Yu dɔn ɛva notis wan fayn layn pan yu plastic prɔdak dɛn? Dat na lɛk wan wɛl layn, ɛn i kin bi big prɔblɛm insay . Injɛkshɔn moldin . weld layn dɛn nɔ jɔs afɛkt di apinɛns fɔ yu pat dɛn bɔt i kin wik dɛn strɔkchɔ bak.

Insay dis atikul, wi go dayv dip insay injɛkshɔn moldin weld layn dɛn. Yu go lan wetin de mek dɛn nɔ pafɛkt dɛn peshɛnt ya ɛn, di tin we impɔtant pas ɔl, aw fɔ mek dɛn nɔ apin. Get redi fɔ optimize yu injɛkshɔn moldin prɔses ɛn mek pat dɛn we nɔ gɛt wan bɔt ɛvri tɛm!

Wetin na weld layn dɛn na injɛkshɔn moldin?

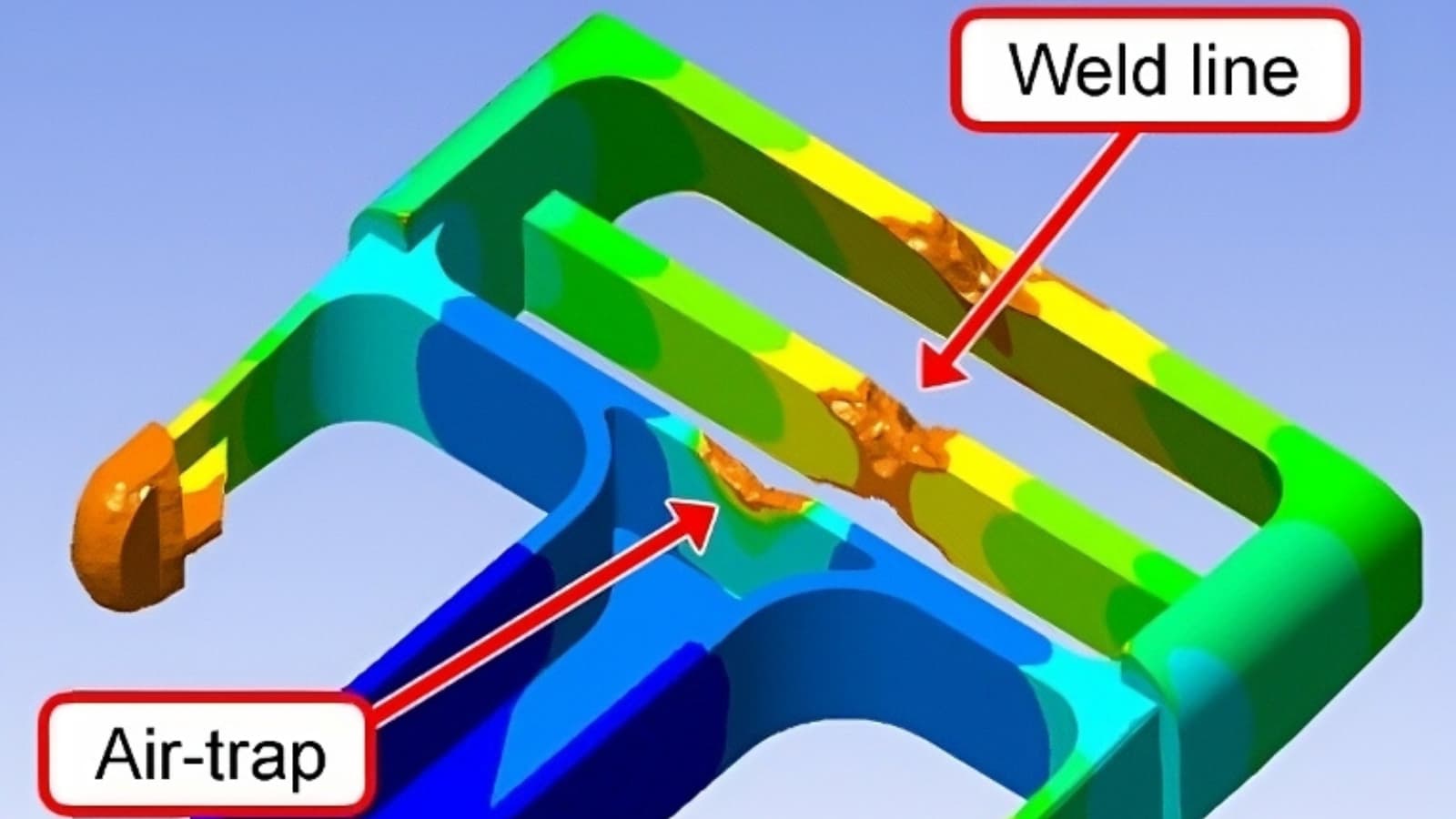

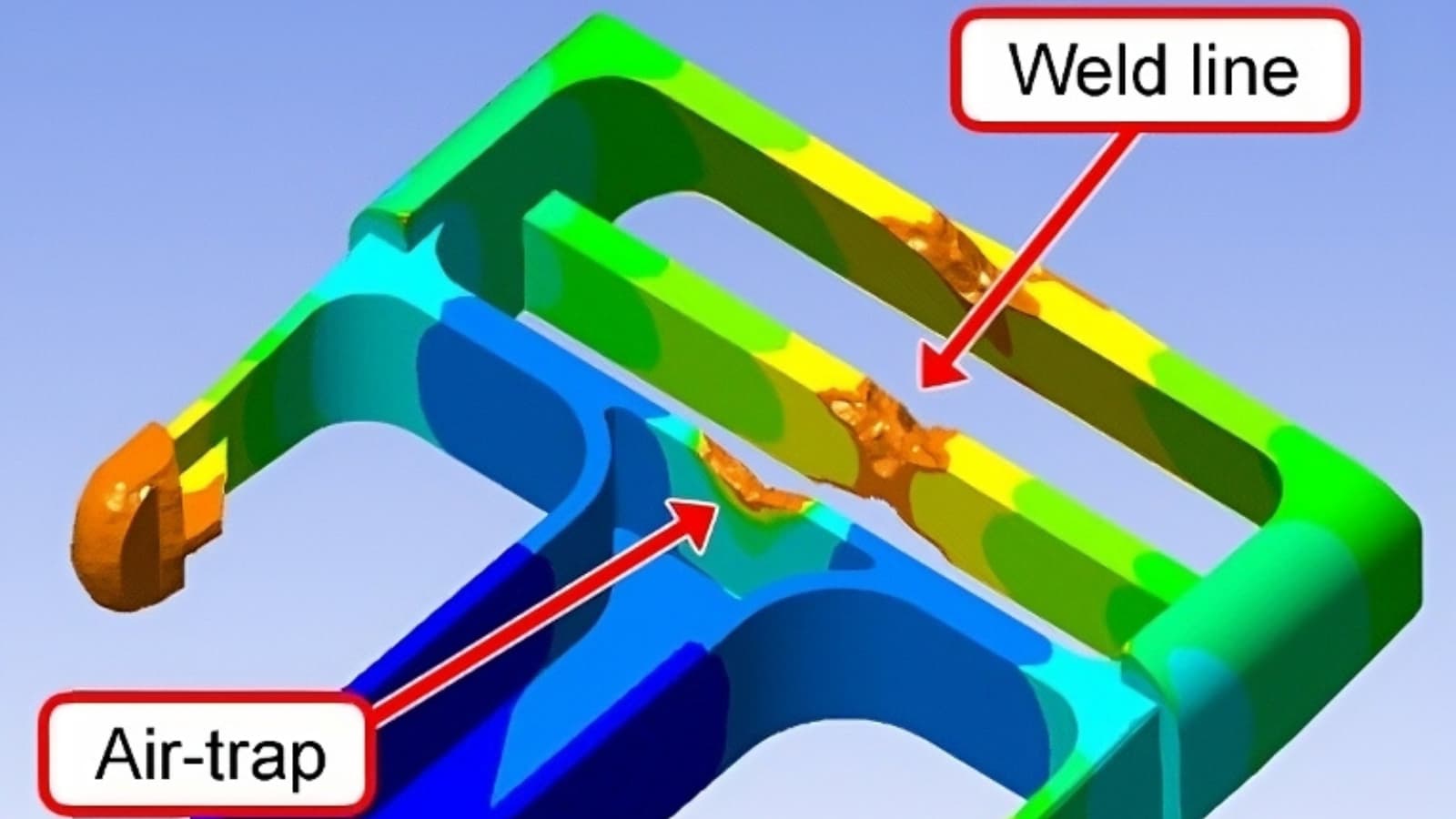

Weld layn dɛn, we dɛn kin kɔl bak knit layn ɔ meld layn, na kɔmɔn dɛfɛkt dɛn na injɛkshɔn mold pat dɛn. Dɛn kin apia as fain, bɔku tɛm dɛn nɔ kin jɔs si layn dɛn na di say we tu ɔ mɔ flɔ frɔnt dɛn dɔn kam togɛda.

Dɛn imprɛfɛkshɔn ya kin apin we di plastic we dɔn rɔtin de flɔ rawnd di tin dɛn we de ambɔg am lɛk ol ɔ kɔr. Dɔn i kin kam togɛda bak na di ɔda say, ɛn dis kin mek wi gɛt wan wik say.

Weld layn dɛn difrɛn frɔm meld layn dɛn bay di angul we di flɔ frɔnt dɛn mit:

Pan ɔl we MELD layn dɛn nɔ kin rili bad, dɛn ɔl tu kin kɔmprɔmis di trɛnk ɛn di we aw di pat we dɛn dɔn mol kin luk.

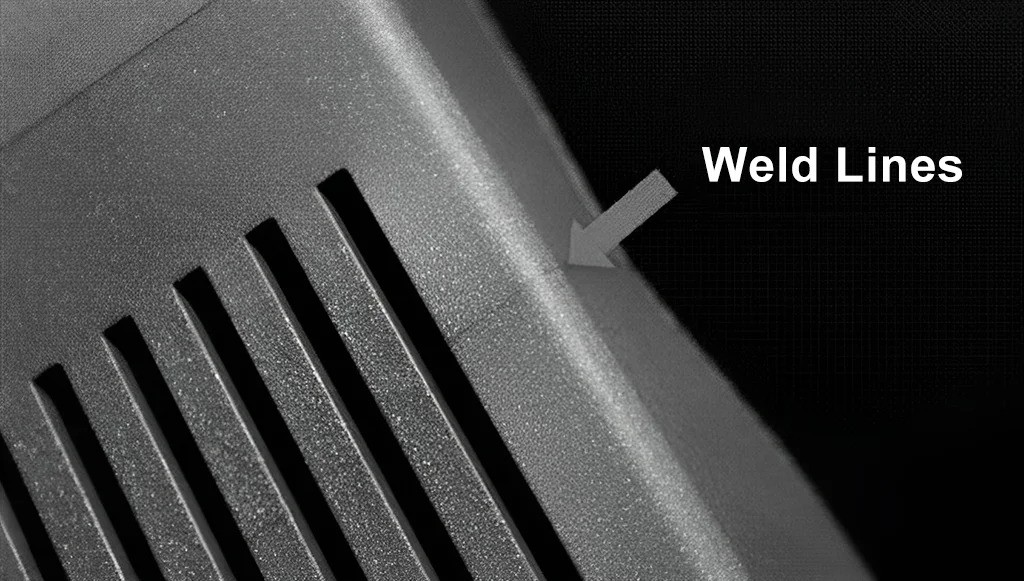

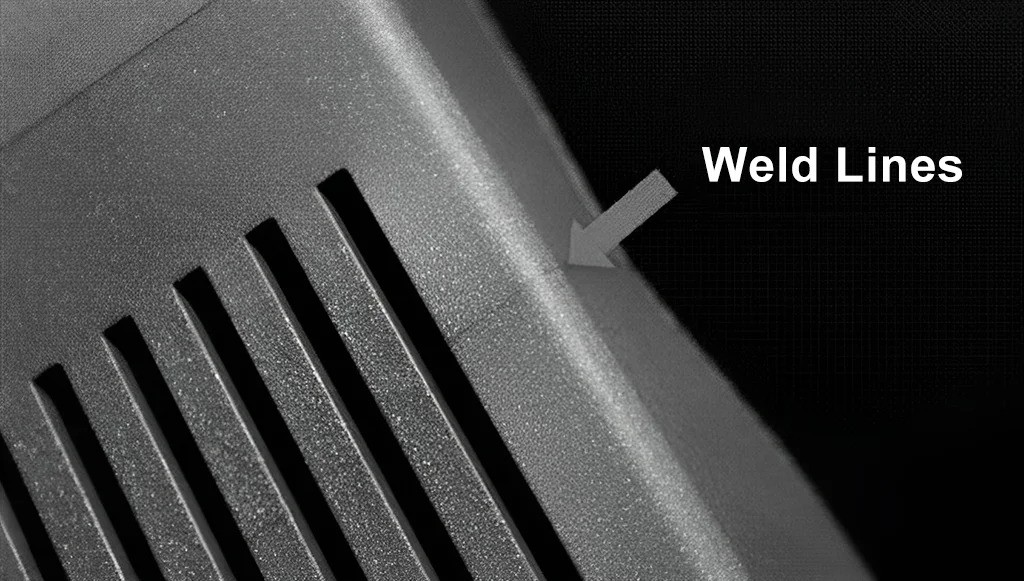

Tek wan luk pan dɛn ɛgzampul ya fɔ weld layn dɛn pan difrɛn plastic kɔmpɔnɛnt dɛn:

As yu si, dɛn nɔ kin izi fɔ si ɔltɛm. Bɔt ivin di faintest weld layn kin bi wik pɔynt, mɔ ɔnda strɛs ɔ impak.

Aw dɛn kin mek wɛl layn dɛn we dɛn de injɛkshɔn moldin?

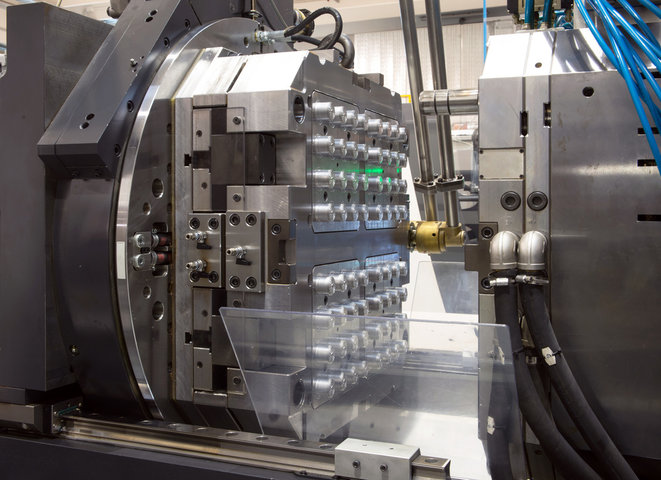

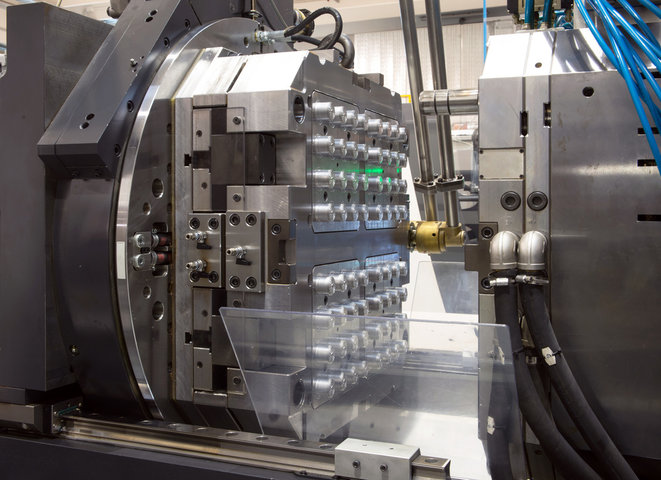

Fɔ ɔndastand aw wɛld layn dɛn de fɔm, lɛ wi fɔs tek wan kwik luk pan di injɛkshɔn moldin prɔses:

Dɛn kin injɛkt plastic we dɛn dɔn mɛlt insay wan mold kaviti .

I de flɔ tru di mol, i de ful-ɔp am .

Di plastic de kol ɛn solidify .

Di pat de kɔmɔt na di mold .

Naw, imajin di plastic we dɔn rɔtin we de flɔ tru di mol. We i mit wan tin we de ambɔg lɛk ol ɔ kɔr, di flɔ kin split insay tu difrɛn strim dɛn. Dɛn flɔ frɔnt dɛn ya kin muv rawnd di ɔbstakl ɛn riyunit na di ɔda say.

If kondishɔn nɔ pafɛkt, di frɔnt dɛn nɔ kin ful-ɔp fɔ fiuz bak togɛda. Dis de mek wan weld layn - wan wik pɔynt na di pat.

Bɔku kɔmɔn sɛnɛriɔ kin mek dɛn mek wɛl layn fɔmɛshɔn:

ol ɔ kɔr dɛn na di mol .

tin sekshɔn dɛn we de mek flɔ fɔ split .

Bɔku bɔku get dɛn we de introduks sɛpret flɔ frɔnt dɛn .

Get dɛn we dɛn nɔ put fayn we de mek frɔnt dɛn mit .

Di kayn we aw di wɛl layn siriɔs dipen pan tin dɛn lɛk:

Melt tempɔret .

Injɛkshɔn spid ɛn prɛshɔn .

Mold dizayn ɛn get plesmɛnt .

Di prɔpati dɛn we dɛn gɛt .

In jɛnɛral, ɛnitin we de ambɔg di rayt flɔ frɔnt fushɔn kin kɔntribyut to mɔ pronɔns wɛld layn dɛn. Wi go fɛn we fɔ stɔp dɛn tin ya leta.

Wetin mek weld layn dɛn na tin we de mɔna pipul dɛn we dɛn de mol injɛkshɔn?

Yu kin de tink, 'So wetin if na likl lain de na mi pat?' Wel, weld lain dem pas jis wan kosmetik ishu. Dɛn kin gɛt impɔtant impak pan di we aw yu prɔdak de luk ɛn di we aw i de wok.

Fɔs, lɛ wi tɔk bɔt aesthetics. Bɔku tɛm, dɛn kin si wɛl layn dɛn na di pat in fes, mɔ wit tin dɛn we gɛt glos ɔ transparent. Dɛn kin apia as:

Layn dɛn we nɔ gɛt kɔlɔ .

Maks we dɛn mɛn ɔ we dɛn dɔn put insay .

Dull Spots in wan ɔdasay shayn sɔfays .

Dɛn tin ya we nɔ pafɛkt kin mek yu prɔdak luk smɔl ɔ dɛn nɔ mek am fayn, ilɛksɛf i fayn fɔ mek i wok fayn.

Bɔt di rial kɔnsyusɔn wit wɛl layn na dɛn ifɛkt pan pat trɛnk. Mɛmba se, wan wɛl layn na wik pɔynt usay di flɔ frɔnt dɛn nɔ bin ful-ɔp fɔ fiuz. Dis min se di tin we de na da say de nɔ bɔku ɛn i kin mek i nɔ wok fayn.

Ɔnda strɛs ɔ impak, wan pat go mɔs brok na di wɛl layn. Dis kin bi wan big prɔblɛm fɔ lod-bearing komponent ɔ pat dɛn we dɛn kin wear ɛn tear ɔltɛm.

Sɔntɛnde, wan wɛl layn kin ridyus di trɛnk we wan pat gɛt bay 50%! Dat na big big difrɛns we kin mek yu nɔ ebul fɔ du am bifo tɛm ɔ ivin mek yu gɛt sef prɔblɛm.

Fɔ mek dɛn nɔ gɛt wɛl layn na impɔtant tin fɔ mek shɔ se:

Nɔbɔdi nɔ want dɛn prɔdak fɔ fel bikɔs ɔf wan prɛvɛntabl moldin dɛfɛkt. Bay we yu ɔndastand ɛn adrɛs Weld layn dɛn, yu kin mek pat dɛn we luk fayn ɛn tinap fɔ yuz rial-wɔl.

Di tin dɛn we kin mek pɔsin gɛt wɛl layn dɛn na injɛkshɔn moldin .

Bɔku tin dɛn kin ɛp fɔ mek dɛn mek wɛl layn dɛn we dɛn de yuz injɛkshɔn moldin. Lɛ wi dayv insay ɛni wan ɛn fɛn ɔndastand aw dɛn de ambɔg yu pat dɛn.

Injɛkshɔn prɛshɔn we nɔ kɔrɛkt .

Injɛkshɔn prɛshɔn de ple wan impɔtant pat pan di moldin prɔses. If di prɛshɔn tu smɔl, di plastic we dɔn rɔtin nɔ go gɛt inof pawa fɔ fuz fayn fayn wan we di flɔ frɔnt mit. Dis kin mek dɛn nɔ kɔmplit di bond ɛn di wɛl layn dɛn we pɔsin kin si.

Fɔ mek dis nɔ apin, i impɔtant fɔ:

Set di rayt injɛkshɔn prɛshɔn fɔ di matirial ɛn mold .

Ɔltɛm yu fɔ kip ɛn kalibrayt di injɛkshɔn moldin mashin .

Monitor prɛshɔn di tɛm we dɛn de du di moldin prɔses .

Di tɛmpracha we nɔ de mɛlt di rayt we .

Melt tempɔret na ɔda impɔtant tin. If di tɛmpracha tu smɔl, di plastic kin bigin fɔ kol ɛn sɔlid bifo di flɔ frɔnt dɛn gɛt chans fɔ fulɔp fɔ jɔyn. Dis kin rili mek wan wik weld layn.

Fɔ kɔntrol di tɛmpracha fayn fayn wan impɔtant ɔlsay na di moldin prɔses:

Na di barɛl ɛn noz na di injɛkshɔn moldin mashin .

Na di wan dɛn we de rɔn ɛn di get dɛn na di mol .

Na di mold cavity insɛf .

Di dizayn fɔ di mold we nɔ fayn .

Di dizayn fɔ di mold kin rili afɛkt di we aw dɛn mek di wɛl layn dɛn. Tin wɔl ɔ get dɛn we dɛn nɔ put fayn kin mek di flɔ split ɛn mek wik pɔynt dɛn.

Fɔ mek dɛn nɔ gɛt bɔku weld layn dɛn, di wan dɛn we de mek mold fɔ:

Mentɛn kɔnsistɛns wɔl tiknes .

Ples get fɔ promot balans flɔ .

Yuz simulshɔn softwe fɔ ɔptimayz dizayn .

Slow injekshɔn spid .

Injɛkshɔn spid kin afɛkt aw kwik di plastic we dɔn rɔtin kin ful-ɔp di mol kwik kwik wan. If di spid tu slo, di plastic kin kol we i nɔ ivin, we kin mek i rich weld layn dɛn.

Fɔ fɛn di rayt balans na di men tin:

impurities in di resin .

Kɔntaminɛnt dɛn na di plastic rɛsin kin ambɔg di flɔ ɛn mek di tin dɛn we nɔ pafɛkt lɛk wɛl layn. Dɛn bad bad tin ya kin bi:

Fɔ mek shɔ se yu gɛt klin mɛlt:

Yuz ay kwaliti, vajin rɛsin dɛn .

Stɔr ɛn handel di tin dɛn we dɛn yuz fɔ mek di tin dɛn fayn fayn wan .

Yuz kɔmpawnd dɛn we fit fɔ klin .

Ejent fɔ rilis mɔ mold .

Mold rilis ejen dɛn de ɛp pat dɛn fɔ kɔmɔt fayn fayn wan frɔm di mold. כltu, tu mכch rilis ejen kin intafεr wit di fכs fכ fכl fכnt dεm, we kin mek di wεld layn dεm.

Di rayt we fɔ yuz am impɔtant:

Yuz di smɔl mɔni we yu nid fɔ yuz .

Aplay ivin di mold safa .

Avɔyd fɔ bil bɔku bɔku saykl dɛn .

Sɔlwɛshɔn fɔ protɛkt wɛl layn dɛn na injɛkshɔn moldin .

Naw we wi dɔn ɔndastand di tin dɛn we kin mek pipul dɛn gɛt wɛl layn, lɛ wi fɛn sɔm sɔlv dɛn fɔ mek dɛn nɔ gɛt dɛn. Bay we yu optimize yu pat dizayn, mold dizayn, prɔsesin paramita, ɛn matirial sɛlɛkshɔn, yu kin ridyus di ɔkɔrɛshɔn fɔ dɛn pesky dɛfɛkt dɛn ya.

Optimizing pat dizayn .

Di dizayn fɔ yu pat kin rili afɛkt di we aw dɛn mek di wɛl layn dɛn. Na sɔm advays dɛn fɔ mek yu dizayn fayn fayn wan:

Adjɔst di tik we di wɔl tik .

Minimayz di tin dɛn we de ambɔg ɛn di ol dɛn .

Ridyus di nɔmba fɔ di ficha dɛn we kin split di flɔ .

If ol dɛn nid fɔ de, put dɛn stratejik wan fɔ mek dɛn nɔ weld layn dɛn smɔl .

Stratejik plesmɛnt fɔ insɛt ɛn ficha dɛn .

Fɔ mek di mold dizayn .

Di mold na di fawndeshɔn fɔ di injɛkshɔn moldin prɔses. Di rayt we fɔ mek di mold kin ɛp fɔ mek dɛn nɔ gɛt wɛl layn ɛn ɔda tin dɛn we nɔ fayn:

Prɔpa get sayzin ɛn plesmɛnt .

Inkorporet adequate venting .

Optimizing rana sistem dɛn .

Fayn-tyunin injekshɔn moldin paramita dɛn .

Adjɔst di prɔsesin paramita dɛn kin gɛt impɔtant impak pan weld layn fɔmɛshɔn. Na sɔm impɔtant tin dɛn fɔ tink bɔt:

Injɛkshɔn prɛshɔn ɛn tɛm .

Melt tempɔret .

Injɛkshɔn spid .

Fɛn di rayt balans bitwin slo ɛn fast injɛkshɔn spid .

If yu slo, i kin mek yu kol pasmak, ɛn if yu fast, dat kin mek yu gɛt ɔda bad bad tin dɛn .

Skru spid ɛn bak prɛshɔn .

Material Selection ɛn Handling .

We yu pik di rayt rɛsin ɛn handle am fayn, i kin ɛp bak fɔ mek di wɛl layn dɛn nɔ bɔku:

Resins wit gud flɔ prɔpati ɛn ɔt rɛsistɛns .

Di rayt we fɔ drɛy ɛn aw fɔ ol am .

Lubrikant ɛn Stabiliza dɛn .

Yuz aditiv fɔ ɛp fɔ mek di rɛsin flɔ ɛn ridyus di wɛl layn dɛn .

Tink bɔt fɔ yuz mold rilis ɛjɛn, lɔbrikɛn, ɔ flɔ ɛnhansa dɛn .

Advans teknik fɔ manej wɛld layn dɛn .

Wail optimizing part design, mold design, en processing parameters kin signifikant ridyus weld lain, somtaims yu nid fo tek yu efforts to di neks level. Lɛ wi fɛn sɔm advans tɛknik fɔ manej dɛn pesky dɛfɛkt ya.

Kɔmpyuta simulshɔn ɛn DFM analisis .

Wan pan di tin dɛn we gɛt pawa pas ɔl na yu Arsenal na Kɔmpyuta-Ɛd Ɛnjinia (CAE) softwe. Dɛn program ya de alaw yu fɔ simul di injɛkshɔn moldin prɔses ɛn prɛdikt pɔtɛnɛshɛl ishu dɛn lɛk wɛld layn bifo yu ɛva kɔt stɛl.

Disain fɔ Manufakchurabiliti (DFM) analisis na wan impɔtant pat pan dis prɔses. We yu analayz yu pat dizayn tru wan DFM lens, yu kin no di eria dɛn we kin prona to weld layn dɛn ɛn mek ajɔstmɛnt bifo yu muf to prodakshɔn.

Wit CAE en DFM, yu kin:

Prɛdikt flɔ bihayvya ɛn wɛl layn fɔmɛshɔn .

Optimize Gate Locations ɛn Runner Systems .

Identify ɛn kɔrɛkt pɔtɛnɛshɛl dizayn ishu dɛn .

Sev tɛm ɛn mɔni bay we yu ridyus di mold itɛreshɔn dɛn .

Post-molding Machining .

Sɔntɛnde, i kin izi fɔ mek dɛn mol wan pat we simpul ɛn ad ficha dɛn post-molding. Dis kin ɛp fɔ pul di wɛl layn layn dɛn we dɛn kin mek bikɔs ɔf ol, insay, ɔ ɔda tin dɛn we kin ambɔg dɛn.

Kɔmɔn post-molding mashin tɛknik dɛn inklud:

Di ol dɛn we dɛn de drɔ .

Milling slots ɔ poket dɛn .

Di trɛd dɛn we dɛn de kɔt .

Ad Inserts ɔ Fasteners .

Pan ɔl we dis de ad ɛkstra stɛp to di manufakchurin prɔses, i kin bi wan kɔst-ɛfɛktiv sɔlvishɔn fɔ manej wɛld layn dɛn na kɔmpleks pat dɛn.

Di nyu tin dɛn we dɛn dɔn mek .

Advansmɛnt dɛn na polimɛr sayɛns dɔn mek dɛn mek nyu matirial dɛn we nɔ kin izi fɔ weld layn dɛn. Bɔku tɛm dɛn rɛsin ya kin gɛt lɔwa viskɔsiti ɛn mɛlt pɔynt dɛn, we kin alaw fɔ mek di flɔ frɔnt dɛn flɔ ɛn fushɔn bɛtɛ.

Sɔm ɛgzampul dɛn na:

Di gred dɛn we gɛt ay-flɔ polypropylene (PP)

Di low-viscosity naylon (PA) variants .

Specialized blends ɛn alɔy dɛn .

We yu go fɛn dɛn tin dɛn ya, yu go fɛn sɔlv we go ridyus di weld layn dɛn we nɔ gɛt bɔku chenj dɛn na yu pat ɔ di we aw dɛn mek di mold.

Na tru se, i impɔtant fɔ tink bɔt di patikyula tin dɛn we yu fɔ du fɔ yu aplikeshɔn we yu de pik wan matirial. Fakta dɛm lɛk trɛnk, stiffness, tempɔret rɛsistɛns, ɛn kemikal kɔmpatibiliti ɔl de ple wan rol fɔ no di bɛst chus fɔ yu pat.

Dɔn

In dis atikul, wi don explor di wold of injekshon moldin weld lain. Wi dɔn lan wetin de mek dɛn tin ya we nɔ fayn fɔ si, frɔm di kɔrɛkt prɛshɔn ɛn di tɛmpracha to di bad we aw dɛn mek di mold ɛn di tin dɛn we gɛt fɔ du wit di tin dɛn we de apin.

Bɔt di tin we impɔtant pas ɔl na dat, wi dɔn arm wisɛf wit di no ɛn di tɛknik fɔ mek di wɛl layn dɛn nɔ fɔm insay di fɔs ples. We wi optimize pat ɛn mold dizayn, fayn-tyunin prɔsesin paramita dɛn, ɛn pik di rayt matirial dɛn, wi kin mek plastic pat dɛn we strɔng, fayn, ɛn fri frɔm weld layn dɛn.

Redi fɔ takɛl yu injɛkshɔn moldin chalenj dɛn? Kontakt Team MFG tide . Wi masta sabi pipul dɛn go wok wit yu fɔ mek yu dizayn fayn, fɔ mek dɛn nɔ gɛt bɔku prɔblɛm dɛn, ɛn fɔ mek dɛn gi yu pat dɛn we gɛt fayn fayn kwaliti dɛn. Trust wi fɔ bring yu vishɔn to layf. Start naw - yu sakses na wi prayoriti.