Nonne tu scis quod super LXXX% omnium plastic products circa te sunt facta usura aut iniectio CUMATIUM et vacuum formatam? Haec duo vestibulum Titanas figura nostra cotidiana items aliter.

Faciens ad iniuriam arbitrium inter haec processus can cost tua negotium millia pupa. Multi fabrica certamen hoc consilium, impacting eorum productio costs et timelines.

In hoc comprehensive duce, ut youll 'explorarent clavem differences inter infusionem et iniectio et vacuo formatam. Disce quomodo quisque processus operatur, eorum sumptus effectus, et quod modum optimus lites vestri specifica vestibulum necessitates.

Intelligendo Basics: Iniectio CUMATIUM vs. Vacuum Formans processibus

Quid est iniectio CUMATIUM?

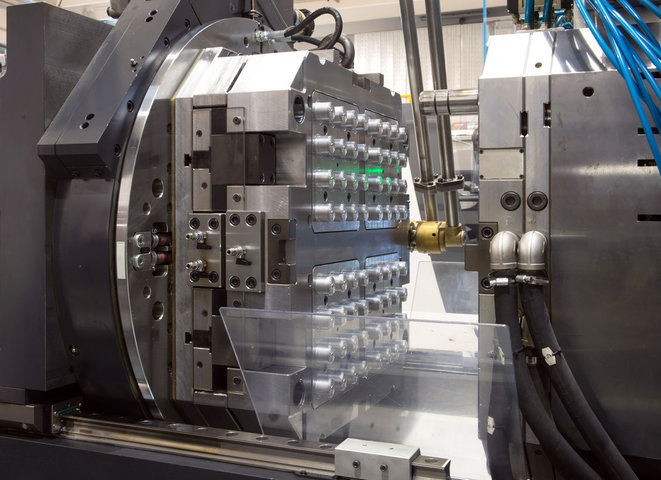

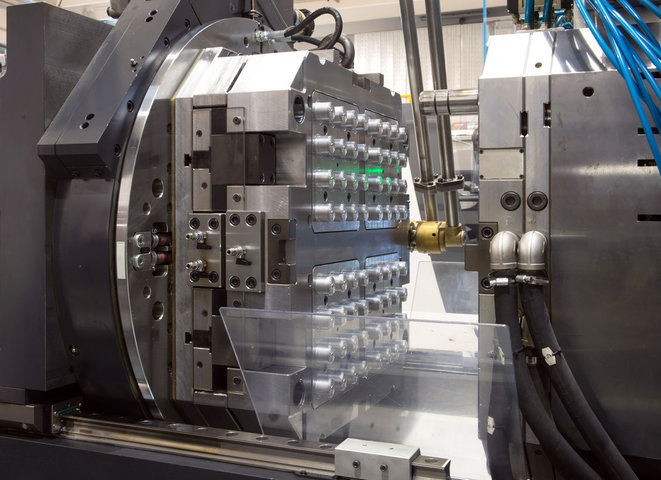

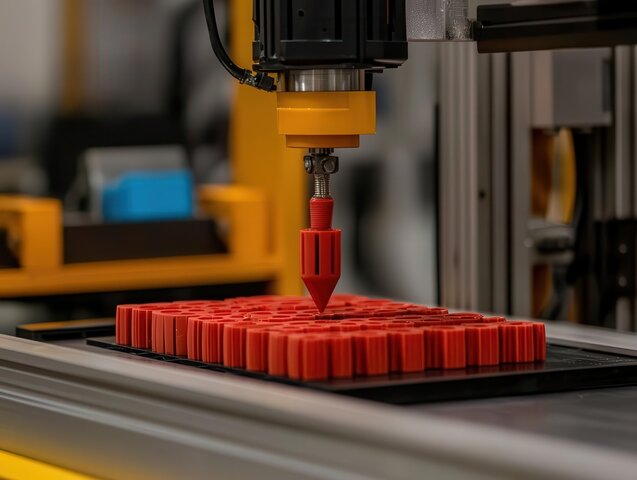

Iniectio CUMATIUM est valde versatile vestibulum processus, quae creates precise, durabile plastic partes. Hoc involves liquescens plastic pellets, injiciunt eos in fingunt sub alto pressura et refrigerationem eos in solidae figuris.

Gradus-per-gradus processus:

Loading Pellets : Plastic pellets aut granulis infudit in Hopper.

Calefactio et liquescens : pellets calefacta in dolio, conversus in conflatis plastic.

Iniectio : et conflatile est in fingunt cavitatis usura summus pressura cochlea vel arietem.

Refrigerant : De plastic refrigerari intra fingunt, induratio in ultima pars figura.

Effusa quondam refrigeratum, ex parte ejicitur, parata consummatione.

Key components iniectio CUMATIUM Machinery:

Hopper : tenet et pascit plastic pellets in apparatus.

Arma , ubi plastic calefacta et liquefactum.

Screw / Reciprocating Screw : vires fusilia plastic in fingunt.

Formare cavitatis , in spatio ubi plastic formas in desideravit parte.

Clamping Unit : servat fingunt clausis in iniectio et refrigerationem.

Quid est vacuum formans?

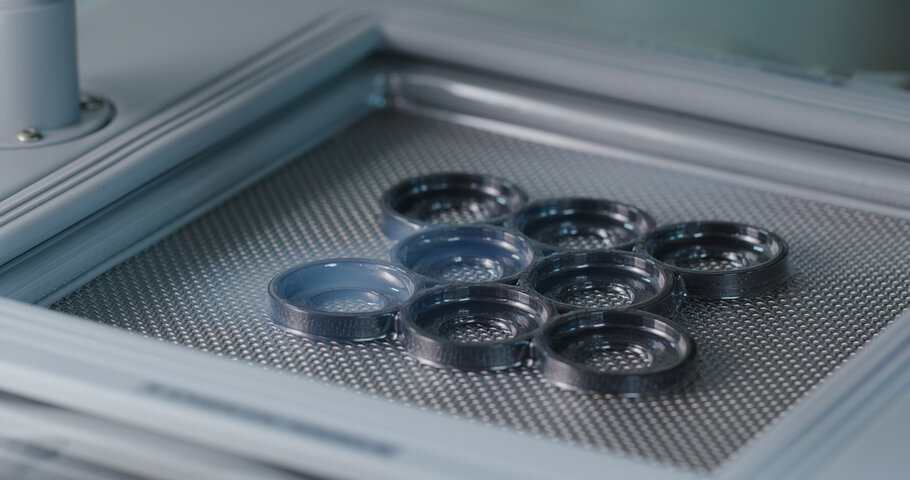

Vacuum formans, simplicior processus comparari iniectio coronam, est specimen pro creando magna, lightweight partibus. Non involves calefacit a plastic sheet usque mollis, tum usura vacuum pressura ad fingunt eam in desideravit figura.

Gradus-per-gradus thermoforming processus:

Clamping , plastic sheet est clamped in loco.

Calefactio : et sheet est calefacta donec fiat fiat.

CUMATIUM : mollia sheet extenta super fingunt et vacuum applicatur ad figura ex parte.

Refrigerant : et fingitur plastic refrigerari et indurat in loco.

Trimming : Excessus materia est ornata off, relinquens ad ultima uber.

Essential apparatu et components:

Calefactio elementum , mollit plastic sheet ad CUMATIUM.

Fingunt (Convex / Concavum) definit figura de ultima parte.

Vacuum : Suctions in plastic contra formam formare figura.

Talis Tools : Conscidisti excessus plastic post CUMATIUM.

Comparet vestibulum capabilities

Design complexitate et limitations

Manufacturing capabilities variari significantly inter iniectio CUMATIUM et vacuum formans. Quisque processus offert unicum commoda specifica consilio elit.

Iniectio CUMATIUM excellit in:

Partum Intricate Details Down Microscopic campester

Producendo solidum, complexu geometries inter internum structurae

Vestibulum partibus requiring precisances

Incorporating multiple materia genera in una components

Vacuum formans vires includit:

Fabricating magna scale componently efficiently

Partum uniformis murum crassitudine trans Expansive superficiebus

Developing Lightweight, cavae structurae

Producendo simplex geometrica figuras cost-efficaciter

Magnitudine et crassitudine considerations

| pluma | iniectio CUMATIUM | vacuo formans |

| Maximam partem magnitudine | Limited per machina facultatem | Praeclara |

| Minimum murum crassitudine | 0.5mm | 0,1mm |

| Crassitudine consistency | Altus imperium | Variatur per proten |

| Design flexibilitate | Geometries complexu | Simple moderari figuras |

Material Electio

Et materiae in iniectio CUMATIUM et vacuum formatam differunt in utroque varietate et applicationem, afficiens productum perficientur.

Materials apta iniectio CUMATIUM

Iniectio CUMATIUM sustinet amplis thermoplastics et thermosets, comprehendo:

Polypropylene (Pp) , Abs , Nylon , et Polycarbonate (PC) pro summus perficientur applications.

Repleti Polymers , sicut vitrum-repleti vel fibra, confirmat materiae, quod augendae vires et diuturnitatem.

Materials compatible cum vacuo formando

Vacuum formans limitatur ad Thermoplastics in sheet forma, ut:

Polyethylene (PE) , acrylic , PVC et coxis (summus impulsum polystyrene).

UV-firmum et ignis-retardant materiae ad propria applications.

Materia proprietas comparationes

Iniectio CUMATIUM : offert laide lectio, comprehendo calor repugnans, eget, repugnans et summus viribus polymers.

Vacuum Format : Opera optimus cum Lightweight, flexibile Thermoplasticas sed offert paucioribus altus-perficientur materia options.

Special materia considerations

Iniectio CUMATIUM potest accommodare materiae, quae eget compositio, ut antistatic aut biocompatible plastics.

Vacuum formans est specimen pro simplicior, bulkier partes in materia flexibilitate et sumptus sunt primaria de.

Pretium Analysis: Iniectio CUMATIUM vs. Vacuum Formans

Cum aestimandis sumptus-efficaciam de iniectio CUMATIUM et vacuo formans, intellectus est consociata expensis est crucial. Utrumque processus habere unique sumptus structurae afficit a tooling, productio volumen et labore.

Initial investment et tooling costs

Initial investment variatur significantly inter haec vestibulum modos. Intelligentes haec differentias adjuvat negotiis informari financial decisions.

Iniectio CUMATIUM Setup costs:

FORM Tooling: $ 10,000- $ 100,000 + fretus in complexionem

Machina Investment: $ 50,000- $ 200,000 ad vexillum apparatu

Additional peripherals: $ 15,000- $ 30,000 ad refrigerationem systems, materia tractantem

Vacuum formans setup costs:

Instrumentum creaturae: $ 2,000- $ 15,000 pro typical applications

Equipment investment: $ 20,000- $ 75,000 pro basic systems

Support Equipment: $ 5,000- $ 10,000 ad torulo, calefactio systems

Apparatu requisitis collatio:

| component | iniectio CUMATIUM | vacuo formatam |

| Prima apparatus | Summus pressura iniectio ratio | Vacuum formatam station |

| Tooling Material | Duram ferrum, aluminium | Lignum, aluminium, epoxy |

| Auxilia apparatu | Material Dryers, Chillers | Sheet calefactio systems |

| Imperium | Advanced mensura Tools | Basic inspectionem apparatu |

Productio costs

Productio expensas depend onera in volumine et operational factores.

Sumptus per unitas Analysis:

Iniectio CUMATIUM:

Princeps initial costs propagationem per maius productionem fugit

Inferior materia vastum per precise materia potestate

Reducitur laborem costs in automated operationes

Optimal enim quantitates excedens 10,000 unitates

Vacuum formans:

Inferius Satus sumptibus productio productio fructum

Superiore materia vastum a sheet tondet

Auctus labore requisitis consummatione

Sumptus-effective sub 3000 unitates

Confractus, et analysis:

Humilis volumen (<1,000 unitatibus): vacuo formatam probat magis frugi

Medium Volubilis (1,000-10,000): Custus collatio opus fundatur in partem specifications

High volumine (> 10,000) Iniectio CUMATIUM fit significantly magis cost-effective

Operational Custus Factors:

| Custus elementum | iniectio CUMATIUM | vacuo formatam |

| Labore requisitis | Minimum (automated) | Medium ad altum |

| Materia efficientiam | XCVIII% | 70-85% |

| SPECTATIO | Altum | Medium |

| Victum costs | Ad altum moderari | Minimum moderari |

Productionem considerations

Quando eligens inter infusionem coronam et vacuum formatam fabrica debet aestimare plures productionem relatas factores, ut volumine, celeritas et tempora. Intellectus quomodo haec processibus compare iuvat in faciens certiorem decisiones.

Productio volumen

Productio volumine significantly influit vestibulum modum lectio. Quisque processus offert distincta commoda diversis squamis.

Humilis-volumine productio (<3,000 unitates)

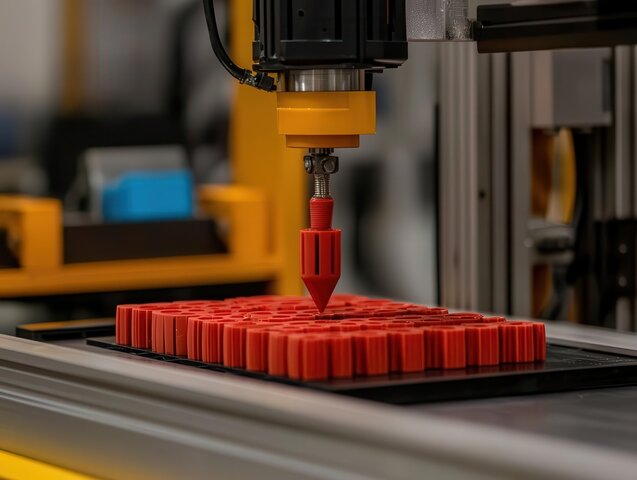

Vacuum formans praebet cost-effective solutions ad prototypum fugit

Tooling modifications manere simplex et parabilis

Velox setup enables celeri consilio iterations

Inferiori initial investment lites limited productio necessitates

High-volumine vestibulum (> 10,000 unitates)

Iniectio CUMATIUM delivers superior Economics

Automated processus reducere labore costs

Consistent qualis trans magna productio fugit

Multiple cavum tools augmentum output efficientiam

Scalability collatio:

| factor iniectio | CUMATIUM | vacuo formans |

| Initialis | Medium ad altum | Humilis ad medium |

| Scaling otium | Complex instrumentum modifications | Simple tool adjustments |

| Output rate | 100-1000 + partes / hora | 10-50 partes / hora |

| Flexibility productio | Limited | Altum |

Plumbum temporibus et tempore, ad forum

Intellectus timeline iudicium adjuvat optimize project planning et resource destinatio.

Development Timeframes:

Iniectio CUMATIUM:

Tool Design et vestibulum 12-16 septimanas

Material Electio et Testing: 2-3 septimanas

Productio Setup et Validation: 1-2 weeks

Primo articuli inspectionem: I Week

Vacuum formans:

Fabrication tool: 6-8 weeks

Materia procuracionis: 1-2 weeks

Processus Setup: 2-3 diebus

Sample Validation: 2-3 diebus

Vestibulum Cycle collatio:

| processus tempus | iniectio CUMATIUM | vacuo formatam |

| Setup Tempus | 4-8 horis | 1-2 horas |

| Exolvuntur tempore | 15-60 seconds | 2-5 minuta |

| Mutet tempore | 2-4 horis | 30-60 minutes |

| Qualis checks | Continua | Batch, secundum |

Project Timeline Consid:

Product Complexity impacts tool progressionem

Material Availability afficit plumbum temporibus

Qualis requisita Validation Tempora

Productio volumen decernit totalis project durationem

Qualis et perficientur factors

Praecisione et tolerances

Vestibulum qualis differt significantly inter haec processibus. Intelligendo haec variationes adjuvat ut productum specifications par processus elit.

Dimensional accurate collatio:

| pluma | iniectio CUMATIUM | vacuo formatam |

| Tolerantia range | ± 0.1mm | ± 0.5mm |

| Detail resolutio | Praeclarus | Moderor |

| Consistentia | ALIENTIA | Variabilis |

| Anguli definition | Acer | Rotundus |

Superficies metam characteres:

Iniectio CUMATIUM Achieves genus superficies directe ex fingunt

Vacuum formatam maintains consistent textura per magnum superficiebus

Tum processibus firmamentum variis texturas per fingunt superficiem treatments

Post-dispensando options augendae finalis species

Quality imperium mensuras superiores:

Iniectio CUMATIUM controls:

In-linea dimensiva magna

Automated visual inspectionem

Statistical processus imperium

Material proprietas verificationem

Vacuum formans controls:

Sheet crassitudine mensurasus

Manual dimensional checks

Visual superficies inspectionem

Temperatus Cras Systems

Fortitudinem et diuturnitatem

Product perficientur requisitis saepe determinare processus lectio. Quisque modum offert distincta structural commoda.

Structural Effectus:

Iniectio CUMATIUM Benefits:

Uniformis materia distribution enhances vires

Possibilities Possibilities

Imperium super material proprietatibus

Geometrica complexu Support pro fabrica elementa

Vacuum formatam characteres:

Congruens Wall Crassitudo in Simple Geometries

Limited structural Design Options

Bonum vires-ut-pondus Ratio

Optimum impulsum effusio in quibusdam applications

Environmental Resistentia chart:

| Factor | iniectio CUMATIUM | vacuo formatam |

| UV stabilitatem | Formula dependens | Bonum |

| Chemical resistentia | Praeclarus | Moderor |

| Temperature range | -40 ° F CL ° C | -20 ° C LXXX ° C |

| Humorem resistentia | Superior | Bonum |

Long-term perficientur factors:

Applications et industria usus

Intelligendo applications et industria usus iniectio CUMATIUM et vacuo formans est discrimine cum eligens ius vestibulum processus. Quisque modum offert distincta commoda quae causa speciei industries et productum types.

Communis

Iniectio CUMATIUM Typicam usus

Iniectio CUMATIUM est late propter producendo complexu, summus volumine partes cum precise features. Et applications includit:

Electronic Housings : protegit internum components et durabile, calor repugnans plastic.

Automotive partes : engine components, clips, et fasteners prodesse ex altum praecisione.

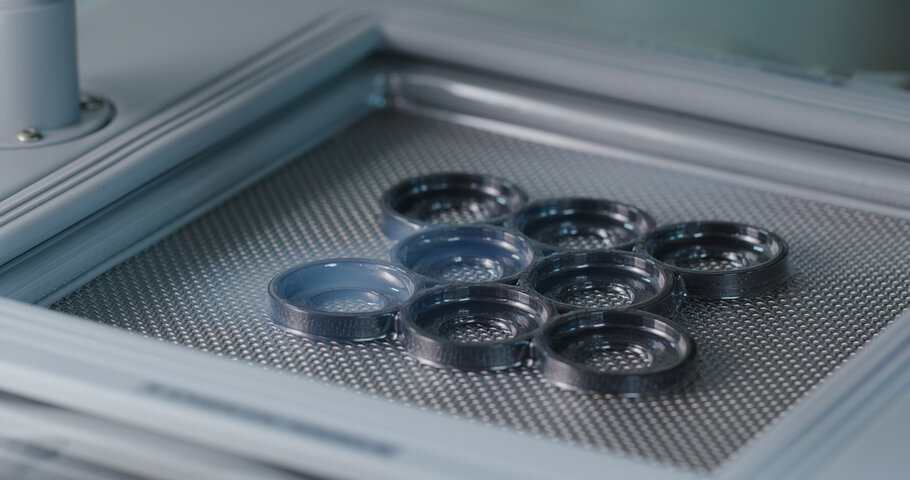

Medical cogitationes : Chirurgicam Tools, Syringes, et Diagnostic apparatu eget mundus, consistent productio.

Vacuum formans typicam usus

Vacuum formans praefertur pro maius, lightweight partes et prototyping. Suus 'vulgo in:

Packaging Trays : Custom-Formatur Scutellas pro Medical, cibum, vel dolor bona.

Automotive Interior Panel : Maior Dashboard et Trim components.

Point-of-sale Displays : Sturdy et Plastic Plastic Displays in retail environments.

Industria-specifica applications

Aerospace : vacuo formatam adhibetur ad lightweight interiora tabulata et scutras, dum iniectio CUMATIUM creates intricate components.

Consumer Electronics : Iniectio CUMATIUM est critica ad tutela casibus, plugs, et fabrica inclusit.

Packaging Packaging cibum et Packaging producat producendo leve protective plastic packaging conformis cibi salutem signa.

| industria | iniectio CUMATIUM exempla | vacuo formans exempla |

| Eget | Engine partes, fasteners | Dashboards, Trim Panels |

| Medicinae cogitationes | Syringes, Diagnostic Tools | Medical Trays, Packaging |

| Consumer products | Electronic Housings, nugas | Magna packaging, Point-of-sale propono |

Industria-specifica requisitis

Automotive industria necessitates

Iniectio CUMATIUM : De Automotive Industry Exigit princeps praecisione pro partibus sicut fasteners, engine components et clips. Iniectio CUMATIO occurrit his indiget per consistent productionem durabile, calor repugnant.

Vacuum formans : propter maiores partes, sicut ostium tabulata, Dashboards et trunci liners, quod requirere PERFUSORIUS constructione.

Medical fabrica vestibulum

Iniectio CUMATIUM : Specimen pro producendo summus praecisione, sterilis components, ut Syringes, diagnostic Kits, et chirurgicam instrumenta.

Vacuum formatam : communiter pro creando mos packaging pro medical instrumenta et sterilis scutulis in hospitalium.

Consumer products

Iniectio CUMATIUM : discrimine ad parva, detailed dolor bona, ut electronic fabrica housings, plastic nugas, et culina utensilia.

Vacuum formatam : Specimen pro magna ostentat, packaging et tutela casibus in retail environments.

Packaging Solutions

Iniectio CUMATIUM : idoneam creando reusable, rigida vasis et tutela concluditur.

Vacuum formatam : late usus est in PRIMUS sarcinas, Clashell packaging et leve scutulas quae potest esse massa-produci cito.

Faciens ius arbitrium

Delectos inter iniectio CUMATIUM et vacuum formatam pendeat pluribus key factores. Assecto project-specifica necessitates et intellectus commoda cuiusque modum, manufacturers potest facere informari arbitrium quod adsimilat cum eorum productio metas.

Arbitrium-faciens factors

Project requisitis aestimationem

EVALUATIating tuum project 's Design Complexity, Part Size: et productionem volumine est. Si vestri project involves intricate partibus cum stricta tolerances, iniectio CUMATIUM potest esse melius optionem. Nam simpliciores maiores vacuum formatam posset melius cost et celeritate commoda.

Donec Consociationes

Iniectio CUMATIUM : Superius upfront tooling costs sed redigatur pretium per partem in summus volumine productio.

Vacuum formans : inferioribus tooling costs, idealis pro low- ad medium-volumine productio vel prototyping.

Timeline Requisita

Iniectio CUMATIUM : Iam plumbum tempore propter fingere productionem et setup.

Vacuum formans , citius turnaround breviori productio fugit vel prototypes.

Species cubits

Considerans requiritur dimensional accurate , superficies metam, et materia vires. Iniectio CUMATIUM delivers superior qualitas et constantia, dum vacuum formans praebet bonum results ad minus postulat applications.

Quando eligere iniectio CUMATIUM

Idealis missionibus

High-volumen productionem parvi, complexu partes.

Projects requiring stricta tolerances et detailed features, ut threaded components et frangeretur, congruat.

ACTIO

Cost-efficaciam pro magna-scale productio.

Precisionem et repeatability ad universa consilia.

Diuturnitatem et longa-term perficientur cum provectus materiae.

Potential limitations

Pretium-beneficium analysis

Dum initial expensas sunt alta, iniectio coronam coronam est magis frugi ad altum volumina ex inferioribus per-unitas costs. Processus est etiam specimen cum praecisione et materia vires sunt discrimine.

| Iniectio CUMATIO | limitations | commoda |

| Specimen enim complexu partes | Princeps upfront costs |

|

| Cost-effective ad magna fugit | Iam setup et plumbum |

|

| Summus parte-ut-pars constantiam |

|

|

Quando eligere vacuo formans

Optimus-usu casibus

Prototyping vel humilis-volumine productio fugit.

Magna, simplex partis sicut automotive dashboards , packaging scutellas, aut punctum-of-sale propono.

Principalis beneficia

Low tooling costs et citius productio setup.

Specimen enim velox turnarounds in prototypes vel limitata fugit.

Idoneam magnarum non requirere intricatus detailing.

Limitations considerare

ROI factors

Vacuum formans offert celeri tempore, ad-forum , praesertim pro humilis-volumine decurrit, sed minus idoneam diu-terminus-scale productio propter altiorem per-unitas costs pro maioris voluminibus.

| Vacuum formans | beneficia | limitations |

| Velox setup ad prototypes | Limited consilium complexionem et praecisionem |

|

| Sumptus-effective ad parva decurrit | Superiore per-unitas costs ad magna voluminibus |

|

| Apta magnas |

|

|

Summary

Iniectio CUMATIUM et vacuo formatam sunt duo key vestibulum modos, inter se distincta commoda. Iniectio CUMATIUM excellit in producendo complexu, summus volumine partes cum superioris praecisione et diuturnitatem. Vacuum formatam est specimen pro magna, simplicior partes et humilis-volumine productio debitum ad suum inferioribus tooling costs et citius setup.

Dum statuendi inter duas considerare project scriptor volumine, consilio complexitate et budget . Usus iniectio CUMATIUM ad altus-praecisione, durabile partes . Elige vacuo formatam ad prototypes aut humilis sumptus, ieiunium productio.

Ultimately dextram modum pendeat in vestri specifica requisitis et longa-term metas.

Reference Sources

Vacuum formans

Iniectio CUMATIUM

Top iniectio CUMATIUM Service

FAQs

Q: Quid est pelagus differentia inter iniectio CUMATIUM et vacuum formatam?

A: Iniectio CUMATIUM injicts liquefacta plastic in formam. Vacuum formatam extenditur calefacta plastic laminas per formas per suctu.

Q: Quod processus melius est summus volumen productionem?

A: Iniectio CUMATIUM excellit ad altum volumina super 10,000 unitates cum citius exolvuntur tempora et automated productio.

Q: can vacuo formans creare partes cum intricate details et stricta tolerances?

A: No. vacuo formatam creates simpliciorem figuras cum Looser tolerances quam iniectio CUMATIUM.

Q: est iniectio CUMATIUM magis pretiosa quam vacuum formans?

A: Coepi Tooling costs sunt altior pro iniectio CUMATIUM, sed unitas costs facti minus in altum voluminibus.

Q: Quid materiae potest esse in iniectio CUMATIUM et vacuo formans?

A: Iniectio CUMATIUM utitur variis plastic pellets. Vacuum formans solum cum Thermoplastic laminas.