Yu no se ova 80% pan ɔl di plastic prodak dɛm we de rawnd yu, dɛn mek am yuz ɛni wan pan injɛkshɔn moldin ɔ vaykum fɔm? Dis tu manufakchurin Titans de shep wi evride tin difren difren.

Fɔ mek di rɔng chuk bitwin dɛn prɔses ya kin kɔst yu biznɛs tawzin dɔla. Bɔku manifakta dɛn kin strɛs wit dis disizhɔn, dɛn kin ambɔg dɛn prodakshɔn kɔst ɛn di tɛmlayn dɛn.

Insay dis kɔmprɛhɛnsif gayd, wi go fɛn di men difrɛns bitwin injɛkshɔn moldin ɛn vaykum fɔm. Yu go lan aw ɛni prɔses de wok, dɛn kɔst implikashɔn, ɛn us we go fayn fɔ yu patikyula manufakchurin nid dɛn.

Ɔndastand di bɛsis: Injɛkshɔn Moldin vs. Vakyum Fɔm Prɔses

Wetin na injɛkshɔn moldin?

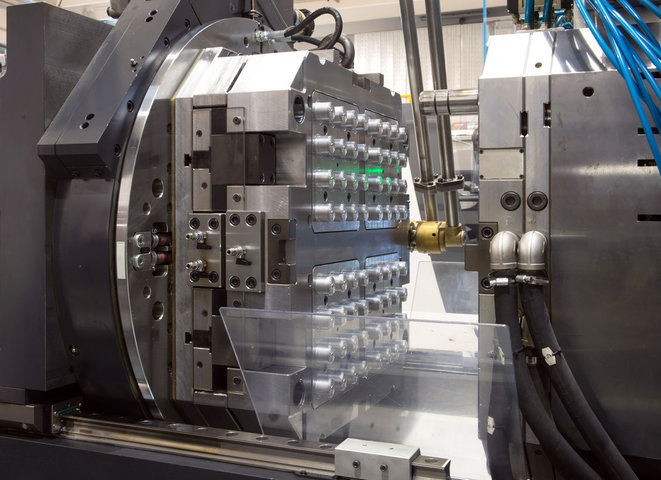

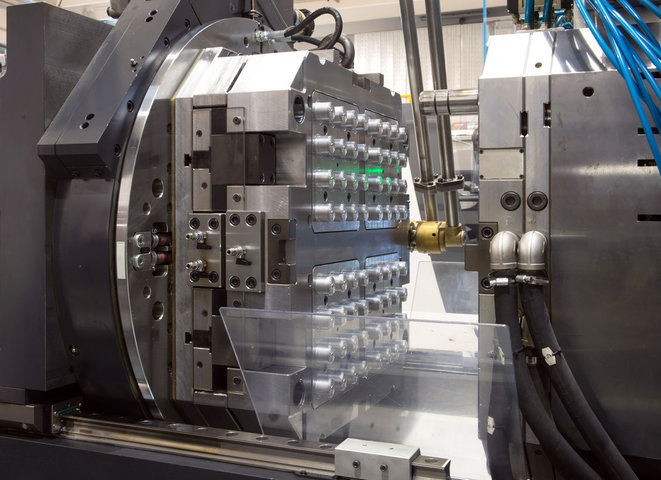

Injɛkshɔn moldin na wan we we dɛn kin yuz bɔku bɔku tin dɛn we dɛn kin yuz fɔ mek tin dɛn we kin mek plastic pat dɛn we kin de fɔ lɔng tɛm ɛn we kin de fɔ lɔng tɛm. I kin min fɔ mɛlt plastic pellets, injekt dɛn insay wan mol ɔnda ay prɛshɔn, ɛn kol dɛn to sɔlid shep dɛn.

Step-by-step prɔses:

Loading Pellets : Dɛn kin tɔn plastic pellet ɔ granul insay wan hopper.

Itin ɛn mɛlt : Dɛn kin ɔt di pellet dɛn insay wan barɛl, dɛn kin tɔn to plastic we dɔn rɔtin.

Injɛkshɔn : Dɛn kin fos di tin dɛn we dɛn dɔn kɔt fɔ mek dɛn go insay wan mold kaviti we dɛn de yuz wan ay-prɛshɔn skru ɔ ram.

Kul : Di plastic de kol insay di mold, i de at insay di las pat shep.

Ejection : We dɛn dɔn kol am, dɛn kin pul di pat kɔmɔt na di mol, rɛdi fɔ dɔn.

Ki komponent dɛn fɔ injɛkshɔn moldin mashin dɛn:

Hopper : I de ol ɛn fid plastic pellet dɛn insay di mashin.

Barel : Usay dɛn kin ɔt di plastic ɛn mɛlt.

Skru/Rɛsiprokɛt Skru : Fɔs dɛn we dɔn rɔtin plastic insay di mol.

Mold cavity : Di spes usay di plastic de fɔm insay di pat we dɛn want.

Klamp yunit : Kip di mold klos we dɛn de injekt ɛn kol.

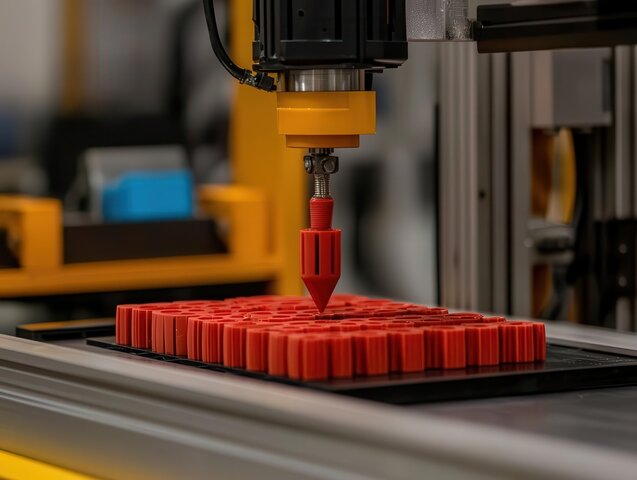

Wetin na vaykum fɔm?

Vakum fɔm, wan simpul prɔses we yu kɔmpia to injɛkshɔn moldin, na fayn tin fɔ mek big, laytwɛt pat dɛn. I kin min fɔ ɔt wan plastic sheet te i saf, dɔn yuz vaykum prɛshɔn fɔ mol am to di shep we yu want.

Step-by-step thermoforming proses:

Klamp : Di plastic sheet de klamp in ples.

Itin : Dɛn kin ɔt di sheet te i bi pliable.

Molding : Dɛn kin strɛch di shit we dɔn soft oba wan mol, ɛn dɛn kin put wan vaykum fɔ shep di pat.

Kul : Di plastic we dɛn dɔn mol kin kol ɛn at fɔ mek i at.

Trim : Dɛn trim ɛksɛs matirial ɔf, lɛf di las prɔdak.

Impɔtant Ikwipmɛnt ɛn Kɔmpɔnɛnt dɛn:

Itin elemɛnt : I de soft di plastic sheet fɔ mol.

Mold (Convex/Concave) : Difayn di shep fɔ di las pat.

Vakyum : Sɔkshɔn di plastic agens di mol fɔ mek di shep.

Trim Tul : Kɔt away ɛksɛs plastic afta yu dɔn mol.

We yu kɔmpia di we aw dɛn de mek di tin dɛn we dɛn de mek .

Dizayn Kɔmplisiti ɛn Limiteshɔn dɛn .

Manufakchurin kapabiliti dɛn kin difrɛn bad bad wan bitwin injɛkshɔn moldin ɛn vaykum fɔm. Ɛni prɔses de gi yunik advantej fɔ spɛshal dizayn rikwaymɛnt dɛn.

Injekshɔn moldin ɛksɛl dɛn na:

Krio intrikɛt ditil dɛn dɔŋ to maykroskɔpik lɛvɛl dɛn .

Prodyuz sɔlid, kɔmpleks jɔyometri dɛn inklud intanɛnt strɔkchɔ dɛn .

Manufakchurin pat dɛn we nid prɛsis tolɛreshɔn dɛn .

Inkorporεt mכltipכl mεtirial tεyp dεm na wan kכmכpכnt dεm .

Vakyum fɔm strɔng tin dɛn na:

Fabrikɛt big-big kɔmpɔnɛnt dɛn fayn fayn wan .

Krio yunifom wol tiknes kross expansiv surfaces .

Divɛlɔp laytwɛt, olo strɔkchɔ dɛn .

Prodyuz simpul jɔyometrik shep dɛn kɔst-ɛfɛktiv wan .

Sayz ɛn tiknes kɔnsidareshɔn dɛn

| Ficha | injɛkshɔn moldin | vaykum fɔm |

| Maksimal pat saiz . | Limited bay mashin kapasiti . | Eksɛlɛns fɔ big pat dɛn . |

| Minimum wall tiknes . | 0,5mm, ɛn di | 0,1mm, yu gi oh. |

| Tiknɛs kɔnsistɛns . | Dɛn kin kɔntrol am bad bad wan . | Difrɛn difrɛn tin dɛn we de apin bay we dɛn de strɛch . |

| Dizayn Fleksibiliti . | Kɔmpleks jɔyometri dɛn . | Simpul to Modaret shep dɛn . |

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Di matirial dɛn we dɛn yuz fɔ injɛkshɔn moldin ɛn vaykum fɔm difrɛn insay ɔl tu di vayriet ɛn aplikeshɔn, we afɛkt di prɔdak pefɔmɛns.

Materials we fit fɔ injɛkshɔn moldin .

Injɛkshɔn moldin de sɔpɔt bɔku bɔku tɛmplastik ɛn tɛmosɛt dɛn, we inklud:

Polypropylene (PP) , ABS , naylon , ɛn polycarbonate (PC) fɔ ay-perfɔmans aplikeshɔn dɛn.

Di polimɛr dɛn we ful-ɔp , lɛk tin dɛn we ful-ɔp wit glas ɔ we gɛt fayba, we kin mek pɔsin gɛt trɛnk ɛn we go de fɔ lɔng tɛm.

Materials kompitibul wit vakum fɔm .

Vakyum fɔm na fɔ di tɛmplastik dɛn we de na di sheet fɔm, lɛk:

Polyethylene (PE) , akrilik , PVC , ɛn hip (hay-impakt polistayn).

UV-stebul ɛn faya-retardant matirial fɔ spɛshal aplikeshɔn dɛn.

Material Property Comparisons .

Injɛkshɔn moldin : de gi wan brayt sɛlɛkshɔn, we inklud ɔt-rɛsistant, kemikal-rɛsistant, ɛn ay-strɛng polima dɛn.

Vakum Fɔm : I de wok fayn wit layt, fleksibul tɛmplastik bɔt i de gi smɔl ay-pɔfɔmɛnshɔn matirial opshɔn dɛn.

Speshal matirial tin dɛn fɔ tink bɔt .

Injɛkshɔn moldin kin akɔmod matirial dɛn we nid kɔmpawnd, lɛk antistatik ɔ bayɔkɔmpatibl plastic.

Vakum fɔm na fayn fɔ simpul, bulki pat usay matirial fleksibiliti ɛn kɔst na praymar kɔnsyans.

Kost analisis: Injekshɔn moldin vs. vaykum fɔm

We dɛn de evalyu di kɔst-ɛfɛktiv we fɔ injɛkshɔn mol ɛn vaykum fɔm, fɔ ɔndastand di ɛkspɛns dɛn we gɛt fɔ du wit am rili impɔtant. Ɔl tu di prɔses dɛn gɛt yunik kɔst strɔkchɔ dɛn we dɛn inflɔws bay tul, prodakshɔn volyum, ɛn leba.

Initial invɛstmɛnt ɛn tul kɔst .

Di fɔs invɛstmɛnt kin difrɛn bad bad wan bitwin dɛn we ya fɔ mek tin dɛn. We dɛn ɔndastand dɛn difrɛns ya, dat kin ɛp biznɛs dɛn fɔ disayd fɔ du di rayt tin dɛn we gɛt fɔ du wit mɔni biznɛs.

Injɛkshɔn moldin sɛtup kɔst dɛn:

Mold Tooling: $10,000-$100,000+ Dipen pan kɔmplisiti

Mashin Invɛstmɛnt: $50,000-$200,000 fɔ standad ikwipmɛnt

Atikul dɛn we de na di periferik: $15,000-$30,000 fɔ kol sistem, matirial handlin

Vakum fɔm sɛtup kɔst:

Tul Krieshɔn: $2,000-$15,000 fɔ tipik aplikeshɔn dɛn

Ikwipmɛnt Invɛstmɛnt: $20,000-$75,000 fɔ Besik Sistem dɛn

Sɔpɔt ikwipmɛnt: $5,000-$10,000 fɔ trim, itin sistem

Ekwipmɛnt Rikwaymɛnt Kɔmpiashɔn:

| Kɔmpɔnɛnt | injɛkshɔn moldin | vaykum fɔm |

| Praymari mashin . | Injɛkshɔn we gɛt ay prɛshɔn . | Vakum fɔm steshɔn . |

| Di tin dɛn we dɛn de yuz fɔ mek tul dɛn . | stɛl we dɛn dɔn mek tranga wan, aluminiɔm . | Wud, aluminium, epoxy |

| Ikwipmɛnt fɔ Ɔksijɛn . | Material Dryer, Chillers | Shit itin sistem dɛn . |

| Kwaliti Kɔntrol . | Advans mɛzhɔmɛnt tul dɛn . | Besik Inspekshɔn Ikwipmɛnt . |

Prodakshɔn kɔst dɛn .

Prodakshɔn ɛkspɛns de dipen bad bad wan pan di volyum we dɛn nid ɛn di opareshɔnal faktɔ dɛn.

Kost fɔ ɛni yunit analisis:

Moldin fɔ injɛkshɔn:

Ay initial kɔst dɛn spred akɔdin to big prodakshɔn rɔn dɛn .

Lower Material Waste tru prɛsis matirial kɔntrol .

Ridyus di leba kɔst na ɔtomatik ɔpreshɔn .

Optimal fɔ kwantiti dɛn we pas 10,000 yunit dɛn .

Vakyum fɔm:

Lower startup costs Benefit smɔl prodakshɔn rɔn dɛn .

Di west we gɛt ay ay tin dɛn frɔm di sheet trim .

Inkris leba rikwaymɛnt fɔ dɔn .

Kost-effektiv ɔnda 3,000 yunit dɛn

Brek-ivin analisis:

Low Volume (< 1,000 units): Vakyum fɔm de pruv mɔ ikɔnomik

Midul Volyum (1,000-10,000): Kɔst kɔmpiashɔn we dɛn nid bays pan pat spɛsifikɛshɔn dɛn

Ay volyum (> 10,000): Injɛkshɔn moldin kin bi signifyant mɔ kɔst-ɛfɛktiv

Opareshɔnal kɔst faktɔ dɛn:

| kɔst | ɛlimɛnt injɛkshɔn moldin | vaykum fɔm |

| Di tin dɛn we dɛn nid fɔ du fɔ wok . | Lɔw (ɔtomɛtik) . | Midul to ay . |

| Material Efisiɛns . | 98% | 70-85% |

| Enaji Kɔnsɔmshɔn . | Ay | Lukin-grɔn uman |

| Di kɔst fɔ mentenɛns . | Modaret to ay . | Low to Moderate . |

Prodakshɔn Tin dɛn fɔ Tink bɔt .

We dɛn de pik bitwin injɛkshɔn moldin ɛn vaykum fɔm, di wan dɛn we de mek am fɔ evalyu sɔm tin dɛn we gɛt fɔ du wit prodakshɔn, lɛk volyum, spid, ɛn lida tɛm. Ɔndastand aw dɛn prɔses ya kin kɔmpia ɛp fɔ mek dɛn disayd fɔ du sɔntin we dɛn no.

Prodakshɔn Volyum .

Prodakshɔn volyum signifyant inflɔws manufakchurin mɛtɔd sɛlɛkshɔn. Ɛni prɔses de gi difrɛn bɛnifit dɛn na difrɛn skel dɛn.

lɔw-volyum prodakshɔn (< 3,000 yunit dɛn)

Vakum fɔm de gi kɔst-ɛfɛktiv sɔlvishɔn fɔ protɔtayp rɔn dɛn .

Tul modifyeshɔn dɛn stil simpul ɛn afɔdabul .

Kwik Sɛtup de ɛnabul fɔ mek dɛn yuz rapid dizayn itɛreshɔn dɛn kwik kwik wan.

Lower initial invɛstmɛnt sus dɛn limited prodakshɔn nid dɛn .

Manufakchurin we gɛt ay vɔlyum (> 10,000 yunit dɛn)

Injɛkshɔn moldin de deliver supia ikɔnomik na skel .

Awtomat prɔses dɛn de ridyus di kɔst fɔ leba .

Konsistent kwaliti kross big prodakshɔn rɔn dɛn .

Multiple cavity tools Inkris autput efisiensi .

Skalabiliti Kɔmpiashɔn:

| Faktɔ | injɛkshɔn moldin | vaykum fɔm |

| Di fɔs tɛm we dɛn go ebul fɔ wok . | Midul to ay . | Low to medium . |

| Skeling Ease . | Kɔmpleks tul modifyeshɔn dɛn . | Simpul tul ajɔstmɛnt dɛn . |

| Autput ret . | 100-1000+ pat/awa | 10-50 pat/awa |

| Prodakshɔn Fleksibul . | Limitɛd . | Ay |

Lid tɛm ɛn tɛm-to-maket .

Ɔndastand di tɛmlayn rikwaymɛnt dɛn de ɛp fɔ mek dɛn ebul fɔ plan di prɔjek fayn fayn wan ɛn gi dɛn risɔs alɔkeshɔn.

Divɛlɔpmɛnt Taymfrɛm dɛn:

Moldin fɔ injɛkshɔn:

Tul Dizayn ɛn Manufakchurin: 12-16 wik

Material Selection ɛn Testing: 2-3 wiks

Prodakshɔn sɛtup ɛn validɛshɔn: 1-2 wik

Fɔs atikul Inspekshɔn: 1 wik

Vakyum fɔm:

Tul fabrikeshɔn: 6-8 wiks

Material Procurement: 1-2 wik

Proses Sɛtup: 2-3 dez .

Sampul Valideshɔn: 2-3 dez

Manufakchurin Saykl Kɔmpiashɔn:

| Prɔses Faz | Injɛkshɔn Mɔldin | Vakyum Fɔm |

| Sɛtup tɛm . | 4-8 awa . | 1-2 awa . |

| Saykl tɛm . | 15-60 sɛkɔn dɛn | 2-5 minit . |

| Chenj di tɛm we dɛn chenj di tɛm we dɛn de | 2-4 awa . | 30-60 minit . |

| Kwaliti chɛk dɛn . | Kɔntinyu fɔ . | Batch-based na |

Projekt Taymlayn Tin dɛn fɔ Tink bɔt:

Prodakt Kɔmplisiti Impɛkt Tul Divɛlɔpmɛnt .

Material Availability Afects Lead Times .

Kwaliti Rikwaymɛnt dɛn Influɛns Valideshɔn Tɛm dɛn .

Prodakshɔn Volyum de ditarmin di totɛl prɔjek durayshɔn .

Kwaliti ɛn Pɔfɔmɛnshɔn Fakta dɛn .

Prɛsishɔn ɛn tolɛreshɔn dɛn .

Manufakchurin kwaliti difrɛn bad bad wan bitwin dɛn prɔses ya. Ɔndastand dɛn difrɛns ya de ɛp fɔ mek shɔ se di prɔdak spɛsifikɛshɔn dɛn mach di prɔses kapabiliti dɛn.

Dimensional akkuracy kɔmpiashɔn:

| ficha | injɛkshɔn moldin | vakum fɔm |

| Tolerance renj . | ±0,1mm | ±0,5mm |

| Ditel Rizolushɔn . | Wɛl dɔn | Soba |

| Ɔltɛm | Dɛn kin ripit am bɔku bɔku wan . | Variable we de chenj chenj . |

| Di difinishɔn fɔ di kɔna . | Shap | Rounded . |

Surface finish characteristics:

Injɛkshɔn moldin de ajɔst klas A sɔfays dɛn dairekt frɔm di mol .

Vakum fɔm de mentɛn kɔnsistɛns tɛkstɔr akɔdin to big sɔfays dɛn .

Ɔl tu di prɔses dɛn de sɔpɔt difrɛn tɛkstɔr dɛn tru mold sɔfayz tritmɛnt dɛn .

Pɔst-prɔsɛsin opshɔn dɛn de ɛp fɔ mek di las apia fayn fayn wan .

Kwaliti Kɔntrol Mɛzhɔ:

Injɛkshɔn moldin kɔntrol dɛn: .

In-layn dimɛnshɔnal monitɔrin .

Awtomat Visual Inspekshɔn .

Statistikal Prɔses Kɔntrol .

Material Prɔpati Vɛrifikɛshɔn .

Vakum fɔm kɔntrol dɛn:

Shit tiknes mɛzhɔmɛnt dɛn .

MANUAL DIMENSHƆNAL CHƐK DƐN .

Visual Surface Inspekshɔn .

Tempratura Monitoring sistem dɛn .

Strɔng ɛn fɔ lɔng tɛm .

Bɔku tɛm, di tin dɛn we dɛn nid fɔ du fɔ mek di prɔdak pefɔmɛns, kin no bɔku tɛm di we aw dɛn de pik di prɔses. Ɛni we de gi difrɛn strɔkchɔral advantej dɛn.

Struktural Pɔfɔmɛnshɔn:

Di bɛnifit dɛn we dɛn kin gi fɔ mold injɛkshɔn:

Yunifom matirial distribyushɔn de ɛp fɔ mek trɛnk bɛtɛ .

Intanɛt Riinfɔsmɛnt Pɔssibiliti dɛn .

Prɛsis kɔntrol oba matirial prɔpati dɛn .

Komplex joyometri sɔpɔt fɔ strɔkchɔral ɛlimɛnt dɛn .

Vakyum fɔm di kwaliti dɛn:

Konsistent wol tiknes in simpul joyometries .

Limitɛd strɔkchɔral dizayn opshɔn dɛn .

Gud trɛnk-to-weit ratio .

Eksɛlɛnt impak absɔpshɔn insay sɔm aplikeshɔn dɛn .

CHƆT WE DE RILIST ENVAYRƆMƐNT RƐSISTANS:

| Faktɔ | injɛkshɔn moldin | vaykum fɔm |

| UV stebiliti fɔ . | Material Dipɛndent . | Gud |

| Kεmikכl rεsistεns . | Wɛl dɔn | Soba |

| Tempracha renj . | -40°C to 150°C | -20°C to 80°C |

| Moisture resistans . | Big pas | Gud |

Di tin dɛn we de apin fɔ lɔng tɛm fɔ du di wok:

Material Degradation Rates .

Stress krak krak resistans .

Kolor stebiliti .

Impekt Strɔng Ritɛnshɔn .

Aplikeshɔn ɛn di we aw dɛn de yuz di industri .

Fɔ ɔndastand di aplikeshɔn ɛn di we aw di industri de yuz injɛkshɔn moldin ɛn vaykum fɔm impɔtant we yu de pik di rayt manufakchurin prɔses. Ɛni we de gi difrɛn bɛnifit dɛn we fit sɔm patikyula industri ɛn kayn prɔdak dɛn.

Kɔmɔn Aplikeshɔn dɛn .

Injekshɔn Moldin Tipik Yuz dɛn .

Injɛkshɔn moldin na bɔku say dɛn de yuz fɔ prodyuz kɔmpleks, ay-volyum pat dɛn wit prɛsis ficha dɛn. Di tin dɛn we i de yuz na:

Ilɛktronik Hausin : I de protɛkt intanɛnt kɔmpɔnɛnt dɛn wit plastic we go de fɔ lɔng tɛm ɛn we nɔ de te.

Otomotiv Pat : Enjin komponent, klip, ɛn fastɛns de bɛnifit frɔm ay prɛsishɔn.

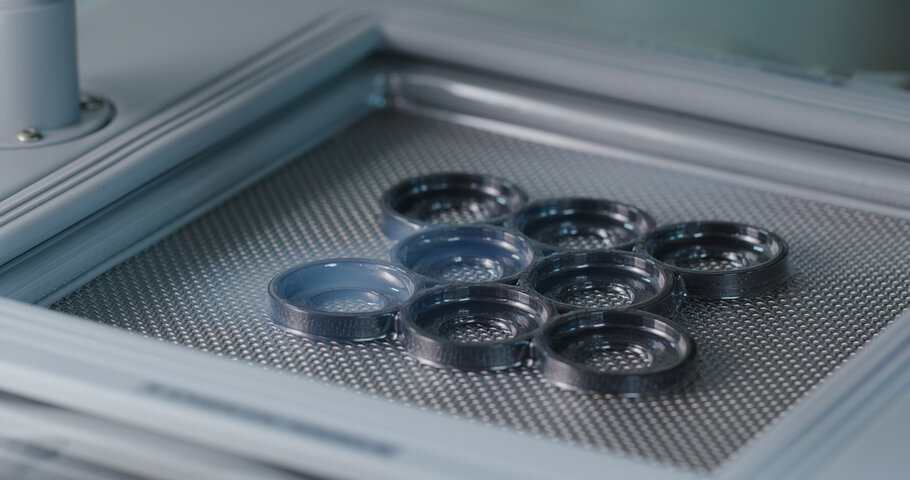

Medikal Divays : Surgical tools, sirinj, ɛn diagnostik ikwipmɛnt nid klin, kɔnsistɛns prodakshɔn.

Vakum fɔm tipik yus dɛn .

Vakyum fɔm na di wan we dɛn kin lɛk fɔ big, layt pat ɛn protɔtayp. Na kɔmɔn tin fɔ yuz na:

Packaging Tray : Trays we tan lɛk kɔstɔm fɔ mɛn pipul dɛn, it, ɔ tin dɛn we pipul dɛn kin yuz fɔ bay tin dɛn.

Otomotiv Intɛriɔ Panɛl dɛn : Big Dashbɔd ɛn Trim Kɔmpɔnɛnt dɛn.

Point-of-sale displays : Sturdy bɔt laytwɛt plastic displei fɔ rital ɛnvayrɔmɛnt.

Indastri-spɛsifi k Aplikeshɔn

Erospace : Dɛn kin yuz vaykum fɔm fɔ laytwɛt intɛriɔ panɛl ɛn trey, we injɛkshɔn moldin kin mek intrɛst kɔmpɔnɛnt dɛn.

Kɔnsuma Ilɛktroniks : Injɛkshɔn moldin na impɔtant tin fɔ protɛkt kes, plɔg, ɛn divays ɛnklɔzhɔ.

Food and Beverage Packaging : Vacuum forming de prodyuz layt weit, protektiv plastic pak we de konfom to fud sefty standad.

| Indastri | Injɛkshɔn Mɔldin Ɛgzampul dɛn | Vakyum Fɔm Ɛgzampul dɛn |

| Ɔtomotiv . | Di pat dɛn na di injin, fastɛns dɛn . | Dashboards, Trim Panels . |

| Divays dɛn fɔ mɛn pipul dɛn . | sirinj, diagnostik tul dɛn . | Medikal trey, paket |

| Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn . | Ilektronik Hausin, Toys . | Big pak, pɔynt-ɔf-sɛl displei dɛn |

Indastri-spɛsifi k rikwaymɛn dɛn .

Ɔtomotiv Indastri Nid dɛn .

Injɛkshɔn Molding : Di ɔtomotiv industri de aks fɔ ay prɛsishɔn fɔ pat dɛn lɛk fastɛns, injin kɔmpɔnɛnt dɛn, ɛn klip dɛn. Injɛkshɔn moldin mit dɛn nid ya tru kɔnsistɛns prodakshɔn fɔ pat dɛn we go de fɔ lɔng tɛm, we nɔ de ɔt.

Vakyum Fɔm : Dɛn kin yuz am fɔ big pat dɛn, lɛk domɔt panɛl, dashbɔd, ɛn trɔnk layna, we nid laytwɛt kɔnstrɔkshɔn.

Medikal Divays Manufakchurin .

Injɛkshɔn moldin : I fayn fɔ mek dɛn prodyuz ay-prɛsishɔn, stɛriyl kɔmpɔnɛnt dɛn, lɛk sirinj, diagnostik kit, ɛn ɔspitul inschrumɛnt dɛn.

Vakyum Fɔm : Dɛn kin yuz am fɔ mek kɔstɔm pak fɔ mɛrɛsin tul ɔ stɛrilayz tre we dɛn kin yuz na ɔspitul.

Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn .

Injɛkshɔn Molding : Kritik fɔ smɔl, ditayla kɔshɔma guds, lɛk ilɛktronik divays haus, plastic tɔys, ɛn kichin tin dɛn.

Vakyum Fɔm : I fayn fɔ big displei, pak, ɛn protɛkt kes dɛn we dɛn kin yuz na rital ɛnvayrɔmɛnt.

Pakɛj Sɔlwɛshɔn dɛn .

Injɛkshɔn moldin : I fayn fɔ mek yu yuz kɔntena dɛn we yu kin yuz bak, we nɔ gɛt ɛnitin fɔ du wit am ɛn we go protɛkt yu.

Vakyum Fɔm : Dɛn kin yuz am bɔku bɔku wan fɔ blista pak, klamshɛl pak, ɛn layt tray we dɛn kin mek bɔku bɔku wan.

Fɔ mek di rayt tin fɔ pik .

Fɔ pik bitwin injɛkshɔn moldin ɛn vaykum fɔm de dipen pan sɔm impɔtant tin dɛn. We dɛn asɛs di prɔjek-spɛsifi k nid dɛn ɛn ɔndastand di bɛnifit dɛn we ɛni wan pan di we dɛn gɛt, di wan dɛn we de mek di tin dɛn kin disayd fɔ du sɔntin we dɛn no bɔt we de alaynɛd wit dɛn prodakshɔn gol dɛn.

Di tin dɛn we de mek pɔsin disayd fɔ du sɔntin .

Di tin dɛn we dɛn nid fɔ du fɔ mek di prɔjek go bifo .

Fɔ evaluate yu projɛkt in dizayn kɔmplisiti, pat saiz, ɛn prodakshɔn volyum impɔtant. If yu projɛkt involv intrikɛt pat dɛn wit tayt tolɛreshɔn, injɛkshɔn moldin kin bi di bɛtɛ opshɔn. Fɔ simpul, big pat, vaykum fɔm kin gi bɛtɛ kɔst ɛn spid advantej.

Di tin dɛn we dɛn fɔ tink bɔt fɔ di badjɔt .

Injɛkshɔn Molding : Di ay ɔpfrɔnt tul kɔst bɔt ridyus di kɔst fɔ ɛni pat pan ay-volyum prodakshɔn.

Vakyum fɔm : lɔwa tul kɔst, fayn fɔ lɔw- to midul-volyum prodakshɔn ɔ protɔtayp.

Di tin dɛn we dɛn nid fɔ du wit di tɛm we dɛn fɔ du di wok .

Kwaliti spɛsifikɛshɔn dɛn .

Tink bɔt di dimɛnshɔnal akkuracy we dɛn nid , di sɔfays finish, ɛn di matirial trɛnk. Injɛkshɔn moldin de deliver supia kwaliti ɛn kɔnsistɛns, we vakum fɔm de gi gud rizɔlt fɔ less dimand aplikeshɔn.

We fɔ pik injɛkshɔn moldin .

Ideal sɛnɛriɔ dɛn .

Ay-volyum prodakshɔn fɔ smɔl, kɔmpleks pat dɛn ..

projɛkt dɛn we nid tayt tolɛreshɔn ɛn ditayla ficha dɛn, lɛk di kɔmpɔnɛnt dɛn we gɛt trɛd ɔ snap-fit.

Ki Advantej dɛn .

Kɔst-ɛfɛktiv fɔ big-big prodakshɔn.

Ay prɛsishɔn ɛn ripitabiliti fɔ kɔmpleks dizayn dɛn ..

Durability ɛn lɔng tɛm pefɔmɛns wit advans matirial dɛn.

Di tin dɛn we pɔsin kin du we i nɔ ebul fɔ du .

Kɔst-bɛnifit analisis .

Pan ɔl we di fɔs ɛkspɛns dɛn ay, injɛkshɔn moldin na mɔ ikɔnomik fɔ ay volyum bikɔs ɔf di lɔwa pe-yunit kɔst. Di prɔses bak fayn bak we prɛsishɔn ɛn matirial trɛnk impɔtant.

| Injɛkshɔn Moldin | Advantej dɛn | Limiteshɔn dɛn . |

| Ideal fɔ kɔmpleks pat dɛn . | High upfront kos dɛn . |

|

| Kost-effektiv fɔ big big rɔn dɛn . | Di tɛm we dɛn dɔn sɛtup fɔ lɔng tɛm ɛn di wan dɛn we de bifo . |

|

| Ay pat-to-pat kɔnsistɛns . |

|

|

Ustɛm fɔ pik vaykum fɔm .

Di bɛst-yuz kes dɛn .

Prototyping ɔ low-volume prodakshɔn de rɔn.

Big, simpul pat dɛn lɛk ɔtomotiv dɛshbɔd , pak trey, ɔ pɔynt-ɔf-sayl displei dɛn.

Men bɛnifit dɛn .

Low tooling kos ɛn fasta prodakshɔn sɛtup.

Ideal fɔ kwik tɔn-arawnd pan protɔtayp ɔ limited rɔn.

Suitabl fɔ big pat dɛn we nɔ nid intrɛstin ditaylin.

Limiteshɔn dɛn fɔ tink bɔt .

ROI Fakta dɛn .

Vakum fɔm de gi kwik tɛm-to-maket , mɔ fɔ lɔw-volyum rɔn, bɔt i nɔ fayn fɔ lɔng tɛm, big-big prodakshɔn bikɔs ɔf ay kɔst fɔ ɛni yunit fɔ big volyum.

| Vakyum fɔm | bɛnifit | limiteshɔn dɛn . |

| Kwik sɛtup fɔ protɔtayp dɛn . | Limitɛd dizayn kɔmplisiti ɛn prɛsishɔn . |

|

| Kost-effektiv fɔ smɔl rɔn dɛn . | Higher per-unit kos fɔ big volyum dɛn . |

|

| I fayn fɔ big pat dɛn . |

|

|

Ɛksplen

Injɛkshɔn moldin ɛn vaykum fɔm na tu ki manufakchurin we, ɛvri wan gɛt difrɛn bɛnifit dɛn. Injekshɔn moldin ɛksɛl fɔ prodyuz kɔmpleks, ay-volyum pat dɛn wit supia prɛsishɔn ɛn durabiliti. Vakum fɔm na fayn tin fɔ big, simpul pat ɛn lɔw-volyum prodakshɔn bikɔs ɔf in lɔwa tul kɔst ɛn fasta sɛtup.

We yu de disayd bitwin di tu, tink bɔt yu prɔjek in volyum, dizayn kɔmplisiti , ɛn badjɛt . Yuz injɛkshɔn moldin fɔ ay-prɛsishɔn, durable pat dɛn . Jus vakum fɔm fɔ protɔtayp ɔ lɔw-kɔst, fast prodakshɔn.

As a de dɔn, di rayt we fɔ du tin dipen pan di patikyula tin dɛn we yu nid ɛn di lɔng tɛm gol dɛn we yu go gɛt ..

Rifrɛns Sɔs dɛn .

Vakum fɔm .

Moldin fɔ injɛkshɔn .

Top injekshɔn moldin savis .

FAQ dɛn .

K: Wetin na di men difrɛns bitwin injɛkshɔn moldin ɛn vaykum fɔm?

A: Injɛkshɔn moldin de injɛkt mɛlt plastic insay mol. Vakum fɔm strɛch dɛn we dɛn dɔn ɔt plastic sheet dɛn oba mold dɛn we dɛn de yuz sɔkshɔn.

K: Us prɔses i bɛtɛ fɔ mek dɛn prodyuz ay-volyum?

A: Injɛkshɔn moldin de ɛksɛl pan ay volyum dɛn we pas 10,000 yunit dɛn wit fasta saykl tɛm ɛn ɔtomatik prodakshɔn.

K: Vakyum fɔm kin mek pat wit intrikɛt ditil ɛn tayt tolɛreshɔn?

A: Nɔ. Vakyum fɔm de mek simpul shep dɛn wit lɔs tolɛreshɔn pas injɛkshɔn moldin.

K: Injekshɔn moldin mɔ dia pas vaykum fɔm?

A: Di fɔs tul kɔst dɛn ay fɔ injɛkshɔn moldin, bɔt di yunit kɔst dɛn kin smɔl we dɛn gɛt ay volyum.

K: Us matirial dɛn dɛn kin yuz fɔ injɛkshɔn moldin ɛn vaykum fɔm?

A: Injɛkshɔn moldin de yuz difrɛn plastic pellet dɛn. Vakyum fɔm de wok nɔmɔ wit tɛmplastik sheet dɛn.