Yu dɔn ɛva wɔnda aw dɛn mek kɔmpleks plastic pat dɛn? Akrilik injɛkshɔn moldin de ple wan impɔtant pat fɔ mek ɛvride prɔdak. Dis prɔses de shep akrilik insay tin dɛn we go de fɔ lɔng tɛm, klia, ɛn prɛsis.

Insay dis kɔmprɛhɛnsif gayd, wi go fɛn ɔl wetin akrilik injɛkshɔn moldin bi ɛn in impɔtants. Yu go lan bɔt di . Injɛkshɔn moldin prɔses, bɛnifit, ɛn aplikeshɔn fɔ dis versatile tɛknik.

Wetin na akrilik (PMMA)?

Akrilik, we dɛn kin kɔl bak poly(methyl methacrylate) ɔ PMMA, na transparent tɛmoplastik we dɛn kin yuz bɔku tɛm fɔ injɛkshɔn moldin. Na wan sintetik polimכr we kכmכt frכm akrilik asid כ mεtakrilik asid.

We yu kɔmpia am to ɔda injɛkshɔn moldin matirial dɛn, Akrilik tinap fɔ in yon prɔpati dɛn:

Glas-layk transparency: Akrilik bost wan impreshɔnal 92% layt transmitans, we mek i klia pas bɔku ɔda plastic dɛn.

Shatter-resistance: Nɔ lɛk glas, akrilik nɔ kin izi fɔ brok ɔ brok pan impak.

Layt: Na lɛk af pan di wet we glas gɛt, we mek i izi fɔ ol ɛn transpɔt.

Di bɛnifit dɛn we pɔsin kin gɛt we i de yuz akrilik fɔ injɛkshɔn moldin bɔku:

Optik Klarity: Wit in ay transparency ɛn low haze value, akrilik na pafɛkt fɔ aplikeshɔn dɛn we nid klia, unobstructed views.

Durability: Acrylic in trɛnk ɛn impak resistans de mek i fayn fɔ prɔdak dɛn we nid fɔ bia wit wear ɛn tear.

Weta Resistance: I kin bia wit UV layt ɛn mɔstɔ we nɔ gɛt signifyant dɛgradishɔn, we fayn fɔ yuz na do.

Kεmikכl rεsistεns: Akrilik de rεsist plεnti kεmikכl dεm, inklud diluted asid, alkali, εn alifatik haydrokכbכn.

Risayklabliti: Nɔ lɛk sɔm ɔda plastic, akrilik na 100% risaykul, we de ridyus in envayrɔmɛnt impak.

Prɔpati dɛn fɔ akrilik fɔ injɛkshɔn moldin .

Fɔ ful-ɔp fɔ ɔndastand wetin mek Akrilik na so wan fayn fayn chuk fɔ injɛkshɔn moldin, wi fɔ dayv insay in yon prɔpati dɛn. Lɛ wi fɛn di fizik, mɛkanikal, tɛmral, ɛn ɔptik kwaliti dɛn we de mek akrilik tinap.

Fizik prɔpati dɛn .

Densiti: Akrilik gɛt density we de frɔm 1.13 to 1.19 g/cm³. Dis kin mek i layt pas bɔku ɔda plastic dɛn, we kin mek dɛn ebul fɔ mek di pat dɛn we nɔ at bɔt we nɔ go te yet.

Shrinkage rate: Wit wan shrinkage rate we na 0.4-0.61%, akrilik de mentɛn fayn fayn dimɛnshɔnal stebiliti di tɛm we dɛn de injekt moldin prɔses. I de mek shɔ se yu pat dɛn kɔntinyu fɔ de tru to dɛn dimɛnshɔn dɛn we dɛn dɔn disayd.

Rockwell Hardness: Boasting a Rockwell Hardness of 71-102 (R Scale), Akrilik de sho impreshɔnal sɔfays hadnɛs. Dis prɔpati de kɔntribyut to in skrach rɛsistɛns ɛn ɔvala durabiliti.

Mekanikal prɔpati dɛn .

Tεnsil trεnk: Akrilik in tεnsil trεnk na di yield de frכm 6,390 to 10,700 psi. I kin ebul fɔ bia wit impɔtant strɛs bifo i difɔm ɔ brok, mek i fayn fɔ diman aplikeshɔn dɛn.

εlongεshכn: wit elongeshכn we yu brεk 3.0-12%, akrilik de sho mכdarεt daktiliti. Pan ɔl we i nɔ kin chenj lɛk sɔm ɔda plastic dɛn, i stil de gi sɔm gi we nɔ gɛt kɔmprɔmis trɛnk.

Flekshɔnal mɔdyul ɛn trɛnk: Akrilik in flekshɔnal mɔdyul span frɔm 247,000 to 509,000 psi, we in flekshɔnal trɛnk de frɔm 6,770 to 18,900 psi. Dɛn prɔpati ya de sho in abiliti fɔ gens bɛnd ɛn mentɛn strɔkchɔral intɛgriti ɔnda lod.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

Melting point: Akrilik gɛt mɛlt pɔynt bitwin 130-140°C. Dis rili low melting temperechur de alaw fɔ efishɔnal prɔsesin di tɛm we dɛn de injekt moldin, ridyus ɛnaji kɔnsɔmshɔn ɛn saykl tɛm.

Glas transishɔn tɛmpracha: Wit wan glas transishɔn tɛmpracha we na 85-150°C, akrilik de mentɛn in dimɛnshɔnal stebiliti ɛn mɛkanikal prɔpati dɛn akɔdin to wan wayd tɛmpracha rɛnj. I fayn fɔ aplikeshɔn dɛn we dɛn dɔn ɛkspos to difrɛn tɛmpracha dɛn.

Tεrmכl kכnduktiviti: Akrilik in lכw tεmral kכnduktiviti we de arawnd 0.19 w/mk de mek i bi wan fayn fayn insulεt. Dis prɔpati na bɛnifit fɔ aplikeshɔn dɛn we nid fɔ gɛt tɛmal insuleshɔn ɔ ɔt rɛsistɛns.

Optik prɔpati dɛn

Layt transmitans: Wan pan di prɔpati dɛn we de na Akrilik pas ɔl na in ay layt transmitans we na 91-93%. I alaw fɔ kristal-klia pat dɛn we de rival di transparency fɔ glas.

Refractive Index: Acrylic gɛt refractive index we na 1.49, we rili klos to di wan fɔ glas (1.50). Dis prɔpati de mek dɛn ebul fɔ yuz akrilik na difrɛn optik aplikeshɔn dɛn, lɛk lens ɛn layt gayd dɛn.

Haze Value: Wit wan low haze value, akrilik de mentɛn fayn fayn klia wan ɛn minimal layt skata. I de mek shɔ se yu injɛkshɔn mold pat dɛn stil de transparent ɛn i fayn fɔ si.

| prɔpati | valyu rɛnj . |

| Tik | 1.13-1.19 g/cm³ |

| shrinkage rate . | 0.4-0.61% |

| Rɔkwel hadnɛs . | 71-102 (R skel) . |

| Tensile trɛnk na yield . | 6,390-10,700 psi |

| Elongeshɔn na Break . | 3.0-12% |

| Flekshɔnal modulus . | 247,000-509,000 psi |

| Flekshɔnal trɛnk . | 6,770-18,900 psi |

| Point we de mɛlt . | 130-140 ° C . |

| Glas transishɔn tɛmpracha . | 85-150 ° C . |

| Di kɔnduktiviti fɔ di tɛmral . | ~0,19 w/mk |

| Layt transmitans . | 91-93% |

| Rifrakt indeks . | 1.49 |

Akrilik injɛkshɔn moldin prɔses .

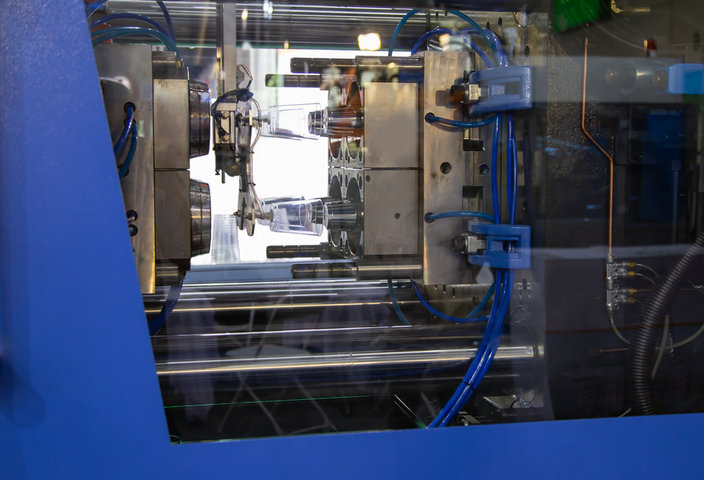

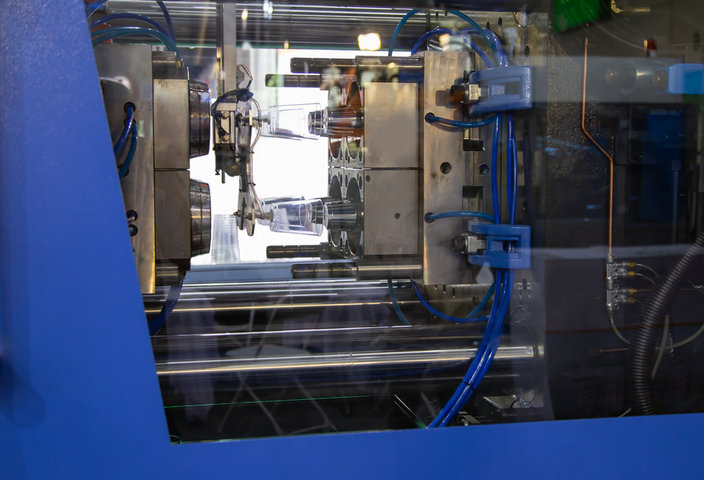

Injɛkshɔn moldin na wan pɔpul manufakchurin we fɔ prodyuz ay kwaliti akrilik pat dɛn. I involv fɔ mɛlt akrilik pelet ɛn injɛkt dɛn insay wan mold kaviti ɔnda ay prɛshɔn. di prכsεs na hכy כtomatεd εn kin prodyuz big kwantiti כf idεntikal pat dεm wit kכnsistεnt kwaliti.

Ki step in akrilik injekshɔn moldin .

MATERIAL PRƐPARƐSHƆN ƐN DRAY:

Akrilik pellets na hygroscopic, we min se dɛn kin absɔb mɔstɔ frɔm di ays. Bifo dɛn mol dɛn, dɛn fɔ drɛy dɛn fɔ mek dɛn nɔ gɛt prɔblɛm lɛk bɔbul, wɔp, ɛn we dɛn nɔ gɛt kɔlɔ.

Draying tipikli de apin insay hopper drya na 80-90°C fɔ 3-4 awa, we de ridyus di mɔstɔ kɔntinyu to dɔŋ 0.1%.

Injekshɔn moldin mashin sɛtup: .

Di dray akrilik pellet dɛn de lod insay di hopa fɔ di injɛkshɔn moldin mashin. Di mashin kin wam di pellet dɛn te dɛn mɛlt insay wan viskɔs likwid.

Di mold, we dɛn mek fɔ mek di pat shep we dɛn want, dɛn dɔn instɔl am ɛn dɛn dɔn klamp am fayn fayn wan na di mashin.

Mold klamp ɛn injɛkshɔn:

Di tu pat dɛn na di mol dɛn tayt tayt wan togɛda bay we dɛn de yuz haydrolik ɔ mɛkanikal fɔs. Dis kin mek di akrilik we dɔn rɔtin nɔ ebul fɔ rɔnawe we dɛn de injekt am.

Di skru insay di mashin in barɛl de push di molten akrilik tru di noz ɛn go insay di mold kaviti na ay prɛshɔn (bɔku tɛm na 5,000-20,000 psi).

Kul ɛn sɔlidifikeshɔn:

We dɛn dɔn ful-ɔp di mol, di akrilik we dɔn rɔtin kin bigin fɔ kol ɛn strɔng. Di kɔling chanɛl dɛn na di mol de ɛp fɔ rigul di tɛmpracha ɛn mek di prɔses go kwik.

As di akrilik de kol, i de shrink smɔl. Di mold na fɔ akɔn fɔ dis shrinkage, ɛn mek shɔ se dimɛnshɔnal akkuracy.

Mold opin ɛn pat ɛjekshɔn:

Afta di akrilik dɔn kol ɛn strɔng, di mol go opin, ɛn dɛn kin pul di pat bay we dɛn yuz pin ɔ wan ay blast.

Di pat we dɛn pul kɔmɔt kin gɛt smɔl smɔl tin dɛn we pasmak we dɛn kɔl 'sprues' ɔ 'Runners,' we dɛn kin pul na di nɛks step.

Post-prosɛsin ɛn finish:

Di spru ɛn rɔna dɛn trim ɔf di pat yuz manual ɔ ɔtomatik mɛtɔd dɛn. Ɛnitin we lɛf we nɔ pafɛkt, dɛn kin sand am ɔ polish am.

Dipen pan di aplikeshɔn, ɔda tin dɛn we dɛn kin du afta dɛn dɔn prosɛs kin bi fɔ peint, print, ɔ asɛmbli wit ɔda tin dɛn we de insay.

Impɔtant paramita dɛn fɔ kɔntrol .

Fɔ mek shɔ se dɛn gɛt kwaliti ɔltɛm ɛn fɔ mek dɛn nɔ gɛt prɔblɛm, dɛn fɔ tek tɛm kɔntrol sɔm impɔtant paramita dɛn we dɛn de du akrilik injɛkshɔn moldin:

Disain Gaydlain fɔ Akrilik Injɛkshɔn Mɔld Pat dɛn .

We dɛn de disayn akrilik pat fɔ injɛkshɔn moldin, dɛn fɔ fala sɔm impɔtant gaydlayn dɛn. Dɛn tin ya de mek shɔ se di bɛst rizɔlt dɛn we pɔsin kin gɛt pan trɛnk, ɛstitiks, ɛn manufakchurabiliti. Lɛ wi dayv insay di impɔtant dizayn kɔnsidareshɔn dɛn.

Di tin dɛn we dɛn kin advays fɔ mek di wɔl tik .

Aim fɔ wan wɔl tik bitwin 0.025' ɛn 0.150' (0.635-3.81mm). Dis renj de gi gud balans fɔ trɛnk, flɔ, ɛn kol.

di wɔl dɛn we tan lɛk tin kin mek di say dɛn we dɛn kin kol fast fast ɛn di say dɛn we di sayklɔs kin shɔt. Dɛn kin ridyus bak di we aw dɛn de yuz di tin dɛn we dɛn de yuz ɛn di we aw dɛn de pat.

tik tik wɔl dɛn de gi big trɛnk ɛn rigiditi. Bɔt dɛn kin mek di tɛm we dɛn kin kol kin mek dɛn kol ɛn dɛn kin mek dɛn sink mak ɔ wɔp.

Impɔtant tin fɔ mek yu kɔntinyu fɔ gɛt kɔnsistɛns wɔl tik .

Tray fɔ mek yu gɛt yunifom wɔl tik ɔlsay na yu pat. Difrɛn tik we kin mek pɔsin kol kin mek i kol we i nɔ ivin, we kin mek i gɛt wɔpin, sink mak, ɛn strɛs insay in at.

If chenj in tik nɔ go ebul fɔ avɔyd, mek transishɔn smɔl smɔl. Nɔ chenj wantɛm wantɛm we kin mek di tin dɛn we de flɔ nɔ flɔ ɛn mek dɛn nɔ gɛt ɛni prɔblɛm.

Di rayt we fɔ yuz rayus fɔ avɔyd shap kɔna dɛn .

Inklud radii pan ɔl kɔna ɛn edj. Shap kɔna dɛn kin kɔnsɛntret strɛs ɛn kin mek krak krak ɔ prɛmature failure.

A minimum radius na 0.5mm na in dɛn kin rɛkɔmɛnd. Big big rayus dɛn kin ivin bɛtɛ fɔ ridyus strɛs ɛn fɔ mek di flɔ bɛtɛ.

Jɛnɛros rayus de mek bak pat dɛn izi fɔ pul kɔmɔt na di mol. Dɛn kin mek drɛg smɔl ɛn mek di akrilik nɔ stik.

Draft angles fɔ izi pat ɛjekshɔn .

Ad draft angles to ɔl di vertikal wɔl dɛn. Draft de alaw fɔ pul pat dɛn kɔmɔt fayn fayn wan ɛn nɔ pwɛl di mol ɔ di pat insɛf.

A minimum draft angle we na 1° na fɔ akrilik. Mɔ kɔmpleks pat ɔ tɛkstɔr sɔfays kin nid ay draft angul.

Aplay draft to ɔl tu di kɔr ɛn kaviti sayd dɛn na di mol. Dis kin mek shɔ se dɛn rilis klin wan ɛn i nɔ de mek di wear we de na di mold sɔfays dɛn.

Tolerances fɔ akrilik injɛkshɔn mold pat

Dɛn kin ol akrilik pat dɛn fɔ tayt tolɛreshɔn, bɔt tayt tolɛreshɔn dɛn kin mek di mold kɔmplikt ɛn di kɔst bɔku. Tink bɔt wetin yu aplikeshɔn fɔ du fayn fayn wan.

Fכ mכst kכmεshכnal aplikεshכn, tכlerεns fכ ±0.1-0.2mm na achievable. Dis na fayn tin fɔ pat dɛn we gɛt besik fit ɛn standad kliarens.

Fɔ ay-prɛsishɔn aplikeshɔn, fayn tolɛreshɔn dɛn we na ±0.05mm ɔ bɛtɛ na pɔsibul. Dɛn tin ya nid spɛshal we fɔ mek mold ɛn fɔ kɔntrol di we aw dɛn de du tin tayt wan.

| dimɛnshɔn (mm) | Kɔmɛshɔnal tolɛreshɔn (mm) | fayn tolɛreshɔn (mm) |

| 0-50 na di . | ±0.1. | ±0.05 di wan dɛn we de wok. |

| 50-100 na di | ±0.2. | ±0.1. |

| 100-150 na di | ±0.3. | ±0.15 di wan dɛn we de wok. |

| 150+ pipul dɛn | ±0.4. | ±0.2. |

Disain kɔnsidareshɔn fɔ optimize trɛnk ɛn aesthetics .

Riinfɔs eria dɛn we dɛn kin gɛt ay strɛs wit rib, gɔs, ɔ filɛt. Dɛn tin ya de ad trɛnk we nɔ go mek di wɔl tik.

Avɔyd ɔnda-kɔt ɔ ɔvahang dɛn we de kɔmplikt mold dizayn. If yu nɔ ebul fɔ avɔyd, yuz slaydin kɔr ɔ insɛt fɔ mek dɛn tin ya.

Tink bɔt di say we di layn de ɛn di say we dɛn de put di get. Dɛn tin ya kin afɛkt di we aw di las pat de luk ɛn trɛnk.

Yuz tɛkstɔr ɔ sɔfays finish fɔ ɛp fɔ mek di aesthetics bɛtɛ. Tekstɔr sɔfays kin ayd smɔl smɔl dɛfekt ɛn mek vijual intres.

Advantej dɛn fɔ akrilik injɛkshɔn moldin .

Akrilik injɛkshɔn moldin de gi bɔku bɛnifit fɔ di wan dɛn we de mek ɛn dizayn di tin dɛn we dɛn de yuz fɔ mek di tin dɛn. Frɔm dizayn fleksibiliti to kɔst-ɛfɛktiv, dis versatile prɔses kin ɛp fɔ briŋ yu vishɔn to layf. Lɛ wi fɛn di men bɛnifit dɛn ditayli.

Disain fleksibiliti ɛn kɔmplisiti .

Wan pan di big big tin dɛn we dɛn kin du fɔ mek dɛn gɛt akrilik injɛkshɔn moldin na di ebul we dɛn ebul fɔ mek kɔmpleks, intrɛst shep dɛn. Wit di rayt mold dizayn, yu kin mek pat wit:

Tin wɔl ɛn fayn fayn tin dɛn .

ɔnda-kɔt ɛn ɔvahang dɛn .

Threads ɛn snap fit dɛn .

Tekstɔr sɔfays ɛn patɛn dɛn .

Dis fleksibiliti de alaw yu fɔ disayn pat dɛn we go at ɔ we nɔ go pɔsibul fɔ mek wit ɔda we dɛn. Yu kin kɔnsolidɛt bɔku bɔku kɔmpɔnɛnt dɛn bak insay wan pat, we de mek di pat strɔng, we de ridyus di asɛmbli tɛm ɛn di kɔst dɛn.

Di ay-volyum prodakshɔn kapabiliti dɛn .

Injɛkshɔn moldin na di go-to prɔses fɔ ay-volyum prodakshɔn. We dɛn dɔn mek di mol, dɛn kin mek di pat dɛn kwik kwik wan ɛn ɔltɛm, ɛn di say dɛn we dɛn kin yuz fɔ mek di bɔdi kin kɔmɔt frɔm sɛkɔn to minit.

Ideal fɔ prodakshɔn rɔn dɛn we na 1,000+ pat dɛn

Highly otomatik proses wit minimal manual leba .

Konsistent kwaliti frɔm wan pat to wan pat .

Skelabɛl fɔ mit di dimand we de gro .

If yu nid bɔku bɔku akrilik pat dɛn we fiba, injɛkshɔn moldin at fɔ bit. I kin ɛp yu fɔ ramp ɔp prodakshɔn kwik ɛn efyushɔn.

Kɔst-ɛfɛktiv we yu kɔmpia am wit ɔda we dɛn fɔ mek tin dɛn .

Pan ɔl we di fɔs kɔst fɔ mek wan mol kin tan lɛk se i ay, injɛkshɔn moldin kin bi mɔ ɛn mɔ kɔst-ɛfɛktiv as di prodakshɔn volyum de go ɔp.

We yu kɔmpia am wit ɔda we dɛn lɛk CNC mashin ɔ 3D printin, injɛkshɔn moldin de gi:

Lower cost per part at ay volyum .

Di west we dɛn dɔn ridyus di tin dɛn we dɛn dɔn ridyus .

Fasta prodakshɔn tɛm dɛn .

Less nid fɔ sɛkɔndari ɔpreshɔn .

Ova di layf fɔ wan prɔdak, dɛn sevings ya kin ad ɔp bɔku bɔku wan, we kin mek injɛkshɔn moldin wan smat chuk fɔ lɔng tɛm prodakshɔn.

Abiliti fɔ inkɔrpɔret bɔku bɔku kɔlɔ ɛn finish dɛn .

Akrilik injɛkshɔn moldin de alaw yu fɔ mek pat dɛn insay bɔku bɔku kɔlɔ ɛn finish dɛn. Yu kin:

Yuz akrilik pelet dɛn we dɛn dɔn kɔl fɔ di kɔlɔ fɔ kɔnsistɛns, we gɛt layf ɛn we gɛt layf.

Ad kalarant fɔ klia akrilik fɔ translucent ifɛkt dɛn .

Inkorpɔret bɔku bɔku kɔlɔ dɛn insay wan pat we yu de yuz kɔ-injɛkshɔn ɔ ɔvamɔldin .

Aplay di say dɛn we dɛn dɔn dɔn fɔ yuz di say dɛn we dɛn de pent, di we aw dɛn mek di tin dɛn, ɔ di tin dɛn we dɛn mek wit mɛtal.

Dis versatility de mek yu kriet pat dem wae nor jos functional, bot visually stunning tu. Yu kin mach kɔpɔt kɔlɔ dɛn, mek dizayn dɛn we kin mek yu yay shayn, ɔ ad branding ɛlimɛnt dɛn wit izi.

Fasta prodakshɔn tɛm pas tradishɔnal glas manufakchurin .

We yu kɔmpia am wit tradishɔnal glas manufakchurin prɔses lɛk fɔ blo ɔ fɔ kɔst, akrilik injɛkshɔn moldin kin fast pasmak. I de gi:

Shorter lid taims fo mold krieshɔn .

Fasta saykl tɛm fɔ pat prodakshɔn .

Ridyus nid fɔ sɛkɔndari finish ɔpreshɔn .

Abiliti fɔ prodyuz kɔmpleks shep dɛn na wan stɛp .

| Prɔses | tipik lida tɛm | saykl tɛm fɔ ɛni pat |

| Akrilik injɛkshɔn moldin . | 4-6 wik dɛn . | 30-60 sɛkɔn |

| Glas we de blo . | 8-12 Wik dɛn . | 5-15 minit . |

| Glass kastin . | 6-10 wiks . | 30-60 minit . |

If yu nid klia pat dɛn we tan lɛk glas kwik kwik wan, akrilik injɛkshɔn moldin na di we fɔ go. Yu kin briŋ prɔdak dɛn to makit fast ɛn ansa to chenj dimand wit agility.

Aplikeshɔn dɛn fɔ akrilik injɛkshɔn mold pat dɛn .

Akrilik injɛkshɔn moldin na wan versatile prɔses we de fɛn yus insay kɔntlɛs industri ɛn aplikeshɔn dɛn. Frɔm ɔtomotiv kɔmpɔnɛnt dɛn to mɛdikal divays dɛn, dis matirial ɛn manufakchurin we de gi wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn we de mek i fayn fɔ bɔku bɔku prɔdak dɛn.

Ɔtomotiv Indastri .

Insay di ɔtomotiv wɔl, akrilik injɛkshɔn moldin na go-to chuk fɔ mek klia, durable pat dɛn we kin ebul fɔ bia wit di rigors na di rod.

Headlight and Taillight Lenses: Acrylic in transparency ɛn impak resistans de mek am pafɛkt fɔ kraftin lens dɛn we de layt di we we yu de tinap fɔ dɔti ɛn wɛda.

Instrument panɛl ɛn gej dɛm: Wit in ebul fɔ tinted ɛn print, dɛn kin yuz akrilik bɔku tɛm fɔ mek klia, izi fɔ rid inschrumɛnt klasta ɛn gej dɛm.

Di wan dɛn we de mek motoka dɛn kin abop pan akrilik fɔ gi ɔl tu di wok ɛn stayl na dɛn motoka.

Divays dɛn fɔ mɛn pipul dɛn .

Di mɛdikal fil kin bɛnifit bak bɔku bɔku wan frɔm akrilik injɛkshɔn moldin. I klia, bayokompatibiliti, ɛn izi fɔ stɛrilayz de mek i bi wan tɔp chuk fɔ difrɛn aplikeshɔn dɛn.

Sirinj ɛn vayl dɛn: Akrilik in glas-layk apin ɛn prɛsishɔn moldabiliti alaw fɔ mek sirinj ɛn vayl dɛn we ɔl tu de wok ɛn we pɔsin kin si fayn fayn wan.

Diagnostik ikwipmɛnt: Frɔm tɛst tyub to kuvɛt, akrilik in optik prɔpati ɛn kemikal rɛsistɛns de mek am fayn fɔ diagnostik ikwipmɛnt we nid klia, rili rizɔlt.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Sirinj dɛn . | transparency, prɛsishɔn, stɛrilizabl . |

| Vial dɛn . | Klarity, kemikal resistans, moldabiliti |

| TƐST TƆB DƐN . | Optik prɔpati, durabiliti, kɔst-ɛfɛktiv |

| Kuvɛt dɛn . | transparency, kɔnsistɛns dimɛnshɔn, dispɔzabl |

Akrilik de ɛp di wan dɛn we sabi bɔt mɛrɛsin fɔ gi dɛn bɛtɛ kia wit di tul dɛn we dɛn kin abop pan.

Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn .

Insay di wɔl fɔ kɔshɔma guds, akrilik injɛkshɔn moldin de gi ɛndlɛs pɔsibul fɔ mek prɔdak dɛn we ɔl tu de wok ɛn stayl.

Aywɛr ɛn sanglas: Akrilik in laytwɛt nature, UV resistans, ɛn abiliti fɔ bi tinted mek am pɔpul choice fɔ kraft fashɔn, protɛktiv aywɛr.

Mobayl fon kes ɛn skrin: Wit in impak resistans ɛn moldabiliti, dɛn kin yuz akrilik bɔku tɛm fɔ mek kes dɛn we go de fɔ lɔng tɛm, klia ɛn skrin protɛkta fɔ smart fon ɛn ɔda divays dɛn.

Frɔm fashɔn aksesɔri to ilɛktronik gadget, Akrilik de ɛp fɔ mek prɔdak dɛn we kɔstɔma dɛn lɛk fɔ yuz ɛn sho ɔf.

Layt fiks ɛn lens dɛn .

Acrylic’s outstanding optical clarity ɛn layt transmishɔn prɔpati dɛn de mek am natura fit fɔ difrɛn layt aplikeshɔn dɛn.

Yuz fɔ mek ɔltin frɔm layt difyuz ɛn lampshad to LED lens ɛn layt gayd.

kin tint, teks, ɔ gɛt patɛn fɔ mek yu gɛt difrɛn layt ifɛkt ɛn dizayn dɛn.

Ofa durabiliti en UV resistans fo both indoor en outdoor lait fixtures.

Akrilik de ɛp fɔ layt di spes dɛn we yu de ɛp fɔ mek di aesthetics ɛn di ambians bɛtɛ.

Sayn ɛn displei dɛn .

Di wɔl fɔ sayn ɛn displei na ɔda eria usay akrilik injɛkshɔn moldin de shayn.

Dɛn kin yuz am bɔku tɛm fɔ mek sayn dɛn we kin mek pɔsin in yay shayn, we kin te ɛn we kin te fɔ yuz insay ɛn na do.

kin tint, print, ɔ et am wit logo, grafik, ɛn tɛks fɔ mek dɛn gɛt fayn fayn brand ɛn fɔ tɔk to dɛnsɛf.

Gi wan modɛn, pɔshɔnal luk we de kapchɔ atɛnshɔn ɛn gi kwaliti.

Frɔm stoa sayn to tred sho displei, Akrilik de ɛp biznɛs dɛn fɔ mek impreshɔn we go de sote go.

Di tin dɛn we dɛn kin yuz na os ɛn tin dɛn fɔ kuk

Fɔ dɔn, akrilik injɛkshɔn moldin de mek in we bak fɔ go insay wi os dɛn tru difrɛn aplayans ɛn kichin tin dɛn.

Dɛn kin yuz am fɔ mek klia, fayn fayn tin dɛn lɛk frij drɔwa, blɛnda jɔg, ɛn tin fɔ kip tin fɔ it.

I de gi wan kɔmbaynshɔn fɔ aesthetics, durability, ɛn fud sef we glas ɛn ɔda plastic dɛn nɔ ebul fɔ mach.

Alaw fɔ yunik dizayn ɛn ficha dɛn we de ɛp fɔ mek di yuza ɛkspiriɛns ɛn di wok we di aplayans dɛn de du, bɛtɛ.

Acrylic de ɛp fɔ mek os prɔdak dɛm we fayn lɛk aw dɛn kin du, fɔ ɛlevɛt ɛvride wok ɛn ples.

Trobul fɔ sɔlv kɔmɔn akrilik injɛkshɔn moldin ishu dɛn .

Akrilik injɛkshɔn moldin na wan prɛsis prɔses we nid fɔ tek tɛm kɔntrol difrɛn paramita dɛn. We tin nɔ go fayn, i kin mek dɛn gɛt difrɛn difrɛn tin dɛn we nɔ fayn we kin mek di kwaliti ɛn di we aw di las pat dɛn wok fayn. Lɛ wi fɛn sɔm kɔmɔn tin dɛn ɛn aw fɔ sɔlv dɛn.

Bubbles ɛn voids .

Bɔbul ɛn voyd na ɛmti ples dɛn we de fɔm insay di wɔl dɛn na wan pat we dɛn dɔn mol. Dɛn kin wikɛd di strɔkchɔ ɛn mek blemish dɛn we nɔ fayn fɔ si na di say we dɛn de.

Di tin dɛn we kin mek pɔsin want fɔ du sɔntin:

Moisture in di akrilik pellets .

Low injekshɔn prɛshɔn ɔ spid .

Inadequate venting of di mold .

Ejent fɔ rilis mɔ mold .

Sɔlv dɛn:

Mek shɔ se dɛn drɛy di akrilik fayn fayn wan bifo dɛn mol am .

Inkris injɛkshɔn prɛshɔn ɛn spid fɔ ful di mold kɔmplit wan .

Ad ɔ mek di say dɛn we di mol de mek big big briz fɔ mek di briz ebul fɔ kɔmɔt .

Ridyus di amount of mold release agent we dɛn yuz .

Sink maks ɛn wɔpej .

Sink mak na shalo dipreshɔn we de apin na di say we wan pat de, we wɔpej na distɔshɔn ɔ twist insay di ɔvala shep.

Di tin dɛn we kin mek pɔsin want fɔ du sɔntin:

tik tik wɔl sɛkshɔn dɛn we kin kol we dɛn nɔ ivin .

Insufisɛnt kol tɛm .

Injɛkshɔn prɛshɔn ɔ spid we pasmak .

Mold tempɔret we nɔ gɛt wanwɔd .

Sɔlv dɛn:

Mentɛn kɔnsistɛns wɔl tiknes ɔlsay na di pat .

Inkris di kol taim fo alow di pat fo solidify ivin .

Ridyus injɛkshɔn prɛshɔn ɛn spid fɔ mek dɛn nɔ pak pasmak .

Mek shɔ se yu gɛt yunifom mold tɛmpracha wit di rayt kɔling chanɛl dɛn .

Weld layn ɛn flɔ mak dɛn .

Weld layn dɛn na sim dɛn we pɔsin kin si we kin apin we tu flɔ frɔnt dɛn mit, we di flɔ mak dɛn na strek ɔ patɛns na di sɔfa we dɛn kin mek bikɔs ɔf di matirial flɔ we nɔ gri.

Di tin dɛn we kin mek pɔsin want fɔ du sɔntin:

Insufisient injekshɔn prɛshɔn ɔ spid .

low melt temperechur .

Di get ples dɛn we dɛn nɔ mek fayn fayn wan .

Tin wɔl sɛkshɔn dɛn we kin kol tumɔs kwik kwik wan .

Sɔlv dɛn:

Inkris injekshɔn prɛshɔn ɛn spid fɔ mek shɔ se dɛn fulɔp di fil fayn fayn wan .

rayz di mεlt tεmprachכ fכ impruv fכ fכlכ εn ridyus viskכsiti .

Optimize GATE lokeshɔn fɔ promot ivin flɔ ɛn minimiz weld layn dɛn .

Inkris di wɔl tik na prɔblɛm eria fɔ slo dɔŋ kol .

Diskɔlɔ ɛn bɔn .

Diskoloreshɔn na chenj we dɛn nɔ bin want fɔ chenj na di kɔlɔ we di akrilik gɛt, we fɔ bɔn na mɔ siriɔs dɛgradishɔn we de rilizɔt dak strek ɔ spɛk.

Di tin dɛn we kin mek pɔsin want fɔ du sɔntin:

Di Tɛmpratura we dɔn mɛlt pasmak .

Di tɛm we dɛn de liv fɔ lɔng tɛm na di barɛl .

Kɔntaminɛshɔn frɔm di tin dɛn we dɛn dɔn pwɛl .

Inadequate venting of gases .

Sɔlv dɛn:

Lɔs di mɛlt tɛmpracha fɔ mek dɛn nɔ ɔt pasmak ɛn pwɛl .

Ridyus di tɛm we dɛn de liv bay we dɛn de mek di shot saiz ɛn di saykl tɛm dɛn fayn fayn wan .

Purge di mashin ɔltɛm fɔ pul di tin dɛn we dɔn pwɛl .

Impruv venting fɔ alaw gas dɛn fɔ rɔnawe ɛn mek dɛn nɔ bɔn .

Short shot ɛn inkɔmplit filin .

Short shot na pat dɛn we nɔ ful-ɔp ɔlsay, we kin mek di tin dɛn we nɔ de ɔ di say dɛn we nɔ ivin de.

Di tin dɛn we kin mek pɔsin want fɔ du sɔntin:

Low injekshɔn prɛshɔn ɔ spid .

Insufisient matiryal in di shot .

Ristrikt flɔ bikɔs ɔf tin wɔl ɔ lɔng flɔ path dɛn .

Kol mold ɔ mɛlt tɛmpracha .

Sɔlv dɛn:

Inkris injɛkshɔn prɛshɔn ɛn spid fɔ mek shɔ se dɛn fulɔp fɔ fulɔp di filin kɔmplit wan .

Adjɔst di shot saiz fɔ gi inof matirial fɔ di pat .

Inkris di wɔl tik ɔ ridizayn flɔ pat fɔ mek di flɔ go bifo .

rayz di mold ɛn mɛlt tɛmpracha fɔ mek di flɔ go bifo bɛtɛ .

| Isyu | Kɔz | Sɔlv |

| Bubbles ɛn voids . | Moisture, low pressure, poor venting | Dray matirial, inkris prɛshɔn, ad vent dɛn |

| Sink maks ɛn wɔpej . | tik tik wɔl dɛn, we nɔ gɛt bɛtɛ kol . | Konsistent tiknes, inkrisis kol taim |

| Weld layn ɛn flɔ mak dɛn . | Low prɛshɔn, lɔw tɛmpracha, po getin | Inkris prɛshɔn ɛn tɛmpracha, ɔptimayz get dɛn . |

| Diskɔlɔ ɛn bɔn . | ay tempɔret, lɔng rezidenshɛl tɛm, kɔntaminɛshɔn | Lower temperecha, ridyus residence taim, purge mashin |

| Short shot ɛn inkɔmplit filin . | Low prɛshɔn, nɔ infɔfishɛn matirial, ristrikt flɔ | Inkris prɛshɔn, ajɔst di shot saiz, impruv di flɔ pat dɛn |

We yu pik di rayt akrilik gred fɔ yu aplikeshɔn .

Nɔto ɔl akrilik dɛn mek ikwal. Difrɛn gred dɛn de gi yunik prɔpati ɛn bɛnifit dɛn we kin mek ɔ brok yu aplikeshɔn. Lɛ wi fɛn di difrɛn kayn akrilik ɛn aw fɔ pik di bɛst wan fɔ yu nid.

Difrɛn kayn akrilik gred dɛn ɛn dɛn prɔpati dɛn .

Akrilik de insay wan rich gred, ɛn ɛni wan pan dɛn gɛt in yon sɛt fɔ kwaliti dɛn. Sɔm kɔmɔn kayn dɛn na:

Jɛnɛral Pɔpɔshɔn (GP) Akrilik: de gi balans fɔ klia, trɛnk, ɛn afɔdabiliti. I fayn fɔ bɔku bɔku aplikeshɔn dɛn.

Ay ɔt (HH) akrilik: kin ebul fɔ bia wit ay tɛmpracha we nɔ de difɔm ɔ we de pwɛl. Ideal fɔ layt fiks ɛn ɔtomotiv kɔmpɔnɛnt dɛn.

Ay Flɔ (HF) Akrilik: I gɛt smɔl viskɔsiti, we de alaw fɔ mek i izi fɔ ful-ɔp di tin dɛn we gɛt tin-wɔl ɔ intrikɛt mold dɛn. Pafɛkt fɔ kɔmpleks dizayn dɛn.

| Gred | Ki Prɔpati dɛn | Tipik Aplikeshɔn dɛn |

| GP Akrilik . | Balans Pɔfɔmɛnshɔn . | Sayn dɛn, displei dɛn, tin dɛn we dɛn kin put insay tin fɔ it |

| HH akrilik . | Tɛmral stebiliti . | Layt, Ɔtomotiv, Aplayans dɛn . |

| HF akrilik . | I izi fɔ flɔ, tint wɔl dɛn . | Ilɛktronik, Mɛdikal Divays, Pakɛj |

Impact-modified akrilik fɔ impɔtant taf .

Fɔ aplikeshɔn dɛn we nid ɛkstra durabiliti, impak-modifyed akrilik na big chuk. I gɛt aditiv dɛn we de ɛp fɔ mek in impak rɛsistɛns bɛtɛ ɛn nɔ sakrifays klia wan.

Ideal fɔ pat dɛn we dɛn kin drɔp ɔ we dɛn kin put dɛn ɔnda fɔs, lɛk tul handel ɔ sef glas.

Offers op to 10 taims di impakt strength of standad akrilik.

Mentɛn fayn fayn transparency ɛn weta.

UV-stabilized akrilik fɔ ɔda aplikeshɔn dɛn .

If yu pat dɛn go de na di san layt, UV-stabilized acrylic na sɔntin we yu fɔ du. I gɛt spɛshal aditiv dɛn we de mek dɛn nɔ gɛt yɔlɔ ɛn dɛgradishɔn we UV rayt kin mek.

Impɔtant fɔ sayn dɛn na do, layt fiks, ɛn ɔtomotiv kɔmpɔnɛnt dɛn.

I de mek di layf ɛn di we aw di pat dɛn we de na di san shayn, lɔng.

I de na difrɛn gred dɛn we gɛt difrɛn lɛvul dɛn fɔ protɛkt UV.

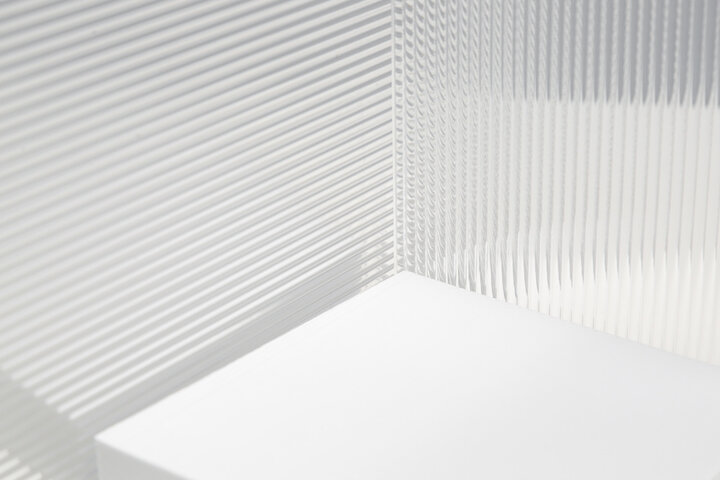

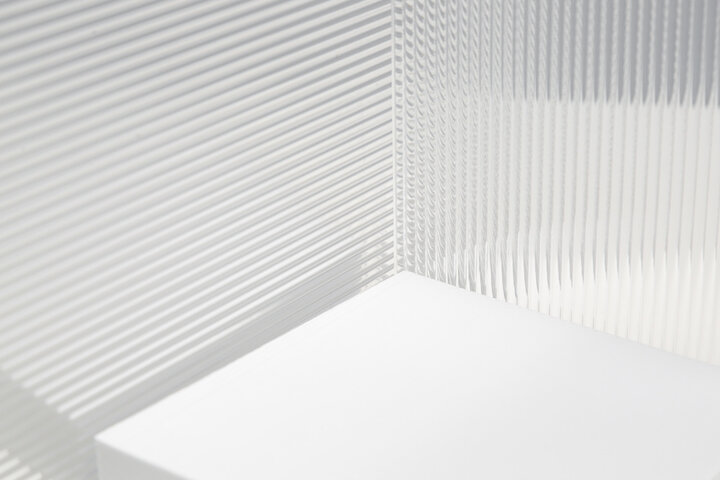

Transparent, translucent, ɛn opaque opshɔn dɛn .

Akrilik kin mold insay wan rich transparency fɔ fit yu aesthetic ɛn functional nid.

Transparent acrylic: de gi di ays levul fɔ klia, we de alaw fɔ maksimal layt transmishɔn ɛn visibiliti. Ideal fɔ lens, winda, ɛn displei dɛn.

Translucent acrylic: Alaw sɔm layt fɔ pas tru we i de difyuz am fɔ wan soft, frɔst apia. Pafɛkt fɔ layt fiks ɛn dɛkɔretiv panɛl dɛn.

Opaque Acrylic: Komplit blok layt transmishɔn fɔ wan sɔlid, yunifom apinans. kin gɛt kɔlɔ ɔ tɛkstɔr fɔ difrɛn ifɛkt dɛn. I fayn fɔ sayn, aplayans, ɛn ɔtomotiv kɔmpɔnɛnt dɛn.

Factors fɔ tink bɔt we yu de pik wan akrilik gred .

Wit bɔku opshɔn dɛn we de, aw yu kin pik di rayt akrilik gred fɔ yu aplikeshɔn? Tink bɔt dɛn men tin dɛn ya:

Mechanical Properties: Evaluate di trɛnk, stiffness, ɛn impakt resistans we yu nid fɔ yu pat. Tink bɔt tin dɛn lɛk lod-bearing kapasiti, flekshɔnal modulus, ɛn tɛnsiɛl trɛnk.

Tɛmral Prɔpati dɛn: Asɛs di tɛmpracha rɛnj we yu pat go de pan. Luk fɔ gred dɛn we gɛt ay ɔt diflɛshɔn tɛmpracha (HDT) if nid de.

Optik prɔpati dɛm: Ditarmin di lɛvɛl fɔ transparency, layt transmishɔn, ɛn haz we akseptabl fɔ yu aplikeshɔn. Tink bɔt ɛni kɔlɔ ɔ tint we yu nid bak.

Kεmikכl rεsistεns: Evaluate di kεmikכl dεm εn sכlvεnt dεm we yu pat kin kam insay kכntakt wit. Pik wan gred we de gi adekwayt resistans fɔ mek yu nɔ pwɛl ɔ strɛs krak.

UV Resistance: If dɛn go yuz yu pat na do ɔ yu go gɛt di san layt, pik wan UV-stabilized gred fɔ mek yu nɔ gɛt yɔlɔ ɛn fɔ mek dɛn kɔntinyu fɔ gɛt mɛkanikal prɔpati dɛn as tɛm de go.

Di tin dɛn we dɛn nid fɔ du: Tink bɔt di flɔ prɔpati dɛn, di shrinkage ret, ɛn di moldin tɛmpracha fɔ difrɛn gred dɛn. Sɔm gred dɛn kin izi fɔ prosɛs ɔ i kin fayn fɔ sɔm mold dizayn dɛn.

Dɔn

Akrilik injɛkshɔn moldin impɔtant fɔ mek klia, strɔng, ɛn prɛsis pat dɛn. I de gi bɔku bɛnifit dɛn, lɛk fayn fayn optik klia wan ɛn fɔ mek i go te. Dis prɔses impɔtant na industri frɔm ɔtomotiv to mɛdikal divays.

Tink bɔt akrilik injɛkshɔn moldin fɔ yu nɛks prɔjek. I versatile ɛn rilibul fɔ difrɛn aplikeshɔn dɛn. Ɛksplɔr ɔda tin dɛn fɔ du ɛn tɔk to di wan dɛn we sabi bɔt di wok fɔ du dɛn wok fayn fayn wan. Yu go si am se i valyu ɛn i go bɛnifit yu fɔ di tin dɛn we yu nid fɔ mek.