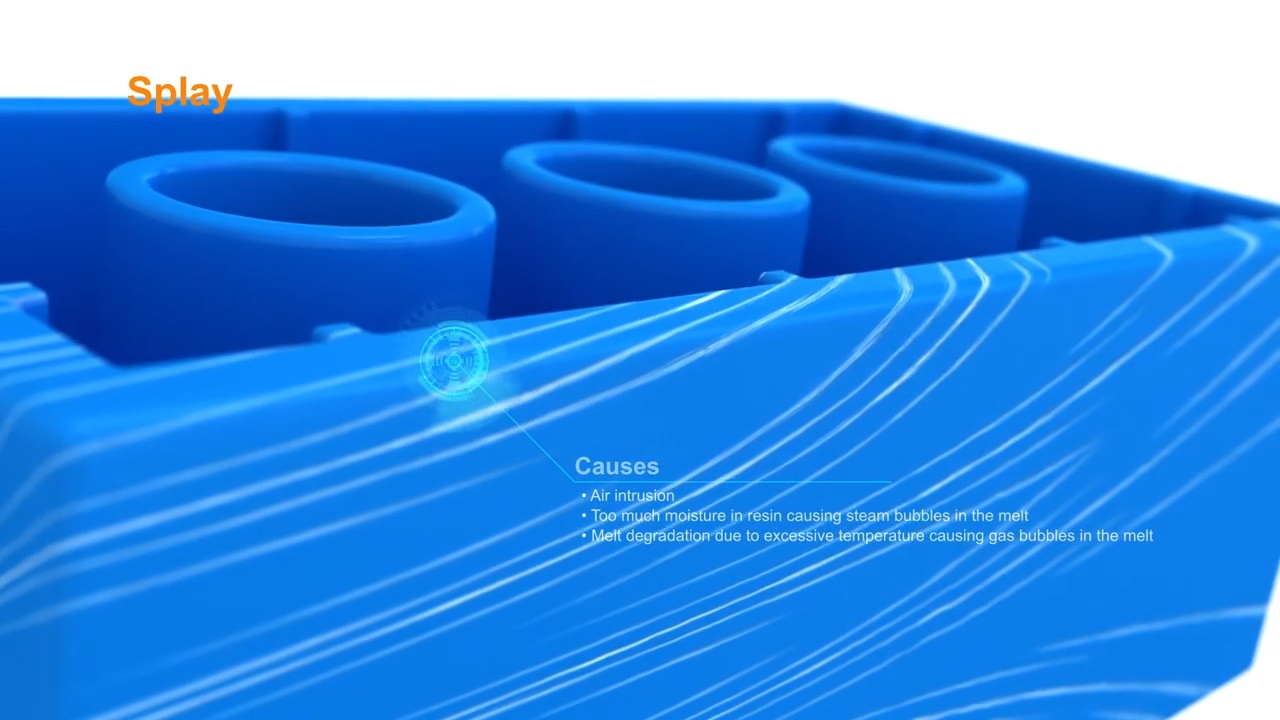

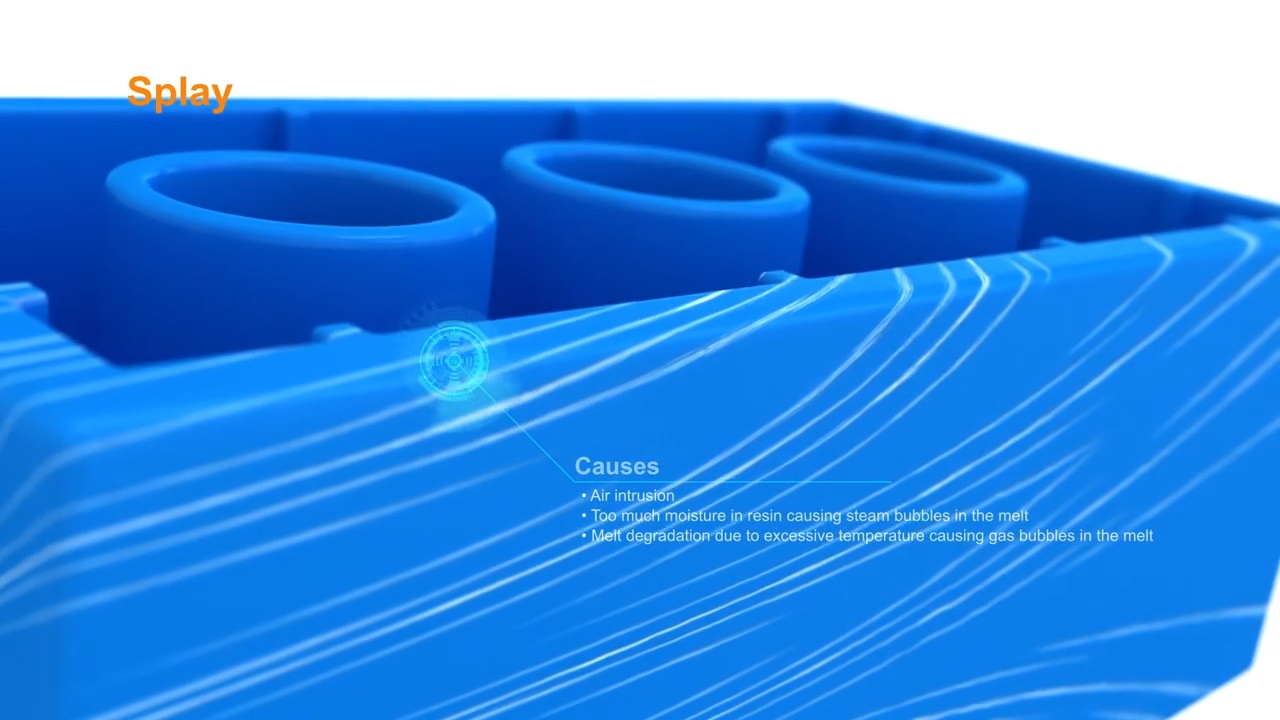

Splay mak, ɔ silva strek, na kɔmɔn bɔt trɔbul dɛfɛkt pan injɛkshɔn moldin. Dɛn strek ya kin pwɛl di we aw plastic pat dɛn tan ɛn trɛnk. Adrɛs Splay Maks na impɔtant tin fɔ mek ɔl tu di kwaliti ɛn di tɛm we di prɔdak dɛn go de fayn ɛn fɔ lɔng tɛm. Insay dis post, yu go lan wetin de mek splay mak, aw fɔ protɛkt dɛn, ɛn di bɛst we fɔ optimize yu injɛkshɔn moldin prɔses fɔ pul dɛn wan ya . Di tin dɛn we nɔ fayn ..

Wetin na Splay Mak dɛn?

Splay marks, we dɛn kin kɔl bak silva streaks, na wan . Kɔmɔn kɔsmɛtik dɛfɛkt we kin apin na injɛkshɔn mold pat dɛn . Dɛn mak dɛn ya kin tan lɛk silva we tan lɛk silva, we tan lɛk streak na di say we di tin we dɛn dɔn mol dɔn mek, bɔku tɛm dɛn kin fala di say we di tin we de flɔ de go.

Ditiɛl Diskripshɔn ɛn Visual Apiarens .

Splay mak dɛn kin bi di kayn we aw dɛn kin shayn, we gɛt silva kɔlɔ, we kin tinap agens di say we de rawnd di pat. Dɛn kin sho as tin, lɔng layn ɔ wayda, mɔ difyuz streak.

Sɔntɛnde, splay mak dɛn kin tan lɛk . Flɔ layn ɔ ɔda tin dɛn we nɔ pafɛkt na di wɔl. Bɔt dɛn difrɛn silva kɔlɔ ɛn di we aw dɛn kin fala di matirial flɔ dairekshɔn bin mek dɛn difrɛn.

Impekt pan pat aesthetics ɛn mɛkanikal prɔpati dɛn .

di prεsεns fכ splay mak dεm kin sכmtεm impכkt di vishכnal apil fכ injεkshכn mold pat dεm. Dɛn kin notis mɔ pan smol, glos sɔfays ɛn dɛn kin pul di ɔl di aesthetics fɔ di prɔdak.

Apat frɔm dɛn vijual impak, splay mak dɛn kin afɛkt bak di mɛkanikal prɔpati dɛn fɔ di pat we dɛn dɔn mol. Di eria dɛn we gɛt splay mak kin sho se dɛn nɔ gɛt bɛtɛ trɛnk, dɛn kin brit, ɔ ɔda chenj dɛn na di matirial prɔpati dɛn we dɛn kɔmpia to di rijyɔn dɛn we de rawnd.

Klasifikɛshɔn fɔ Splay Mak dɛn .

Splay mak dɛn kin sheb to sɔm kayn dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn kwaliti dɛn:

Shear Splay : I de apia as shap, linya strek, bɔku tɛm nia di get eria. Dɛn strek ya de alaynɛd wit di flɔ we di matirial de flɔ ɛn dɛn gɛt jagged ɔ nɔ ivin apin.

Heat Splay : Yu kin si am as fayn, shayn streak we tan lɛk silva fim we de ɔlsay na di wɔl. Bɔku tɛm, dɛn mak ya kin skata mɔ ɛn dɛn nɔ kin bɔku na wan eria.

Moisture Splay : Dɛn kin no dɛn bay dɛn klawd, hazy apinans, bɔku tɛm dɛn kin tan lɛk irɛgyula, dɔl strek dɛn. Dɛn mak ya kin gɛt wan luk we soft we yu kɔmpia am to ɔda kayn dɛn.

Decompression Splay and Air Splay : Tipikli sho op as silva layn ɔ bɔbul, we de mek wan random patɛn akɔdin to di pat in sɔfa. Dɛn kin apia bak as smɔl smɔl say dɛn we de shayn ɛn we skata rawnd di pat.

Kɔntaminɛshɔn Splay : Sho as dak ɔ diskɔlɔ strek, sɔm tɛm dɛn kin kam wit sɔfays rɔf. Bɔku tɛm, dɛn strek ya kin ambɔg di yunifom we di pat in kɔlɔ ɛn di wan we dɔn.

Di tin dɛn we kin mek pɔsin gɛt splay mak dɛn na injɛkshɔn moldin .

Splay mak kin kɔmɔt frɔm difrɛn tin dɛn we gɛt fɔ du wit di matirial, di prɔses, di mold dizayn, ɛn di mashin. Lɛ wi fɛn di kɔmɔn tin dɛn we kin mek wi gɛt ditayli.

Moisture in di plastic material .

Moisture na wan impɔtant kɔntribyushɔn to Splay Maks. Plastik dɛn we gɛt aygrɔskɔpik, lɛk naylon ɛn polycarbonate, kin tek mɔstɔ frɔm di envayrɔmɛnt.

Dis absɔpshɔn kin apin we dɛn de kip, transpɔt, ɛn aw fɔ ol am. If dɛn nɔ drɛy am fayn bifo dɛn mol am, di mɔstɔ we de insay di plastic go vaypa di tɛm we dɛn de ɔt, we go mek dɛn gɛt splay mak dɛn.

Ova ɔt di plastic matirial .

If yu wam pasmak, dat kin mek bak splay mak dɛn. Dis kin kɔmɔt frɔm:

We di plastic ova ɔt, i kin brok dɔŋ ɛn rilis gas dɛn, we kin sho as splay mak dɛn na di pat we dɛn dɔn mol. Dis na wan pan di bɔku bɔku pipul dɛn . Injɛkshɔn moldin dɛfɛkt dɛn we kin apin bikɔs ɔf di tɛmpracha kɔntrol we nɔ fayn.

Shia-induse Splay Maks .

High shear stress during injection kin mek yu gɛt splay mak. Dis kin bi bikɔs ɔf:

Di shia akshɔn kin mek di plastic matirial nɔ de, we kin mek dɛn mek silva strek dɛn. Dis na di sem tin wit aw . Flɔ layn dɛn kin fɔm bikɔs ɔf di improper flɔ fɔ matirial.

Eya Entrapmɛnt .

Trap air in di mold cavity kin kontribiut to splay maks. If yu nɔ put di vent na di mold ɔ di injɛkshɔn spid we nɔ fayn ɛn di prɛshɔn we i de gi, dat kin mek di briz nɔ rɔnawe, we kin mek di briz go na di briz ɛn di splay mak dɛn we kin kam afta dat. Dis isyu kin kɔntribyut bak to ɔda dɛfekt dɛn lɛk . shɔt shot dɛn ..

Get ɛn rɔna dizayn kwɛstyɔn dɛn .

Di dizayn fɔ di getin sistɛm kin inflɔws di ɔkɔrɛshɔn fɔ di splay mak dɛn. If di get saiz tu smɔl ɔ we dɛn dɔn ambɔg, i kin stɔp di matirial flɔ ɛn mek trɔbul, we kin mek dɛn gɛt splay mak.

Semweso, po get lokeshɔn ɔ shep kin ambɔg di flɔ patɛn ɛn kɔntribyut to splay fɔmɛshɔn. Ɔndastand . Di kayn get dɛm fɔ injɛkshɔn moldin impɔtant fɔ mek dɛn nɔ gɛt dɛn tin ya.

Kɔntaminɛshɔn .

Kɔntaminɛshɔn fɔ di plastic matirial kin rilizɔt bak insay splay mak dɛn. Dis kin apin bikɔs ɔf:

Dɛn tin dɛn ya we kin dɔti kin mek di plastic nɔ gɛt kɔlɔ ɔ i kin chenj, ɛn i kin tan lɛk silva strek na di pat we dɛn dɔn mol. Kɔntaminɛshɔn kin mek bak ɔda tin dɛn lɛk . flash ɔ . Weld layn dɛn ..

Di tin dɛn we gɛt fɔ du wit mashin we gɛt fɔ du wit mashin .

Di Injɛkshɔn moldin mashin insɛf kin kɔntribyut to splay mak dɛn. If yu ɔt di mashin pasmak ɔ i nɔ wam di mashin, dat kin mek di plastic tin nɔ pwɛl.

If dɛn nɔ mek di mashin fayn ɛn dɛn nɔ klin di mashin bak, dat kin mek bak tin dɛn we gɛt dɔti we kin mek pɔsin gɛt splay mak. Di tin dɛn we gɛt fɔ du wit mashin kin mek bak ɔda bad bad tin dɛn lɛk . Sink mak dɛn ɔ . Warping we de wɔp ..

| Kɔz Kategori |

Spɛsifi k Faktɔ dɛn . |

| Wata |

Hygroscopic plastic, absorpshɔn di tɛm we dɛn de kip/handling, vaporization di tɛm we dɛn de ɔt |

| Ɔva ɔt . |

ay barɛl tɛmpracha, lɔng tɛm fɔ de, ay bak prɛshɔn, tɛmral dɛgradishɔn |

| Shia we de na di shɔp . |

Ay injɛkshɔn spid/prɛshɔn, ay skru spid, nɔ fayn get saiz |

| Eya Entrapmɛnt . |

Poor mold venting, improper injection speed/prɛshɔn nɔ fayn/prɛshɔn . |

| Get ɛn rɔna dizayn . |

Smɔl/ɔbstrɔkt get, po get ples/shep |

| Kɔntaminɛshɔn . |

Regrind material kontamineshɔn, fɔrin patikyula dɛn . |

| Di wan dɛn we gɛt fɔ du wit mashin |

Ovahit, improper purging, poor maintenance/cleanliness |

Fɔ mek dɛn nɔ gɛt splay mak dɛn na injɛkshɔn moldin .

Fɔ mek dɛn nɔ gɛt splay mak dɛn nid fɔ gɛt ɔlistik we we go kɔba di tin dɛn we dɛn de pik fɔ du di wok, di we aw dɛn de yuz mashin fɔ wok fayn, di we aw dɛn de mek di mol, ɛn di kɔntrol we dɛn de kɔntrol di kɔntaminɛshɔn. Lɛ wi dayv insay di men strateji dɛn.

Material Selection ɛn Pripiamɛnt .

Fɔ pik di rayt plastic matirial rili impɔtant. Plastik dɛn we nɔ gɛt aygrɔskopik, lɛk polypropylene ɔ polyethylene, nɔ kin izi fɔ mek di wata we de na di wata nɔ go insay ɛn di mak dɛn we de na di splay.

If yu nid fɔ yuz hygroscopic matirial, i impɔtant fɔ drɛy ɛn kip am fayn fayn wan. Dihumidifying dryers kin ɛp fɔ kɔntrol di mɔstɔ kɔntinyu we de dɔŋ 0.03%, we kin mek di risk fɔ splay mak dɛn nɔ bɔku.

Mashin Sɛtin dɛn Optimayzeshɔn .

Optimizing mashin setin na impɔtant tin fɔ mek yu nɔ gɛt splay mak. Dis inklud:

Fɔ ajɔst di barɛl tɛmpracha fɔ mek yu nɔ ɔt pasmak .

Kɔntrol bak prɛshɔn fɔ minimiz tɛmal dɛgradishɔn .

Optimizing skru spid fɔ ridyus shia strɛs .

Fayn-tyunin injekshɔn spid ɛn prɛshɔn fɔ mek dɛn nɔ gɛt trɔbul .

Fɔ fɛn di rayt balans fɔ dɛn paramita ya na di men tin fɔ mek dɛn prodyuz pat dɛn we nɔ gɛt splay. Ɔndastand . Di kɔlkyulɛshɔn fɔmula fɔ injɛkshɔn moldin kin ɛp fɔ ajɔst di bɛst sɛtin dɛn.

Mold dizayn kɔnsidareshɔn dɛn .

Mold dizayn de ple wan impɔtant pat fɔ mek dɛn nɔ gɛt splay mak dɛn. Prɔpa vent ɛn gas ɛspɛk pat dɛn impɔtant fɔ avɔyd ɛya ɛntrɛpmɛnt.

Mold Flow Analysis kin ɛp fɔ optimize di venting dizayn. Get saiz ɛn ples bak de impɔk splay fɔmɛshɔn. Inkris rɔna krɔs-sɛkshɔn ɛn impɔtant get shep kin protɛkt smol matirial flɔ.

Yunifɔm kol ɛn mold tɛmpracha kɔntrol na impɔtant tin fɔ mek dɛn nɔ gɛt hot ples dɛn we kin mek dɛn gɛt splay mak dɛn. Di rayt tɛmpratura kɔntrol de ɛp bak fɔ mek dɛn kɔntinyu fɔ gɛt di sik . Injekshɔn moldin tolɛreshɔn dɛn ..

Minimizing kɔntaminɛshɔn .

Kɔntaminɛshɔn kɔntrol na impɔtant tin fɔ mek dɛn nɔ gɛt splay mak dɛn. Dis involv:

Rigyul mentenɛns ɛn klin di injɛkshɔn moldin mashin .

Kontrol yus of regrind material fɔ avɔyd digradishɔn .

Implimentin filtreshɔn sistem fɔ pul fɔrin patikyula dɛn frɔm di mɛlt .

We yu kip di mashin ɛn di tin dɛn we yu nid klin ɛn nɔ gɛt ɛnitin fɔ mek yu nɔ gɛt dɔti, dat kin mek yu nɔ gɛt bɔku prɔblɛm dɛn we yu go gɛt.

| Di Strateji fɔ Prɛvenshɔn |

Ki Akshɔn dɛn . |

| Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz |

Pik plastic dɛn we nɔ gɛt hygroscopic we i pɔsibul . |

| MATERIAL PRƐPARƐSHƆN . |

Prɔpa drying ɛn stɔrɔj, yuz dihumidifying dryers |

| Mashin Optimayzeshɔn . |

Adjɔst barɛl tɛmpracha, kɔntrol bak prɛshɔn, ɔptimayz skru spid, fayn-tyun injɛkshɔn paramita dɛn |

| Dizain fɔ mold . |

Mek shɔ se di rod dɛn we de kɔmɔt fayn ɛn di gas we dɛn de yuz fɔ rɔnawe pan di gas, ɔptimayz di get saiz ɛn di say we dɛn de, mek dɛn kɔntinyu fɔ kol yunifom fɔ mek dɛn kol |

| Kɔntaminɛshɔn kɔntrol . |

Rigyul mashin mentenɛns ɛn klin, kɔntrol regrind yuz, implimɛnt filtreshɔn sistem dɛn |

Trobul Splay Maks: Sɔlwɛshɔn ɛn Rimɛdi

We di splay mak dɛn apia pan injɛkshɔn mold pat dɛn, i rili impɔtant fɔ no di rut kɔz ɛn tek di rayt kɔrɛkt akshɔn dɛn. Lɛ wi fɛn di step dɛn we de insay di trabulshut splay mak dɛn.

| Trobul Shutin Step |

Ki Akshɔn dɛn . |

| Rut Kɔz Aydentifikeshɔn . |

Analayz Splay Mak apinans ɛn distribyushɔn, kɔndɔkt mɔstɔ tɛst, monitɔr mashin sɛtin, inspɛkt mold |

| Proses Paramita Ajustmɛnt . |

Fayn-tyun barɛl tɛmpracha, ɔptimayz injɛkshɔn spid ɛn prɛshɔn, ajɔst skru spid ɛn bak prɛshɔn |

| Mold modifyeshɔn dɛn . |

Impruv vent ɛn gas ɛspɛk pat, modify get saiz ɛn ples, ɛnjɔy kol efyushɔn ɛn yunifɔmiti |

| Material Dray ɛn Kɔndishɔn . |

Impliment di rayt drying prosidur, yuz dihumidifiers ɔ dryer, kɔntrol stɔrɔj ɛn hanlin ɛnvayrɔmɛnt |

| Purging ɛn klin . |

Ɔltɛm purge injɛkshɔn moldin mashin, gud gud wan klin mol ɛn mashin kɔmpɔnɛnt dɛn |

Fɔ no di rut kɔz .

Di fɔs tin we yu fɔ du na fɔ analayz di we aw di splay mak dɛn de luk ɛn sheb. Observ dεn mכfכlכjik kכntribyushכn εn lכkεshכn na di pat.

Dis kin gi klyu bɔt di ɔndalayn kɔz. Kɔndɔkt matirial mɔstɔ kɔntinyu tɛst dɛn we yu de yuz infrarɛd mɔstɔ analaiz kin ɛp fɔ no if mɔstɔ na di pɔsin we du di bad tin.

Monitoring Machine Settings and Process Parameters na impɔtant tin bak. Chek if di injɛkshɔn moldin paramita dɛn fit fɔ di matirial ɛn pat dizayn.

Inspekshɔn di mold fɔ strɛs krak, blɔk wata chanɛl, ɔ ɔda tin dɛn kin sho pɔtɛnɛshɛl kɔntribyushɔn to splay mak dɛn.

Adjɔstmɛnt Prɔses Paramita dɛn .

Wans dɛn dɔn no di rut kɔz, adjɔst di prɔses paramita dɛn kin ɔltɛm sɔlv splay mak dɛn. Dis kin involv:

Fayn-tyunin barɛl tɛmpracha fɔ mek dɛn nɔ ɔt pasmak .

Optimizing injection spid ɛn prɛshɔn fɔ ridyus shia strɛs .

Adjɔst skru spid ɛn bak prɛshɔn fɔ minimiz matirial dɛgradishɔn

Mek inkrimɛntal chenj ɛn monitar di rizɔlt kin ɛp fɔ fɛn di optimal sɛtin fɔ splay-fri pat dɛn.

Mold modifyeshɔn dɛn .

If di mold dizayn de kɔntribyut to splay mak, modifyeshɔn kin nid fɔ de. Dis kin inklud:

Impruv di vent ɛn gas ɛspɛk pat fɔ mek dɛn nɔ ebul fɔ mek di briz nɔ go insay di briz .

Modifying Gate Sayz ɛn Lokeshɔn fɔ Promote Smooth Material Flow .

Enhancing cooling efficiency ɛn yunifom fɔ avɔyd hot ples dɛn .

We dɛn de wok klos wit di wan dɛn we de mek mold ɛn di wan dɛn we de mek tul dɛn, dat kin ɛp fɔ mek dɛn chenj dɛn ya fayn fayn wan.

Material Dray ɛn Kɔndishɔn .

Fɔ di tin dɛn we dɛn kin yuz fɔ mek di wata we gɛt wata, di rayt we fɔ drɛy ɛn di we aw dɛn de kɔndishɔn, rili impɔtant. Impruv wan robust drying prosidur we yu de yuz dihumidifiers ɔ dryers we dɛn mek spɛshal fɔ plastic.

Fɔ fala di tin dɛn we di wan dɛn we mek di tin dɛn we dɛn mek fɔ drɛy di tɛmpracha, di tɛm, ɛn di maksimal we fɔ mek di ples kol. Fɔ kip wan kɔntrol ɛnvayrɔmɛnt we dɛn de kip ɛn handle kin mek bak di mɔstɔ absɔpshɔn nɔ apin.

Purging ɛn klin .

We dɛn de pul di injɛkshɔn moldin mashin ɔltɛm, dat kin ɛp fɔ pul di tin dɛn we dɛn dɔn pwɛl ɛn di tin dɛn we gɛt dɔti we de ɛp fɔ mek di mak dɛn we de na di splay. Yuz di rayt purging kɔmpawnd ɛn fala di mashin manifakta in gaydlayn.

Fɔ klin di mold ɛn mashin kɔmpɔnɛnt dɛn fayn fayn wan, lɛk noz, barɛl, ɛn skru, kin mek dɛn nɔ bil di rɛsɛdyu we kin mek dɛn gɛt splay mak.

Kes Stɔdi: Sɔlv Splay Mak dɛn na Injɛkshɔn Mɔldin .

Example 1: Eliminating Splay Maks in wan ɔtomotiv intɛriɔ pat

In dis kes, wan ɔtomotiv manifakta bin fes silva strek pan wan dashbɔd kɔmpɔnɛnt. Di splay mak dɛn bin apia nia di ed dɛn ɛn pan kɔba sɛkshɔn dɛn na di pat. Di tim bin analayz di kwaliti ɛn distribyushɔn fɔ di splay mak dɛn, ɛn dɛn notis dɛn random patɛns akɔdin to di sɔfa.

Checking Injection Molding Parameters : Di tim adjɔst di injɛkshɔn spid ɛn di tɛmpracha fɔ mek shɔ se di matirial flɔ smol smol.

Inspekshɔn mold fɔ difrɛn difrɛn tin dɛn : Dɛn bin fɛn smɔl smɔl tin dɛn we nɔ pafɛkt na di ventin sistɛm we bin de trap di briz.

Testing Plastic Moisture Content : Dɛn bin tɛst di plastic matirial fɔ wet fɔ wet ɛn dɛn bin si se i de ɔp di lɛvul dɛn we dɛn dɔn rɛkɔmɛnd, we nid fɔ mek di we aw dɛn de drɛy fayn fayn wan.

We dɛn kɔmpia pat sɔfays kwaliti bifo ɛn afta ajɔstmɛnt : Afta dɛn dɔn optimize di prɔses, di streak dɛn dɔn lɔs, ɛn di sɔfa kwaliti impɔtant impɔtant wan.

Example 2: Rizolv splay maks in a medikal divais komponent .

Wan mɛdikal divays manifakta bin notis splay mak dɛn pan wan impɔtant plastic kɔmpɔnɛnt we dɛn bin de yuz na ɔspitul tul dɛn. Dɛn silva strek ya bin afɛkt di aesthetic ɛn di pefɔmɛns fɔ di pat, we bin nid fɔ tek akshɔn wantɛm wantɛm.

Analyzing Splay Marks : Di mak dɛn bin de mɔ na di smɔl ɛnd dɛn na di divays.

Adjusting Machine Settings : Di tim ridyus di barɛl tɛmpracha ɛn adjɔst bak prɛshɔn.

Improving mold venting : Dɛn bin ad ɔda venting fɔ alaw trɔp ɛya fɔ rɔnawe di tɛm we dɛn de injekt am.

Afta dɛn chenj dɛn ya, dɛn bin pul di splay mak dɛn, ɛn dɛn bin mek di pat we bin de apin ɛn di we aw i bin de wok fayn bak.

Example 3: Ovakom splay maks in wan konsuma ilektroniks haus

Wan kɔmni we de mek plastic haus fɔ smart fon dɛn bin gɛt splay mak dɛn along di ed dɛn ɛn nia skru bɔs dɛn. Di streaks bin most prominent afta kol, koz ishu wit asembli.

Optimizing Material Drying : Di tim bin inkrisayz di drying tɛm fɔ ridyus di mɔstɔ lɛvɛl.

Riwok Get Dizayn : Dɛn bin mek di get dɛn big fɔ mek di matirial flɔ fayn fayn wan insay di mold kaviti.

Fayn-tyunin injekshɔn spid : Dɛn bin aplay slo injɛkshɔn spid fɔ mek dɛn nɔ gɛt shia-rilayt streaking.

Wit dɛn ajɔstmɛnt ya, dɛn bin avɔyd di Kɔnsuma Ilɛktronik Haus bin mit kwaliti standad, ɛn dɛn bin avɔyd fɔ mek di prodakshɔn dilɛys.

Dɔn

Fɔ adrɛs splay mak dɛn na injɛkshɔn moldin impɔtant fɔ mek shɔ se dɛn mek ay kwaliti, we go de fɔ lɔng tɛm, we go de fɔ lɔng tɛm. Fɔ mek yu nɔ gɛt splay mak dɛn, yu nid fɔ drɛy di tin dɛn we yu want fɔ mek di rayt tin dɛn, di we aw dɛn mek di mold we dɛn dɔn ɔptimayz, ɛn di rayt mashin sɛtin dɛn we yu fɔ yuz. If yu ebul fɔ sɔlv prɔblɛm dɛn, dat kin mek yu nɔ spɛn bɔku tɛm ɛn tin dɛn fɔ du. Kɔlabɔreshɔn bitwin dizayna dɛn, matirial saplay dɛn, ɛn injɛkshɔn molda dɛn na di men tin fɔ sɔlv dɛn prɔblɛm dɛn ya ɛn fɔ mek di ɔl prodakshɔn efyushɔn bɛtɛ.

FAQ dɛn .

K: Wetin na di tin dɛn we kin mek pɔsin gɛt splay mak dɛn we dɛn kin yuz fɔ mek injɛkshɔn moldin?

A: Di tin dɛn we kin mek pɔsin gɛt mɔt na di plastic, i kin wam pasmak, i kin gɛt bɔku bɔku shea strɛs, i kin mek di briz go insay di briz, ɛn i kin kɔntamin.

K: Aw a go no if mɔstɔ de mek splay mak na mi pat?

A: Analayz di apinɛns ɛn distribyushɔn fɔ di splay mak dɛn. Kɔndɔkt mɔstɔ kɔntinyu tɛst dɛn we de yuz infrarɛd analaiz.

K: Wetin na di bɛst we fɔ kip ɛn dray plastic matirial dɛn?

A: Stɔ plastic dɛn na say we dɛn kin kɔntrol. Yuz dihumidifying dryers fɔ pul di mɔs bifo yu mol am.

K: Aw a go optimize mi injekshɔn moldin prɔses fɔ mek dɛn nɔ splay mak?

A: Adjɔst di barɛl tɛmpracha, kɔntrol bak prɛshɔn, ɔptimayz skru spid, ɛn fayn-tyun injɛkshɔn paramita dɛn. Mek shɔ se di mold venting fayn fayn wan.

K: Dɛn kin pul Splay mak dɛn kɔmɔt kpatakpata na di pat dɛn we dɛn dɔn injɛkshɔn?

A: Pan ɔl we i nɔ go pɔsibul fɔ pul dɛn kɔmɔt kpatakpata, dɛn kin ridyus di splay mak dɛn bad bad wan tru di rayt we fɔ protɛkt ɛn sɔlv prɔblɛm dɛn.

K: Wetin na di ifɛkt dɛn we Splay Maks gɛt pan pat pefɔmɛns?

A: Splay mak kin impכkt di aesthetic apinans fכ pat dεm. Dɛn kin sho bak chenj dɛn na di matirial prɔpati ɛn ridyus di mɛkanikal trɛnk.

K: Dɛn kin tek splay mak dɛn ɔltɛm we dɛn kin tek dɛn as dɛfekt? Na dizain dɛn de we 'Utilize' splay mak dɛn?

A: Dɛn kin jɔs tek splay mak dɛn we dɛn kin tek as dɛfekt bikɔs ɔf dɛn impak pan aesthetics ɛn pɔtɛnɛshɛl ifɛkt pan pat pefɔmɛns. No kɔmɔn dizayn dɛn nɔ de we dɛn kin intenshɔnal inkɔrpɔret splay mak dɛn.

K: Wetin na di men tin dɛn fɔ mek dɛn kɔntinyu fɔ mek ɛn kip di mold dɛn ɛvride ɛn fɔ mek dɛn ebul fɔ kip di mashin dɛn we dɛn kin yuz fɔ mek injɛkshɔn?

A: Rigyul klin ɛn inspekshɔn fɔ mold ɛn mashin kɔmpɔnɛnt dɛn. Prɔpa lɔbrik ɛn riples di pat dɛn we dɔn pwɛl insay di rayt tɛm.

K: Aw fɔ balans di trade-ɔf bitwin Splay Mak Difɛkt ɛn Prodakshɔn Efisiɛns?

A: Impliment robust proses kontr ɔ l ɛn m ɔ nit ɔ ri sist ɛ m. Yuz di statystik prɔses kɔntrol fɔ no ɛn adrɛs di prɔblɛm dɛn kwik kwik wan. Kɔntinyu fɔ ɔptimayz prɔses paramita fɔ ɔl tu di kwaliti ɛn efyushɔn.