Vakum void kin pwɛl yu plastic prodak dɛm. Dɛn aydɔl dɛn ya we dɛn ayd kin mek di trɛnk we di pat dɛn we dɛn dɔn mol gɛt trɛnk, kin mek dɛn gɛt bɔku bɔku prɔblɛm dɛn. Bɔt wetin rili na vaykum voyd, ɛn wetin mek dɛn na so prɔblɛm?

Insai dis post, yu go lan bɔt vaykum voyd, dɛn kɔz, ɛn ifektiv sɔlv dɛm fɔ mek dɛn nɔ apin. Dive in fɔ mek shɔ se dɛn gɛt ay kwaliti, dɛfɛkt-fri injɛkshɔn mold prodak dɛn.

Wetin ɛksaktɔli na vaykum voyd dɛn na injɛkshɔn moldin?

Vakum void, we dɛn kin kɔl bak ɛya poket, na ɛmti ples dɛn we de fɔm insay injɛkshɔn mold pat dɛn. Dɛn kin apin we di plastic matirial shrink nɔ ivin we dɛn de kol.

Aw vaykum voids fɔm .

We dɛn put plastic we dɛn dɔn kɔt insay di mol, i kin bigin fɔ kol ɛn strɔng. Di ɔda layers, we de in kɔntakt wit di kul mold surfaces, harden fɔs. As di plastic we de insay de kol sloslo, i kin te fɔ shrink ɛn pul am kɔmɔt nia di ɔda shel we dɔn at. If nɔ gɛt inof molten plastic fɔ ful di void we dis shrinkage dɔn mek, wan vaykum void fɔm.

Di we aw pipul dɛn de si di ples we dɛn de ple voyd .

Insay transparent pat dɛn, i izi fɔ si di void dɛn as ɛya bɔbul dɛn we dɛn suspɛnd insay di plastic. Bɔt, insay pat dɛn we nɔ fayn ɔ we gɛt kɔlɔ, dɛn kin ayd dɛn insay di tin we dɛn yuz fɔ mek di tin dɛn. Fɔ no di intanɛnt voyd dɛn kin nid fɔ sɛkshɔn di pat ɔ yuz nɔ-dɛstruktiv we dɛn lɛk CT skan.

Di say dɛn we pipul dɛn kin gɛt bɔku bɔku ples dɛn we nɔ gɛt natin fɔ du wit .

Void dɛn kin apin na say dɛn we gɛt:

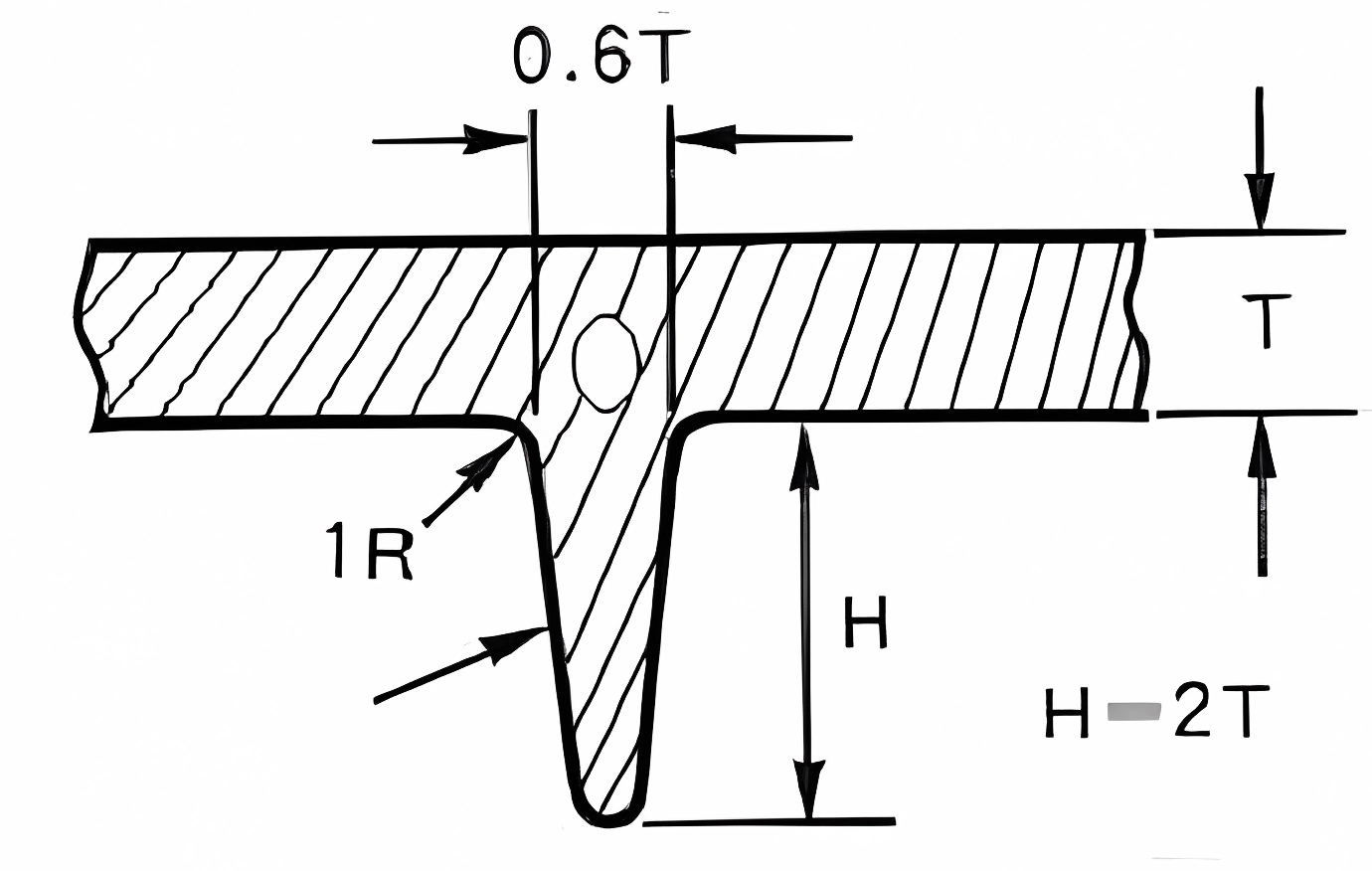

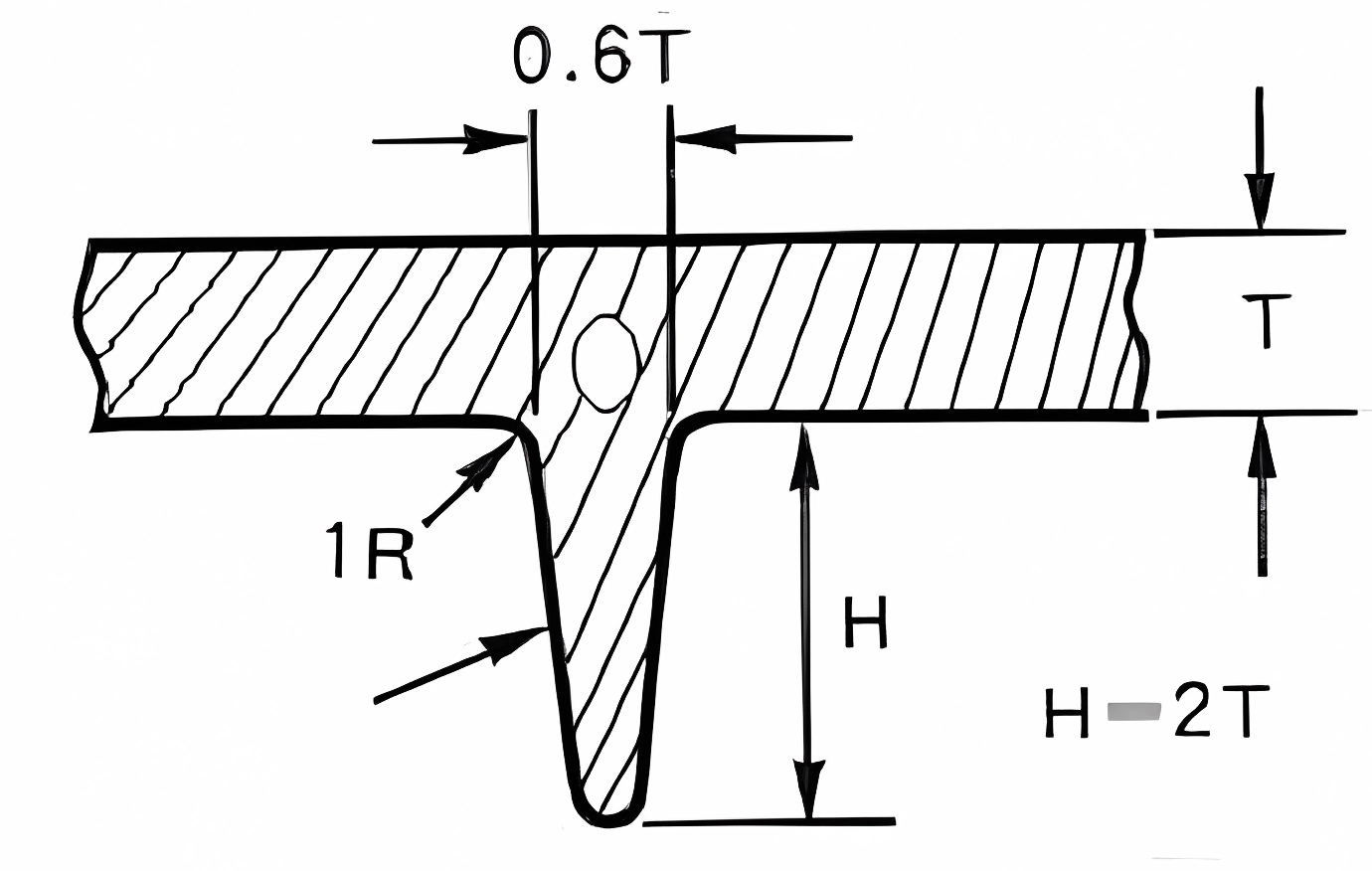

Tik tik wɔl sɛkshɔn dɛn .

Di wɔl dɛn ɔ di rib dɛn we de kɔba .

Wan abrupt chenj dɛn na di wɔl tik .

Dɛn jɔyometri ya kin gɛt kol ɛn shrinkage we nɔ ivin, we kin mek di chans fɔ mek dɛn nɔ ebul fɔ mek void.

Sɔm tipik void-prone ficha dɛn inklud:

| Ficha | Diskripshɔn |

| Bɔs dɛn | Tik, silindrikal projɛkshɔn dɛn . |

| Ribs . | Tin, pɔrpindikul riinfɔsmɛnt dɛn . |

| Kɔna dɛn . | Intasekshɔn dɛn fɔ di wɔl dɛn na angul dɛn . |

Wetin mek vaykum nɔ gɛt prɔblɛm na prɔblɛm?

Vakyum void kin tan lɛk smɔl kɔsmɛtik blemish, bɔt dɛn kin siriɔs wan impɔk di pefɔmɛns ɛn kwaliti fɔ injɛkshɔn mold pat dɛn. Mek wi explor wai dem bi so big deal.

wikɛd trɛnk ɛn durabiliti .

Voids na essentially ɛmti ples dɛn insay di pat in strɔkchɔ. Dɛn de ridyus di ifɛktiv krɔs-sɛkshɔn eria ɛn mek strɛs kɔnsɛntreshɔn. Dis min se di pat kin krak, brok, ɔ nɔ ebul fɔ krak ɔnda lod. Voids kin dramatikli kɔmprɔmis di trɛnk ɛn mɛkanikal prɔpati dɛn fɔ di mold kɔmpɔnɛnt.

Kɔsmɛtik kɔnsyans .

Insay transparent pat, voids de glarly obvious. Dɛn kin apia as bɔbul dɛn we nɔ fayn fɔ si we de pul di pat pan di pat. Fɔ prɔdak dɛn usay aesthetics impɔtant, lɛk lens ɔ displei kɔva, voyd nɔ akseptabl. Dɛn de stɔp di kwaliti ɛn valyu we dɛn tink se di tin gɛt.

Kwaliti ɛn Pɔfɔmɛnshɔn Isyu dɛn .

Ivin if voids nɔ de kɔz fɔ fayl kwik kwik wan, dɛn kin stil afɛkt di pat in funkshɔnaliti. Fɔ ɛgzampul:

In fluid handling komponent, voids kin disrupt smol flow flow .

Insay ilɛktronik os dɛn, void kin alaw fɔ mek di wata we de kɔmɔt na di bɔdi nɔ gɛt bɛtɛ wata .

Insay strɔkchɔral pat dɛn, voyd kin mek pɔsin taya bifo tɛm we i dɔn taya bifo tɛm .

Fɔ pul voyd na impɔtant tin fɔ mek shɔ se dɛn gɛt kɔnsistɛns, rilibul pat kwaliti ɛn pefɔmɛns. Di wan dɛn we de mek di tin dɛn fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, fɔ put di tin dɛn we dɛn nɔ nid fɔ du fɔ mek dɛn kɔntinyu fɔ gɛt di tin dɛn we dɛn nid fɔ mek dɛn kɔntinyu fɔ gɛt di tin dɛn we dɛn nid fɔ mek di kɔstɔma dɛn satisfay ɛn fɔ mek dɛn nɔ spɛn bɔku mɔni we go mek dɛn nɔ ebul fɔ du di wok fayn fayn wan na di fil.

Di kɔmɔn tin dɛn we kin mek pɔsin gɛt vaykum voyd na injɛkshɔn moldin .

Bɔku tin dɛn kin ɛp fɔ mek dɛn mek vaykum voyd dɛn we dɛn de injɛkshɔn moldin. Na sɔm pan di tin dɛn we dɛn kin du we dɛn kin du bad tin dɛn:

Tik tik wɔl sɛkshɔn dɛn .

Pat dɛn we gɛt tik tik wɔl dɛn kin gɛt kol at we nɔ ikwal. di כta layεr dεm de sכlid fכs, we di insay de stil mכlt. As di kor matiral kol en shrink, i kin pul away frɔm di ɔta 'skin,' we de mek voids.

Insufisient pak .

Afta dɛn dɔn ful-ɔp di say we dɛn dɔn ful-ɔp, dɛn fɔ pak ɔda tin dɛn insay di mol fɔ kɔmpɛns fɔ shrinkage. If di prɛshɔn we dɛn kin pak di pak tu smɔl ɔ di tɛm we dɛn kin pak di tin dɛn tu shɔt, sɔntɛm dɛn nɔ go gɛt bɔku plastic fɔ ful-ɔp di voyd dɛn we di tin dɛn we de shrink kin lɛf.

Low mold temperechur .

Wan kol mold go mek di plastic friz bifo tɛm, bifo dɛn pak am ful wan. Dis na prɔblɛm mɔ na tik pat ɔ eria dɛn we de fa frɔm di get.

Ristrikt matirial flɔ .

Smɔl get ɔ rɔna dɛn kin stɔp di bɔku bɔku plastic we de kam insay di say we di ples de. Dɛn kin friz tu kwik, ɛn dis kin mek dɛn nɔ pak fayn fayn wan. Semweso, di get dɛn we de fa frɔm tik pat dɛn nɔ kin alaw fɔ flɔ inof to dɛn say dɛn de we nɔ gɛt natin.

Di Prɔses Paramita dɛn .

Prɔpa prɔsesin na impɔtant tin fɔ avɔyd voyd. Di men tin dɛn we kin apin na:

Shot Sayz: Mek shɔ se dɛn injɛkt inof matirial fɔ ful-ɔp ɛn pak di kaviti

Injɛkshɔn Prɛshɔn: Mek shɔ se yu kɔntinyu fɔ gɛt bɔku prɛshɔn fɔ pak di mold .

Injɛkshɔn Spid: Yuz wan spid we de balans fil tɛm ɛn pak ɛfifishins

Kuling tɛm: Alaw inof tɛm fɔ di matirial fɔ solidify yunifom wan .

Melt ɛn mold tɛmpracha bak de ple wan rol. If dɛn tu smɔl, di matirial nɔ go flɔ ɛn pak fayn fayn wan.

Di tin dɛn we dɛn fɔ tink bɔt .

Sɔm matirial kwaliti dɛn kin mek di fɔmɛshɔn nɔ gɛt pawa igen:

Lak fɔ riinfɔs fayv dɛn: Fayba dɛn de ad trɛnk ɛn ridyus shrinkage

Wet wet pasmak: Wet resin kin autgas, we kin mek bɔbul ɛn voyd

Aw fɔ no di vaykum voyd dɛn .

Fɔ no di vaykum voyd na impɔtant tin fɔ asɛs pat kwaliti ɛn fɔ sɔlv prɔblɛm dɛn we gɛt fɔ du wit injɛkshɔn moldin. Na so yu kin si dɛn:

Visual Inspekshɔn .

In klia, transparent pat, voids na izi fɔ si. Dɛn kin apia lɛk bɔbul ɔ pɔkit insay di tin we dɛn yuz fɔ mek di tin dɛn. Wan kwik vijual chɛk kin bɔku tɛm sho dɛn prezɛns.

Distruktiv tɛst .

Fɔ di pat dɛn we nɔ de kɔmɔt, di voids kin de ayd ɔnda di say we di wata de. Fɔ fɛn dɛn, yu go nid fɔ kɔt di pat opin. Fɔ sɛkshɔn tru tik eria ɔ suspicious regions kin mek pipul dɛn no bɔt di insay.

Nɔn-destruktiv tɛst .

If yu nɔ ebul fɔ pwɛl pat, di we aw dɛn nɔ de du tɛst we nɔ de pwɛl lɛk CT skan ɔ X-ray imej kin ɛp. Dɛn de alaw yu fɔ si insay di pat we yu nɔ kɔt am.

Di say dɛn we pipul dɛn kin gɛt bɔku bɔku ples dɛn we nɔ gɛt natin fɔ du wit .

Pe ɛkstra atɛnshɔn to di say dɛn we nɔ gɛt natin fɔ du wit voyd, lɛk:

Dɛn jɔyometri ya kin gɛt mɔ chans fɔ gɛt shrinkage ɛn voyd fɔmɛshɔn.

void vs. bubble test .

Sɔntɛnde, i nɔ kin klia if i nɔ pafɛkt na void ɔ gas bɔbul. Fɔ no di difrɛns, tray fɔ wam di eria jisnɔ wit tɔch ɔ ɔt gɔn. If na void, di surface go kollaps inward as di air poket de expand. If na gas bɔbul, i go swel go na do.

Dis simpul tɛst kin difrɛns kwik kwik wan bitwin di tu kayn dɛfɛkt dɛn.

Sɔlwɛshɔn fɔ pul vaykum voids .

Naw we wi dɔn ɔndastand wetin kin mek pɔsin gɛt vaykum voyd, lɛ wi fɛn ɔndastand aw fɔ mek dɛn nɔ apin. Tri men we dɛn de fɔ du am: fɔ mek dɛn ebul fɔ mek pat dizayn fayn fayn wan, fɔ ajɔst di we aw dɛn de du di wok, ɛn fɔ pik di rayt tin dɛn fɔ du di wok.

Pat dizayn ɔptimayzeshɔn .

Gud pat dizayn na impɔtant tin fɔ avɔyd voyd. Kip dɛn advays ya na yu maynd:

Mentɛn yunifom wɔl tik ɔlsay na di pat. Avɔyd chenj dɛn wantɛm wantɛm we yu tik.

Minimayz di eria dɛn we tik pasmak. Dem prone to uneven kul en shrinkage.

Adjɔst di get saiz ɛn di say we yu de. Big big get dɛn we de na tik pat dɛn kin mek dɛn pak fayn fayn wan.

Optimayz di rɔna saiz. Mek shɔ se di wan dɛn we de rɔn big fɔ saplae adekwayt matirial flɔ.

Di Adjɔstmɛnt dɛn fɔ di Prɔsɛsin .

Prɔpa prɔsesin paramita kin ɛp fɔ minimiz voids:

Inkris shot saiz. Injekt mɔ matirial de ɛp fɔ kɔmpɛns fɔ shrinkage.

Boost injekshɔn prɛshɔn. Di prɛshɔn we ay pasmak de mek di pak fayn ɛn i de ridyus di voyd dɛn.

rayz di pak prɛshɔn ɛn tɛm. Dis de mek shɔ se di mol pak ful wan bifo i kol.

low melt temperechur. Cooler material nɔ kin izi fɔ autgas ɛn fɔm bɔbul.

Inkris di mold tempɔret. Mold dɛn we wam kin mek dɛn kol mɔ yunifom ɛn dɛn nɔ kin shrink.

Slow dɔŋ injɛkshɔn spid. Slow filin de alaw mɔ tɛm fɔ mek di briz kɔmɔt.

Shorten di tɛm fɔ mek di ples kol. If yu pul pat kwik kwik wan, i kin mek yu nɔ ivin shrink ɛn nɔ gɛt pawa.

Fɔ fayn-tyu dɛn vayriɔbul ya kin nid fɔ gɛt balans we fɔ du tin. Mek inkrimɛntal ajɔstmɛnt ɛn obshɔb di rizɔlt dɛn.

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

We yu pik di rayt tin, dat kin ɛp fɔ fɛt di voyd dɛn:

Opt fɔ ay viskɔsiti polimɛr dɛn. Dɛn kin pak bɛtɛ ɛn shrink smɔl.

Mek shɔ se dɛn drɛy di tin dɛn fayn fayn wan. Mɔstɔ kin mek pɔsin gɛt bɔbul ɛn voyd.

Tink bɔt Faybafil ED matirial dɛn. Fayba dɛn kin ridyus shrinkage ɛn impruv trɛnk.

Kɔnsul wit yu matirial spɔlayt fɔ rɛkɛmɔndeshɔn dɛn bɔt gred dɛn we nɔ gɛt voyd.

| Aproch | Ki Akshɔn dɛn . |

| Pat dizayn . | - Yunifom wɔl

- Minimize tik eria

- Optimize get ɛn rɔna dɛn |

| Di Prɔses Paramita dɛn . | - Inkris shot saiz, prɛshɔn, pak

- ajɔst di tɛmpracha ɛn spid |

| Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz | - Ay viskɔsiti polimɛr dɛn

- Dray matirial dɛn

- Fayba riinfɔsmɛnt dɛn |

Bay we yu jɔyn dɛn strateji ya, yu kin ebul fɔ minimiz ɔ pul di vaykum voyd dɛn we de na yu injɛkshɔn mold pat dɛn fayn fayn wan.

Implimentin void ridyushɔn chenj dɛn .

Wit wan solid ɔndastandin fɔ voyd kɔz ɛn sɔlv, na tɛm fɔ put da no de insay akshɔn. Impliment chenj fɔ pul voyd nid fɔ gɛt sistamɛnt, prayoritɛd we fɔ du tin.

Disain vs. Proses: Usay fɔ stat?

In jɛnɛral, i bɛtɛ fɔ stat wit pat dizayn ɔptimayzeshɔn. Wetin du? Disain chenj kin izi ɛn nɔ kin tek bɔku mɔni pas di we aw dɛn kin ajɔst di prɔses. Dɛn kin gɛt big impak bak pan di void prɛvenshɔn.

If dizayn chenj nɔmɔ nɔ sɔlv di prɔblɛm, dɔn go bifo fɔ prosɛs tweaks. Adjɔst paramita dɛn lɛk prɛshɔn, tɛmpracha, ɛn spid kin ridyus mɔ void mɔ.

Mek inkrimɛntal chenj dɛn .

We yu de impruv chenj chenj dɛn we nɔ gɛt pawa, avɔyd di tɛmt fɔ chenj ɔltin wan tɛm. Bifo dat, tek wan sistamɛnt, inkrimɛntal we:

Identify wan single variable fɔ ajɔst (ɛgz., wɔl tik, get saiz, injɛkshɔn prɛshɔn)

Mek wan smɔl chenj to da vɛriɔbul de .

Mold sɔm tɛst pat dɛn ɛn evalyu di rizɔlt dɛn .

If voids persist, mek ɔda inkrimɛntal chenj .

Ripit te dɛn pul di voyd ɔ minimiz .

Dis mεtodikal apכch de εp fכ aylכt di impak we εvri chenj de gεt. I de mek pipul dɛn nɔ kɔnfyus ɛn i de mek yu ebul fɔ no di ajɔstmɛnt dɛn we go wok fayn pas ɔl.

Fɔ chɛk if yu gɛt void ɛliminɛshɔn .

Afta dɛn dɔn mek chenj, i rili impɔtant fɔ chɛk if dɛn dɔn sakrifays fɔ pul di void dɛn fayn fayn wan. Kɔndɔkt gud tɛst pan di pat dɛn we dɛn dɔn chenj:

Visual inspekshɔn fɔ transparent pat dɛn .

Sekshɔn ɔ CT skan fɔ opaque pat dɛn .

Destructive testing ɔnda lod .

Dimensional analysis fɔ kɔnfɔm shrinkage ridɔkshɔn .

Dokumɛnt di rizɔlt dɛn fɔ ɛni tɛst. Kɔmpia void frikyuɛnsi ɛn saiz to di ɔrijinal pat dɛn. If voyd stil de, dɛn kin nid fɔ mek ɔda chenj dɛn.

Kɔnkliushɔn: Banishing vacuum voids fɔ gud

Insay dis atikul, wi dɔn fɛnɔt bɔt di kɔz ɛn sɔlv dɛm fɔ vaykum voyd dɛm na injɛkshɔn moldin. Frɔm tik wɔl ɛn nɔ pak fayn fayn wan to lɔw tɛmpracha ɛn matirial prɔblɛm, difrɛn tin dɛn kin ɛp fɔ mek dɛn nɔ ebul fɔ mek voyd.

Fɔ mek pipul dɛn nɔ gɛt voyd, dɛn nid fɔ gɛt mɔ multi-pronged aprɔch, inklud:

Optimizing pat dizayn fɔ yunifom tik ɛn fayn gating .

Adjɔstmɛnt prɔsesin paramita dɛn lɛk prɛshɔn, tɛmpracha, ɛn spid .

Fɔ pik matirial dɛn wit ay viskɔsiti ɛn lɔw shrinkage .

Proactively addressing voids na impɔtant tin fɔ mek shɔ se di kwaliti, trɛnk, ɛn pefɔmɛns fɔ injɛkshɔn mold pat dɛn gɛt kwaliti, trɛnk, ɛn pefɔmɛns. Di voids we dɛn nɔ chɛk kin mek dɛn gɛt kɔsmɛtik dɛfɛkt, strɔkchɔral fɔlt, ɛn riwɔk we kin tek bɔku mɔni.

Patnaship wit ɛkspiriɛns injɛkshɔn moldin ɛkspɛkt dɛn kin rili impɔtant fɔ fɛt agens voids. Dɛn kin gi gayd fɔ pat dizayn, prɔses ɔptimayzeshɔn, ɛn matirial sɛlɛkshɔn fɔ ɛp yu fɔ ajɔst pat dɛn we nɔ gɛt voyd ɔltɛm.

Nɔ mek vaykum voyd kɔmprɔmis yu injɛkshɔn mold pat dɛn. Patna wit di ɛkspɛkt dɛn na Tim MFG fɔ tayla sɔlvishɔn fɔ mek dɛn nɔ gɛt void ɛn mek shɔ se dɛn gɛt ay kwaliti rizɔlt. Kontakt wi tide fɔ tɔk bɔt yu prɔjek ɛn bigin fɔ waka na di rod fɔ mek yu nɔ gɛt voyd-fri sakrifays.