Quid Polymers facile figura processus? Et responsum mendacium in ad conflandum index (mfi). Mfi mensuras quam facile est polymer dissolvit et fluit, ludens a crucial partes in polymer vestibulum. Est vitalis enim lectio ius processus modum et ensuring uber qualitas. In hoc post, youll discere fundamentum MFI, sua momenti in Polymer processui, et quomodo impingit uber perficientur. Nos quoque exploratores factores quod influentiam MFI, modi ad mutare eam, et quomodo suus 'usus est in qualitate potestate.

Quid est ad conflandum influunt index (mfi)?

Index flumine conflandum (mfi) ut a discrimine qualitas moderna mensuræ polymers, flas et conflandum viscosity. Hoc indicat quam facile polymers influunt sub specifica pressura et temperatus conditionibus.

Intellectus MFI et mensuram

Mfi represents Missam fluxus rate metiri per a mensuris mori sub praescriptis conditionibus:

MFI ut fluxus proprietas indicator

MFI correlates directe ad plures polymer characteres:

Molecular properties :

Dispensando mores :

Tondendas Viscosity

Die tumore proprietates

Elongas Viscosity

Conflandum

Application Suitability :

High Mfi (> X g / 10min) → Iniectio Crisere Medium Mfi (2-10 g / 10min) → extrusionem humilis mfi (G (II G / 10min) → CUMEN

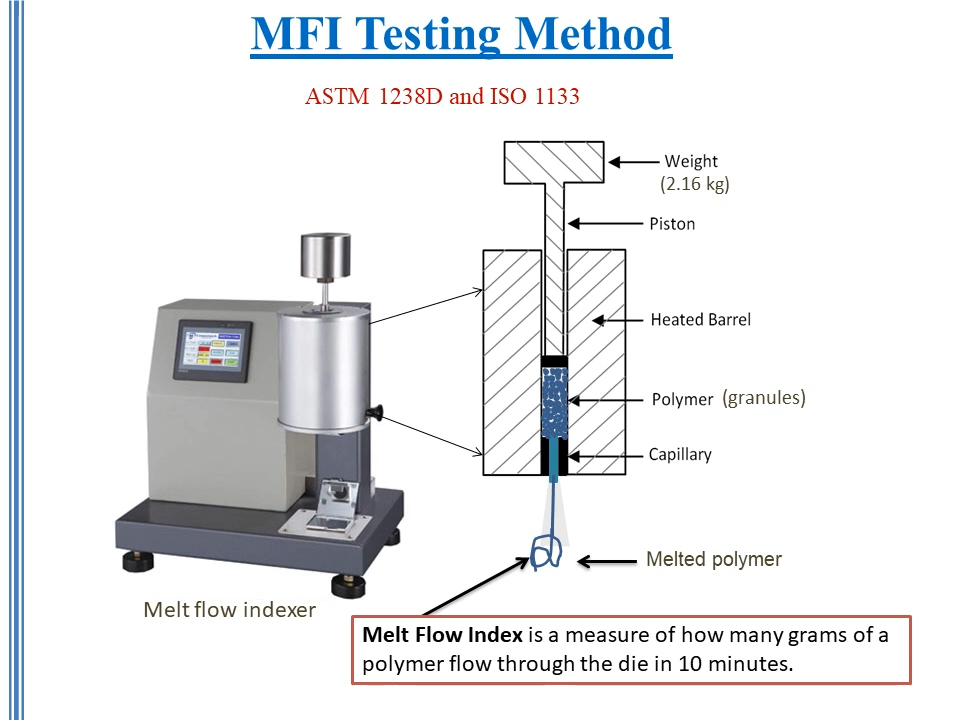

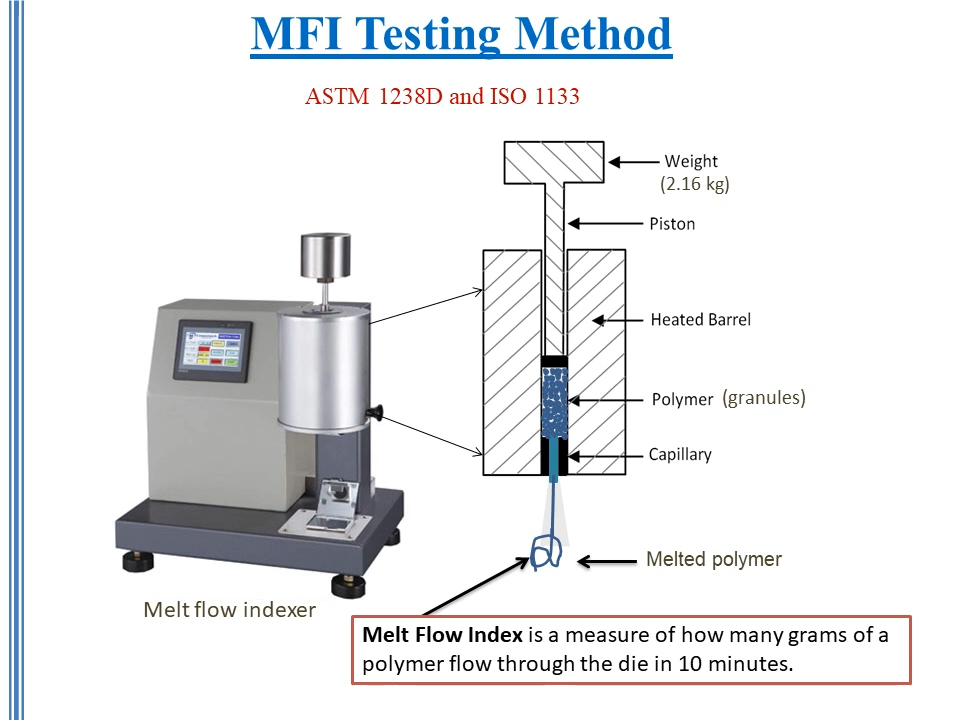

Principium MFI temptationis

Testing processus sequitur normatum ratio ensuring reliable results:

Basic temptationis gradibus :

Calor Polymer ad certa temperatus

Applicare vexillum pondus

Metimur extrudi materia pondere

Calculate rate fluxus

Critical parametri :

Latin test condiciones (Exempla):

| Polymer Type | Temperature (° F) | Lond (kg) |

| Polyethylene | 190 | 2.16 |

| Polypropylene | 230 | 2.16 |

| Polystyrene | 200 | 5.0 |

Testing procedure momenti

Accurate MFI mensurae postulat stricte adhaerentiam ad protocols:

Consistent sample praeparatio

Propriis apparatu calibration

Vexillum testis conditionibus

Iusto sustentationem

Periti operator ars

Nos suadeo haec ISO MCXXXIII aut ASTM D1238 Signa enim reliable results. Hae operandi procedendi per circuitum reproducibility et comparability trans diversis testis facilities.

Nota: MFI values Auxilium determinare idoneam processus modi et finem applications. Intellectus MFI dat optimise productio parametri efficaciter.

Relatio inter MFI et Polymer Properties

Ratio inter MFI et polymer proprietatibus probat fundamental in determinandum processus modi et finalem productum characteres. Intelligendo haec relationes enables opifica ad optimize eorum productio processibus efficaciter.

MFI, M. Molecular Weight Correlation

Mfi exhibet in inverso necessitudinem ad M. pondus, sequens ad equation ad linearem Polymers:

Log MW = 2.47 - 0.234 Log MF

Ubi:

Key Correlationibus:

Superiore MFI valores indicant inferioribus M. pondus Polymers, offering facilius processability sed potentia reducitur mechanica proprietatibus

Inferior MFI values suadeant superiore molacular pondus polymers, providing amplificata mechanica vires sed requiring magis intensa processus conditionibus

M. pondus distribution effectus

Distribution of Molecular weights significantly influit mfi mores per aliquot machinationes:

Distribution : Polymers Exhibensing Wide Momecular Weight Ranges demonstrabo complexu influunt partum, afficiens processability et postulantes diligenter imperium processus parametri ad consequi meliorem results.

Distribution : materials possidentium stricta mulgare pondus distributiones ostende magis praedictio fluunt characteres, enabling precise imperium durante processus sed potentia limited eorum applicationem versatility.

Viscosity, MFI necessitudo

Inverse necessitudinem inter viscositas et mfi manifestat per plures factors:

Temperature Dependency :

Superiore temperaturis redigendum viscositas, augendae mfi

Quisque X ° C Mutare typically modifies MFI a 20-30%

Shear rate effectus :

Processing modum compatibility

Diversity Processing Techniques eget specifica MFI Ranges ad Optimal Euismod:

| Processing Modus | Suspendisse MFI range (G / 10min) | Key Applications |

| Iniectio CUMATIUM | 8-20 | Technical partes, continentia |

| CUMADUS | 0,3-2 | Utres, vasis |

| Extrusio | 2-8 | Films, laminas, profiles |

| Fibra spheara | 10-25 | Textile fibris, nonwovens |

Product-specifica applications

Mfi valores significantly influere ultima productum characteres:

Mfi Applications High (> X g / 10min):

Medium Mfi Applications (2-10 G / 10min):

Humilis mfi applications (<II g / 10min):

Nota: Hi iugis serve ut guidelines. Special applications ut eget values extra hi ranges secundum apparatu capabilities et productum elit.

Factores afficiens ad conflandum fluxus index

Accuracy et reliability de MFI mensuras superiores sunt multa variables. Intelligentes haec factores dat precise qualitas imperium et consistent polymer processus eventus.

Temperatus effectus

Temperatus significantly influit mfi mensuras pluribus machinnis

Viscosity Mutationes :

Altior temperaturis decrescit polymer ad conflandum viscositas, unde auctus fluxus rates et altius mfi values, cum afficiens molecular torquem mobilitatem et polymer structuram stabilitatem per temptationem ratio.

Mobility Mobility :

Degradation Risk :

Pressura auctoritas

Pressio varietate impulsum MFI mensuras per universa rhatical partum:

Meltationem compressibility :

Fluunt mores :

Sample praeparatio impulsum

Propriis sample praeparatio probat crucial pro accurate mfi determinatio:

Imperium humorem :

Physical Condition :

Adjusting testing parametri

Temperatus imperium protocols

Exsequendam stricte temperatus Management:

Pressura standardization

Maintaining consistent pressura condiciones:

| vexillum | pressura range (kg) | temperatus range (° F) |

| ASTM D1238 | 2,16 - 21,6 | CXC - CCC |

| ISO MCXXXIII | 2,16 - 21,6 | CXC - CCC |

Specimen specimen specimen

Essential praeparatio gradibus:

Pre-Lorem procedendi :

Material condiciones :

Loading Technique :

Fluxus Index Testing apparatu et Signa

Moderni MFI temptationis apparatu complicat praecisione mensura capabilities et user-amica operationem. Advanced features ensure certa qualitas imperium per normatum testis ratio.

Equipment Overview

Presto MFI Tester Exemplifies Modern Testing Capabilities:

Imperium Systems

Mensura features

Salus features

Signa obsequio

Moderni testers occursum duram Internationalis Signa:

| Standard | Requirements | Applications |

| ASTM D1238 | Temperature 0.5 ° C, vexillum dimensiones | Global vestibulum |

| ISO MCXXXIII | Auctus temperatus imperium, stricte leo | Europae Certification |

User-amica features

Imperium interface

Digital ostentationem ostendit realis-vicis temperatus, pressura et fluunt mensuras.

Programmable Test Parametri Streamline saepe probationem ratio.

Automated data logging eliminiat manual recording errores.

Reliability features

Sui-Diagnostic Systems identify potential proventus ante tentat incipit.

Calibration verificationem ensures consistent mensuram accurate.

Temperature stabilization tenet precise probatio conditionibus.

Operating ratio

I. Equipment Setup

Apparatus positioning

Ponere testing unitas in stabulum, tremor-liberum superficiem ad accurate mensuras superiores.

Adjust adtritio pedibus usque bulla indicator ostendit perfectum horizontale noctis.

Digital configuratione

Progressio test durationem per digital interface imperium panel.

Set temperatus parametri secundum materiam probationem elit.

Configure notitia collectio intervallis pro comprehensive consequuntur analysis.

Sensor administratione

Calibrate RTD PT-C sensorem secundum fabrica cubits.

Verify temperatus lectiones contra calibrated externa referat signa.

Documenti calibration results ad qualis imperium records.

Ratio Optimization

Admitte Auto-tune pluma ad meliorem temperatus imperium perficientur.

Monitor Ratio responsione durante initial calefactio tempus.

Quin firmum operating conditionibus ante principium probat.

Pre-Test Genus

[] Equipment adtritio verificatur per bulla indicator lectionum

[] Temperature stabilization effectum in certa tolerances

[] Sample materia recte paratus et conditionata

[] Test parametri figuram secundum ad vexillum requisita

Nota: iusto sustentationem ensures consistent apparatu perficientur. Document omnes calibration ratio.

Mfi de repleti polymers et composita

In incorporationem fillers significantly influences polymer Mfi values. Intelligentes his effectus optimal processus modularis lectio ad repleti polymer systems.

Filler labefactum Analysis

Firmfroging fillers

Speculum fibra

Pulveri

Non-firmfroging fillers

Calcium carbonate

TALCUS

Processus considerations

Princeps MFI basi polymers

Enable effective filler dispersionem per polymer matrix

Provideant melius dispensando characteres sub vexillum condiciones

Ponere gratum fluxus proprietatibus ad altiorem filler loadings

Humilis MFI basi polymerers

Result in provocantes filler dispersionem processibus

Requirere mutatio processui parametri ad effective productio

Show limitata compatibility ad auctus filler concentratione

Hygroscopic materiae administratione

Humorem, sensitivo polymers

| polymer genus | siccat temperatus (° F) | Maximum humorem content |

| Nylon | 80-85 | 0,2% |

| Pet / PBT | 120-140 | 0.02% |

| Abs | 80-85 | 0.1% |

| PC | 120-125 | 0.02% |

Pre-siccatio requisitis

Temperatus imperium

Tempus administratione

Material Ordo

Hygroscopic polymers

Engineering Plastics

Technical Polymers

Non-hygroscopic polymers

Commodity Plastics

Nota: Ordinarius humorem contentus verificationem ensures consistent processus results.

Mfi de REDIVIVUS Polymers et Polymer mixtionis

Et growing demanda ad sustineri vestibulum habet ducitur ad auctum usum recycled Polymers in Polymer processui. Tamen, mechanica redivivus et polymer miscere potest significantly afficiunt ad conflandum fluunt index (mfi), quod impingit materiam perficientur et dispensando efficientiam.

MFI mutationes per redivivus

Degradation effectus

Molecular pondus reductionem

Mechanica accentus durante redivivus erumpit Polymer vincula, augendae altiore fluxus rates.

Scelerisque nuditate durante Reprocessing accelerat catenae, et mulgeti degradation processibus.

Res mutationes

MFI Modification Strategies

Torquem extensio technology

Chemical Modification

Processus exsequendam

originale mfi → torquem extender Praeterea → mutatio MFI altus fluunt rate → Molecular pondus incremento → continetur fluxus proprietatibus

Euismod Enhancement

| Modification modum | MFI impulsum | application beneficia |

| Torquem extensio | Decrescit mfi | Melius mechanica proprietatibus |

| Peroxide | MFI imperium | Enhanced dispensando stabilitatem |

| Miscere Optimization | Targeted mfi | Applicationem-specifica proprietatibus |

Polymer Blend characteres

Virgin-Recycled junctiones

Blend rationes

Processing Fenestra

Quality imperium mensuras

Testis protocols

Monitoring iusto

Res verificationem

Optimization Insidijs

Material Electio

Processus imperium

Conclusio

Index conflandum fluunt (mfi) ludit a crucial partes in polymer processus et qualitas imperium. Hoc adjuvat fabrica eligere ius materiae et optimize productio. Intellectus factores quod afficit MFI, sicut molecular pondus et dispensando conditionibus, est essentialis pro meliorem uber qualitas. Adjusting ad haec factores ensures consistent results durante vestibulum.

Incorporating MFI temptationis in Polymer Testing ratio est clavis est enhancing productio efficientiam. Hoc ensures quod Polymers occursum requiritur signa et praestare bene in real-mundi applications. Iusto MFI testing est simplex gradus ad bonum polymer processui et uber reliability.

Reference Sources

Ad conflandum influunt index

PPS plastic

Plastic iniectio CUMATIUM