Yala aw b’a dɔn ko aw lamini plastiki fɛn minnu bɛɛ kɛra, olu 80% ni kɔ kɛra ni pikiri kɛli ye walima ni vacuum ye wa? Nin titan fila ninnu bɛ an ka don o don fɛnw cogoya cogoya wɛrɛ la.

Ka sugandili jugu kɛ o walew ni ɲɔgɔn cɛ, o bɛ se ka dɔrɔmɛ ba caman bɔ i ka jago la. Dilanbaga caman bɛ gɛlɛya sɔrɔ o latigɛ in na, o bɛ nɔ bila u ka fɛn dilanni musakaw la ani u ka waati bolodalenw na.

Nin gafe in kɔnɔ, an bɛna danfara jɔnjɔnw sɛgɛsɛgɛ pikiri kɛcogo ni vacuum dilanni cɛ. Aw bɛna a dɔn taabolo kelen-kelen bɛɛ bɛ baara kɛ cogo min na, u musaka bɛ na ni min ye, ani fɛɛrɛ jumɛn bɛ bɛn aw ka fɛn dilanni mago kɛrɛnkɛrɛnnenw ma kosɛbɛ.

Faamuyali basigilenw: pikiri kɛcogo ni vacuum dilanni taabolo .

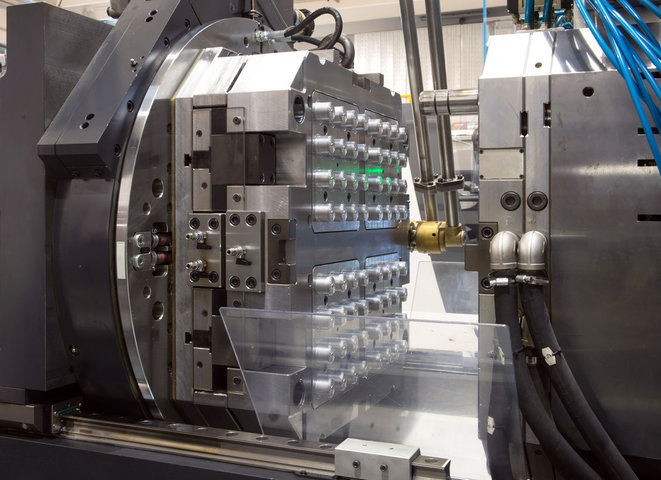

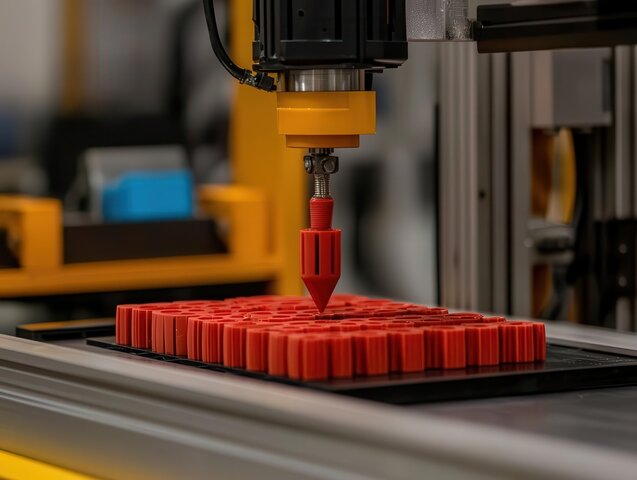

Pikiri kɛli ye mun ye?

pikiri kɛli ye fɛn dilanni ye min bɛ se ka kɛ fɛn caman na, min bɛ plastiki yɔrɔ tigitigiw dilan, minnu bɛ mɛn. O ye ka plastiki bɔgɔlanw wuli, k’u pikiri kɛ nɔgɔ la degunba la, k’u nɛnɛ cogoya gɛlɛnw na.

Taabolo min bɛ kɛ senfɛ-senfɛ:

Loading pelets : plastiki peletiw walima granules bɛ bɔn hopper kɔnɔ.

So funteni ni a wulicogo : Pellets bɛ sumaya bara kɔnɔ, ka wuli ka kɛ plastiki sɔgɔlen ye.

Pikiri : Fɛn min bɛ wuli, o bɛ waajibiya ka kɛ nɔgɔbɔlan ye ni a bɛ ni tansiyɔnba ye walima ni a bɛ kɛ ni RAM ye.

Nɛnɛ : Plastiki bɛ nɛnɛ foroko kɔnɔ, ka gɛlɛya ka don a yɔrɔ laban cogoya la.

Ejection : Ni a nɛnɛna, a yɔrɔ bɛ bɔ foroko la, a labɛnnen don ka ban.

Pikiriw dilanni masinw yɔrɔ kolomaw:

Hopper : a bɛ plastiki peletiw minɛ ani ka u balo masin na.

Barrel : Yɔrɔ min na plastiki bɛ sumaya ani ka wuli.

Vis/reciprocating vis : Wajibiyalen plastiki la ka don foroko kɔnɔ.

Mold Cavity : Yɔrɔ min na plastiki bɛ kɛ yɔrɔ ɲininen na.

CLAMPING UNIT : A bɛ mɔli dabila pikiri ni nɛnɛ waati la.

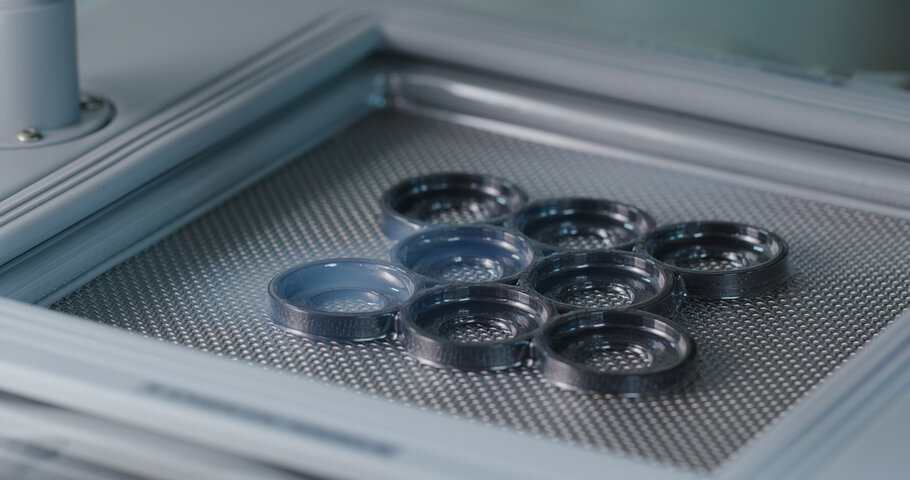

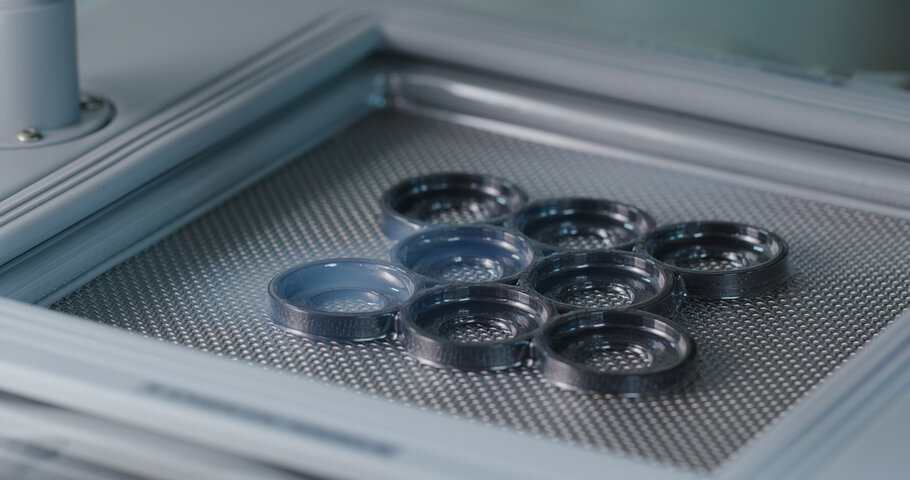

Vacuum bɛ kɛ mun ye?

Vacuum forming, o ye wale nɔgɔman ye ni a bɛ tali kɛ pikiri kɛli la, o ka ɲi kosɛbɛ walasa ka yɔrɔbaw dilan minnu ka nɔgɔn. O ye ka plastiki sɛbɛn dɔ sumaya fo ka a mɔ, o kɔ, a bɛ kɛ ni fɛnɲɛnamafagalan ye walasa k’a kɛ cogo la min b’a fɛ.

thermoforming thermoforming step-sen:

CLAMPING : Plastiki sɛbɛn bɛ siri a nɔ na.

Sumaya : Sɛbɛn in bɛ sumaya fo a ka kɛ fɛn ye min bɛ se ka wuli.

Moli : sɛbɛn nɔgɔlen bɛ sɔgɔ nɔgɔ kan, ka sɔrɔ ka yɔrɔ in cogoya.

Nɛnɛ : plastiki mɔlen bɛ nɛnɛ ani ka gɛlɛya a nɔ na.

Trimming : Fɛn tɛmɛnenw bɛ tigɛ, ka fɛn laban to yen.

Minɛnw ni u kɔnɔfɛnw nafamaw:

So funteni : A bɛ plastiki sɛbɛn nɔgɔya walasa ka a mɔ.

Mold (Convex/Concave) : A bɛ yɔrɔ laban cogoya ɲɛfɔ.

Vacuum : A bɛ plastiki sumaya ka ɲɛsin nɔgɔ ma walasa a ka kɛ cogoya ye.

Trimming Tools : Aw bɛ plastiki tɛmɛnenw tigɛ ka bɔ u dilanni kɔfɛ.

Ka fɛn dilanni sekow suma ɲɔgɔn na .

Design complexité et limitions .

A dilanni seko bɛ danfaraba don pikiri kɛcogo ni vacuum dilanni cɛ. Taabolo kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di dilancogo kɛrɛnkɛrɛnnenw ma.

Pikiri molding ka fisa ni nin ye:

ka kunnafoni gɛlɛnw dilan fo ka se hakɛ fitininw ma .

ka jateminɛ kɛ ni jateminɛ gɛlɛnw ye, minnu ka gɛlɛn, kɔnɔna fɛnw sen bɛ o la .

Fɛn dilanni yɔrɔ minnu bɛ muɲuli tigitigiw wajibiya .

ka fɛn suguya caman don a kɔnɔ fɛn kelenw kɔnɔ .

Vacuum sɔrɔli fanga dɔw ye:

Fɛn minnu bɛ kɛ ka fɛnw dilan ka ɲɛ .

Ka kogo janya kelen dilan yɔrɔw la minnu ka bon kosɛbɛ .

Ka fɛnw labɛn minnu ka nɔgɔn, minnu kɔnɔna ka nɔgɔn .

ka jateminɛ kɛcogo nɔgɔmanw dilan musaka-nɔgɔya la .

Bonya ni janya jateminɛw

| bɛ kɛ ni | pikirijikɛlan ye min | bɛ kɛ ka fɛn dɔ kɛ . |

| A yɔrɔ hakɛ maksimali . | dan ye masin seko ye . | A ka ɲi kosɛbɛ yɔrɔbaw kama . |

| Minimum kogo janya . | 0,5mm . | 0,1mm . |

| A ka bon kosɛbɛ . | A bɛ mara kosɛbɛ . | A bɛ danfara ka kɛɲɛ ni a sɔgɔli ye . |

| Dilancogo sɛgɛsɛgɛli . | Geometries complexe . | Siginiden nɔgɔmanw ka se hakɛ danmadɔw ma . |

Material Selection .

Fɛn minnu bɛ kɛ pikirijikɛlan ni vacuum dilanni na, olu tɛ kelen ye suguya ni a kɛcogo la, o bɛ nɔ bila fura baaracogo la.

Fɛn minnu bɛnnen don pikiri kɛli ma .

Pikirili moulding bɛ se ka funteni ni funteni suguya caman dɛmɛ, i n’a fɔ:

Poliporopilini (pp) , ABS , nilon , ani polikarbonati (PC) ka baara kɛ ka ɲɛ.

Polimɛri falenw , i n’a fɔ fɛn minnu falen don gilasi la walima minnu barika ka bon, minnu bɛ fanga ni muɲuli sabati.

Fɛn minnu bɛ bɛn ni vacuum ye .

Vacuum forming bɛ dan thermoplastiques ma sɛbɛncogo la, i n’a fɔ:

Poliɛtilɛni (PE) , akiriliki , PVC , ani kɔkiliw (polisitirini min bɛ se ka kɛ fɛn caman ye).

UV-stable ani tasuma-fanga -minɛnw ka ɲɛsin baara kɛrɛnkɛrɛnnenw ma.

Material Property Comparaisons .

Pikiri mɔli : A bɛ sugandili caman di, i n’a fɔ polimɛri minnu bɛ se ka funteni sɔrɔ, minnu bɛ se ka kɛ ni kemikɛli ye, ani minnu fanga ka bon.

Vacuum Forming : A bɛ baara kɛ ka ɲɛ ni thermoplastique nɔgɔman ye, min bɛ se ka wuli ka bɔ a nɔ na nka a bɛ fɛnw sugandi minnu bɛ se ka baara kɛ kosɛbɛ.

Jateminɛ kɛrɛnkɛrɛnnenw .

Pikiri dilanni bɛ se ka fɛnw ladon minnu bɛ kɛ ka fɛnw fara ɲɔgɔn kan, i n’a fɔ plastiki minnu bɛ kɛ ka antistatiki walima biologiki kɛ.

Vacuum dilanni ka ɲi kosɛbɛ yɔrɔw la minnu ka nɔgɔn, minnu ka bon kosɛbɛ, yɔrɔ minnu na fɛnw sɛgɛsɛgɛli ni u musaka ye haminanko fɔlɔw ye.

musaka sɛgɛsɛgɛli: pikiri kɛli ni vacuum ye .

Ni aw bɛ pikirijikɛlanw dilanni ni u labɛncogo musaka jateminɛ, musaka minnu bɛ tali kɛ o la, olu faamuyali nafa ka bon kosɛbɛ. O wale fila bɛɛ bɛ ni musaka sigicogo kɛrɛnkɛrɛnnenw ye minnu bɛ nɔ bila baarakɛminɛnw na, fɛn dilanni hakɛ la, ani baara la.

Investissement fɔlɔ ani baarakɛminɛnw musakaw .

Nafolo fɔlɔ in bɛ danfaraba don o fɛn dilanni fɛɛrɛw ni ɲɔgɔn cɛ. O danfara ninnu faamuyali bɛ jagokɛlaw dɛmɛ u ka wariko latigɛw kɛ ni kunnafoniw ye.

Pikiri molding setup musakaw:

Mɔbili baarakɛminɛnw: $10,000-$100.000+ ka kɛɲɛ ni u ka gɛlɛya ye .

Masiniw ka wari bilali: $50.000-$200.000 ye minɛnw ye minnu bɛ kɛ ka kɛɲɛ ni sariya ye .

Periferikɛli wɛrɛw: $15.000-$30.000 ka ɲɛsin nɛnɛmafɛnw ma, fɛnw minɛcogo .

Vacuum Forming Setup musakaw:

Baarakɛminɛnw dilanni: $2,000-$15000 ka ɲɛsin baarakɛcogo misaliw ma .

Minɛnw bilali: $20.000-$75.000 ye sigida jɔnjɔnw ye .

Dɛmɛnminɛnw: $5000-$10000 ka ɲɛsin a tigɛcogo ma, sofaw

Minɛnw wajibiyalenw sumacogo:

| A yɔrɔ | pikiriw dilanni | vacuum formation . |

| Masina fɔlɔ . | Pikirini min bɛ kɛ ni tansiyɔnba ye . | Vacuum Forming Station . |

| Baarakɛminɛn minnu bɛ baara kɛ ni baarakɛminɛnw ye . | Nɛgɛ gɛlɛn, aluminiyɔmu . | jiri, aluminiyɔmu, epoxy . |

| dɛmɛnanw . | Materiel jalenw, chillers . | Sheet chauffage systèmes . |

| Quality Contrôle . | Sumanikɛlan minnu bɛ taa ɲɛ . | Sɛgɛsɛgɛli minɛn jɔnjɔnw . |

Sɛnɛ musakaw .

Sɛnɛ musakaw bɛ bɔ kosɛbɛ hakɛ wajibiyalenw na ani baarakɛcogo la.

Muɲu kelen-kelen bɛɛ musaka:

Pikirili mɔli:

musaka fɔlɔ caman bɛ jɛnsɛn sɛnɛfɛnw bɔli bolibaw kɔnɔ .

Fɛnw tiɲɛni minnu bɛ kɛ ka fɛnw mara tigitigi .

Baara musakaw dɔgɔyali otomatiki baara la .

Optimal for quantités ka ca ni 10.000 ye .

Vacuum Forming:

Daminɛ musakaw dɔgɔyali bɛ nafa sɔrɔ sɛnɛko misɛnninw na .

Fɛn minnu ka ca ni fɛn tiɲɛnenw ye ka bɔ sɛbɛnw tigɛcogo la .

Baara minnu ka kan ka kɛ walasa ka ban .

A musaka ka dɔgɔ ni 3000 ye .

Break-Even Analysis:

Volume dɔgɔman (< 1000 units): Vacuum sɔrɔli bɛ nafa sɔrɔ sɔrɔko la .

hakɛ cɛmancɛ (1 000-10 000): musaka sumacogo min ka kan ka kɛ ka da a yɔrɔ ɲɛfɔlenw kan .

A hakɛ ka ca (> 10.000): Pikirili bɛ kɛ fɛn ye min musaka ka dɔgɔ kosɛbɛ .

Baara musaka fɛnw:

| musaka element | pikiri molding | vacuum formation . |

| Baarakɛlaw ka wajibiw . | A ka dɔgɔ (otomatiki) . | cɛmancɛ ni sanfɛ . |

| Material ka baarakɛcogo ɲuman . | 98% . | 70-85% . |

| Enerji sɛnɛcogo . | Jamanjan | Hakɛ |

| Ladonni musakaw . | A bɛ se ka kɛ cogo min na . | A ka dɔgɔ fo ka se a danma ma . |

Production Considerations .

Ni aw bɛ pikiri kɛ pikiri kɛli ni vacuum dilanni cɛ, a dilannikɛlaw ka kan ka fɛn caman jateminɛ minnu bɛ tali kɛ fɛn dilanni na, i n’a fɔ a hakɛ, a teliya ani a bɔli waatiw. Nin wale ninnu bɛ ɲɔgɔn sanga cogo min na, o faamuyali bɛ dɛmɛ don ka latigɛw kɛ ni kunnafoniw ye.

Production Volume .

Sɛnɛ hakɛ bɛ nɔba bila fɛn dilanni fɛɛrɛ sugandili la. Taabolo kelen-kelen bɛɛ bɛ nafa danfaralenw di sɛgɛsɛgɛli suguya wɛrɛw la.

Volume dɔgɔman sɔrɔli (< 3000 unit) .

Vacuum formation bɛ fura minnu musaka ka dɔgɔ, olu bɛ kɛ ka ɲɛsin prototype runs ma .

Baarakɛminɛnw bεε bε bεn cogo min na .

Setup teliya bɛ se ka kɛ sababu ye ka iterations design rapides .

Investissement fɔlɔw ka dɔgɔya bɛ dan sigi sɛnɛko magow la .

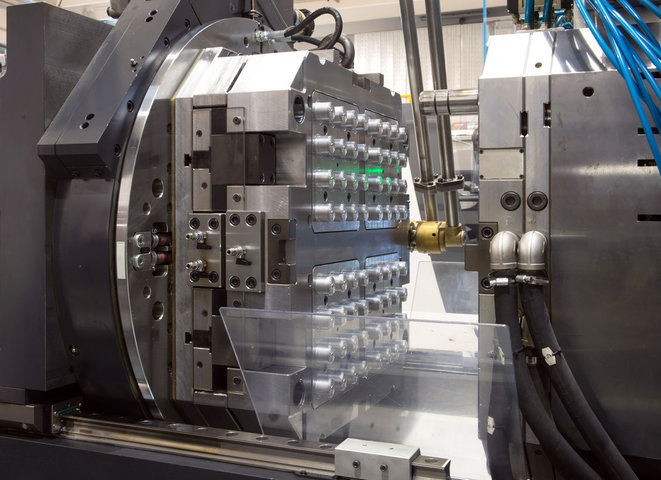

A ka ca ni fɛn caman dilanni ye (> 10.000 unit) .

Pikirili Molding bɛ sɔrɔko fisaman di sɛgɛsɛgɛli la .

Otomatiki taabolo bɛ dɔ bɔ baara musakaw la .

Jogo ɲuman min bɛ to ka kɛ fɛn dilanni bolibaw kɔnɔ .

Cavité baarakɛminɛn caman bɛ dɔ fara bɔli nafa kan .

Scalability comparaison:

| factor | injection moulding | vacuum formation . |

| A daminɛ na seko ni dɔnko . | cɛmancɛ ni sanfɛ . | A ka dɔgɔn fo ka se a cɛmancɛ ma . |

| Scaling nɔgɔya . | Baarakɛminɛnw caman caman cili . | Baarakɛminɛnw ladilancogo nɔgɔmanw . |

| Bɔli hakɛ . | 100-1000+ yɔrɔw/lɛrɛ . | 10-50 yɔrɔw/lɛrɛ . |

| Fɛnw dilanni sɛgɛsɛgɛli . | Limited . | Jamanjan |

Ɲɛnabɔli waatiw ani waati-ni-sɛnɛ .

Waatibolodacogo wajibiyalenw faamuyali bɛ dɛmɛ ka poroze bolodacogo n’a nafolo tilacogo ɲuman sɔrɔ.

Yiriwali waati dantigɛliw:

Pikirili mɔli:

Baarakɛminɛnw dilanni ani u dilanni: dɔgɔkun 12-16 .

Fɛn minnu bɛ kɛ ka fɛnw sugandi ani ka u sɛgɛsɛgɛ: Dɔgɔkun 2-3 .

Labɛnni sigicogo ani a tiɲɛni: Dɔgɔkun 1-2 .

Barokun fɔlɔ sɛgɛsɛgɛli: dɔgɔkun 1 .

Vacuum Forming:

Baarakɛminɛnw dilanni: dɔgɔkun 6-8 .

Fɛnw sanni: dɔgɔkun 1-2 .

Taabolo sigicogo: tile 2-3 .

Sample validation: tile 2-3 .

Manufacturing Cycle Comparaison:

| Process Fase | Injection Molding | Vacuum Formulaire . |

| Setup waati . | sanga 4-8 . | sanga 1-2 . |

| Sikili waati . | 15-60 segin . | Minutɛri 2-5 . |

| Yɛlɛma waati . | sanga 2-4 . | 30-60 minutes . |

| Quality checks . | Continuel . | Batch-based . |

Porozɛ ka waati bolodacogo jateminɛ:

Fɛn dilannenw ka gɛlɛya bɛ nɔ bila baarakɛminɛnw yiriwali la .

Material sɔrɔli bɛ nɔ bila plɔmu waatiw la .

Jogoɲumanya wajibiyalenw bɛ nɔ bila tiɲɛni waatiw la .

Sɛnɛ hakɛ bɛ poroze kuntaala bɛɛ lajɛlen latigɛ .

Jogoɲumanya ni baarakɛcogo fɛnw .

Tiɲɛni ni muɲuli .

Fɛn dilanni cogoya bɛ danfaraba don o walew ni ɲɔgɔn cɛ. Nin fɛn caman ɲɔgɔnna faamuyali bɛ dɛmɛ ka fɛn dilannenw ɲɛfɔcogo bɛn.

Dimensional accuracy comparaison:

| Feature | Injection Moulding | Vacuum Formulaire . |

| Tolerance range . | ±0,1mm . | ±0,5mm . |

| Detail resolution . | Ɲuman ɲuman | Ka bɛrɛbɛn |

| Fasaya | A bɛ se ka segin-ka-bɔ kosɛbɛ . | Variable . |

| Nkɔni ɲɛfɔli . | Daduman | Rounded . |

Surface finish jogo:

Pikirili modulu bɛ se ka kɛ kalasi A bɛ sɔrɔ ka bɔ mold la ka ɲɛ .

Vacuum Forming bɛ sɛbɛnni kɛcogo basigilen mara yɔrɔbaw la .

O kɛcogo fila bɛɛ bɛ fɛn suguya caman dɛmɛ ni nɔgɔw bɛ furakɛli kɛ .

Post-Processing Options bɛ labanko ɲɛ .

Jogoɲini fɛɛrɛw:

Pikiriw dilanni kunbɛncogo:

In-line Dimensional Monitoring .

Inspection visuelle automatique .

Jateminɛ kɛcogo ɲɛnabɔli .

Matériel ka nafolo sɛgɛsɛgɛli .

Vacuum forming controls:

Sheet thickness sumanikɛlanw .

Manuel dimensions checks .

Surface inspection visuelle .

Funteni hakɛ kɔlɔsili siraw .

Fanga ni muɲuli .

Fɛn dilannenw ka baarakɛcogo wajibiyalenw ka teli ka taabolo sugandili latigɛ. Fɛɛrɛ kelen-kelen bɛɛ bɛ nafa danfaralenw di sigicogo la.

Jɛkulu ka baarakɛcogo:

Pikirili nafa:

Fɛnw tilatilali kelen bɛ fanga bonya .

Kɔnɔna barika bonya sekow .

Kɔrɔsili tigitigi ka ɲɛsin fɛnw cogoyaw ma .

Geometry complex dɛmɛ don structurel elements .

Vacuum formation jogo:

Kogo janya basigilen bɛ jateminɛ nɔgɔmanw na .

Dantigɛliw sigicogo sugandili .

fanga ni girinya hakɛ ɲuman .

Impact minɛcogo ɲuman bɛ sɔrɔ baara dɔw la .

Sigida ka banaw kunbɛncogo jatebɔsɛbɛn:

| Factor | Injection Molding | Vacuum Formulaire . |

| UV sabatili . | Material dependant . | Duman |

| kemikɛli resistance . | Ɲuman ɲuman | Ka bɛrɛbɛn |

| Funteni hakɛ . | -40°C ka se 150°C ma . | -20°C fo 80°C . |

| Ji kɛlɛli . | A sanfɛ | Duman |

Baarakɛcogo kuntaalajanw:

Aplikasi ani industri baarakɛcogo .

Pikiriw dilanni ni u dilanni baara kɛcogo n’u dilanni baara faamuyali nafa ka bon kosɛbɛ ni aw bɛ fɛn dilanni kɛcogo ɲuman sugandi. Fɛɛrɛ kelen-kelen bɛɛ bɛ nafa danfaralenw di minnu bɛ bɛn izini kɛrɛnkɛrɛnnenw ma ani fɛn dilannenw suguya ma.

Aplikasi minnu bɛ kɛ tuma bɛɛ .

Pikiri molding typique baarakɛcogo .

Pikiri dilanni bɛ kɛ ka caya walasa ka yɔrɔ gɛlɛnw dilan, yɔrɔ minnu ka bon kosɛbɛ, ni fɛn tigitigiw bɛ u la. A ka baarakɛcogo dɔw ye:

Elektroniki so : A bɛ kɔnɔnafɛnw lakana ni plastiki ye min bɛ mɛn, min bɛ se ka funteni sɔrɔ.

Mobili yɔrɔw : motɛri yɔrɔw, klipuw, ani fɛnw sirilanw bɛ nafa sɔrɔ tiɲɛniba la.

Furakɛminɛnw : opereli minɛnw, pikirijikɛlanw, ani sɛgɛsɛgɛli minɛnw bɛ u mago ɲɛ ka ɲɛ, ka u kɛ cogo kelen na.

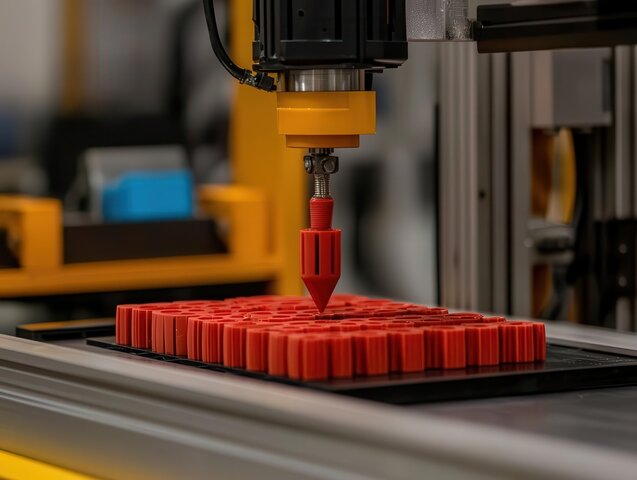

Vacuum formation typiques .

Vacuum formation ka fisa yɔrɔw ma minnu ka bon, minnu ka nɔgɔn ani prototying. A bɛ kɛ ka caya:

Packaging sarɛtiw : furakɛli, dumuni, walima fɛn minnu bɛ kɛ ka fɛnw feere, olu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye.

Panneau intérieur automotive : Dashboard belebeleba ani trim components.

Point-of-sale jiralanw : Plastiki jiralan barikamaw nka minnu ka nɔgɔn feerelikɛyɔrɔw la.

Industri-specifique applications

Aerospace : Vacuum formation bɛ kɛ ka kɔnɔna panɛriw ni sanubɔlan nɔgɔmanw kɛ, ka sɔrɔ pikiri kɛli bɛ fɛn gɛlɛnw dilan.

Consumer Electronics : Pikirili molili nafa ka bon kosɛbɛ lakanani ko la, fiɲɛw, ani minɛnw datugucogo.

Dumuni ni minfɛnw foroko : Vacuum dilanni bɛ plastiki foroko nɔgɔmanw dilan minnu bɛ u tanga dumuni lakanani ma.

| industry | injection molding misaliw | vacuum formation misaliw . |

| Mobili . | Motɛri yɔrɔw, Fasteners . | Dashboards, panneaux trim . |

| Furakɛcogo minɛnw . | Sinsinnanw, Diagnostic Baarakɛminɛnw . | furakɛli sarɛtiw, pakew . |

| Fɛn minnu bɛ kɛ ka mɔgɔw balo . | Elektronikiw ka so, tulonkɛfɛnw . | A ka ca a la, a bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye . |

Industri kɛrɛnkɛrɛnnenw ka ɲininiw .

Mobili industry magow .

Pikiri Moli : Mobili baarakɛlaw bɛ fɛn caman ɲini yɔrɔw la i n’a fɔ fɛnw sirilanw, motɛri yɔrɔw, ani klipuw. Pikiri dilanni bɛ o magow ɲɛ ni yɔrɔw dilanni ye tuma bɛɛ, yɔrɔ minnu bɛ mɛn, minnu bɛ se ka funteni kɛlɛ.

Vacuum Forming : A bɛ kɛ yɔrɔbaw la, i n’a fɔ da panɛriw, dashboards ani trunk liners, minnu bɛ jɔli nɔgɔman wajibiya.

Dɔgɔtɔrɔso minɛnw dilanni .

Pikiri Moli : A ka ɲi kosɛbɛ walasa ka fɛnw dilan minnu bɛ se ka kɛ fɛn ye, i n’a fɔ pikirijikɛlanw, sɛgɛsɛgɛlikɛminɛnw, ani opereli minɛnw.

Vacuum formation : A bɛ kɛ ka caya ka kɛɲɛ ni furakɛli baarakɛminɛnw walima sarɛti sterilizelenw ye minnu bɛ kɛ dɔgɔtɔrɔsow la.

Fɛn minnu bɛ kɛ ka mɔgɔw balo .

Pikiri Moli : A nafa ka bon fɛn misɛnninw na, fɛn minnu bɛ kɛ ka fɛnw feere, i n’a fɔ ɛntɛrinɛti minɛnw, plastiki tulonkɛfɛnw, ani dumunikɛminɛnw.

Vacuum Forming : A ka ɲi jiralanbaw ma, a pakew dilanni, ani a lakanani kow ma minnu bɛ kɛ feerekɛyɔrɔw la.

Fura minnu bɛ kɛ ka fɛnw falen .

Pikiri molidali : A bɛnnen don ka minɛnw dilan minnu bɛ se ka baara kɛ kokura, minnu ka gɛlɛn ani minnu bɛ u tanga.

Vacuum formation : A bɛ kɛ ka caya ka ɲɛsin blister packs ma, clamshell pakew ma, ani safinɛ nɔgɔmanw ma minnu bɛ se ka dilan teliya la.

Ka sugandili ɲuman kɛ .

Ni aw ye pikiri kɛcogo ni vacuum dilanni cɛ, o bɛ bɔ fɛn jɔnjɔn caman na. Ni porozɛ kɛrɛnkɛrɛnnenw magow jateminɛna ani ni fɛɛrɛ kelen-kelen bɛɛ nafaw faamuyara, fɛn dilannikɛlaw bɛ se ka latigɛ kɛ ni kunnafoni ye min bɛ bɛn u ka fɛn dilanni kuntilenna ma.

Desizɔnw tacogo .

Porozɛ ka ɲininiw jateminɛ .

Aw ka poroze dilanni gɛlɛya, a yɔrɔ hakɛ, ani a dilanni hakɛ jateminɛni nafa ka bon kosɛbɛ. Ni aw ka poroze bɛ tali kɛ yɔrɔ gɛlɛnw na minnu bɛ toli gɛlɛnw na, pikiri kɛli bɛ se ka kɛ fɛɛrɛ ɲuman ye. Yɔrɔ minnu ka nɔgɔn, yɔrɔ minnu ka bon, vacuum dilanni bɛ se ka musaka ɲuman ni teliya di.

baarakɛnafolo jateminɛw .

Pikiri Moli : Baarakɛminɛnw musaka minnu bɛ kɛ ka kɔn o ɲɛ, olu ka ca nka u musaka bɛ dɔgɔya yɔrɔ kelen na, u dilanni na, u hakɛ ka ca.

Vacuum Forming : Baarakɛminɛnw musakaw dɔgɔyali, a ka ɲi kosɛbɛ ka ɲɛsin fɛn dilanni ma walima a kɛcogo cɛmancɛ la walima a prototyping.

Waatibolodacogo wajibiyalenw .

Quality specifications .

Aw ye jateminɛ kɛ wajibiyalen na min bɛ sɔrɔ hakɛ , surface fini, ani fɛnw fanga. Pikiri mɔli bɛ jogo ɲuman ni ɲɔgɔndɛmɛ di, ka sɔrɔ vacuum sɔrɔli bɛ nɔ ɲumanw di baara kɛcogo ɲuman ma.

Waati min na pikiri kɛli molding .

scenarios idéals .

dilanni hakɛ caman . Yɔrɔ misɛnninw, yɔrɔ gɛlɛnw .

Porozɛ minnu bɛ muɲuli gɛlɛnw ni fɛn ɲɛfɔlenw de wajibiya, i n’a fɔ fɛnw minnu bɛ kɛ ni jiri ye walima minnu bɛ kɛ ni snap-fits ye.

Nafa jɔnjɔnw .

musaka-dɛsɛ ka ɲɛsin sɛnɛfɛnw dilanni ma.

Precision ni repeability ka bon dilancogo gɛlɛnw na ..

muɲuli ani baara kuntaalajan ni fɛnw ye minnu bɛ taa ɲɛ.

Dantigɛli minnu bɛ se ka kɛ .

Baarakɛminɛn fɔlɔw musaka ka bon.

ma Setup ani lead times , kɛrɛnkɛrɛnnenya la ka ɲɛsin mɔli gɛlɛnw .

musaka-nafa sɛgɛsɛgɛli .

Hali ni musaka fɔlɔw ka ca, pikiri kɛli bɛ sɔrɔ ka caya hakɛ caman na k’a sababu kɛ fɛn kelen-kelen bɛɛ musakaw dɔgɔyali ye. O kɛcogo fana ka ɲi ni tiɲɛni ni fɛnw fanga ka bon kosɛbɛ.

| Pikiri molding | nafaw | dantigɛli . |

| Ideal ka ɲɛsin yɔrɔw ma minnu ka gɛlɛn . | musaka minnu bɛ kɛ ka kɔn o ɲɛ . |

|

| A musaka ka dɔgɔ bolibaw la . | Setup (labɛn) ka jan ani a ka baara kɛta waati . |

|

| A yɔrɔ ni a yɔrɔ kelen-kelen bɛɛ ka ɲɔgɔndɛmɛba . |

|

|

Waati min na a bɛ Vacuum Forming sugandi .

A ka fisa ka baara kɛ ni a ye .

Prototyping walima low-volume production runs.

Yɔrɔ belebelebaw, minnu ka nɔgɔn i n’a fɔ mobili dashboards , pakew kɔnɔ fɛnw, walima feerekɛyɔrɔw jiralanw ..

Nafa kunbabaw .

Baarakɛminɛnw musaka dɔgɔyali ani a dilanni sigicogo teliya.

A ka ɲi kosɛbɛ fɛn caman tigɛli la prototypes walima runs danma kan.

A bɛnnen don yɔrɔbaw ma minnu tɛ kunnafoni gɛlɛnw wajibiya.

Dantigɛli minnu bɛ kɛ ka jateminɛ kɛ .

ROI factors .

Vacuum formation bɛ waati-ni-sɔgɔli teliya di , kɛrɛnkɛrɛnnenya la boli hakɛ dɔgɔmanw na , nka a man ɲi kosɛbɛ ka sɔrɔ ka sɔrɔ ka caya, ka caya ka da a kan, a bɛ sɔrɔ fɛn kelen-kelen bɛɛ musaka ka ca hakɛ caman na.

| Vacuum formation | nafaw | dantigɛli . |

| Setup teliya ka ɲɛsin prototypes ma . | Dantigɛli danma ani a tiɲɛni . |

|

| A musaka ka dɔgɔ boli misɛnninw na . | Unit kelen-kelen bɛɛ musaka ka bon hakɛ caman na . |

|

| A bɛnnen don yɔrɔbaw ma . |

|

|

Farankan

Pikiriw dilanni ni vacuum dilanni ye fɛn dilanni fɛɛrɛ jɔnjɔn fila ye, u kelen-kelen bɛɛ nafa tɛ kelen ye. Pikiri mɔli bɛ tɛmɛ yɔrɔ gɛlɛnw dilanni kan , yɔrɔ minnu ka bon kosɛbɛ, ni u ka ɲi kosɛbɛ ani minnu bɛ mɛn. Vacuum formation ka ɲi kosɛbɛ yɔrɔbaw la minnu ka nɔgɔn ani minnu bɛ kɛ ka caya ka da a kan a ka baarakɛminɛnw musakaw ka dɔgɔ ani a sigili teliya la.

Ni aw bɛ a latigɛ u fila cɛ, aw bɛ aw ka poroze hakɛ, a dilanni gɛlɛya , ani a ka baarakɛnafolo jateminɛ . Aw bɛ pikiri kɛcogo kɛ yɔrɔw la minnu ka ɲi kosɛbɛ, minnu bɛ mɛn . Aw bɛ vacuum formation sugandi prototypes walima musaka dɔgɔman, teliya la ..

A laban na, fɛɛrɛ ɲuman bɛ bɔ i ka ɲinini kɛrɛnkɛrɛnnenw na ani kuntilenna kuntaalajanw na ..

Reference sources .

Vacuum formation .

Pikirili Molidali .

Top Injection Molding Service .

Ɲininkaliw jaabiw .

J: Danfaraba jumɛn bɛ pikiri kɛli ni vacuum dilanni cɛ?

A: Pikiri molding bɛ plastiki wuli ka don moliw kɔnɔ. Vacuum formation stretches plastiques chauffes sur moules ni suction ye.

J: Taabolo jumɛn de ka fisa ni fɛn caman sɔrɔli ye?

A: Injection moulding bɛ tɛmɛ hakɛ caman kan ni 10.000 ye ni cycle waatiw teliya ye ani automatique production.

J: Yala vacuum bɛ se ka yɔrɔ dɔw dilan ni kunnafoni gɛlɛnw ye ani muɲuli sirilenw wa?

A: Ayi vacuum formation bɛ cogoya nɔgɔmanw dilan ni muɲuli lafiyalenw ye ka tɛmɛ pikiri kɛli kan.

J: Yala pikiri kɛli ka gɛlɛn ka tɛmɛ vacuum dilanni kan wa?

A: Baarakɛminɛnw musaka fɔlɔw ka ca pikiri kɛli la, nka unit musakaw bɛ dɔgɔya hakɛ caman na.

J: Fɛn jumɛnw bɛ se ka kɛ pikiri kɛli la ni vacuum ye?

A: Pikirili modulu bɛ baara kɛ ni plastiki jiri suguya caman ye. Vacuum formation bɛ baara kɛ ni thermoplastic sɛbɛnw dɔrɔn de ye.