Mun de bɛ polimɛriw cogoya n’u baara nɔgɔya? Jaabi bɛ sɔrɔ fɛnɲɛnamafagalanw (MFI) kɔnɔ. MFI bɛ jateminɛ kɛ cogo min na polimɛri bɛ wuli ani ka woyo nɔgɔya la, a jɔyɔrɔ ka bon kosɛbɛ polimɛri dilanni na. A nafa ka bon kosɛbɛ walasa ka baarakɛcogo ɲuman sugandi ani ka fɛn dilannenw cogoya sabati. Nin sɛbɛn in kɔnɔ, aw bɛna MFI jɔnjɔnw dɔn, a nafa ka bon polimɛri baarakɛcogo la, ani a bɛ nɔ bila fɛn dilannenw ka baarakɛcogo la cogo min na. An bɛna fɛnw fana sɛgɛsɛgɛ minnu bɛ nɔ bila MFI la, a b’a sɛmɛntiya cogo min na, ani a bɛ kɛ cogo min na jogoɲini na.

Melt Flow Index (MFI) ye mun ye?

Melt Flow Index (MFI) bɛ kɛ jogoɲini paramɛtiri kɔrɔlen ye min bɛ polimɛriw ka bolicogo jateminɛ walima ka wuli. A b’a jira cogo min na polimɛriw bɛ wuli nɔgɔya la degun ni funteni cogoya kɛrɛnkɛrɛnnenw na.

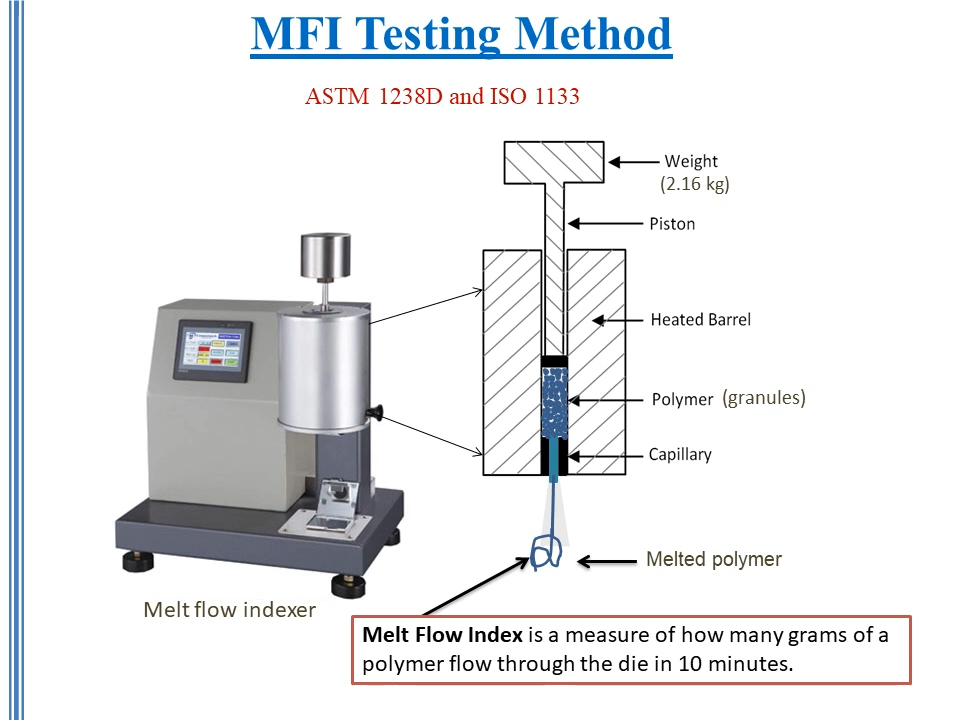

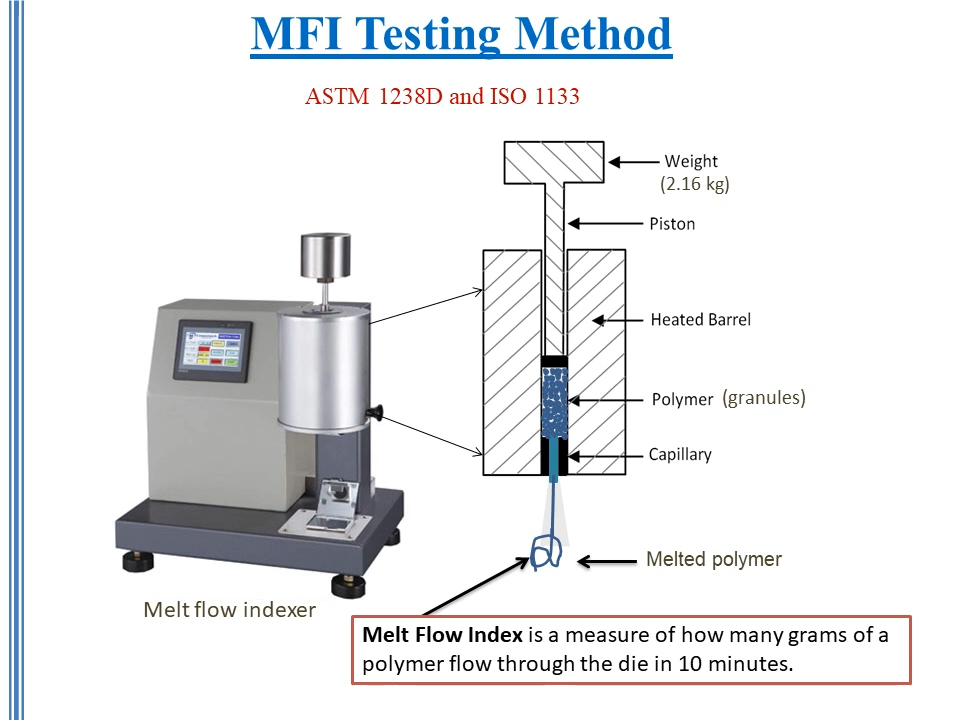

MFI ni a sumanikɛcogo faamuyali .

MFI bɛ mass flow rate jira min bɛ suman ni die standardized ye cogoyaw la minnu latigɛra:

MFI iko flow property indicateur .

MFI bɛ tali kɛ polimɛri jogo caman na:

Molecules proprétés : .

Baarakɛcogo : .

A kɛcogo ɲuman :

MFI ka ca (>10 g/10min) → pikirijikɛlan MFI (2-10 g/10min) → fɛnɲɛnamafagalanw bɔli MFI dɔgɔman na (<2 g/10min) → Fiɲɛbɔlan

MFI sɛgɛsɛgɛli sariya .

Kɔrɔbɔli kɛcogo bɛ tugu fɛɛrɛw la minnu bɛ kɛ ka kɛɲɛ ni sariya ye:

Kɔrɔbɔli kɛcogo jɔnjɔnw : .

Polimɛri min bɛ funteni na ka se funteni hakɛ fɔlen ma .

Aw bɛ girinya hakɛ jateminɛ .

Sumanikɛlan min bɛ bɔ kɛnɛ kan .

Jatebɔ kɛ jibɔ hakɛ kan .

Paramɛtɛrɛw kɔrɔfɔli : .

Kɔrɔbɔli cogoya minnu bɛ kɛ ka kɛɲɛ ni sariya ye (misali la):

| Polimɛri suguya | funteni (°C) | Load (kg) |

| Poliɛtilɛni . | 190 | 2.16 |

| Poliporopilini . | 230 | 2.16 |

| Polisitiri . | 200 | 5.0 |

Kɔrɔbɔli kɛcogo nafa .

MFI sumanikɛcogo tigitigi bɛ protocoles (porotokɔliw) labato kosɛbɛ:

Misali labɛnni basigilen .

Minɛnw jateminɛcogo ɲuman .

Sɛgɛsɛgɛli kɛcogo minnu bɛ kɛ ka kɛɲɛ ni sariya ye .

Ladonni tuma bɛɛ .

Operatɛri setigi .

An bɛ ladilikan di ka tugu ISO 1133 walima ASTM D1238 sariyaw la walasa ka jaabiw sɔrɔ minnu bɛ se ka da u kan. Nin wale ninnu bɛ kɛ sababu ye ka segin-ka-bɔ ani ka ɲɔgɔn sanga sɛgɛsɛgɛli kɛyɔrɔw la.

KƆLƆSI: MFI nafaw bɛ dɛmɛ ka baarakɛcogo bɛnnenw dɔn ani ka baara labanw kɛ. MFI faamuyali bɛ kɛ sababu ye ka dilanbagaw dɛmɛ u ka se ka fɛn dilanni paramɛtiriw kɛ ka ɲɛ.

Jɛɲɔgɔnya min bɛ MFI ni polimɛri jogo cɛ .

Jɛɲɔgɔnya min bɛ MFI ni polimɛri nafaw cɛ, o bɛ kɛ fɛn jɔnjɔn ye baarakɛcogo fɛɛrɛw ni fɛn labanw cogoya dɔnni na. O jɛɲɔgɔnyaw faamuyali bɛ kɛ sababu ye ka dilanbagaw dɛmɛ u ka se ka u ka baarakɛcogo ɲɛ ka ɲɛ.

MFI-molecular weight correlation .

MFI bɛ jɛɲɔgɔnya inversé jira ni molekiyɔmu girinya ye, ka tugu empirical equation for linear polymers:

log MW = 2.47 – 0.234 Log MF .

Min:

Jɛɲɔgɔnya jɔnjɔnw:

MFI hakɛ caman bɛ polimɛriw girinya dɔgɔyali jira, minnu bɛ baarakɛcogo nɔgɔya nka u bɛ se ka dɔgɔya masinw na .

MFI hakɛ minnu ka dɔgɔn, olu b’a jira ko polimɛri minnu girinya ka bon, olu bɛ fanga bonya masin na nka u bɛ baarakɛcogo juguw wajibiya .

Molecules girinya tilali nɔ .

Molecules girinyaw tilatilali bɛ nɔba bila MFI kɛcogo la fɛɛrɛ caman fɛ:

Jatebɔba : Polimɛri minnu bɛ girinya hakɛ caman jira, olu bɛ jibɔ kɛcogo gɛlɛnw jira, minnu bɛ nɔ bila u ka baarakɛcogo la ani ka baarakɛcogo paramɛtiriw kɔlɔsi kosɛbɛ walasa ka ɲɛtaa ɲuman sɔrɔ.

Jatebɔ surun : Fɛn minnu bɛ ni molekiyɔmu girinya tilali gɛlɛnw ye, olu bɛ jibɔcogo jira min bɛ se ka fɔ ka ɲɛ, o bɛ se ka kɛ sababu ye ka kɔrɔsili tigitigi kɛ baarakɛwaati la nka a bɛ se ka dan sigi u kɛcogo caman na.

Viscosité-MFI jɛɲɔgɔnya .

Jɛɲɔgɔnya min bɛ sɔrɔ fɛnɲɛnamafagalanw ni MFI cɛ, o bɛ jira fɛn caman fɛ:

Funteni hakɛ dantigɛli : .

Funteni caman bɛ dɔ bɔ sɔgɔli la, ka dɔ fara MFI kan .

Each 10°C change typically modifies MFI by 20-30%

Shear rate effects : .

Sɔgɔsɔgɔninjɛ hakɛ cayalenba caman na, a ka ca a la, a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

O jɛɲɔgɔnya bɛ kɛ ko kɔrɔba ye teliyaba baarakɛcogo la .

baarakɛcogo ɲuman baarakɛcogo .

Baarakɛcogo suguya wɛrɛw bɛ MFI hakɛ kɛrɛnkɛrɛnnenw de wajibiya walasa ka baara kɛcogo ɲuman sɔrɔ:

| Baarakɛcogo | ɲuman MFI hakɛ (G/10min) | Baarakɛcogo jɔnjɔnw . |

| Pikirili Molidali . | 8-20 . | Tekniki yɔrɔw, minɛnw . |

| Blow Molding . | 0,3-2. | buteliw, minɛnw . |

| Extrusion . | 2-8 . | Filimuw, sɛbɛnw, Profiles . |

| Fibre spinning . | 10-25 . | Fibres de textile, nonwons . |

Fɛn minnu bɛ kɛ ka fɛnw sɔrɔ .

MFI nafaw bɛ nɔba bila fɛn labanw cogoya la:

MFI ka baarakɛcogo caman (>10 g/10min):

Precision injection moulded components minnu bɛ moule fali seko gɛlɛnw de wajibiya, olu bɛ nafa sɔrɔ bolicogo caman na, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw dɛmɛ ka jateminɛ gɛlɛnw kɛ ka sɔrɔ ka tolerances dimensions sirilenw mara.

MFI cɛmancɛ baarakɛcogo (2-10 g/10min):

MFI ka dɔgɔn (<2 g/10min):

KƆLƆSI: Nin yɔrɔ ninnu bɛ kɛ bilasiralikanw ye. Baara kɛrɛnkɛrɛnnenw bɛ se ka kɛ ni nafaw ye minnu tɛ o yɔrɔw la ka da minɛnw seko kan ani fɛn dilannenw wajibiyalenw kan.

Fɛn minnu bɛ nɔ bila melt flow index la .

MFI sumanikɛlanw ka tiɲɛni ni u ka dannaya bɛ bɔ fɛn caman na. Nin ko ninnu faamuyali bɛ se ka kɛ sababu ye ka jogoɲini tigitigi kɛ ani ka polimɛri baarakɛcogo sɔrɔ cogo basigilen na.

Funteni nɔfɛkow .

Funteni bɛ nɔba bila MFI sumani na fɛɛrɛ caman fɛ:

Ɲɛnamaya kɛcogo caman b’a jira ko .

Funteni caman bɛ dɔ bɔ polimɛri sɔgɔli sɔgɔli la, o bɛ na ni jibɔ hakɛ caya ye ani MFI hakɛ caman, ka sɔrɔ ka nɔ bila molekiyɔmu cakɛda lamagacogo la ani polimɛri jɔcogo sabatili sɛgɛsɛgɛli kɛcogo la.

Molecules Mobilité : .

Tiɲɛni farati : .

Degun fanga .

Degun caman ɲɔgɔnna bɛ nɔ bila MFI sumanikɛlanw na ni rheologique kɛcogo gɛlɛnw ye:

melt compressibilité : .

Flow kɛcogo : .

Sample labɛnni nɔfɛta .

Misali labɛnni ɲuman bɛ kɛ kosɛbɛ MFI dantigɛli tigitigi la:

Jiko ɲɛnabɔli : .

Polimɛri minnu bɛ ji la, olu bɛ ja ka ɲɛ sani u ka sɛgɛsɛgɛli kɛ, barisa ji tolen bɛ nɔba bila jibɔ kɛcogo la, wa o bɛ na ni MFI sumanikɛcogo ye min tɛ bɛn ɲɔgɔn ma.

Farikolo cogoya : .

Kɔrɔbɔli paramɛtɛrɛw ladilanni .

Funteni hakɛ kɔlɔsili protocolw .

Funteni maracogo gɛlɛnw waleyali:

Tansiyɔn sɛgɛsɛgɛli .

Ka tansiyɔn cogoya basigilen mara: Tansiyɔn hakɛ

| dantigɛlen | (kg) | funteni hakɛ (°C) . |

| ASTM D1238 . | 2,16 - 21,6. | 190 - 300 . |

| ISO 1133 . | 2,16 - 21,6. | 190 - 300 . |

Sample Quality Assurance .

Labɛncogo nafamaw:

Fɛɛrɛ minnu bɛ kɛ ka kɔn sɛgɛsɛgɛli ɲɛ : .

Matériel conditionnement : .

loading technique : .

Melt flow index sɛgɛsɛgɛli minɛnw ni sariyaw .

Bi MFI sɛgɛsɛgɛli minɛnw bɛ sumanikɛcogo tigitigiw ni baarakɛcogo ɲuman fara ɲɔgɔn kan. Fɛn minnu bɛ taa ɲɛ, olu bɛ jogoɲini dannayalen sabati sɛgɛsɛgɛli kɛcogo la min bɛ kɛ ka kɛɲɛ ni sariya ye.

Minɛnw lajɛlen .

Presto MFI sɛgɛsɛgɛlikɛla bɛ misali di bi sɛgɛsɛgɛli sekow kan:

Contrôle systèmes .

Baara minnu bɛ kɛ ni mikroporosesɛri ye, olu bɛ kɛ sababu ye ka funteni ni tansiyɔn kunbɛnni tigitigi kɛ sɛgɛsɛgɛli kɛcogo bɛɛ la.

Nizɛri ɲɔgɔndanw bɛ sɛgɛsɛgɛli kɛcogo kɔrɔlenw kɔlɔsili waati yɛrɛ la.

Sumanikɛlanw .

Lakanali fɛnw .

Sariyaw labatoli .

Bi sɛgɛsɛgɛlikɛlaw bɛ diɲɛ sariyaw labato minnu ka gɛlɛn:

| sariya | wajibiyalenw | baarakɛcogo . |

| ASTM D1238 . | Funteni hakɛ ±0,5°C, Die hakɛ dantigɛlenw . | Duniya bɛɛ ka fɛn dilanni . |

| ISO 1133 . | Funteni hakɛ kɔlɔsili bonya, waati gɛlɛn . | Erɔpu jamanaw ka seereyaw . |

Baarakɛcogo ɲuman fɛnw .

Contrôle interface .

Nizɛri jiralan bɛ funteni, degun ani jibɔ sumanikɛlanw jira waati yɛrɛ la.

Sɛgɛsɛgɛli kɛcogo minnu bɛ se ka porogaramu, olu bɛ sɛgɛsɛgɛli kɛcogo segin-segincogo ɲɛnabɔ.

Donanw sɛbɛnni otomatiki bɛ bololabaara filiw ban.

dannaya bɛ se ka da minnu kan .

Yɛrɛlabɛnni fɛɛrɛw bɛ ko minnu bɛ se ka kɛ, olu jira sani sɛgɛsɛgɛli ka daminɛ.

Calibration verification bɛ a to sumani kɛcogo ɲuman bɛ kɛ cogo basigilen na.

Funteni sabatili bɛ sɛgɛsɛgɛli cogoya tigitigiw mara.

Baarakɛcogo taabolo .

1. Minɛnw sigicogo .

Masina sigicogo .

Aw bɛ sɛgɛsɛgɛli kɛyɔrɔ bila yɔrɔ la min bɛ sabati, min tɛ yɛrɛyɛrɛ walasa ka sumani kɛ ka ɲɛ.

Aw bɛ senw nivoya ladilan fo ka se bulon jiralan ma, o bɛ ɲɔgɔndan dafalen jira.

Numérique Configuration .

Porogaramu sɛgɛsɛgɛli waati ka tɛmɛ nitiriyali ye min bɛ wele ko interface contrôle numérique.

Set temperature paramètres ka kɛɲɛ ni fɛnw sɛgɛsɛgɛli wajibiyalenw ye.

Donanw lajɛ waatiw labɛn walasa ka sɔrɔw sɛgɛsɛgɛli bɛɛ lajɛlen kɛ.

Sensor ɲɛnabɔli .

Aw bɛ RTD PT-100 sensɛri jateminɛ ka kɛɲɛ ni a dilannikɛlaw ka sariyaw ye.

Aw bɛ funteni hakɛ jateminɛlenw sɛgɛsɛgɛ ka kɛɲɛ ni kɛnɛya jateminɛ sariyaw ye minnu bɛ se ka jateminɛ.

Sɛbɛnw jateminɛ jaabiw ka ɲɛsin jogoɲini sɛbɛnw ma.

Sisεmεti Optimisation .

Aw bɛ auto-tune kɛcogo ɲɛ walasa ka funteni kunbɛncogo ɲuman sɔrɔ.

Aw bɛ sistɛmu jaabi kɔlɔsi tasuma fɔlɔ waati la.

Aw bɛ baarakɛcogo sabatilenw sɛgɛsɛgɛ sani sɛgɛsɛgɛliw ka daminɛ.

Pre-test sɛgɛsɛgɛli sɛbɛn .

[ ] Minɛnw nivoya min sɛgɛsɛgɛra bulon jiralan kalanniw fɛ .

[ ] funteni sabatili min bɛ sɔrɔ muɲuli kofɔlenw kɔnɔ .

[ ] misali fɛnw labɛnna ka ɲɛ ani u cogoya .

[ ] Kɔrɔbɔli paramɛtiriw labɛnna ka kɛɲɛ ni sariyaw ye .

KƆLƆSI: Ladonni tuma bɛɛ bɛ minɛnw baaracogo sabati. Aw bɛ jateminɛ kɛcogo bɛɛ sɛbɛn.

MFI ka polimɛriw ni fɛnɲɛnamafagalanw falen .

Filɛriw donli bɛ nɔba bila polimɛri MFI hakɛw la. Nin nɔ ninnu faamuyali bɛ kɛ sababu ye ka baarakɛcogo ɲuman paramɛtiriw sugandili kɛ polimɛri sitɛmuw falen na.

Filler Impact Analysis .

Fasirilanw bɛ fanga di mɔgɔ ma .

Fibre de verre .

Nɛgɛmuguw .

Filɛlikɛlaw minnu tɛ barika sɔrɔ .

Karɔbɔni kalisiyɔmu .

Talc .

Baarakɛcogo jateminɛw .

MFI basi polimɛriw ka ca .

Aw bɛ se ka fasa jɛnsɛnni nafama kɛ polimɛri matiriyali bɛɛ kɔnɔ .

Aw bɛ baarakɛcogo ɲumanw di cogoya la min bɛ kɛ ka kɛɲɛ ni sariya ye .

Aw bɛ jibɔcogo minnu bɛ sɔn ka kɛ, olu mara fasaw la minnu ka bon .

MFI basi polimɛriw ka dɔgɔn .

A bɛ na ni filler dispersion processes gɛlɛnw ye .

A bɛ ɲini ka baarakɛcogo caman sɛmɛntiya walasa ka baara kɛ ka ɲɛ .

A jira ko bɛnkan danma bɛ sɔrɔ fasa hakɛ cayalenba la .

Hygroscopic matériels ɲɛnabɔli .

Polimɛri minnu bɛ ji la,

| olu ye polimɛri suguya | jalen ye (°C) | ji hakɛ min bɛ se ka kɛ . |

| Nylon . | 80-85 . | 0,2% . |

| PET/PBT . | 120-140 . | 0,02% . |

| ABS . | 80-85 . | 0,1% . |

| PC . | 120-125 . | 0,02% . |

Fɛn minnu bɛ kɛ ka kɔn ja ɲɛ .

Funteni hakɛ kɔlɔsili .

Waati bolodacogo .

Material ka danfara .

Polimɛri minnu bɛ ji la .

Plastiques en étérieure .

Polimɛri Teknikiw .

Polimɛriw minnu tɛ tansiyɔn ye .

Plastikiw ka jagofɛnw .

KƆLƆSI: Ji kɔnɔkow sɛgɛsɛgɛli basigilen bɛ a to a ka baara kɛcogo ɲumanw sɔrɔ.

MFI ka polimɛriw ni polimɛri ɲagaminenw .

Fɛn dilanni sabatili ɲinini min bɛ ka bonya, o kɛra sababu ye ka baara kɛ ni polimɛriw ye minnu bɛ segin ka kɛ fɛn wɛrɛw ye polimɛri baarakɛcogo la. Nka, masinw ka segin-ka-bɔ ani polimɛri ɲagaminen bɛ se ka nɔba bila melt flow index (MFI) la, o min bɛ nɔ bila fɛnw ka baarakɛcogo la ani u ka baarakɛcogo ɲuman na.

MFI bɛ Changé waati min na a bɛ segin ka kɛ .

Degradation effects .

Molecules girinya dɔgɔyali .

Mekaniki degunw lasegin waati la, olu bɛ polimɛri cakɛdaw tiɲɛ, ka dɔ fara u bɛɛ lajɛlen wulicogo hakɛ kan.

Funteni-yɔrɔ-ko-ɲɛnabɔli-ko-ɲɛnabɔli waati bɛ cakɛda sisi ni molekiyɔmu tiɲɛni taabolo teliya.

Propriété changements .

PET min bɛ kɛ kɔfɛ, o bɛ MFI caya jira siɲɛ duuru ni a bɛ tali kɛ fɛn npogotigininw na.

Poliɛtiriw minnu bɛ se ka tiɲɛ, olu bɛ fɛn caman sɛmɛntiya flow property modifications la recyclage cycles waati la.

MFI caman sɛgɛsɛgɛli fɛɛrɛw .

Chain Extension Technologie .

chimique modification .

Chain Extenders bɛ molekiyɔmu girinya jɔ kokura ni reactive processing fɛɛrɛw ye.

Fɛn kɛrɛnkɛrɛnnen minnu bɛ fara ɲɔgɔn kan, olu bɛ se ka MFI ladilanni laɲinitaw kɛ baarakɛcogo wajibiyalenw danfaralenw na.

Taabolo waleyali

MFI fɔlɔ → cakɛda janya farali → MFI caman sɛmɛntiyalen → molekiyɔmu girinya bonya → Jibɔcogo kɔrɔsilenw .

Baarakɛcogo

| ɲɛtaa fɛɛrɛ | MFI nɔfɛta | baarakɛcogo nafaw . |

| Cakɛda janya . | A bɛ dɔ bɔ MFI la . | Mekaniki jogo ɲumanw . |

| Perokisidi farali . | MFI Contrôle . | Baarakɛcogo sabatili min bɛ bonya . |

| Blend optimisation . | MFI laɲininen . | Aplikasi-kɛrɛnkɛrɛnnenya nafaw . |

Polimɛri ɲagaminen jogo .

Npogotigiw ka ɲɔgɔndanw .

Blenko hakɛw .

Kɔnɔmaya hakɛ min bɛ segin ka kɛ fɛn wɛrɛ ye, o bɛ dɔ fara a bɛɛ lajɛlen wulicogo hakɛ kan kosɛbɛ.

Strategic Virgin Material farali bɛ dɛmɛ ka baarakɛcogo ɲininenw mara.

Windows baarakɛcogo .

Jogoɲumanya fɛɛrɛw .

Kɔrɔbɔli protocoles .

Kɔlɔsili kɛli tuma bɛɛ .

Propriétés ka sɛgɛsɛgɛli .

Aw bɛ ɲagaminen jogo suma ni fɛn dilannenw ɲɛfɔcogo sigilenw ye tuma bɛɛ.

Sɛbɛn MFI caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman

Optimisation fɛɛrɛw .

Material Selection .

Fɛn minnu bɛ segin ka kɛ fɛn wɛrɛw ye, olu bɛ sɔrɔ ka da u girinya kan ani u tiɲɛni hakɛ kan.

Polimɛri virgin minnu bɛ se ka baara kɛ ɲɔgɔn fɛ, olu sugandi walasa ka fɛnw ɲɛnabɔ cogo ɲuman na.

Taabolo kɔlɔsili .

Kuncɛli

Melt Flow Index (MFI) jɔyɔrɔ ka bon kosɛbɛ polimɛri baarakɛcogo la ani jogoɲini na. A bɛ dilanbagaw dɛmɛ ka fɛn bɛnnenw sugandi ani ka u dilanni kɛcogo ɲɛ. Faamuyali fɛn minnu bɛ MFI nɔ na, i n’a fɔ molekiyɔmu girinya ani baara kɛcogo, o nafa ka bon kosɛbɛ walasa ka fɛn dilannenw jogo ɲɛ. Ni aw ye o kow ladilan, o bɛ a to a bɛ sɔrɔ cogo basigilen na a dilanni waati.

MFI sɛgɛsɛgɛli don aw ka polimɛri sɛgɛsɛgɛli kɛcogo la, o ye fɛnba ye walasa ka fɛn dilanni nafa bonya. A b’a to polimɛriw ka sariyaw wajibiyalenw dafa ani ka baara kɛ ka ɲɛ diɲɛ kɔnɔ baarakɛcogo lakikaw la. MFI sɛgɛsɛgɛli basigilen ye fɛɛrɛ nɔgɔman ye ka ɲɛsin polimɛri baarakɛcogo ɲuman ma ani a ka fɛn dilannenw dannaya ma.

Reference sources .

Melt flow index .

PPS Plastique .

Plastiki pikiri kɛcogo .