Yu dɔn ɛva wɔnda aw dɛn de mek prɛsishɔn plastic pat dɛn wit dis kayn kɔrɛkt? Di sikrit de insay di injɛkshɔn moldin noz. Dis impɔtant pat de mek shɔ se di plastic flɔ we dɔn rɔtin de flɔ fayn fayn wan frɔm di mashin in barɛl insay di mol. If i nɔ bin de, fɔ ebul fɔ gɛt kɔnsistɛns kwaliti na di prɔdak dɛn we dɛn dɔn mol nɔ go pɔsibul.

Insay dis kɔmprɛhɛnsif gayd, wi go dayv dip insay di wɔl fɔ injɛkshɔn moldin nɔz. Yu go lan bɔt dɛn difrɛn kayn dɛn, di men kwaliti dɛn, di kɔmɔn tin dɛn we nɔ fayn, ɛn di bɛst we fɔ mek dɛn kɔntinyu fɔ de.

Jɛnɛral Introdyushɔn fɔ Injɛkshɔn Mɔldin Nɔzl dɛn .

Injɛkshɔn moldin noz na di ki fɔ shep ɛn dayrɛkt molten plastic frɔm di mashin insay di mold. Bɔt nɔto ɔl di noz dɛn we dɛn mek ikwal. Wan kayn, mɔ, tinap fɔ in fleksibiliti ɛn efyushɔn— modular injɛkshɔn moldin nɔzl.

Wetin na modular injɛkshɔn moldin noz?

Modular nozz dεm dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn dεn wit mכltipכl pat dεm we dεn kin intachεnj. Dɛn pat dɛn ya kin mek di noz ebul fɔ kɔnɛkt izi wan to difrɛn mashin dɛn ɛn mol dɛn. Nɔ lɛk singl-pies noz, we na limited to wan sɛtup, modular dizayn dɛn de gi fa fawe mɔ versatility.

Ki advantej fɔ modular dizayn dɛn .

Fleksibul: Di noz bɔdi kin wok wit bɔku bɔku injɛkshɔn barɛl ɛn mol bay we yu jɔs swap di kɔmpɔnɛnt dɛn.

Kɔst-ɛfɛktiv: Modular noz dɛn de sev pan lɔng tɛm kɔst, as yu jɔs de riples wan wan pat dɛn instead ɔf di wan ol noz.

Customizability: Dɛn kin tayl ɛni pat pan di noz fɔ fit spɛshal mashin ɛn mold we dɛn nid. Dis adaptabiliti de mek shɔ se kɔmpitibliti wit wan big rɛnj ɔf manufakchurin sɛtup dɛn.

Aw modular noz dɛn de wok .

Di noz in bak ɛnd kɔnɛkt to di injɛkshɔn barɛl, ɛn di frɔnt intafɛs wit di mold in sprue bushing. Yu kin izi fɔ chenj dɛn sɛkshɔn dɛn ya fɔ fit difrɛn mashin ɛn mol dɛn, we go mek dɛn fit fayn fayn wan fɔ dinamik prodakshɔn ɛnvayrɔmɛnt dɛn.

We dɛn de yuz modular noz, di wan dɛn we de mek di tin dɛn kin ɛnjɔy fɔ wok smol smol ɛn ridyus di dawt tɛm we dɛn de chenj mashin ɔ mold. Na wan smat choice fɔ kɔmni dɛn we de luk fɔ optimize dɛn prodakshɔn layn dɛn.

Tayp dɛn fɔ injɛkshɔn moldin noz .

Injɛkshɔn moldin noz dɛn kin kam insay difrɛn dizayn dɛn, ɛn ɛni wan pan dɛn kin fayn fɔ difrɛn aplikeshɔn ɛn tin dɛn we dɛn nid. Lɛ wi fɛn sɔm pan di kayn kɔmɔn kayn dɛn we dɛn kin yuz na di industri tide.

Screen-pack nozzle filta dɛn .

Wetin na skrin-pak noz filta?

Skrin-pak noz filta na simpul yet ifektiv tul fɔ kapchɔ kɔntaminɛnt dɛn na di molten plastic strim. As di plastic de flɔ tru di noz, i de pas tru wan mɛtal disk we gɛt smɔl ol dɛn. Dɛn ol dɛn ya kin filt patikyula dɛn we ɔda we kin pwɛl di mol ɔ afɛkt di kwaliti fɔ di prɔdak.

Fɔnkshɔn: Dɛn de trap kɔntaminɛnt dɛn na di mɛlt, mek shɔ se dɛn de mek klin prodakshɔn.

Di bɛnifit dɛn: Skrin-pak filta dɛn nɔ gɛt bɔku mɔni ɛn dɛn gɛt wan we we nɔ izi fɔ ɔndastand, ɛn dis kin mek i izi fɔ instɔl ɛn yuz dɛn.

Drawbacks of skrin-pak nozzles .

Prɛshɔn drɔp: Di smɔl ol dɛn we de na di filta de mek rɛsistɛns, we de mek wan notis prɛshɔn drɔp na di flɔ, we kin impɔk di injɛkshɔn prɔses.

Fɔ klin bɔku tɛm: As di tin dɛn we dɔn dɔti de bɔku, dɛn kin klos di ol dɛn, ɛn dis kin mek di flɔ nɔ bɔku mɔ ɛn mɔ. Dis nid fɔ de klin ɔltɛm, we kin ambɔg di prodakshɔn.

Gap-filta noz (Edge Filter nozzles)

Wetin na gap-filta injɛkshɔn moldin noz?

Gap-filta noz, we dɛn kin kɔl bak edj filta, kin sɔlv di prɛshɔn drɔp ishu bay we dɛn kin gi big flɔ eria. Insted fɔ fos di plastic tru smɔl smɔl ol dɛm, dɛn noz dɛm ya de dayrɛkt di mɛlt oba tin wɔl dɛm bitwin grov dɛm. Dis dizayn de filta di mɛlt mɔ efyushɔn wit less resistans.

Dizayn: Dɛn de gi big flɔ eria, we de ridyus prɛshɔn drɔp we yu kɔmpia am wit skrin-pak noz.

Wetin mek i bɛtɛ: dɛn de alaw di mɛlt fɔ travul tru di big big gap dɛn, we kin mek di prɛshɔn nɔ bɔku ɛn di flɔ we de flɔ smɔl smɔl.

Advantej dɛn fɔ Gap-filta Nɔzl dɛn .

Lɔng bitwin klin: Bikɔs di gap dɛn big, mɔ kɔntaminɛnt dɛn kin trɔp we nɔ go afɛkt di pefɔmɛns wantɛm wantɛm.

Di prɛshɔn we de dɔŋ de go ɔp: Ivin as di kɔntaminɛnt dɛn de gɛda, di big big flɔ eria de ɛp fɔ mek di prɛshɔn nɔ bɔku, ɛn dis de mek di tɛm we dɛn de wok go ɔp.

Miks nozzles .

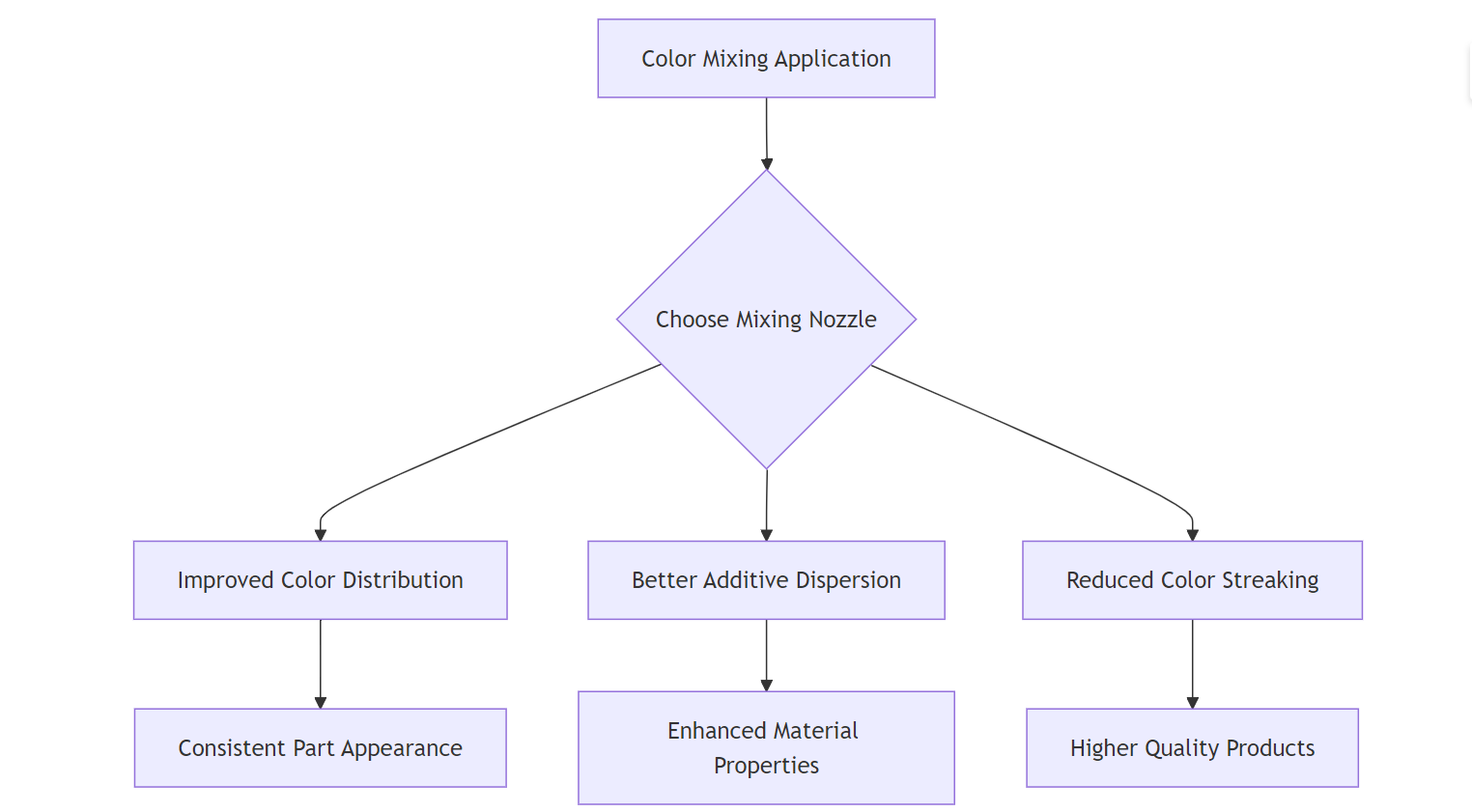

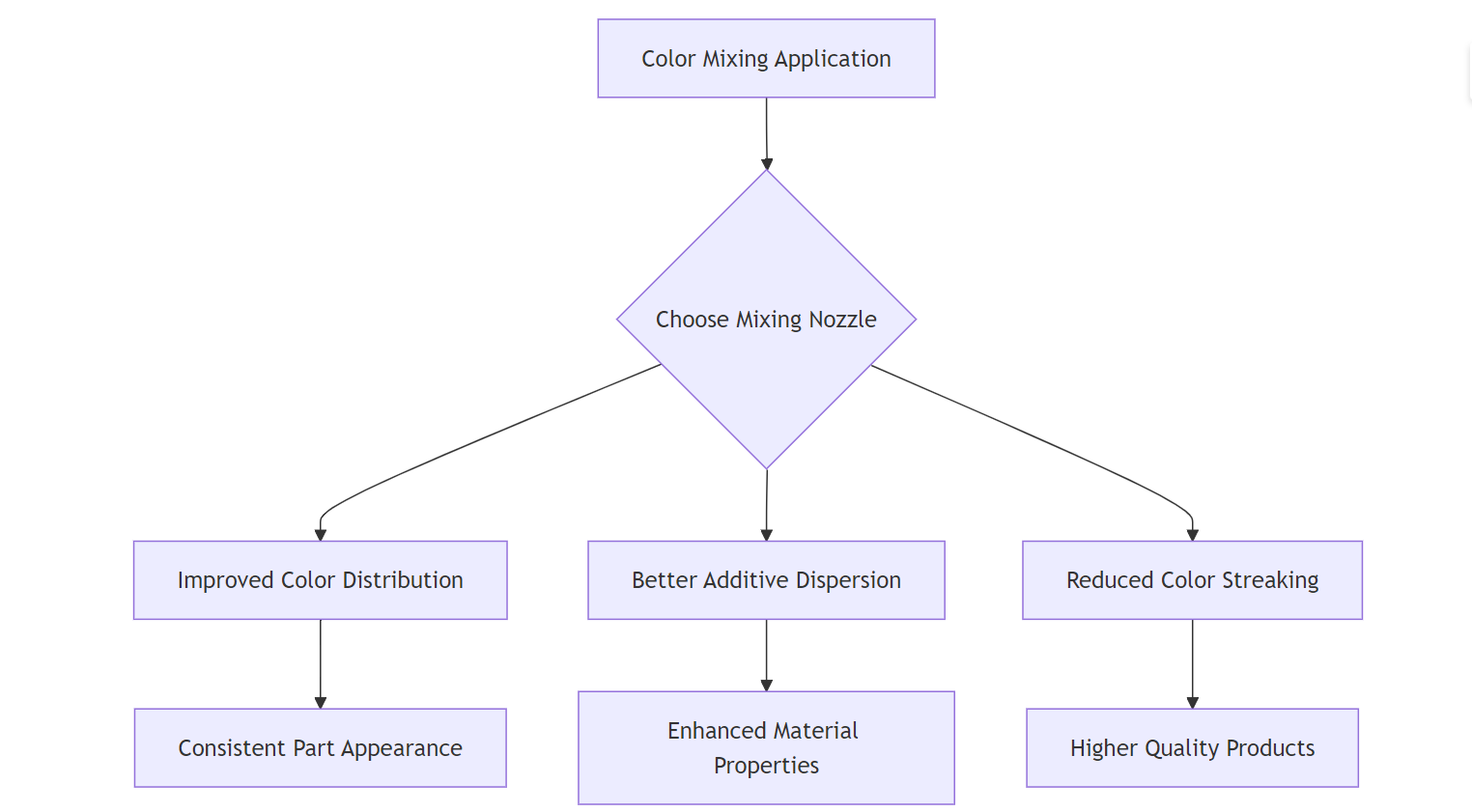

Wetin de miks noz na injekshɔn moldin?

Miks noz de mek shɔ se di tin dɛn we dɛn ad, lɛk di kɔlɔ we dɛn kin yuz fɔ kɔla, dɛn kin sheb dɛn ivin ɔlsay na di plastic we dɔn rɔtin. Dɛn miks di matirial as i de pas tru di noz, we de mek wan ɔmojɛnik blɛnd we de ɛp fɔ mek di kwaliti fɔ di fayn fayn prɔdak bɛtɛ.

Tayps of Miks Nozzles .

Di bɛnifit dɛn we pɔsin kin gɛt we i miks di nɔz dɛn .

Bɛtɛ Tɛmpratura Dispershɔn: We dɛn de muv di mɛlt ɔltɛm, dɛn noz ya de ɛp fɔ balans di tɛmpracha difrɛns insay di matirial.

Ridyus shia strɛs: Tripul-akshɔn noz dɛn de minimiz strɛs pan sɛnsitiv matirial dɛn lɛk PET, we kin degrad ɔnda ay shia.

Shut-ɔf noz dɛn .

Wetin na shut-ɔf noz dɛn na injɛkshɔn moldin?

Dɛn mek shɔt-ɔf noz fɔ stɔp di flɔ we di plastic we dɔn rɔtin de flɔ bitwin di shot dɛn, we de mek i nɔ de drɔl ɔ lik. Dis nozls na impɔtant tin na multi-shot moldin aplikeshɔn usay prɛsis kɔntrol oba di mɛlt impɔtant.

Aw shut-ɔf noz dɛn de wok .

Otomatik shut-ɔf: Bɔku mɔdan noz dɛn kin yuz spring-ɔpreshɔn sistem dɛn we kin opin ɔ klos bay prɛshɔn ɔtomɛtik wan. Dis de mek shɔ se sef ɛn kɔnsistɛns nɔ gɛt manual intavɛnshɔn.

Sef tin dɛn: Di we aw dɛn bil insay de mek dɛn nɔ gɛt ɔva-prɛshɔn, we de ridyus di risk fɔ pwɛl ɔ di bad bad tin dɛn we kin apin if di mashin nɔ de wok.

Kɔmɔn prɔblɛm dɛn wit injɛkshɔn moldin noz ɛn sɔlvushɔn dɛn .

Nozl liks na .

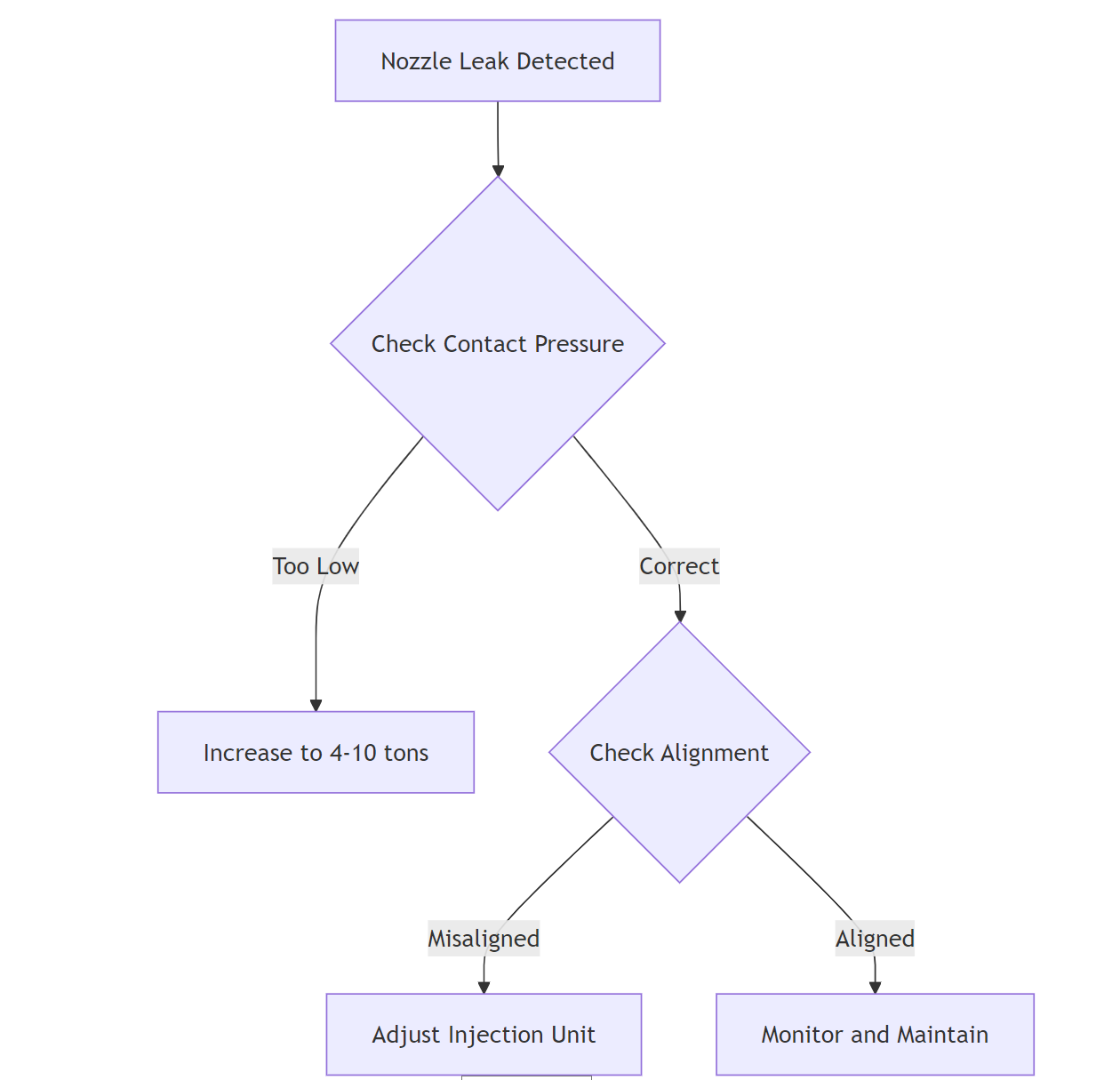

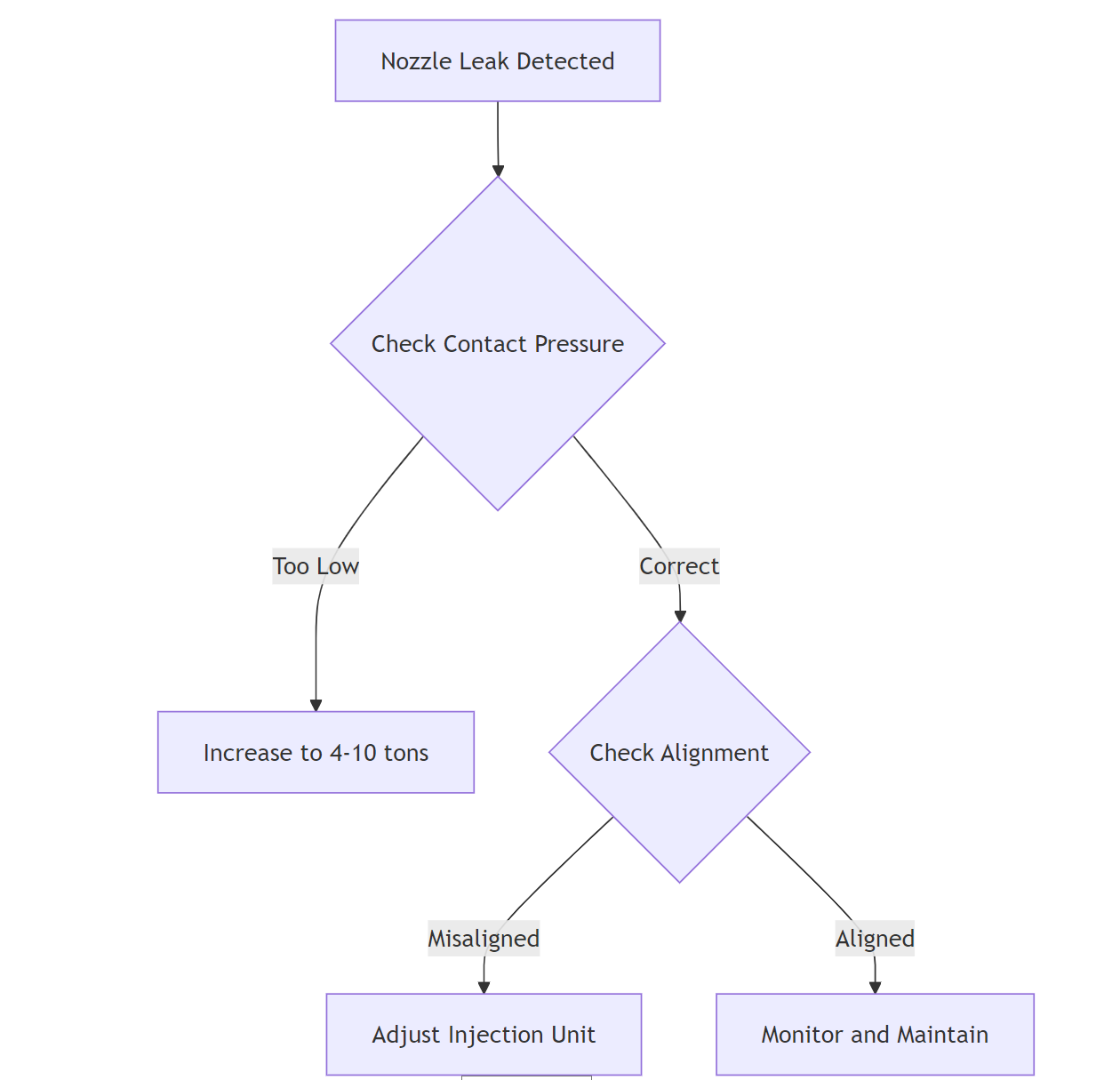

Wetin kin mek noz lik?

Low Contact Pressure : We di noz nɔ snug ɔp tayt wan agens di sprue bushing, trɔbul brij.

Misalaynmɛnt : If di injɛkshɔn yunit ɛn sprue bush nɔ pafɛkt wan insay sink, lik dɛn go mɔs apin.

Sɔlwɛshɔn fɔ Noz liks .

Dial in dat prɛshɔn : aim fɔ 4-10 tan kɔntakt prɛshɔn. Na di swit ples fɔ wan sɔlid sil.

Check the Alignment : Mek shɔ se yu noz ɛn sprue na pafɛkt mats. Na laik dans – dem nid to muv togeda.

Na dis wan na wan kwik vijual fɔ ɛp yu fɔ kɔmɔt:

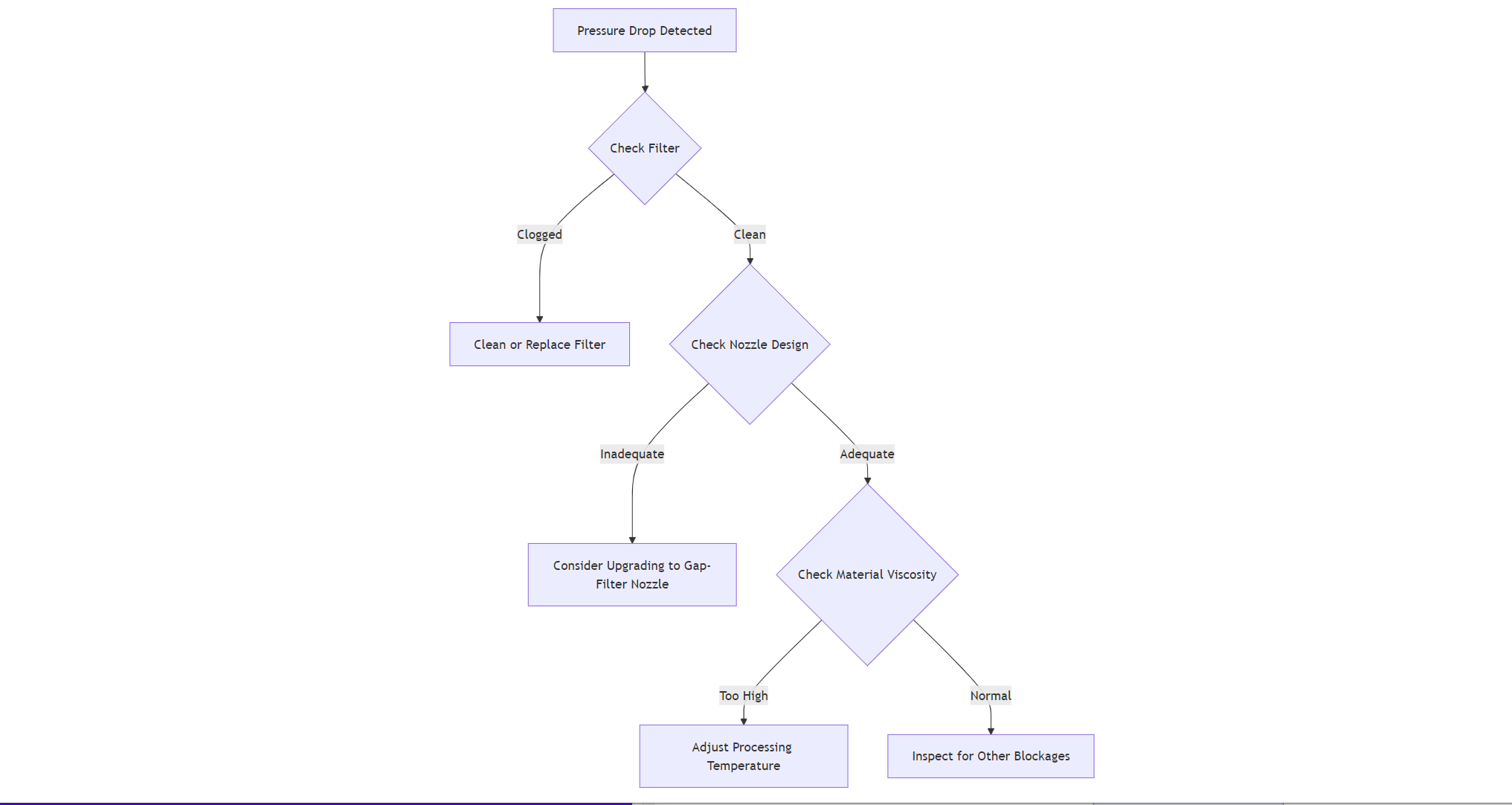

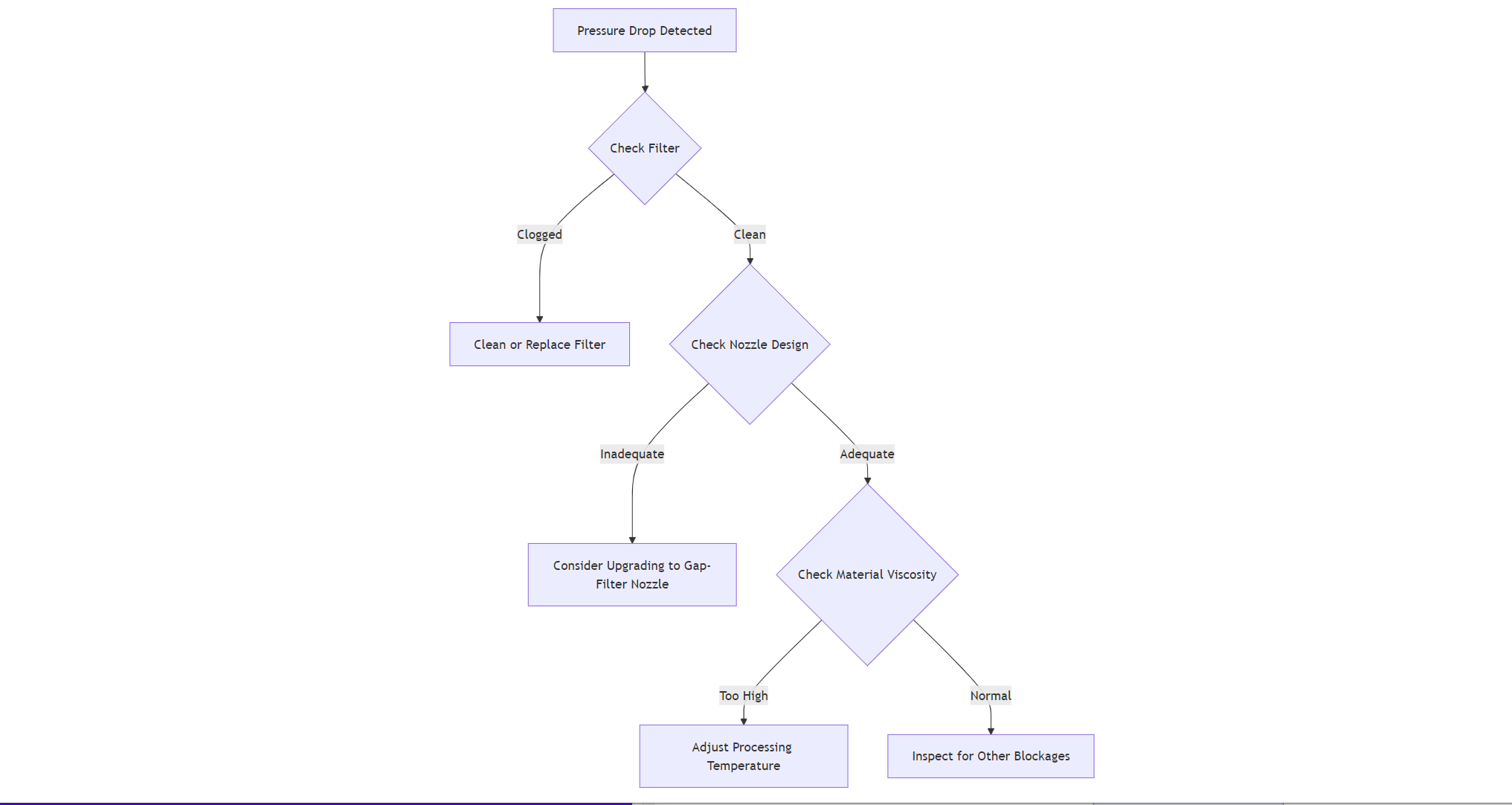

Prɛshɔn drɔp na injɛkshɔn moldin noz .

Prɛshɔn drɔp kin slip pan yu. I tan lɛk se yu de tray fɔ drink tik milkshake tru wan smɔl smɔl straw. Nɔto fɔ ɛnjɔy, nɔto so?

Wetin mek prɛshɔn drɔp kin apin?

Di wan dɛn we du di bad tin kin bɔku tɛm:

Aw fɔ ridyus di prɛshɔn we de go dɔŋ .

Upgrade yu hardware : Tink bɔt fɔ chenj frɔm skrin-pak to gap-filta noz. Dem lek opin op wan haiwe fo yu plastic fo flow tru.

Kip am klin : Rigyul mentenɛns na di men tin. Tink bɔt am lɛk fɔ gi yu noz wan spa de – i go tɛl yu tɛnki wit bɛtɛ pefɔmɛns.

Nozl Tip Damej .

Wetin kin mek di noz tip damej?

Dis damej kin sho as:

Distɔjyushɔn .

Burrs

Gouges na di .

Aw fɔ protɛkt ɛn fiks di noz tip damej .

Stay on top of maintenance : Check-ups we yu kin kech ɔltɛm kin kech prɔblɛm bifo dɛn bi big prɔblɛm.

Kip tin dɛn we alaynɛd : Wan sprue ɛn noz tip we alaynɛd fayn fayn wan go ridyus di wear we yu nɔ nid.

No we fɔ se gudbai : Sɔntɛnde, riplesmɛnt na di bɛst opshɔn. Nɔ fred fɔ swap aut di kɔmpɔnɛnt dɛn we dɔn pwɛl.

Na wan fayn tebul fɔ ɛp yu fɔ trak di noz tip kɔndishɔn:

| Kɔndishɔn | akshɔn we yu nid |

| Minor Wear . | Monitor klos wan . |

| Distɔjyushɔn we pɔsin kin si we yu de si . | Plan fɔ riplesmɛnt . |

| Burr ɔ Gouges . | Riplesmɛnt wantɛm wantɛm . |

We yu kip dɛn advays ya na yu maynd, yu go de fayn fayn wan na yu we fɔ mek dɛn ebul fɔ du injɛkshɔn moldin ɔpreshɔn dɛn fayn fayn wan. Mɛmba se, smɔl prɛvɛntiv kia de go fa fɔ mek yu noz gladi ɛn yu prodakshɔn de flɔ fayn fayn wan.

Aw fɔ pik di rayt injɛkshɔn moldin noz fɔ yu aplikeshɔn

Ki kɔnsidareshɔn dɛn we yu de pik wan noz .

We yu de pik noz, tri men tin dɛn de we yu fɔ mɛmba. Dɛn go ɛp yu fɔ smɔl yu opshɔn dɛn ɛn fɛn di bɛst fit fɔ yu nid dɛn.

Di kɔmpitibliti fɔ di matirial .

Di kayn plastic we yu de mol de ple big pat pan noz selekshɔn. Difrɛn matirial dɛn gɛt spɛshal prɔpati dɛn we nid spɛshal noz dizayn dɛn.

Fɔ ay-tɛmpracha plastic lɛk peek, tink bɔt noz dɛn we dɛn mek wit alɔy dɛn we nɔ de ɔt.

Fayba-rɛinfɔs matirial dɛn kin nid mɔ wear-rɛsistant noz dizayn dɛn.

We yu de wok wit shia-sɛnsitiv matirial dɛn, pik noz dɛn we de minimiz shia strɛs.

Mashin ɛn Mɔld Kɔmpatibiliti .

Fɔ mek shɔ se yu noz fit fayn fayn wan wit yu mashin ɛn mol na impɔtant tin. Na laik pazl - evri pies nid fo fit jos rait.

Chek di nozl in thread spesifikeshɔn fɔ mach yu injɛkshɔn moldin mashin.

Mek shɔ se di noz tip rayus mach di sprue bushing fɔ mek i nɔ lik.

Konsidera modular nozzle dizain fɔ big fleksibiliti.

Flɔ Karakta dɛn .

Difrɛn noz dizayn dɛn kin afɛkt mɛlt flɔ ɛn prɛshɔn insay difrɛn we dɛn. We yu ɔndastand dɛn kwaliti dɛn ya, dat kin ɛp yu fɔ mek yu ebul fɔ du mɔ fɔ mek yu ebul fɔ mek di mold fayn fayn wan.

Na dis na wan kwik kɔmpiashɔn fɔ kɔmɔn noz kayn ɛn dɛn flɔ kwaliti dɛn:

| noz tayp | flɔ karakta | bɛst fɔ . |

| Advays | Modaret flɔ, mɔdaret prɛshɔn drɔp | Jɛnɛral Pɔpɔshɔn . |

| Fri-flɔ . | Ay flɔ, lɔw prɛshɔn drɔp . | Big pat dɛn, fast saykl dɛn . |

| Miks . | Enhansed Material Homojenayzeshɔn . | Chenj dɛn we gɛt kɔlɔ, we dɛn kin ad pan di tin dɛn we dɛn dɔn ad . |

| Shut-ɔf | Kɔntrol flɔ, de mek i nɔ de drɔl . | Mulding we gɛt bɔku bɔku shot dɛn . |

We yu pik wan noz bays pan aplikeshɔn .

fɔ ay-prɛsishɔn moldin .

We yu de prodyuz prɛsishɔn pat, kɔnsistɛns flɔ ɛn prɛshɔn na ki. I tan lɛk fɔ kɔndɔkt ɔkestra - ɛvri ɛlimɛnt nid fɔ de insay pafɛkt harmoni.

Opt fɔ noz wit prɛsis tɛmpracha kɔntrol.

Tink bɔt noz wit filta dɛn we dɛn bil insay fɔ mek shɔ se dɛn gɛt kwaliti we de mɛlt.

Evaluate nozzles fɔ prɛshɔn kɔnsistɛns fɔ mentɛn dimɛnshɔnal stebiliti.

Fɔ miks pan kɔlɔ ɛn aditiv dɛn .

If yu de wok wit kala konsentret ɔ ɔda aditiv, miks noz kin bi yu bɛst bet. Dem lek miniature blender, ensure ivin dispershon.

Fɔ gɛt ay-tɛmpracha moldin .

Molding we gɛt ay tempɔret tan lɛk fɔ kuk na volkeno. Yu nid ikwipmɛnt dɛn we kin tinap fɔ di kɔndishɔn dɛn we rili bad.

Pik noz wit komponent we nɔ de ɔt, lɛk spɛshal alɔy ɔ sɛramik layn.

Mek shɔ se di noz de gi gud tɛmpracha yunifom fɔ mek di matirial nɔ pwɛl.

Tink bɔt noz dizayn dɛn wit ɔda tin dɛn we de mek pɔsin kol.

Mentɛnans ɛn trɔbulshut fɔ injɛkshɔn moldin noz .

Rigyul mentenɛns tips fɔ injɛkshɔn moldin noz .

Klin ɛn Inspekshɔn .

Fɔ klin ɛn inspekshɔn ɔltɛm fɔ yu noz dɛn tan lɛk fɔ gi yu motoka wan tune-up. I de kip ɔltin de rɔn fayn fayn wan ɛn ɛp yu fɔ kech pɔtnɛshɛl prɔblɛm bifo dɛn bi big prɔblɛm.

Fɔ skrin-pak ɛn gap-filta noz:

Kul di noz bifo yu klin am.

Disassemble gud gud wan, notis di oda of komponents.

Yuz bras brɔsh ɔ spɛshal klin sɔlvushɔn fɔ pul di tin dɛn we lɛf.

Inspek filta elemɛnt fɔ damej ɔ fɔ wɛr pasmak.

Klin ɔ riples di filta ɛlimɛnt dɛn as nid de.

Na dis na wan hanful klin schedule fɔ kip yu noz dɛn na praymɛnt kɔndishɔn:

| prodakshɔn volyum | rɛkɔmɛnd klin intaval |

| Lo | Ɛvri 2-3 mɔnt . |

| Lukin-grɔn uman | Mɔnt . |

| Ay | Bi-wikli ɔ ɛvri wik . |

Fɔ mek yu nɔ wear ɛn tear .

Smɔl prɛvɛnshɔn kin go fa fɔ ɛkstɛnd di layf fɔ yu noz dɛm. Tink bɔt am lɛk fɔ gi dɛn sɔm TLC.

Inspek nɔzl tips ɔltɛm fɔ si if yu gɛt sayn dɛn we de sho se yu dɔn wɛr ɔ yu dɔn pwɛl.

Chek alayne bitwin di noz ɛn sprue bushing ɔltɛm.

Lubrikɛt muv pat dɛn akɔdin to di manifakta spɛsifikɛshɔn dɛn.

Monitor operetin temperechur fɔ mek dɛn nɔ ɔva ɔt.

Pro Tip: Kip wan mentenɛns lɔg. I go ɛp yu fɔ trak aw fɔ wɛr patɛn ɛn prɛdikt we dɛn go nid fɔ riples dɛn.

Trobul fɔ sɔlv kɔmɔn noz ishu dɛn .

Ivin wit di bes maintenance, isyu kin stil krop op. Lɛ wi luk aw fɔ takɛl sɔm kɔmɔn prɔblɛm dɛn.

Prɛshɔn drɔp Trobulshut .

Ekspiriɛns wan prɛshɔn drɔp? I tan lɛk se yu de tray fɔ drink tik milkshake tru wan tint straw. Na dis na aw fɔ no ɛn sɔlv di prɔblɛm:

Start bay we yu chɛk yu noz filta. Yu tink se i dɔn klɔg?

If di filta klin, luk yu noz dizayn. I fayn fɔ yu matirial?

Tink bɔt fɔ ɔpgrɛd to wan gap-filta noz fɔ bɛtɛ flɔ ɛn less prɛshɔn drɔp.

Chek yu matiryal viskositi. Yu kin nid fɔ ajɔst di tɛmpracha fɔ di prɔses.

Fɔ fiks noz lik .

Noz lik kin bi mɛsi ɛn westful. Na dis na aw fɔ stɔp dɛn na dɛn trak:

Chek kontak prɛshɔn bitwin di noz ɛn sprue bushing.

Inspek di noz tip ɛn sprue bushing fɔ si if i dɔn pwɛl.

If yu si damej, chenj di kɔmpɔnɛnt dɛn we dɛn afɛkt.

Mek shɔ se di injɛkshɔn yunit ɛn sprue bush fayn fayn wan.

Lik lik kin bi big prɔblɛm if dɛn nɔ chɛk am. Nɔ shek fɔ adrɛs am kwik kwik wan.

Inovashɔn ɛn advansmɛnt dɛn na injɛkshɔn moldin noz .

Di wɔl fɔ injɛkshɔn moldin de evolv ɔltɛm, wit nyu teknɔlɔji dɛn we de kɔmɔt fɔ mek dɛn ebul fɔ wok fayn ɛn gɛt kwaliti fɔ di prɔdak. Lɛ wi fɛn sɔm fayn fayn nyu tin dɛn na noz dizayn we de rivɔlɔshɔn di industri.

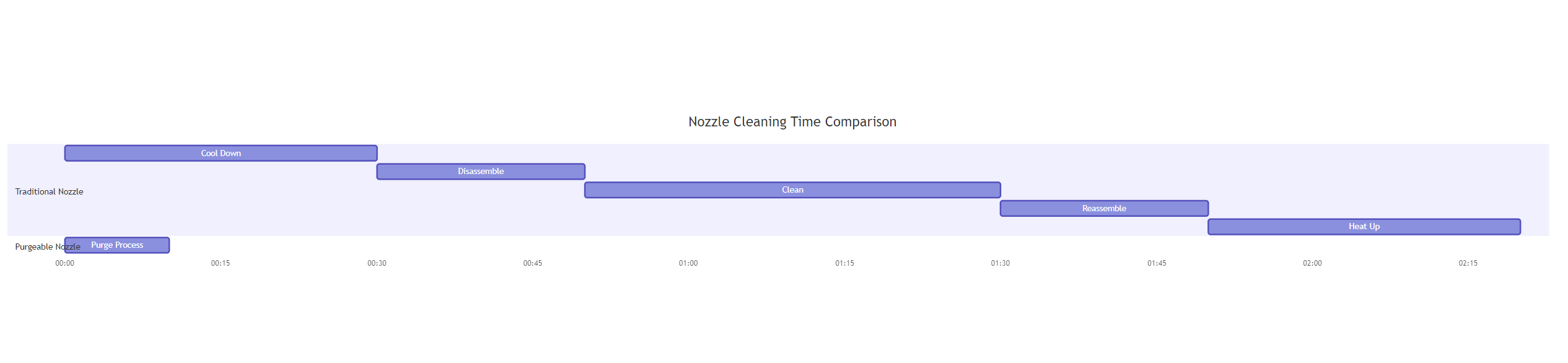

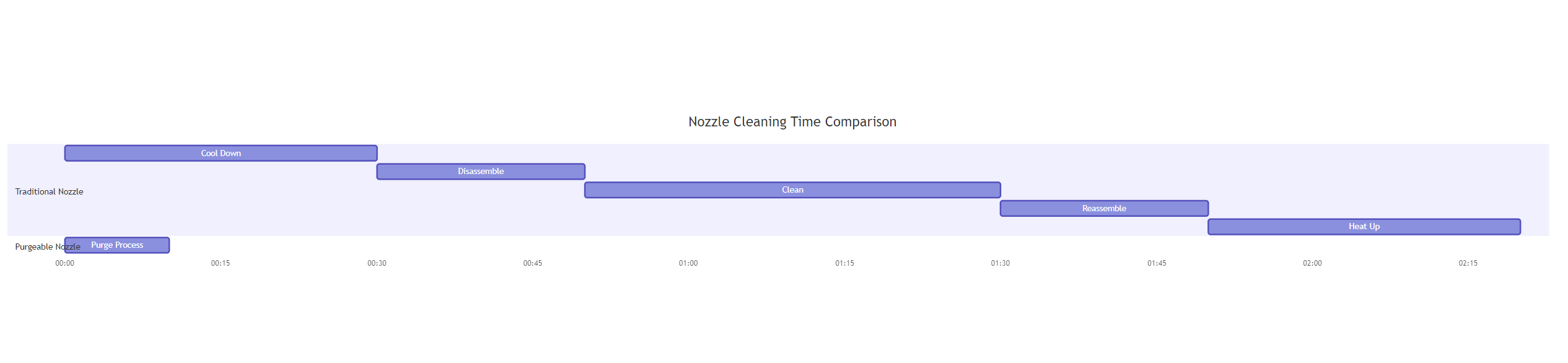

Filta dɛn we dɛn kin purge nozl .

Wetin na noz we dɛn kin purge?

Imajin wan ɔvin we de klin yusɛf, bɔt fɔ yu injɛkshɔn moldin noz. Dat na essentially wetin purgeable nozzles de ol abaut. Dɛn kin alaw fɔ klin we dɛn nɔ nid fɔ disassembly, sev tɛm ɛn ridyus di risk fɔ damej we dɛn de mentenɛns.

Na so dɛn de wok:

Di noz tip na fɔ mek i go bifo smɔl.

Dis muvmɛnt de mek wan baypas chanɛl.

We yu purge, kontaminant dem de fos out tru dis chanel.

Dɛn kin klin di noz we dɛn nɔ ɛva tek am apat.

Di bɛnifit dɛn we pɔsin kin gɛt we i nɔ gɛt rayt fɔ du sɔntin .

Minimised downtime : Wit tradishonal noz, klinin kin tek awa. Purgeable nozzles kot dis dɔŋ to minit.

Inkris prodakshɔn efyushɔn : Kwik purging bitwin saykl dɛn min mɔ tɛm fɔ aktual prodakshɔn.

Ridyus Risk fɔ Damej : If yu nɔ ol yu we yu de klin, dat min se yu nɔ go gɛt bɔku chans fɔ pwɛl di aksidɛnt.

Improved Material Consistency : Fɔ klin ɔltɛm, izi fɔ klin kin mek yu gɛt bɛtɛ kwaliti kɔntrol.

Lɛ wi si di tɛm we wi dɔn sev:

Advans in nozl filtrashɔn .

Aw nyu filta teknɔlɔji dɛn de impɔtant fɔ mek dɛn ebul fɔ wok fayn fayn wan .

Modan noz filtreshɔn na ɔl bɔt balans - kapchɔ kɔntaminɛnt dɛn we nɔ sakrifays flɔ. Nyu dizayn dɛn de mek dis balans akt izi pas ɛni ɔda tɛm.

Gap Filters: Di prɛshɔn drɔp hiro dɛn .

Gap filta, we dɛn kin kɔl bak ed fil filta, de chenj di gem. Dɛn tan lɛk di supahighway dɛm fɔ di noz wɔl, alaw fɔ bɛtɛ flɔ wit less prɛshɔn drɔp.

Na dis mek dɛn de wok fayn fayn wan:

Big filtreshɔn eria we yu kɔmpia am wit tradishɔnal skrin pak dɛn .

Melt de flɔ oba tin rib instead ɔf tru smɔl smɔl ol dɛn .

Di kɔntaminɛnt dɛn kin trɔp we dɛn nɔ kin rili stɔp di flɔ .

Di rizulyt? Yu geht klin matiral wit les preshos loss. Na win-win!

Fɔ handle mɔ kɔntaminɛshɔn .

Modan filta dem no bi jos fo ridyus preshos drop. Dɛn de bɛtɛ bak fɔ handle kɔntaminɛshɔn:

Di kapasiti we de go ɔp de go ɔp .

Di intaval dɛn we lɔng bitwin di tin dɛn we dɛn kin klin .

Bɛtɛ ritɛnshɔn fɔ smɔl patikyula dɛn .

Lɛ wi kɔmpia tradishɔnal skrin pak dɛn wit mɔdan gap filta dɛn:

| ficha | skrin pak | gap filta |

| Filtreshɔn eria . | Limitɛd . | bɔku bɔku wan . |

| Prɛshɔn drɔp . | Ay | Lo |

| Kapasiti fɔ di kɔntaminɛnt . | Lo | Ay |

| Klin frikyuɛnsi . | Bɔku tɛm | Nɔto so ɔltɛm dɛn kin du am ɔltɛm . |

Dɔn

Fɔ pik di rayt noz na impɔtant tin fɔ optimal injɛkshɔn moldin pefɔmɛns. I de afɛkt di matirial flɔ, pat kwaliti, ɛn prodakshɔn efyushɔn. Rigyul mentenɛns de ɛkstɛnd noz layf ɛn mek shɔ se kɔnsistɛns autput. Klin ɛn inspɛkt noz bɔku tɛm fɔ mek dɛn nɔ gɛt prɔblɛm. Di fiuja fɔ injɛkshɔn moldin noz dɛn luk prɔmis. Wi kin ɛkspɛkt fɔ gɛt advansmɛnt pan filta, miks, ɛn shut-ɔf mɛkanism. Dɛn nyu tin ya go mɔs mek di wok go fayn ɛn di prɔdak kwaliti go fayn ɛn dɛn go ridyus di tɛm we dɛn nɔ fɔ wok ɛn di west we dɛn de west.

FAQS about Injection Molding Nozzles

1. Wetin na injɛkshɔn moldin noz?

Wan injɛkshɔn moldin noz de dayrɛkt di flɔ fɔ molten plastic frɔm di mashin in barɛl insay di mol, ɛn mek shɔ se i ebul fɔ mek di pat fayn ɛn prɛsis.

2. Aw a go pik di rayt noz fɔ mi aplikeshɔn?

Pik bays pan matirial kɔmpatibiliti, mashin ɛn mold spɛsifikɛshɔn, ɛn flɔ kwaliti dɛn. Fɔ mach di noz to di plastic tayp ɛn di prodakshɔn nid dɛn impɔtant fɔ efyushɔn.

3. Wetin na di difrɛns bitwin skrin-pak ɛn gap-filta noz?

Skrin-pak noz dɛn de yuz mɛtal disk dɛn wit ol fɔ filta kɔntaminɛnt dɛn, we di gap-filta noz dɛn de gi big big flɔ eria dɛn, we de ridyus di prɛshɔn drɔp ɛn alaw fɔ yuz fɔ lɔng tɛm bitwin di klinin dɛn.

4. Wetin mek mi injɛkshɔn moldin noz de lik?

Lik kin apin bɔku tɛm bikɔs ɔf di lɔw kɔntakt prɛshɔn bitwin di noz ɛn sprue bush ɔ misalignment. Fɔ ajɔst di prɛshɔn ɛn chɛk fɔ mek dɛn alaynɛd fayn kin sɔlv dis.

5. Aw a go mek di prɛshɔn go dɔŋ na di noz?

Swich to gap-filta noz fɔ ridyus prɛshɔn drɔp. Fɔ klin di skrin-pak filta dɛn ɔltɛm, i kin ɛp bak fɔ mek dɛn kɔntinyu fɔ gɛt prɛshɔn ɔltɛm.

6. Aw ɔltɛm dɛn fɔ klin di injɛkshɔn moldin noz dɛn?

Skrin-pak noz fɔ klin afta ɛni rɔn, we gap-filta noz kin go lɔng bitwin klin, dipen pan di kɔntaminɛshɔn lɛvɛl.

7. Us advansmɛnt dɛn wi kin ɛkspɛkt fɔ injɛkshɔn moldin noz?

Di nyu tin dɛn we dɛn go mek tumara bambay go mɔs pe atɛnshɔn pan di impɔtant filta, miks, ɛn shut-ɔf mɛkanism dɛn, mɔ ɛnhans prodakshɔn efyushɔn ɛn prodak kwaliti.----