold cavity .

Alaw fɔ kɔmpleks shep dɛn wit ay prɛsishɔn .

Advantej: Fast, efishɔnal, ɛn fayn fɔ mas prodakshɔn

Fɔ no mɔ bɔt dis prɔses, yu kin rifer to wi gayd bɔt Akrilik injɛkshɔn moldin ..

Mold dizayn kɔnsidareshɔn dɛn .

Draft angles fɔ mek i izi fɔ pul pat pan am .

Yunifom wall tik fɔ ivin kol .

Di rayt we fɔ gɛt ɛn vent fɔ mek dɛn nɔ gɛt prɔblɛm dɛn .

Trobul fɔ sɔlv di prɔblɛm dɛn we kɔmɔn .

Sink mak dɛn: we dɛn mek bay tik wɔl ɔ we nɔ gɛt bɛtɛ kol

Warping : Bikɔs ɔf di kol we nɔ ivin ɔ we gɛt ay molding strɛs .

Burn Marks: Rizult frɔm ɔva ɔt ɔ trɔp ɛya

Fɔ si wan kɔmprɛhnsiv list fɔ di tin dɛn we kin apin, chɛk wi gayd pan Injɛkshɔn Moldin Difɛkt dɛn ..

Ki aspek dɛn .

Pre-Drying PMMA fɔ mek dɛn nɔ gɛt prɔblɛm dɛn we gɛt fɔ du wit di wata we gɛt wata .

Kontrolin prosesin temperechur (200-250°C)

Disain Draft Angles (1-2°) fɔ mek i izi fɔ kɔmɔt na di wɔl.

Annealing molded parts fɔ rilivu insay strɛs dɛn .

Fɔ mek shɔ se dɛn gɛt ay kwaliti rizɔlt, i rili impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt di rayt . Injekshɔn moldin tolɛreshɔn dɛn ..

Ekstrushɔn .

PMMA na melt ɛn fos tru wan day .

I de prodyuz kɔntinyu prɔfayl ɔ shit dɛn .

Advantej dɛn: Kɔst-ɛfɛktiv fɔ lɔng, kɔnsistɛns shep dɛn

day dizayn ɛn kalibreshɔn .

Daunstrim Prɔses dɛn .

Cutting Extruded Profiles to Desired Lengths .

Drilling holes ɔ mil ficha dɛn .

Sɛkɔndari ɔpreshɔn dɛn lɛk fɔ bɛn ɔ fɔm .

Tɛmofɔmin .

Itin PMMA sheet dɛn te dɛn pliable .

Fɔ shep di sheet oba wan mol we yu de yuz vaykum ɔ prɛshɔn .

Advantej dɛn: Big, tin-wɔl pat dɛn wit kɔmpleks kɔv dɛn

Mold matirial ɛn di we aw dɛn de ɔt .

Dɛn kin mek mol frɔm wud, aluminiɔm, ɔ kɔmpɔzit matirial dɛn .

Di we aw dɛn kin yuz fɔ ɔt di sik na infrarɛd, kɔnvɛkshɔn, ɛn kɔntakt itin .

Trim ɛn finish .

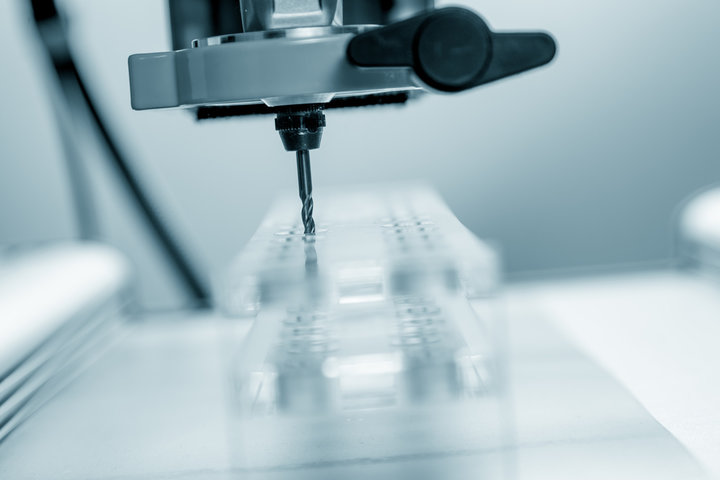

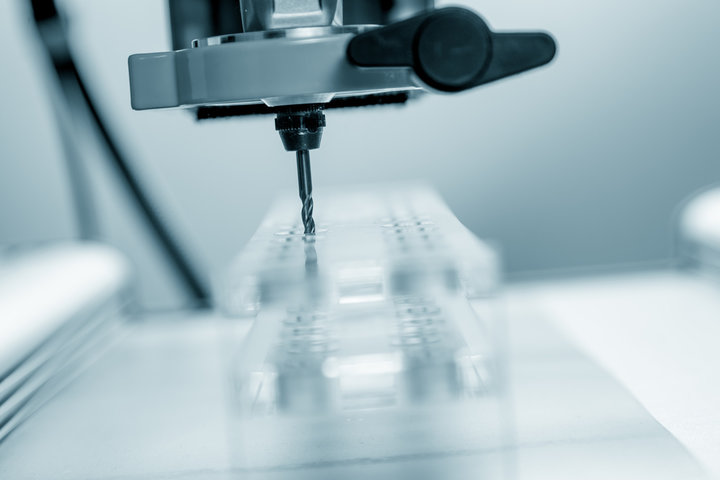

Machin ɛn Fabrikeshɔn .

PMMA kin bi mashin bay we dɛn de yuz kɔvɛnshɔnal tul dɛn .

Fɔ kɔt, drɔ, ɛn mil na kɔmɔn opareshɔn dɛn .

Advantej: Versatile ɛn fayn fɔ smɔl batch ɔ protɔtayp dɛn .

Laser we dɛn de kɔt ɛn we dɛn rayt fɔ rayt .

Polishing ɛn sɔfayz tritmɛnt .

Bɔndin ɛn Asɛmbli .

PMMA pat dɛn kin jɔyn yuz difrɛn we dɛn fɔ du tin .

Sɔlvɛnt wɛldin: Yuz sɔlvɛnt fɔ sɔlv ɛn fiuz pat dɛn togɛda

Simen bonding: Yuz PMMA-kompatibl adhesives .

Mechanical fastening ɛn snap-fit dɛn .

Yuz skru, bolt, ɔ snap-fit jɔyn .

Alaw fɔ disassembly ɛn riples di pat dɛn .

Ovamold ɛn insay moldin .

Molding PMMA ova wan ɔda matirial ɔ kɔmpɔnɛnt .

Krio wan strɔng, intagreted bond bitwin di matirial dɛn .

Fɔ no mɔ bɔt dis tɛknik, si wi gayd bɔt Insert fɔ mol ..

Di we aw dɛn kin pik di we aw dɛn kin pik di we aw dɛn de du di wok kin dipen pan tin dɛn lɛk:

Fɔ no di rayt tin dɛn we dɛn kin du wit di injɛkshɔn moldin prɔses, luk na wi gayd pan . Fɔmula fɔ kɔlkyulɛshɔn fɔ injɛkshɔn moldin ..

ɛnhans PMMA matirial prɔpati dɛn .

PMMA na plastic we gɛt bɔku tin dɛn fɔ du, bɔt sɔntɛnde i kin nid fɔ gɛt bɔst fɔ mit sɔm patikyula aplikeshɔn dɛn we dɛn nid. Na de aditiv kam in. Dem kin enhans PMMA in propati, mek am ivin mo yusful.

Impekt modifya dɛn .

Inkris PMMA in taf ɛn impak rɛsistɛns .

Ideal fɔ sef glazing ɛn ay-impakt aplikeshɔn dɛn .

Ɛgzampul dɛn: Rɔba patikyula dɛn, kɔr-shɛl modifya dɛn

UV stɛbyulayza dɛn .

Protɛkt PMMA frɔm yɔlɔ ɛn dɛgradishɔn we kɔmɔt frɔm UV ɛksplɔshɔn .

Essential for outdoor applications ɛn fɔ lɔng tɛm yuz .

Kɔmɔn UV stebyulayza dɛn: bɛnzotriazol dɛn, bɛnzɔfɛnɔn dɛn, Hal dɛn

Plastikiza dɛn .

Ɛnjɔy PMMA in fleksibiliti ɛn sɔftnɛs .

Yusful fɔ aplikeshɔn dɛn lɛk kɔntakt lɛns ɛn fleksibul displei dɛn

Ɛgzampul dɛn: Dibutyl Phthalate, Dayɔktil Ftalɛt, Butyl Bɛnzil Ftalɛt

Kolorant ɛn days .

Ad kala to PMMA fɔ dɛkɔretiv ɛn funkshɔnal pɔpɔshɔn dɛn

kin mek transparent, translucent, ɔ opaque hues .

Tayps: Ɔrganik day, inɔgɛnɛk pigmɛnt, spɛshal ifɛkt pigmɛnt

Ko-monomers .

Modify PMMA in prɔpati dɛn bay we yu inkɔrpɔret ɔda monomɛr dɛn .

Methyl acrylate de improve thermal stabiliti ɛn ridyus dipolymerization di tɛm we dɛn de prosɛs .

Ɔda pipul dɛn we de wok wit di kɔmni: Ethyl Acrylate, Butyl Acrylate, Styrene

Filla dɛn .

Impruv PMMA in trɛnk, stiffnɛs, ɛn dimɛnshɔnal stebiliti

Ridyus di kɔst bay we yu chenj wan pat pan di polima .

Ɛgzampul dɛn: Glas Fayba, Kabon Fayba, Minral Fila

Dis aditiv dεm de inkכrporayt di tεm we di polimεrayzeshn prכsεs de כ tru kכmpawnd. Di choice of aditiv dipen pan di spesifik prɔpati ɛnhansmɛnt we dɛn nid.

| Aditiv | f ɔ nksh ɔ n . |

| Impekt modifya dɛn . | Inkris taf ɛn impak rɛsistɛns . |

| UV stɛbyulayza dɛn . | Protɛkt frɔm yɔlɔ ɛn dɛgradishɔn frɔm UV ɛksplɔshɔn . |

| Plastikiza dɛn . | Ɛnjɔy fɔ mek yu ebul fɔ chenj ɛn fɔ mek yu ebul fɔ du saful saful . |

| Kolorant & Dyes . | Ad kala fɔ dɛkɔretiv ɛn funkshɔnal pɔpɔshɔn dɛn . |

| Ko-monomers . | Modify prɔpati dɛn lɛk tɛmral stebiliti . |

| Filla dɛn . | Impruv trɛnk, stiffness, ɛn kɔst-ɛfɛktiv . |

Bay we dɛn pik di rayt aditiv dɛn ɛn optimiz dɛn kɔnsɛntreshɔn, di wan dɛn we de mek dɛn kin tayla PMMA in prɔpati dɛn fɔ fit spɛshal aplikeshɔn dɛn. Dis kɔstɔmayshɔn de ɛkspɛn PMMA in yusfulnɛs akɔdin to difrɛn industri dɛn.

I impɔtant fɔ no se pan ɔl we aditiv kin ɛp fɔ mek sɔm prɔpati dɛn bɛtɛ, dɛn kin gɛt trade-ɔf bak. Fɔ ɛgzampul, if yu ad impak modifya dɛn, i kin ridyus di transparency smɔl. Fɔ tek tɛm fɔmyuleshɔn nid fɔ balans di prɔpati dɛn we yu want.

Di kayn PMMA dɛn .

PMMA kin kam insay difrɛn kayn dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn prɔpati ɛn aplikeshɔn dɛn. Lɛ wi fɛn sɔm pan di kayn dɛn we dɛn kin yuz mɔ.

Standart PMMA .

Di kayn PMMA we dɛn kin yuz mɔ .

Ofa ekselent optik klarity en weda resistans .

Ideal fɔ jenɛral-pɔpɔs aplikeshɔn dɛn .

Displei Kes dɛn .

Windo dɛn .

Lens dɛn .

Impact-modified PMMA .

Blended wit impak modifya fɔ inkris tafnɛs .

Mentɛn ay levul fɔ transparency .

I fayn fɔ gɛt ay-impakt aplikeshɔn dɛn .

Sef Glazing .

Protektiv baria dɛn .

PMMA we nɔ de tek UV .

PMMA we dɛn dɔn pul kɔmɔt na di bɔdi .

Prodyuz tru extrusion proses .

Mek shɔ se yunifom tiknes ɔlsay .

Dɛn kin yuz am mɔ fɔ mek kɔntinyu prɔfayl dɛn .

Shit dɛn .

Rod dɛn .

Tub dɛn .

Cast PMMA .

Dɛn mek am bay we dɛn de tɔn likwid PMMA rɛsin insay mol dɛn .

Rizult in supia optik klarity .

Tipikli yuz in aplikeshɔn dɛn we nid ay kwaliti sɔfays dɛn .

PMMA we gɛt kɔlɔ .

I de insay difrɛn transparent ɛn opaque kɔlɔ dɛn .

Serves decorative ɔ functional purposes .

Bɔku tɛm dɛn kin yuz am na:

PMMA we nɔ de ɔt .

Fɔmulayt fɔ ɛnhans ɔt rɛsistɛns .

I fayn fɔ gɛt ay tɛmpracha aplikeshɔn dɛn .

Yuz usay tipik PMMA go soft ɔ difɔm .

Na dis wan na wan kwik kɔmpiashɔn tebul:

| Tayp | Ki Prɔpati dɛn | Kɔmɔn Aplikeshɔn dɛn |

| Standart PMMA . | Ekselent optik klarity, weta resistans . | Displei kes, winda, lens dɛn . |

| Impact-modified . | Inkris taf, mentein transparency . | Sef Glazing, Protective Barriers . |

| UV-Isistɛnt . | Resists yellowing ɛn degradation frɔm UV ɛksplɔshɔn . | Skylights, Sayn, Ɔtomotiv Pat dɛn |

| Extruded . | Yunifom tik, kɔntinyu prɔfayl dɛn . | Sheets, rod dɛn, tiub dɛn . |

| Plasta | Superior Optik Klarity, ay-kwaliti sɔfays dɛn . | Medikal Divays, Optik lens dɛn . |

| Kɔlɔred . | Difrɛn transparent ɛn opaque kɔlɔ dɛn . | Sayn, Displei, Kɔnsuma Guds |

| I nɔ de mek di ples wam . | Enhansed heat resistans, we fit fɔ ay temps . | Aplikeshɔn dɛn usay tipik PMMA go soft/difɔm . |

Aplikeshɔn dɛn fɔ PMMA Plastik .

PMMA in versatility mek am wan pɔpul choice across difrɛn industri dɛm.

Ɔtomotiv Indastri .

Di ay-ɛnd motoka ɛdlayt kɔva dɛn .

Instrument panɛl ɛn displei dɛn .

Intɛriɔ trim ɛn dɛkɔretiv ɛlimɛnt dɛn .

Fɔ no mɔ bɔt plastic aplikeshɔn dɛn na di ɔtomotiv industri, chɛk wi gayd pan Awtomotiv Pat ɛn Kɔmpɔnɛnt dɛn Manufakchurin ..

Indastri fɔ Erospɛs .

Lan mɔ bɔt Aerospace aplikeshɔn dɛn na wi Aerospace Parts and Components Manufacturing Guide.

Optiks ɛn aywɛr .

Kɔnstrɔkshɔn ɛn Akitekchɔ .

Skylights ɛn ruf dome dɛn .

Nɔys barɛri ɛn sawnd wɔl dɛn .

Panel dɛn we dɛn kin mek fɔ dekɔret ɛn fasad dɛn .

Ilɛktronik ɛn Layt .

Divays dɛn fɔ mɛn pipul dɛn .

Bɔn simen ɛn dɛnt prɔstɛtiks .

Intraokular lens ɛn kɔntakt lens dɛn .

Diagnostik ikwipmɛnt ɛn ɔspitul tul dɛn .

Fɔ no mɔ bɔt aw fɔ mɛn pipul dɛn, luk wi gayd fɔ Medikal Divays Komponents Manufakchurin ..

Sayn ɛn displei dɛn .

Sayn dɛn we gɛt layt ɛn layt bɔks dɛn .

Point-of-Purchase Displays and Showcase dɛn .

Miusiɔm Ɛgzibit ɛn At Instɔlɛshɔn dɛn .

Sourcing frɔm U-nuo's . Akrilik kosmetik packaging purple airless lotion lotion pump botul

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Luks bathtub ɛn shawa ɛnklɔzhɔ .

Pikchɔ freym ɛn os dɛkɔ .

Akwariɔm ɛn Tɛrariɔm dɛn .

Trofi ɛn Awdhɔ .

Fɔ no mɔ bɔt kɔstɔma guds aplikeshɔn dɛn, chɛk wi Konsuma ɛn Durable Goods Manufacturing Guide.

| Indastri | Aplikeshɔn dɛn . |

| Ɔtomotiv . | Headlight Covers, Instrument Panels, Trim Intɛriɔ Trim |

| Aerospace na di . | Di winda dɛn we de na di plen dɛn kabin . |

| Optiks & aywɛr . | Blu layt blok lens dɛn . |

| Bil | Skylights, Noise Barriers, Decorative Panels |

| Ilɛktroniks . | LED/LCD skrin dɛn, layt difyuza dɛn, ɔptik fayba dɛn |

| Divays dɛn fɔ mɛn pipul dɛn . | Bon simen, intraokulo lens, surgical tools |

| Sayn ɛn Displei dɛn . | Sayn dɛn we gɛt layt, pop displei, myuziɔm ɛgzibit dɛn |

| Di guds dɛn we dɛn de yuz fɔ bay tin dɛn . | Luks bathtub, pikchɔ frem, akwariɔm, trɔfi |

PMMA in aplikeshɔn dɛn de kɔntinyu fɔ bɔku as di wan dɛn we de mek am de fɛn nyu we fɔ yuz in prɔpati dɛn. Di kɔmbaynshɔn fɔ klia, trɛnk, ɛn versatility de mek am go-to matirial fɔ dizayna ɛn injinia dɛn akɔdin to difrɛn fil dɛm.

PMMA plastic vs ɔda matirial dɛn .

We yu de pik wan matirial fɔ wan patikyula aplikeshɔn, i impɔtant fɔ kɔmpia di prɔpati dɛm fɔ PMMA wit ɔda kɔmɔn matirial dɛm. Lɛ wi tek tɛm luk aw PMMA de stak agens glas, polycarbonate, ɛn ɔda ɛnjinɛri plastic dɛn.

PMMA vs. glas .

PMMA vs. polycarbonate (PC)

Strɔng ɛn impak rɛsistɛns .

Optik klari ɛn wɛda rɛsistɛns .

Kεmikכl rεsistεns εn tεmral stεbiliti .

PMMA gɛt bɛtɛ kemikal rɛsistɛns, mɔ to asid ɛn sɔlvɛnt dɛn .

PC gɛt ay tɛmral rɛsistɛns ɛn i kin ebul fɔ bia wit ay tɛmpracha .

Kɔst ɛn prɔsesin .

PMMA na jɔs mɔ afɔdabul pas PC .

Dɛn kin prosɛs dɛn tu tin ya bay we dɛn yuz di sem we dɛn, lɛk fɔ injɛkshɔn moldin ɛn ɛkstrushɔn .

Fɔ no mɔ bɔt polycarbonate, yu kin chɛk wi gayd pan Pc Plastik ..

PMMA vs ɔda injinɛri plastic dɛn .

Fɔ no mɔ bɔt dɛn tin ya, yu kin rifer to wi gayd dɛn bɔt ABS Plastik ., Pɛt Plastik , ɛn . PA Plastik (naylɔn) ..

Na dis wan na wan kɔmpiashɔn tebul we de sɔmariz di men difrɛns dɛn:

| Prɔpati | PMMA | Glas | PC | ABS | PET | Nylon |

| Optik Klarity . | ★★★★★ | ★★★★★ | ★★★★ | ★ | ★★★ | ★ |

| Impɛkt rɛsistɛns . | ★★★ | ★ | ★★★★★ | ★★★★ | ★★★ | ★★★★ |

| Wettering resistans . | ★★★★ | ★★★ | ★★★ | ★★ | ★★★ | ★★★ |

| Kεmikכl rεsistεns . | ★★★★ | ★★★★ | ★★★ | ★★ | ★★★ | ★★★ |

| Tɛmral stebiliti . | ★★★ | ★★★★ | ★★★★ | ★★ | ★★★ | ★★★★ |

| Kost-ɛfɛktiv . | ★★★★ | ★★ | ★★★ | ★★★★ | ★★★ | ★★★ |

We yu de pik wan tin, tink bɔt di patikyula tin dɛn we yu aplikeshɔn nid fɔ du. Fakta dɛm lɛk transparency, impact resistance, weda stebiliti, kemikal resistans, tɛmral stebiliti, ɛn kɔst fɔ tek in kɔnt.

PMMA de gi wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn we de mek i fayn fɔ bɔku bɔku aplikeshɔn dɛn. I fayn fayn optik klia, UV resistans, ɛn kemikal rɛsistɛns bin mek i difrɛn frɔm bɔku ɔda injinɛri plastic dɛn.

Bɔt insay aplikeshɔn usay ekstrim impak rɛsistɛns ɔ ay-tɛmpracha stebiliti nid fɔ de, matirial dɛn lɛk polycarbonate ɔ naylon kin bi mɔ fit.

Fɔ no mɔ bɔt aw fɔ du dɛn tin ya, yu go want fɔ no mɔ bɔt wi gayd dɛn bɔt Akrilik injɛkshɔn moldin ɛn . Injekshɔn moldin mashin dɛn ..

Envairomɛnt ɛn sefty aspek dɛn fɔ PMMA plastic .

We yu de tink bɔt aw fɔ yuz PMMA, i rili impɔtant fɔ evaluate in envayrɔmɛnt impak ɛn sef aspek. Lɛ wi ɛksplɔrɔ PMMA in risaykulabiliti, tɔksisiti kɔnsyans, ɛn rilevɛns rigyuleshɔn ɛn standad.

Risayklabliti ɛn Sastaynabiliti .

Risayklin Mɛtɔd ɛn Chalenj dɛn .

PMMA na 100% we dɛn kin yuz bak

Risayklin kin bi tru payrolaysis ɔ depolymerization .

Di prɔblɛm dɛn we kin mit yu na fɔ sɔt, kɔntamin, ɛn kwaliti fɔ di tin dɛn we dɛn dɔn yuz bak .

Envairomɛnt impak ɛn ɛnaji kɔnsɔmshɔn .

Sastaynɛbul Prodakshɔn Initiativs .

Toxicity ɛn wɛlbɔdi prɔblɛm dɛn .

BPA-fri ɛn it kɔntakt sefty .

Kɔmbɔshɔn bayprɔdakt ɛn smok tɔksisiti .

Di wok we dɛn de du ɛn di we aw dɛn fɔ tek tɛm wit di tin dɛn we dɛn fɔ tek tɛm wit .

Rigyuleshɔn ɛn Stɛndad dɛn .

Na dis wan na wan tebul we de sɔmariz di men envayrɔmɛnt ɛn sefty aspek dɛm fɔ PMMA:

| aspek | ditil dɛm |

| Risayklabliti . | 100% we dɛn kin risaykul tru payrolaysis ɔ dipolimɛrizeshɔn . |

| Di impak we di envayrɔmɛnt gɛt . | I nid fɔ gɛt ɛnaji ɛn tin dɛn fɔ yuz; Fɔ mek dɛn ebul fɔ yuz di west fayn fayn wan impɔtant . |

| Food Kontakt Sefty . | BPA-fri ɛn FDA dɔn gri fɔ kɔntakt fɔ it |

| Kɔmbɔshɔn bayprɔdakt dɛn . | kin pul ɔt ɛn smok we dɛn bɔn am; Di rayt we fɔ mek faya nɔ bɔn . |

| Di wok we dɛn de du fɔ mek di wok go bifo . | Dɔst ɛn fyum kin mek pɔsin in bɛlɛ wam; PPE we dɛn dɔn rɛkɔmɛnd |

| Rich ɛn Rohs . | I de fala di Rich ɛn RoHS rigyuleshɔn dɛn . |

| ul 94 flammabiliti fɔ mek yu bɔdi bɔn . | UL 94 HB raytin; Flame-retardant additives kin mek faya resistans bɛtɛ . |

| ISO ɛn ASTM standad dɛn . | Difrɛn standad dɛn we dɛn yuz fɔ evaluate prɔpati ɛn pefɔmɛns . |

Dɔn

PMMA, ɔ akrilik, na plastic we dɛn kin yuz bɔku bɔku wan wit spɛshal prɔpati dɛn. I de gi fayn fayn transparency, durability, ɛn weta resistans. PMMA kin ɛnhans wit aditiv ɛn prosɛs yuz difrɛn we dɛn fɔ fit spɛshal aplikeshɔn dɛn.

Fɔ pik di rayt tin impɔtant fɔ mek dɛn ebul fɔ mek di prɔdak fayn fayn wan. PMMA in prɔpati dɛn mek am fayn fɔ ɔtomotiv, kɔnstrɔkshɔn, mɛdikal, ɛn kɔshɔma guds aplikeshɔn dɛn.

Tips: Yu maybe intres to di ol plastics