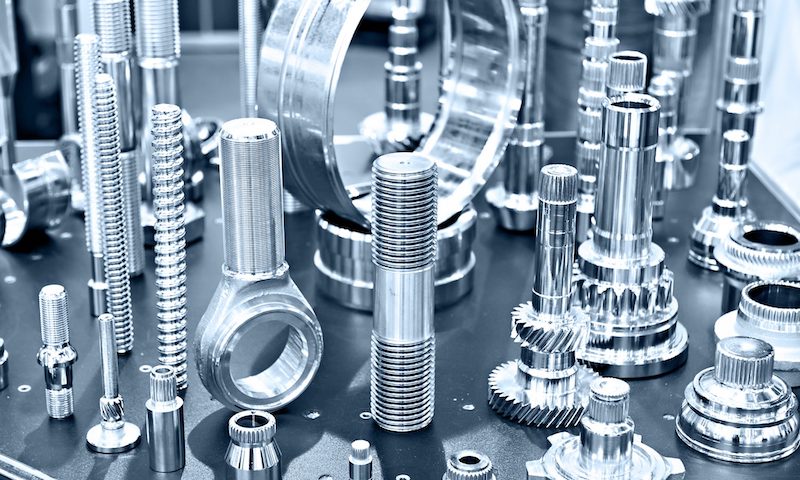

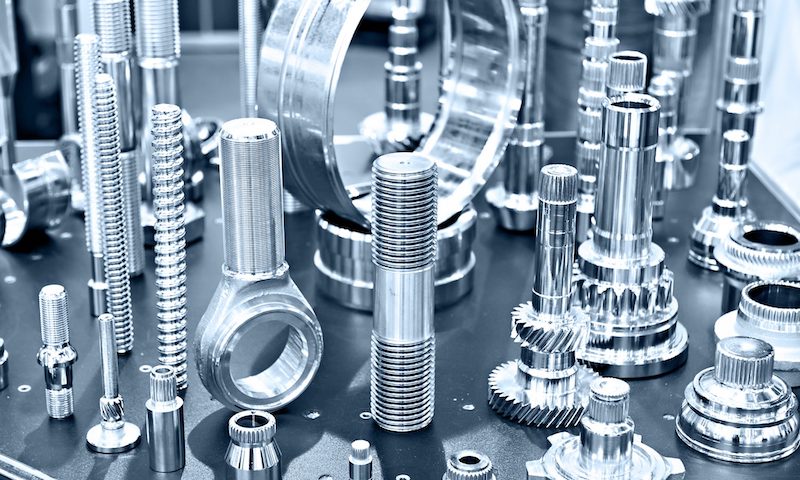

4130 ɛn 4140 na kɔmɔn stɛl tayp dɛn we dɛn kin yuz insay difrɛn manufakchurin ɔpreshɔn dɛn. Di aplikeshɔn fɔ 4130 stɛl gɛt motoka strɔkchɔ, plen fɔ yuz soja, mashin tul, kɔmɛshɔnal ayrakt, ɛn tubing fɔ di ɔyl ɛn gas industri. Di aplikeshɔn dɛn fɔ 4140 stɛl gɛt kɔnstrɔkshɔn bildin dɛn, piston rod dɛn, gia dɛn, bolt dɛn, ɛn mashin dɛn ikwipmɛnt dɛn. 4130 ɛn 4140 ɔl tu gɛt dɛn sem kayn kwaliti ɛn difrɛns. We yu ɔndastand di difrɛns dɛn we de bitwin 4130 vs. 4140 stɛl, dat kin ɛp yu fɔ pik di bɛst fɔ yu manufakchurin prɔjek. Wi go fɛn ɔl di gud ɛn bad tin dɛn we dɛn mɛtal ya gɛt.

4130 vs. 4140 Stilin: 4130 stiel type

4130 Stilin na kromiɔm ɛn molibdɛnam stɛl alɔy. Di ɔda nem fɔ dis stɛl na kromozom.

4130 Stiɛl Tayp: Pros .

• I fayn fɔ mek yu ebul fɔ mek mashin dɛn fayn fayn wan .

4130 Stilin gɛt kɔmpitibliti wit difrɛn mashin prɔses dɛn, we inklud fɔ drɔ, kɔt, tɔn, grind, ɛn mil. Di mashin prɔses kin ɔltɛm smol wit dis stɛl tayp. I nɔ nid ɛni spɛshal tritmɛnt ɔ mashin tul fɔ du wan saksesful mashin prɔses. Bɔt di bɛst mashin prɔsis na fɔ kip di mashin spid ɛn fid ɔnda kɔntrol fɔ mek di tul nɔ wear. I bɛtɛ bak fɔ yuz kɔt tul dɛn wit fayn fayn durabiliti fɔ mashin 4130 stɛl.

• Modaret lɛvɛl fɔ daktiliti .

Di moderate level of malleability of di 4130 steel giv dis steel taip versatility en fleksibiliti in difren aplikeshon. Yu kin wok pan dis kayn stɛl ɛn nɔ wɔri bɔt krak krak ɔ pwɛl di tin. Bɔku aplikeshɔn dɛn nid mɔdaret daktiliti insay 4130 stɛl fɔ mek dɛn kɔntinyu fɔ gɛt in mɛkanikal prɔpati dɛn we dɛn de difɔm ɛn wok pan.

• Strɔng-to-weyt rɛsɛshɔn .

Di wet we di stɛl gɛt, na di mɔ i strɔng. 4130 Stilin na di bɛst fɔ mek strɔkchɔral kɔmpɔnɛnt dɛn we nid fayn fayn durabiliti. Enhancing di strength of 4130 steel na posibul bay we yu ad sɔm elements to di matirial.

• SMƆL TƆK: Fatigue Strɔng .

If yu put ay strɛs pan di 4130 stɛl, dat nɔ go pwɛl ɔ brok di matirial bɔku. Yu kin yuz dis stɛl matirial insay ekstrim envayrɔmɛnt kɔndishɔn. Dis kwaliti de mek dis stɛl pafɛkt fɔ di tul ɔ mold krieshɔn prɔses.

4130 Stiɛl Tayp: Kɔns .

• Nɔ kɔmpitabl wit ARC wɛldin .

Arc welding kin vaypa dis stɛl tayp. Di bɔku bɔku ɔt we dɛn de mek na ak wɛldin go pwɛl di strɔkchɔ dɛn fɔ dis matirial. Yu kin yuz TIG ɔ MiG fɔ wok wit dis mɛtal we yu nɔ pwɛl am. Bɔt pan ɔl dat, yu fɔ rili tek tɛm we dɛn de du TIG ɔ MIG wɛldin.

• SMƆL TƆK: Di rayt we fɔ trit di ɔt na sɔntin we yu fɔ du .

Una tek tɛm wit di zon we dɛn dɔn ɔt rawnd di say we 4130 stɛl de. If dɛn nɔ trit di ples fayn fayn wan, dat kin mek i krak ɔ i kin brok rawnd di say we di stɛl de. I kin ridyus bak di ɔvala trɛnk fɔ dis mɛtal we yu aplay po ɔt tritmɛnt.

• SMƆL TƆK: Di kɔst ɛn di we aw dɛn go ebul fɔ gɛt am .

4130 Stilin kin kɔst insay sɔm manufakchurin aplikeshɔn dɛn, lɛk insay di ɔtomotiv industri. Di avaylabl factor na wan kɔnsyans bak. Sɔntɛnde, 4130 stɛl nɔ kin de ɔlsay bikɔs i gɛt bɔku dimand. Yu fɔ wok wit di wan dɛn we yu kin trɔst fɔ gɛt di bɛst kwaliti 4130 stɛl.

4130 vs. 4140 Stilin: 4140 stiel type

Yu kin yuz 4140 stɛl tayp fɔ bil strɔkchɔral kɔmpɔnɛnt dɛn wit di bɛst hadnɛs ɛn durabiliti. Dis mɛtal de gi bɔku bɛnifit fɔ di tin dɛn we yu nid fɔ mek.

4140 Stiɛl Tayp: Pros .

• SMƆL TƆK: Kɔroshɔn rɛsistɛns .

4140 Steel gɛt wan fayn fayn kɔrɛshɔn rɛsistɛns prɔpati frɔm di get-go. Yu nɔ nid fɔ ad nyu tin dɛn fɔ mek dɛn gɛt mɔ prɔpati dɛn we de agens di say we dɛn de. Na di pafɛkt stɛl fɔ bil kɔmpɔnɛnt dɛn wit lɔng layf saykl. Di anti-kɔroshɔn prɔpati go ɛp dis stɛl fɔ bia wit damp ɔpreshɔn ɛnvayrɔmɛnt dɛn fayn fayn wan.

• Di ay yield .

4140 Stilin kin tinap fɔ wan ay amɔnt fɔ strɔkchɔral lod dɛn we nɔ gɛt prɔblɛm. Bɔt yu nid fɔ yuz di rayt tritmɛnt fɔ mek yu ebul fɔ gɛt di bɛst yield trɛnk fɔ dis mɛtal. Di ay yield factor mek dis stiel fit fɔ kɔnstrɔkshɔn, erospace, ɛn ɔda kayn aplikeshɔn dɛn.

• SMƆL TƆK: Fatigue Strɔng .

High fatigue strength na wan ɔda fayn fayn advantej fɔ 4140 stɛl. Put wan ay saykl fɔ strɛs pan dis stɛl, ɛn i nɔ go brok izi wan. I bɛtɛ fɔ aplikeshɔn dɛn we nid kɔntinyu strɛsful fɔs wit ekstrim wok ɛnvayrɔmɛnt.

• SMƆL TƆK: I fayn fɔ gɛt fayn fayn taf .

Di ay levul fɔ taf na 4140 stɛl de mek dis matirial versatil fɔ difrɛn aplikeshɔn dɛn. I kin ɔnda difɔmeshɔn afta difɔmeshɔn dɛn di tɛm we dɛn de mek di prɔses dɛn we nɔ de rupchɔ in strɔkchɔral intɛgriti. 4140 Stilin de gi di fleksibiliti fɔ mek kɔmpɔnɛnt dɛn wit difrɛn shep ɛn jɔyometrik intrikas.

• SMƆL TƆK: Faktɔ fɔ mek di mashin go bifo .

Wan ɔda big advantej fɔ 4140 stɛl na di ay mashinabiliti faktɔ. Machining di 4140 stɛl go rili izi fɔ du. Yu kin aplay klos to ɔl di mashin prɔses fɔ di 4140 stɛl we nɔ gɛt prɔblɛm. 4140 Stilin de bak as matirial wokpies fɔ ɛni CNC ɔpreshɔn.

• SMƆL TƆK: Ɔt Resistans .

Hɛt rɛsistɛns na ɔda tin we de mek 4140 stɛl valyu pas di sem kayn stɛl matirial dɛn. 4140 Stilin kin ebul fɔ bia wit di wam wam ɔt we nɔ de ambɔg in praymari strɔkchɔ dɛn. Na wan fayn fayn mɛtal fɔ yuz fɔ aplikeshɔn dɛn we gɛt ekstrim ɔt. Di ay ɔt rɛsistɛns fɔ dis mɛtal de kɔntribyut bak to in durabiliti fɔ lɔng tɛm yuz.

4140 Stiɛl Tayp: Kɔns .

• Welding nid fɔ gɛt ɛkstra tin dɛn fɔ tek tɛm wit .

Welding kin mek krak krak insay 4140 stɛl, mɔ fɔ di kayn we we dɛn dɔn at fɔ du bifo tɛm. If yu yuz di rayt tritmɛnt fayn fayn wan bifo dɛn wɛl am, dat kin mek yu nɔ ebul fɔ krak. I kin slo di kol rɛt ɛn mek i nɔ krak rawnd di stɛl strɔkchɔ. Fɔ yuz spɛshal wɛldin tɛknik dɛn impɔtant fɔ dis kayn stɛl.

• Risk fɔ brok mashin tul dɛn .

4140 Stilin na izi fɔ mashin. Bɔt, i impɔtant fɔ yuz di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt fɔ am. Na fɔ avɔyd tul wear ɔ damej di tɛm we dɛn de mek di mashin. I toughness factor kin bi disadvantageous fɔ yu prodakshɔn prɔses.

• Dia

4140 stɛl kin kɔst bikɔs ɔf ɔl di kwaliti dɛn we di mɛtal gɛt. Kwaliti-ways, 4140 stɛl bak bɛtɛ pas ɔda tin dɛn we fiba am. So, di ay prays na jɔstifaybul. Yu kin yuz dis stɛl mɛtal fɔ mek mɔ polish ɛn ay kwaliti prɔdak dɛn.

Konklushɔn fɔ 4130 vs. 4140 stɛl .

Dɛn tu mɛtal matirial ya kin bɛnifit difrɛn industrial aplikeshɔn dɛn. Di 4130 na wan smɔl sɔlvishɔn fɔ lɔw-badjɛt prodakshɔn. Na di ɔda say, di 4140 de gi bɛtɛ kwaliti prodakshɔn rizɔlt fɔ ay mɔni invɛstmɛnt. Pik yu stɛl matirial fayn fayn wan bifo yu bigin yu manufakchurin prodakshɔn. Yuz di savis dɛm fɔ reputed ɛn trɔst manufakchurin saplayers fɔ mek yu stɛl matirial dɛn rɛdi. Dis we, yu kin avɔyd fɔ gɛt 'fake' 4130 stɛl na sɔm makit ples dɛn.

Apat frɔm frɔm 4130 ɛn 4140 Stilin, Tim MFG de gi di ɔda mɛtal dɛn bak fɔ yu Rapid prototypein ., CNC MACHINING , ɛn . day kastin nid dɛn. Kontakt wi tide!