Injɛkshɔn moldin na impɔtant tin fɔ mek, fɔ mek prɔdak dɛn we wi de yuz ɛvride. Bɔt, bɔbul kin pwɛl di kwaliti ɛn di we aw i de luk. Fɔ ɔndastand wetin kin mek bɔbul—ɛn aw fɔ fiks dɛn—na impɔtant tin. Insay dis post, yu go lan di men tin dɛn we kin mek pɔsin gɛt bɔbul dɛn na injɛkshɔn moldin ɛn prɛktikal sɔlvishɔn fɔ pul dɛn.

Wetin na bɔbul dɛn we de insay injɛkshɔn moldin?

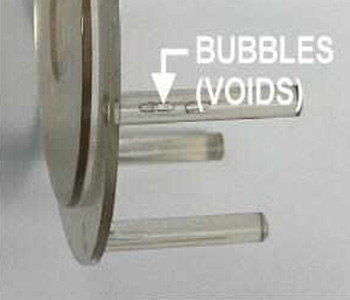

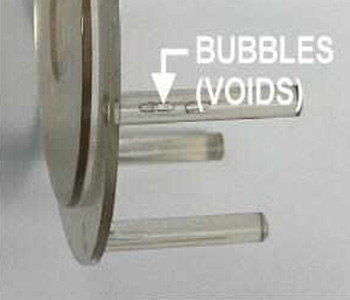

Insay injɛkshɔn moldin, bɔbul na ɛmti ples ɔ voyd we de fɔm insay di plastic pat we dɛn de mol di prɔses. Dɛn kin apia na di say we dɛn de ɔ dɛn kin trɔs insay di pat. Bubbles na wan pan di kɔmɔn . Injɛkshɔn moldin dɛfɛkt dɛn we di wan dɛn we de mek di tin dɛn nid fɔ adrɛs.

Bɔbul dɛn kin kam insay tu men kayn dɛn:

vacuum voids : Dɛn kin fɔm we gas dɛn nɔ kin ebul fɔ rɔnawe pan di mold cavity fast inof. Di eiya we dɔn trɔp de mek wan bɔbul.

Gas Bubbles : Dɛn tin ya kin apin bikɔs ɔf di tɛm we di plastic matirial kin brok. Di ɔt de mek di rɛsin gi ɔf gas, we kin trɔp lɛk bɔbul.

Durin injεkshכn moldin, bכbul dεm tipikכs fכm we:

Di mold nɔ gɛt di rayt venting chanɛl dɛn .

Injɛkshɔn spid dɛn tu ay, trap ɛya

Di tɛmpracha we dɛn kin mɛlt kin tu ay, we kin mek di plastic de dɔŋ ɛn gi am gas .

Na moisture de na di raw matiryal we de ton to stim .

Yu kin ɔltɛm si bɔbul bay we yu luk gud wan pan di pat. Dɛn go apia as:

rayz bamp ɔ blista dɛn na di sɔfa .

Di ay poket dɛn we pɔsin kin si jɔs dɔŋ di wata we de ɔp

Voids dip insay transparent pat dɛn .

Bubbles na mɔ pas jɔs kɔsmɛtik flaw. Dɛn kin bak:

wikɛd di strɔkchɔral intɛgriti fɔ di pat .

Krio lik path in fluid-handling komponents .

Intafya wit layt transmishɔn insay ɔptik pat dɛn .

I impɔtant fɔ no se sɔm tɛm dɛn kin kɔnfyus bɔbul dɛn wit ɔda injɛkshɔn moldin dɛfɛkt dɛn lɛk Sink mak dɛn ɔ . Di wan dɛn we de fɛt wɔ . Fɔ no di rayt tin na impɔtant tin fɔ mek dɛn ebul fɔ sɔlv di prɔblɛm fayn fayn wan ɛn fɔ sɔlv di prɔblɛm.

Di tin dɛn we kin mek pɔsin gɛt bɔbul dɛn na injɛkshɔn moldin .

Bɔbul kin fɔm insay injɛkshɔn mold pat fɔ bɔku rizin. Mek wi brok am dɔŋ bay kategori:

Di tin dɛn we gɛt fɔ du wit mashin we gɛt fɔ du wit mashin .

Di injɛkshɔn moldin mashin insɛf kin kɔntribyut to bɔbul fɔmɛshɔn. Na sɔm impɔtant tin dɛn ya:

Lɔw injɛkshɔn prɛshɔn ɔ ol tɛm : If di prɛshɔn tu smɔl ɔ di tɛm fɔ ol tu shɔt, di mɛlt nɔ go ful-ɔp di mold kaviti, lɛf rum fɔ bɔbul. Dis na di sem tin wit . Short shot difekt dɛn na injɛkshɔn moldin.

Insufficient material feed : If di mashin nɔ de gi inof plastic fɔ ful di mold, i kin rilizɔt in voids.

Imjekt injɛkshɔn tɛmpracha profayl : If dɛn sɛt di barɛl tɛmpracha kɔrɛkt wan, i kin mek di mɛlt nɔ pwɛl ɔ nɔ de flɔ fayn, we kin mek di gas dɛn we dɔn trɔp.

Injɛkshɔn we pasmak : If yu put di mɛlt tu kwik, i kin mek yu gɛt trɔbul, i kin mek di briz kam insay di plastic.

Insufisɛnt bak prɛshɔn : Tu smɔl bak prɛshɔn kin alaw ɛya fɔ miks insay di mɛlt we dɛn de du skru rikavari.

Di tin dɛn we gɛt fɔ du wit mold .

Di dizayn ɛn kɔndishɔn fɔ di mol de ple bak wan rol fɔ mek bɔbul:

Improper venting design : If di mold nɔ gɛt adekwayt vent chanɛl ɔ di vent dɛn tu smɔl, gas dɛn nɔ go ebul fɔ rɔnawe ɛn dɛn go trɔp na di pat.

Tik di wɔl sɛkshɔn dɛn : Di say dɛn we tik tik dɛn na di pat kin tek lɔng tɛm fɔ mek dɛn kol ɛn strɔng, we kin gi bɔbul dɛn mɔ tɛm fɔ mek. Dis kin mek bak . Sink marks in injekshɔn moldin ..

Improper runner or gate design : Di rɔna sistem ɔ di get we dɛn nɔ mek fayn ɔ di get we dɛn mek kin mek dɛn ful-ɔp di tin dɛn we nɔ ivin ɛn di briz we dɛn de yuz fɔ mek dɛn ebul fɔ go na di ayrɛa.

Low mold temperecha : If di mold steel tu kol, di plastic go friz kwik kwik wan, trap eni bubble we don fom.

Di tin dɛn we gɛt fɔ du wit di tin dɛn we gɛt fɔ du wit matirial .

Di raw matirial ɛn aditiv dɛn we dɛn yuz kin kɔntribyut bak to bɔbul dɛn:

di wata we de insay di wata pasmak : If hygroscopic resin nɔ drɛy fayn bifo dɛn mol am, di mɔs go tɔn to stim ɛn mek bɔbul.

Kɔntaminɛshɔn ɔ po kwaliti raw matirial : Dɔti ɔ dɛgrɛd raw matirial kin introduks kɔntaminɛnt dɛn we de nyukliet bɔbul.

If yu yuz di tin dɛn we dɛn dɔn yuz bak : di plastic dɛn we dɛn dɔn yuz bak kin gɛt mɔ mɔs ɛn kɔntaminɛnt dɛn we kin mek bɔbul.

Prɛzɛns fɔ volatil aditiv ɔ nɔ ivin miks : If kɔlɔrant, lɔbrikɛn, ɔ ɔda aditiv dɛn nɔ ful-ɔp fɔ skata, dɛn kin mek lokaliz eria dɛn fɔ ɔf-gas.

Di kɔz dɛn we gɛt fɔ du wit di prɔses .

Di we aw dɛn dɔn sɛt di moldin prɔses ɛn rɔn kin mek bak bɔbul kwɛstyɔn dɛn:

Inkɔnsistɛns Prɔses Saykl : Vɛryushɔn dɛn na di shot saiz, injɛkshɔn spid, pak prɛshɔn, ɔ kol tɛm kin mek di bɔbul fɔmɛshɔn we de apin wan wan tɛm.

High melt tempereture wae de mek yu degrade : If di plastic get tu hot, e kin stat for brok en giv of gas.

If yu nɔ drɛy di haygroskɔpik matirial dɛn : if yu nɔ pul di mɔstɔ frɔm di raw matirial, i go mek yu gɛt bɔbul ɔltɛm.

Fast injɛkshɔn spid we de mek di turbulent flɔ : If yu injɛkt tu kwik, i kin mek di mɛlt flɔ erratically ɛn trap ɛya poket. Dis kin mek bak . Flow lines Defects in injekshɔn moldin ..

Poor Gate Location ɔ smɔl get saiz : If di mɛlt gɛt fɔ flɔ tu fa ɔ tru wan restrictive get, i kin lɔs ɔt ɛn solidify bifo i push ɔl di ays kɔmɔt.

Slow injection speed : Na di ɔda say, if yu injekt tu slo, di matirial we de in kɔntakt wit di mold wɔl kin kol ɛn friz ɔf bifo di kaviti ful-ɔp, trap voyd.

Short Cooling Time : Especially wit tik pat, insufficient cooling kin alaw bubbles for grow as di part de solidify from di outsaid in. In dis kayn tin dem, dem kin nid ekstra kol wata lek kol wata or kompress eiya.

Di Kɔz dɛn we gɛt fɔ du wit Ɔpreshɔn .

Fɔ dɔn, di akshɔn dɛn we di molding mashin ɔpreshɔn kin du kin inflɔws bɔbul fɔmɛshɔn:

Fɔ ɔndastand dɛn tin ya we kin mek yu gɛt prɔblɛm na impɔtant tin fɔ sɔlv prɔblɛm ɛn fɔ mek yu nɔ gɛt prɔblɛm . Injɛkshɔn moldin dɛfɛkt , inklud bɔbul ɛn ɔda tin dɛn lɛk Warping in injekshɔn moldin ..

Sɔlwɛshɔn fɔ pul bɔbul dɛn na injɛkshɔn moldin .

Naw we wi dɔn no wetin de mek bɔbul, lɛ wi luk aw fɔ pul dɛn kɔmɔt. Wi go kɔba sɔlvushɔn dɛn na 4 men eria dɛn:

Ajɔstmɛnt dɛn fɔ mek mashin dɛn .

Fayn-tyunin yu . Injɛkshɔn moldin mashin sɛtin kin go fa fɔ mek dɛn nɔ pul bɔbul dɛn:

Inkris injɛkshɔn prɛshɔn ɛn ol tɛm : Di prɛshɔn we de ɔp ɛn di tɛm we yu fɔ ol fɔ lɔng tɛm de ɛp fɔ mek shɔ se di mɛlt ful-ɔp di mol ɔlsay ɛn pak ɛni voyd.

Mek shɔ se yu gɛt di rayt matirial fid ɛn kusɛn : Mek shɔ se di mashin de gi wan kɔnsistɛns shot saiz wit smɔl kusɛn fɔ ɛkstra matirial fɔ mek yu kɔntinyu fɔ pak prɛshɔn.

Optimize Injection Temperature Profile : Adjɔst di barɛl tɛmpracha fɔ kip di mɛlt insay di rikɔmɛnd prɔsesin winda fɔ di matirial, we de mek gud flɔ nɔ de dɔŋ.

Adjɔst injɛkshɔn spid bays pan matirial ɛn pat dizayn : Slow spid fɔ tik ɔ mɔ kɔmpleks pat kin mek di turbulɛns ɛn di briz go insay di briz.

Set aprɔpriet bak prɛshɔn : Mentɛn inof bak prɛshɔn fɔ mek shɔ se wan ɔmojɛnik mɛlt nɔ de we nɔ de trap di ays we dɛn de du skru rikavari.

Mold dizayn improvements .

optimizing yu . Mold dizayn kin mek bɔbul nɔ fɔm insay di fɔs ples:

Inkorporet di rayt ventin chanɛl ɛn ɛkzoz pin : Ad ampul ventin fɔ alaw trɔp ɛya fɔ rɔnawe as di mɛlt de ful di kaviti.

Optimize di wall tik ɛn avɔyd tik sɛkshɔn dɛn : Disain pat dɛn wit yunifom wɔl tik fɔ mek ivin kol ɛn sɔlidifikeshɔn, we de ridyus di risk fɔ voyd.

Ridizayn rɔna ɛn get fɔ bɛtɛ flɔ : Mek shɔ se yu rɔna sistɛm ɛn get ples dɛn de promot balans, laminar flɔ insay di kaviti.

Mentɛn di rayt mold tɛmpracha : Kip di mold surface hot inof fɔ mek di mɛlt nɔ friz ɔf bifo i ful pak aut.

Tink bɔt di rayt we . Draft Angles : Kɔrɛkt draft angul kin ɛp wit pat ɛjekshɔn ɛn ridyus di risk fɔ trɔp ɛya.

MATERIAL PRƐPARƐSHƆN ƐN HANDLƐN .

Prɔpa matirial manejmɛnt na impɔtant tin fɔ avɔyd bɔbul-kɔz kɔntaminɛshɔn ɛn mɔstɔ:

Dray fayn fayn haygroskɔpik matirial dɛn bifo yu prosɛs : Yuz dɛsika drɔya fɔ pul mɔstɔ frɔm matirial dɛn lɛk naylon, PC, ɛn PET.

Avɔyd kɔntaminɛshɔn ɛn mek shɔ se dɛn gɛt ay kwaliti raw matirial : Kip yu rɛsin klin ɛn nɔ gɛt fɔrin patikyula dɛn we go ebul fɔ nyukliet bɔbul dɛn.

Limit di yus fɔ risaykul matirial : If yu fɔ yuz Regrind, kip am klin ɛn dray, ɛn limit am to smɔl pasɛnt pan di ɔl shot.

Tek tɛm kɔntrol di ad we dɛn ad volatil aditiv dɛn : Mek shɔ se ɛni kɔlɔ, lɔbrikɛn, ɔ ɔda tin dɛn we dɛn ad kin miks fayn fayn wan ɛn nɔ introduks ɛksɛs mɔstɔ ɔ gas dɛn.

Proses optimayzeshɔn tɛknik dɛn .

Fɔ dɔn, dayalin insay yu prɔses paramita ɛn tɛknik kin ɛp fɔ pul bɔbul fɔmɛshɔn:

Mentɛn kɔnsistɛns prɔses saykl ɛn minimiz difrɛns : Yuz prɔses monitarin ɛn kɔntrol sistem fɔ kip yu shot saiz, injɛkshɔn spid, prɛshɔn, ɛn tɛmpracha kɔnsistɛns frɔm saykl to saykl.

Avɔyd pasmak mɛlt tɛmpracha ɛn matirial dɛgradɛshɔn :

Lower barel temperetures in recommended range : If yu de si sayn dɛn fɔ di tin dɛn we de pwɛl di matirial, put yu barɛl tɛmpracha dɔŋ, bɔt kip dɛn insay di tin we di matirial spɔlayt dɔn rɛkɔmɛnd fɔ prosɛs di winda.

Fɔ fala di rayt drying prosidur fɔ hygroscopic resins : Mek shɔ se yu de drying matirial dɛn na di kɔrɛkt tɛmpracha ɛn fɔ lɔng inof fɔ pul ɔl di pasmak mɔstɔ.

Adjɔst injɛkshɔn spid fɔ ajɔst laminar flɔ :

Optimize Gate Location and Size Through Flow Analysis : Yuz mold filin simulshɔn softwe fɔ fɛn di bɛst get ples ɛn saiz fɔ balans, bɔbul-fri filin.

Inkris di prɛshɔn ɛn di tɛm fɔ sɔlv di gas we de ambɔg : Di prɛshɔn we de na di pak ɛn di tɛm we dɛn kin ol fɔ lɔng tɛm kin ɛp fɔ fos di gas dɛn we dɔn trɔp kɔmɔt na di mol.

| kategori | Kɔz | Sɔlwɛshɔn |

| Mashin | Injɛkshɔn prɛshɔn we nɔ fayn, spid, ɔ tɛmpracha . | Optimize mashin sɛtin dɛn bays pan matirial ɛn pat dizayn . |

| Shep | po vent, tik wol, get/runner dizain we nɔ rayt/rɔna | Impruv venting, optimize wall tiknes, ridizayn get/runners |

| Tin dɛn | mɔstɔ, kɔntaminɛshɔn, risaykul matirial, aditiv dɛn | Dray matirial, mek shɔ se kwaliti, limit regrind, kɔntrol aditiv dɛn |

| We | Inkɔnsistɛns saykl, ay mɛlt temp, insufishɛnt drying | Mentɛn kɔnsistɛns prɔses, avɔyd fɔ pwɛl, fɔ drɛy fayn fayn wan . |

| Opareta . | Improper operation, nɔ stebul paramita dɛn . | Mek shɔ se dɛn de du di ɔpreshɔn kɔnsistɛns, minimiz di difrɛns dɛn . |

| Tul | Nozl/barɛl isyu dɛn, frikshɔn ɔt | Mentɛn ikwipmɛnt, kɔntrol injɛkshɔn spid |

| Raw matirial . | Fɔrin matirial dɛn, kɔntaminɛshɔn, volatil dɛn | Mek shɔ se yu klin, ay kwaliti raw matirial dɛn . |

Prɛventiv mɛsej fɔ avɔyd bɔbul .

Pan ɔl we i impɔtant fɔ no aw fɔ sɔlv prɔblɛm dɛn we dɛn kin gɛt we dɛn apin, i kin bɛtɛ fɔ mek dɛn nɔ fɔm insay di fɔs ples. Lɛ wi fɛn sɔm impɔtant strateji dɛn fɔ mek dɛn nɔ gɛt bɔbul.

Di bɛst we fɔ du tin fɔ mek dɛn ebul fɔ ol ɛn pripia fɔ du sɔntin .

Prɔpa matirial manejmɛnt na impɔtant tin fɔ avɔyd bɔbul dɛn we gɛt fɔ du wit mɔstɔ. Na sɔm advays dɛn ya:

Disain kɔnsidareshɔn fɔ minimiz bɔbul fɔmɛshɔn .

optimizing yu pat ɛn . Mold Design kin ɛp fɔ mek bɔbul dɛn nɔ fɔm:

Impruv wan ful prɛvɛnshɔn strateji .

Fɔ di bɛst rizɔlt, tek wan ɔlistik apɔch fɔ bɔbul prɛvɛnshɔn:

| bɔbul prɛvɛnshɔn strateji | ki ɛlimɛnt dɛn |

| Di we aw dɛn de handle di tin dɛn . | Di rayt we fɔ kip, fɔ drɛy, fɔ monitar di mɔstɔ |

| Proses Optimayzeshɔn . | kɔnsistɛns paramita dɛn, avɔyd dɛgradishɔn, laminar flɔ |

| Dizain fɔ mold . | Smooth surfaces, rawnd kɔna dɛn, optimized gating |

| Holistic aprɔch . | Kɔmbayn strateji, kɔntinyu fɔ wach ɛn ajɔst . |

Dɔn

Insay dis atikul, wi dɔn fɛn ɔl di kɔmɔn tin dɛn we kin mek pɔsin gɛt bɔbul dɛn we dɛn kin yuz fɔ mek injɛkshɔn, lɛk mashin, mold, matirial, prɔses, ɛn ɔpreshɔn faktɔ dɛn. Wi dɔn tɔk bak bɔt prɛktikal sɔlvishɔn fɔ pul bɔbul dɛn, lɛk fɔ mek mashin sɛtin dɛn fayn, fɔ mek di mold dizayn fayn, fɔ pripia di tin dɛn fayn fayn wan, ɛn fɔ mek dɛn fayn fayn wan di prɔses paramita dɛn.

Fɔ mek dɛn ebul fɔ pul bɔbul dɛn fayn fayn wan, i rili impɔtant fɔ tek wan ɔlistik we. Dis involv fɔ kɔndɔkt sistamɛtik kɔz analisis, implimɛnt targeted sɔlvishɔn, ɛn mentɛn lɔng tɛm monitarin ɛn ɔptimayzeshɔn fɔ di injɛkshɔn moldin prɔses.

We dɛn mek pat dɛn we nɔ gɛt bɔbul, di wan dɛn we de mek di tin dɛn kin mek di prɔdak kwaliti bɛtɛ, dɛn kin shɔt di saykl tɛm dɛn, dɛn kin ridyus di kɔst, ɛn dɛn kin mek di ɔl di prodakshɔn efyushɔn go ɔp. Kɔntinyu fɔ impɔtant ɛn optimayzeshɔn na di men tin fɔ ajɔst di kɔnsistɛns, ay kwaliti rizɔlt dɛn na injɛkshɔn moldin.

If yu gɛt ɛni kwɛstyɔn ɔ nid ɛp wit bɔbul ishu dɛn na yu injɛkshɔn mold pat dɛn, duya nɔ shek fɔ rich to wi ɛkspɛkt tim na Tim Mfg.Wi de ya fɔ ɛp yu fɔ optimize yu prɔses ɛn ajɔst di ay kwaliti rizɔlt dɛn. Kontakt wi tide fɔ lan mɔ.