Shin kun san cewa sama da kashi 80% na duk samfuran filastik da ke kewaye da ku an yi amfani da su ta amfani da allurar rigakafi ko injin da aka yi? Waɗannan Titans na masana'antu guda biyu suna fasalta abubuwanmu na yau da kullun.

Yin zaɓin da ba daidai ba tsakanin waɗannan hanyoyin na iya kashe ɗakunan dabi'unku na daloli. Yawancin masana'antun suna fama da wannan shawarar, yana tasiri farashin samarwa da tsarin lokaci.

A cikin wannan jagora mai girma, zamu bincika mahimman bambance-bambance tsakanin ƙwararrun allurar da ke haifar da tsari. Za ku koyi yadda kowane tsari yake aiki, abubuwan da suka dace, kuma wanne hanya mafi kyau ke amfani da takamaiman abubuwan keɓaɓɓun bukatunku.

Fahimtar kayan yau da kullun: allurar gyara ta vs. Vsuum forming tafiyar matakai

Mene ne allurar rigakafi?

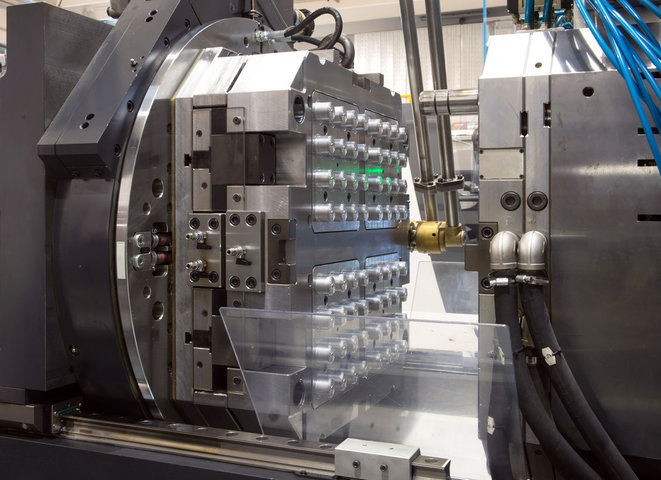

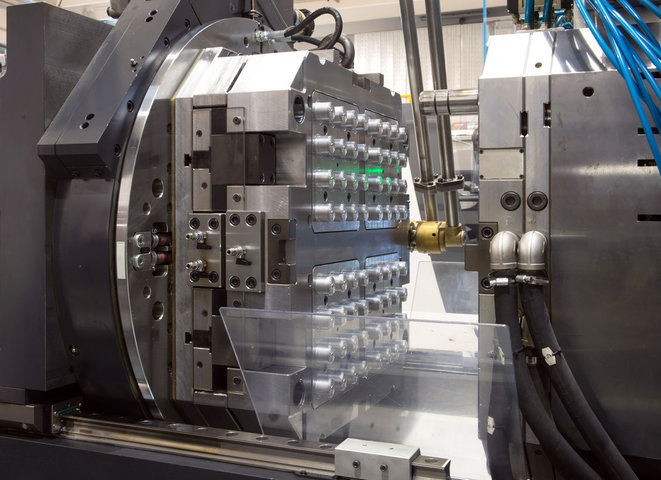

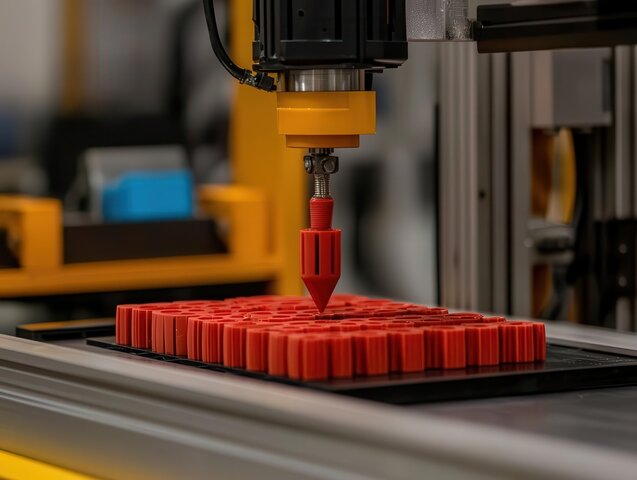

Tsarin allurar rigakafi shine tsarin masana'antar masana'antu mai mahimmanci wanda ke haifar da madaidaici, sassan filayen filastik. Ya ƙunshi narkar da filastik filastik, yana ba da su zuwa ga mold a ƙarƙashin matsin lamba, kuma sanyaya su cikin siffofi masu sauki.

Mataki-mataki tsari:

Loading pellets : pellets na filastik ko granules ana zuba cikin hopper.

Humama da Melting : pellets suna mai zafi a cikin ganga, juyawa zuwa filastik na molten.

Yin allura : An tilasta kayan molten a cikin kogon mold ta amfani da dunƙule mai matsin lamba ko rago.

Sanyaya : Filastik yana sanyaya a cikin mold, hardening zuwa sifar na ƙarshe.

Ke : Da zarar an sanyaya, ɓangaren an fitar da shi daga ƙirar, a shirye don kammalawa.

Abubuwan da ke cikin kayan mold na kayan aikin gyara:

Hopper : Yana riƙe da ciyar da filastik filastik a cikin injin.

Barrel : inda filastik yake mai zafi kuma ya narke.

DUCKOR / Aadin da aka daidaita . Source Molten a cikin ƙirar.

Mold kog : sarari inda siffofin filastik a cikin kayan da ake so.

Unit na Matsa : Yana kiyaye murfin a cikin allura da sanyaya.

Mecece tayi?

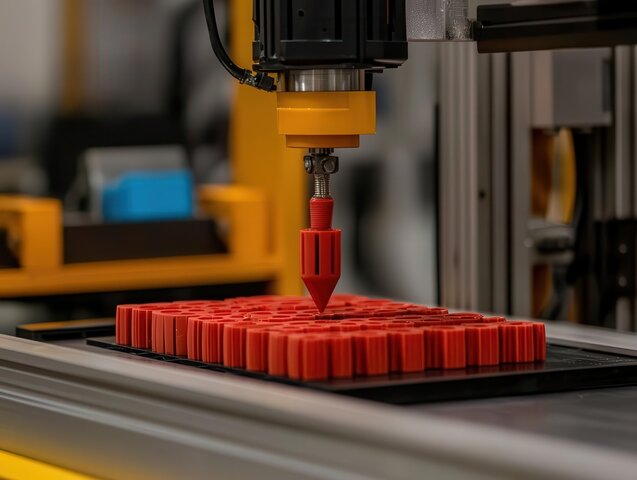

Vacay forming, tsari mafi sauki idan aka kwatanta da yin allurar gyada, ya dace da ƙirƙirar manyan wurare, sassan nauyi. Ya ƙunshi dumama takardar filastik har sai da taushi, to, amfani da matsin lamba na wuri don rufe shi cikin siffar da ake so.

Mataki-by-Matermorming tsari:

Clamping : takardar filastik ya rungume a wurin.

Humama : takardar mai zafi har sai ta zama mai jan hankali.

Matsa : An shimfiɗa mayafin mai taushi a kan mold, kuma ana amfani da injin don tsara sashin.

Sanyaya : filastik filastik yayi sanyi kuma a wuri.

Trimming : An cire kayan aiki, barin samfurin ƙarshe.

Mahimmancin kayan aiki:

Hadin gwiwa : Samfuraren filastik na laushi don gyaran gyada.

Mold (Convex / Concave) : Yana bayyana siffar ta ƙarshe.

Vacuum : hada da filastik a kan mold don samar da siffar.

Kayan aikin trimming : yanke da yawa filastik bayan da m.

Kulawa da masana'antu

Tsarin tsari da iyakance

Masana'antu ta bambanta daban-daban tsakanin allurar rigakafi da injin ruwa. Kowane tsari yana ba da fa'idodi na musamman don takamaiman abubuwan ƙira.

Allurar rigakafi ta hanyar:

Creairƙiri bayani dalla-dalla zuwa matakan microscopic

Samar da m, hadaddun geometries gami da tsarin ciki

Masana'antu na gano dalilai daidai

Hada nau'ikan kayan da yawa a cikin kayan haɗin guda ɗaya

Vockuum yana haifar da ƙarfi sun haɗa da:

Ƙirƙira manyan abubuwa masu yawa

Ingirƙiri Kauri Worange Kayan Worning

Ingantaccen nauyi, m tsarin

Samar da launuka masu sauƙi geometric

Girma da kauri la'akari da

| fasalin | allurar | ckination |

| Matsakaicin sashi | Iyakance ta hanyar injin inji | Mai kyau ga manyan sassa |

| Mafi qarancin kauri | 0.5mm | 0.1mm |

| Kauri na daidaito | Sosai sarrafawa | Ya bambanta ta hanyar shimfiɗa |

| Tsarin zane | Hadaddun geometries | Sauki ga matsakaici siffofi |

Zabin Abinci

Abubuwan da aka yi amfani da su a cikin allurar rigakafi da kuma injin samar da bambanci daban-daban da aikace-aikace, rinjayar aikin samfurin.

Kayan da suka dace da allurar rigakafi

Minding na allurar rigakafi yana goyan bayan kewayon thermofastics da thermosets, ciki har da:

Polypropylene (PP) , Abs na , Nshelon , da polycarbonate (PC) don aikace-aikacen aiwatar da aiki.

Cika polymers , kamar gilashin cike da gilashi ko kayan zare-karfafa ƙarfi, wanda haɓaka ƙarfi da karko.

Kayan aiki masu dacewa tare da yin injin forming

Vaduum forming yana iyakance ga thermoplastics a cikin takardar takarda, kamar:

Polyethylene (pe) , acrylic , pvc , da kwatangwalo (babban-tasiri polystyrene).

UV-barga da kayan dodawa don takamaiman aikace-aikace.

Kwatancen kayan kayan duniya

Yin allurar rigakafi : Yana ba da zaɓi zaɓi, gami da ruwan hoda mai tsauri, da kuma polymers masu ƙarfi.

Vermuum forming : Yana aiki mafi kyau tare da Haske, sassauƙa thermoplastics amma yana ba da ƙarancin zaɓuɓɓukan kayan aiki.

Na musamman

Yin allurar rigakafi na iya ɗaukar kayan da ke buƙatar haɓakar da ke buƙatar haɗi, kamar masu maganin rigakafi ko na bitaCompic.

Baƙaƙen wuri yana da kyau don mafi sauƙin, sassan Bulkier inda sassauci abu kuma farashin abin da ya faru ne na farko.

Bincike na kuɗi: Yin allurar Molding vs. Vsuum forming

Lokacin da kimantawa da tasirin ingancin allurar rigakafi da kuma injin forming, fahimtar cowsens cowsens yana da mahimmanci. Dukansu Tsarin aiki suna da tsarin farashi na musamman ta kayan aiki, ƙarar samarwa, da aiki.

Farkon hannun jari da kayan aikin kayan aiki

Sa hannun jarin na farko ya bambanta da muhimmanci tsakanin waɗannan masana'antun. Fahimtar wadannan bambance-bambance suna taimaka wa kasuwanci su ba da sanarwar shawarar kudi.

Kudin sauya kudin saiti na allura:

Kayan aiki mai kyau: $ 10,000- $ 100,000 + ya danganta da rikitarwa

Injin Injin: $ 50,000- $ 200,000 don daidaitattun kayan aiki

Ariarin tushen: $ 15,000- $ 30,000 don tsarin sanyaya, tsarin aiki

Madaidaita samar da kudin saiti:

Tsarin kayan aiki: $ 2,000- $ 15,000 don aikace-aikacen hali

Zuba jari: $ 20,000- $ 75,000 don asali tsarin

Kayan aiki: $ 5,000- $ 10,000 don trimming, tsarin dumama

Abubuwan Bukatun Kwancewa da hankali:

| Abubuwan | allurar | rigakafi |

| Na farko inji | Tsarin allura | Tashar wuri |

| Kayan aiki | Karfe mai taurare, aluminum | Itace, aluminum, epoxy |

| Kayan aiki na taimako | Masu bushewa na zamani, cilers | Takardar dumama |

| Iko mai inganci | Kayan aikin ma'auni | Kayan bincike na asali |

Kudin samarwa

Kudaden samarwa sun dogara da bukatun ƙara da abubuwan aiki.

Kudin kowane nazarin naúrar:

Yin allurar rigakafi:

Farashin farko ya bazu ko'ina cikin manyan abubuwa

Ƙananan sharar gida ta hanyar ainihin sarrafa kayan duniya

Rage kuɗin kashe kudi a cikin ayyukan sarrafa kansa

Mafi kyau duka ga adadin 10,000 raka'a

Vacay forming:

Kudin farawa yana amfana da ƙananan samarwa

Mafi girma sharar gida daga triimming

Kara yawan bukatun aiki na karewa

Ingantattun abubuwa a ƙarƙashin raka'a 3,000

Break - ma nazarin:

Counterarancin ƙara (<1,000 raka'a): voacing forming ya tabbatar da ƙarin tattalin arziki

Matsakaicin matsakaici (1,000-10,000): kwatancen farashi da aka buƙata akan takamaiman ɓangare

Babban Volume (> 10,000): allurar rigakafi na zama mafi tsada mai tsada

Abubuwa masu tsada masu tsada: kayan

| farashi | na ciyarwa | na comming |

| Bukatun Kwadago | Low (atomatik) | Matsakaici zuwa babba |

| Abu ingancin | 98% | 70-85% |

| Amfani da makamashi | M | Matsakaici |

| Kudin Kulawa | Matsakaici zuwa babba | Low zuwa matsakaici |

Sarrafa samarwa

Lokacin da zabar tsakanin allurar rigakafi da kuma injin samaka dole ne, masana'antun dole ne su tantance wasu dalilai da yawa, kamar ƙarawa, saurin, da kuma jigogi. Fahimtar Yadda waɗannan Hanyoyin Kwatantawa suna taimakawa wajen yin sanarwar sanarwar.

Girma

Varaukaka samarwa yana tasiri ga zaɓin hanyar masana'antu. Kowane tsari yana ba da bambanci game da sikeli daban-daban.

Wucewa-girma (<3,000 raka'a)

Veruum forming yana samar da mafita mafi tsada don prototype yana gudana

Gyara kayan aikin kayan aiki yana da sauki kuma mai araha

Saurin Sauri yana ba da damar saurin ƙirar iskaran

Yawan saka hannun jari ya dace da kayan aikin samarwa

Masana'antu mai girma (> haruffa 10,000)

Ingantawa na allurar rigakafi yana ba da cikakkiyar tattalin arziƙi a sikeli

Jirgin sama mai sarrafa kansa yana rage farashin aiki

Daidaitaccen inganci a duk manyan samarwa

Kayan aiki da yawa suna ƙaruwa da fitarwa

kwatanta

| ScALability | | |

| Karfin farko | Matsakaici zuwa babba | Low zuwa matsakaici |

| Scalming sauƙin | Hadaddun kayan aiki | Gyare-gyare mai gyara kayan aiki |

| Adadin fitarwa | 100-1000 + sassan / awa | 10-50 sassa / awa |

| Samar da sassauƙa | Iyakance | M |

Jagoran Times da-zuwa-kasuwa

Fahimtar bukatun tsarin lokaci yana taimakawa inganta tsarin aikin aikin da kuma rarraba kayan aiki.

Tasanin Lokaci:

Yin allurar rigakafi:

Tsarin kayan aiki da masana'antu: 12-16 makonni

Zabi na kayan da gwaji: 2-3 makonni

Saita samarwa da tabbatarwa: 1-2 makonni

Tarihin farko na farko: 1 mako

Vacay forming:

Kayan masana'antu: 6-8 makonni

Kayan aiki: Makonni 1-2

Tsarin saiti: kwanaki 2-3

Batun samfurin: 2-3 kwanaki

Kamfanin Kamfanin

| Kamfanin | masana'antu | Kamfanin |

| Saita lokaci | 4-8 hours | 1-2 hours |

| Lokacin sake zagayawa | 15-60 seconds | Minti 2-5 |

| Lokacin canza lokaci | 2-4 hours | 30-60 minti |

| Hakikawa mai inganci | M | Batch-tushen |

Ayyukan Timeline na aikin:

Samfurin Halitta Halitta

Samun kayan duniya yana shafar lokutan jagora

Abubuwan buƙatu masu inganci suna tasiri lokacin inganci

Polumen samarwa yana da iko duka tsawon lokaci

Inganci da ayyukan motsa jiki

Daidaitawa da Yin haƙuri

Masana'antu masana'antu ya bambanta da muhimmanci a tsakanin waɗannan hanyoyin. Fahimtar wadannan bambance-bambancen suna taimakawa tabbatar da bayanan bayanan abubuwan da suka dace.

Cikakken kwatancen daidaito na daidaito:

| Fasalin | allurar | rigakafi |

| Rahamar haƙuri | ± 0.1mm | ± 0.5mm |

| Cikakken tsari | M | Matsakaici |

| Daidaituwa | Sosai maimaitawa | M |

| Fassarar kusurwa | M | Zagaye |

Matsakaicin halaye:

Yin allurar rigakafi yana samun aji a saman saman kai tsaye daga mold

Baƙaƙewa yana tabbatar da zane mai saurin zama a cikin manyan wurare

Dukansu tafiyar matakai suna tallafawa rubutu daban-daban ta hanyar jiyya na mold

Zaɓuɓɓukan bayan-bayan haɓaka bayyanar ƙarshe

Matakan sarrafawa mai inganci:

Gudanar da Ingantawa na alluna:

Vacay forming iko:

Ƙarfi da karko

Bukatun aikin kayan aiki sau da yawa ƙayyade zaɓi tsari. Kowace hanya tana ba da fa'idodi daban-daban.

Aikin tsari:

Fa'idodi na allurar rigakafi:

Uniform kayan rarraba yana inganta ƙarfi

Yuwanniyar abubuwa masu ƙarfi

Madaidaicin iko akan kayan abu

Hadaddun talla game da tallafi na Geometry don abubuwan tsari

Vacuum forming halaye:

Kauri mai kauri a cikin geometries mai sauki

Lissafi Tsarin Tsarin Tsarin Tsarin Kayayyakin

Kyakkyawan ƙarfi-da-nauyi rabo

Kyakkyawan tasiri na tasiri a wasu aikace-aikace

Alamar Tsara ta Tsorewa:

| Factor | allure Molding | Vacing |

| UV karewa | Kayan aiki ya dogara | M |

| Juriya na sinadarai | M | Matsakaici |

| Ranama | -40 ° C zuwa 150 ° C | -20 ° C zuwa 80 ° C |

| Tsabtace danshi | M | M |

Abubuwan Dogon Dogon lokaci na lokaci:

Yankunan Degradation

Danniya fashe juriya

Launuka masu launi

Tasiri karfin riƙe

Aikace-aikace da Amfani da masana'antu

Fahimtar aikace-aikacen da masana'antu na gyara yanayin allurar rigakafi da injiniyoyi suna da mahimmanci lokacin zabar tsarin masana'antu na dama. Kowace hanya tana ba da fa'idodi daban-daban waɗanda suka dace da takamaiman masana'antu da nau'ikan samfur.

App na gama gari

Allurar rigakafi na al'ada

Ana amfani da kayan allurar rigakafi sosai don samar da hadaddun, kashi-uptionaramin sassa tare da fasali daidai. Aikace-aikacen sa sun hada da:

Gidajen lantarki : Yana kare abubuwan ciki tare da dorewa, filastik-mai tsauri.

Kayan aiki da motoci : Abubuwan haɗin injin, shirye-shiryen, da ƙugenta suna amfana daga babban daidaito.

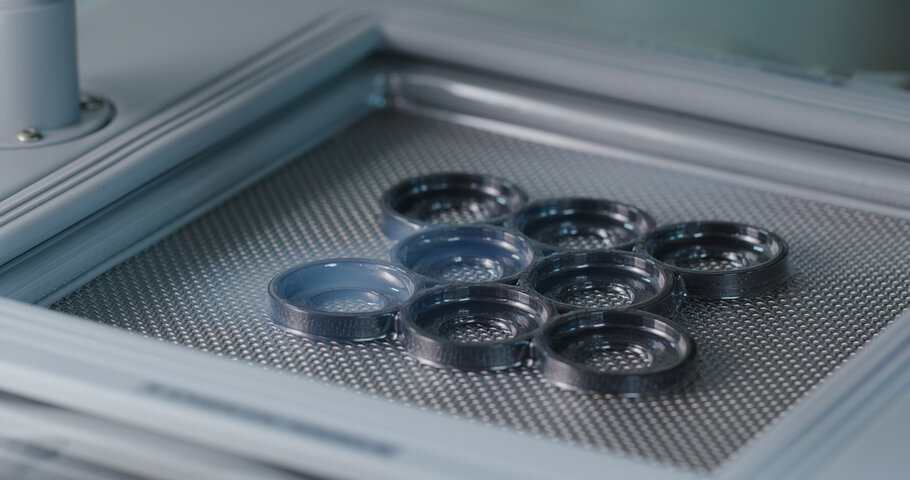

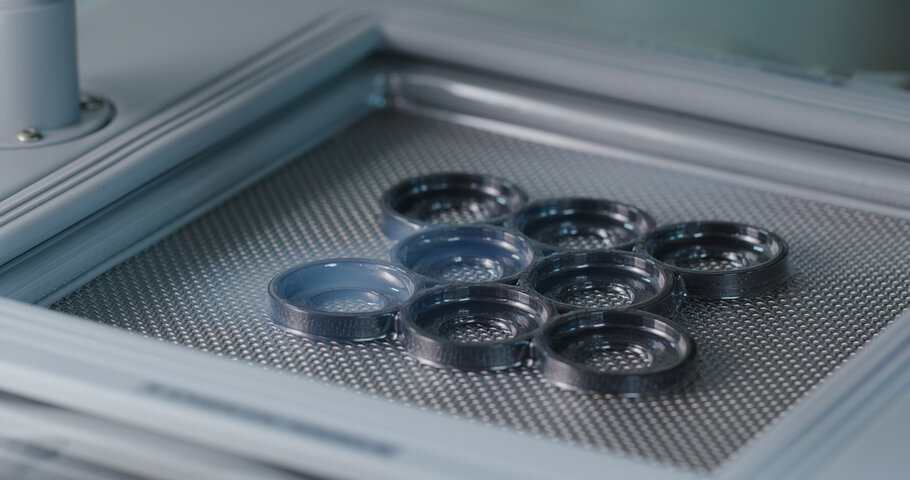

Kayan aikin likita : Kayan aikin kayan aiki, sirinji, da kayan aikin bincike suna buƙatar tsarkakewa, daidaitawa.

Ba tare da tsari na yau da kullun ba

Baƙaƙen wuri ya fi dacewa don girma, sassan nauyi da kuma prototyy. Ana amfani da shi a cikin:

Traves trays : trays mai siffar al'ada don likita, abinci, ko kayan masu amfani.

Bangarori na ciki : Babban dashboard da dashiyar masana'antu.

Nunin ma'ana na musamman : Sturdy amma yana nuna alamun filastik don rage mahalli.

Masana'antu da takamaiman aikace-aikace

Aerospace : Ana amfani da forming forming na ciki da kuma trays, yayin da allurar rigakafi yana haifar da abubuwan da ake amfani da su.

Mai amfani da kayan lantarki : Rashin daidaituwa Mold yana da mahimmanci ga lokuta masu kariya, matosai, da na'urar haɗin na'urar.

Abinci da abin sha mai ban sha'awa : injin motsa jiki yana haifar da nauyi, kayan aikin filastik wanda ya dace da ƙa'idodin amincin abinci.

| na masana'antu | na gyara | Misalai |

| Mayarwa | Kayan injin, masu ɗaure | Dashboards, datsa bangarori |

| Kayan aikin likita | Songajiya, kayan aikin bincike | Trays likita, marufi |

| Samfuran masu amfani | Gidajen lantarki, Toys | Babban kayan talla, nuni-da-sayarwa |

Abubuwan da aka tsara masana'antu

Abun sarrafa masana'antu yana buƙata

Yin allurar rigakafi : Masana'antar kayan aiki suna buƙatar babban daidaici ga ɓangaren fastoci, abubuwan haɗin injin, da shirye-shiryen injin, da shirye-shiryen injiniyoyi. Yin allurar rigakafi ya haɗu da waɗannan bukatun ta hanyar daidaita samar da dorewa, sassan mai tsauri.

Vockuum forming : amfani da manyan sassan, kamar bangarori, dashbox ɗin, da kuma layin gangar jikin, wanda ke buƙatar nauyin nauyi.

Masana'antar likita

Yin allurar rigakafi : An yi kyau don samar da babban-daidaito, kamar sirinji, da kayan bincike, da kuma kayan aikin.

Vaculum forming : Amfani da shi don ƙirƙirar marufi na al'ada don kayan aikin likita ko mastoci masu haifuwa da aka yi amfani da su a asibitoci.

Samfuran masu amfani

Abubuwan da ake ciki : Mahimmanci ga kananan, kayan masu amfani da kayan masarufi, kamar su na'urar lantarki, kayan kwalliyar filastik, da kayan aikin dafa abinci, da kuma kayan aikin dafa abinci.

Vacay forming : Mafi dacewa ga manyan nuni, marufi, da lokuta kariya da aka yi amfani da su a cikin mahalli na kayan aiki.

Focaging mafita

Yin allurar rigakafi : Ya dace da ƙirƙirar rizable, kwantena masu tsauri da keɓaɓɓun kariya.

Vockuum forming : Wuya sosai don fakitoci, Clamhall feaging, da trays mai nauyi wanda zai iya zama da sauri-da sauri.

Yin dace da zabi

Zabi tsakanin allurar rigakafi da injiniyoyi ya dogara da dalilai masu yawa. Ta hanyar tantance bukatun musamman da na fahimta da fahimta game da kowane hanya, masana'antun za su iya yin sanarwar shawarar da ke aligns tare da manufofin samar da su.

Abubuwan da suka yanke shawara

Bukatar bukatun aikin

Kimanin rikitarwa na kayan aikin ku, sigar sashi, da kuma yawan samarwa yana da mahimmanci. Idan aikinku ya shafi sassa mai haƙuri tare da haƙurin yarda, maganin allura na iya zama zaɓi mafi kyau. Don sauƙi, wurare mafi girma, injin motsa jiki na iya samar da mafi kyawun farashi da fa'idodin sauri.

Kasafin kuɗi

Yin allurar rigakafi : Babban kayan aikin kayan aiki amma rage farashi a kowane bangare a cikin babban-girma girma.

Verugum forming : Lastarancin kayan aikin kayan aiki, daidai yake da karancin matsakaici-matsakaici ko fasoting.

Bukatun lokaci

Bayani dalla-dalla

Yi la'akari da daidaitaccen daidaitaccen abu , farfajiya, da ƙarfin kayan duniya. Abubuwan da ake ciki na allurarsa suna kawo cikakkiyar inganci da daidaito, yayin da suke samar da kyakkyawan sakamako ga aikace-aikacen da basu buƙata.

Lokacin da za a zabi allurar

Yanayin abin da ya dace

Babban girma na kananan, sassa masu hade.

Ayyuka suna buƙatar wadatar haƙuri da kuma cikakkun abubuwa, kamar su kayan haɗin zaren ko kuma tsinkaye.

Mahimman fa'ida

Ci gaba mai tsada don manyan-sikelin samarwa.

Babban daidaito da maimaitawa don tsayayyen zane.

Karkatar da aiki na dogon lokaci tare da kayan ci gaba.

Zuwato iyaka

Bincike mai tsada

Yayin da farashin farko sukeyi, ingin rigakafi ya fi tattalin arziƙi don babban kundin ƙasa saboda ƙananan farashin kuɗi. Tsarin yana da kyau lokacin da aka tsara shi da ƙarfin ikon mallaka yana da mahimmanci.

| Ingantaccen tsari na | inganci | rashin |

| Mafi dacewa ga abubuwan hadaddun | Kudin sama |

|

| Mai tsada don manyan ayyukan | Saiti na tsayi da lakabi |

|

| Babban aiki-sashi |

|

|

Lokacin da za a zabi injin tsari

Mafi kyawun lokuta

Prototyping ko ƙarancin girma yana gudana.

Babba, sassa masu sauƙi kamar dashboards dashboard , ko trays cocraging, ko nuni na musamman.

Babban fa'idodi

Lowerancin kayan aikin kayan aiki da kuma saitin samarwa da sauri.

Mafi dacewa don saurin juyawa a kan prototypes ko iyakance gudu.

Ya dace da manyan sassan da basu buƙatar amfani da cikakken bayani.

Iyakantarwa don la'akari

Dalilai

Veruum forming yana ba da saurin lokaci-zuwa-kasuwa , musamman don ƙarancin gudu, amma ba ya dace da mafi yawan farashin farashi mai girma don manyan farashin. Ba

| tare da samar da | fa'idodi | ba |

| Saurin Sauri don Prototypes | Limitedirƙirar Tsarin Tsara da Daidaici |

|

| Tsada mai tsada don kananan gudu | Mafi girman farashin farashi don manyan kundin |

|

| Ya dace da manyan sassan |

|

|

Taƙaitawa

Yin allurar rigakafi da injiniyoyi suna haifar da mahimman masana'antu guda biyu, kowannensu yana da bambanci daban. Rashin allurar rigakafi na haifar da hadadden cikin samar da hadadden, manyan kashi tare da madaidaicin daidaito da karko. Versium forming ya dace da manyan, mafi sauki sassa da samar da karami saboda ƙananan kayan aikin sa da saiti da sauri.

A lokacin da yanke shawara tsakanin biyu, yi la'akari da ƙarar aikin ku, tsarin ƙirar ku , da kuma kasafin kuɗi . Yi amfani da zane mai narkewa don babban tsari, da dorewa . Zabi Vacay forming don Prototypes ko araha, Ci gaba mai sauri.

A ƙarshe, hanyar da ta dace ya dogara da takamaiman bukatunku da burin dogon lokaci.

Takamatsu

Vacay forming

Allurar gyara

Babban Siffar Siyarwa

Faqs

Tambaya: Mene ne babban bambanci tsakanin ƙirar allura da injin da ke haifar?

A: Cindigin Molding Incings An narke filastik cikin molds. Madarar ciki yana miƙa shinge mai zafi a kan molds ta amfani da tsotsa.

Tambaya: Wanne tsari yake mafi kyau ga haɓaka girma?

A: Ciniki na allurar rigakafi a babban juzu'i sama da raka'a 10,000 tare da lokutan sarrafa kansa.

Tambaya: Zai iya yin fim ɗin ƙirƙirar sassa da cikakkun bayanai da yarda da su?

A: A'a. Kirkirar samar da siffofi da sauki siffofi tare da haƙuri haƙuri fiye da allurar m.

Tambaya: Shin allurar rigakafi ce mai tsada sosai fiye da compium forming?

A: Farashin kayan aiki na farko sun fi girma don yin allurar rigakafi, amma farashin naúrar ya zama ƙasa da manyan kundin.

Tambaya: Abin da kayan za a iya amfani da kayan a cikin allurar rigakafi da kuma injin forming?

A: allurar rigakafi yana amfani da pellets daban-daban. Baƙaƙe tsari yana aiki kawai tare da zanen thermoplastic.