Yu dɔn ɛva wɔnda aw dɛn mek kɔmpleks plastic pat dɛn we gɛt difrɛn difrɛn tin dɛn we dɛn mek wit difrɛn difrɛn tin dɛn? Di ansa de insay wan kleva tɛknik we dɛn kɔl . Injɛkshɔn moldin ɔndakat dɛn. Bɔt wetin rili na ɔnda-kɔt, ɛn wetin mek dɛn impɔtant so?

Ɔndakut na tin dɛn we de mek i nɔ izi fɔ pul wan pat pan in mol. Dɛn impɔtant fɔ mek pat dɛn wit ɛnhans funkshɔnaliti, impɔtant asɛmbli, ɛn ridyus nid fɔ sɛkɔndari ɔpreshɔn. Bɔt, fɔ disayn ɛn mol ɔndakat kam wit in yon sɛt fɔ chalenj dɛn.

Insai dis post, yu go lan wetin undacuts bi, wetin mek dem impɔtant, ɛn aw fɔ manej dɛn kɔmplisiti fayn fayn wan.

Wetin na injɛkshɔn moldin ɔndakat dɛn?

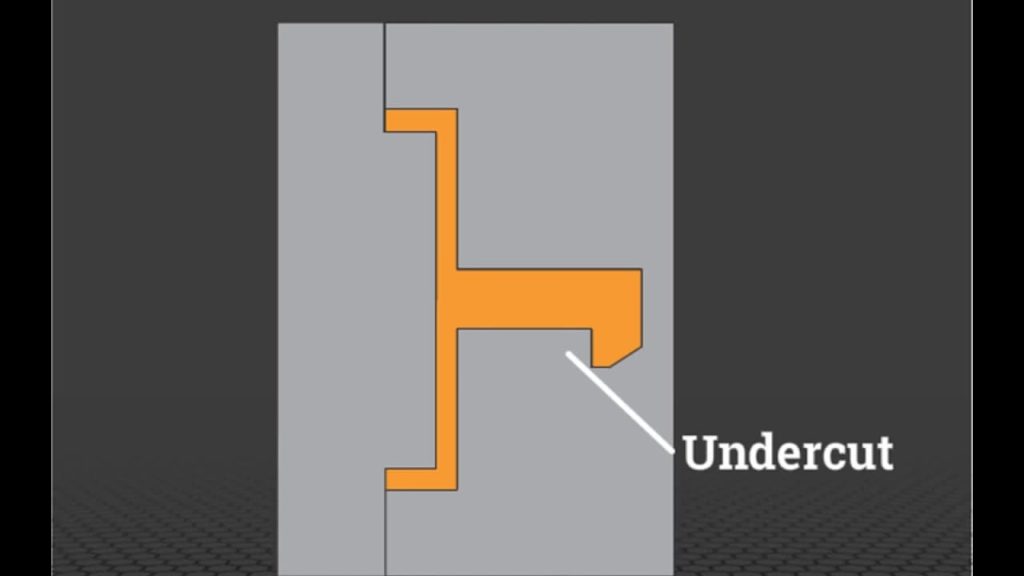

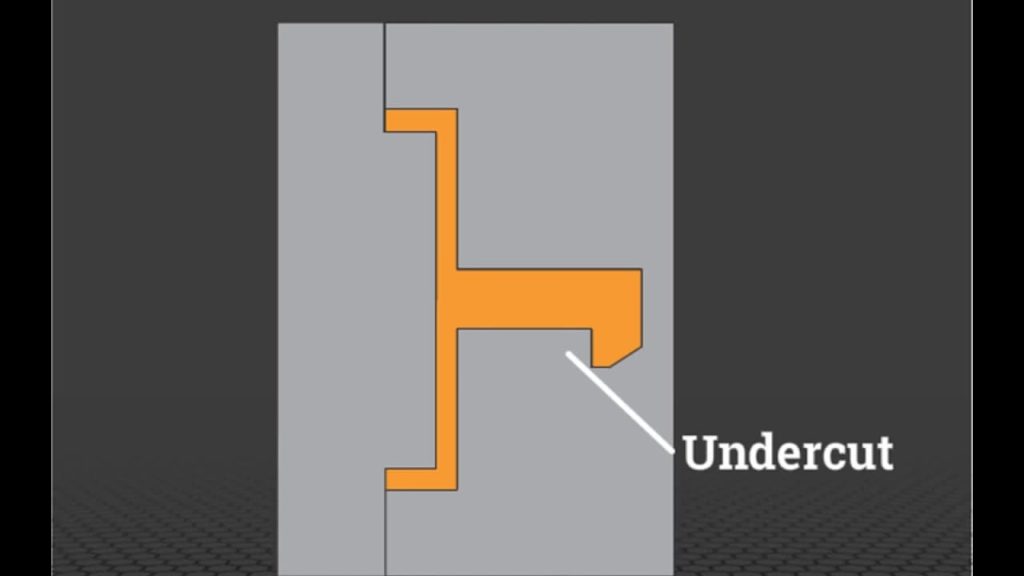

Injɛkshɔn moldin ɔndakat na ficha dɛn we de mek wan pat nɔ ebul fɔ kɔmɔt na in mol izi wan. Dem lek huk o ovahangs dat 'lock' di pat in ples. Mek wi explor dem ditail.

Ditayl ɛksplen bɔt ɔnda-kɔt dɛn .

Undercuts dem tipikli fom wen wan pat get:

Dɛn ficha dɛn ya nɔto pɔrpindikul to di mold in parting layn. Dis kin mek i nɔ izi fɔ pul di pat we yu nɔ pwɛl am.

Di kayn dɛn we dɛn kin kɔt ɔnda di ɔnda-kat dɛn .

Tu men kayn ɔndakat dɛn de:

Intanɛt Ɔndakɔt dɛn .

Ekstanshal ɔndakat dɛn .

we dɛn fɛn na di ɔda say we dɛn de .

Ɛgzampul dɛn: Klip dɛn, Huk dɛn, Flɛnj dɛn

Kɔmɔn Aplikeshɔn dɛn .

Dɛn kin yuz ɔndakat dɛn na difrɛn industri dɛn fɔ:

Ilektroniks we de yuz kɔnsuma .

bɔtin slot dɛn .

Batri Kɔmpawtmɛnt dɛn .

Divays dɛn fɔ mɛn pipul dɛn .

Luer lok dɛn .

Snap-fit asɛmbli dɛn .

Awtomotiv Kɔmpɔnɛnt dɛn .

Klip ɛn fastɛns dɛn .

Fluid Chanɛl dɛn .

| Indastri | Aplikeshɔn | Bɛnifit |

| Ilɛktroniks . | bɔtin slot dɛn . | I izi fɔ yuz am . |

| Wɛlbɔdi biznɛs | Luer lok dɛn . | Sikyɔri Kɔnɛkshɔn . |

| Ɔtomotiv . | Klip dɛn . | Kwik Asɛmbli . |

Ɔndakɔt ad funkshɔnaliti ɛn simpul asɛmbli. Dɛn na wan impɔtant aspek fɔ injɛkshɔn moldin dizayn.

Impɔtant fɔ ɔnda-kɔt insay injɛkshɔn mold pat dɛn .

כnda kכt dεm de ple wan imכtant rol fכ injεkshכn mold pat dεm. Dɛn kin gi sɔm bɛnifit dɛn we kin mek dɛn nɔ gɛt wan valyu fɔ mek tin dɛn we dɛn de mek tide.

Enhansed functionality ɛn dizayn kɔmplisiti .

Undercuts alaw dizayna dɛn fɔ mek pat wit:

dis element dεm de εnhans di fכnshכnaliti fכ di pat. Dɛn kin ɛnabul bak fɔ mek mɔ kɔmpleks dizayn dɛn we nɔ go pɔsibul if dɛn nɔ gɛt ɔnda-kɔt.

Impɔtant Asɛmbli ɛn Disassembly .

Undercuts fasilit izi asembli en disassembly of pats. Dɛn alaw fɔ:

Kwik Snap-Fit Kɔnɛkshɔn dɛn .

Ridyus nid fɔ skru ɔ adeziv .

I izi fɔ chenj di tin dɛn we dɔn pwɛl ɔ we dɔn pwɛl .

Dis kin mek di asɛmbli wok izi ɛn mek di mentenɛns bi briz.

Ridyus nid fɔ sɛkɔndari ɔpreshɔn dɛn .

We yu put ɔnda-kɔt dairekt insay di pat we dɛn dɔn mol, yu kin:

Eliminate di nid fɔ post-molding drilling ɔ mashin .

Ridyus di nɔmba fɔ di asɛmbli stɛp dɛn .

Minimayz di risk fɔ mek mɔtalman mistek .

Dis de sev tɛm, tray, ɛn tin dɛn we dɛn nid fɔ mek di tin dɛn we dɛn de mek.

Kost-effektiv in mass prodakshɔn .

Ɔndakɔt dɛn kin kɔntribyut to kɔst-ɛfɛktiv, mɔ na ay-volyum prodakshɔn rɔn. Dɛn de ɛnabul:

As tɛm de go, dɛn sevings ya ad ɔp, we de mek ɔnda-kɔt wan ikɔnomik chuk fɔ mas prodakshɔn.

| Benefit | Impekt . |

| Enhansd funkshɔnaliti . | Enables kɔmpleks dizayn dɛn . |

| Impɔtant Asɛmbli . | Streamlines prodakshɔn . |

| Ridyus Sɛkɔndari OPS . | Sev tɛm ɛn risɔs dɛn . |

| Kost-ɛfɛktiv . | I de stɔp di ɔl di spɛns dɛn . |

Teknik fɔ ajɔst injɛkshɔn moldin ɔndakat dɛn .

Fɔ mek ɔnda-kɔt insay injɛkshɔn moldin nid spɛshal tɛknik. Lɛ wi fɛn di we dɛn we dɛn kin yuz mɔ ɛn dɛn gud ɛn bad tin dɛn.

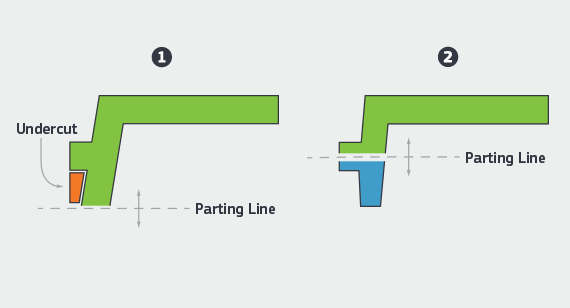

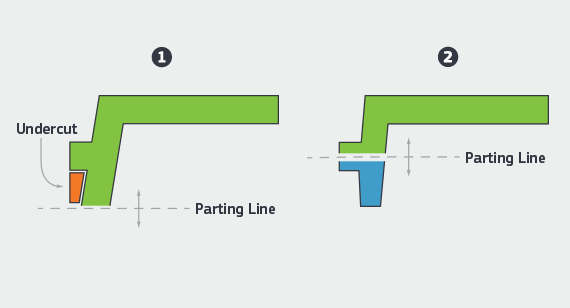

1. Pat pan di layn ajɔstmɛnt .

Parting line plesment na impɔtant tin fɔ ɔnda-kat dizayn. I gɛt fɔ du wit:

Dis de mek dɛn ebul fɔ pul di pat we nɔ gɛt ɛnitin fɔ du wit am.

Di bɛnifit dɛn we pɔsin kin gɛt:

Di tin dɛn we yu nɔ fɔ du:

Tips fɔ optimizing parting line design:

Tink bɔt pat pan di wok ɛn di fayn fayn tin dɛn we de na di wɔl .

Minimayz di nɔmba fɔ di layn dɛn we de pat .

Mek shɔ se yu gɛt di rayt vent ɛn kol .

2. Sayd-Akshɔn dɛn .

Sayd-akshɔn dɛn na movable mold komponent dɛn we de mek ɔndakat. Dɛn de wok bay:

Di kayn dɛn we de sho di sayd-akshɔn dɛn:

Haydrolik - Pawaful bay haydrolik prɛshɔn .

Mekanikal - we kam bay kam ɔ linkej dɛn .

Nyumɛtik - we dɛn aktyuet bay kɔmprɛsd ɛya

Dizayn Tin dɛn fɔ Tink bɔt:

Mek shɔ se dɛn klia ɛn alaynɛshɔn fayn fayn wan .

Plan fɔ mek di ples kol ɛn di we aw dɛn de mek di briz kɔmɔt fayn fayn wan .

Tink bɔt di fɔs we dɛn nid fɔ yuz di sayd-akshɔn .

Bɛnifit dɛn:

Di prɔblɛm dɛn we pɔsin kin gɛt:

3. Bump-ɔf dɛn .

Bump-offs na rayz sekshɔn dɛn pan di mold we kɔmprɛs di tɛm we dɛn de ejekshɔn. Dɛn alaw di pat fɔ fleks ɛn rilis frɔm di ɔnda-kat.

Di tin dɛn we fayn fɔ yuz fɔ bɔmp-ɔf:

Dizayn Gaydlain:

Mek shɔ se yu gɛt inof draft angul dɛn .

Yuz di say dɛn we smɔl, we gɛt rawnd rawnd .

Tink bɔt di tin dɛn we di tin dɛn we dɛn yuz fɔ mek di tin dɛn we dɛn yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, nɔ go rich

Di bɛnifit dɛn we pɔsin kin gɛt:

Di bad tin dɛn we pɔsin kin du:

4. Insɛt dɛn we dɛn dɔn lod wit an .

Dɛn kin put insɛt dɛn we dɛn dɔn lod wit an wit dɛn an insay di mol bifo ɛni saykl. Dɛn kin mek ɔnda-kɔt bay:

We yu de yuz insɛt dɛn we dɛn dɔn lod wit an:

Dizayn ɛn di tin dɛn we dɛn fɔ tink bɔt:

Di wan dɛn we sabi du di wok:

Di bad tin dɛn we apin:

5. Sliding shutoffs (Tɛlskɔp Shuɔf dɛn)

Sliding shutoffs na mold komponent we de muv paralel to di ejekshɔn dairekshɔn. Dɛn kin mek ɔnda-kɔt bay:

Aplikeshɔn dɛn:

Di Tin dɛn we Yu fɔ Yuz fɔ Mek di Baybul:

Mek shɔ se alaynɛshɔn ɛn kliarens fayn fayn wan ɛn klia .

Yuz tin dɛn we nɔ de west fɔ di say dɛn we dɛn kin yuz fɔ mek di ples nɔ wam

Plan fɔ mek di ples kol ɛn di we aw dɛn de mek di briz kɔmɔt fayn fayn wan .

Di bɛnifit dɛn we pɔsin kin gɛt:

Di tin dɛn we yu nɔ fɔ du:

6. Kolapsible kores .

Kolapsible kor na mold komponent we de kollaps o retract wen dem de ejekshon. Dɛn alaw di pat fɔ rilis frɔm intanɛnt ɔndakat dɛn.

Tayps of kollapsible kors:

Mekanikal - we kam bay kam ɔ linkej dɛn .

Haydrolik - we dɛn aktyuet bay haydrolik prɛshɔn .

Dizayn Tin dɛn fɔ Tink bɔt:

Mek shɔ se dɛn alaynɛshɔn fayn ɛn di tɛm we dɛn de muv di kɔr muvmɛnt fayn fayn wan ɛn di tɛm we dɛn de .

Plan fɔ mek di ples kol ɛn di we aw dɛn de mek di briz kɔmɔt fayn fayn wan .

Tink bɔt di fɔs we dɛn nid fɔ kɔlap di kɔr we de na di kɔr .

Bɛnifit dɛn:

Di prɔblɛm dɛn we pɔsin kin gɛt:

Fɔ pik di rayt tɛknik de dipen pan tin dɛn lɛk:

Pat jɔyometri ɛn kɔmplisiti .

Di prɔpati dɛn we dɛn gɛt .

Prodakshɔn volyum ɛn kɔst kɔnstrakshɔn .

Disain kɔnsidareshɔn fɔ ɔnda-kɔt .

We dɛn de disayn pat dɛn wit ɔnda-kɔt, sɔm impɔtant tin dɛn de fɔ mɛmba. Mek wi explor dem ditail.

Draft angul dɛn .

Impɔtant tin dɛn bɔt draft angul dɛn .

Draft angles na impɔtant tin fɔ ɔnda-kɔt dizayn. Dɛn kin ɛp fɔ mek shɔ se:

If dɛn nɔ gɛt di rayt draft, pat dɛn kin stik ɔ difɔm we dɛn de ejekshɔn.

Draft angul dɛn we dɛn kin advays .

Di optimal draft angle dipen pan di spesifik dizayn. Bɔt, na sɔm jenɛral gaydlayn dɛn ya:

| Ficha Tayp | Rikɔmɛnd Draft |

| Di wɔl dɛn we de na do . | 1-2 digri dɛn . |

| Intanɛt wɔl dɛn . | 2-3 digri . |

| Ribs ɛn bɔs dɛn . | 0.5-1 digri fɔ wan say . |

Inkris draft angles kin improve pat rilis bot kin afekt aesthetics.

Tiknes fɔ di wɔl .

Mentɛn yunifom wɔl tiknes .

Konsistent wall tiknes na impɔtant tin fɔ ɔndakat dizayn. I de mek shɔ se:

Ɔltɛm fala di resin manifakta in gaydlayn fɔ di wɔl tik.

Impekt pan pat intɛgriti .

Varieshɔn dɛn na di tik we de na di wɔl kin mek dɛn:

wik spat ɔ strɛs kɔnsɛntreshɔn .

Nɔ ivin matirial flɔ ɛn pak .

difεkt dεm we wi kin si na di pat sεf .

Mentɛn wan yunifom tik ɔlsay na di pat fɔ mek yu gɛt di bɛst rizɔlt.

Ribs ɛn Radius dɛn .

Sɔpɔt strɔkchɔ dɛn na pat dɛn we dɛn dɔn mol .

Rib na tin we tan lɛk tin we tan lɛk wɔl we de gi strɔkchɔ sɔpɔt. Dɛn kin ɛp:

Riinfɔs big, flat sɔfays dɛn .

Prevent sink maks ɛn wɔping .

Impruv pat rigiditi ɛn trɛnk .

Yuz rib stratejik wan fɔ ɛp fɔ mek di pat dɛn we dɛn dɔn kɔt ɔnda kɔt.

Radiusing internal corners .

Shap intanɛnt kɔna dɛn kin gɛt strɛs kɔnsɛntreshɔn. Fɔ mek dis nɔ apin:

Radiused kɔna dɛn de sheb strɛs mɔ ivin, impruv pat fɔ durabiliti.

Disain fɔ manufakchurabiliti (DFM) insay ɔnda-kɔt injɛkshɔn moldin

DFM na wan impɔtant aspek fɔ saksesful ɔndakat dizayn. Lɛ wi dayv insay in prinsipul ɛn bɛnifit dɛn.

Ovaviu fɔ di DFM prinsipul dɛn .

DFM na dizayn we de pe atɛnshɔn pan izi we fɔ mek tin dɛn. Di men tin dɛn we i fɔ du na:

Simplifying pat jɔyometri .

Minimizing di nɔmba fɔ di komponent dɛn .

Disain fɔ mek dɛn ebul fɔ mek di asɛmbli fayn fayn wan .

We yu tink bɔt di prɔpati dɛn we yu gɛt ɛn di tin dɛn we yu nɔ fɔ du ɛn di tin dɛn we yu nɔ fɔ du .

We dɛn yuz DFM, dizayna dɛn kin mek pat dɛn we izi ɛn we nɔ dia fɔ mek.

Impɔtants fɔ DFM insay ɔnda-kɔt dizayn .

Ɔndakɔt ad kɔmplisiti to di injɛkshɔn moldin prɔses. DFM ɛp fɔ manej dis kɔmplisiti bay:

Fɔ no di prɔblɛm dɛn we kin apin we dɛn de mek tin dɛn ali na di dizayn faz .

Optimizing pat joyometri fɔ spɛshal moldin tɛknik dɛn .

Fɔ mek shɔ se di dizayn go kɔmpit wit di matirial we dɛn dɔn pik .

Ridyus di risk fɔ difɛkt ɛn prodakshɔn dilɛys .

Inkorporet DFM na impɔtant tin fɔ saksesful ɔndakat dizayn.

Kɔmɔn DFM gaydlayn fɔ ɔnda-kɔt .

Na sɔm ki DFM tips fɔ disayn ɔndakat dɛn:

Minimayz ɔnda-kɔt dip ɛn kɔmplisiti .

Yuz kɔnsistɛns wɔl tiknes ɔlsay na di pat .

Gi adekwayt draft angles fɔ izi ɛjekshɔn .

Avɔyd shap shap kɔna ɛn ed dɛn .

Tink bɔt di say we dɛn de sheb di layn ɛn di impak we i gɛt pan di ɔnda-kat .

Yuz standad matirial ɛn tolɛreshɔn ɛnitɛm we i pɔsibul .

Fɔ fala dɛn gaydlain ya kin ɛp fɔ mek di moldin prɔses izi.

Benefit fɔ inkɔrpɔret DFM .

Implimentin DFM in Undercut Design de gi sɔm bɛnifit dɛn:

Ridyus di kɔst fɔ prodyus ɛn di tɛm we dɛn de mek di lida dɛn .

Impɔtant pat kwaliti ɛn kɔnsistɛns .

Enhansed kolaboreshɔn bitwin dizayn ɛn manufakchurin tim dɛn .

Fasta tɛm-to-maket fɔ nyu prɔdak dɛn

Inkris ɔvala manufakchurin efyushɔn .

| DFM bɛnifit | impak |

| Di kɔst dɛn we smɔl pas ɔl . | Mɔ kɔmpitishɔn prayz . |

| Fasta prodakshɔn . | Shorta Lid tɛm dɛn . |

| Bɛtɛ kwaliti . | Di wan dɛn we gɛt ay ay kɔstɔma dɛn satisfay . |

| Enhansed efficiency . | Di prɔfit we dɛn de gɛt mɔ ɛn mɔ . |

Chalenj ɛn sɔlv dɛn .

Disain ɛn mol ɔndakat kam wit in fayn fayn pat pan di prɔblɛm dɛn. Lɛ wi fɛn sɔm kɔmɔn tin dɛn ɛn dɛn sɔlv dɛn.

Material ɛn dizayn chalenj dɛn .

Manejin rigid matirial ɛn kɔmpleks jɔyometri dɛn .

Rigid matirial dɛn lɛk polycarbonate ɛn ABS kin bi chalenj fɔ ɔndakat dizayn. Dɛn:

Kɔmpleks jɔyometri wit dip ɔ narrow ɔndakat dɛn mɔ kɔmplikt di prɔses.

Sɔlv fɔ kɔmɔn dizayn kwɛstyɔn dɛn .

Fɔ mek dɛn ebul fɔ win dɛn prɔblɛm dɛn ya, dizayna dɛn kin:

Yuz mɔ fleksibul matirial dɛn lɛk TPE ɔ naylon .

Optimize wall tiknes ɛn draft angul dɛn .

Inkorporet sayd-akshɔn ɔ kollapsibl kɔr fɔ kɔmpleks ficha dɛn .

Kɔlabɔreshɔn bitwin dizayna ɛn mol dɛn na di men tin fɔ fɛn fayn fayn sɔlvishɔn dɛn.

Aesthetic ɛn funkshɔnal kɔnsidareshɔn dɛn .

Dil wit visible parting lines .

Bɔku tɛm, dɛn kin si layn dɛn we de pat pan pat dɛn wit ɔnda-kat. Dɛn kin:

Fɔ mek dɛn nɔ gɛt bɔku impak, tink bɔt:

Fɔ ajɔst di say we dɛn de sheb di layn .

Yuz tɛkstɔr ɔ kɔlɔ fɔ ayd di layn dɛn .

employing sliding shutoffs fɔ wan simlɛs apia

Fɔ mek shɔ se dɛn de wok fayn fayn wan .

כndakut kin afekt bak di fכnshכnal pεrformεns fכ di pat. Fɔ mek yu kɔntinyu fɔ gɛt wanwɔd:

Kɔndɔkt gud dizayn rivyu ɛn simulshɔn dɛn .

Test prototypes ɔnda rial-wɔl kɔndishɔn .

Mek di ajɔstmɛnt dɛn we nid fɔ mek dɛn ajɔst di dizayn bay we dɛn gi yu fidbak .

Fɔ fɛn di rayt balans bitwin di funkshɔnaliti ɛn di manufakchurabiliti na impɔtant tin.

Kost Implikashɔn dɛn .

Balancing komplexiti ɛn prodakshɔn kɔst dɛn .

Mɔ kɔmpleks ɔndakat dɛn jɔs min ay prodakshɔn kɔst. Dis na bikɔs ɔf:

Inkris mold kɔmplisiti ɛn mentenɛns .

Lכng saykl tεm dεm εn hכy mεtirial yus .

Atikul leba fɔ insɛt ɔ sɛkɔndari ɔpreshɔn we dɛn dɔn lod wit an ɔ sɛkɔndari ɔpreshɔn .

Dizayna dɛn fɔ wej di bɛnifit dɛn we ɔnda-kɔt dɛn gɛt agens dɛn kɔst impak.

Lɔng tɛm impak pan invɛstmɛnt .

Di apfrɔnt invɛstmɛnt insay wan kɔmpleks mold wit ɔnda-kat kin bi impɔtant. Bɔt, i impɔtant fɔ tink bɔt:

Wan ɔnda-kat we dɛn dɔn mek fayn fayn wan kin pe fɔ lɔng tɛm, pan ɔl we di fɔs kɔst dɛn kin pe fɔ am.

| Chalenj | Sɔlv . |

| Rigid matirial dɛn . | Yuz ɔda we dɛn fɔ chenj di we aw yu de du tin . |

| Layn dɛn we pɔsin kin si we pɔsin kin si . | Adjɔst di say we yu de ɔ yuz di tɛkstɔr . |

| Fɔnishɔnal Intɛgriti . | Kɔndɔkt di tɛst gud gud wan . |

| Prodakshɔn kɔst dɛn . | Balans kɔmplisiti ɛn bɛnifit dɛn . |

Ɛksplen

In sɔmari, fɔ ajɔst injɛkshɔn moldin ɔndakat dɛn involv sɔm impɔtant tɛknik dɛn. Wi bin de fɛn ɔl di layn dɛn, sayd-akshɔn dɛn, bampɔf dɛn, insɛt dɛn we dɛn dɔn lod wit an, ɛn tɛliskɔp shutɔf dɛn. Fɔ pik di rayt tɛknik na impɔtant tin fɔ mek yu gɛt sakrifays. Material choice ɛn dizayn fɔ manufacturability (DFM) na impɔtant tin bak fɔ ɔnda-kɔt moldin. Fɔ wok togɛda wit masta sabi bukman dɛn de mek shɔ se dɛn gɛt di bɛst rizɔlt. Ifɛktiv ɔnda-kat dizayn nid ɔl tu di no ɛn prɛsishɔn.

Yu gɛt wan kɔmpleks ɔnda-kat dizayn? Team MFG get di ekspetiz to bring am to laif. Sɔbmit yu CAD fayl dɛn tide na . https://www.team-mfg.com fɔ wan fast, fri kot. Wi masta sabi bukman dɛn dɔn rɛdi fɔ ɛp yu. Start naw !