Yin allurar rigakafi yana buƙatar daidaito, kuma mahimmancin mahimmancin abu sau da yawa ana watsi da shi: kauri na bango. Ta yaya wannan zai shafi ingancin samfurin da farashi?

Kauri kauri a cikin filayen filastik yana shafar ƙarfi, lokacin sanyaya, da kuma kayan aikin. Rashin ƙarfi mara kyau yana haifar da lahani ko alamun ruwa.

A cikin wannan post, zaku koyi mahimmanci jagororin tsara kauri mai kyau don hanyoyin gama gari. Zamu rufe mafi kyawun ayyuka, da aka bada shawarar yayan kayan, da kuma mahimman abubuwan tasiri zaɓin ku.

Mene ne kauri a cikin allurar rigakafi?

Kaurin kauri yana nufin nisan da ke tsakanin saman abubuwa biyu na allurar da aka gyara. Maganin zane ne na musamman wanda ke tasiri ɓangarantaccen tsarin tsarin, bayyanar, da abubuwan kirkirori.

Mahimmancin kauri na kauri a cikin samfurin samfurin

Tsarin kauri da ya dace yana da mahimmanci don nasarar maganin da aka yi. Yana tasiri mahaɗan mahimman abubuwan ci gaban samfurin da masana'antu:

Rage amfani da albarkatun kasa

Mafi kyau duka bangon bango yana taimakawa rage yawan abubuwan. Wannan yana kaiwa zuwa:

Inganta ingancin inganci

Warfin da aka tsara da aka tsara da aka yi na taimaka wa mafi kyawun sashi ta:

Rage lahani kamar alamomin rami, warpage, da kuma voids

Haɓaka ƙarfin tsari da kuma tsauri

Inganta gamawa da daidaitaccen daidaitawa

Saurin haɓaka sauri

Kauri mai kauri da ya dace na iya haɓaka haɓaka:

Lokacin shawo kan lokaci, yana rage lokacin sake zagayowar gaba ɗaya

Ingantattun abubuwa na kwarara, yana sauƙaƙa cika sauƙaƙe

Kadan da Post-Post da ake buƙata, samar da rashawa

Kauri bangon bango na kauri don matsalolin gama gari

Shawarwarin kauna na bango ya bambanta dangane da takamaiman kayan filastik. Gabaɗaya, sun haɗu daga 0,.020 inci zuwa inci 0.500. Waɗannan jagororin suna tabbatar da kyakkyawan aiki da abubuwan da suka dace.

An yi amfani da zane mai amfani da filastik na ƙwaƙwalwa na thermoplastics

Don robobi daban-daban, kyakkyawan katangar bango sun fadi a tsakanin wasu yaki. A ƙasa akwai jadawalin da aka ba da shawarar don kayan da ake amfani da su na yau da kullun:

| kayan da | aka | ba da shawarar bangon bango (mm) |

| Abin da | 0.045 - 0.140 | 1.14 - 3.56 |

| PC + Abs | 0.035 - 0.140 | 0.89 - 3.56 |

| Acetal | 0.030 - 0.120 | 0.76 - 3.05 |

| Na acrylic | 0.025 - 0.500 | 0.64 - 12.7 |

| Nail | 0.030 - 0.115 | 0.76 - 2.92 |

| Polycarbonate (PC) | 0.040 - 0.150 | 1.02 - 3.81 |

| Polyethylene (pe) | 0.030 - 0.200 | 0.76 - 5.08 |

| Polypropylene (PP) | 0.025 - 0.150 | 0.64 - 3.81 |

| Polystyrene (PS) | 0.035 - 0.150 | 0.89 - 3.81 |

| Polyurehane | 0.080 - 0.750 | 2.03 - 19.05 |

Abubuwan da suka shafi zaɓin kayan

Zabi filastik na dama don wani sashi ya shafi fiye da zabi kawai kauri bangon. Abubuwa da yawa suna shafan zaɓin abubuwan, wanda a ƙarshe yake ƙayyade wasan kwaikwayon da tsawon rai na ɓangaren.

Sinadarai da ja juriya

Kayan aiki dole ne mu tsayayya da fuskantar sinadarai, gyada, da kuma ultraviolet (UV). Rikici kamar ABS da PC + Abs Abs suna ba da juriya na sarkar sinadarai amma zai iya lalata ƙarƙashin tsananin bayyanar UV. Sabanin haka, polypropylene (PP) da acrylic kula da kyau UV juriya, mai sanya su dace da aikace-aikacen waje.

Zafi juriya

Heat juriya wani mummunan tunani ne. Polycarbonate (PC) na iya sarrafa babban yanayin zafi idan aka kwatanta da Abs, wanda ke nunawa a ƙananan matakan zafi. Nylon yana ba da kyakkyawan yanayin zafi tare da ƙari na fillers, yayin da pe da pp figh a cikin ƙananan yanayin zafi zuwa matsakaici zazzabi.

Ƙarfi da sassauci

Kayan aiki da sassauci na juzu'i na jimlar jimlar a ƙarƙashin matsananciyar damuwa. Abs yana ba da ƙarfi sosai tare da juriya tasiri mai tasiri, yayin da nailan da PC om sanannu ne ga mafi girman ƙarfinsu. Don sassauƙa sassauƙa, polyurethane da polypropylene galibi shine kayan zaɓi.

Launi da opacity

Bukatun ado na sashin zai yi tasiri na zaɓi. Wasu robobi, kamar su acrylic da polycarbonate, an fi son bayyanar da gaskiyarsu da tsabta a bayyane. Abs da PP na iya cinye launuka takamaiman launuka, yayin da ke riƙe da daidaituwa.

Karfin lantarki

Wasu aikace-aikace suna buƙatar kayan tare da takamaiman kaddarorin lantarki. Polycarbonate da kuma cakuda (PC + Abs) ana buƙatar amfani da shi a cikin lantarki a cikin lantarki (EMI) ana buƙatar garkuwa da nailan lantarki a cikin abubuwan lantarki.

Ka'idodin tsarin filastik na kauri

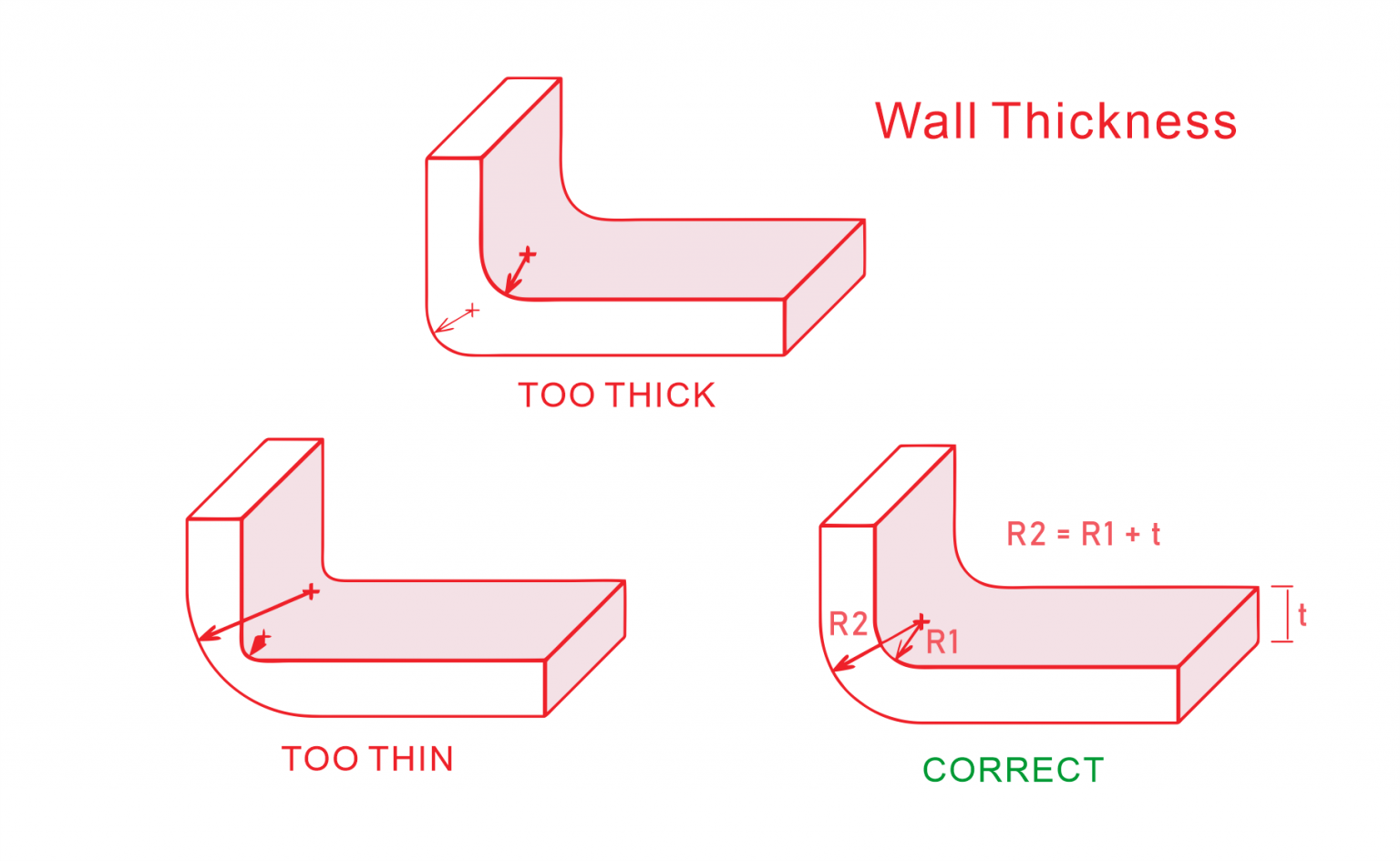

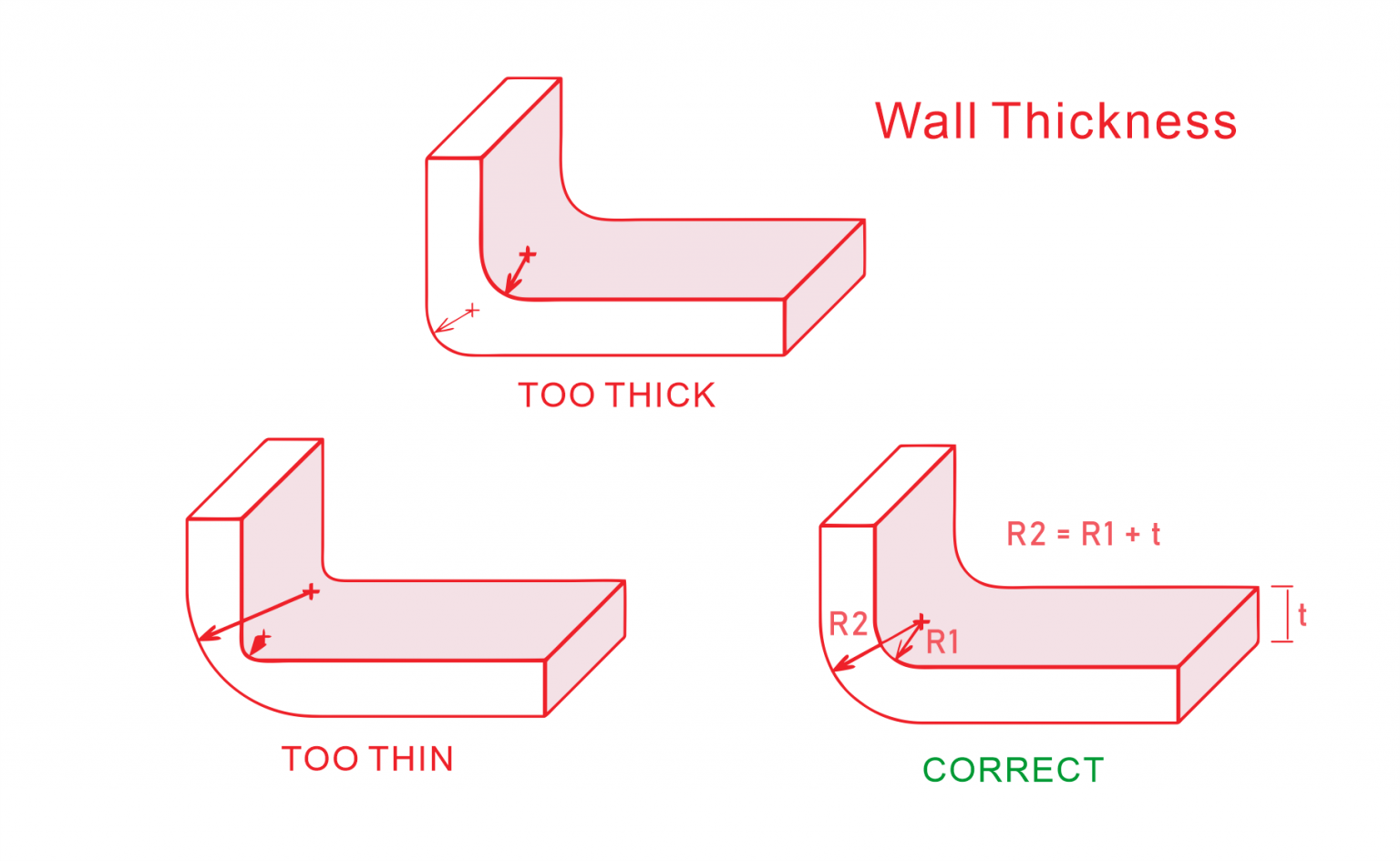

Atried tufafi na kauri

Kulawa da kauri bangon waya yana da mahimmanci ga mafi kyawun sashi na aiki:

Takamaiman jagororin kauri

Abubuwan da aka ware daban-daban suna buƙatar takamaiman kewayon kauri:

| kayan da | aka bayar da shawarar kauri (mm) |

| Harsashi (shugabanci na kauri) | 1.2 - 1.4 |

| Bangon gefen | 1.5 - 1.7 |

| Lens na waje | 0.8 |

| Lens Inner | 0.6 |

| Murfin baturin | 0.8 - 1.0 |

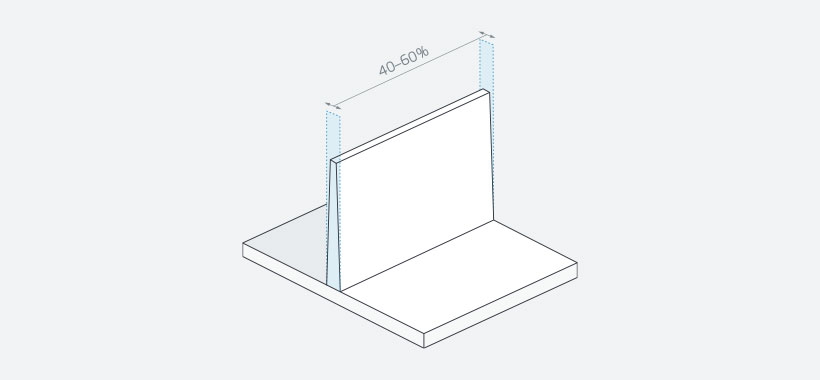

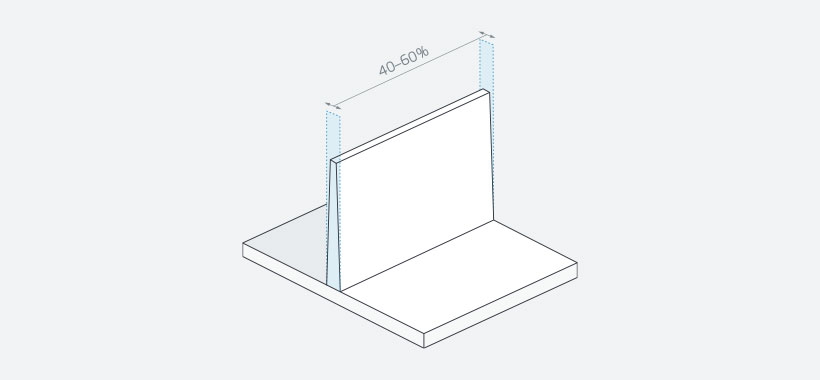

Sauyawa na kauri

M canuwan wurare tsakanin launuka daban-daban na hana lahani:

Kula da ɗan bambanci na kauri a lokacin haɗin bango na bakin ciki

Manufar 4-60% na kusa da bangon bangon bango

HUKUNCIN ARC a cikin Jigon Wall

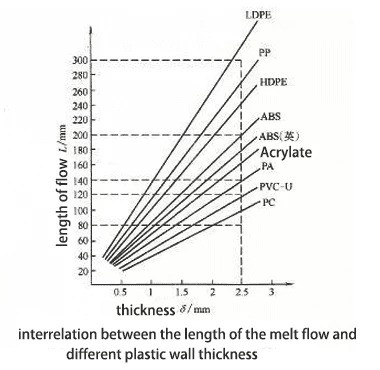

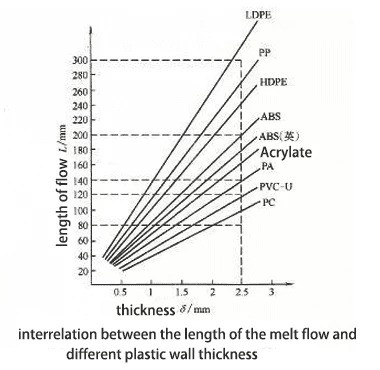

Kayan duniya da cika kaddarorin

Kauri katangar ta shafi kwararar kayan abu yayin yin alluna:

Rage girman kauri

Daidaita aiki da kayan aiki:

La'akari da dankan duniya

Abubuwan da kayan abu suna tasiri da ƙirar kauri:

Tsarin kauri na bangon bango ya dogara ne da ƙa'idodi masu tsada

Dangantaka tsakanin lokacin sanyaya da kauri

Kauri kauri yana tasiri lokacin sanyi, yana shafar samar da samarwa da farashi:

Ganuwar Thicker suna buƙatar tsawon lokacin sanyaya

Lokacin da aka tsawaita lokacin sanyaya kayan aiki

Extara yawan lokacin zagaye na haifar da mafi girman farashi

Yi la'akari da dangantaka mai zuwa:

| Girman Kayan | Girlo |

| 10% | 20% |

| 20% | 45% |

| 30% | 70% |

Rage girman kauri don ingantaccen inganci

Daidaita aiki da Inganci yana buƙatar la'akari da hankali:

Bukatar aiki:

Ingantacciyar amincin:

Kayan kwalliya:

Tabbacin inganci:

Ta hanyar inganta waɗannan dalilan, masu zanen kaya na iya:

Tasirin kauri mara kauri

Kauri madaidaicin bangon ado a cikin allurar rigakafi na iya haifar da yawan batutuwan da suka shafi duka ingancin samfurin da kuma ingancin masana'antu. Wadannan bambance-bambancen zasu iya haifar da lahani, rashin daidaito mai sanyaya, da matsaloli yayin aiwatar da tsari.

Laifi na kwaskwarima

Ofaya daga cikin matsalolin da aka fi sani da ke da kauri daga kayan bango marasa kauri shine lahani masu kwaskwarima. Wadannan ajizanci suna shafan bayyanar kuma, a wasu yanayi, tsarin tsarin tsarin.

Alamar sanya alama : sassan da kuka yi sanyi a hankali, suna haifar da farfajiya don nutsar da ciki, samar da alamun gani.

Warpage : Rashin kunya tsakanin Sashin kauri da bakin ciki suna haifar da murdiya, ko kuma warping, kamar yankuna daban-daban suna da kyau a cikin ƙimar daban daban.

Bambancin Bambancin sanyaya

Rashin amfani da kayan aiki yana haifar da yawan sanyaya a duk faɗin sashin. Sashin kauri yana ɗaukar lokaci mai tsawo don kwantar da hankali, yayin da wuraren bakin ciki suka tabbatar da sauri. Wannan rashin daidaituwa na iya haifar da lahani kuma yana buƙatar lokatai na sake zagayowar don tabbatar da duk wuraren sanyaya duk wuraren da ya dace.

Talubale Gating

Gating a cikin allurar rigakafi ya zama mafi rikitarwa yayin ma'amala da bangon ado na da ba. Kayan Molten na iya samun wahala a cikin sassan bakin ciki bayan cika wuraren shakatawa na kauri. Wannan katsewar kwarara na iya haifar da cika ko kuma fakitin fakiti, wanda ya haifar da lahani da rashin tsaro.

Bayyanar bayyanar bayyanar

Rashin daidaituwa yana haifar da haifar da matsalolin bayyanar bayyanar kamar:

Layin da ke gudana : Bambancin cikin kauri yana haifar da tsarin kwararar da ba na gudana ba, ƙirƙiri abubuwan da ake iya gani ko layuka a kan farfajiya.

Matsala ta sadu da Concity Contentaya : sassan kauri na iya kula da cikakken daidaitaccen logara yayin sanyaya, yana sa shi wahala don cimma nasarar karewar da ake so ko kuma kayan maye.

Karfi da damuwa da fadada fiber

Kauri a bangon bangon ado kuma yana haifar da tsarin ciki na ƙauyukan da aka gyara, musamman a cikin robobi masu karfafa gwiwa. Bangarorin na bakin ciki suna fuskantar matsananciyar ƙarfi, suna kaiwa ga abubuwan fiber daban-daban. Wannan bambance-bambancen a cikin fiber jeri yana shafar ƙarfin ɓangaren kuma zai iya ba da gudummawa ga warping ko gazawa a ƙarƙashin kaya.

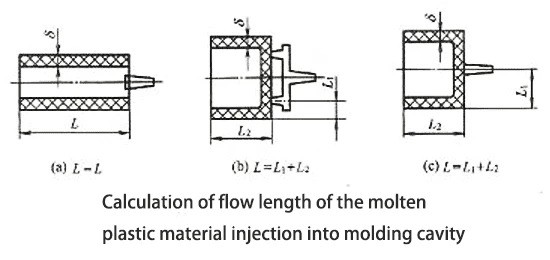

Lissafin kauri na kauri ta amfani da rabo (L / t)

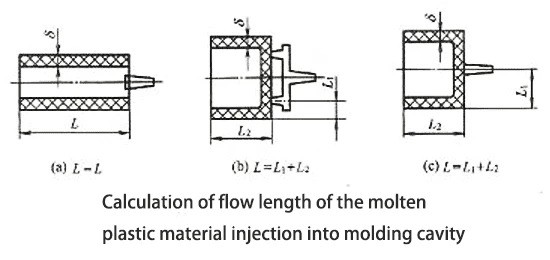

Ma'anar rarar rarar (L / t)

Rikici na kwarara (L / t) yana wakiltar dangantakar da ke tsakanin tsayin daka (L) da kauri na bango (T) a cikin allurar. Yana nuna yadda filastik quine filastik na iya tafiya cikin kauri bangon da aka bayar.

Mahimmanci na l / t rabo

L / t rabo yana taka muhimmiyar rawa a cikin:

A mafi girma l / t rarar bango na bakin ciki ko mafitsara kwarara mai gudana, tasiri a gaba ɗaya zane da kuma ingancin samarwa.

Abubuwa masu tasiri L / T Raco

Abubuwa da yawa suna shafar da L / T rabo:

Kayan aiki

Zazzabi na mold

Farfajiya

Resin danko

Shirya

Waɗannan abubuwan suna yin ma'amala da rikitarwa, suna yin daidai lissafin kalubale. Gogaggen molds suna dogara ne da kusan kewayon da kuma ilimin aiki.

Misali L / T Rareo lissafi

Yi la'akari da sashin PC tare da:

L / t (Jimlar) = L1 / T1 (Runner) + L2 / T2 (Samfurin) = 100/5 + 200/2 = 120

Wannan ya wuce kwatankwacin L / T rabo na PC (90), yana nuna yiwuwar matsaloli masu ƙarfi.

Inganta karfin gwiwa

Don haɓaka karfafa gwiwa:

Daidaita Coat Coating:

Gyara kauri na bango:

Wadannan gyare-gyare suna inganta tsarin da aka sarrafa, tabbatar da mafi kyawun sashi da ingancin samarwa.

Sauran la'akari da ingantaccen tsari na kariya

Kirkirar daidai bango na kauri don allurar allurai ta hadar sama da ka'idodi na asali. Abubuwa da yawa suna tasiri da zane na ƙarshe, suna tasiri duka aikin da ingancin samarwa.

Tsari na asali da bukatun girma

Asalin Tsarin Samfurin Samfurin Muhimmi Muhimmi Muhimmi Muhimmancin Inganta Kaurin Kaurin Kaure:

Matsayi na gaba ɗaya da girman rikodin buƙatun kauri

Ka'idojin Geometries na iya zama dole a wajabta kauri

Hakikirar tsarin da ake bukata yana buƙatar mafi yawan ƙimar ƙwaƙwalwar ƙwaƙwalwa

Masu zanen kaya dole ne su daidaita waɗannan dalilai tare da abubuwan da suka shafi masana'antu don inganta aikin aiki da ingancin samarwa.

Kadarorin da halaye na albarkatun kasa

Zaben kayan aiki yana taka muhimmiyar rawa a cikin Tsarin Worning na bango: tasirin

| kayan kayan aiki | akan kauri |

| Narke kwarara | MFI mafi girma yana ba da damar bango na bakin ciki |

| Addinin Shari | Yana shafar daidaito da warpage |

| A halin da ake yi na thereral | Tasirin lokacin sanyi lokaci da kuma ƙarfin tsarin kula |

Fahimtar wadannan kaddarorin yana taimaka wa masu zanen kaya suna zaɓar masu kauri da suka dace don takamaiman kayan.

Mold Design da allurar gyara sigogi

Mormold da aiwatar da la'akari suna shafar yanke shawara na kauri na bango:

Matsakaicin Gate Cover da girman tasirin tasirin da kuma bukatun kauri

Tsarin Tsarin Tsarin Kayan sanyaya kayan sanyaya hoto

Matsakaicin allura da sauri na iya rikita mafi ƙarancin baƙin ciki

Hadauki tare da masu zanen kaya masu ƙira da kuma aikin injiniyoyi masu amfani suna tabbatar da ingantaccen bango na kauri don abubuwan kirkirori.

Taro da bukatun amfani

Amfani da Amfani da Karshe dole ne ya haifar da zane-zanen kaji na bango:

Snap ya yi daidai da hings masu rai suna buƙatar takamaiman lokacin kauri mai kauri

Yankunan da ke da nauyi na iya buƙatar karfafawa bango

Tsarin zafin jiki ko kuma rufin wutar lantarki na lantarki na iya tasiri ga zabi mai kauri

Masu zanen kaya sun kamata la'akari da dukkan samfuran rayuwar rayuwar da ya dace yayin tantance kauri mai kauri.

Ƙarshe

A cikin zane don allurar rigakafi mai kyau, kula da ingantaccen katse bangon waya shine mabuɗi. Yana tasiri ƙarfi, lokacin sanyaya, da kuma ƙarfin samarwa. Masu bin jagororin da aka ba da shawarar don kayayyaki daban-daban na tabbatar da sakamako daban-daban kuma yana rage lahani kamar alamomin rami ko kuma warping.

Yin aiki tare da ƙwararren ƙwararren ƙwararrun yana taimakawa kyakkyawan kauri bango don takamaiman aikin bukatun. Suna bayar da kyakkyawar fahimta cikin halayyar kayan aiki, kayan aiki, da dabarun zane.

Inganta ma'auni na kauri, inganci, da aiki. Yana rage amfani da kayan rayuwa, lokacin sanyaya gajere, da haɓaka sashin. Tsarin kauri da ya dace yana haifar da inganci, samar da inganci.